Page 1

APPLICATION

APPLICATION

NNootte

e

T

T

EELLEECCOOM

M

S

S

OOLLUUTTIIOONNSSFFOORRTTHHE

E

221

1

SST

T

C

C

EENNTTUURRY

Y

EWP

EWP

Enhanced Weather

Protection

March 3, 2004

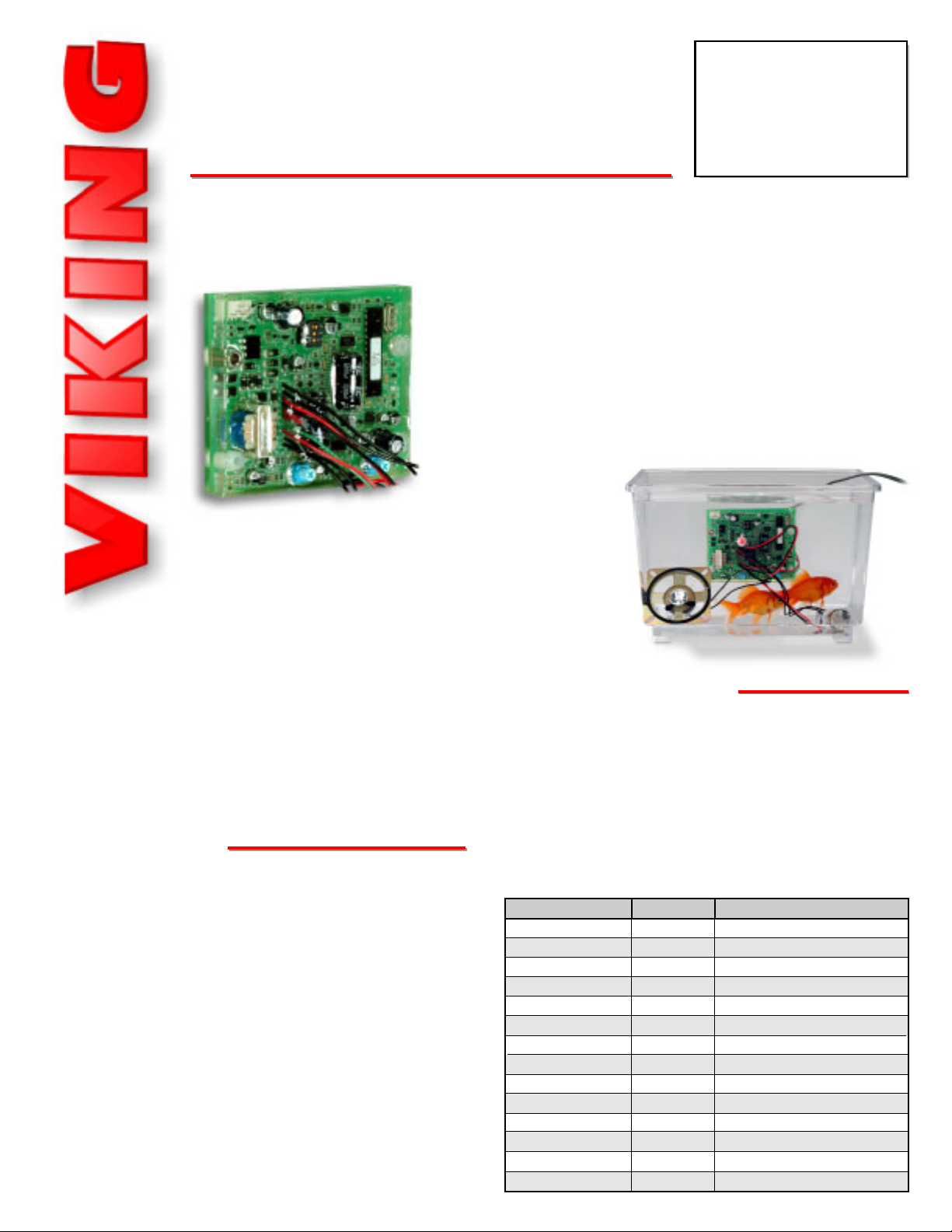

Standard practice for manufacturing emergency phones is to provide them

with standard uncoated circuit boards (like the ones in your PC). A few manufacturers, including Viking, spray the circuit boards with a water resistant

material such as acrylic conformed coating to protect them.

Some emergency phone applications demand extra protection. Phones that

are mounted outside exposed to the elements in salty air near the ocean, in

high humidity, exposed to a corrosive atmosphere or vehicle exhaust all

need an extra measure of weather and corrosion resistance.

Our EWP (Enhanced Weather Protection) phones are designed with total

reliability in mind. First,

we use weather-sealed

push button switches, trim

pots and DIP switches so

FFeeaattuurrees

s

• Urethane potting for:

- Maintaining flexibilty at low temperatures

- Excellent electrical insulation

- Low stress on sensative componenants

- Unaffected by moisture at high temperatures

- Thermal cycling ability

- Hydrolytic stability

- No shrinkage

• Sealed switch, LED, trim pots, push button and

microphone connections

• All wires are hand soldered

• Mylar speaker with special weather-proof boot

• Field adjustable trim pots and DIP switches

• Closed cell foam gasketing to prevent water penetration

• Weatherproof connectors filled with anti-corosive sealing gel

PPhhoonnee......771155..338866..8888661

1

Enhanced Weather Protection Now Available

on Selected Viking Products

you can adjust microphone and speaker volumes and set programming features right at the installation site.

Then, we hand solder all wires to eliminate the kind of corrosion that

can occur in ordinary electrical connectors. We also hand seal the

connections at the push button switch, microphone, and "Call

Connected" LED using a special non-corrosive silicone sealant. We

use a special microphone boot that acts as a shield against water penetration. A mylar

speaker is used with rubber mounting gasket. Closed cell foam gasketing is used

behind front panels to prevent water penetration.

Finally we "Pot" the entire board in a clear flexible urethane

encapsulating material leaving the weather sealed fieldadjustable trim pots and DIP switches accessible. Our flexible

polyurethane sealant allows the circuit board and it’s components

to expand and contract, while maintaining weather resistance. To

protect tip and ring connections, we include connectors filled with

anti-corrosive sealing gel.

Model

BLK-3-EWP

E-10/20A-EWP

E-1600A-EWP

E-1600-03A-EWP

E-1600-20A-EWP

E-1600-45A-EWP

E-1600-50A-EWP

E-1600-52A-EWP

E-1600-55A-EWP

E-1600A-BLT-EWP

E-30-EWP

K-1700-3-EWP

W-1000/2000A-EWP

W-3000-EWP

Fax Back #

653

210

215

215

215

215

215

215

215

217

212

157

170

180

Description

Line Status Strobe Light Kit

Speaker Phones

ADA Compliant Handsfree Emergency Phone

ADA Compliant Handsfree Emergency Phone

ADA Compliant Handsfree Emergency Phone

ADA Compliant Handsfree Emergency Phone

ADA Compliant Emergency Phone Kit

ADA Compliant Emergency Phone Kit

Univeral Emergency Phone Kit

Emergency Tower Phone with Strobe Light

Stainless Steel Handsfree Phone

Stainless Steel Handsfree Phone with Keypad

Handsfree Doorboxes

Vandal-Resistant Stainless Steel Doorbox

AApppplliiccaattiioonns

s

• Exposure to harsh elements (outdoor emergency phones)

• Exposure to a salty atmoshere near the ocean (beach, boardwalk or lifeguard emergency phones)

• High-humidity environments (tropical environments and areas

where it gets very hot and humid)

• Corrosive-atmosphere environments

• High-pollution environments

• High-vehicle exhaust environments (roadside assistance and

emergency phones)

Loading...

Loading...