Page 1

USE/INSTALLATION

INSTRUCTIONS

15” W. UNDERCOUNTER/FREESTANDING

ICE MACHINE

RReettaaiinn ffoorr FFuuttuurree RReeffeerreennccee

VIKING RANGE CORPORATION

111 FRONT STREET

GREENWOOD, MISSISSIPPI 38930 USA

(662) 455-1200

IMPORTANT - PLEASE READ AND FOLLOW

••

Before beginning, please read these instructions completely and carefully.

• Do not remove permanently affixed labels, warnings, or plates from the product. This may void the warranty.

• Please observe all local and national codes and ordinances.

• Please ensure that this product is properly grounded.

• The installer should leave these instructions with the consumer who should retain them for local inspector’s use and

for future reference.

WARNING

::

TToo rreedduuccee tthhee rriisskk ooff ffiirree,, eelleeccttrriiccaall sshhoocckk,, oorr iinnjjuurryy wwhheenn uussiinngg yyoouurr uunnddeerrccoouunntteerr iiccee mmaacchhiinnee,, ffoollllooww bbaassiicc

pprreeccaauuttiioonnss iinncclluuddiinngg tthhee ffoolllloowwiinngg::

•FOR YOUR SAFETY•

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR

ANY OTHER APPLIANCE. THE FUMES CAN CREATE A FIRE HAZARD OR EXPLOSION.

IItt iiss yyoouurr rreessppoonnssiibbiilliittyy ttoo bbee ssuurree yyoouurr iiccee mmaacchhiinnee iiss::

•located so the front is not blocked to restrict incoming or discharge air flow.

•properly leveled.

•located in a well ventilated area.

•properly connected to a water supply and drain.

•connected to the proper kind of outlet, with the correct electrical supply and grounding. A 115 volt, 60 Hz, 15 amp

fused electrical supply is required.

NNOOTTEE::

Time delay fuse or circuit breaker is recommended.

•not used by anyone unable to operate it properly.

•used only for its intended purpose.

•properly maintained.

•SAVE THESE INSTRUCTIONS•

SSuuffffooccaattiioonn HHaazzaarrdd

RReemmoovvee ddoooorrss ffrroomm yyoouurr oolldd iiccee

mmaacchhiinnee..

FFaaiilluurree ttoo ddoo ssoo ccaann rreessuulltt iinn

cchhiilldd eennttr

raappmmeenntt,, wwhhiicchh ccaann

ccaauussee ddeeaatthh oorr bbrraaiinn ddaammaaggee..

IIMMPPOORRTTAANNTT::

Child entrapment and suffocation are not problems of the past.

Junked or abandoned refrigeration products are still dangerous, even if they will

sit for “just a few days.” If you are getting rid of your refrigeration product,

please follow the instructions below to help prevent accidents.

BBEEFFOORREE YYOOUU TTHHRROOWW AAWWAAYY YYOOUURR OOLLDD RREEFFRRIIGGEERRAATTIIOONN PPRROODDUUCCTT::

•Take off the doors.

•Leave the shelves in place so that children may not easily climb inside.

DANGER

PROPER DISPOSAL OF YOUR OLD REFRIGERATION PRODUCT

41006471

Rev. E

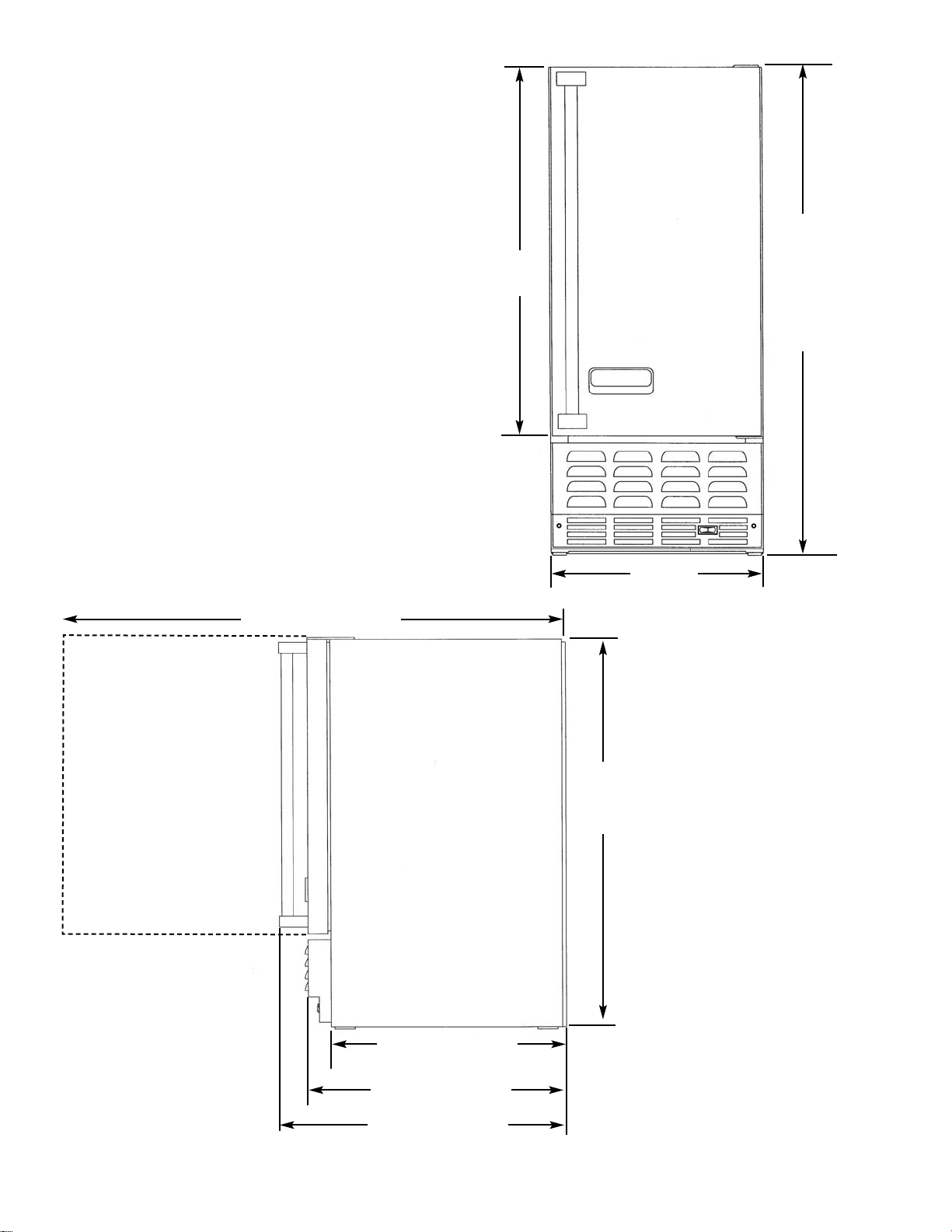

Page 2

2

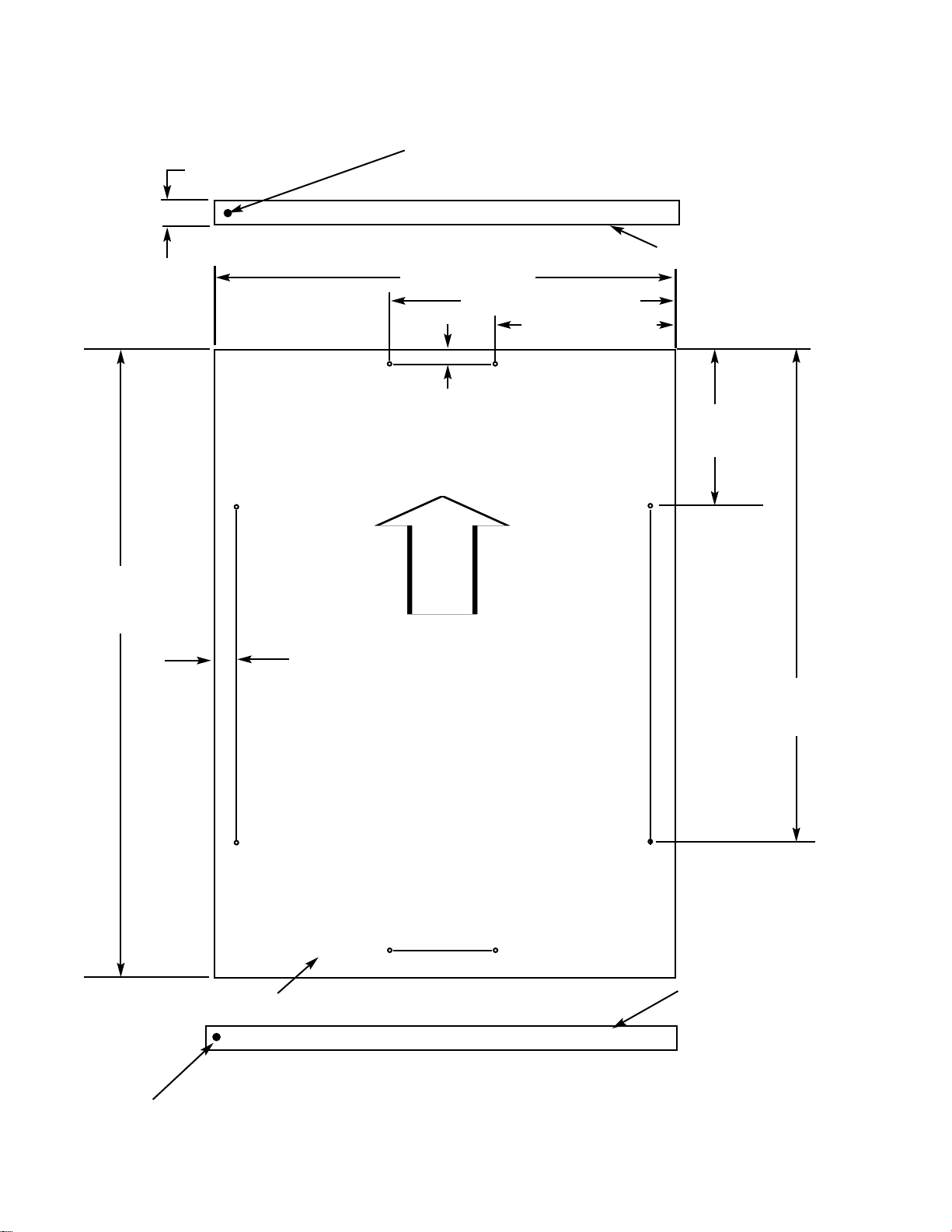

A

B

UNDERCOUNTER CABINET

CUTOUT

AA

15” (38.1 cm)*

BB

Min. 34 1/2” (87.6 cm)

Max. 35 1/8” (89.2 cm)

CC

24” (61.0 cm)

C

GENERAL INFORMATION

Unpack

1. Remove banding from bottom of carton. Lift carton up and off of the ice machine

2. Remove all tape and packaging material from the outside and inside of the cabinet.

3. Keep all carton packaging until your ice machine has been thoroughly inspected and found to be in good

condition.

Area Requirements

1. Place unit so the front side will be completely unobstructed to provide proper air flow. The unit may be closed in

on the top and three sides, but the front

MMUUSSTT BBEE

unobstructed for air circulation and proper operation.

Installation should be such that the cabinet can be moved for servicing if necessary.

2. Unit should be in a well ventilated area. Best results are obtained at temperatures between 55

0

F (130C) and 800F

(27

0

C) for built-in indoor models, between 550F (130C) and 900F (320C) for indoor freestanding models, and between

45

0

F (7.20C) and 1100F (430C) for outdoor models.

3. Provisions for electricity should be determined before placing unit in proper place.

4. For best performance, outdoor units should be installed away from direct sunlight or under a counter or sink.

*15” (38.1 cm) width for cabinet only. If door

is recessed between cabinets, cabinet cutout

must be 15-1/4” (38.7 cm.).

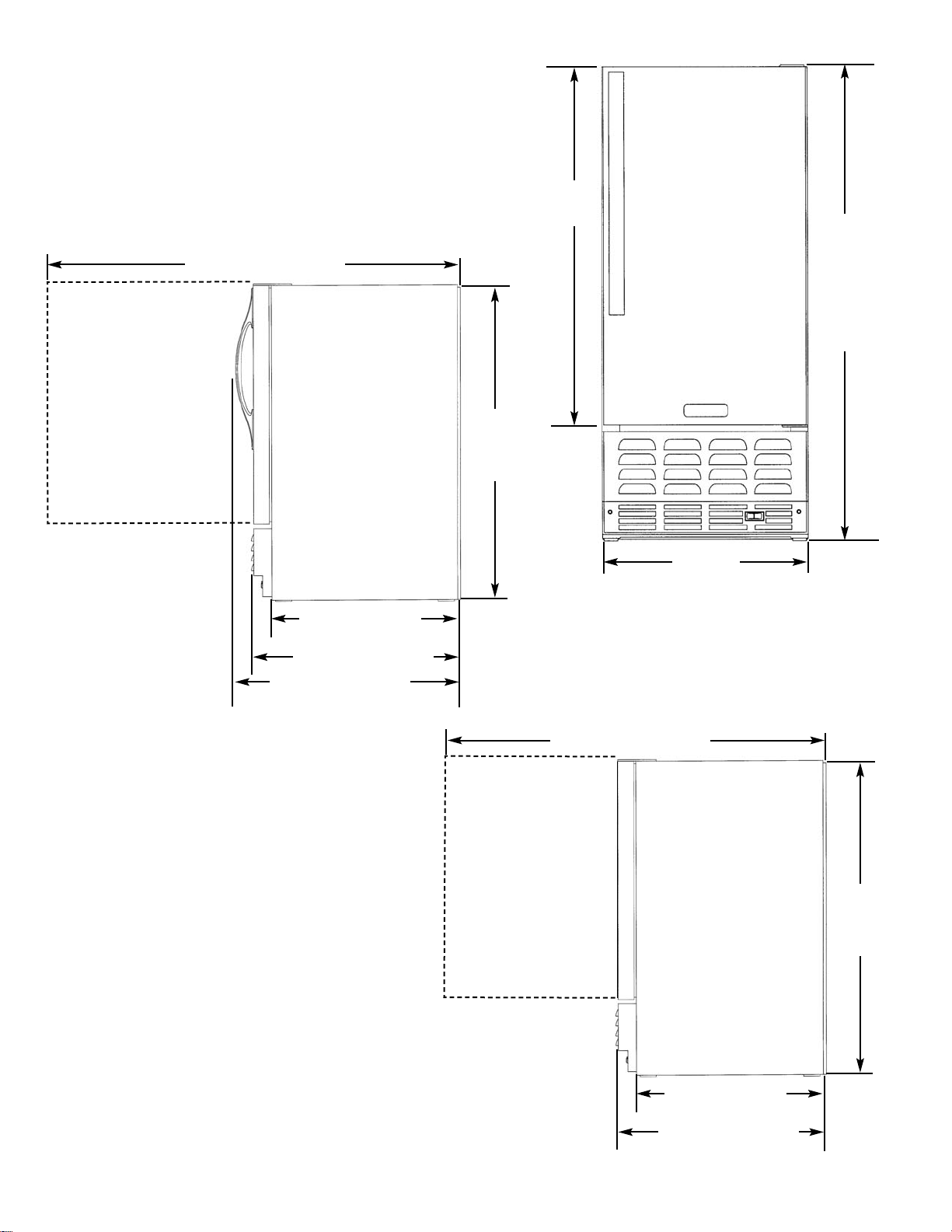

Page 3

3

SPECIFICATIONS/DIMENSIONS

PROFESSIONAL MODELS

BBaassiicc EElleeccttrriicc DDaattaa

•115 VAC/60 Hz

•Maximum amps - 3.0

Approximate Shipping Weight - 110 lbs.

(49.5 kg)

Front View

VUIM

Side View

VUIM

34 1/4”

(87.0 cm)

22” (55.9 cm)

27 1/8” (68.9 cm)

24 5/8” (62.6 cm)

37 9/16” (95.4 cm)

Min. 34 1/4”

(87.0 cm)

Max. 35”

(88.9cm)

26”

(66.0 cm)

14 3/4”

(37.5 cm)

Page 4

4

SPECIFICATIONS/DIMENSIONS

DESIGNER MODEL

BBaassiicc EElleeccttrriicc DDaattaa

•115 VAC/60 Hz

•Maximum amps - 3.0

•Approximate Shipping Weight - 110 lbs. (49.5 kg)

Front View

DUIM

Side View

DUIM

Side View

DFIM

34 1/4”

(87.1 cm)

22” (55.9 cm)

25 5/8” (65.1 cm)

24 5/8” (62.6 cm)

37 9/16” (95.4 cm)

34 1/4”

(87.1 cm)

22” (55.9 cm)

24 5/8” (62.6 cm)

37 9/16” (95.4 cm)

Min. 34 1/4”

(87.0 cm)

Max. 35”

(88.9cm)

26”

(66.0 cm)

14 3/4”

(37.5 cm)

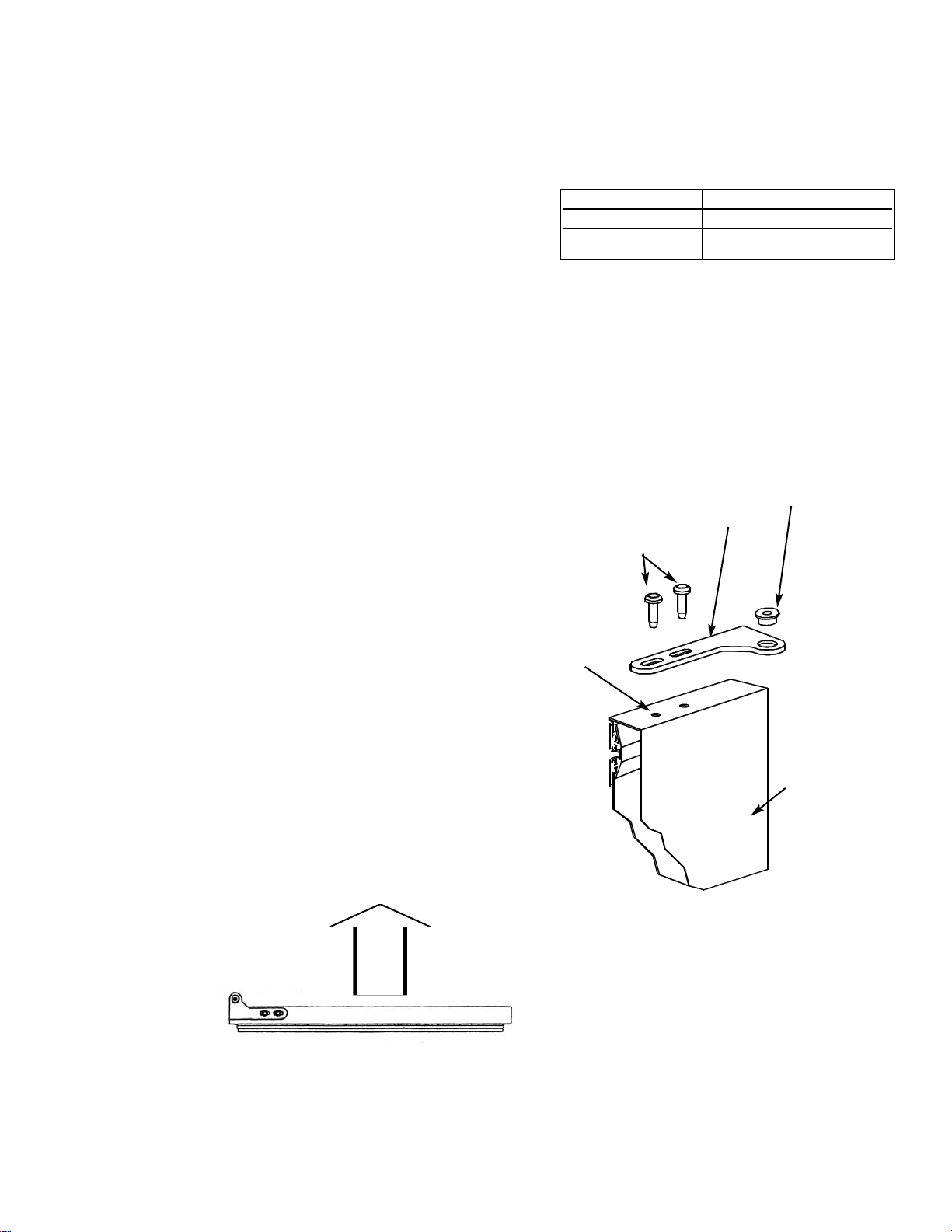

Page 5

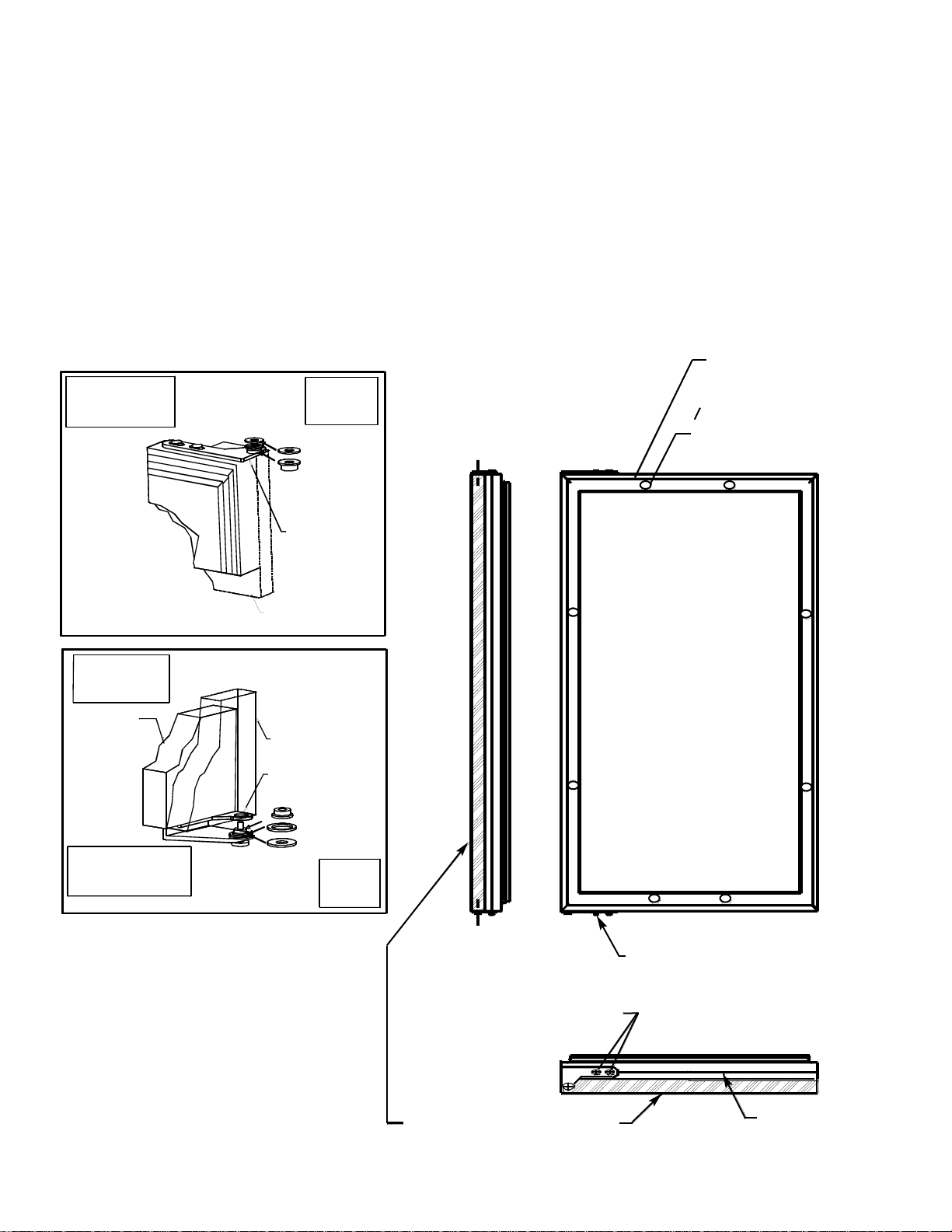

FULL OVERLAY PANEL INSTALLATION

Note: Weight of wood panel must not exceed 20 lbs.

WWoooodd SSccrreewwss

1. A #8 pan head wood screw should be used to properly secure the wood panel. A total of 8 screws will be needed.

2. Only use pan head screws.

3. DO NOT select a screw that is longer than the wood thickness at

the screw locations.

4. Use recommended pilot holes for the frame material. (See chart)

WWoorrkkiinngg MMaatteerriiaall WWoooodd SSccrreeww SSiizzee ##88

Hardwood 3/32 (0.24 cm)

Softwood 5/64 (0.20 cm)

AAsssseemmbblliinngg DDoooorr HHiinnggee BBrraacckkeettss

(Disregard if hinge brackets are already attached)

1. Attach the top and bottom door hinge brackets to the door with the #10-32 machine screws and a 1/8”

allen head driver as shown in Figure 1 below.

2. Press in the shoulder bushings to the top and bottom door hinge brackets. Make certain that the shoulder

is to the outside of the door as shown in Figure 1 below.

3. Test fit the door to the unit to make certain door will hang correctly. The door is hung correctly when the

top of the door is parallel to the top of the unit. Adjustments can be made by loosening the door hinge

machine screws and moving the door hinge brackets on the door.

4. Tighten all four (4) machine screws after adjustments have been made.

5. Remove the door from the unit by removing the units top hinge set

screw and angling the door off of the bottom hinge pin.

Shoulder Bushing

Door Hinge Bracket

#10-32 Machine

Screw

Door Hinge

Screw Holes

Door Front

Surface

FFIIGGUURREE 11

TTyyppiiccaall TToopp aanndd BBoottttoomm DDoooorr

HHiinnggee BBrraacckkeett AAsssseemmbbllyy

FRONT

5

BBoottttoomm VViieeww ooff DDoooorr wwiitthh LLeefftt HHaanndd SSwwiinngg

Page 6

6

SELECTING AND PREPARING THE OVERLAY PANEL (DFIM MODELS)

MMiinn.. 55//88”” ((11..77 ccmm))

MMaaxx.. 33//44”” ((11..99 ccmm))

1144 33//44”” ((3377..55 ccmm))

88 1155//1166”” ((2222..77 ccmm)) TTYYPP

55 1133//1166”” ((1144..88 ccmm))

2233//3322 ““ TTYYPP

((11..88 ccmm))))

1/4” x 3/8” Deep hinge screw clearance hole. Locate and drill

using door hinge hole after the door has been aligned to the unit

and when the wood is positioned on door.

MMoouunnttiinngg ssuurrffaaccee ((nnoonn--ffaaccee)) ssiiddee

1/4” x 3/8” Deep hinge screw clearance hole. Locate and drill using door hinge hole

after the door has been aligned to the unit and when the wood is positioned on door.

MMoouunnttiinngg ssuurrffaaccee ((nnoonn--ffaaccee)) ssiiddee

MMoouunnttiinngg ssuurrffaaccee ((nnoonn--ffaaccee)) ssiiddee

1133//1166”” TTYYPP

((22..11 ccmm))

BBootthh SSiiddeess

55””

((1122..77 ccmm))

TTYYPP

1199 33//1166””

((4488..77 ccmm))

TTYYPP

PPrree--ddrriilllleedd ppiilloott hhoolleess

88 ppllaacceess

2255 55//88””

((6655..11 ccmm))

TOP

OF

DOOR

Page 7

7

ATTACHING THE OVERLAY PANEL TO THE DOOR

1. If the door is attached to the unit, remove by unscrewing the top allen head set screw at the top hinge. Remove

the door by angling the door off of the bottom hinge pin.

2. Peel back the door gasket to expose the screw holes.

3. Set the overlay panel flush to the front of the door in the desired location. Clamp the overlay panel to the door if

necessary.

4. Insert the wood screws through the back of the door into the pilot holes in the overlay panel and tighten.

5. Reinstall the door gasket by pressing into the door channel. Make certain the corners are inserted fully.

6. Install the door to the unit. Use the supplied plastic washer as shown in the figure below.

7. Realigning the door may be necessary. Any final door adjustments can be made using a 1/8” allen head driver to

adjust the door’s brackets. (See figure below)

8. Attach the door to the unit by reversing step number 1 above.

HHiinnggee HHaarrddwwaarree IInnssttaallllaattiioonn

DDeettaaiillss

MAGNETIC

DOOR GASKET

1/8 INCH ALLEN HEAD SCREWS

FOR HINGE ADJUSTMENT

ATTACHED OVERLAY PANEL

DOOR HINGE

ADJUSTMENT SCREWS

BOTTOM OF DOOR

REAR OF DOOR

Ø0.38 CLEARANCE HOLES

FOR SCREWS

8 HOLES

DOOR HINGE

BUSHING BRACKET

TOP HINGE CORNER

SHOULDER BUSHING

WASHER

OVERLAY PANEL

.625 OD X .218 ID

HARDWARE

COMPONENTS

AT TOP HINGE

(2) NYLON

CAUTION

DOOR CAN BECOME

DISENGAGED IF

WASHERS ARE

NOT INSTALLED

BOTTOM HINGE CORNER

DOOR HINGE

BUSHING BRACKET

SHOULDER BUSHING

.75 OD X .443 ID

.75 OD X .257 ID

OVERLAY PANEL

REFRIGERATOR

DOOR

WASHER

WASHER

CAUTION

DOOR MAY NOT SWING

PROPERLY IF ALL NYLON

COMPONENTS ARE NOT

INSTALLED AS SHOWN

(3) NYLON

HARDWARE

COMPONENTS

AT BOTTOM

HINGE

CAUTION

DOOR CAN BECOME

DISENGAGED IF

WASHERS ARE

NOT INSTALLED

0 3/8” CLEARANCE HOLES

FOR SCREWS

8 HOLES

1/8” ALLEN HEAD SCREWS

FOR HINGE ADJUSTMENT

Page 8

8

Screw

Impressions

LEG LEVELER INSTALLATION

READ BEFORE INST

ALLING LEG LEVELERS

WARNING

Do not lay unit on top, side, back, or front. If unit is accidentally laid in any position other than right side up, then the

unit must remain in the right side up position for at least 24 hours before plugging the unit in.

1. Tip unit backwards so there is (1) foot of clearance on front of the unit. Have someone to assist you in tilting the

unit, to prevent it from falling on you while installing the leg levelers.

2. Screw front two leg levelers into the screw impressions. Leg levelers should be screwed in until snug.

3. Repeat steps 1 & 2, with the exception of tipping the unit forwards now, to screw in the back two leg levelers.

4. Your leg levelers are now installed.

5. The unit should be level from front to back and side to side. If floor conditions do not allow the unit to sit level,

adjust leg leveler(s) by turning the required leg leveler(s) counter-clockwise to increase their height and clockwise to

reduce their height.

Page 9

9

WIRING DIAGRAM

UNDERCOUNTER 15” W. ICE MACHINE

WWAARRNNIINNGG:: EELLEECCTTRRIICCAALL

GGRROOUUNNDDIINNGG

IINNSSTTRRUUCCTTIIOONNSS

This appliance is equipped with a

three prong grounding plug for

your protection against shock

hazard and should be plugged

directly into a properly grounded

three prong receptacle. Do not

cut or remove the grounding

prong from this plug.

ELECTRICAL CONNECTION

EElleeccttrriiccaall RReeqquuiirreemmeennttss

A 115 volt, 60 Hz, AC only 15 amp fused electrical supply is required. (A time delay

fuse or circuit breaker is recommended.) It is recommended that a separate circuit,

serving only this appliance, be provided.

••EELLEECCTTRRIICCAALL GGRROOUUNNDD IISS RREEQQUUIIRREEDD OONN TTHHIISS AAPPPPLLIIAANNCCEE..

••DDOO NNOOTT UUNNDDEERR AANNYY CCIIRRC

CUUMMSSTTAANNCCEESS RREEMMOOVVEE TTHHEE PPOOWWEERR

SSUUPPPPLLYY CCOORRDD GGRROOUUNNDD PPLLUUGG..

••DDOO NNOOTT UUSSEE AANN EEXXTTEENNSSIIOONN CCOORRDD..

RReeccoommmmeennddeedd GGrroou

unnddiinngg MMeetthhooddss

For your personal safety, this refrigeration product must be grounded. This appliance is equipped with a 5’ power supply cord

having a 3-prong grounding plug. To minimize possible shock hazard, the cord must be plugged into a mating 3-prong

grounding type wall receptacle grounded in accordance with the National Electrical Code and local codes and ordinances. If

the circuit does not have a grounding type receptacle, it is the responsibility and obligation of the customer to exchange the

existing receptacle in accordance with the National Electrical Code and applicable local codes and ordinances. The third

ground plug SHOULD NOT, under any circumstances, be cut or removed. All UL listed refrigerated products are equipped

with this type of plug.

Power Supply

with 3-prong

grounding plug

Grounding type wall

receptacle

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow these instructions could result in fire or electrical shock.

Page 10

10

Water Supply

•This ice machine must be connected to a potable, active cold water supply line delivering water pressure at a minimum

pressure of 20 psi and maximum of 120 psi.

•Water connection is made through a 1/4” (.64 cm) compression right angle garden hose fitting.

DDoo nnoott uussee aannyy tthhrreeaadd

sseeaalleerrss.. NNOOTTEE:: TThhee wwaatteerr lliinnee ffiittttiinngg ssuupppplliieedd wwiitthh yyoouurr iiccee mmaacchhiinnee iiss t

too bbee uusseedd oonn aa 11//44”” ((..6644 ccmm)) ccooppppeerr wwaatteerr ssuuppppllyy

lliinnee oonnllyy.. DDoo nnoott aattttaacchh aa ppllaassttiicc ssuuppppllyy lliinnee ttoo

yyoouurr uunniitt uussiinngg tthhiiss ffiittttiinngg..

••AA wwaatteerr ffiilltteerr iiss rreeccoommmmeennddeedd ffoorr tthhiiss uunniitt..

A quality filter can remove particles as well as remove taste and odors from water.

•Do not use a reverse osmosis water filtration system with the ice machine.

•

SSoofftteenneedd wwaatteerr iiss nnoott rreeccoommmmeennddeedd..

This will produce mushy, cloudy ice cubes that will stick together.

•

DDee--iioonniizzeedd w

waatteerr iiss nnoott rreeccoommmmeennddeedd

. This water will not form solid ice cubes.

•A water specialist can recommend proper water treatment.

•After installation of water line, turn on water and check for any leaks. Additional tightening may be needed.

DDoo nnoott uussee aannyy

ttyyppee ooff tthhrreeaadd sseeaalleerr..

•Allow extra water line for easy removal of unit and to help prevent the water line from kinking.

Rubber washer

Adapter

Fitting valve

Compression fitting

Compression nut

1/4” (.64 cm) copper

water supply line

(supplied by customer)

From water supply

to ice machine

COMPRESSION FITTING

REAR OF UNIT

GARDEN HOSE

FITTING

5/8" (.63 cm) I.D. DRAIN

TUBING BARB

MAKE CERTAIN ALL HOSE

CLAMPS ARE SECURE

1/4" (.64 cm) TUBING FROM

COLD WATER LINE

5 1/2" (14.0 cm)

2 1/8" (5.4 cm)

WATER CONNECTION

Page 11

11

DRAIN PLUMBING

Your ice machine uses a gravity drain that requires 5/8” (.63 cm) ID tubing from the back of the

ice maker to a plumbed connection to a sanitary sewer (see Gravity Drain drawing below).

Remove the access panel, with a 5/16” (0.8 cm) wrench to plumb in drain connection. Gravity

drain location for built-in units can be within the area shown in illustration below. An optional

drain pump can be purchased for your ice machine if a gravity drain is not accessible.

Observe and follow all local codes when installing an ice machine.

FFaaiilluurree ttoo uussee aaddeeqquuaattee

ddrraaiinnaaggee ssyysstteemm wwiillll rreessuulltt

iinn ssuurrrroouunnddiinngg wwaatteerr

ddaammaaggee aanndd//oorr ppoooorr iiccee

pprrood

duuccttiioonn..

WARNING

1 1/2" (3.8 cm) DRAIN

PIPE

DRAIN TRAP

5/8" (.63 cm) I.D.

DRAIN TUBING

AND HOSE CLAMP

ICE MAKER

POWER CORD

ACCESS PANEL

DRAIN FROM

ICE MAKER

DRAIN PUMP

DISCHARGE TUBE GOES THRU

THIS OPENING IN THE ACCESS PANEL

VENT TUBE

TUBING CLAMPS

DRAIN PUMP

POWER CORD

DRAIN FROM

ICE MAKER

ACCESS PANEL

VENT TUBE GOES THRU THIS

OPENING}{ IN THE ACCESS PANEL

DRAIN PUMP'S}{ DISCHARGE

LINE THRU}{ THIS OPENING

SUPPLIED SCREWS

GRAVITY DRAIN LOCATION

TToopp ooff

UUnniitt

FFrroonntt ooff

UUnniitt

22” (55.9 cm)

24 5/8” (62.6 cm)

2 3/8” (6.0 cm)

4 1/16”

(10.3 cm)

14 3/4”

(37.5 cm)

6 3/4”

(17.1 cm)

GRAVITY DRAIN

DRAIN PUMP

Model Number - VUIM-DP

((SSoolldd sseeppaarraatteellyy -- sseeee iinnssttaallllaattiioonn

iinnssttrruuccttiioonnss ssuupppplliieedd wwiitthh ddrraaiinn

ppuummpp))

VENT TUBE GOES THRU THIS OPENING

IN THE ACCESS PANEL

DRAIN PUMP’S DISCHARGE

LINE THRU THIS OPENING

Page 12

12

ICE MACHINE FEATURES

HOW THE ICE MACHINE WORKS

Your ice machine is unique in forming ice. It uses fractional freezing to form a slab of ice that is clear and has less

mineral content than the water it is produced from. This is accomplished by running water over the cold evaporator

plate which gradually freezes the water to produce the ice slab. Mineral deposits are left in the reservoir.

When the ice slab reaches the correct thickness determined by the temperature of the evaporator plate, the electronic

control switches to the harvest cycle to harvest the ice slab. During the harvest cycle, the ice slab falls from the

evaporator to the ice grid cutter. Here, the ice slab is cut into 3/4” squares by the grid cutter’s low voltage heated

wires. During the harvest cycle, the drain valve will remain open for 45 seconds to drain the reservoir of remaining

deposits. After that, the water valve will open for 2 minutes providing 2 quarts of water to the reservoir for the next ice

production cycle.

The ice machine will keep producing ice until the ice machine’s storage bin is full and will restart automatically when ice

needs to be replenished in the storage bin.

To begin ice production, turn the switch to the “ON” position.

Ice Machine Safety and Operation Tips

•Avoid leaning on the cabinet door. You may bend the door hinge or tip the unit.

•Exercise caution when sweeping, vacuuming, or mopping near the front of the unit. Damage to the grill and/or switch

can occur.

•Periodically clean the inside of the ice machine components and inside of the unit.

•Periodically check and/or clean the front grill and condenser coils.

Ice Scoop

Ice Storage Bin

Escutcheon Panel

On/Off/Clean Rocker Switch

Page 13

13

USING YOUR ICE MACHINE

1. Allow your ice machine to run for at least 48 hours to accumulate ice in the ice bin.

2. The unit will cycle off between ice production and ice harvest cycles.

3. Your ice machine will make unusual noises that you do not normally hear form your household refrigerator/freezer.

These noises do not mean your ice machine is not functioning properly. They occur as a normal part of the ice

machine’s operations.

4. The unit will automatically shut down when the ice bin is full.

5. Unplug the ice machine before working on the unit.

6. Keep the ice machine clean for proper ice quality, production, and unit life.

7. Room and water supply temperatures will greatly affect the output of ice in the unit. (See table below.) Ice will also

melt away, especially at the start of an empty bin, but will slow down as ice accumulates.

PRODUCTION

RATE (LB/DAY)*

WATER TEMPERATURE

0

F

70

80

90

100

50

33

30

23

17

70

32

27

20

13

70

80

90

100

50

31

41

60

85

70

34

58

82

∞**

ROOM

TEMPERATURE

0

F

ROOM

TEMPERATURE

0

F

**NNOOTTEE::

DDuuee ttoo vvaarriiaabblleess iinn iinnssttaallllaattiioonn aanndd uussee,, iinnddiivviidduuaall rreessuullttss mmaayy vvaarryy..

****CCoonnttiinnuuoouuss rruunn,, bbiinn wwiillll ffiil

lll ssiiggnniiffiiccaannttllyy,, bbuutt hheeaatt ffllooww aanndd wwaatteerr tteemmppeerraattuurree ddoo nnoott

aallllooww iiccee bbiinn ttoo ffiillll ttoo sshhuutt--ooffff tthheerrmmi

issttoorr..

APPROXIMATE

TIME TO FILL BIN (HOURS)*

WATER TEMPERATURE

0

F

Outdoor Use

1. For best performance, install under a counter or shelter. Avoid direct sunlight.

2. If the ice machine is not used for an extended period of time or if temperatures are below 45

0

F (7.20C), it is

necessary to remove remaining water in the ice making system. (See Preparing Ice Machine for Storage, p. 12).

3. Chlorine gas from swimming pools and spas may discolor stainless steel. (See Cleaning and Maintenance below for

instructions on cleaning).

CLEANING AND MAINTENANCE

Any piece of equipment works better and lasts longer when maintained properly and kept clean.

CCoonnddeennsseerr

The condenser tubing inside the cabinet does not require frequent cleaning; however, satisfactory cooling depends on

adequate ventilation over the coils. Be sure that nothing obstructs the required air flow openings in front of the cabinet.

Spiders and insects can nest in and around the ice machine causing damage to the unit. Frequently brush or vacuum

(twice yearly) lint and dirt from the condenser for efficient performance by unscrewing the grill and kickplate on the

bottom front of cabinet.

CCaabbiinneett

The cabinet can be washed with mild soap and water and thoroughly rinsed with clear water. Never use abrasive scouring

powders.

IInntteerriioorr//IIccee SSccoooopp

Wash interior compartment and ice scoop with mild soap and water or a baking soda and water solution. Do not use

abrasive powder, solvent, polish cleaner or undiluted detergent.

Page 14

14

SSttaaiinnlleessss SStteeeell PPaarrttss

All stainless steel parts should be wiped regularly with hot soapy water. Use a liquid cleaner designed for stainless steel

when soapy water will not do the job.

DDoo nnoott uussee

bleach, steel wool, abrasive cloths, cleansers, or powders. Do not

permit citrus or tomato juice to remain on stainless steel surfaces, as citric acid will permanently discolor stainless steel.

Note: Under rare conditions, such as an extremely salty environment, small amounts of rust may accumulate on stainless

steel parts. These small amounts of surface rust can easily be removed by apply Soft Scrub® Gel to a damp sponge and

wiping with the stainless steel grain. It is important to make sure you wipe with the grain for the most efficient removal of

surface rust.

BBrraassss PPaarrttss

CCAAUUTTIIOONN::

All brass parts have an epoxy coating.

DDOO NNOOTT UUSSEE BBRRAASSSS OORR AABBRRAASSIIVVEE CCLLEEAANNEERRSS O

ONN TTHHEE BBRRAASSSS

PPAARRTTSS..

All brass parts should be wiped regularly with hot soapy water. When hot soapy water will not do the job, use

every day non-abrasive household cleaners.

DDoooorr GGaasskkeett

The vinyl gasket may be cleaned with mild soap and water, a baking soda and water solution, or a mild scouring powder.

PPaaiinntteedd SSuurrffaacceess

Wash with warm soapy water.

DDOO NNOOTT UUSSEE

steel wool, abrasive cleansers, ammonia, acids or commercial oven cleaners

which may damage the finish.

The ice machine will regularly (at the very least, annually) need to be cleaned of this build-up, depending on use and

water hardness. You can use an acid such as one specified for ice machine cleaning or you can use citric acid to

remove the build-up. To clean the ice machine:

1. Switch the selector switch to the “OFF” position.

2. Remove the drain plug at the bottom of the reservoir to drain any

remaining water and then reinstall.

3. Remove the escutcheon panel.

4. Add cleaning solution to the reservoir. NOTE: Three quarts of water

will automatically be added to the reservoir. Therefore, cleaning

solution should not be diluted. Please follow manufacturer’s

instructions for mixing with 3 quarts of water.

5. Replace escutcheon panel and close door.

6. Switch selector switch on the grill of the machine to the clean position.

7. The cleaning cycle will end in 49 minutes. The cleaning cycle will automatically rinse the evaporator plate, drain

the cleaning solution, and rinse the components.

8. After the cleaning cycle has ended, remove the escutcheon panel again and check that build-up has been

removed. The evaporator plate should be clean, shiny, and smooth to the touch. If not and build-up is still visible,

repeat the cleaning cycle above. If build-up is removed, continue below.

9. Remove the distributor tube, hose clamp, hose and its rubber ends.

10. Thoroughly clean the inside of the distributor tube and the spray holes. You can use the same cleaning solution as

before and an old tooth brush to reach the inside of the distributor tube.

11. Reinstall the rubber end, hose, and hose clamp to the distributor tube and then reinstall the distributor tube to the

evaporator with the spray holes pointed to the bottom of the evaporator plate. Reinstall the escutcheon panel.

Your ice machine is now clean and sanitized. It can be placed back into operation by switching the selector switch to

the “ON” position. Please wait 48 hours for maximum ice production.

RReeaadd aanndd ffoollllooww mmaannuuffaaccttuurreerr’’ss wwaarrnniinnggss oonn iiccee

mmaacchhiinnee cclleeaanneerr pprroodduuccttss..

WARNING

CLEANING THE ICE MACHINE SYSTEM

Some impurities will remain and buildup in the ice machine and stick to the ice machine’s parts over time. This buildup must be removed for proper ice production, ice quality, and ice machine life. Your ice machine is equipped with a

cleaning mode that will help in cleaning out these impurities.

Page 15

15

PREPARING THE ICE MACHINE FOR

STORAGE

If the ice machine is moved, not used for an extended

period of time, or will be in a area below 45

o

F (7.2oC), it

is necessary to remove the water from the ice making

system.

TThhiiss iiccee mmaacchhiinnee mmuusstt hhaavvee aallll wwaatteerr ddrraaiinneedd aanndd rreemmoovveedd

ttoo pprreevveenntt iiccee mmaacchhiinnee ddaammaaggeess aass wweellll aass p

poossssiibbllee wwaatteerr

ddaammaaggee ttoo tthhee ssuurrrroouunnddiinngg aarreeaa iinn ffrreeeezziinngg ccoonnddiittiioonnss..

TThheessee ddaammaaggeess aarree nnoott ccoovveerreedd u

unnddeerr wwaarrrraannttyy..

CAUTION

SStteepp 11::

Clean the ice machine (refer to page 11.)

SStteepp 22::

Drain and remove water from ice making system.

1. Turn off the water supply to the ice machine.

2. Disconnect the water supply fitting at the inlet of the water valve.

3. Switch the rocker switch to “CLEAN” for approximately 1 minute. This will energize and open the water valve

and remove most of the water from the water valve and the water valve’s outlet water line to the reservoir.

4. Switch the rocker switch to “OFF”. This will energize and open the drain valve to drain the reservoir and the

ice machine drain system.

5. Unplug the unit from the electrical outlet.

6. Remove the back panel from the rear of the unit.

7. Disconnect the water valve’s outlet water line to the reservoir and drain the remaining water left in the water

line trap area.

8. Reconnect the water valve outlet water line and tighten the compression nut to a watertight seal.

9. Reinstall the unit’s back panel.

10. Clean and dry the ice machine’s storage bin.

11. Prop the door open for air circulation to prevent mold and mildew.

12. Leave the water supply line disconnected or reconnect the supply line and leave it shut off. DO NOT turn the

water and allow water to enter back into the water valve.

SSTTEEPP 33::

Drain water from optional drain pump, if applicable.

1. Remove the drain pump from the ice machine. (Refer to drain pump installation instructions).

2. Drain the water in the drain pump’s reservoir by running the pump upside down and allowing water to drain

through the pump’s inlet and vent tube fittings.

3. After all water is drained, reinstall the drain pump. Make certain all tubing is installed and all hose clamps are

tight. (Refer to drain pump installation instructions).

SStteepp 44::

Restart the ice machine when ready for use.

1. With the rocker switch in the “OFF” position, plug the unit into an electrical outlet.

2. Reconnect or turn on the water supply line.

3. Reconnect drain tubing if removed.

4. Turn the rocker switch to the “ON” position.

5. Check the water inlet, drain lines, and fittings for any water leaks.

6. Check drain pump, (if applicable), operation by pouring approximately 2 quarts (1.9 L) of water into the ice

storage bin. The drain pump should activate and discharge water. (Refer to drain pump installation

instructions). Check for water leaks at all hose connections.

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE CORRECTION

Water keeps backing up Drain pump tubing kinked or

Check inlet, discharge, and vent line tubing for

into ice bin (drain pump). restricted any kinks or restrictions and repair as needed.

Inlet screen to the drain pump is Clean the inlet screen to the drain pump.

restricted.

Drain pump and/or the ice machine Check and level the drain pump and the

are not level. ice machine if necessary.

The drain pump cycles on Vent line to the drain pump is Check the vent line for any restrictions or kinks

and off erratically. restricted or kinked. and repair as needed.

Discharge line is restricted or kinked. Check the discharge line and connection to the desired

drain for any restrictions or kinks and repair as needed.

The drain pump is not level. The drain pump must be level. Check for level on the

top of the drain pump case and adjust the tubing or use

shims to level.

DDoo nnoott uussee aannyy ttyyppee ooff aannttii--ffrreeeezzee oorr ootthheerr ssoolluuttiioonnss aass aa

ssuubbssttiittuuttiioonn ffoorr pprrooppeerrllyy ddrraaiinniinngg tthhee iic

cee mmaacchhiinnee..

WARNING

Page 16

16

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE CORRECTION

Unit does not operate. The unit is unplugged Plug in the unit.

Breaker is tripped or fuse is blown. Reset breaker or replace fuse. Check to make

sure there is not a short in the electrical circuit.

Ice machine selector switch is in the Set the rocker switch on the grill of the

“OFF” position. machine to the “ON” position.

Unit operates but does not The unit has just been started and Ice produced when the unit is initially

produce any ice. it has been less than 6 hours. started will melt off in the bin. This is normal

operation. Check the unit in 24 hours for ice

accumulation in the bin.

Typical ice production cycle can

Check the unit in 24 hours for ice

take up to 1.5 hours. accumulation in the bin.

The selector switch is in the “OFF” Set the rocker switch on the grill of the

or “CLEAN” position. ice machine to the “ON” position.

No water in the reservoir.

Make sure that the reservoir drain plug is installed.

Check the water line to the unit to make sure it is

on and that there are no restrictions or kinks in the

line. Check all filters to make sure they are not

restricted or plugged.

Distributor tube is restricted. See “Cleaning the Ice Machine System” section for

cleaning the unit for proper operation.

Build-up of deposits on evaporator See “Cleaning the Ice Machine

plate. System” section for cleaning the unit for proper

operation.

Condenser fan air flow is restricted Make certain the grill in the front of the unit is free

and open for proper air circulation. Check and

clean the condenser coil by removing the grill in the

front of the unit. Clean the condenser with a

vacuum and brush attachment.

Room and/or water temperature

Move the unit to an area where

is too warm.

ambient temperature is below 90

o

F. The unit should

not be placed next to a heat source such as an

oven. Check for cold water connection.

Leaking drain valve See “Cleaning the Ice Machine System” section for

cleaning the unit. This will also dissolve and flush

out foreign material in the drain valve.

Inadequate drain system Restriction in drain lines will cause ice in the bin to

melt. If using a gravity drain, make certain there are

no kinks or restrictions in the drain lines. If using a

drain pump, check the inlet screen, discharge line,

and vent line for any build-up or restrictions.

Grid cutter is unplugged Plug in the grid cutter so that ice slabs can be cut

into cubes.

Ice is not clear Low water in level in reservoir. Make sure that the reservoir drain plug is installed

properly. Check the water line to the unit to make

sure there are no restrictions or kinks in the line.

Check all filters to make sure they are not restricted

or plugged.

Softened water supply Make certain that water line is not connected to the

water softener.

Room temperature it too cold. Move to an area where room temperature is above

55oF.

Page 17

17

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE CORRECTION

Ice cubes are too small Low ice consumption Ice is slowly melting in the ice bin and will

(less than 1/2” thick)

affect the size of the ice cube. This is normal

operation. When the ice bin needs to be

replenished, cubes will return to regular size.

Not enough water in reservoir.

Make sure that the reservoir drain plug is installed

properly. Check the water line to the unit to make

sure there are no restrictions or kinks in the line.

Check all filters to make sure they are not restricted

or plugged.

Distributor tube is restricted.

See “Cleaning the Ice Machine System” section for

cleaning the unit for proper operation.

Build-up of deposits on evaporator See “Cleaning the Ice Machine System”

plate. section for cleaning the unit for proper operation.

Leaking drain valve See “Cleaning the Ice Machine System” section for

cleaning the unit. Cleaning the unit will also

dissolve and flush out foreign material in the drain

valve.

Inadequate drain system. Restriction in drain lines will cause ice in the bin to

melt to a thinner cube. If using a gravity drain,

make certain there are no kinks or restrictions in the

drain lines. If using a drain pump, check the inlet

screen, discharge line, and vent line for any build-up

or restrictions

.

Room temperature is too warm.

Move to an area where temperature is below 90

o

F.

Ice cubes are too big Ice slab not releasing.

See “Cleaning the Ice Machine System”

(greater than 3/4” thick)

section for cleaning the unit for proper operation.

Condenser fan air flow is restricted.

Make certain the grill in the front of the unit is free

and open for proper air circulation. Check and

clean the condenser coil by removing the grill in the

front of the unit. Clean the condenser with a

vacuum and brush attachment.

Room temperature is too warm. Move to area where temperature is below 90

o

F.

Hollow ice slab Distributor tube is restricted.

See “Cleaning the Ice Machine System” section for

cleaning the unit for proper operation.

Build-up of deposits on evaporator See “Cleaning the Ice Machine System”

plate. section for cleaning the unit for proper operation

and cube size.

Low water level in reservoir. Make sure that the reservoir drain plug is installed

properly. Check the water line to the unit to make

sure there are no restrictions or kinks in the line.

Check all filters to make sure they are not restricted

or plugged.

Unit continues to run Ice bin is not full. The unit will automatically shut down when

and produce ice. ice reaches the sensing tube.

Ice bin is full. The unit will automatically shut down when ice

reaches the sensing tube and has completed the

harvest of the ice slab.

Room temperature is too warm. Move to an area where room temperature is below

90oF.

Ice machine is not level. Use a level to check the unit from side to side and

front to rear.

Ice cubes are sticking Ice consumption is low. Use the ice in the bin frequently. Ice will stick

together. together if left in insulated bin over long periods of

time.

Room temperature is too warm Move the unit to an area where temperature is

below 90

o

F.

Page 18

18

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE CORRECTION

Low ice production. Unit Low water level in reservoir.

Make sure that the reservoir drain plug is

is running, has run over a 48

installed properly. Check the water line to

hour period, and there is

the unit to make sure there are no restrictions

little ice in bin. or kinks in the line. Check all filters to make sure

they are not restricted or plugged.

Distributor tube is restricted.

See “Cleaning the Ice Machine System” section for

cleaning the unit for proper operation.

Build-up of deposits on evaporator See “Cleaning the Ice Machine System”

plate. section for cleaning the unit for proper operation.

Inadequate drain system.

Restriction in drain lines will cause ice in the bin to

melt to a thinner cube. If using a gravity drain,

make certain there are no kinks or restrictions in the

drain lines. If using a drain pump, check the inlet

screen, discharge line, and vent line for any build-up

or restrictions.

Condenser fan air flow is restricted Make certain the grill in the front of the unit is free

and open for proper air circulation. Check and

clean the condenser coil by removing the grill in the

front of the unit. Clean the condenser with a

vacuum and brush attachment.

Grid cutter is not cutting The selector switch is not in the

Set the rocker switch on the grill of the ice

ice slab. “ON” position. machine to the “ON” position.

The grid cutter is not plugged into Remove the escutcheon panel and plug the

receptacle. grid cutter into the receptacle on the side of the

liner.

It has not had time to cut It can take up to 35 minutes to cut through a

through the slab. harvested ice slab. This is normal operation.

Ice level is too low. The ice machine is not level Use a level to check the unit from side to side and

front to rear.

Room temperature is too cold.

Move the unit to an area where temperature is

above 55oF.

The selector switch is not in the Set the rocker switch on the grill of the ice

“ON” position.

machine to the “ON” position.

Ice level is too high. The ice machine is not level

Use a level to check the unit from side to side and

front to rear.

Room temperature is too warm. Move the unit to an area where temperature is

below 90oF.

Ice deflector is not in place or Check to see that the ice deflector is in place

secured properly.

and secured below the grid cutter.

Bin level sensing tube needs

Adjust the bin level sensing tube by simply

adjusting.

pressing directly down on the tube 5 inches from

the front of the tube to get a desired bin level.

Water keeps backing up Inadequate drain system. Restriction or improperly installed drain lines

into ice bin (gravity drain). will cause water to back up into the ice bin. Make

certain there are no kinks or restrictions in the drain

lines. If necessary, consult a qualified plumber.

Foreign material in ice bin drain Foreign material is restricting or blocking the ice bin

drain located at the right rear corner of the ice bin.

The drain will need to be cleared

.

Page 19

19

Record the following information indicated below. You will need it if service is ever required. The serial number and

model number for your ice machine is located on the front of the unit at the base of the door frame.

Model Number Serial Number

Date of Purchase Date Installed

Dealer’s Name

Address

IIff sseerrvviiccee rreeqquuiirreess iinnssttaallllaattiioonn ooff ppaarrttss,, uussee oonnllyy aauutthhoorriizzeedd ppaarrttss ttoo eennssuurree pprrootteeccttiioonn uunnddeerr t

thhee wwaarrrraannttyy..

TThhiiss mmaannuuaall sshhoouulldd rreemmaaiinn wwiitthh tthhee iiccee mmaacchhiinnee ffoorr ffuuttuurree rreeffeerreennccee..

SERVICE INFORMATION

It is assumed that your ice machine has been properly installed in accordance with all specifications and local codes and

the appliance has been properly grounded. If your ice machine should fail to operate, review the troubleshooting chart

before calling for service.

If service is required:

1. Call your dealer or authorized service agency. The name of the authorized service agency can be obtained from the

dealer or distributor in your area.

2. Have the following information readily available:

•Model number

•Serial number

•Date of purchase

•Name of dealer from whom purchased

If you are unable to obtain the name of an authorized service agency, or if you continue to have service problems, contact

Viking Range Corporation at (888) 845-4641 or write to:

VVIIKKIINNGG RRAANNGGEE CCOORRPPOORRAATTIIOONN

PPRREEFFEERRRREEDD SSEERRVVIICCEE

111111 FFrroonntt SSttrreeeett

GGrreeeennwwoooodd,, MMiissssiissssiippppii 3388993300 UUSSA

A

FINAL PREPARATION

1. Some stainless steel parts may have a plastic protective wrap which must be peeled off. The interior of the ice machine

should be washed thoroughly with hot, soapy water, rinsed and wiped dry to remove film residue and any installation dust

or debris before being used. Solutions stronger than soap and water are rarely needed.

2. All stainless steel parts should be wiped with hot soapy water. If buildup occurs, do not use steel wool, abrasive cloths,

cleaners, or powders. If it is necessary to scrape stainless steel to remove encrusted materials, soak with hot, wet cloths to

loosen the material, then use a wood or nylon scraper. Do not use a metal knife, spatula, or any other metal tool to scrape

stainless steel; scratches are almost impossible to remove.

Page 20

UNDERCOUNTER/FREESTANDING ICE MACHINE WARRANTY

(Units certified for Indoor Use)

TTWWOO YYEEAARR FFUULLLL WWAARRRRAANNTTYY

Undercounter/freestanding ice machines and all of their components and accessories, except as detailed below*, are warranted to be free from defects in material or

workmanship under normal household use for a period of two (2) years from the date of original retail purchase. Viking Range Corporation, warrantor, agrees to repair

or replace, at its option, any part which fails or is found to be defective during the warranty period

*Painted and decorative items are warranted to be free from defective materials or workmanship for a period of ninety (90) days from the date of original retail

purchase. ANY DEFECTS MUST BE REPORTED TO THE SELLING DEALER WITHIN NINETY (90) DAYS FROM DATE OF ORIGINAL RETAIL PURCHASE.

SSIIXX YYEEAARR FFUULLLL WWAARRRRAANNTTYY

Any sealed refrigeration system component, as listed below, is warranted to be free from defective materials or workmanship in normal household use during the third

through the sixth year from the date of original retail purchase. Viking Range Corporation, warrantor, agrees to repair or replace, at its option, any part which fails or is

found to be defective during the warranty period.

SSeeaalleedd RReeffrriiggeerraattiioonn SSyysstteemm CCoommppoonneennttss::

Compressor, Evaporator, Condenser, Connecting Tubing, Dryer/Strainer

TTWWEELLVVEE YYEEAARR LLIIMMIITTEEDD WWAARRRRAANNTTYY

Any sealed refrigeration system component, as listed above, which fails due to defective materials or workmanship in normal household use during the seventh

through the twelfth year from the date of original retail purchase will be repaired or replaced, free of charge for the part itself, with the owner paying all other costs,

including labor.

NNIINNEETTYY ((9900)) DDAAYY RREESSIIDDEENNTTIIAALL PPLLUUSS WWAARRRRAANNTTYY

This warranty applies to applications where use of the product extends beyond normal residential use.

Examples are, but not limited to, bed and breakfasts, fire stations, private clubs, churches, etc. This warranty excludes all commercial locations such as

restaurants, food service locations and institutional food service locations.

This warranty extends to the original purchaser of the product warranted hereunder and to each transferee owner of the product during the term of the warranty.

This warranty shall apply to products purchased and located in the United States and Canada. Pr

oducts must be pur

chased in the country where service is requested.

Warranty labor shall be performed by an authorized Viking Range Corporation service agency or representative. Warranty shall not apply to damage resulting from

abuse, accident, natural disaster, loss of electrical power to the product for any reason, alteration, improper installation, improper operation or repair or service to the

product by anyone other than an authorized Viking Range Corporation service agency or representative. Warranty shall not apply to damage resulting from indoor

units being used in outdoor situations. This warranty does not apply to commer

cial usage. Warrantor is not responsible for consequential or incidental damage

whether arising out of breach of warranty, breach of contract, or otherwise. Some jurisdictions do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

Owner shall be responsible for proper installation, providing normal care and maintenance, providing proof of purchase upon request, and making the appliance

reasonably accessible for service. If the product or one of its component parts contains a defect or malfunction during the warranty period, after a reasonable number

of attempts by the warrantor to remedy the defects or malfunctions, the owner is entitled to either a refund or replacement of the product or its component part or

parts. Replacement of a component part includes its free installation. Warrantor’s liability on any claim of any kind, with respect to the goods or services covered

hereunder, shall in no case exceed the price of the goods or service or part there of which gives rise to the claim.

WWAARRRRAANNTTYY SSEERRVVIICCEE::

Under the terms of this warranty, service must be performed by a factory authorized Viking Range Corporation service agent or representative.

Service will be provided during normal business hours, and labor performed at overtime or premium rates shall not be covered by this warranty. To obtain warranty

service, contact the dealer from whom the product was purchased, an authorized Viking Range Corporation service agent, or Viking Range Corporation. Provide

model and serial number and date of original purchase. For the name of your nearest authorized Viking Range Corporation service agency, call the dealer from whom

the product was purchased or Viking Range Corporation.

IIMMPPOORRTTAANNTT::

Retain proof of original purchase to establish warranty period.

The r

eturn of the Owner Registration Card is not a condition of warranty coverage. You, however, should return the Owner Registration Card so that Viking Range

Corporation can contact you should any question of safety arise which could affect you.

Any implied warranties of merchantability and fitness applicable to the above described undercounter ice machine are limited in duration to the period of coverage of

the applicable express written limited warranties set forth above. Some jurisdictions do not allow limitations on how long an implied warranty lasts, so the above

limitation may not apply to you.

This warranty gives you specific rights, and you may also have other rights which may vary from jurisdiction to jurisdiction.

20

Page 21

UNDERCOUNTER/FREESTANDING ICE MACHINE WARRANTY

(Units certified for Outdoor Use)

OONNEE YYEEAARR FFUULLLL WWAARRRRAANNTTYY

Undercounter/freestanding ice machines and all of their components and accessories, except as detailed below*, are warranted to be free from defects in material or

workmanship under normal household use for a period of one (1) year from the date of original retail purchase. Viking Range Corporation, warrantor, agrees to repair or

replace, at its option, any part which fails or is found to be defective during the warranty period.

*Painted and decorative items are warranted to be free from defective materials or workmanship for a period of ninety (90) days from the date of original retail purchase.

ANY DEFECTS MUST BE REPORTED TO THE SELLING DEALER WITHIN NINETY (90) DAYS FROM DATE OF ORIGINAL RETAIL PURCHASE.

FFIIVVEE YYEEAARR LLIIMMIITTEEDD WWAARRRRAANNTTYY

Any sealed refrigeration system component, as listed below, is warranted to be free from defective materials or workmanship in normal household use during the second

through the fifth year from the date of original retail purchase. Viking Range Corporation, warrantor, agrees to repair or replace, at its option, any part which fails or is found

to be defective during the warranty period.

SSeeaalleedd RReeffrriiggeerraattiioonn SSyysstteemm CCoommppoonneennttss::

Compressor, Evaporator, Condenser, Connecting Tubing, Dryer/Strainer

It is recommended that in temperatures above 110

o

F (43.0oC) and below 45oF (7.2oC) the unit be shut off. The normal operating range for the unit is between 45oF (7.2oF)

and 110

o

F (43.0oC).

NNIINNEETTYY ((9900)) DDAAYY RREESSIIDDEENNTTIIAALL PPLLUUSS WWAARRRRAANNTTYY

This warranty applies to applications where use of the product extends beyond normal residential use.

Examples are, but not limited to, bed and breakfasts, fire stations, private clubs, churches, etc. This warranty excludes all commercial locations such as restaurants,

food service locations and institutional food service locations.

This warranty extends to the original purchaser of the product warranted hereunder and to each transferee owner of the product during the term of the warranty.

This warranty shall apply to products purchased and located in the United States and Canada. Pr

oducts must be purchased in the country where service is requested.

Warranty labor shall be performed by an authorized Viking Range Corporation service agency or representative. Warranty shall not apply to damage resulting from abuse,

accident, natural disaster, loss of electrical power to the product for any reason, alteration, improper installation, improper operation or repair or service to the product by

anyone other than an authorized Viking Range Corporation service agency or representative. Warranty shall not apply to damage resulting from indoor units being used in

outdoor situations. This warranty does not apply to commer

cial usage. Warrantor is not responsible for consequential or incidental damage whether arising out of breach

of warranty, breach of contract, or otherwise. Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

Owner shall be responsible for proper installation, providing normal care and maintenance, providing proof of purchase upon request, and making the appliance reasonably

accessible for service. If the product or one of its component parts contains a defect or malfunction during the warranty period, after a reasonable number of attempts by

the warrantor to remedy the defects or malfunctions, the owner is entitled to either a refund or replacement of the product or its component part or parts. Replacement of a

component part includes its free installation. Warrantor’s liability on any claim of any kind, with respect to the goods or services covered hereunder, shall in no case exceed

the price of the goods or service or part there of which gives rise to the claim.

WWAARRRRAANNTTYY SSEERRVVIICCEE::

Under the terms of this warranty, service must be performed by a factory authorized Viking Range Corporation service agent or representative.

Service will be provided during normal business hours, and labor performed at overtime or premium rates shall not be covered by this warranty. To obtain warranty service,

contact the dealer from whom the product was purchased, an authorized Viking Range Corporation service agent, or Viking Range Corporation. Provide model and serial

number and date of original purchase. For the name of your nearest authorized Viking Range Corporation service agency, call the dealer from whom the product was

purchased or Viking Range Corporation.

IIMMPPOORRTTAANNTT::

Retain proof of original purchase to establish warranty period.

The r

eturn of the Owner Registration Card is not a condition of warranty coverage. You, however, should return the Owner Registration Card so that Viking Range

Corporation can contact you should any question of safety arise which could affect you.

Any implied warranties of merchantability and fitness applicable to the above described undercounter/freestaning ice machine are limited in duration to the period of

coverage of the applicable express written limited warranties set forth above. Some jurisdictions do not allow limitations on how long an implied warranty lasts, so the above

limitation may not apply to you.

This warranty gives you specific rights, and you may also have other rights which may vary from jurisdiction to jurisdiction.

VIKING RANGE CORPORATION

111 Front Street • Greenwood, Mississippi USA • 38930 (662) 455-1200

www.vikingrange.com

Specifications subject to change without notice

F20327B (PS0806VR)

Loading...

Loading...