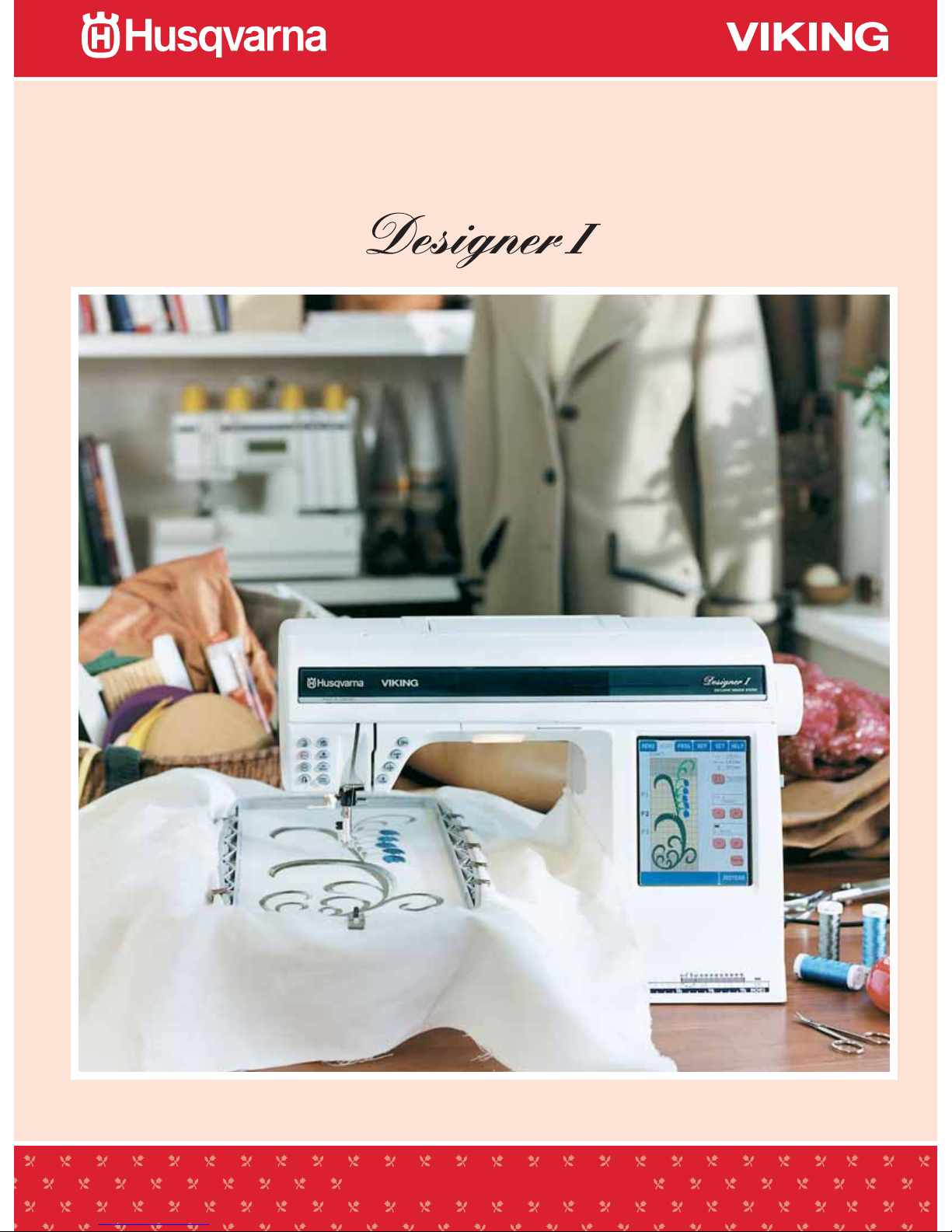

Viking Designer I User Manual

User’s Guide

KEEPING THE WORLD SEWING

This houshold sewing machine is designed to comply with IEC/EN 60335-2-28 and UL1594

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the following:

Read all instructions before using this household Sewing machine.

DANGER – To reduce the risk of electric shock:

• A sewing machine should never be left unattended when plugged in. Always unplug this sewing machine

from the electric outlet immediately after using and before cleaning.

• Always unplug before relamping. Replace bulb with same type rated 5 Watt.

WARNING – To reduce the risk of burns, fi re,

electric shock, or injury to person:

• Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by or

near children or infi rm persons.

• Use this sewing machine only for its intended use as described in this manual. Use only attachments

recommended by the manufacturer as contained in this manual.

• Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has

been dropped or damaged, or dropped into water. Return the sewing machine to the nearest authorised

dealer or service center for examination, repair, electrical or mechanical adjustment.

• Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the

Sewing machine and foot controller free from the accumulation of lint, dust, and loose cloth.

• Keep fi ngers away from all moving parts. Special care is required around the Sewing machine needle.

• Always use the proper needle plate. The wrong plate can cause the needle to break.

• Do not use bent needles.

• Do not pull or push fabric while stitching. It may defl ect the needle causing it to break.

• Switch the Sewing machine off (“0”) when making any adjustment in the needle area, such as threading

needle, changing needle, threading bobbin, or changing presser foot, etc.

• Always unplug Sewing machine from the electrical outlet when removing covers, lubricating, or when

making any other user servicing adjustments mentioned in the instruction manual.

• Never drop or insert any object into any opening.

• Do not use outdoors.

• Do not operate where aerosol (spray) products are being used or where oxygen is being administrated.

• To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Hold plug when rewinding into cord reel. Do not allow plug to whip when rewinding.

• This sewing machine is provided with double insulation. Use only identical replacement parts.

See instructions for Servicing of Double-Insulated Appliances.

SAVE THESE INSTRUCTIONS

SERVICING OF DOUBLE INSULATED

PRODUCTS

In a double-insulated product, two systems of insulation are provided instead of grounding. No ground means is provided on a double-insulated product, nor should a means for grounding be added to the product.

Servicing of a double-insulated product requires extreme care and knowledge of the system, and should be

done only by qualifi ed service personnel. Replacement parts for a double-insulated product must be identical

to those parts in the product. A double-insulated product is marked with the words ‘DOUBLE INSULATION’

or ‘DOUBLE INSULATED’.

Care of your

Designer 1

Page 109 - 113

Care of your

Designer 1

Page 109 - 113

Heirloom

Sewing

Page 101 - 108

Quilting

Page 95 - 100

Decorative/

Crafting

Page 83 - 94

Embroidery

Page 63 - 82

Utility/Garment

Sewing

Page 39 - 62

Learn your

Designer 1

Page 4 - 38

Embroidery

Page 63 - 82

Learn your

Designer 1

Page 4 - 38

Utility/Garment

Sewing

Page 39 - 62

Quilting

Page 95 - 100

Heirloom

Sewing

Page 101 - 108

Decorative/

Crafting

Page 83 - 94

Table of contents

Learn your Designer I 4-38

Overview 4-5

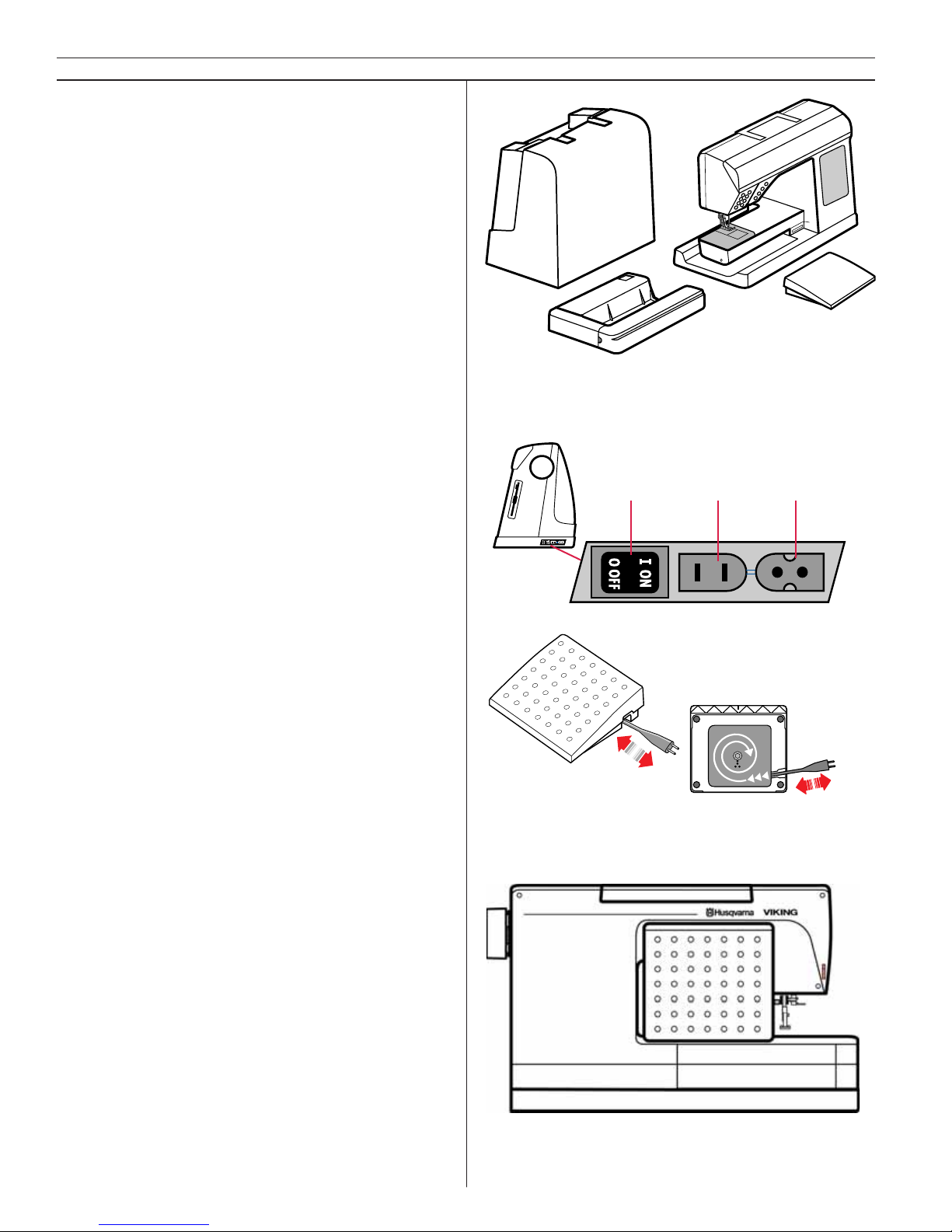

Unpack, Connect, Pack away 6

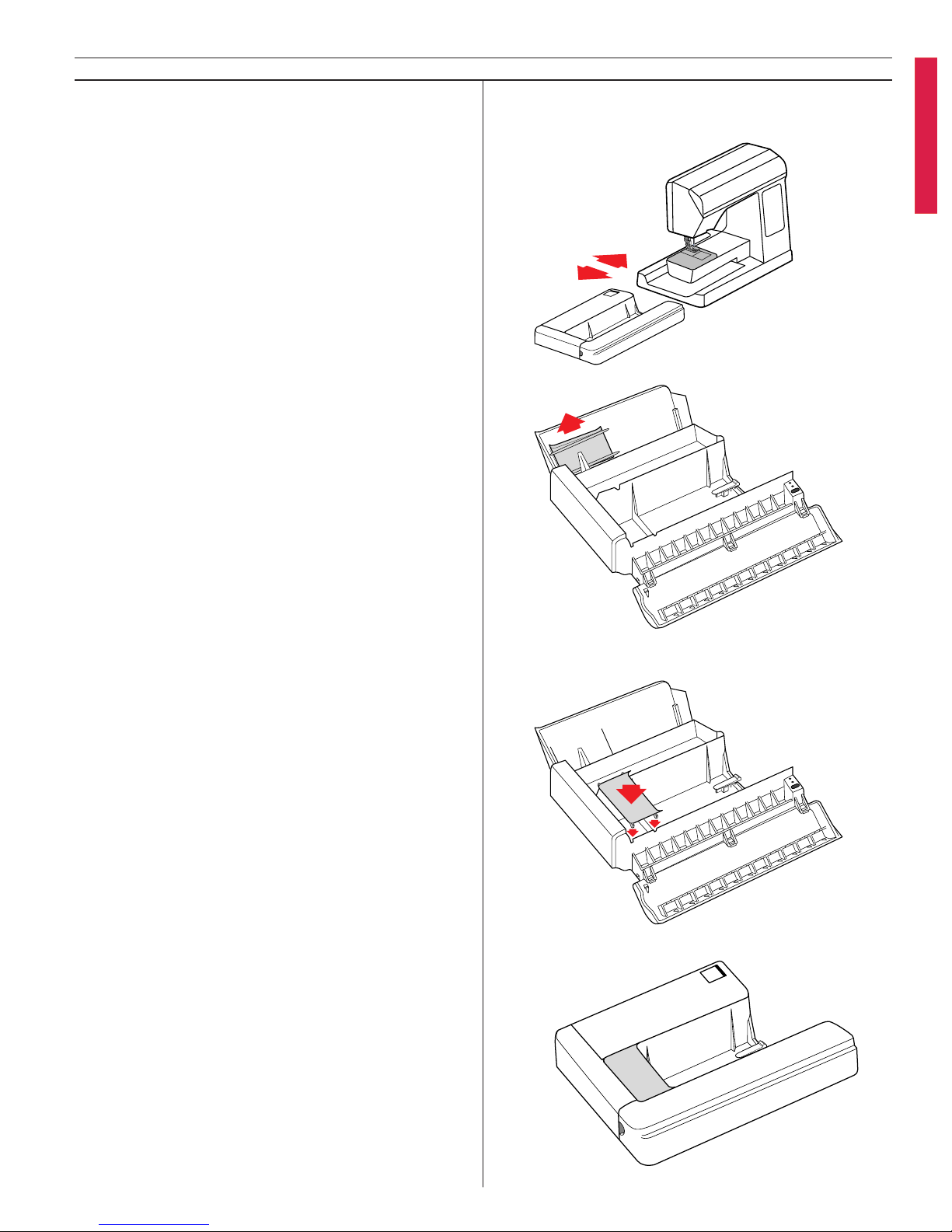

Accessory Tray/Sewing surface 7

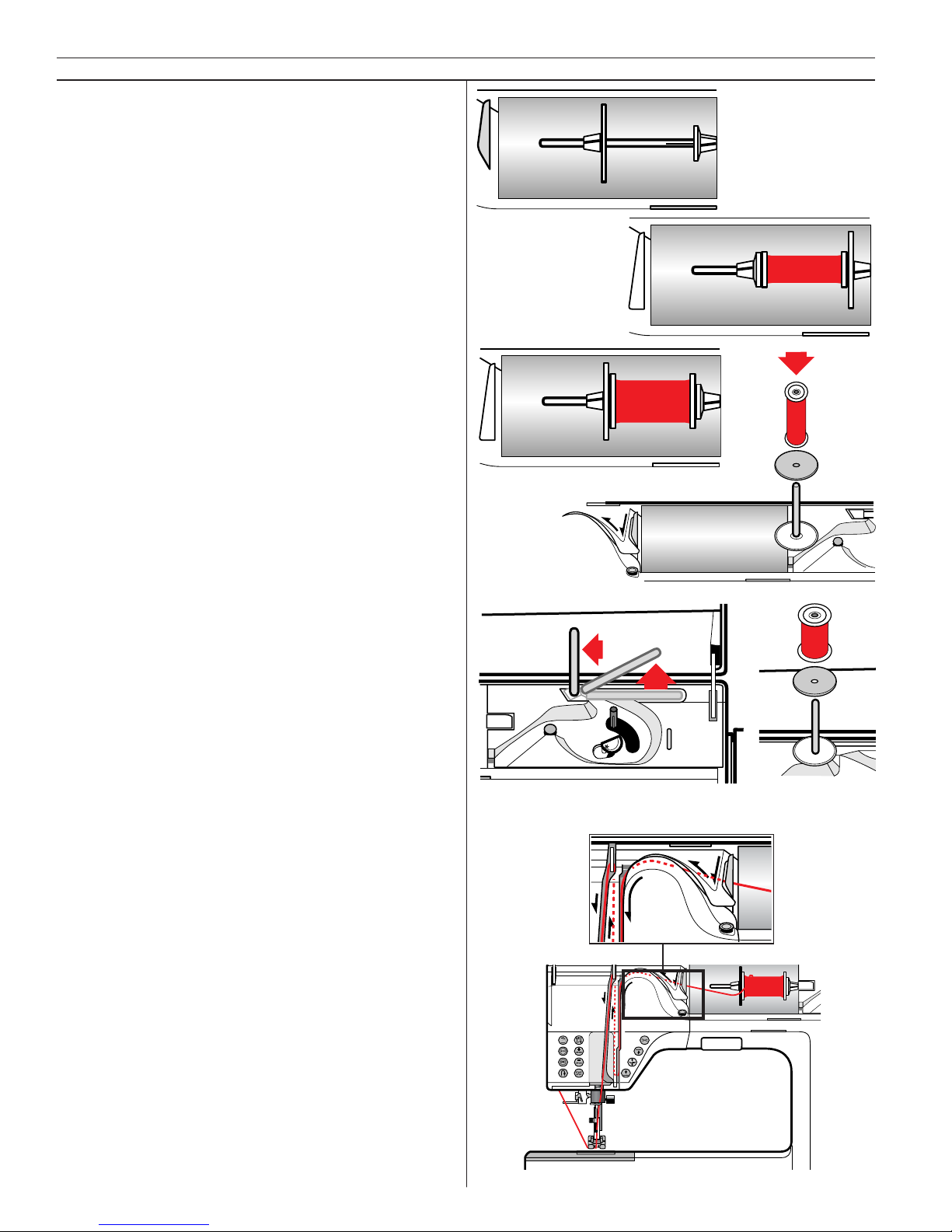

Spool pin 8

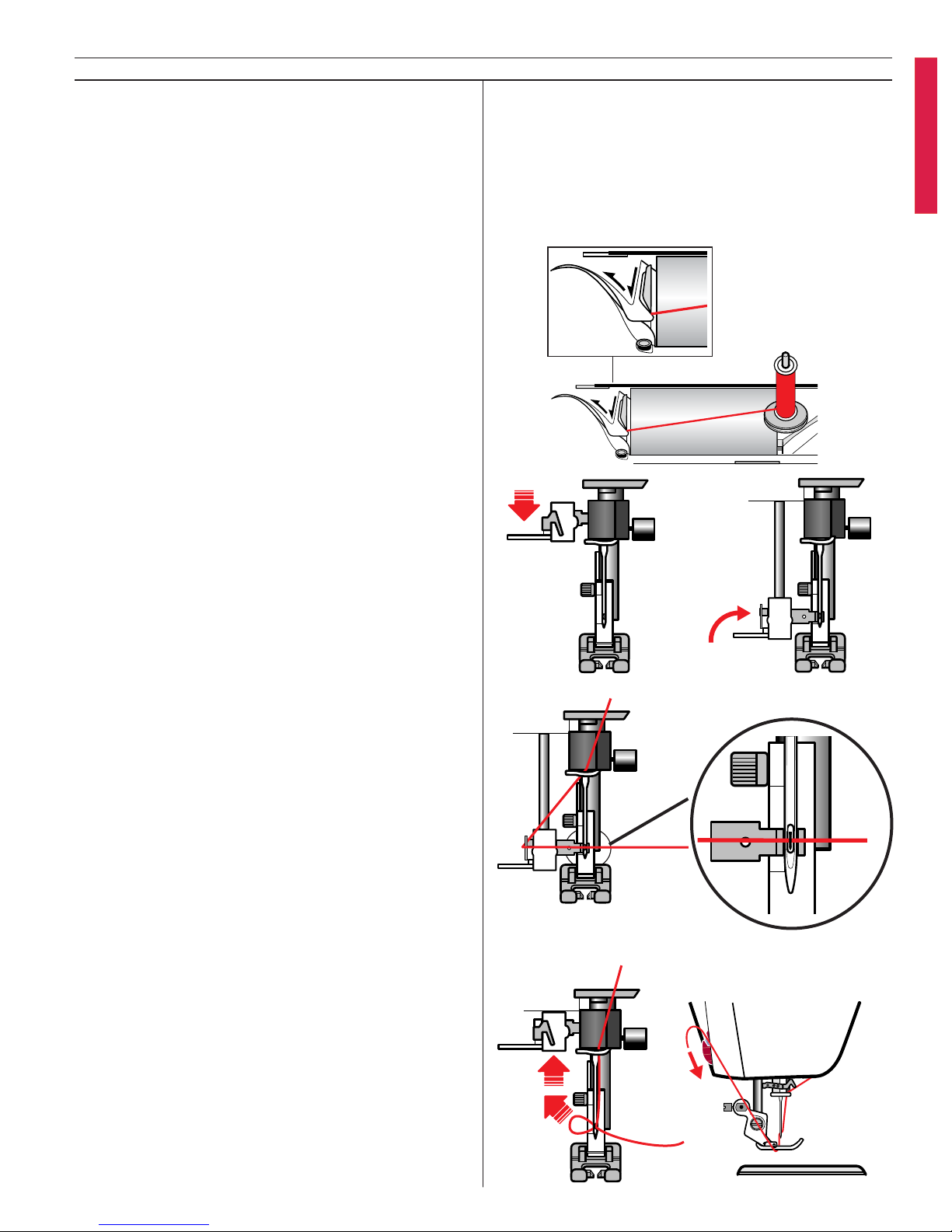

Threading 8-10

Bobbin winding 10-11

Function buttons 12

Sensor Foot 13

Changing the presser foot 13

Presser feet 14-15

Feed teeth 15

Changing the needle, Needles 16

Color Touch Screen 17-38

Main Menu 18

Sewing Advisor – The easy

way to sew 19

Speciality Stitch Menus 20-26

Starting to sew 27

Thread tension 27

Finish the sewing 27

ADJUST Menu 28

SET Menu 29-32

Pop Up Menus 33

HELP Menu 34

Programming 35-38

Utility/Garment Sewing 39-62

Sewing Advisor 40-50

Fabric Selection, Thread 40-41

Seam 42-43

Overcast, Three-step zigzag 44

Seam and Overcast 45

Baste 46

Blind Hem, Hem 47-48

Buttonhole 49-50

Button 50

Menu B – Buttonhole 51-53

Corded Buttonhole 52

Step by Step buttonhole 52

Buttonhole Balance 52

Buttonhole Density 53

Cutting Buttonholes 53

Bound Buttonhole 53

Menu A – Utility Stitches 54-61

Straight Stitch 54

Lightning Stitch 54

Gathering 54

Twenty-fi ve Needle positions 55

Zipper 56

Reinforced Straight Stitch 57

Multiple Zigzag Stitches 58

Darning and Mending 59

Bartacks, Belt loops 60

Stitch Table – Menu A 61

Menu S – 4-Way Stitches 62

Embroidery 63-82

Embroidery Unit, Connect,

Remove 64-65

Built-in Disk Drive 65

Vertical spoolpin,

felt spool pad 65

Embroidery Booklet 65

Hoop, Template 66-67

Getting started 69

Embroidery Screen Menus 70-71

SET in embroidery 71

ADJUST in Embroidery 72

Embroidery colors, features 73

Pop-up menus in Embroidery 74

Start embroidering, thread cut 75

Customizing Design 76-81

Built-in Stitches in the hoop 82

Decorative/Crafting 83-94

Decorative/Crafting 84-88

Appliqué 84-85

Taper Satin Stitch 86

“Handlook” Heirloom Appliqué 87

Appliqué Embroidery 88

Decorative Stitches 89-91

Cross Stitches 92

Lettering 93-94

Quilting 95-100

Quilting 96

Quilting and Piecing Quilts 96

Decorative stitch tie Quilting 96

Crazy Quilting 97

Handlook Quilting 97

Stipple Quilting 98

Channel Quilting 98

Edge/Quilting Guide 99

Quilt Embroidery 99

Heirloom Sewing 101-108

Heirloom Sewing 102

Entredeux 102

Lace Insertion 102

Bridging Stitch 103

Hemstitching/Wing needle 103

Scallop Stitching 104

Smocking 105

Cutwork Embroidery 106

Pictogram 107

Care of your Designer I 109-113

Care of your Designer I 110-111

Trouble Shooting 112-113

How to update

Designer I 113

Index 114-115

4

Learn your Designer I

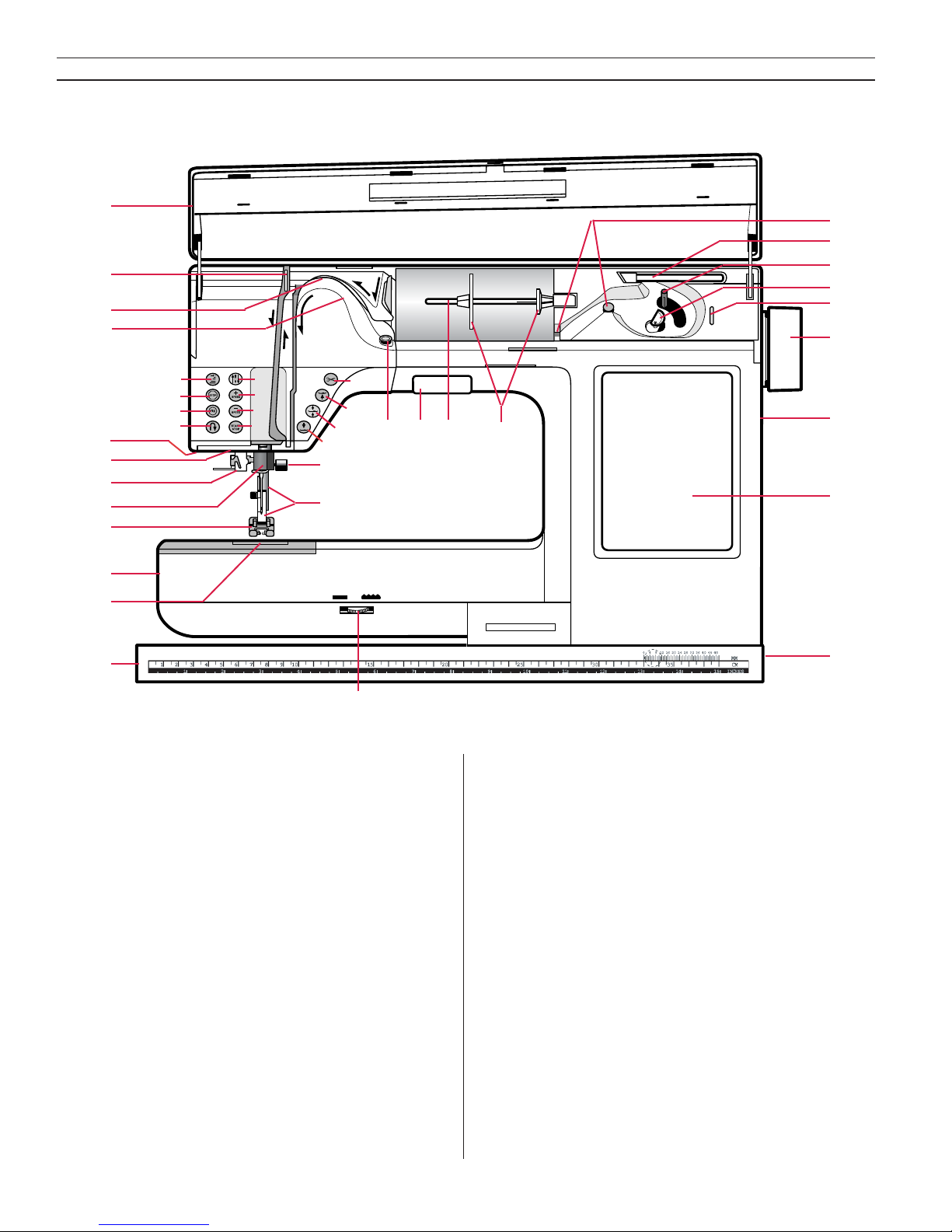

Overview – Front side

1. Door/Lid

2. Thread take-up lever

3. Thread tension

4. Pre-tension disc

5. Stitch Re-Start button

6. Needle stop up/down button

7. Finishing Stop button

8. Sewing speed button – faster

9. FIX button

10. Sewing speed button – slower

11. Reverse button

12. Start/Stop button

13. Sensor Buttonhole Foot socket

14. Light

15. Needle threader

16. Needle bar

17. Presser foot

18. Free arm

19. Bobbin cover

20. Baseplate

21. Drop feed dial

22. Presser foot bar and Presser foot ankle

23. Needle clamp screw

24. Sensor foot lift down button

25. Sensor foot lift pivot button

26. Sensor foot lift up/extra lift button

27. Thread cutter button

28. Thread tension for bobbin winding – vertical

spool pin

29. Horizontal spool pin

30. Spool holders

31. Bobbin winding guides

32. Vertical spool pin

33. Bobbin winder spindle

34. Bobbin stop

35. Thread cutter for bobbin winding

36. Handwheel

37. Built-in disk drive

38. Color Touch Screen

39. Main power switch, Connection to power

supply

1

12345678910111213

INCHES

2 3 4 5 6 7 8 9 10 15 20 25 30

CM

1.

2.

9.

6.

5.

10.

11.

12.

14.

15.

14.

32.

33.

34.

35.

37.

3.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28. 29. 30.

38.

36.

39.

8.

13.

7.

4.

Learn your Designer I

31.

5

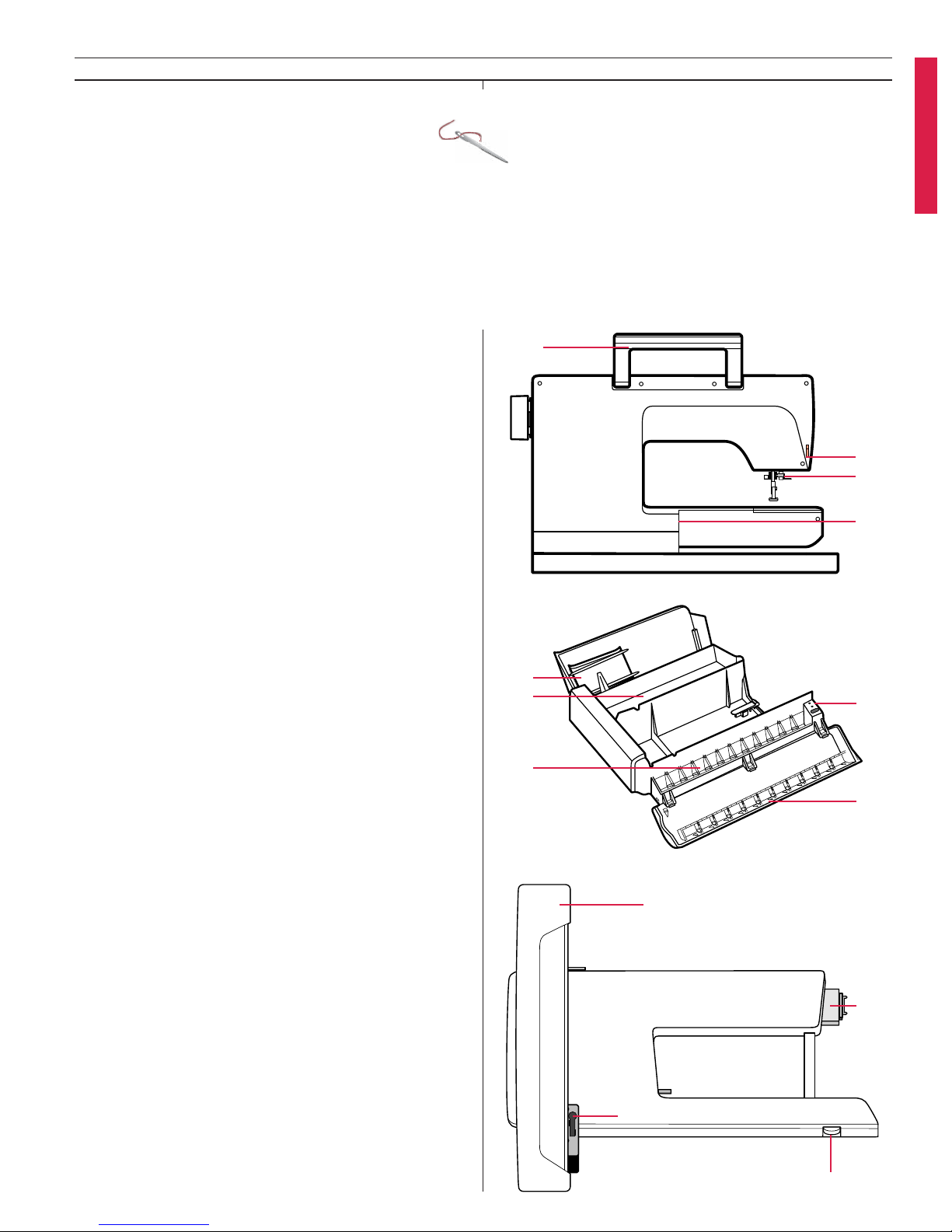

Learn your Designer I

Accessory Tray

44. Flat bed extension

45. Space for other accessories

46. Space for presser feet

47. Space for bobbins

48. Space for needles

Embroidery unit

49. Embroidery arm

50. Embroidery Hoop attachment

51. Embroidery unit socket

52. Release button

40.

41.

42.

47.

48.

52.

51.

50.

46.

49.

43.

44.

45.

Rear side

40. Handle

41. Thread cutter

42. Needle threader

43. Embroidery unit connection socket

Some fabrics have a lot of excess dye which can cause discoloration on other fabric but also

on your sewing machine. This discoloring may be very diffi cult or impossible to remove.

Fleece and denim fabric in especially red and blue often contain a lot of excess dye.

If you suspect that your fabric/ready-to-wear garment contains a lot of excess dye, always

pre-wash it before sewing/embroidering to avoid the discoloring.

6

Learn your Designer I

Unpacking

1. Place the machine on the table or cab i net, re-

move the packaging and lift off the cov er.

2. Remove the packing material, the foot control

and fi nally the protection cover.

3. The machine is delivered with an ac ces so ry bag

and a main cord. The foot control is equipped

with a cord reel.

4. Wipe the machine, particularly around the nee-

dle and needle plate to remove any soil be fore

sewing.

Packing away after sewing

1. Press the main switch to turn off the machine.

2. Unplug the cord from the wall socket and the

machine.

3. Wind the main cord around your hand and

place the cord in the pocket of the cover.

There is also space for the User’s Guide.

4. Unplug the foot control cord from the ma-

chine. Pull the cord gently and release - the

cord will be wound into the foot control.

5. Check to ensure that all accessories are in the

accessory tray. Slide the tray on to the ma chine

around the free arm.

6. Place the foot control, underside towards you,

fi tting into the recess of the accessory tray at

the rear side of the machine.

Connecting to the power supply

Among the accessories you will fi nd the main

cord. On the underside of the machine you will

fi nd information about the power supply (V) and

the frequency (Hz).

For USA and Canada

This sewing machine has a polarized plug (one

blade wider than the other). To reduce the risk of

electric shock, this plug is intended to fi t in a polarized outlet only one way. If the plug does not fi t

fully in the outlet, reverse the plug. If it still does

not fi t, contact a qualifi ed electrician to install the

proper outlet. Do not modify the plug in any way.

Before plugging in, check to ensure that the

foot control is of “type FR3”.

1. Pull out the cord from the foot control. Con-

nect the foot control cord to the front socket

(1) on the bottom right side of the machine.

2. Connect the main cord to the back socket (2)

on the bottom right side of the machine.

3. When you press the power switch to ON (3),

both the machine and the lights are switched on.

3.

1.

2.

7

Learn your Designer I

Accessory Tray / Sewing surface

In the Accessory Tray there are special pockets

for presser feet, bobbins and needles plus space

for other accessories. Store the accessories in the

tray so they are easily accessible.

Slide the Accessory Tray on to the machine to

provide a larger work surface. Slide the Accessory

Tray to the left, passing the stop po si tion and remove it if you wish to use the free arm.

A work surface extension is stored inside the

rear cover of the tray.

1. Slide the Accessory Tray to the left until you

have just passed the stop position.

2. Place the work surface extension into the

space that appears between the tray and the

machine and push the tray back.

8

Learn your Designer I

1.

2.

3.

4.

Spool pins

Your Designer I has spool pins suitable for all

types of thread. The main spool pin (a) is adjustable and can be used in horizontal po si tion for

normal threads or in vertical position for extra

large spools or threads with special char acte ris tics.

Horizontal position

Place the spool so that the thread reels counterclockwise. There are two spool hold ers on the

spool pin. For narrow thread spools, the small

holder (b) is placed in front of the thread. If you

use large thread spools, the large holder (c) is

placed in front of the thread.

Slide the correct size spool holder in place so

the fl at side is pressed fi rmly against the spool,

with no space between spool holder and spool.

Vertical position

To use the spool pin in its vertical position, pull

the spool pin out towards you. Slide on the large spool holder and place a felt pad under the

thread spool. This is to prevent the thread from

reeling off too fast.

Fold up Spool pin

There is also an additional, fold up/down spool

pin (d).

The large spool holder (c) is placed under the

thread. This spool pin is used when winding a

bob bin from a second spool of thread or for a

second spool when sewing with a twin needle.

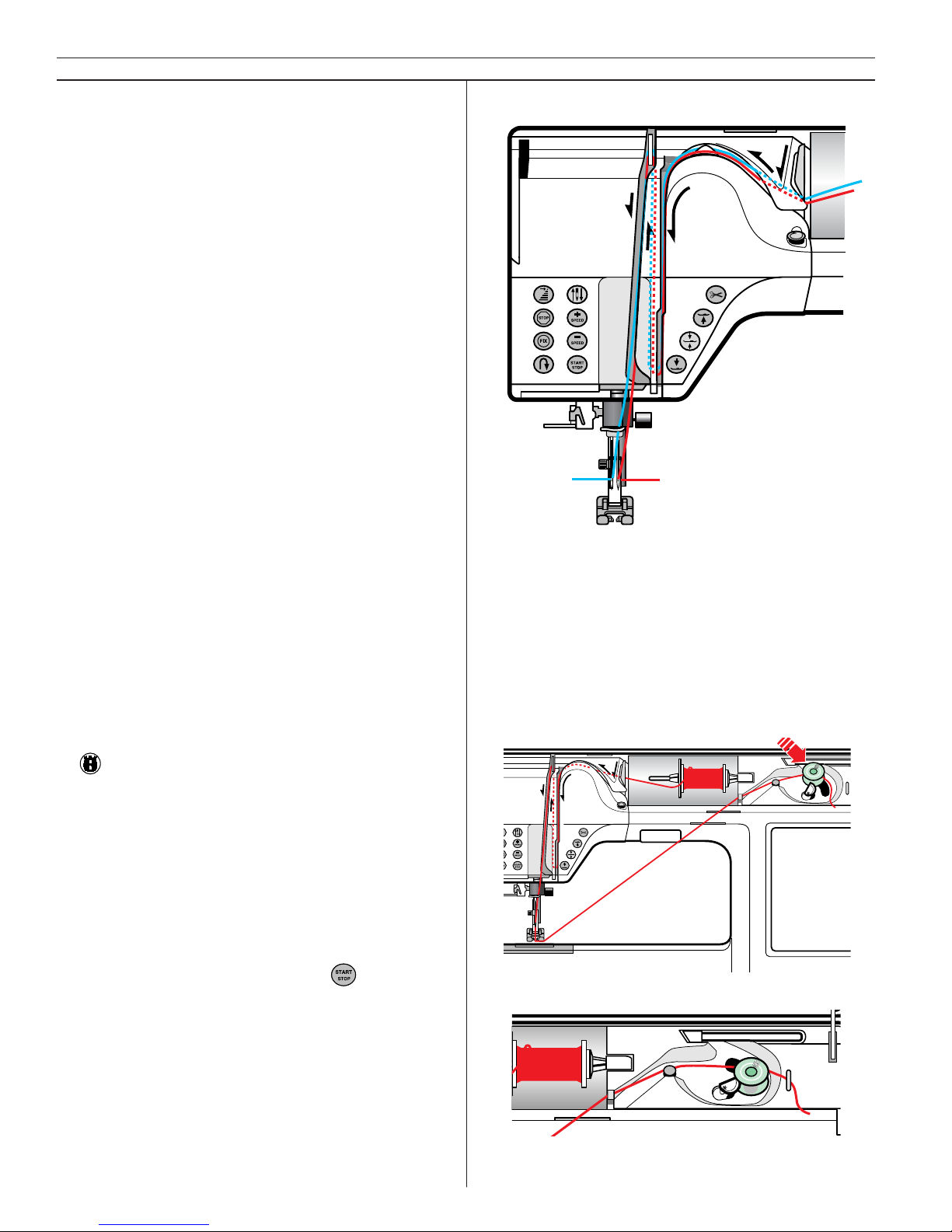

Threading the upper thread

Make sure the presser foot is raised and the

needle is in the up position.

Horizontal spool pin

1. Pull the spool pin out. Place the spool on the

spool pin The thread shall reel counter-clockwise. Push the spool pin back in. Hold the

thread near the spool using your right hand.

Use your left hand to bring the end of the

thread in the direction of the arrow.

2. Bring the thread over the pre-tension thread

guide (a) and under the thread guide (b).

Bring the thread over the thread tension discs

(c).

a

b

c

c

small holder

large holder

a

b

c

d

9

Learn your Designer I

3. Continue threading in the direction indicated

by the arrows. Bring the thread from the right

when threading into the slot on the take-up

lever.

4. Take the thread down to the last guide just

above the needle.

Vertical spool pin

1. Pull the spool pin out. Place the spool on the

spool pin (follow the instructions on previous

page).

2. Thread the machine according to the instruc-

tions with one exception. Instead of bringing

the thread into the pre-tension guide, bring it

directly under the thread guide (b).

Needle threader

The needle must be in the up position to use

the needle threader. We also recommend that

you lower the presser foot.

1. Pull the needle threader all the way down,

behind the needle.

2. Bring it forward until the metal fl anges cover

the needle. A small hook will pass through

the eye.

3. Place the thread around guide (a) and under

the fl anges in front of the needle, so it catches into the small hook.

4. Let the needle threader gently swing back,

the hook pulls the thread through the needle

eye and forms a loop behind the needle. Pull

the thread loop out behind the needle.

5. Place thread under the presser foot and cut

the thread.

Note: You can not use the Needle threader for the

wing needle, twin needle, triple needle, a needle

smaller than size 70 or when the Buttonhole Sensor Foot is on. The needle is threaded from front to

back. The white on the pres ser foot ankle makes it

easy to see the eye of the needle.

Thread warning

If the upper thread breaks or bobbin thread runs

out, the machine stops. Upper thread or bobbin

sym bol appears on a Pop-up Menu on the Color

Touch Screen. If upper thread breaks: Re-thread

the machine and touch OK on the Pop-Up Menu.

The Pop-up disappears. If bob bin thread runs

out: Rem ove your work and the bobbin. Fill the

bobbin. Replace the bob bin and sew.

1.

2.

3.

4.

5.

a

b

10

Learn your Designer I

e

d

c

Threading for twin needle

1. Insert a twin needle. See page 16 “Changing

the needle”.

2. Use a second thread spool or wind a bobbin

with the thread you are going to use as the

second upper thread.

3. Left needle (blue). Thread the machine as

explained on page 9 (Vertical spol pin) and

check to ensure that thread lies between the

inner thread tension discs, inside the last

thread guide. Thread left needle.

4. Right needle (red). Pull up the extra spool

pin.

5. Place a spool holder and a felt pad under the

bobbin with the second thread on the spool

pin.

6. Thread the machine as before but this thread

should lie between the outer thread tension

discs, outside the last thread guide. Thread

right needle.

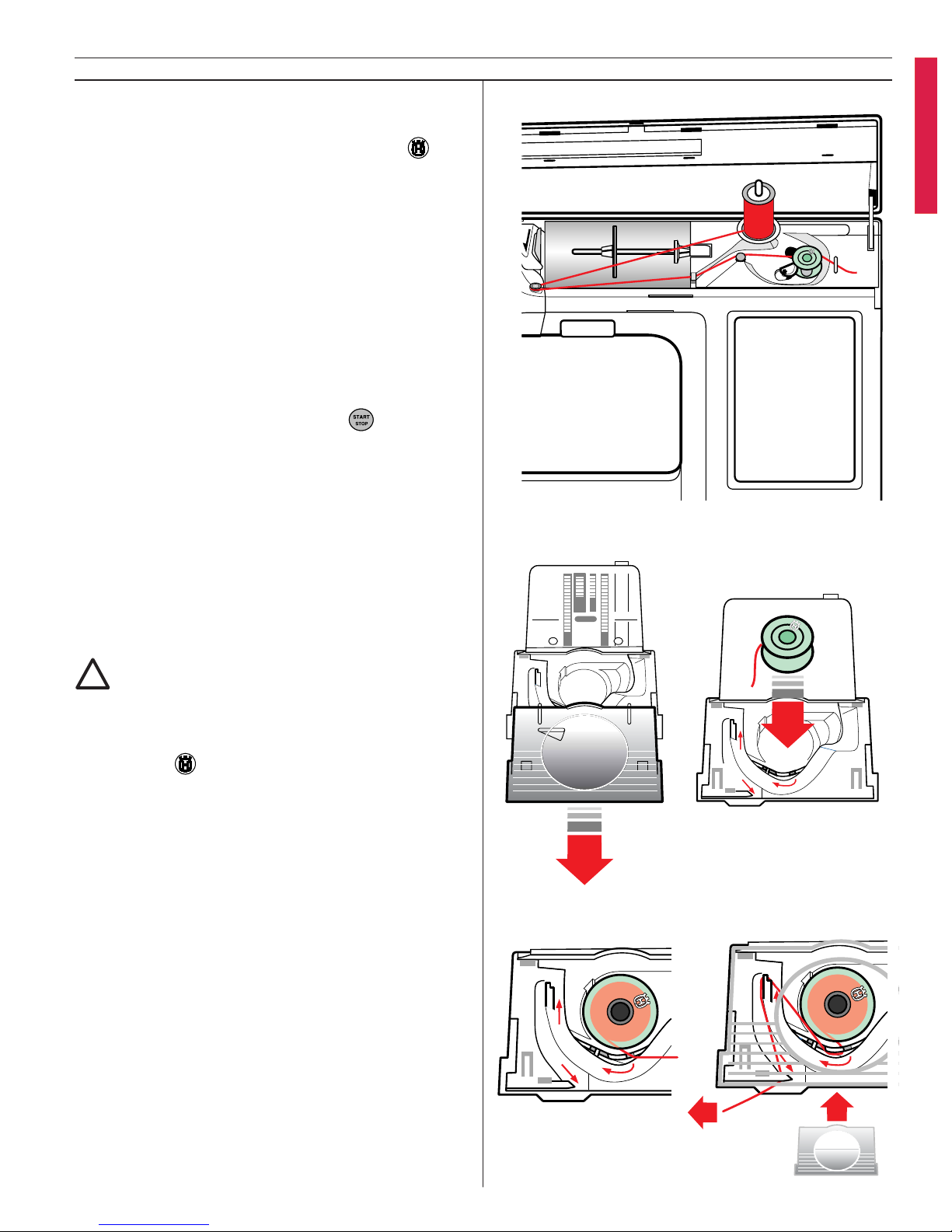

Bobbin winding with the machine

threaded

Make sure that the presser foot and the needle

are in the up position. Use only the original

Husqvarna Viking green bobbins with your

Designer I.

Only use a metal presser foot when bob bin

winding from the needle.

1. Place your empty bobbin with the small mark

out on the bobbin spindle on the front of

the machine. Bring the bobbin spindle down.

A Pop-up menu on the Color Touch Screen

reminds you that bobbin winding is engaged.

2. Pull the thread from the needle under the

presser foot and to the right under the thread

guide (c) and over (d).

3. Start from above and wind a few turns of

thread clockwise around the bobbin. Cut off

the thread on the thread cutter (e).

4. Press the foot control or touch . When

the bobbin is fi lled, the winding will stop automatically. Remove the bobbin, cut off the

thread (e) and bring the bobbin spindle up.

Note: We do not recommend winding specialty

threads such as invisible or other stretchy threads

through the needle. Instead see “Bobbin winding

– vertical spool pin”.

11

Learn your Designer I

Bobbin winding –

vertical spool pin

1. Place an empty bobbin with the mark out

on the bobbin spindle on the front of the machine. Bring the bobbin spindle down. A Popup menu on the Color Touch Screen reminds

you that bobbin winding is engaged.

2. Place the large spool holder under the thread

on the spool pin.

3. Bring the thread around thread guide (b),

then under thread guide (c) and over (d) as

illustrated.

4. From above wind a few turns of thread clock-

wise around the bobbin and into the thread

cutter (e).

5. Press the foot control or touch . When

the bobbin is fi lled, the winding will stop automatically. Remove the bobbin, cut off the

thread (e) and bring the bobbin spindle up.

Note: Depending on the quality of the thread you

can wind the thread one or two times around the

threadguide (b) in order to get the right thread tension.

Placing the bobbin

in the machine

!

Turn off the main switch.

1. Open the cover by sliding it towards you and

remove it.

2. Place the bobbin in the bobbin case with

the mark

facing up and the thread to the

left of the bobbin. The bobbin will then rotate counter clockwise while pulling out the

thread.

3. Place your fi nger on the bobbin to keep it

from turning as you pull the thread fi rmly to

the right and then to the left into the tension

spring (a) until it “clicks” into place.

4. Continue threading around (b) and to the

right of the thread cutter (c). Replace the cover with the lines to the front and slide it into

10 15

1.

2.

4.3.

b

c

e

d

a

b

1

2

b

c

12

Learn your Designer I

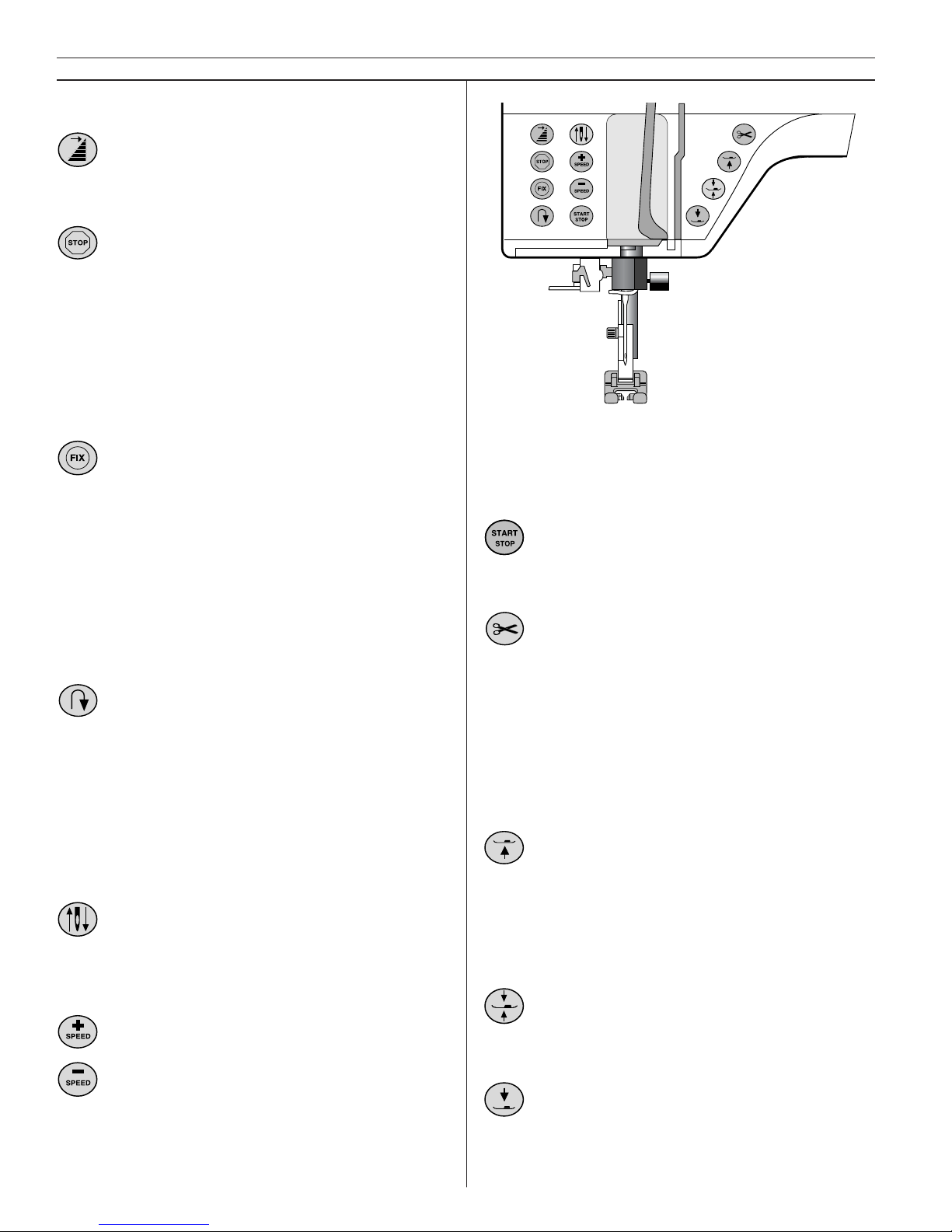

Stitch Re-start. To start sewing your selected stitch at the beginning of the stitch

without having to re-set any special settings you have made.

STOP is used to conclude a stitch. Your

De sig ner I fastens the thread and stops

automatically when one stitch sequence

has been completed. The button lights

up when you touch it. STOP is cancelled

when you touch the button again or by

selecting a new stitch. The button light

will go out. The STOP function can be

programmed. It can also be used for one

color embroidery.

FIX is automatically activated when a

stitch is selected or when Thread Cutter

has been used. The button lights up while

FIX function is active. By touching the

lighted button the function can be turned

off. At the beginning – De sig ner I sews a

few tie off stitches and goes on with the

selected stitch. Touch FIX while sewing

– De sig ner I sews a few tie off stitches

and stops automatically. The FIX function

can be programmed.

Reverse – your Designer I sews in reverse

when this button is touched. The button

lights up. De sig ner I sews forwards when

the button is released and the light goes

out. The longest reverse stitch length is

3mm. For permanent reverse, touch the

button twice in quick succession before

starting to sew. The button will be lit up

and the De sig ner I sews in reverse until

you touch the button again to cancel.

Needle stop up/down. Touch this button

to move the needle down or up. The set ting of the needle stop po si tion is changed

at the same time. You can also tap the

foot control to raise or lower needle.

Touch + SPEED or - SPEED to increase or

decrease the sewing speed. Touch when

not sewing and a Pop-up menu on the

Color Touch Screen indicates the speed

set ting. Touch OK or start sewing and

the pop up goes out. You can change the

speed set ting while sewing but no Pop-up

will appear. All stitches in De sig ner I have

Function buttons

a pre-set, recommended sewing speed.

When you select a stitch, De sig ner I automatically sets the correct sewing speed.

START/STOP. Touch this button to run

and stop the machine without the foot

control. Touch START/STOP to begin and

touch again to stop sewing.

Selective Thread Cutter. Touch the

button and De sig ner I cuts the top and

bobbin threads, raises the presser foot

and the needle to the up po si tion and

activates the FIX function. To cut before

the needle moves to the start position of

next stitch, touch Thread Cutter while the

machine is running. A fl ashing STOP will

indicate that a cut is requested. The Thread cutter function can be programmed.

Sensor Foot Lift up and extra lift.

Touch this button and the pres ser foot

and the needle will be lifted to up po si tion. Touch the button once more and

the pres ser and foot will raise to ex tra lift

to make it easy to get thick fabric under

the pres ser foot.

Sensor Foot Lift pivot. To simplify placing the fabric, touch this button. The

pres ser foot will be lowered to pivot po si tion.

Sensor Foot Lift down. Touch this button and the pres ser foot will be completely lowered and De sig ner I is fi rmly holding your work.

13

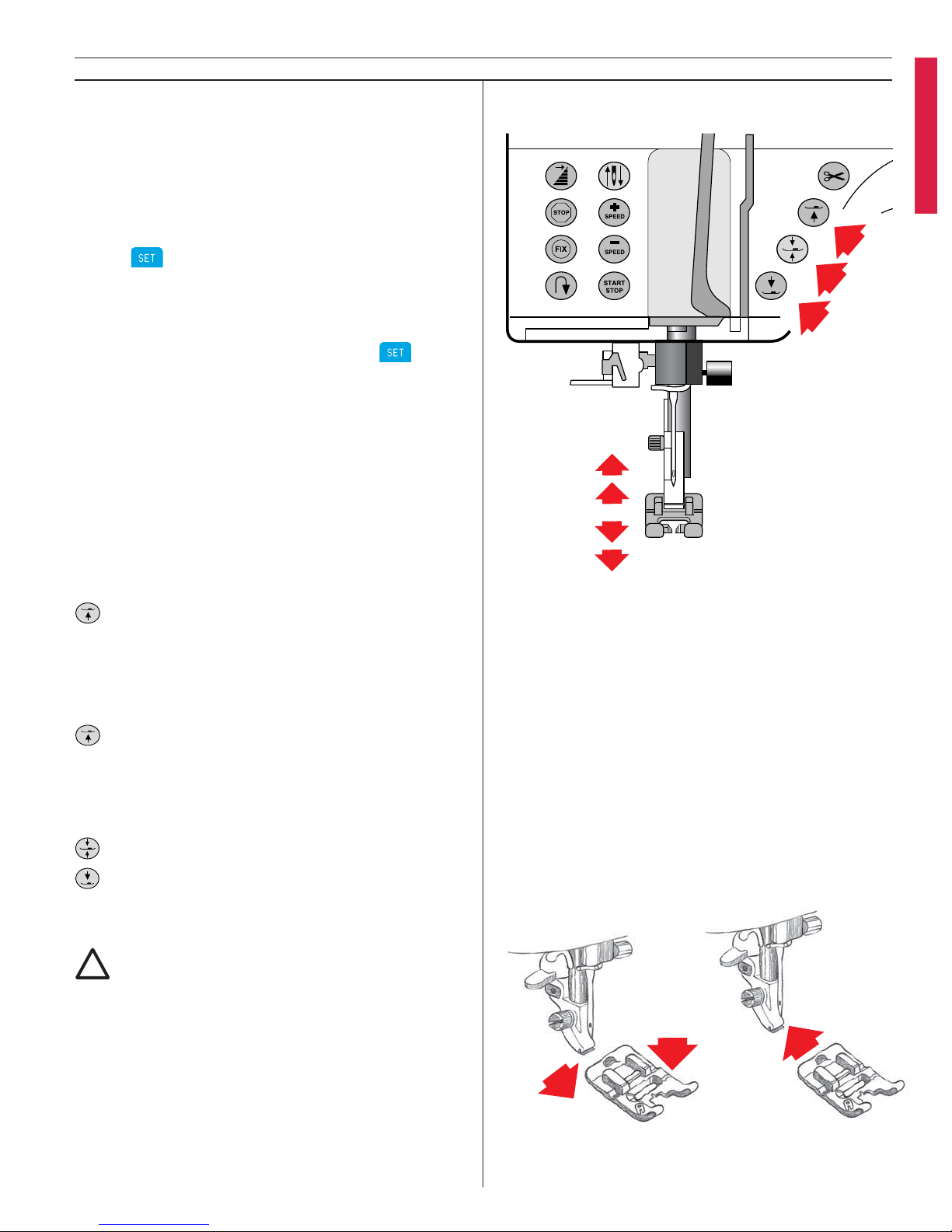

Learn your Designer I

Sensor Foot Pressure

When selecting different fabric weights on the

Sewing Advisor, the pressure will be adjusted

automatically. Thanks to the Sensor Foot Pressure, the presser foot actually senses the thickness

of fabric or embroidery or stitching to sew over

it smoothly and evenly.

Touch

on the Color Touch Screen and you

will see the actual setting of the pres ser foot

pressure for the selected fabric.

You can adjust the presser foot pressure by

pres sing the buttons (+) or (-) on the

menu.

The higher the number the more pressure on

the fabric.

Sensor Foot Lift

The presser foot is automatically lowered when

you start your sewing.

When you stop with the needle in the down

position, the pres ser foot is automatically lifted

to pivot position.

If you have selected Needle stop up:

UP – Raises the pres ser foot and the needle

to up po si tion. Touch twice for ex tra lift. Makes

it easier to get thick garments under the pres ser

foot.

If you have selected Needle stop down:

UP – Raises the presser foot to up position

but the needle stays down in the fabric. Touch

twice – the needle raises to up po si tion and the

pres ser foot to the extra lift for easy removal of

fabric.

PIVOT – Sets foot to pivot position.

DOWN – Lowers the presser foot.

Changing the presser foot

!

Turn off the main switch.

1. Make sure that the needle is in the highest

position. Pull the presser foot towards you.

2. Line up the cross pin on the foot between the

spring and the presser foot ankle. Press back

until the foot snaps into place.

14

Learn your Designer I

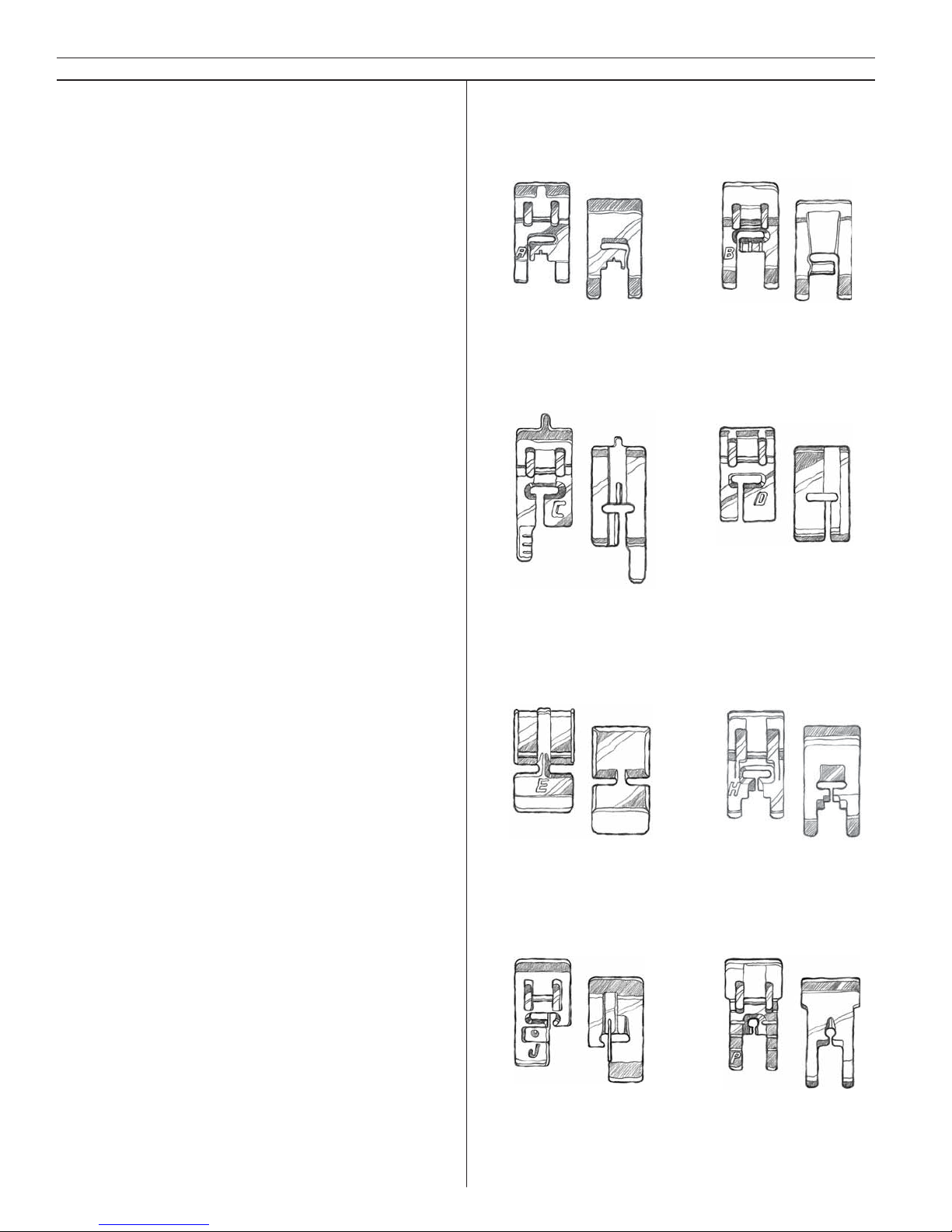

Presser feet

Among the accessories there are a number of

pres ser feet for different purposes.

Presser foot A

Fitted on the machine upon delivery. This foot is

used mainly for straight stitching and zigzag stitching with a stitch length longer than 1.0.

Presser foot B

When sewing close zigzag stitches with less than

1.0 stitch length; other utility stitches or decorative stitches use this foot. The tunnel on the

bottom of the foot is de sig ned to feed smoothly

over the stitches.

Presser foot C

This buttonhole foot has guide lines to determine buttonhole length. The end of the short toe

is 3/8" from needle and end of long toe is 3/4"

from needle. The two tunnels on the bot tom of

the foot feed smoothly and straight over the buttonhole columns.

Presser foot D

This foot is used for blind hem stitches. The in ner edge of this foot guides the fabric. The bot tom of the foot is de sig ned to ride along the

hem edge.

Presser foot E

This is the zipper foot and can be snapped on

either to the right or to the left of the needle,

making it easy to sew both sides of the zipper.

Presser foot H

This foot is made of plastic with exception of a

glide plate underneath. The foot is used when

sewing foam, plastic, or leather, minimizing the

risk of these materials sticking to the foot. Same

as Presser foot A.

Presser foot J

This foot is used for overcasting, seam and over cas ting, i.e. stitches which have a stitch width of

5.0 and 5.5 mm. The pin prevents pucke ring at

the edge of the fabric.

Presser foot P

This foot is used when piecing quilt blocks.

The foot has distance marks 1/4" (6 mm) and

1/8" (3 mm).

A

B

CD

EH

JP

15

Learn your Designer I

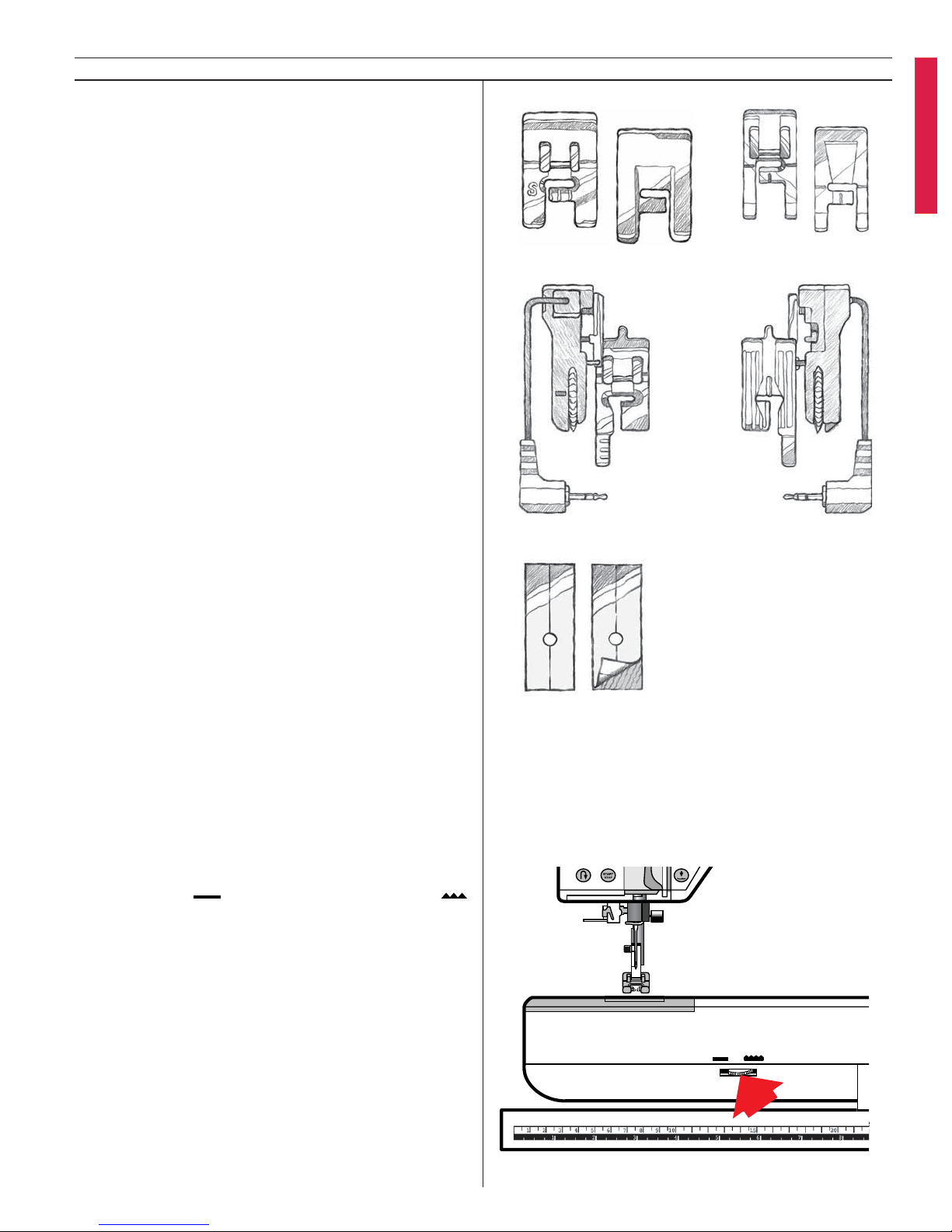

Presser foot S

This foot is used for side-motion stitches.

Transparent presser foot

For decorative sewing. Ma kes it easy to match

patterns. Same as Presser foot B.

Sensor Buttonhole Foot

When connected to the machine it measures buttonhole length and sews the buttonhole size that

has been entered into the machine. The end of

the short toe is 3/8" from needle and end of

long toe is 3/4" from needle

Self-adhesive glide plates

Used for the presser foot C/Sensor Buttonhole Foot

when sewing plastic-coated fabrics, leather etc.

Lowering the feed teeth

The feed teeth are lowered when you turn the

dial to the left . Turn the dial to the right

if you wish to raise the feed teeth. The feed teeth will raise as you begin to sew.

The feed teeth should be lowered for sewing on

buttons and for free-motion work.

Tip: By lowering the feed teeth it is easier to get

thick fabrics like terry cloth under the pres ser

foot. Raise the feed teeth before star ting to sew.

Note: The feed teeth are lowered automatically

when the embroidery unit is put in place. When remo ving the embroidery unit, the feed teeth will raise

as you start to sew.

S

1

1234567

2345678910 15

2

16

Learn your Designer I

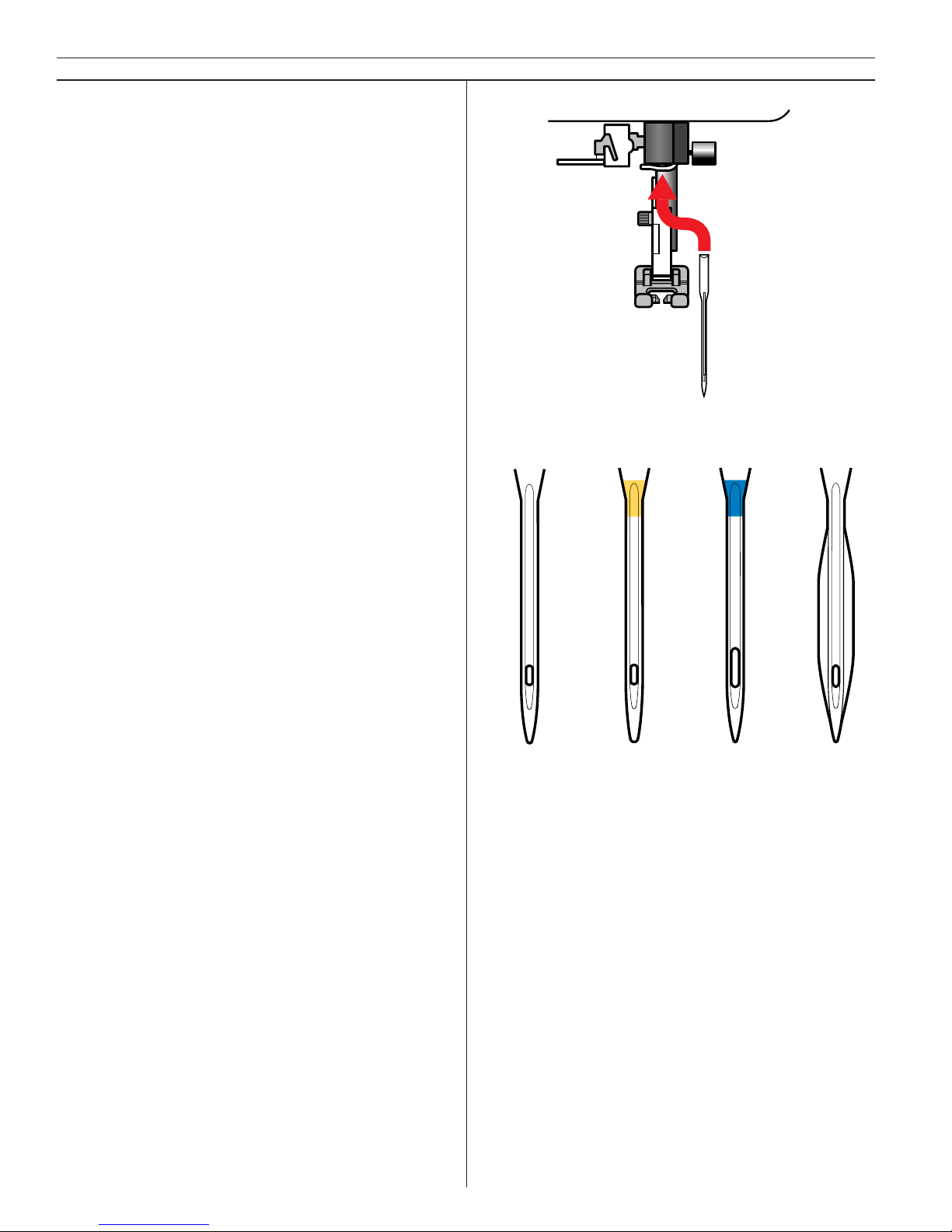

Changing the needle

1. Loosen the screw in the needle clamp by us-

ing a screw driver or screw grip.

2. Remove the needle.

3. Push up the new needle with the fl at side

away from you until it will go no further.

4. Use the screwdriver or screw grip to tighten

the screw properly.

Needles

The sewing machine needle plays an important

role in successful sewing. To ensure you will get

a quality needle, we recommend Schmetz brand

needles of sys tem 130/705H.

The needle case contains needles of the most

used size for sewing woven and stretch fabrics.

A Standard needles 70, 80, 90

These needles are used for sewing all woven

fabrics. The needle point is designed to penetrate between the threads of the fabric so the

fabric will not be damaged.

B Stretch needles 75, 90

These needles are used for sewing knit-

ted and stretch fabrics. The stretch needle is

marked yellow and has a rounded point.

C Jeans needles 90, 100

These needles are used for sewing woven

heavy fabrics, for example denim, canvas fabric. The jeans needle is marked blue and has

an extremely sharp point to facilitate the penetrating of the fabric.

D Wing needle 100

The wing needle is used for hemstitching

in natural fi ber woven fabrics with special

stitches on the Heirloom Stitches Menu. The

needle has “wings” to push the threads of the

fabric aside forming holes where the needle

penetrates the fabric.

A

BC D

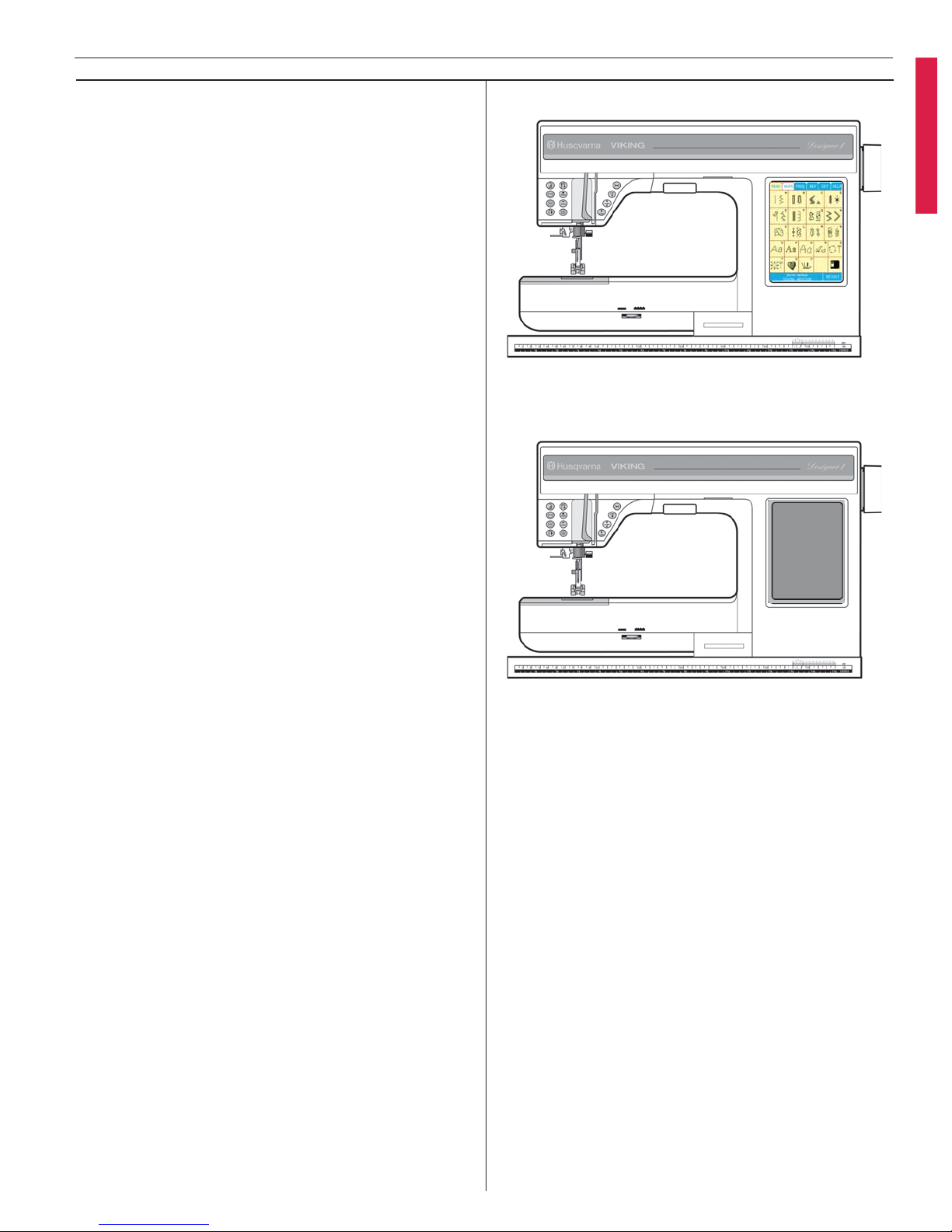

Color Touch Screen

Designer I features an LCD Color Touch Screen

at the front right of the machine.

The Color Touch Screen is very easy to work

with. Just touch it with your fi nger tip to select a

stitch menu or function tab.

On/Off

When Designer I is off the screen will be dark

grey.

When it is turned on you will fi rst see a Welcome Screen, then the Main Menu will appear.

Screen Saver

Your Color Touch Screen can be left on all the

time. If you prefer you can set a screen saver

to come on after 9 minutes. See Screen Saver,

page 30.

17

Learn your Designer I

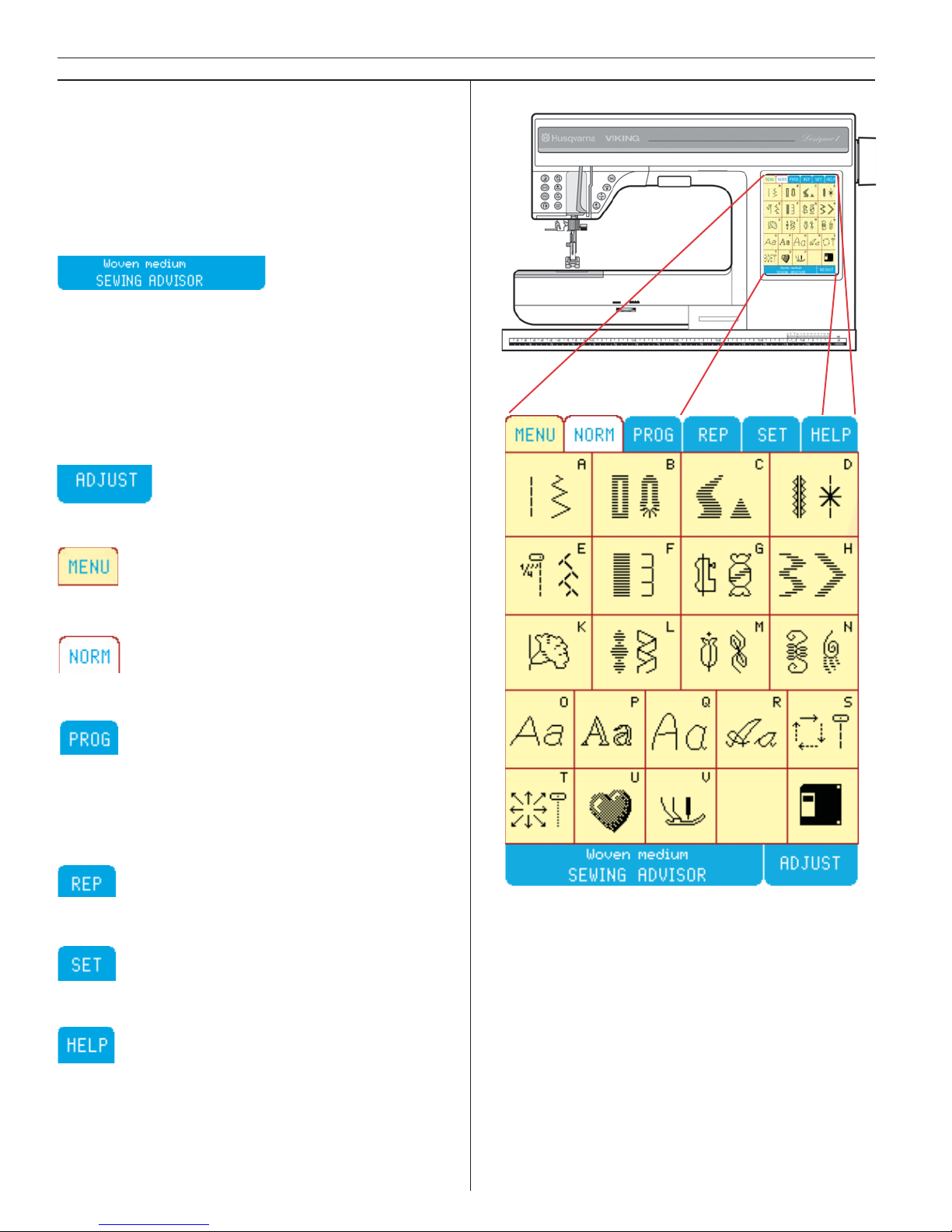

Main Menu

The Main Menu displays 21 Specialty Stitch menus and functions. There are 8 function tabs,

SEWING ADVISOR, ADJUST, MENU, NORM,

PROG, REP, SET and HELP. When you touch a

function tab it becomes active.The MENU tab is

yellow when active, other tabs turn white.

The easy way to get started, see page 27.

Simply select fabric and sewing technique, then

Designer I selects the best stitch, length, width,

tension, presser foot, presser foot pressure and

sewing speed. Your fabric choice in the

Sewing Advisor is shown in the touch area. The

Sewing Advisor is active when sewing all techniques except embroidery.

ADJUST stitch length and stitch width, elongation and mirror image.

Touch MENU to select from 21 menus. Touch

the disk icon to view or load the embroideries.

NORM is used for all sewing and embroidery

except programming and sewing programs.

PROG is used to program stitches such as Pictograms, letters and decorative combinations.

When the Embroidery Unit is connected touch

PROG to customize embroideries and/or lettering.

REP is used to sew out the stitch combinations

and embroideries programmed in PROG.

Touch SET to change current settings and functions. See page 29.

Recommends needle size and type, when to lower feed teeth, stabilize fabric, cord buttonholes

etc. When the embroidery unit is connected, you

can access the embroidery color menu.

18

Learn your Designer I

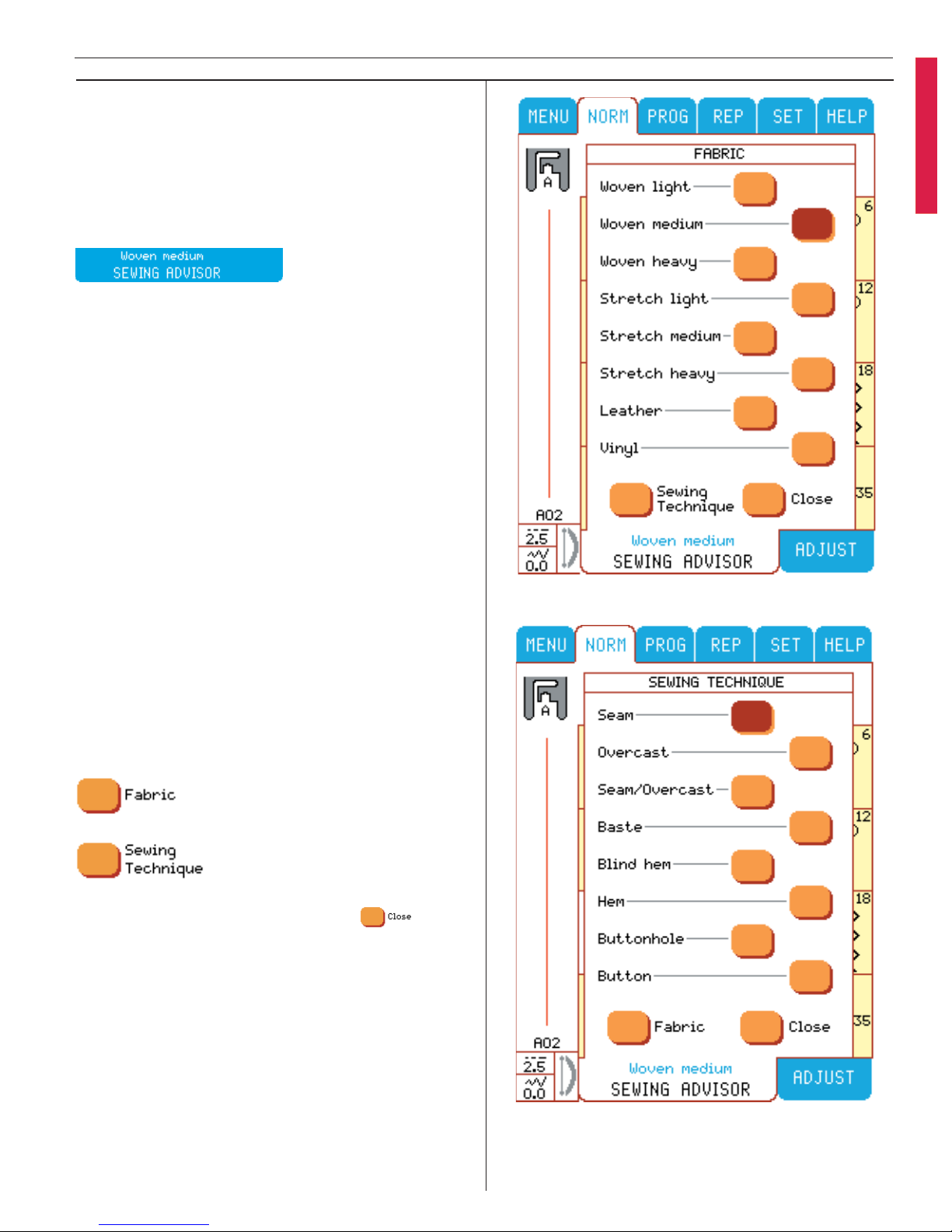

Sewing Advisor –

The easy way to sew

The Sewing Advisor is always active, until the

Embroidery Unit is connected or when you start

to program.

To bring up Sewing Advisor touch

The Sewing Advisor has two different menus,

Fabric and Sewing Technique.

Fabric

In the Fabric menu you select from 8 different

fabric types and weights. Select fabric, the fabric

button turns red and immediately the Sewing

Technique menu appears.

Sewing Technique

Select from 8 different sewing techniques. Your

Designer I immediately selects the best stitch,

thread tension, stitch length, stitch width, sewing

speed, presser foot and presser foot pressure for

your project. The button turns red to indicate the

technique you have chosen. If you want to select a new Sewing Technique just touch an other

technique button.

Move between the Fabric and Sewing Technique

menus by using the following buttons at the bot tom of the screen.

To close the Sewing Advisor touch

19

Learn your Designer I

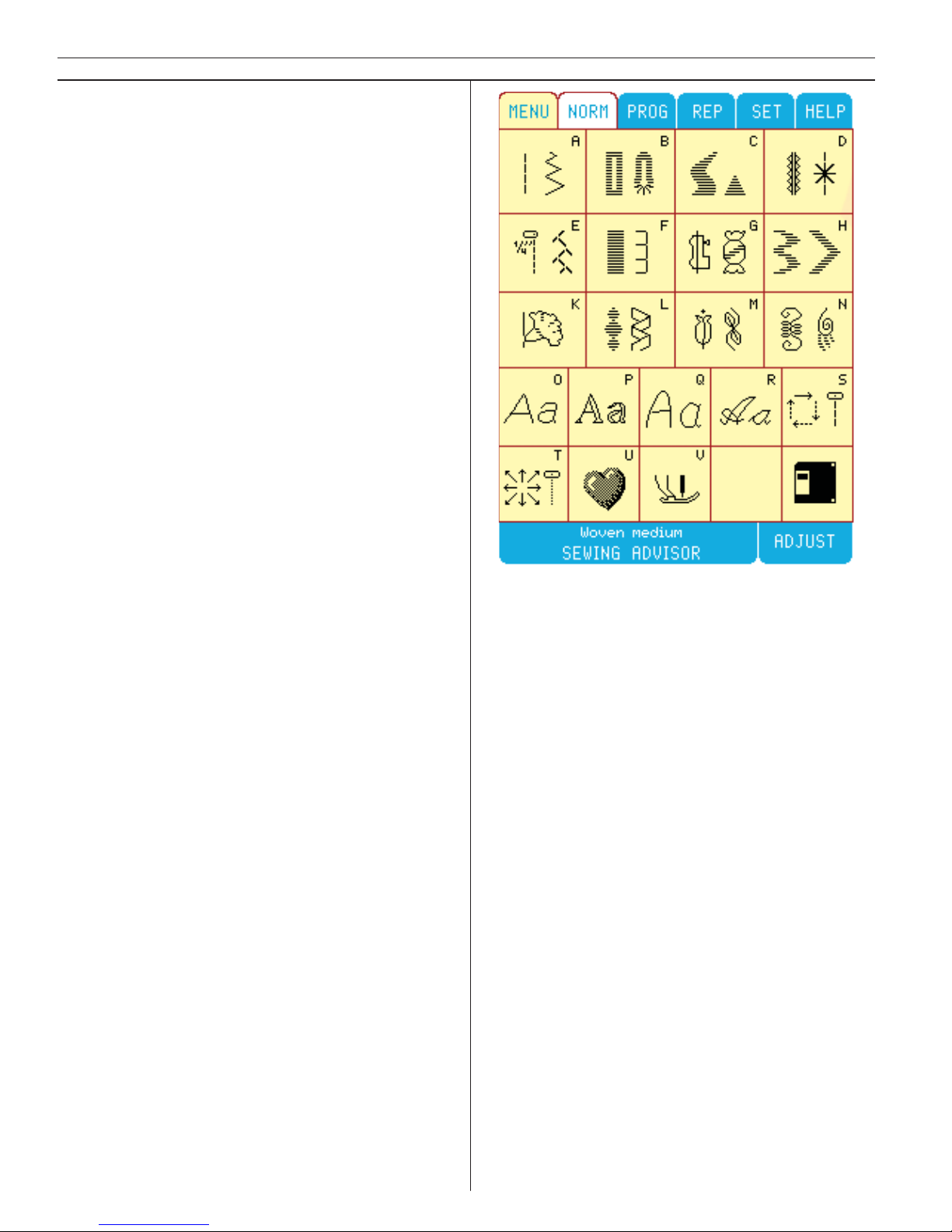

Specialty Stitch Menus

In the Main Menu there are 21 choices, 20 stitch

menus and one disk icon.

Utility Stitches

Menu A features stitches for your garment

sewing, mending and darning.

Buttonholes

Menu B features different styles of buttonholes,

eyelets and button sewing. For best result use

the Sensor Buttonhole Foot.

Decorative Menus

Beautiful stitches for your creative sewing on

stitch menus C -N.

Letters and Numbers

Choose from 4 different types of letters and

numbers. Block, Menu O, Outline block, Menu P,

Brush line, Menu Q (9 mm) and Menu R Script.

Each lettering menu has 3 menus for upper case

and lower case letters and numbers.

4-Way Stitches

Menu S is used to sew stitches in 4 different directions. Stitches are fi xed in length and width.

The arrow indicates sewing direction of stitches.

8-Way Stitches

Menu T is used to sew in 8 different directions.

There are 2 different types of stitches, straight

and reinforced straight.

My Stitches

Use Menu U (My Stitches) to save favorite stitches or special settings to a stitch. Adjustments

made in the ADJUST menu and settings as tension, balance and presser foot pressure in the

SET menu will be saved together with the stitch.

Special Stitches

Menu V includes 4 different types of “free mo tion technique” stitches. When you are using this

menu the feed teeth should be lowered.

Embroidery Disk Icon

View and load embroideries with your Designer

I by sliding an embroidery disk into your

Built-in disk drive. Touch the disk icon. This

allows you to view the embroideries. To load

an embroidery, your embroidery unit must be

attached to your Designer I.

20

Learn your Designer I

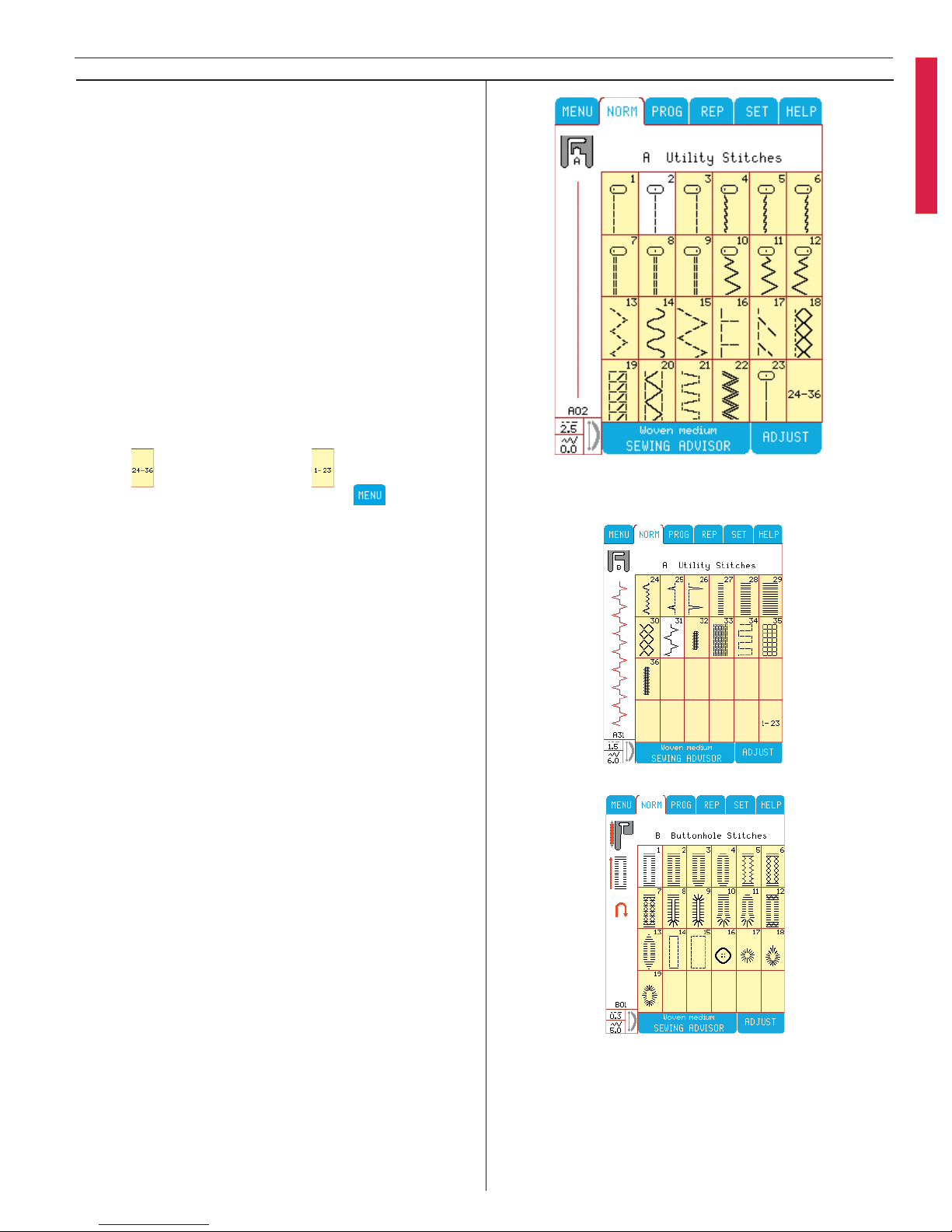

Stitch Menus

Touch Menu A in the Main Menu. Menu

“A Utility Stitches” appears on the Color Touch

Screen. To the left on the screen, your Designer

I displays a selected stitch and a recommended

presser foot, in this case presser foot A. The

number of the stitch (A02) is shown below the

stitch. This is the Designer I default stitch. To

select an other stitch, touch the picture of the

stitch. De sig ner I will always confi rm your choice by highlighting the selected stitch in white,

otherwise it has yellow background.

If there is a submenu, you will fi nd a picture

with a number combination on, in the lower

right corner.

Select stitches number 24-36, submenu.

Touch

. To go back touch .

Return to Main Menu by touching

.

Utility Stitches

For Utility Stitches touch Menu A in the Main

Menu. On Menu A you can fi nd several stitches

used for utility sewing. For example you can

fi nd different kinds of straight stitch and zig-zag

(stitch number 15 is a 4 step zigzag with max i mum width of 9 mm). There are also overlock

(A16-17) and fl atlock (A20) stitches. Stitches

A33-36 are perfect for darning and mending.

Buttonhole Stitches

For Buttonhole stitches touch Menu B.

Stitch number 16 is used to sew buttons and

17-19 are used to sew eyelets. The red wheel to

the left of the presser foot indicates the Sensor

Buttonhole Foot. For buttonhole B6 and B7,

De sig ner I recommends presser foot C. When

sewing buttonhole B14 to B15, Designer I recommends presser foot A. When using the A or

C presser foot, the symbol of the reverse button

is visible on the screen. This indicates that you

have to press the reverse button when the buttonhole has reached the desired length. The red

arrow next to the buttonhole indicates the sewing direction.

21

Learn your Designer I

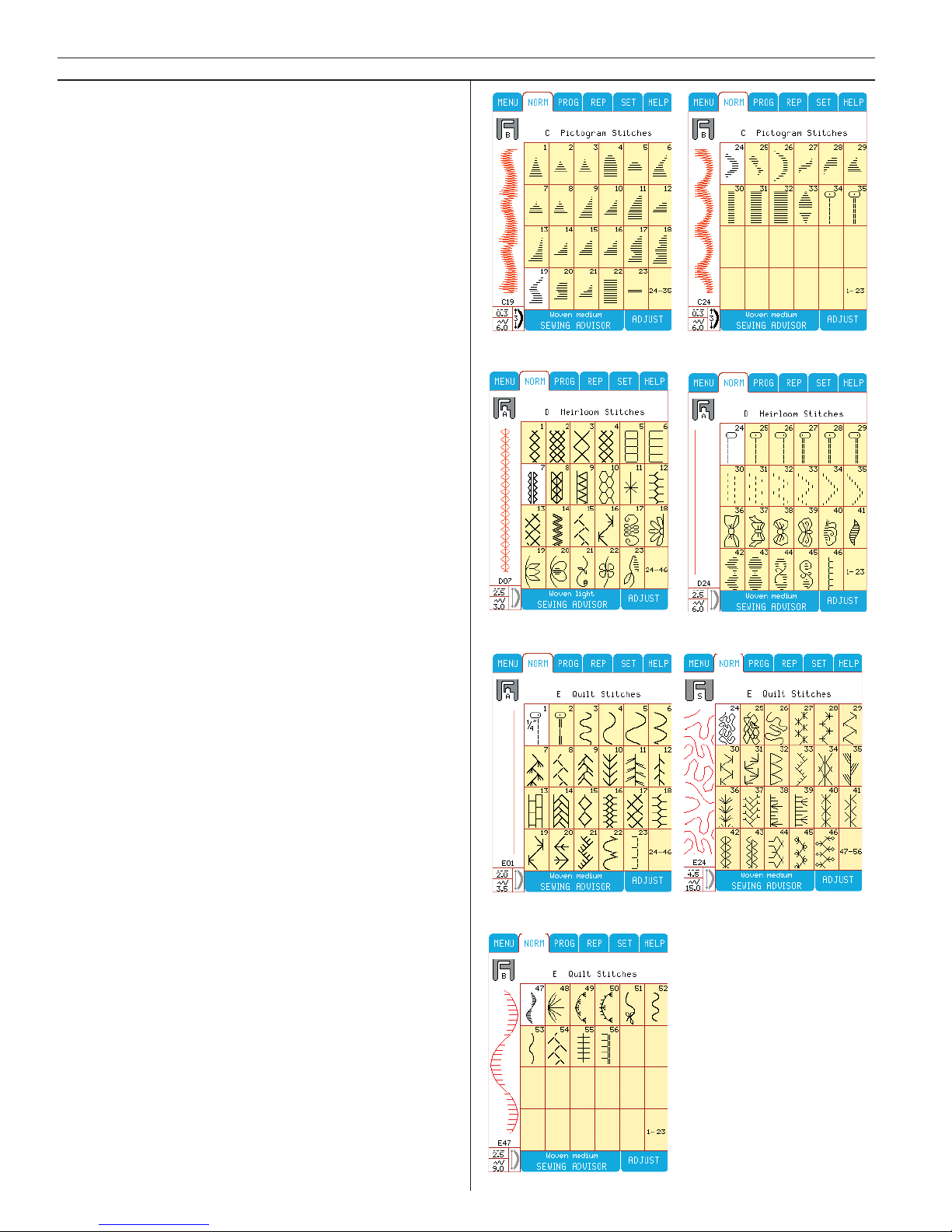

Pictogram Stitches

For Pictogram Stitches, touch Menu C in the

Main Menu. Pictogram elements are generally

programmed to create original satin stitch designs.

Heirloom Stitches

For Heirloom Stitches, touch Menu D in the

Main Menu.

If you are using a wing needle together with the

stitches D4-10 and D12, you can attain beautiful

hemstitches. The stitches D30-35 are used for

smocking and stitch D46 is a pin stitch.

Quilt Stitches

For Quilt Stitches, touch Menu E.

Stitch E1 sews the stitch 1/4" from the right edge

of the presser foot. If you want a handlook quilting stitch, you can use stitch E2. Use stitch E2426 for stippling sewing. There are also stitches

that can be used for Crazy Quilting. The feather

stitches (E7-12) are very typical for quilting.

Stitches E3-6 are 6-9 mm wide and can be used

when channel quilting.

22

Learn your Designer I

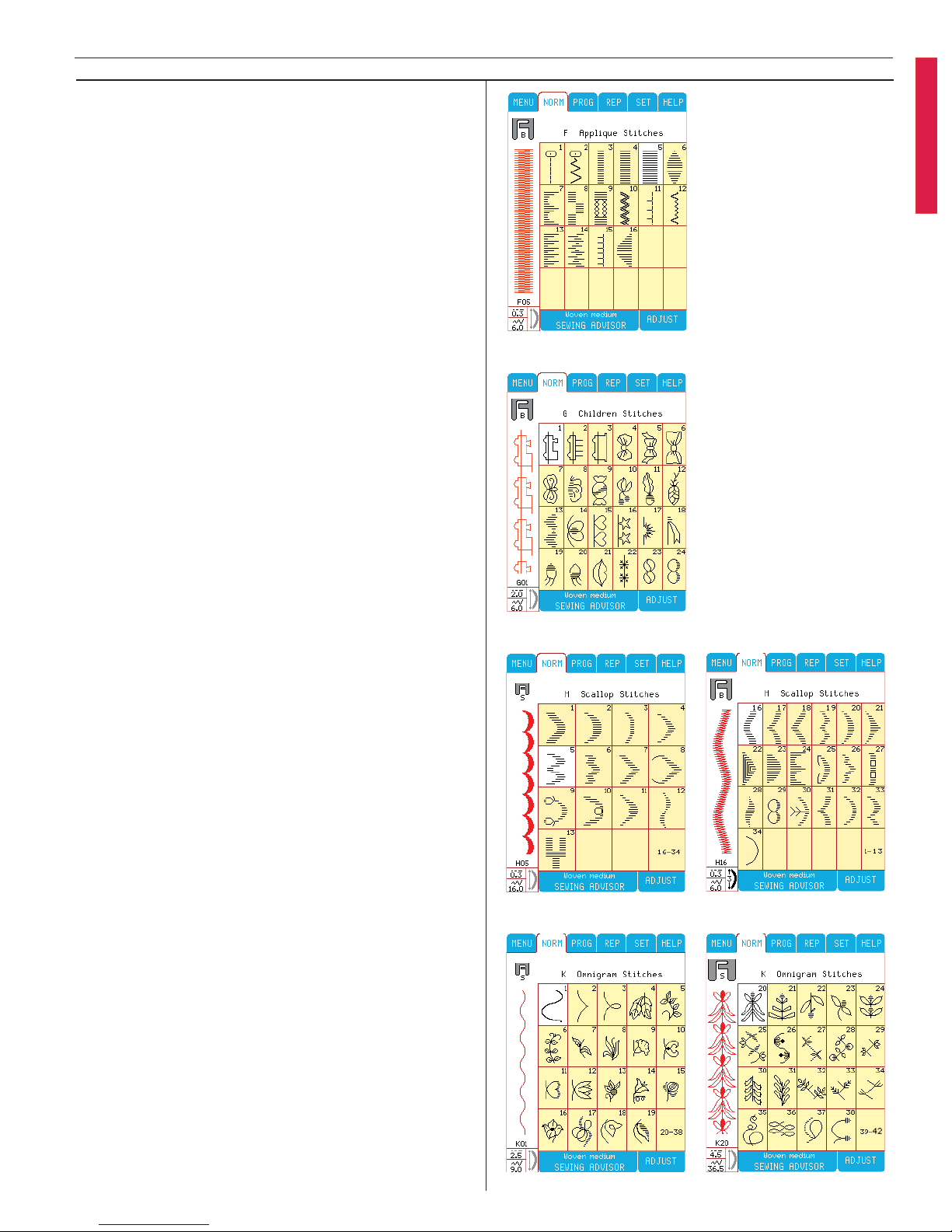

Children Stitches

For Children Stitches touch Menu G in the Main

Menu.

Scallop Stitches

For Scallop Stitches touch Menu H in the Main

Menu.

The scallops 1-13 are Omnimotion scallops and

sew up to 25 mm wide. Scallops 16-34 are up to

9mm wide.

Omnigram Stitches

For Omnigram Stitches touch the Menu K in the

Main Menu.

These stitches are possible to combine with each

other into an unlimited number of sequences.

Applique Stitches

Applique Stitches are in Menu F in the Main

Menu.

Stitch F11 can be used when you want to imitate

the look of appliqué stitched by hand. When

sewing with stitch F13 and F14 you will get a

beautiful shadow effect. Stitch F15 is used for

precision applique and F16 is a mitered frame

stitch.

23

Learn your Designer I

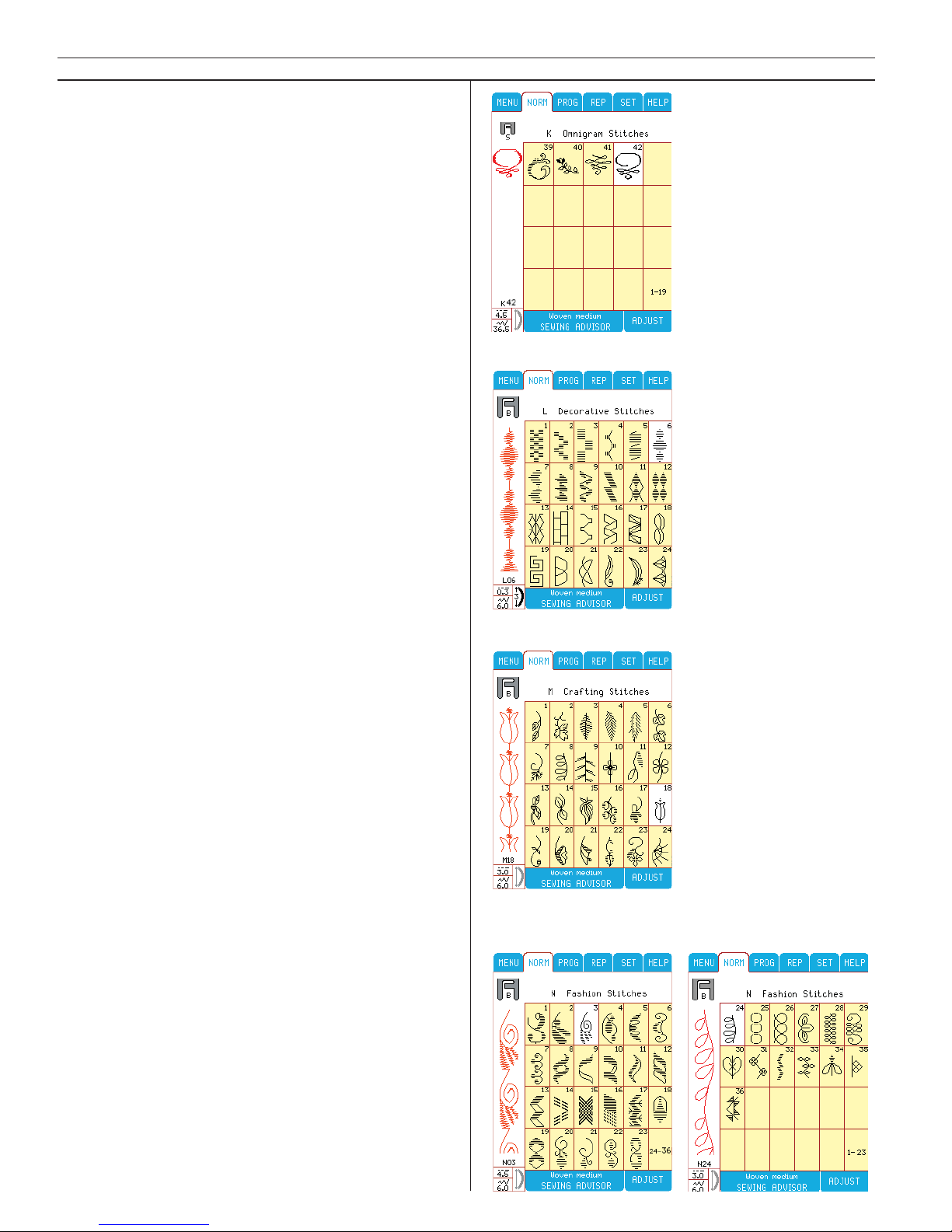

Crafting Stitches

For Crafting Stitches touch Menu M in the Main

Menu.

The width of the stitches varies from 6-9 mm.

Decorative Stitches

For De co ra ti ve Stit ches touch Menu L in the

Main Menu.

Fashion Stitches

For Fashion Stitches touch Menu N in the Main

Menu.

Stitches 39-42 are sewn as a single pattern. After

sewing one pattern your Designer I will fi x the

stitch and then stop.

24

Learn your Designer I

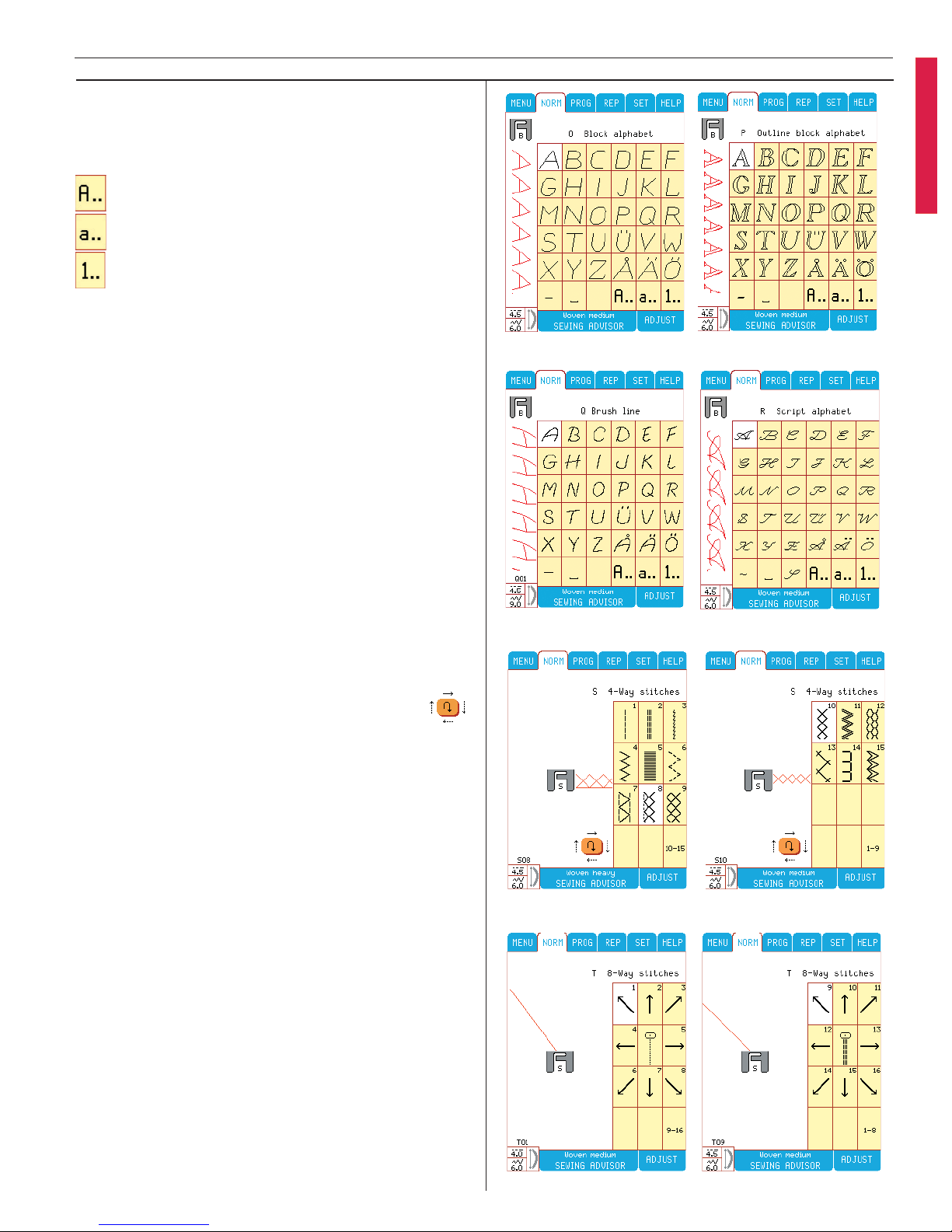

4-Way stitches

Find 4-Way stitches in Menu S in the Main Menu.

4-Way stitches is mainly used to sew one fabric

to another using the free arm. The stitches are

pro gram med at a fi xed width and length.

The selected stitch direction is visible in the

screen beside the presser foot.

If you look at the 4-Way stitch direction icon,

you see 4 different arrows. Each time you touch

the button, the sewing direction changes. You

can also use the reverse button to change sewing direction. Your Designer I always starts sewing in direction from left to right.

8-Way stitches

Find 8-Way stitches in Menu T in the Main

Menu. There are 2 different stitches, straight and

re-inforced straight stitch.

The 8-Way stitch touch buttons display 8 dif fe rent directional arrows. The selected sewing

direction arrow is highlighted in white. Touch

another direction arrow button to change the

sewing direction.

Note: By changing the stitch length, and/or stitch

width for a selected stitch, you also chan ges the

sewing angle. Thereby you have the possibility to

sew in whatever direction you want.

Block, Outline block, Brush line and Script

alphabet

Touch Menu O, P, Q or R for letters and numbers. There are 3 different menus. Touch

for upper case.

for lower case.

for numbers and special letters.

To change the style menu, simply touch the

desired style button above.

25

Learn your Designer I

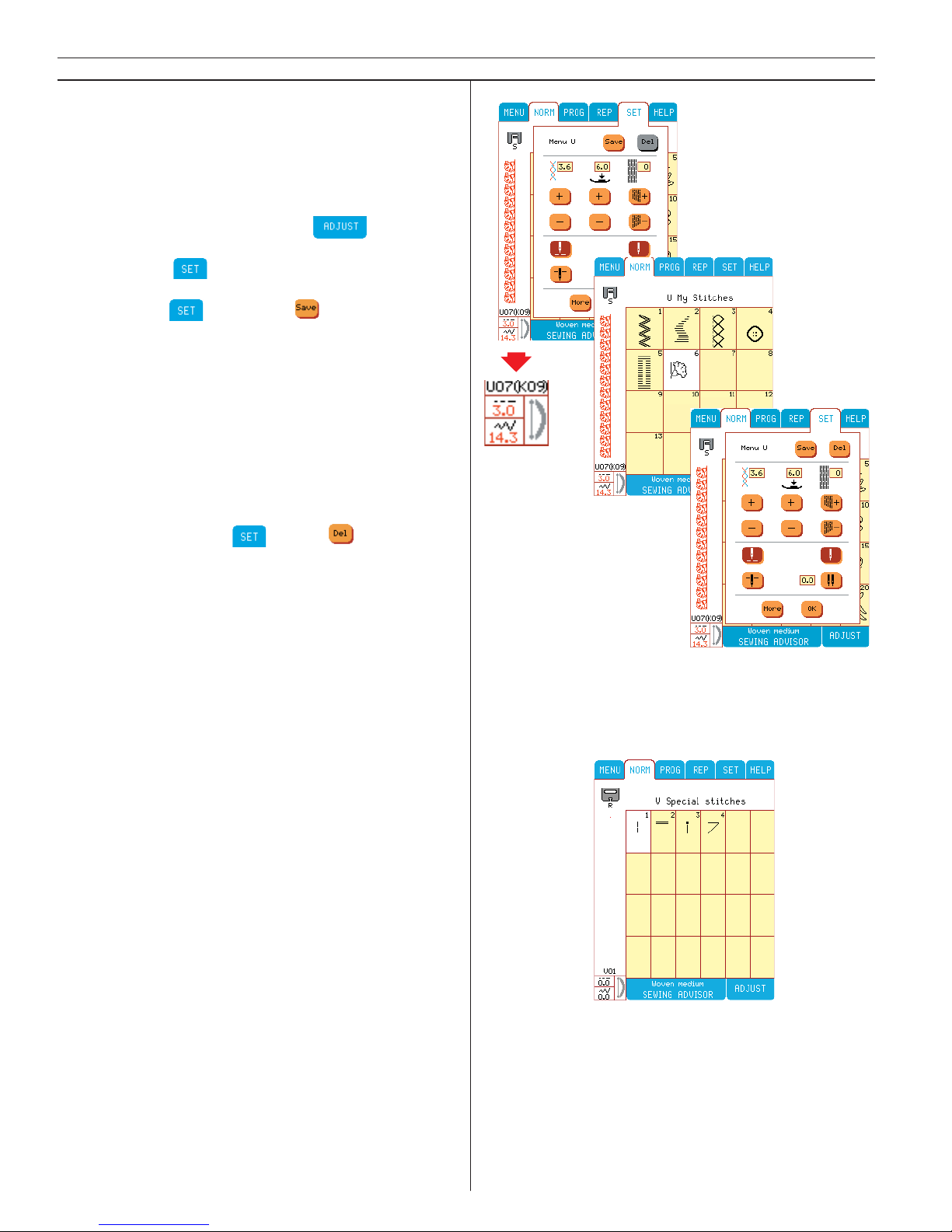

My Stitches

On Menu U, you can customize a favorite stitch

menu, saving your own personal settings for a

stitch. This menu is called “My Stitches” (Menu

U) and is shown on the Main Menu with a heart

symbol. On “My Stitches” you can save 30 stitches with adjustments made in

(length,

width, elongation and mirroring) and with settings made in (tension, balance and pres ser foot pressure). To save your favorite stitch/

setting, go to and select . Menu U will

pop-up. Touch the desired position for your

stitch. The original stitch number is shown in

brackets after the U stitch number.

Note: Stitches from Menu S and Menu T cannot be

saved on Menu U.

When there are no free positions available or if

you want to replace a stitch, touch an occupied

position and its stitch will be replaced by the

new one. To delete a stitch from Menu U, select

the stitch then access . Press and the

active stitch will be deleted. The next stitch will

be selected instead (You can see the selected

stitch to the left on the screen). You can repeat

the procedure until all stitches are deleted. When

Menu U is empty, straight stitch (A02) will be

selected automatically.

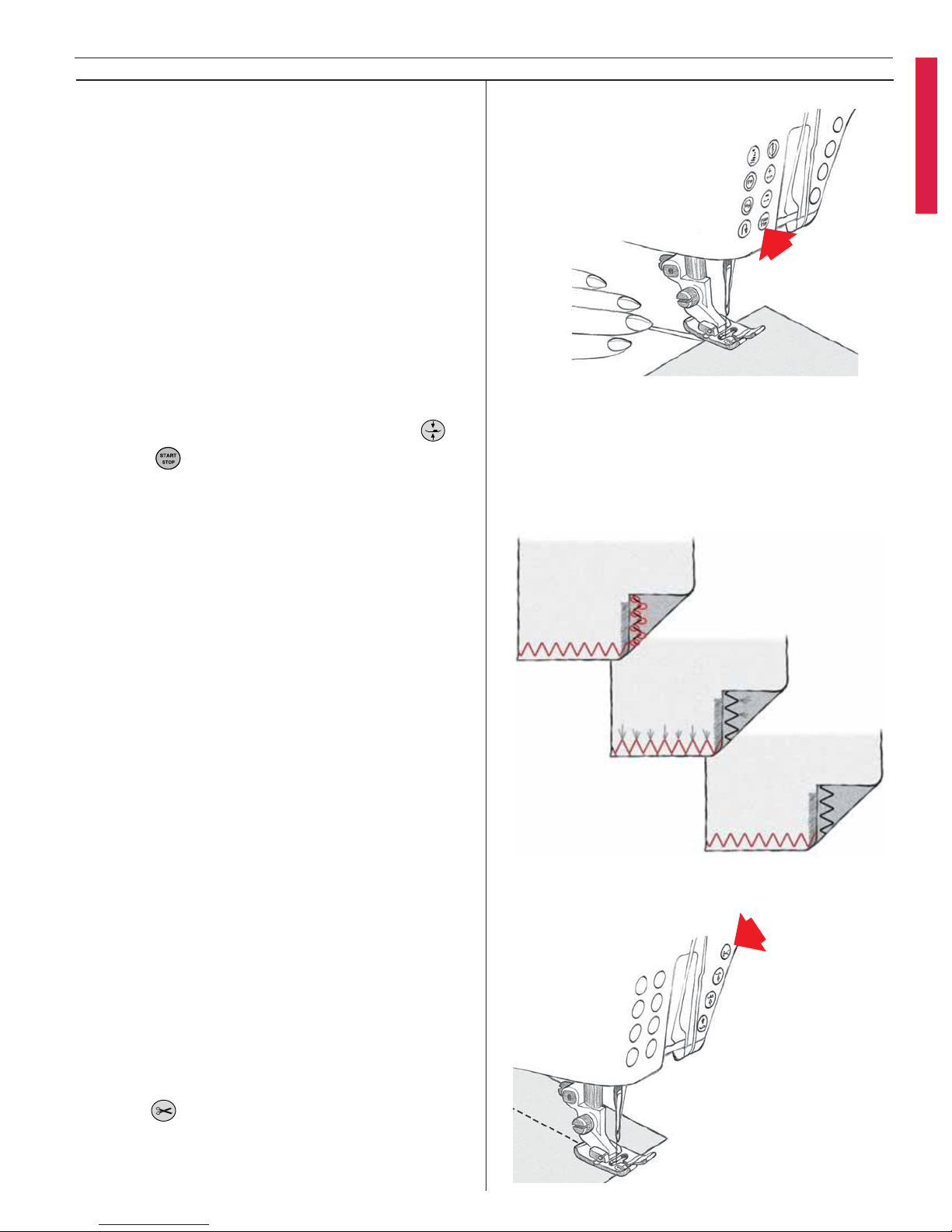

Special Stitches

For free motion sewing, darning, quilting, bas ting and free hand embroidery touch Menu V.

There are four stitch types available, V01, straight

stitch, V02, zigzag and V03 and V04, basting stitches. Lower the feed teeth and for V01 and V02

snap on the R foot or one of the optional free

motion feet. When free motion (free hand) sewing at slow speed (less than 200 rpm) the pressser foot moves up and down. The foot is down

when the needle is down to hold the fabric in

place while the stitch is formed. The foot is raised with the needle so the fabric can be moved

without the risk of ben ding the needle. At faster

sewing speeds (over 200 rpm) the foot stays in

the glide (pivot) po si tion so the fabric can be

moved easily for free motion sewing. Use stitch

V03 and V04 together with the foot control. If

STOP button is canceled you will have automatic

timing. Step on foot control and feed the fabric

manually while the presser foot is up. V03 is a

straight stitch and stitch V04 moves sideways.

26

Learn your Designer I

Starting to sew

• Touch Sewing Advisor on the Color Touch

Screen. Enter the type and weight of fabric

you are sewing. Select the desired sewing

technique from the Sewing Advisor or select a

stitch from one of the menus.

• Place top and bobbin thread under the pres ser foot and to the back. For best results

when beginning at the edge of the fabric,

pla ce a fi ng er on the threads to hold them in

place as you begin.

• Place fabric in position under the presser foot.

• Step on the foot control and begin sewing.

The pres ser foot is lowered automatically.

• If you need to adjust fabric, touch Pivot

.

Note: Use to start and stop the machine wit hout

using the foot control.

Thread tension

The Sewing Advisor will automatically set the

thread ten sion for the fabric and sewing technique selected. To adjust the ten sion for unusual

fabric or thread, see page 29.

To understand the correct thread tension, sew a

few sample zigzag stitches at different settings.

1. Begin with a tension that is too loose, i.e.

set at the lowest number. The lower thread

will lie straight and the up per thread will be

drawn down on the un der si de.

2. If you set the tension at the highest number,

the opposite will occur, and the seam may

pucker.

3. The correct thread tension is provided when

the threads interlock in the middle of both

layers of material or, in the case of decorative

stitches, on the underside.

Make a few tests on a scrap piece of the fabric

you are going to sew and check the tension.

Finish the sewing

• Lift your foot from the foot control.

• Touch

. Designer I cuts the top and bob bin threads. The presser foot and the needle

are raised to the up position automatically.

27

Learn your Designer I

Adjust Menu

Touch to override automatic settings and

make manual adjustments in stitch length, stitch

width and elongation.You can also mirror image

stitches side to side and end to end.

The stitch length, stitch width and elongation

can be changed by touching

or .

You are able to use elongation when you are

sewing satin stitches.

When a setting has been changed, it is indicated

by a bold red frame around the numbers in the

ADJUST menu, and with red numbers in the lower left corner of the Stitch Menu.

Minimum and maximum settings are indicated

with an audible “beep” signal.

Touch buttons for mirror image,

, are

highlighted in brown when selected.

Settings that are not available are colored grey

and can not be selected.

You are able to sew while you are in

.

Close

if you wish to select another stitch.

Touch

to close .

Note: The SET, HELP and ADJUST menus can be

selected at any time and will close automatically.

28

Learn your Designer I

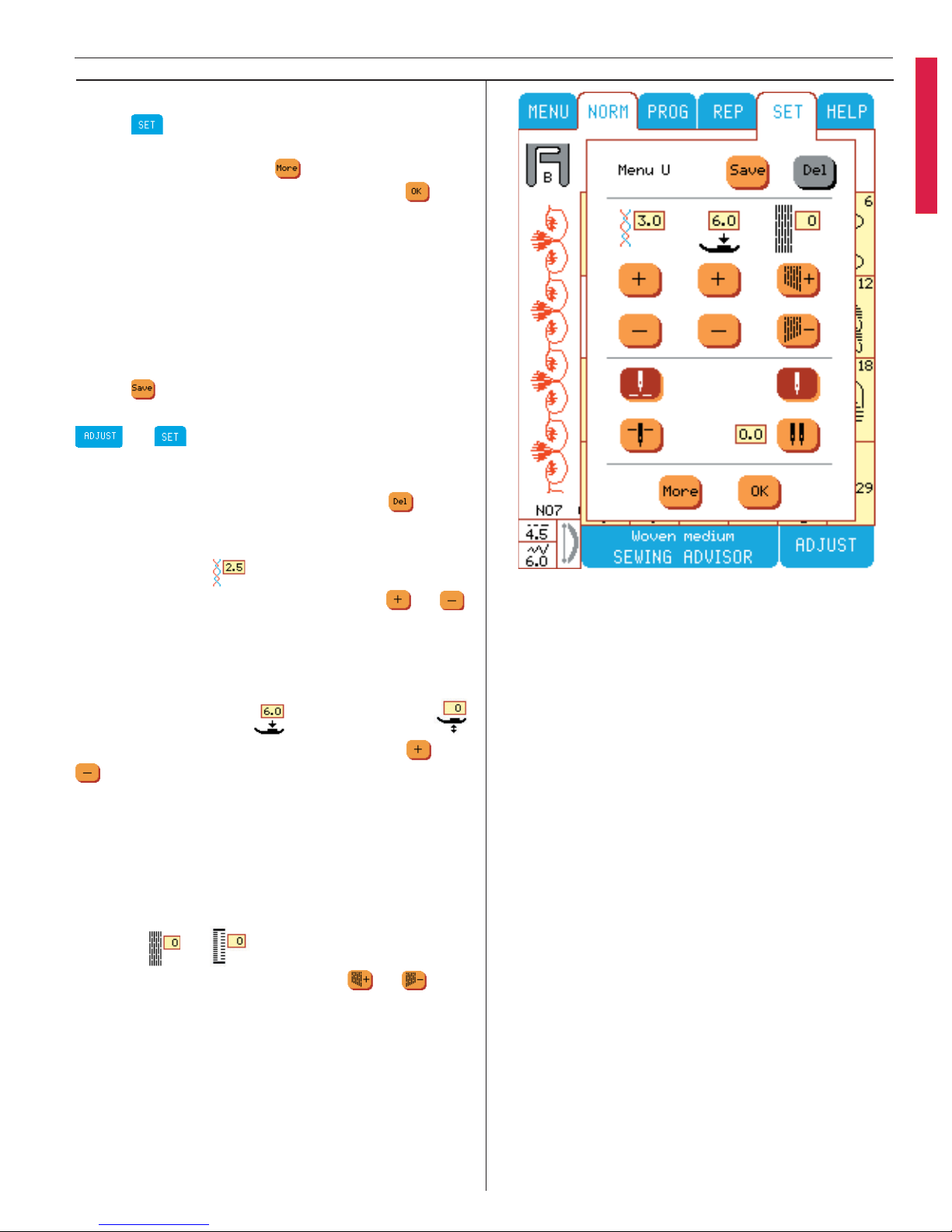

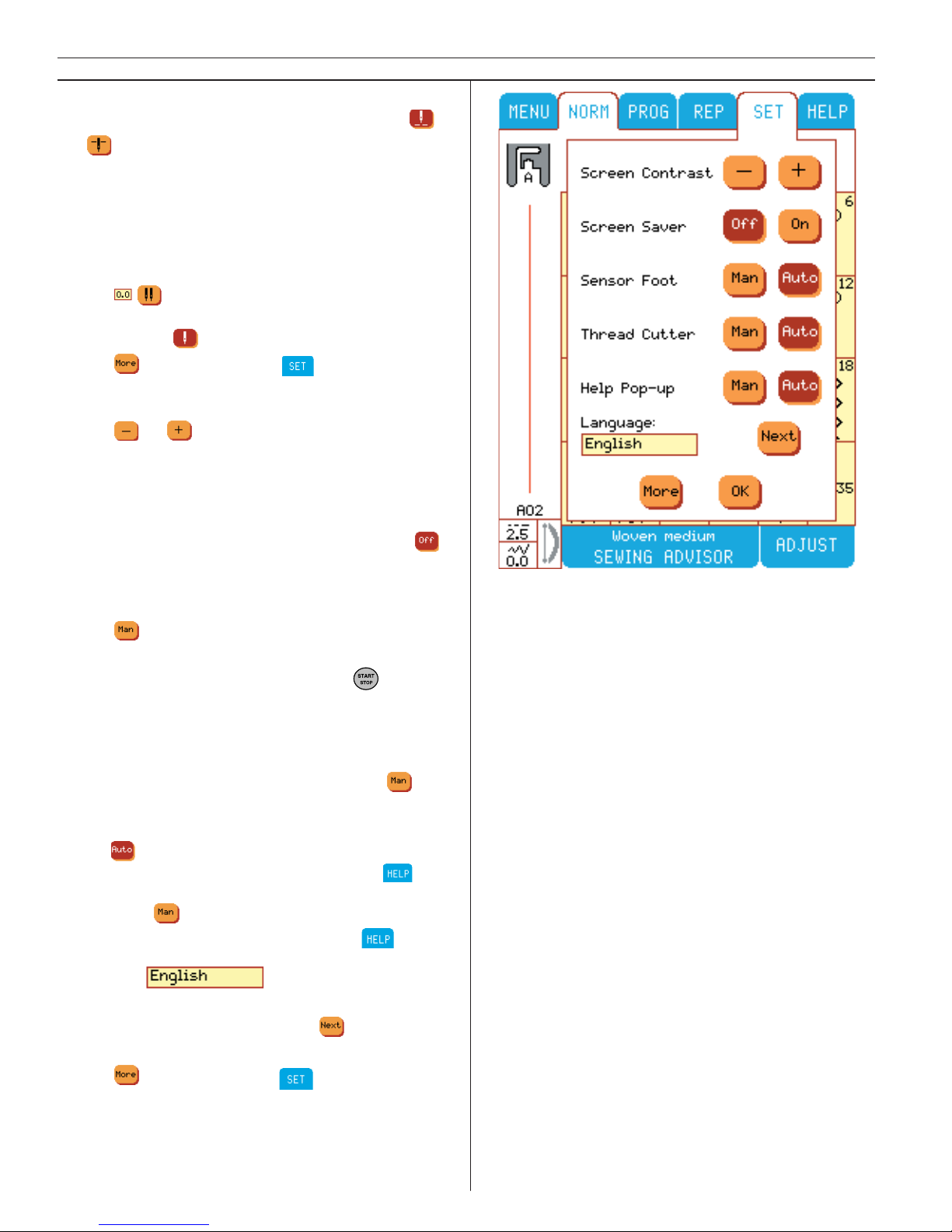

Set Menu

Touch to override automatic setting and

make manual adjustments. There are four dif fe rent set menus. Touch

if you want to jump

between them. To close Set menu touch

When you have made changes in standard settings for thread tension, presser foot pressure,

and balance, the frame around the setting will be

highlighted in red. The changed settings will affect all stitches and the settings remains until the

Designer I is turned off.

Menu U

Touch

to save a favorite stitch on the ”My

Stitches” menu. Any personal settings from

or (including tension, presser foot

pressure, balance) will be saved together with

the stitch.

To delete a stitch from Menu U, touch

. (For

more information see page 26).

Thread tension

Adjust top thread tension by touching

or .

The numbers in the window above indicates the

tension setting. The higher the number the more

tension on the thread.

Presser foot pressure or Pivot position

Adjust presser foot pressure by touching

or

. The number in the window above indicates

the pressure setting. The higher the number the

more pressure the foot puts on the fabric.

When settings changed on stitches in the V Menu

or when embroidering, the height of the pivot

po si tion is set instead of the presser foot pressure.

Balance

or

Adjust stitch balance by touching

or . The

number in the window above indicates the balance setting.

When a buttonhole is selected, the balance buttons will adjust the density of the right column of

the buttonhole. See page 52, Buttonhole Balance.

29

Learn your Designer I

Needle stop position

Needle stop up or down is set by touching

or . The function button (page 12) on the

machine is another option to set needle stop up

or down.

Twin needle safety

When you are going to use a twin needle, enter the size (the distance between the needles).

Touch

step by step until correct value is

dis play ed in the window. For standard single

needle, touch .

Touch

to move to next menu.

Screen Contrast

Touch

or to reduce or increase con trast.

Screen Saver

The screen saver will save the screen by switching off the light if you have not touched the

machine for aproximately 9 minutes. Touch

if you wish to cancel the screen saver.

Sensor Foot

Touch

to cancel the automatic lowering and

pivot position of presser foot, when stepping on

foot control. You can also touch the function

button.

Selective Thread Cutter

If you prefer to activate the selective thread cutter

manually with the function button, touch

.

Help Pop-up menu

When

is selected a Help pop-up will appear

with recommendations for your sewing.

only appears if a sewing circumstance has changed. Touch if you want to bring up help

menu when you need it by touching .

Language

If you want to change language of text on the

Color Touch Screen, then touch

until your

language choice is indicated.

Touch

to move to next menu.

30

Learn your Designer I

Loading...

Loading...