Viking VCBB360R, VCBB362R, VCBB360L, VCBB362L Service Manual

SERVICE NOTEBOOK

REFRIGERATOR

VCBB360R / VCBB362R (Right) – VCBB360L / VCBB362L (Left)

VIKING RANGE CORPORATION, P.O. DRAWER 956, GREENWOOD, MS. 38930 - USA

Table of Contents

Technical Information................................................................................................................... 3

Display Panel................................................................................................................................ 4

Display Panel Operation............................................................................................................... 5

Electronic Functional Description................................................................................................ 6

Power Disconnect Switch

Showroom Switch

Alarms

Temperature Control Operation.................................................................................................... 7

Adaptive Defrost Operation.......................................................................................................... 8

Program Mode............................................................................................................................... 9

Electronic Testing......................................................................................................................... 11

Electronic Function Description................................................................................................... 12

Wiring Diagram............................................................................................................................ 14

Wiring Schematic (Complete)........................................................................................................ 15

Wiring Schematic (Freezer Compartment)..................................................................................... 16

Wiring Schematic (Refrigeration Compartment)............................................................................ 17

Wiring Schematic (Refrigerator and Freezer Compartment).......................................................... 18

Wiring Schematic (Adaptive Defrost)............................................................................................. 19

Component Specification.............................................................................................................. 20

Component Testing....................................................................................................................... 23

Troubleshooting Charts................................................................................................................. 31

System Diagnosis.......................................................................................................................... 33

Service Procedures........................................................................................................................ 34

Refrigerant Flow............................................................................................................................ 40

Cabinet Airflow............................................................................................................................. 41

Machine Compartment Air Flow................................................................................................... 42

Typical External Sweat Pattern..................................................................................................... 43

Disassembly Procedures................................................................................................................ 44

Ice Maker....................................................................................................................................... 47

Ice Maker Troubleshooting Chart.................................................................................................. 52

Ice Maker Wiring Diagram and Part Layout.................................................................................. 55

2

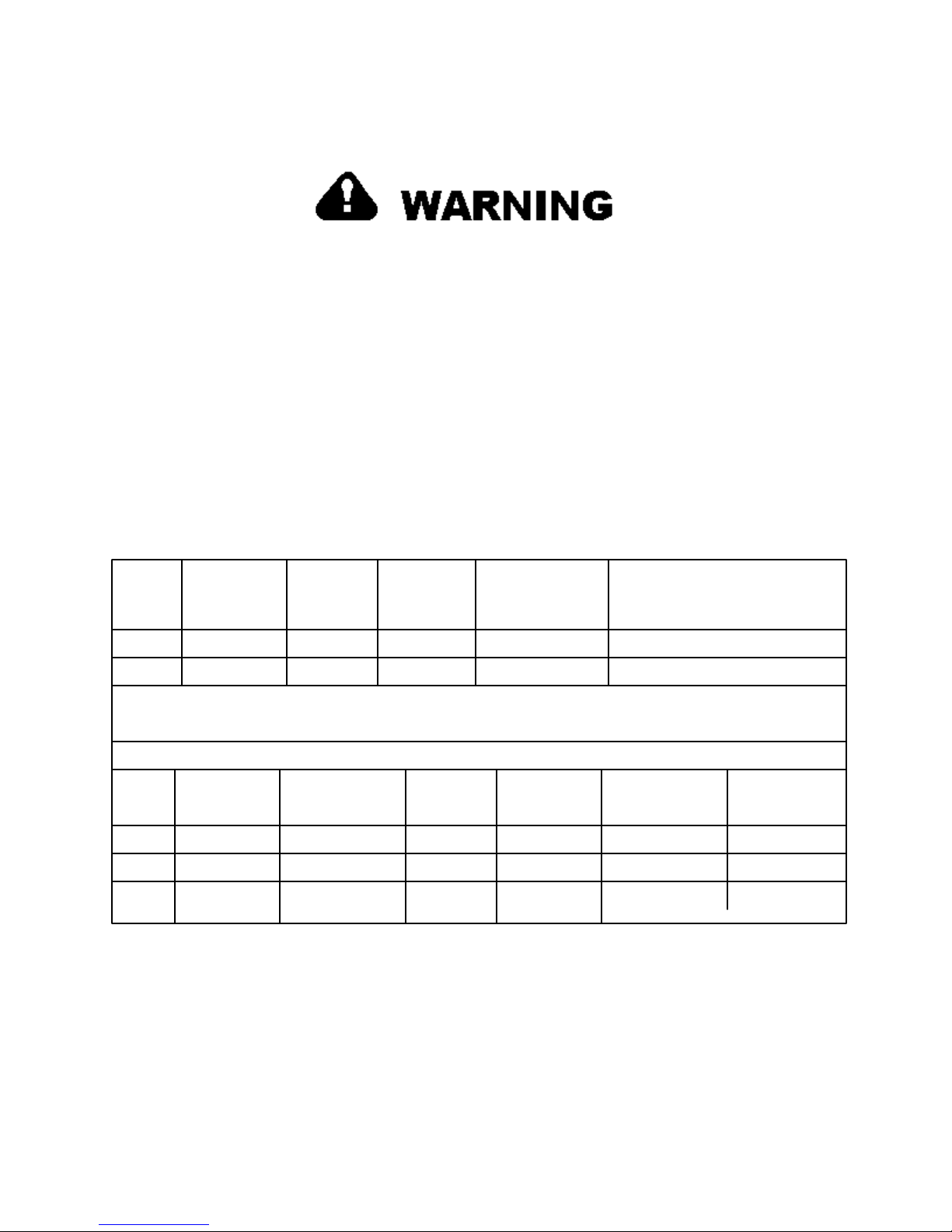

Technical Information – Refrigerator

To avoid electrical shock which can cause severe personal injury or death, disconnect

power to refrigerator using power switch before servicing. Wires removed during

disassembly must be replaced on proper terminals to insure correct earth ground and

polarization. After servicing, reconnect power using power switch.

Refrigerator Center Freezer

Compartment Food Compartment

Percent Run Cycle/24 hr Average temperature Food Average

Kw/24 hr ± 0.4 Time ± 10% ± 25% ± 3°F Temperature ± 3°F

Ambient° F 65° 90° 110° 65° 90° 110° 65° 90° 110° 65° 90° 110° 65° 90° 110°

1.2 2.3 4.2 28 52 100 30 32 0 39 39 45 3 3 3

Temperature Relationship Test Chart

T-3 Suction Average Total Suction Pressure Head Pressure

T-1 Outlet ± 3° F T-1 Inlet ± 3° F Line Wattage ±10% ± 2 PSIG ± 5 PSIG

± 7°F

Ambient °F 65° 110° 65° 110° 65° 110° 65° 110° 65° 110° 65° 110°

-14 -14 -14 -14 25 103 157 168 0 0 110 157

3

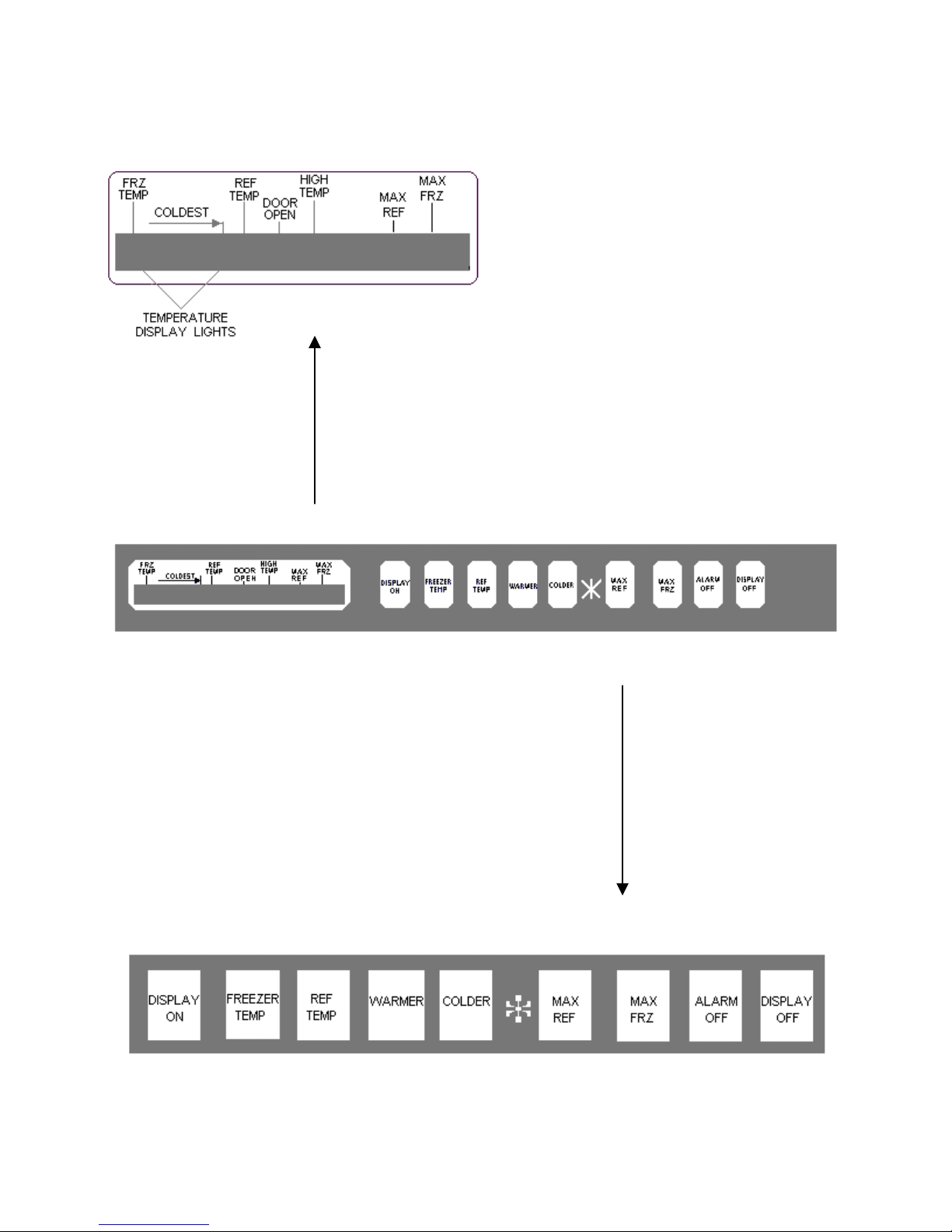

Display Panel Keyboard

Display Panel

4

Display Panel Operation

Keyboard Tone

Entry Tone

Indicates a pad was pressed, command read

and accepted, Turn off entry tone by pressing

and holding Display On pad for 3 to 5 seconds.

Command Accepted Tone

Three short tones indicate command accepted.

Display On Pad

1. Activates control panel. Control panel

remains active at least 10 minutes .

2. Turns off Power Up Alarm (flashing lights)

after power is firs t p lug ged in or af ter p o wer

outage.

All pads, except Alarm Off, are inactive

Note:

until display On is pressed.

Freezer Temp Pad

Activates freezer temperature settings mode.

1. Fr ee zer indic ator light will glow. Freezer

temperature setting will be displa yed.

Factory setting is 5.

2. Change freezer temperature setting by

pressing Warmer or Colder pad.

Ref Temp Pad

Activates refrigerator temperature settings

mode.

!. Refrigerator indicator light will glow.

Refrigerator temperature setting will be

displayed. Factory setting is 5.

2. Change refrigerator temperature setting by

pressing Warmer or Colder pad.

Warmer Pad

Raises temperature settings one bar at a time.

If entry tone is on, tone will sound at each bar

level until top level is reached.

!. Turn on temperature setting function of

control panel by pressing Warmer pad.

2. Press and hold Warmer pad to raise

temperature setting at a faster rate.

Colder Pad

Lowers temperature sett ing one b ar at a tim e. If

entry tone is on, tone will sound at each bar

level until bottom level is reached.

1. Turn on temperature setting function of

control panel be pressing Colder pad.

2. Press and hold Colder pad to lower

temperature setting at a faster rate.

Max Frz Pad

Activates Maximum freezer mode s etting freezer

temperature to coldest setting for 24 hours or

until Max Frz pad is pressed again.

1. Freezer indica t or light wi ll g lo w.

2. To adjust maximum freezer mode time

refer to Program Mode B functions.

Max Ref Pad

Activates Maximum refrigerator mode setting

refrigerator to coldest sett in g f or 24 hours or until

Max Ref pad is pressed again.

!. Refrigerator indicator light will glow.

2. To adjust maximum refrigerator time refer

to Program Mode B functions.

Alarm Off Pad

Turns off alarm signals . See Alarms section to

interpret alarm signals.

!. Press and hold Alarm Off pad for 3 seconds

to deactivate Door Open alarm. To

reactivate Door Open alarm, press and

hold Alarm Off pad for 3

seconds.

2. If Alarm Off pad is pressed and condition

causing alarm is not corrected, alarm will

reset .

**

Activates Program Mode. See Program Mode

section for description of functions available.

1. Open refrigerator door.

2. Press Display On pad.

3. Press * pad.

4. Within 6 seco nds press the following pads

in this sequence; Max Ref, Max Frz, Max

Ref, Max Frz.

5. T one will sound 3 times and contr ol will be

in program mode A.

Display Off Pad

1. Deactivates control panel

2. Deacti vat es tem per ature in dic at ion area of

control panel.

5

Electronic Functional Description

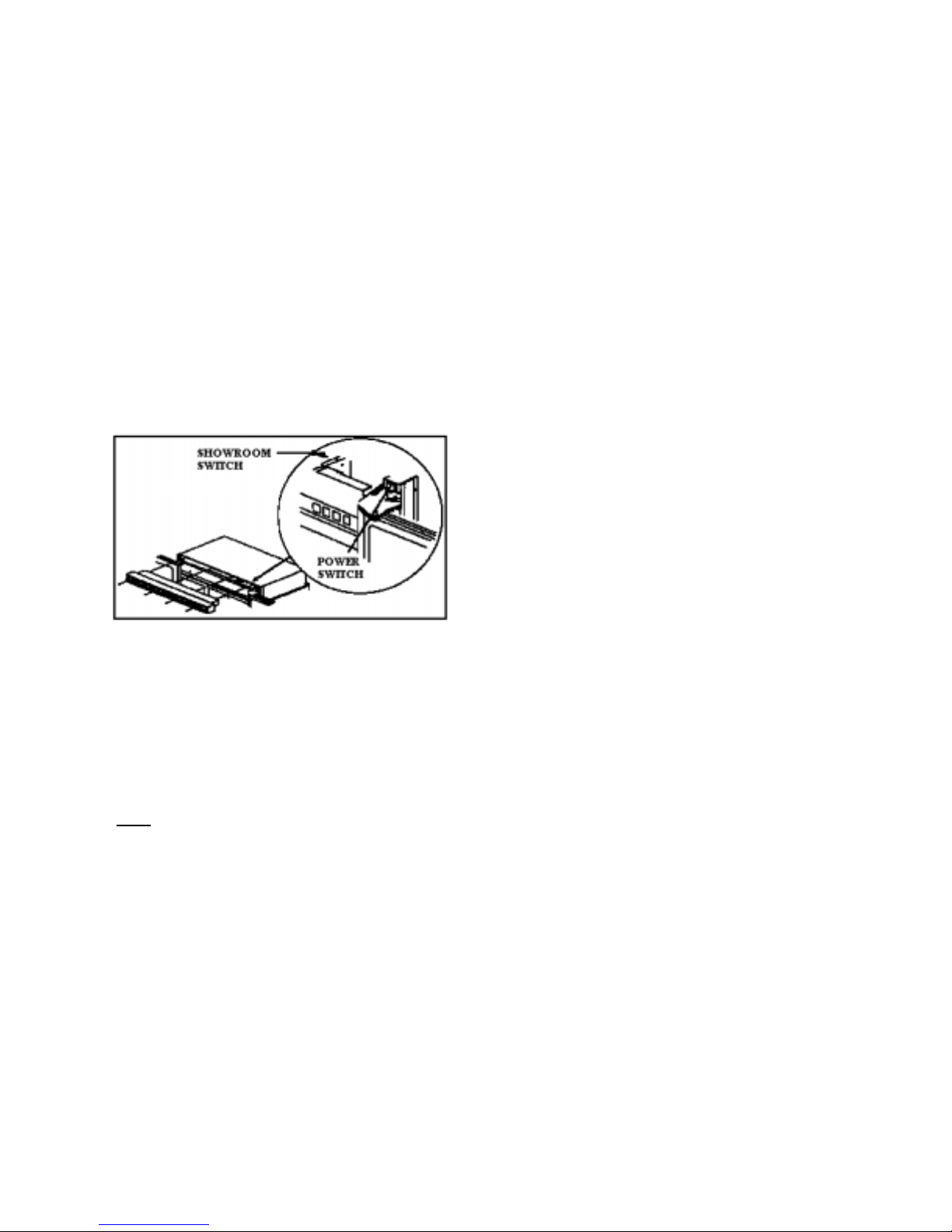

Power Disconnect Switch

Use power disconnect switch to disconnect

power without unplugging refrigerator. Power

disconnect switch is located behind air grille on

top right side. Refrigerator is shipped with

power disconnect switch in the on position.

Showroom Switch

Showroom switch allows electronic controls and

interior lights to function independently of

refrigeration system. Showroom switch is

located behind air grille to right of control panel.

Refrigerator is shipped with showroom switch in

the unit run position.

Alarms

Power Up Alarm

After power is initially plugged in, after a power

loss, or if power switch is turned off, all

temperature indicator lights will flash until

Alarm Off or Display On is pressed.

Note

: All settings return to default factory

settings.

Door Open Alarm

Alarm tone sounds and indicator lights blink if

either refrigerator or freezer door is open more

than 3 minutes.

1. Turn off Door Open alarm by pressing

Alarm Off pad or by closing door.

2. Deactivate door open alarm be pressing

Display On pad and then press and hold

Alarm Off pad for 3 seconds.

3. Door alarm delay can be adjusted in

Program Mode B.

High Temperature Alarm

Alarm sounds and indicator light shows if

freezer or refrigerator temperature has gone

above critical level and remains warm for 2

hours. Alarm tone stops if temperature falls

again.

!. Critical temperature for freezer is +15°F;

for refrigerator critical temperature is

+55°F.

2. Press Alarm Off to turn off alarm.

Thermistor Alarm

Alarm sounds and freezer or refrigerator

indicator light shows and temperature indicators

4 through 7 will turn on in sequence if either

thermistor circuit opens. Refer to Temperature

Control Operation Section and Electronic

Testing Section.

!. Press Alarm Off pad to turn off alarm.

2. Alarm will reset for normal operation. If

condition has not been corrected, alarm will

sound again.

6

Electronic Functional Description

Temperature Control Operation

For any temperature setting, outputs will be

turned off/on based on cut-in, cut-out

temperatures determined by resistance levels of

freezer and refrigerator the r mistors.

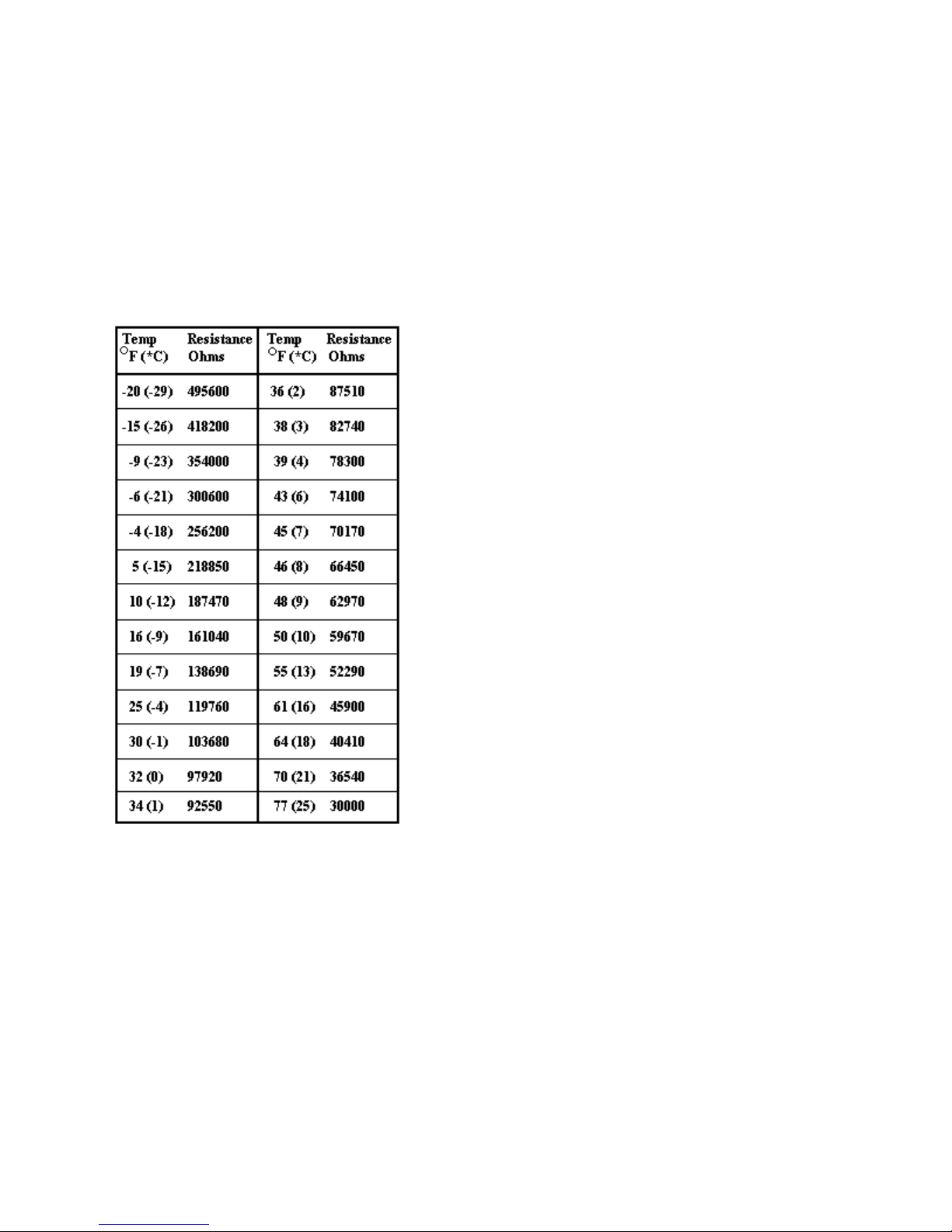

Refrigerator and Freezer Thermist or

As temperature decreases, resistance increases.

As temperature increases, resistance decreases.

Open thermistor or thermistor circuit will result

in failure of refrigerator to cool.

Shorted thermistor will cause refrigerator to run

100 percent of time except for defrost cycle.

• Freezer temperature setting and

thermistor value will determine if

compressor/condenser fan and

evaporator fan switches are open or

closed. Compressor/condenser fan

switch must be open for 6 minutes

before switch can close again

(compressor dwell time.)

• Refrigerator temperature setting and

thermistor valve will determine if fresh

food fan switch is open or closed.

• Cut-out and cut-in temperature values

must be reached and maintained for 15

minutes before output state will change

(digital delay).

• Refrigerator and freezer control

calibration can be adjusted in Program

Mode B.

Factory set freezer and refrigerator

settings.

7

Electronic Functional Description

Adaptive Defrost Operation

Defrost occurs after predetermined length of

compressor run hours. Compressor run time

between defrost changes, or adapts, depending

upon recent history of defrost lengths (time it

takes for defrost terminator to open after defrost

heater has been turned on).

• Defrost terminator opens at 55°F (-

13°C).and closes at 20°F (-7°C).

• Compressor run time between defrost

(CRDT) will be one of 3 values under

normal operation CRDT 1 (8 hours) or

CRDT 2 (12 hours) or CRDT 3 (15

hours).

If defrost length is low (DT-LO defined

as 21 minutes) indication small frost

load, CRDT for next defrost cycle is

advanced to next level.

If defrost length is high (DI-HI defined

as 24 minutes) indicating large frost

load, CRDT for next defrost cycle is

lowered to next level.

If defrost length is between 21 and 24

minutes, CRDT for next defrost cycle

remains the same.

Initial value at power up CRDT is 4 hours.

• Vacation Mode CRDT equals 96

hours. Vacation Mode CRDT is

interrupted with door openings.

Defrost interval will revert back to

interval before vacation mode.

Three things must occur to reach

Vacation Mode CRDT.

1) Defrost interval must be

CRDT 3 (16 hours).

2) Both refrigerator and

freezer doors must have

remained closed since last

defrost cycle.

3) Defrost thermostat must

have opened in less than 21

minutes during last defrost

cycle.

• Six minutes dwell time occurs after

defrost terminator opens before

compressor and condenser fan

motor will operate. Ten minutes

dwell time occurs after defrost

terminator opens before evaporator

fan motor will operate. Dwell time

can be bypassed be disconnecting

power to the unit for 30 seconds.

• Conventional defrost can be selected

in Program Mode B.

8

Program Mode

Accessing Program Mode

Two programming modes are available. Mode A

allows reading refrigerator and freezer thermistor

temperatures. Mode B is used for all other

programmable functions.

1. Open refrigerator door.

2. Press Display On pad.

3. Press * pad.

4. Press the following sequence of pads within 6

seconds; Max Ref, Max Frz, Max Ref, Max

Frz.

5. When access is granted, tone will sound three

times and control will be in Program Mode A.

Unmarked indicator light will illuminate.

6. T o ggle to Program Mode B by pressing Display

On pad. Unmarked indicator light is off.

EEPROM Update in Control Memory

EEPROM is permanent programmable memory of

the control panel.

• Entry tone, door audio alarm and status are

stored in EEPROM after control is

deactivated.

• Information stored in EEPROM me mory is

not affected be power loss.

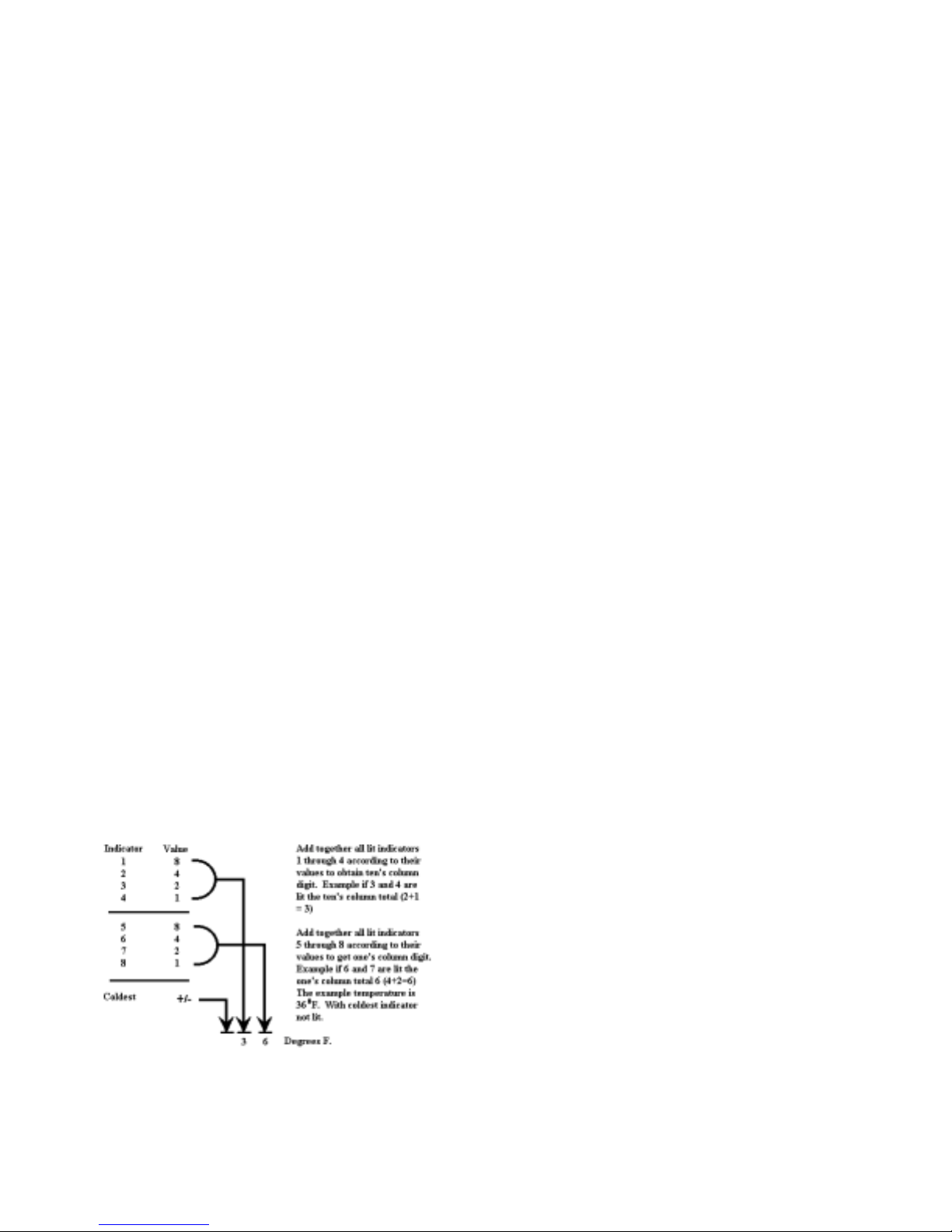

Mode A Function

Reading Temperature Display

Temperature display will show thermistor

temperature in binary coded decimal format (BCD).

Indicator lights 1 through 4 represent the ten’s digit

with 1 being the most significant bit. Indicator lights

5 through 8 represent one’s digit with 5 being the

most significant bit. Positive and negative are shown

be indicator light 9. Light glows to show negative

value.

Freezer Thermistor Temperature

1. Choose freezer thermistor temperature

display be pressing Freezer Temp pad.

2. Freezer thermistor temperature displays.

Refrigerator Thermistor Temperature

1. Choose refrigerator thermistor temperature

display be pressing Ref Temp pad.

2. Refrigerator thermistor temperature displays

Mode B Functions

Automatic Keyboard Functions

Activate and deactivate keyboard by toggling Display

Off pad. If high temperature indicator glows,

keyboard will disable after 10 minutes. If high

temperature indicator is off, keyboard is always

enabled. DO NOT LEAVE KEYBOARD IN

ENABLE MODE AFTER PROGRAMMING IS

COMPLETE.

Door Alarm Delay

1. Press Alarm Off pad. Door open indicator

will glow. One temperature indicator should

glow indicating present delay setting in

minutes (indicator 1 means 1 minute, 2

means 2 minutes, etc.). Default delay is 3

minutes.

2. Press Warmer pad to decrease delay by 1

minute.

3. Press Colder pad to increase delay by 1

minute.

Max Ref Run Time Duration

1. Press Max Ref pad. Max Ref light will

glow. One temperature indicator should

glow indicating present Max Ref run

time duration in 2 hour increments

(indicator 1 means 2 hours, 2 means 4

hours, etc.) . Default del ay is 10 ho urs.

2. Press Warmer pad to decrease Max Ref

duration by 2 hours.

3. Press Colder pad to increase Max Ref

duration by 2 hours.

9

Program Mode

Max Frz Run Time Duration

1. Press Max Frz pad. Max Frz light will

glow. One temperature indicator should

glow indicating present Max Frz run time

duration in 4 hour increments (indicator

1 means 4 hours, 2 means 8 hours, etc.)

Default delay is 24 hours.

2. Press Warmer pad to decrease Max Frz

duration by 4 hours.

3. Press Colder pad to increase Max Frz

duration by 4 hours.

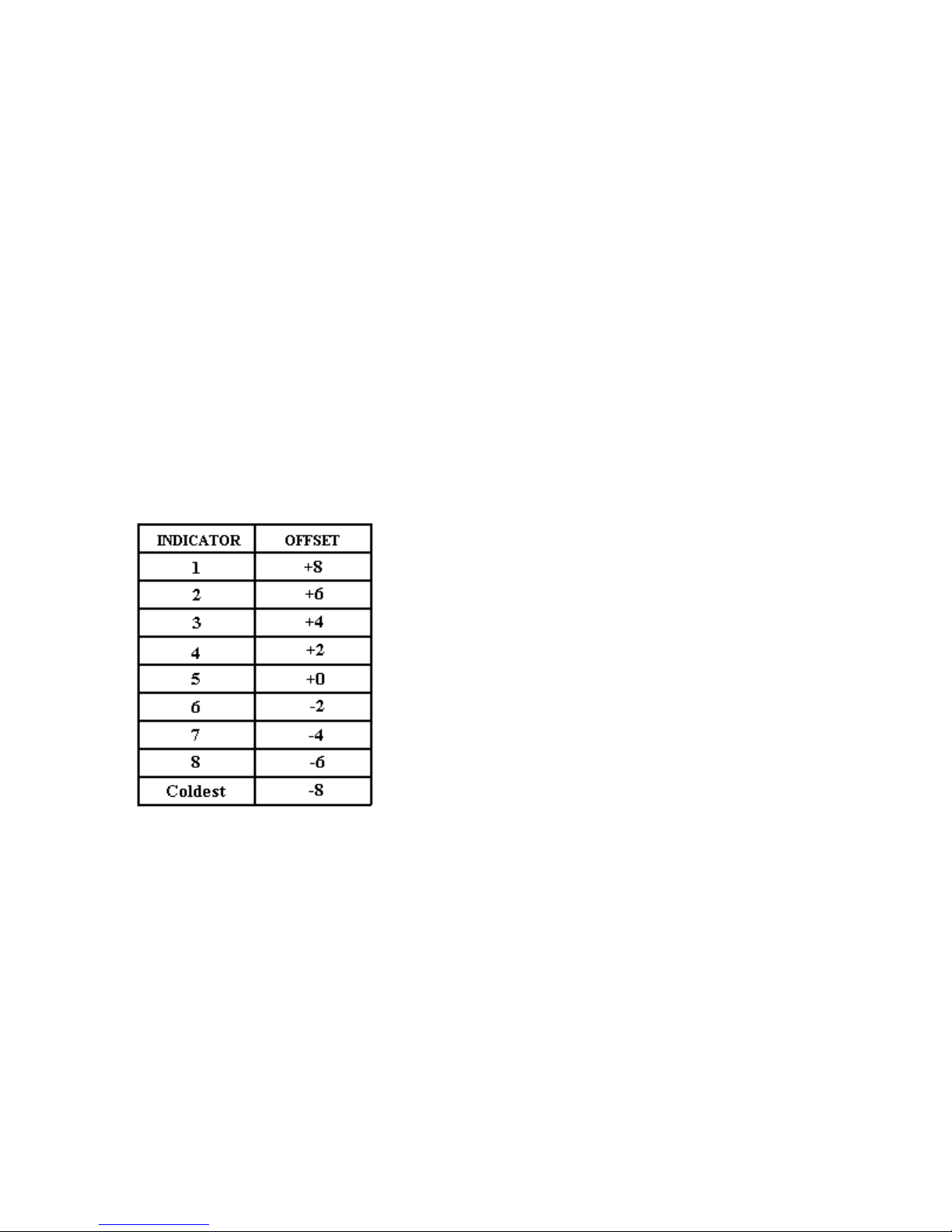

Temperature Offset Calibration

Offset amount adjusts temperatures for

refrigerator cut-ins and cut-outs by the amount

of offset. The chart below shows the indicator

and the amount of offset from the factory default

setting.

• Setting refrigerator Temperature Offset.

Press Ref Temp pad. Refrigerator

indicator and one indicator will glow.

Press Warmer pad to move offset to the

next warmer setting. Press Colder pad

to move to the next colder setting.

Factory default refrigerator offset is +2.

• Setting Freezer Temperature Offset

Press Freezer pad. Freezer temperature

indicator and one indicator will glow.

Press Warmer pad to move offset to the

next warmer setting. Press Colder pad

to move offset to the next colder setting.

Factory default freezer offset is 0.

Defrost Mode Selection

Toggle (*) pad to select adaptive or conventiona l

defrost mode. Vacation indicator glows when

adaptive defrost has been selected. If vacation

indicator is off, conventional defrost is selected.

Conventional defrost uses 8 hour CRDT value.

Forced Defrost

Defrost can be forced to start by pressing and

holding the Alarm Off pad for 3 seconds.

Program changes will be saved permanently in

EEPROM and program mode will exit to Run

Mode.

Forced Pull down (Compresso r Start )

Compressor start can be forced by pressing and

holding Max Frz for 3 seconds. Program

changes will be saved permanently in

EEPROM. Compressor, evaporator fan, damper

heater, and condenser fan will come on.

Exiting Program Mode

Press Display On pad for 3 seconds to exit

Program Mode. Tone will sound three times.

Changes made in Program Mode will be

permanently saved in EEPROM.

Note: If no pad is pressed for 10 minutes,

Program Mode will be automatically exited.

However, no changes will be saved if Program

exits automatically.

10

Electronic Testing

Electronic Testing Mode

Forced Defrost Start

1. Press Display On pad to activate control

panel.

2. Simultaneously press and hold Max Ref and

Display Off pads for 3 seconds.

Forced Compressor Start

1. Press Display On pad to activate control

panel.

2. Simultaneously press and hold Max Frz and Display Off pad for 3 seconds.

Open Thermistor Detect

Alarm sounds and freezer or refrigerator

indicator light shows and temperature indicators

4 through 7 will turn on in sequence if either

thermistor circuit opens. Refer to Temperature

Control Operation Section and Electronic

Testing Section.

1. Press Alarm Off pad to turn off alarm.

1. Check for line voltage on terminal E7 on

high voltage board. With refrigerator

door open (refrigerator light ON)

reading should be 120-VAC. With door

closed (refrigerator light OFF) reading

should be approximately 0 VAC. If

voltage does not change with light

switch and light is turning light off and

on red/white wire is broken between

switch and high voltage board.

2. Check for voltage on terminal E7 on

high voltage board. Output voltage

should toggle with toggling of light

switch. If output voltage does not

toggle, high voltage board needs

replacing.

3. If terminal 7 on high voltage board

changes with opening and closing of

door, orange wire in low voltage

harness is broken (check for continuity

between pin 7 on high voltage board and

pin 10 on low voltage board) or low

voltage board

2. Alarm will retest for normal operation.

If condition has not been corrected,

alarm will sound again.

Evaporator Fan Suppression

The evaporator fan will turn off every time

either refrigerator or freezer door is open.

To test if this function is operating:

1. Perform forced pull down procedure as

noted above--evaporator fan should be

on.

2. Open the refrigerator or freezer door-the fan should turn off.

3. Push the light switch off-the evaporator

fan should start.

If fan does not toggle off and on when

refrigerator light switch is turned off and on it

has been determined evaporator fan motor

operational, perform following tests to

determine failure:

1. Check for line voltage on terminal E8 on

high voltage board. With freezer door

open, reading should be 120VAC. With

door closed, reading should be

approximately 0 VAC. If voltage does not

change with light switch and light switch is

turning light off and on, violet/white wire is

broken between switch and high voltage

board.

2. Check for voltage on pin 7 on pin

connector of high voltage board. Output

voltage should toggle with toggling of

light switch. If it does not toggle, high

voltage board needs replacing.

3. If voltage on pin 7 on pin connector on high

voltage board changes with opening and

closing of door, orange wire in low

voltage harness is broken (check for

continuity between pin 7 on high voltage pin

connector and pin 10 on low voltage board)

or low voltage board needs replacing.

needs replacing.

11

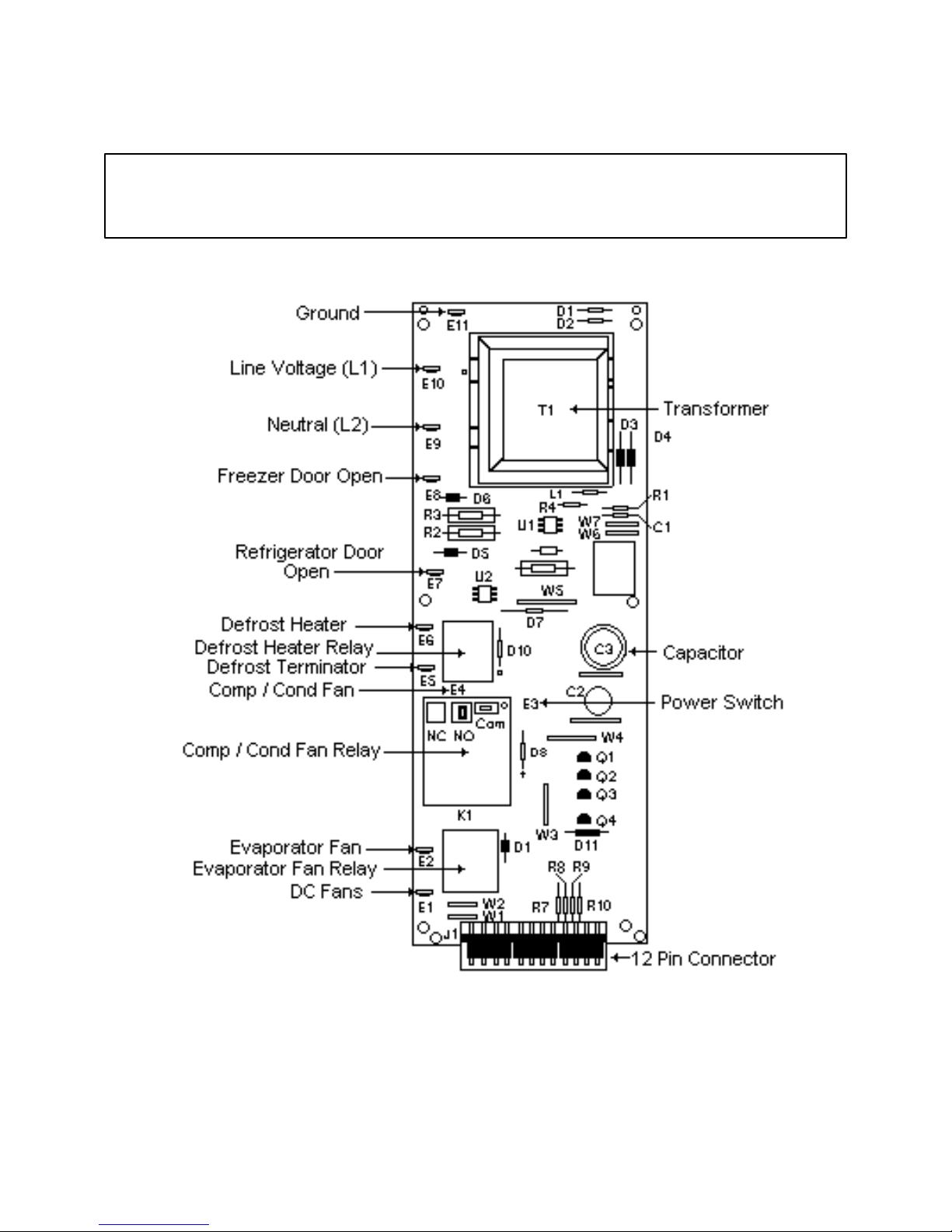

Electronic Function Description

WARNING: To avoid electrical shock which can cause severe personal injury or death, disconnect

power to r efrigerator using power swit ch before ser vicing. Wires removed during d isassembly must be

replaced on proper terminals to insure earth ground and polarization. After servicing, reconnect power

using power switch.

12

Electronic Function Description

WARNING

To avoid electrical shock which can cause severe personal injury or death, disconnect power

to refrigerator using power switch before servicing. Wires removed during disassembly must

be replaced on proper terminals to insure correct earth ground and polarization. After

servicing, reconnect power using power switch

Refrigeration and Defrost Component Checks Made at High Voltage Board

Low voltage board input W1 to D11 approximately -25VDC

E10 to E9 (Neutral) or ground approximately 120VDC

Compressor/condenser fan motor “ON” = E4 to E9 (Neutral) or ground approximately 120VDC

“OFF” = E4 to E9 (Neutral) or ground

Compressor/condenser fan motor “CLOSED” = R7 to ground approximately -11VDC

relay “OPEN” = R7 to ground approximately -25VDC

Evaporator fan motor relay “CLOSED” = R8 to ground approximately -11VDC

“OPEN” = R8 to ground approximately -25VDC

Evaporator fan motor “ON” =E2 (Neutral) or ground approximately 120VDC

“OFF” = E2 (Neutral) or ground 0VDC

Defrost heater “ON” = E6 to E9 (Neutral) or ground approximately 120VDC

“OFF” = E6 to E9 (Neutral) or ground 0VDC

Defrost heater relay “CLOSED” = R9 to ground approximately -11VDC

“ OPEN” = R9 to ground approximately -25VDC

Defrost terminator “CLOSED” =E5 to E9 (Neutral) ground approximately 120VDC

“OPEN” = E5 to E9 (Neutral) or ground 0VDC

DC fan output voltage from “ON’ = E1 to ground approximately -25VDC

high voltage board to fresh food fan “OFF” = E1 to ground 0VDC

or condensate evaporator fan

DC fan input voltage “ON” =R10 to ground approximately -11VDC

signal to high voltage board from “OFF” = R10 to ground approximately -25VDC

low voltage board for fresh food

fan and for condensate evaporator

Filament voltage at pin 11 and 12 = less than 5VDC

13

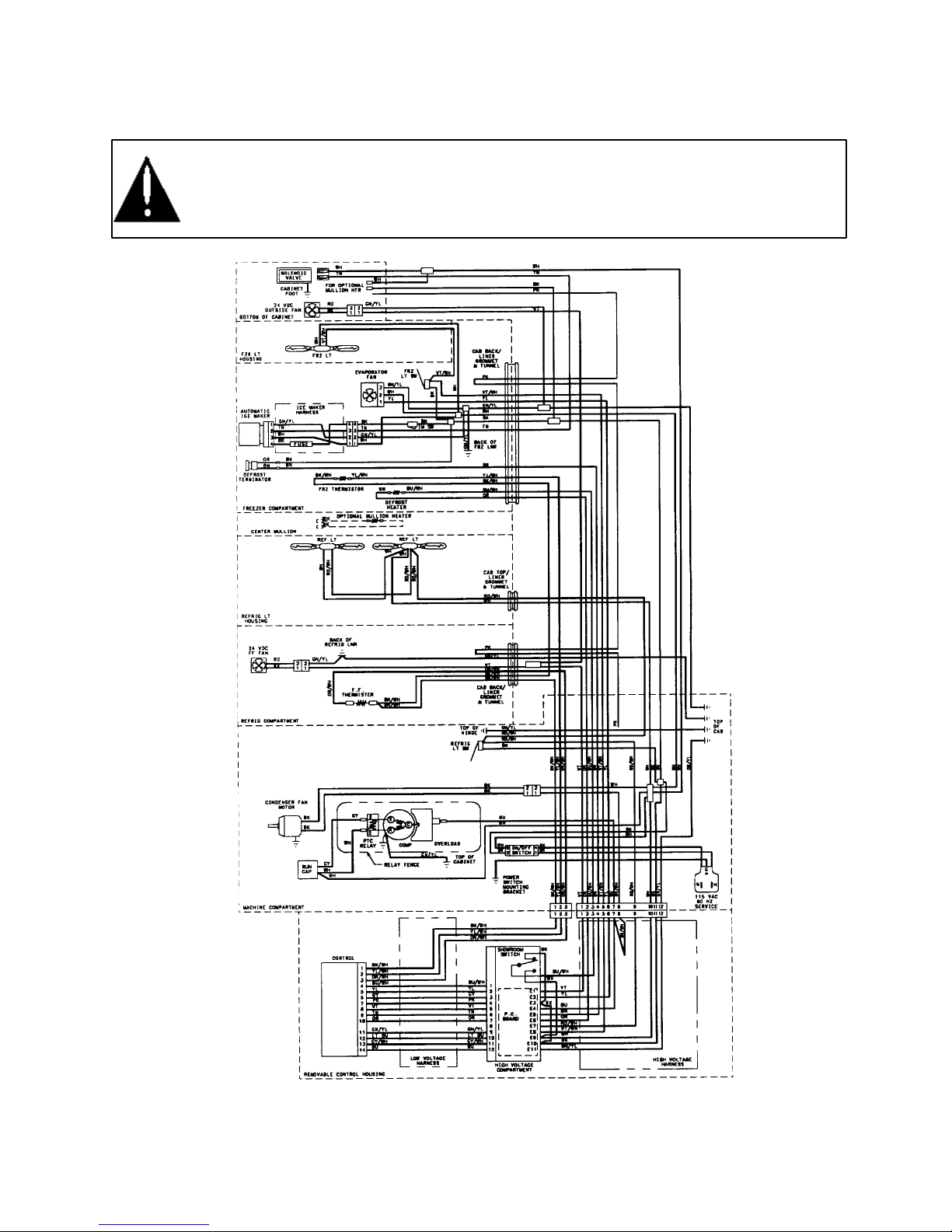

Wiring Diagram

WARNING To avoid electrical shock which can cause severe personal injury or death,

disconnect power to refrigerator using power switch before servicing. Wires removed during

disassembly must be replaced on proper terminals to insure correct earth ground and

polarization. After servicing, reconnect power using power switch.

14

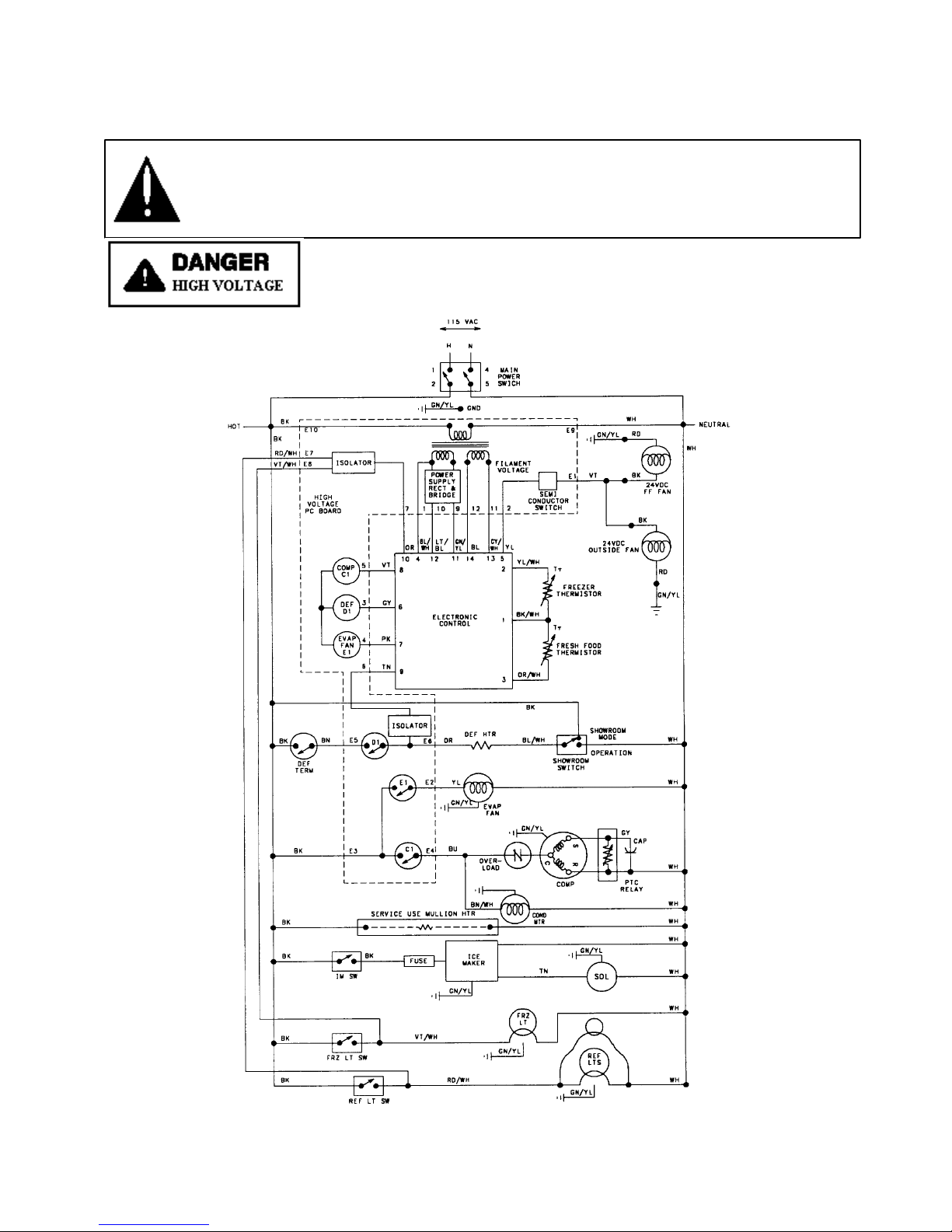

Wiring Schematic

To avoid electrical shock which can cause severe personal injury or death, disconnect power

to refrigerator using power switch before servicing. Wires removed during disassembly must

be replaced on proper terminals to insure correct earth ground and polarization. After

servicing, reconnect power using power switch

15

Electronic Function Description

WARNING: To avoid electrical shock which can cause severe personal injury or death,

disconnect power to refrigerator using power switch before servicing. Wires removed during

disassembly must be replaced on proper ter minals to insure correct grounding and po larization.

After servicing, reconnect power using power switch.

Freezer Compartment Theory of Operation

As a freezer thermistor warm, the resistance decreases allowing low voltage signal to be sent to electronic

control. Electronic control sends two low voltage signals, one to the compressor relay coil (C1) and one

to the evaporator relay coil (E1).

When both relay coils are energized and both relay contacts are closed, high voltage circuits to evaporator

fan motor and compressor / condenser fan motor are complete.

As thermistor cools during refrigeration cycle, resistance through thermistor increases blocking low

voltage signal to electroni c control interrupting circui t.

16

Electronic Function Description

WARNING: To avoid electrical shock which can cause severe personal injury or death,

disconnect power to refrigerator using power switch before servicing. Wires removed

during disassembly must be replaced on proper terminals to insure correct grounding

and polarization. After servicing, reconnect power using power switch.

Refrigeration Compartment Theory of Operation

As fresh food thermistor warms, resistance decreases allowing low voltage signal to be sent to the

electronic control. El ectronic control sends a low voltage signal, to semiconductor switch for DC fresh

food fan and DC condensate evaporator fan.

Both fans begin operating. Fresh food fan circulates freezer air into fresh food compartment. Condensate

evaporator fan circuilates air over condensate drain pan aiding in evaporation.

As fresh food thermistor cools, resistance increases blocking low voltage signal to electronic control

interrupting circuit to DC fresh food fan and DC condensate evaporation fan.

17

Loading...

Loading...