Page 1

Service Manual

ViewSonic VG920

Model No VS10790

19” Color TFT LCD Display

Manufacture Date: Dec-30-05

- 1 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 2

Copyright

Copyright

may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into

any language or manual or otherwise, without the prior written permission of ViewSonic

Corporation.

Disclaimer

ViewSonic makes no representation or warranties, either expressed or implied, with

respect to the contents hereof and specifically disclaims any warranty of merchantability of

fitness for any particular purpose. Further, ViewSonic reserves the right to revise this

publication and to make changes from time to time in the contents hereof without

obligation of ViewSonic to notify any person of such revision or changes.

Trademarks

Optiquest is a registered trademark of ViewSonic Corporation.

ViewSonic is a registered trademark of ViewSonic Corporation.

All other trademarks used within this document are the property of their respective owners.

© 2005 by ViewSonic Corporation. All rights reserved. No part of this publication

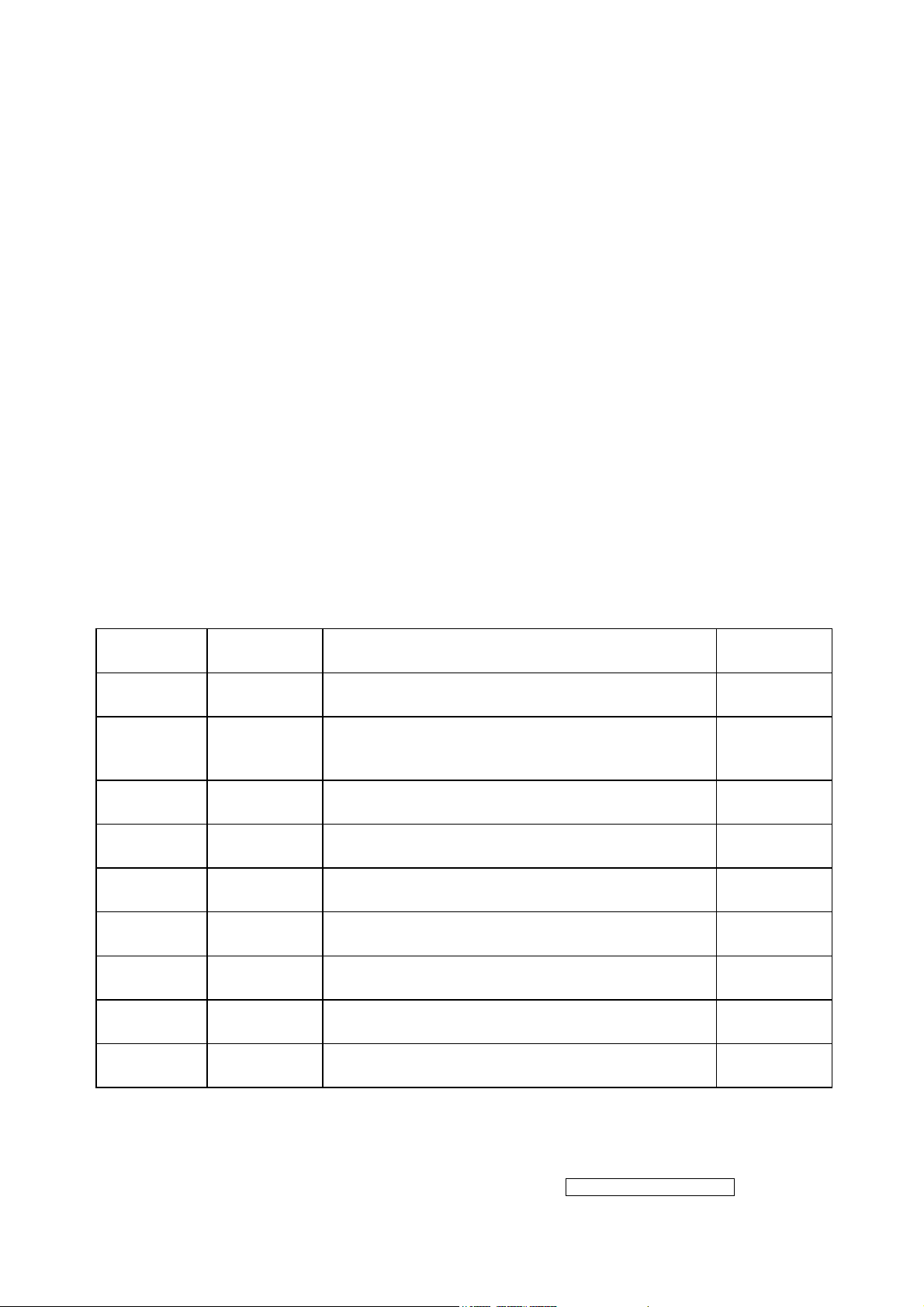

Revision History

Revision Date Description of changes Approval

A00 Aug-24-05 Initial Release YG.WANG

Update the Handing and Placing Methods

A01 Dec-30-05

and the Circuit Description and the

Adjustment Procedure

YG.WANG

- 2 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 3

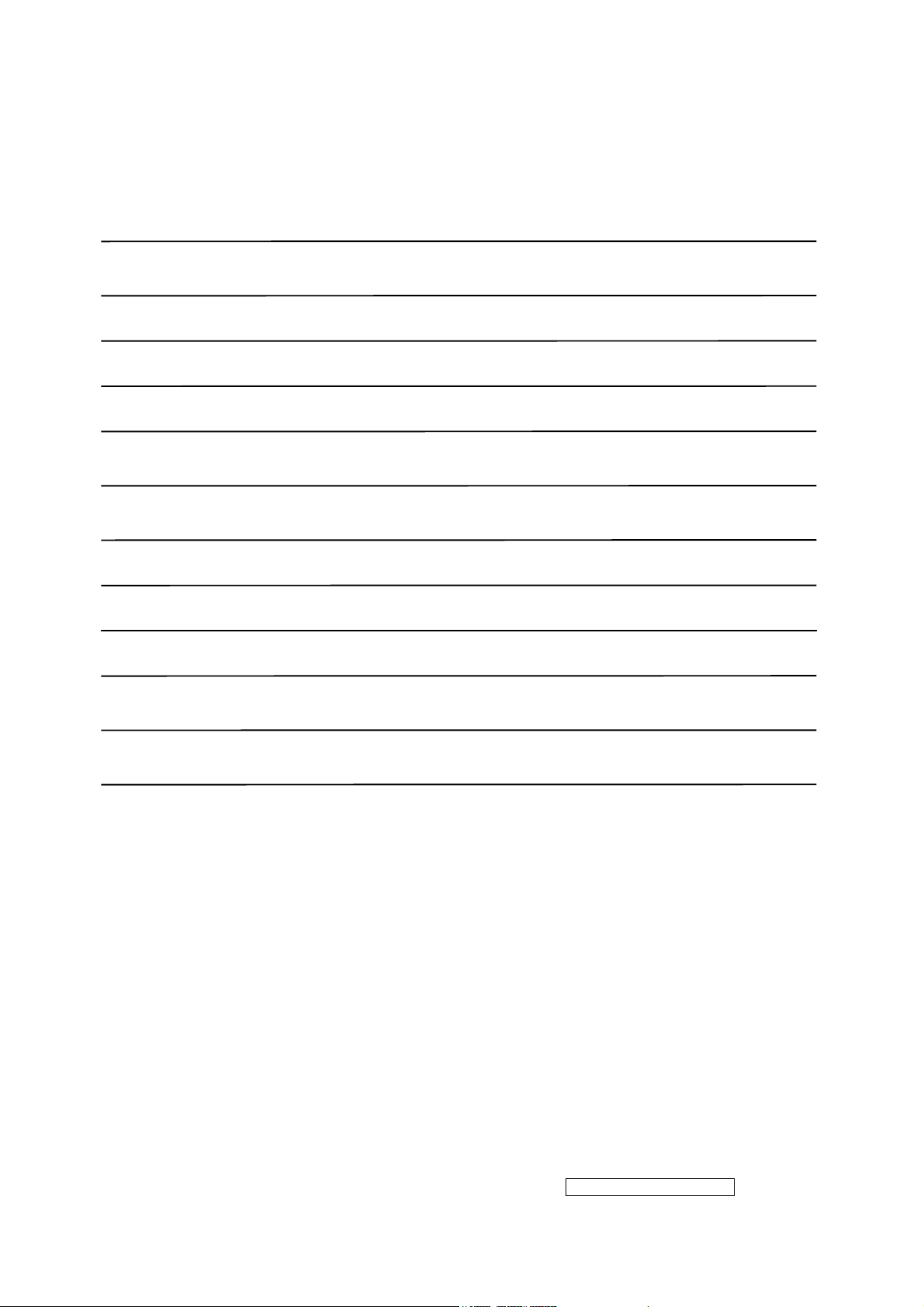

TABLE OF CONTENTS

1. Precautions And Safety Notices 4

2. Specification 7

3. Front Panel Control And Indicators 10

4. Circuit Description 16

5. Adjustment Procedure 23

6. Troubleshooting Flow Chart 43

7. Recommended Spare Parts List 44

8. Exploded Diagram And Spare Parts List 62

9. Disassemble Process 65

10. Block Diagram 72

11. Schematic Diagram 73

12. PCB Layout Diagram 80

- 3 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 4

1. Precautions And Safety Notices

1.1 SAFETY PRECAUTIONS

This monitor is manufactured and tested on a ground principle that a user’s safety comes

first. However, improper use or installation may cause damage to the monitor as well as

the user. Carefully go over the following WARNINGS before installing and keep this guide

handy.

WARNINGS

.This monitor should be operated only at the correct power sources indicated on the label

on the rear end of the monitor. If you’re unsure of the power supply in your residence,

consult you local dealer or power company.

.Use only the special power adapter that comes with this monitor for power input.

.Do not try to repair the monitor your self as it contains no user-serviceable parts. This

monitor should only be repaired by a qualified technician.

.Do not remove the monitor cabinet. There is high-voltage parts inside that may cause

electric shock to human bodies, even when the power cord is unplugged.

.Stop using the monitor if the cabinet is damaged. Have it checked by a service technician.

.Put your monitor only in a clean, dry environment. If it gets wet, unplug the power cable

immediately and consult your service technician.

.Always unplug the monitor before cleaning it .Clean the cabinet with a clean, dry cloth.

Apply non-ammonia based cleaner onto the cloth, not directly onto the glass screen.

.Keep the monitor away from magnetic objects, motors, TV sets, and transformer.

.Do not place heavy objects on the monitor or power cord.

1.2 PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety visual inspections

and the protection afforded by them cannot necessarily be obtained by using replacement

components rated for higher voltages, wattage, etc. Before replacing any of these

components read the parts list in this manual carefully. The use of substitute replacement

parts which do not have the same safety characteristics as specified in the parts list may

create shock, fire ,or other hazards.

1.3 SERVICE NOTES

1. When replacing parts or circuit boards, clamp the lead wires around terminals before

soldering.

2. When replacing a high wattage resistor(more than 1W of metal oxide film resistor) in

circuit board, keep the resistor about 5mm away from circuit board.

3. Keep wires away from high voltage, high temperature components and sharp edges.

4. Keep wires in their original position so as to reduce interference.

5. Usage of this product please refer to also user’s manual.

- 4 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 5

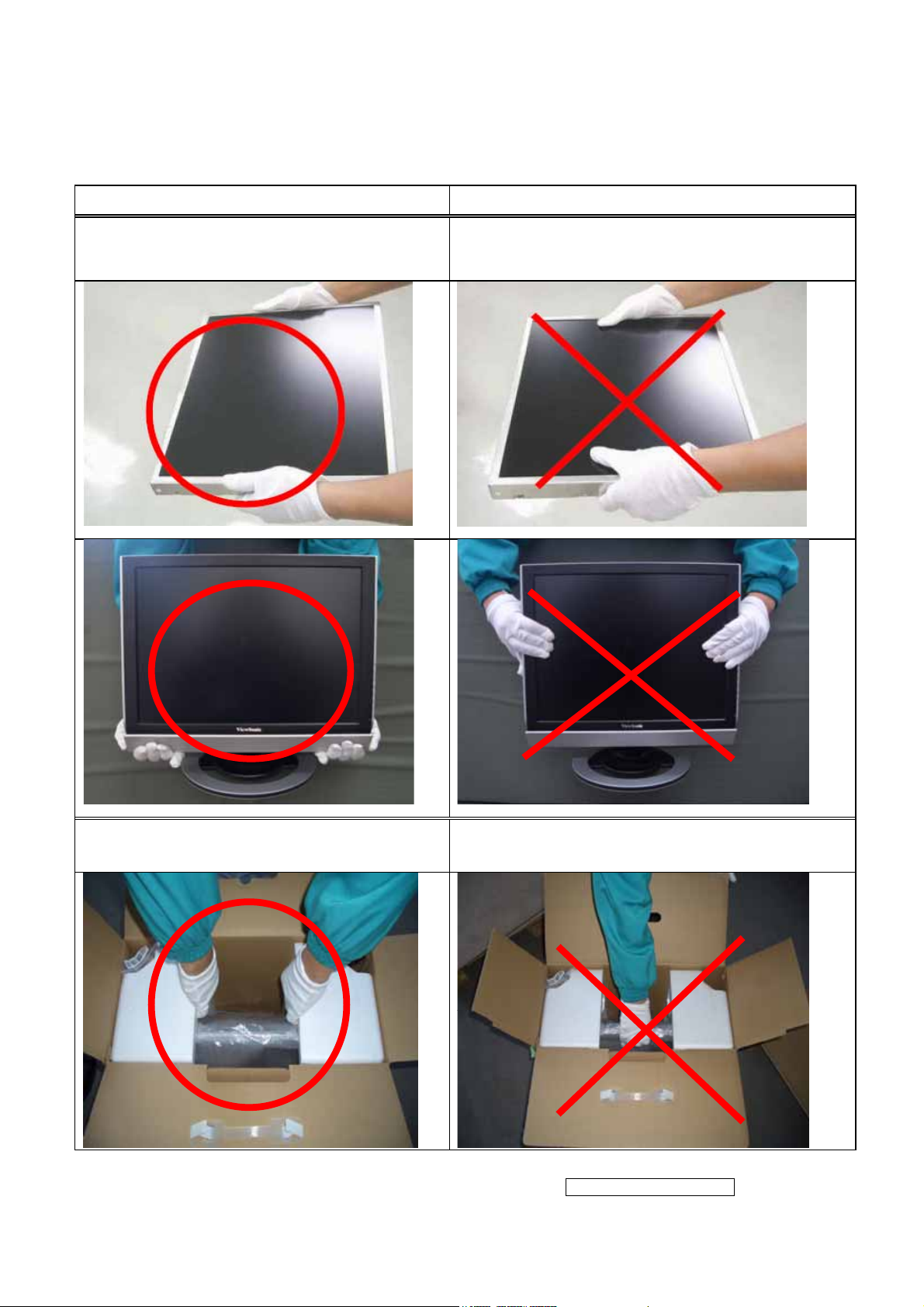

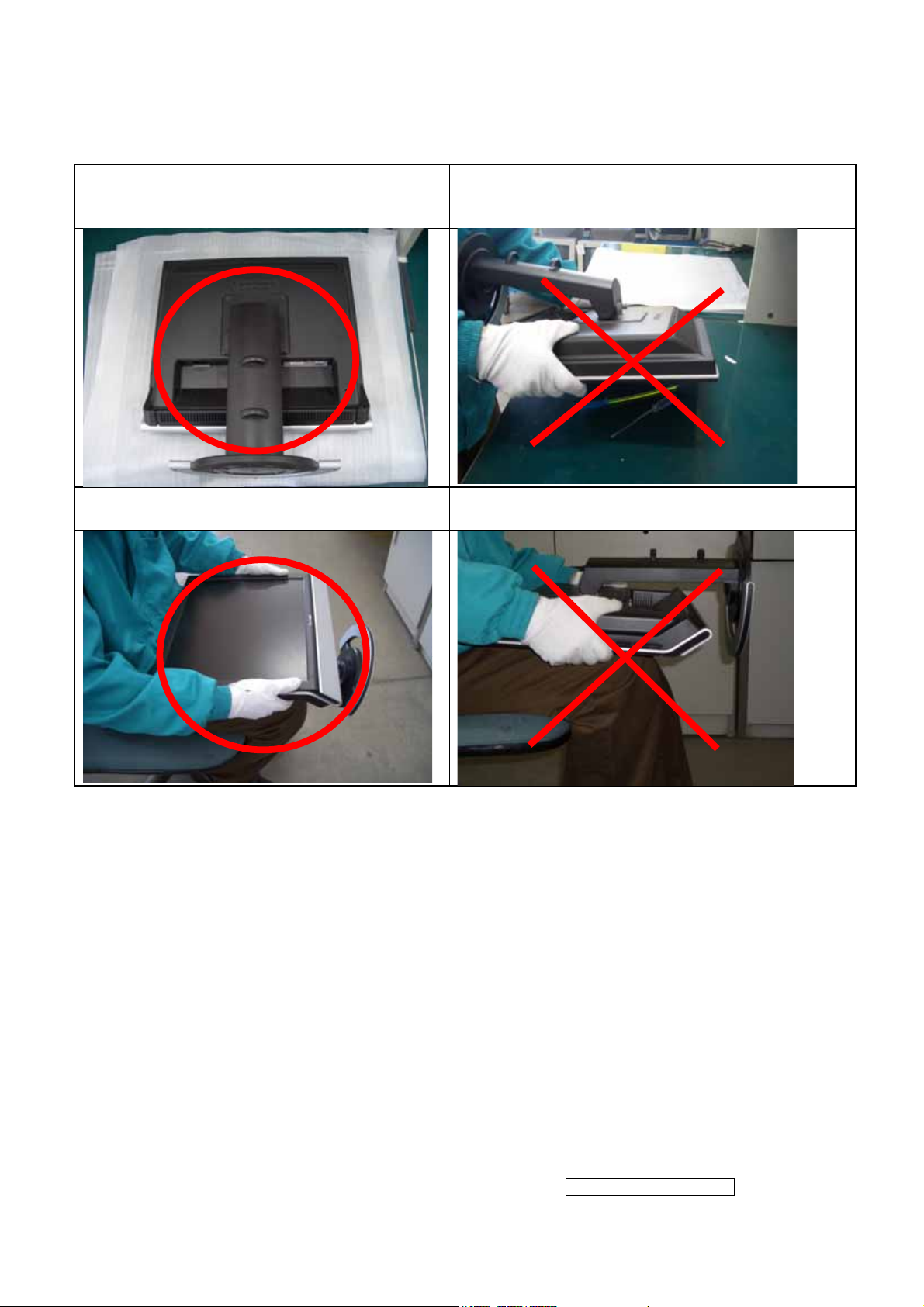

1.4 HANDING AND PLACING METHODS

Correct Methods: Incorrect Methods:

Only touch the metal frame of the LCD

panel or the front cover of the monitor. Do

not touch the surface of the polarizer.

Surface of the LCD panel is pressed by fingers

and that may cause “Mura.”

Take out the monitor with cushions

Taking out the monitor by grasping the LCD

panel. That may cause “Mura.”

- 5 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 6

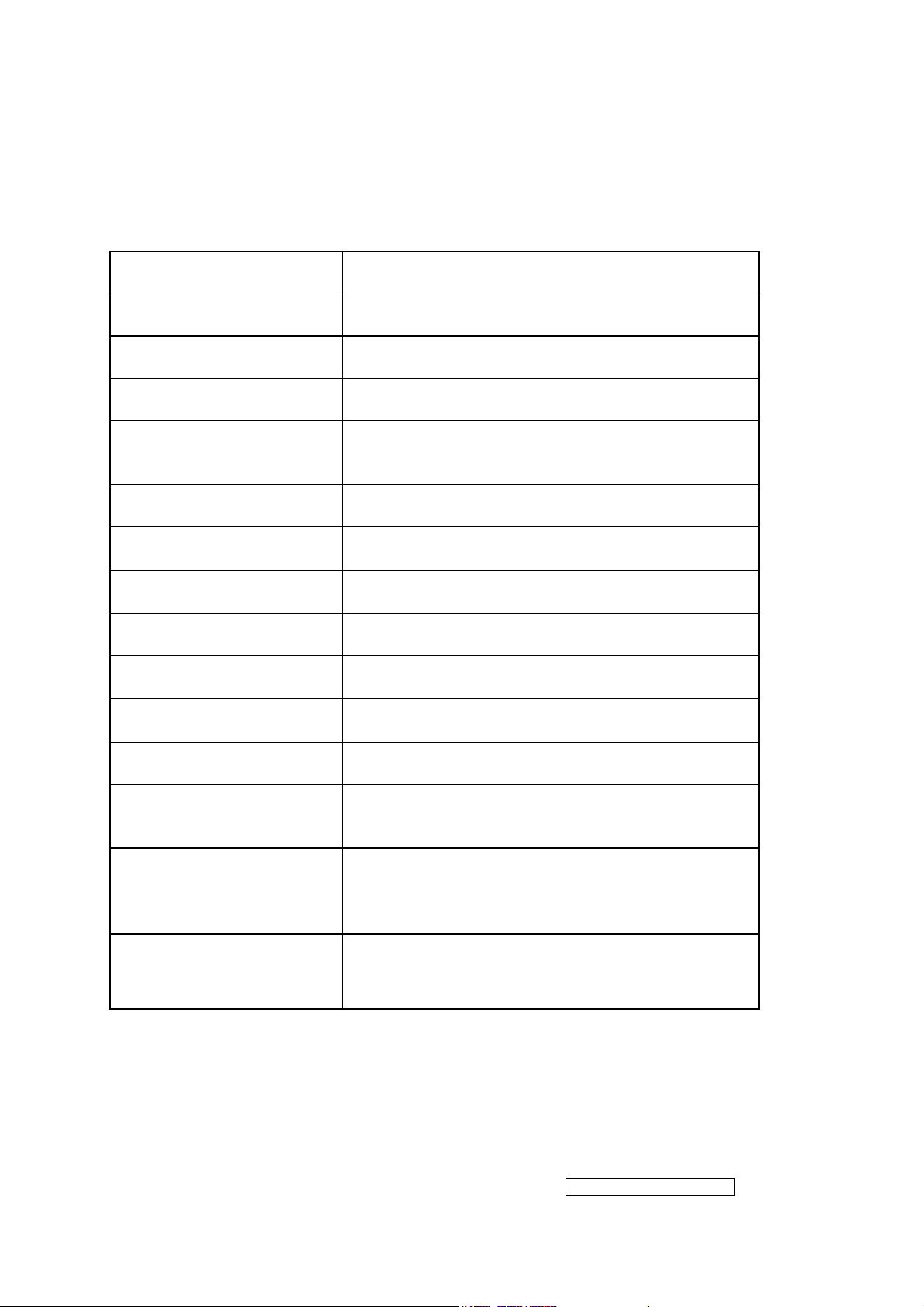

Place the monitor on a clean and soft foam

pad.

Placing the monitor on foreign objects. That

could scratch the surface of the panel or cause

“Mura.”

Place the monitor on the lap, the panel

surface must be upwards.

The panel is placed facedown on the lap. That

may cause “Mura.”

- 6 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 7

2. Specification

2.1 PRODUCT SPECIFICATIONS

LCD Panel 480mm (19” )TFT

Recommend Resolution 1280 x1024@60Hz

Pixel Dimension 0.294(H) x 0.294(V)mm

LCD Display Color 16.2M Colors (RGB 6-bit+FRC data)

Viewing Angle

Horizontal: 140

Vertical: 125 °

°

Contrast Ratio 550:1 (Typ.)

Brightness 270 cd/㎡(Typ.)

Response Time 8ms(Typ.)

Active Display Area 376.32(H) x 301.06(V)

Maximum Pixel Clock 135 MHz

Horizontal Frequency 30 – 82 kHz

Vertical Refresh Rate 50 – 75 Hz.

Temperature

Operating: 0°C to +40°C

Storage: -20°C to +60°C

Energy Star compliant VESA

Power Management

DPMS compatible

<1 W

Input Voltage : 90V~264V

Power

Input Frequency : 47.5Hz~63Hz

Consumption: 53 Watts(Max.) 50 Watts(Typ.)

- 7 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 8

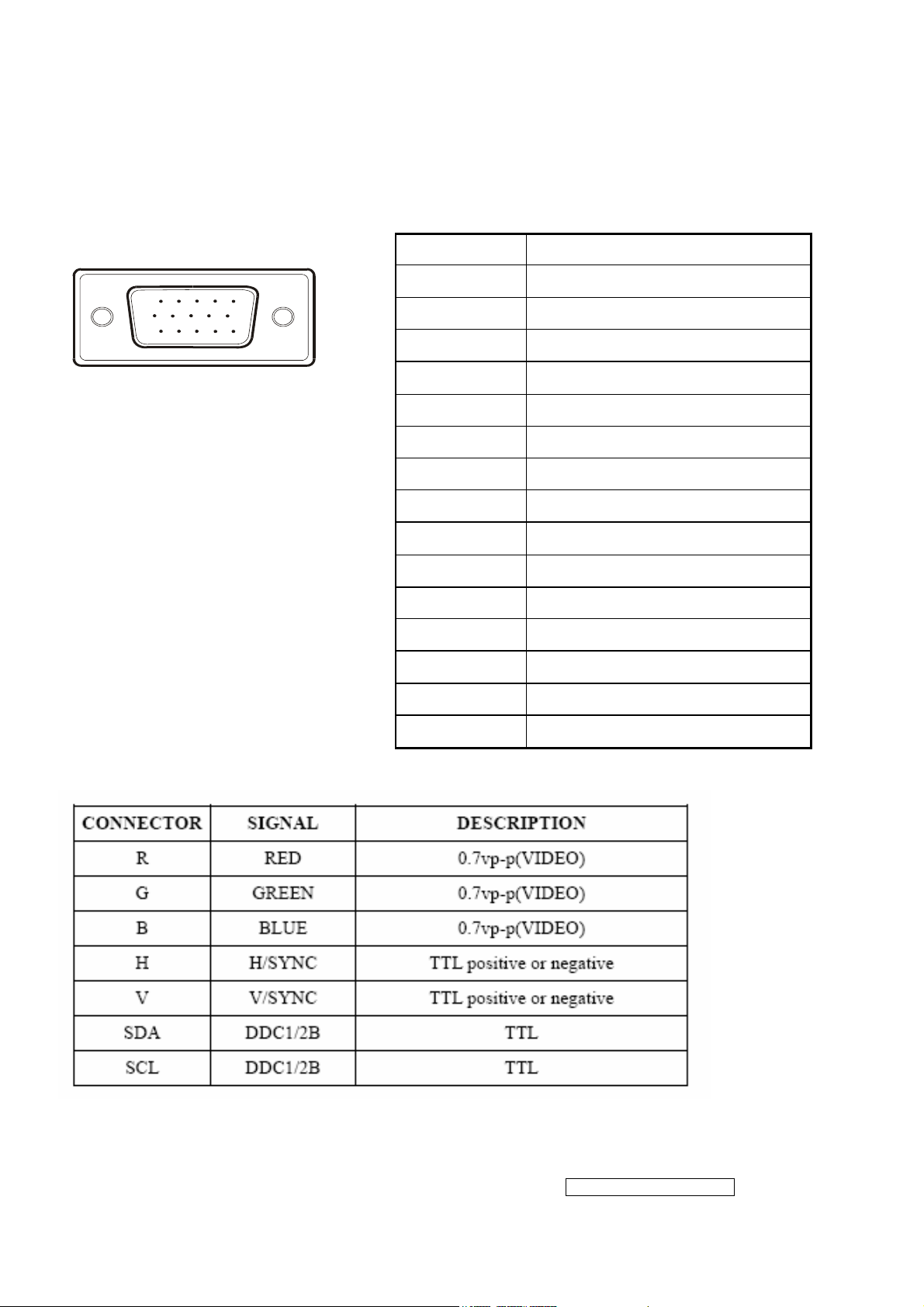

2.2 INTERFACE DESCRIPTION

D-SUB 15 PIN CONNECTOR

15

6

11 15

10

SIGNAL LEVEL

Pin Number Pin Function

1 Red video input

2 Green video input

3 Blue video input

4 No Connection

5 Ground

6 Red video ground

7 Green video ground

8 Blue video ground

9 +5V

10 H/V sync ground

11 No co n nection

12 (SDA)

13 Horizontal sync (Composite sync)

14 Vertical sync

15 (SCL)

- 8 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 9

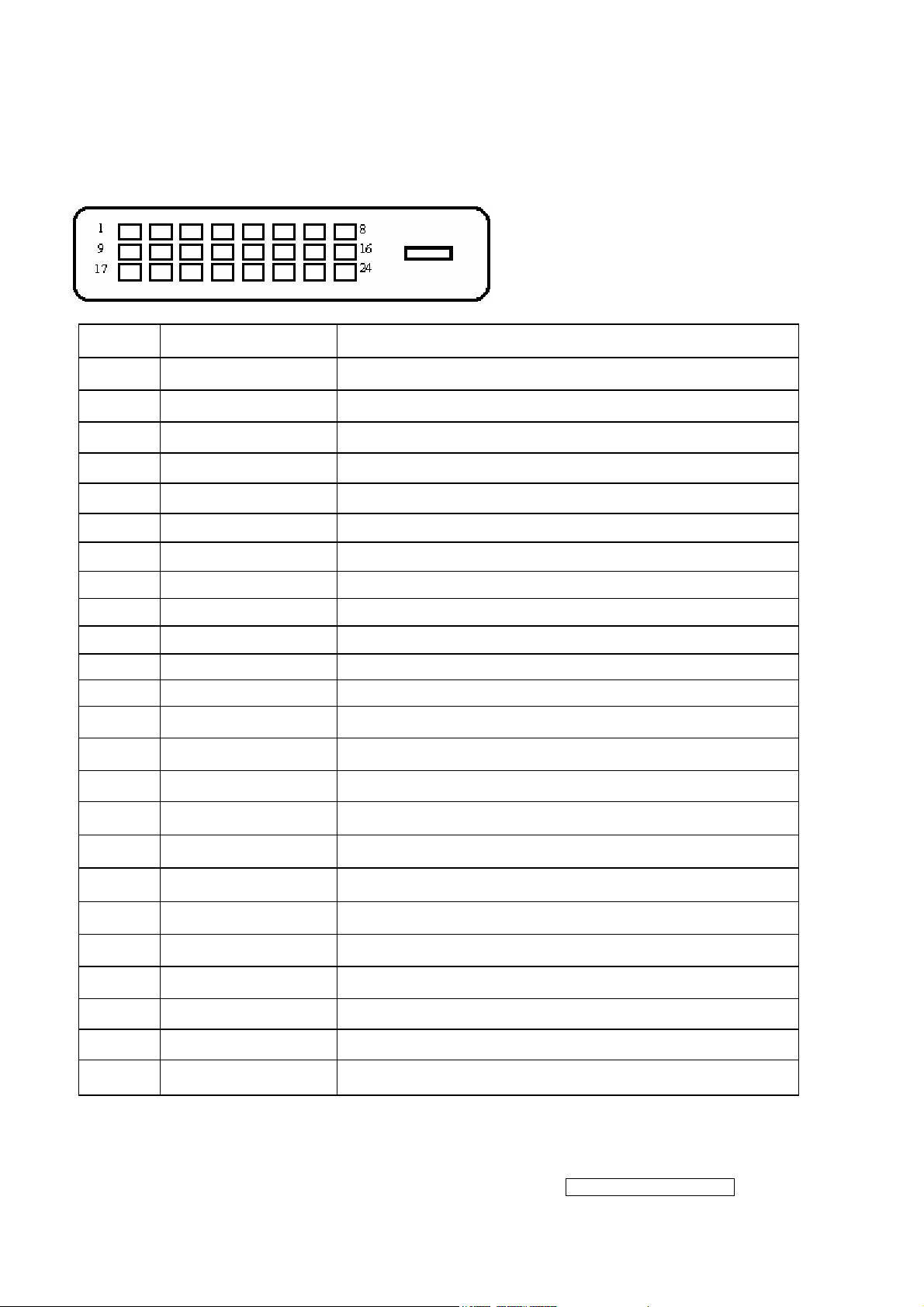

DVI-D 24 PIN CONNECTOR

Pin No. Signal Name Description

1 RX2- TMDS negative differential input, channel 2

2 RX2+ TMDS positive differential input, channel 2

3 GND Logic Ground

4 Reserved 4 Reserved. No connection

5 Reserved 5 Reserved. No connection

6 DDC-CLK DDC2B Clock

7 DDC-DAT DDC2B Data

8 Reserved 8 Reserved. No connection

9 RX1- TMDS negative differential input, channel 1

10 RX1+ TMDS positive differential input, channel 1

11 GND Logic Ground

12 Reserved 12 Reserved. No connection

13 Reserved 13 Reserved. No connection

14 VCCX Power

15 GND Logic Ground

16 SENS SENSE Pin, Pull High

17 RX0- TMDS negative differential input, channel 0

18 RX0+ TMDS positive differential input, channel 0

19 GND Logic Ground

20 Reserved 20 Reserved. No connection

21 Reserved 21 Reserved. No connection

22 GND Logic Ground

23 RXC+ TMDS positive differential input, reference clock

24 RXC- TMDS negative differential input, reference clock

- 9 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 10

3. Front Panel Function Controls And Indicators

Mute: Audio Mute button turns the sound off

Volume+/ Volume-:Decreases or increases volume

Button 1:Scrolls through menu options and adjusts the displayed

control. Also a shortcut to display the Contrast adjustment control

screen.

[▲]、[▼]:Displays the control screen for the highlighted control. Also

toggles between two controls on some screens. Also a shortcut to toggle

analog and digital connection.

Button 2:Displays the control screen for the highlighted control. Also toggles

between two controls on some screens. Also a shortcut to toggle analog and

digital connection.

Power:Standby Power On/Off

Green – ON

Power LED (Front Head)

ViewSonic Corporation

Orange – Active Off

Dark = Soft Power Switch OFF

- 10 –

Confidential - Do Not Copy VG920

Page 11

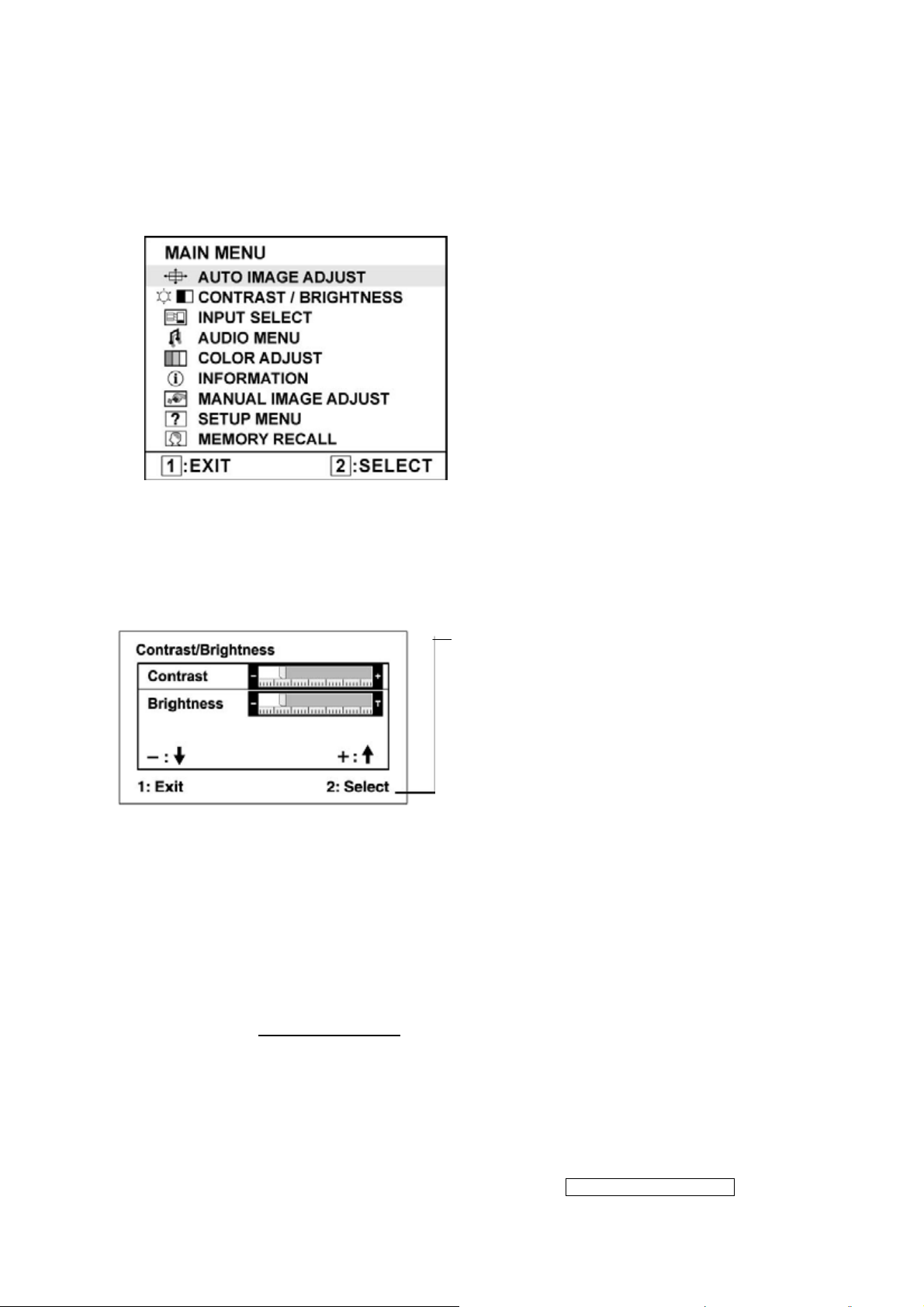

Do the following to adjust the display setting:

1. To display the Main Menu, press button [1].

NOTE: All OSD menus and adjustment screens disappear automatically after about 15

seconds. This is adjustable through the OSD timeout setting in the setup menu.

2. To select a control to adjust, press or ▼ to ▲ scroll up or down in the Main Menu.

3. After the desired control is selected, press button [2]. A control screen like the one

shown below appears.

The command line at the bottom of the control

screen tells what to do next from this screen.

You can toggle between control screens,

adjust the selected option, or exit the screen.

4. To adjust the setting, press the up ▼ or ▲ down T buttons.

5. To save the adjustments and exit the menu, press button [1] twice.

The following tips may help you optimize your display:

• Adjust the computer's graphics card so that it outputs a 1280 x 1024 @ 60Hz video

signal to the LCD display. (Look for instructions on “changing the refresh rate” in the

graphics card's user guide.)

• If necessary, make small adjustments using H. POSITION and V. POSITION until the

screen image is completely visible

. (The black border around the edge of the screen

should barely touch the illuminated “active area” of the LCD display.)

- 11 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 12

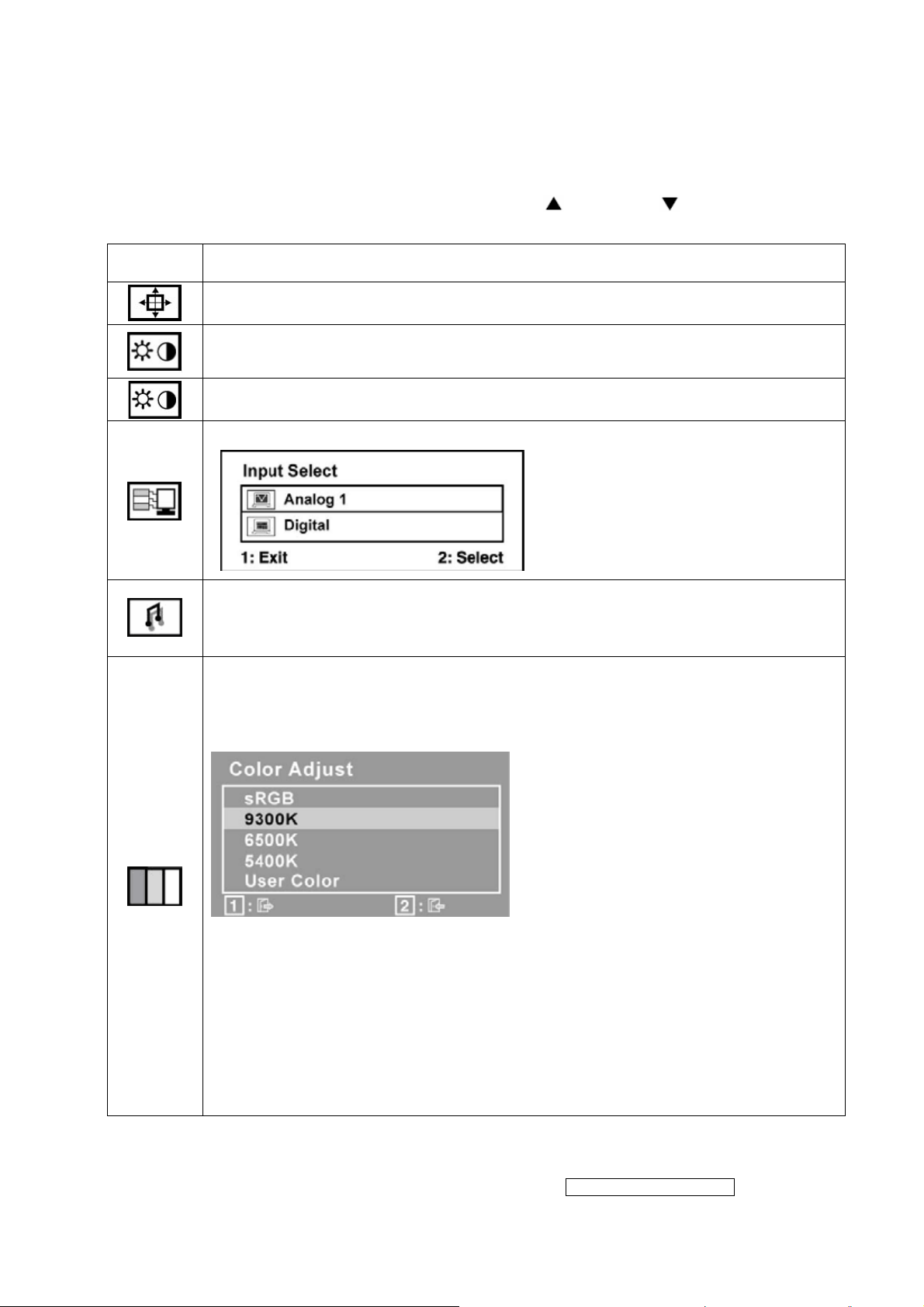

Main Menu Controls

Adjust the menu items shown below by using the up

Control

Explanation

Auto Image Adjust sizes and centers the screen image automatically.

Contrast adjusts the difference between the image background (black level)

and the foreground (white level).

Brightness adjusts background black level of the screen image.

Input Select allows the user to toggle between an analog and a digital signal.

Audio Adjust

Volume increases the volume, decreases the volume, and mutes the audio.

Mute temporarily silences audio output.

and down buttons.

Color Adjust provides several color adjustment modes, including preset color

temperatures and a User Color mode which allows independent adjustment of

red (R), green (G), and blue (B). The factory setting for this product is 6500K

(6500 Kelvin).

9300K-Adds blue to the screen image for cooler white (used in most office

settings with fluorescent lighting).

6500K-Adds red to the screen image for warmer white and richer red.

5400K-Adds green to the screen image for a darker color.

User Color Individual adjustments for red (R), green (G), and blue (B).

1. To select color (R, G or B) press button [2].

2. To adjust selected color, press

▼ and ▲.

Important: If you select RECALL from the Main Menu when the product is

set to a Preset Timing Mode, colors return to the 6500K factory preset.

- 12 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 13

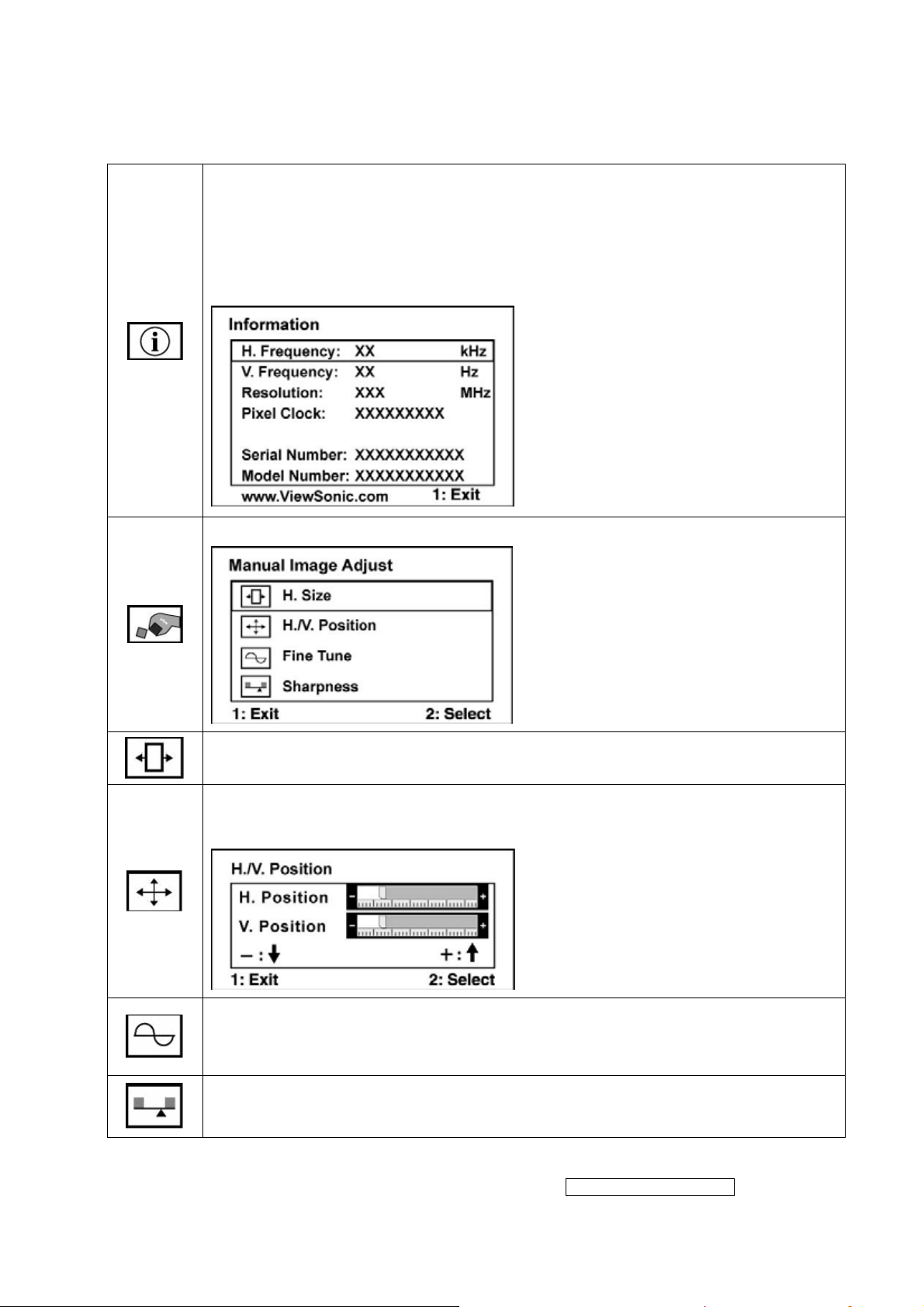

Information displays the timing mode (video signal input) coming from the

graphics card in the computer, the LCD model number, the serial number, and

the ViewSonic

®

website URL. See your graphics card’s user guide for

instructions on changing the resolution and refresh rate (vertical frequency).

NOTE: VESA 1280 x 1024 @ 60Hz (recommended) means that the resolution

is 1280 x 1024 and the refresh rate is 60 Hertz.

Manual Image Adjust Sub-menu

H. Size (Horizontal Size) adjusts the width of the screen image.

H./V. Position (Horizontal/Vertical Position) moves the screen image left or

right and up or down.

Fine Tune sharpens the focus by aligning text and/or graphics with pixel

boundaries.

NOTE: Try Auto Image Adjust first.

Sharpness adjusts the clarity and focus of the screen image.

- 13 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 14

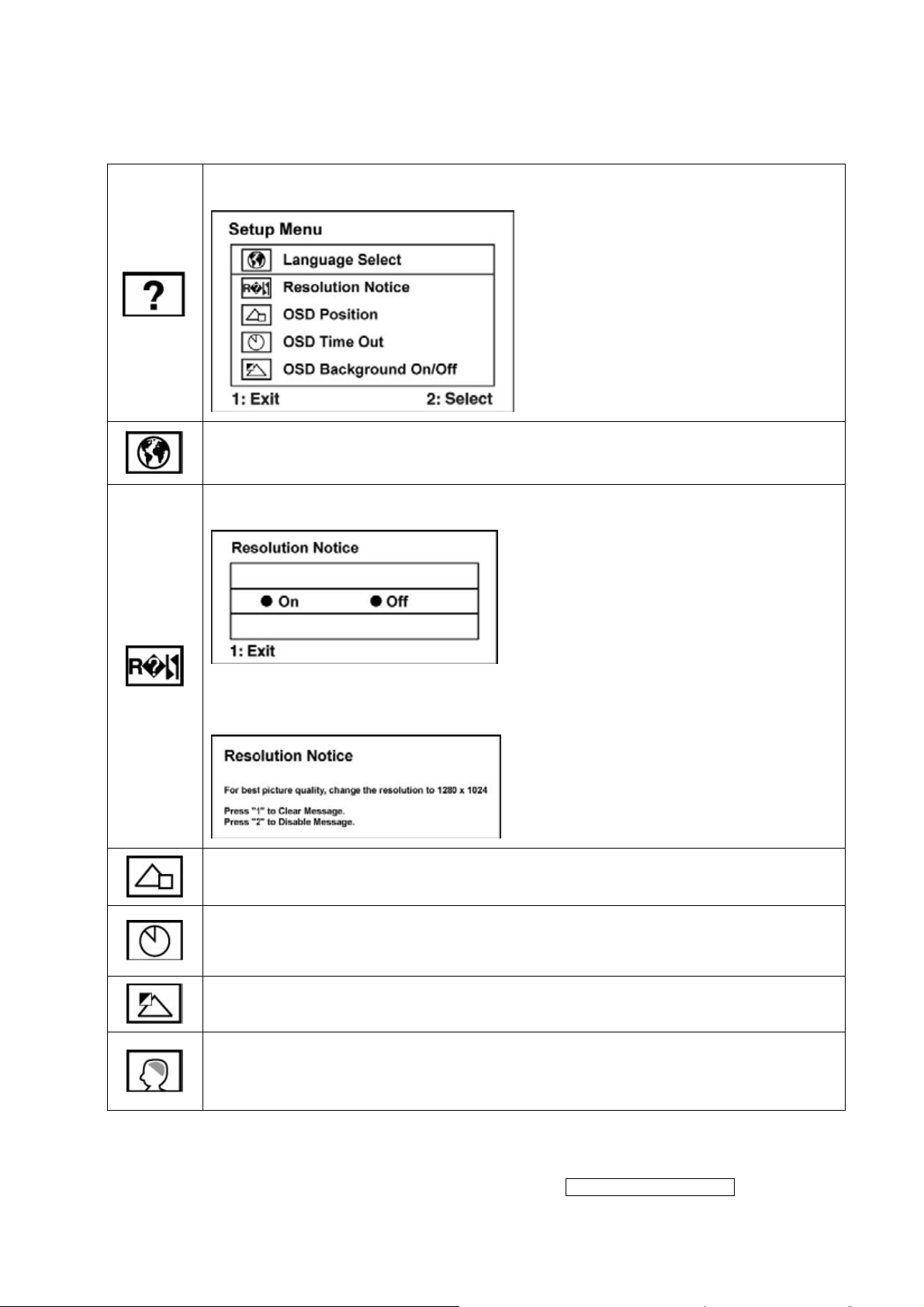

Setup Menu displays the menu shown below:

Language Select allows the user to choose the language used in the menus

and control screens.

Resolution Notice allows the user to enable or disable this notice.

If you enable the Resolution Notice shown above and your computer is set at

a resolution other than 1280 x 1024, the following screen appears.

OSD Position allows the user to move the OSD menus and control screens.

OSD Timeout sets the length of time the OSD screen is displayed. For

example, with a “30 second” setting, if a control is not pushed within 30

seconds, the display screen disappears.

OSD Background allows the user to turn the OSD background On or Off.

Memory Recall returns the adjustments back to factory settings if the display

is operating in a factory Preset Timing Mode listed in the Specifications of this

manual.

- 14 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 15

SHORT CUTS FUNCTION FROM THE BUTTONS

[1]

Main Menu

[2]

[▼] or [▲]

[▼] + [▲]

[;+] or [;-]

[;+] + [;X]

[1] + [2]

[1] + [;X]

[2] + [▼]

[1] + [▲]

Input toggle (Analog or Digital).

To immediately activate Contrast menu. It should be

change to Brightness OSD by push button [2]

recall both of Contrast and Brightness to default

To immediately activate Volume menu for audio volume.

Recall volume to default

toggle 720x400 and 640x400 mode when input 720x400

or 640x400 mode

White Balance. (Not shown on user’s guide)

• Power Button Lock: Press and hold “[2], & ▼” for 10

seconds. If the power button is pressed the message

Power Button Locked will display for 5 seconds. With or

without this setting, after a power failure, your LCD

display’s power will automatically turn ON when power is

restored.

• Power Button Unlock: Press and hold “[2], & ▼” again

for 10 seconds.

• OSD Lock: Press and hold "[1], & (▲)" for 10 seconds.

If any buttons are pressed the message OSD Locked will

display for 5 seconds.

• OSD Unlock: Press and hold “[1], & ▲” again for 10

seconds.

Remark : All the short cuts function are only available while OSD off

- 15 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 16

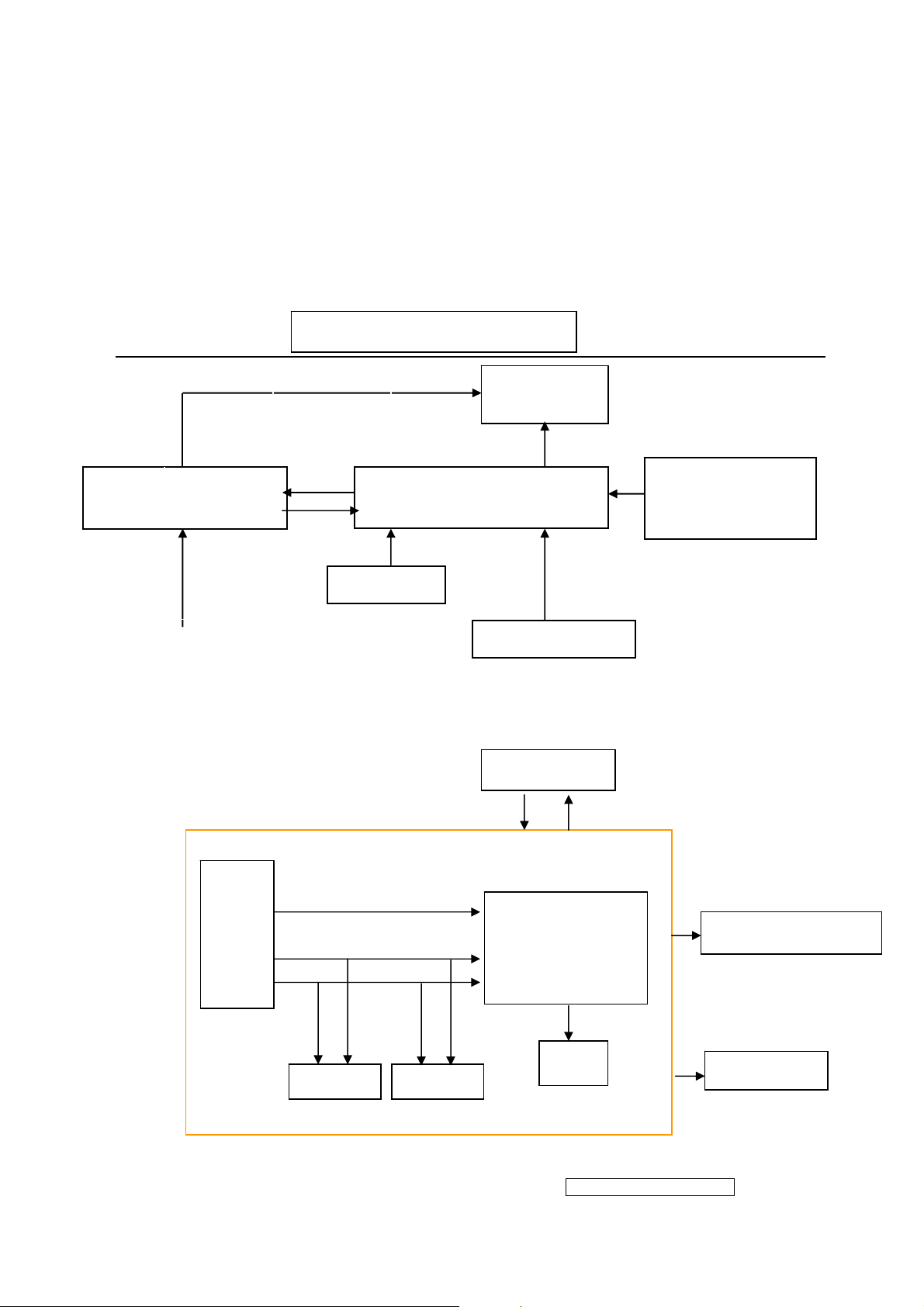

4. Circuit Description

4.1 LCD MONITOR DESCRIPTION

The LCD MONITOR will contain a Main Board, an Power Board, Key Board which

house the flat panel control logic, brightness control logic and DDC.

Monitor Block Diagram

CCFL Drive.

Power Board

(Include: adapter, inverter)

100V-240V

AC-IN

Key Board

4.2 MAIN BOARD BLOCK FUNCTION DESCRIPTION

The main board contains panel control logic, brightness control logic, DDC and DC

convert DC circuit and so on.

R

G

B

H

V

SDA

SCL

EPROM EPROM

Flat Panel and

CCFL backlight

Main Board

HOST Computer

PWPC board

TSUM56AK

OSC

RS232 Connector

For white balance

adjustment in factory

mode

Video signal, DDC

Backlight and Panel

Keyboard

- 16 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 17

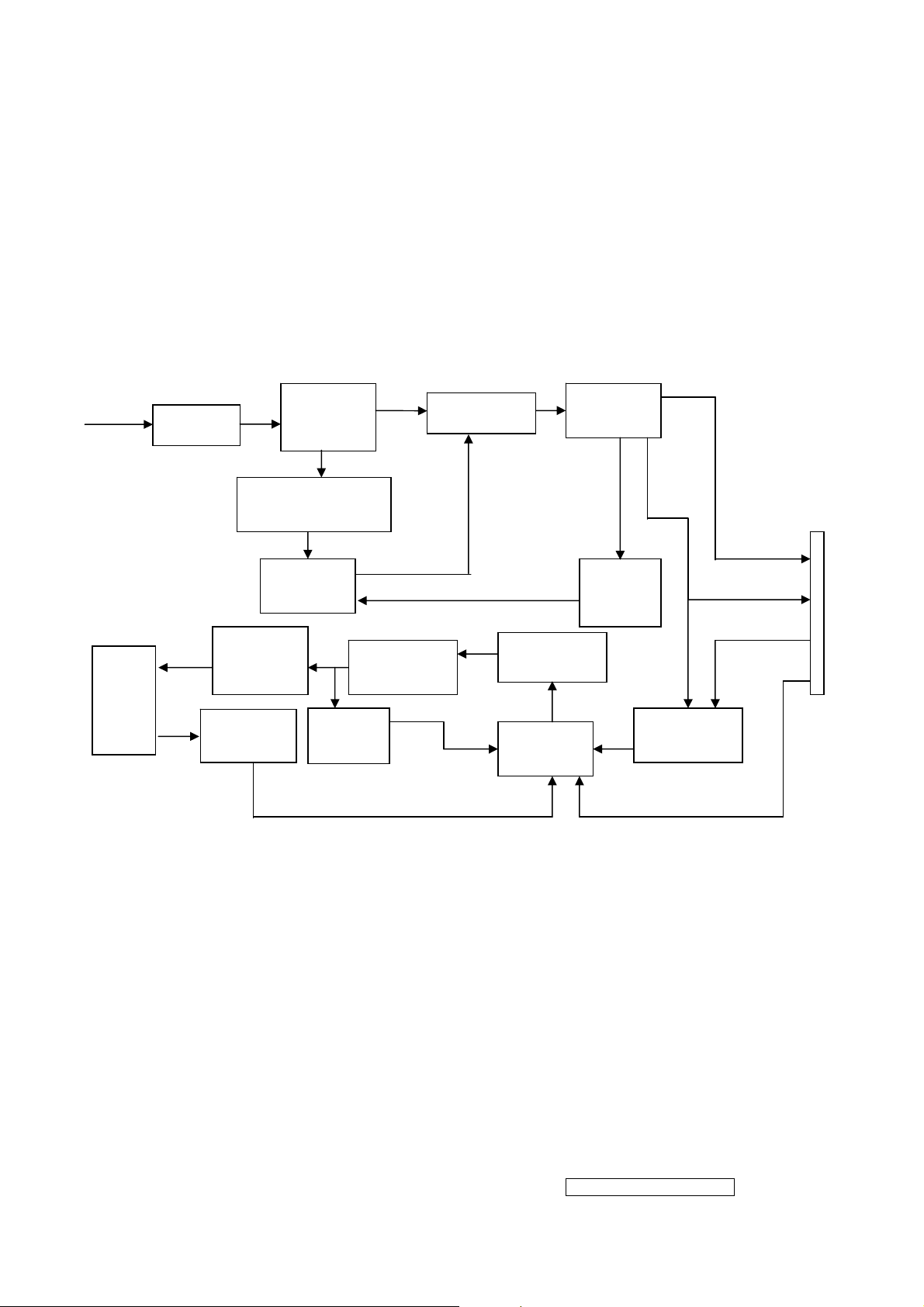

4.3 PWPC BOARD BLOCK FUNCTION DESCRIPTION

PWPC board combines to adapter and inverter, Adapter which commonly consists

of bridge rectifier and filter, start circuit, PWM control circuit, protection circuits and

convert to 12V, 5V DC voltage by input 90V-240V AC voltage that provide power supply

for each chips in the main board and inverter. Inverter is DC TO AC circuit. It changes

the 12v DC of power supply to about 600-800v AC that drives the backlight. It mostly

consists of starting circuit, PWM controller, DC changing circuit, LC surging circuit,

output circuit and protection circuit etc.

AC input

EMI filter

Bridge

Rectifier

and Filter

Transformer

Rectifier

CMOS

Start Circuit

R903, R904,R905

5V

Lamp

OSC and

Output

Circuit

Feedback

Circuit

PWM

Control IC

Over

Voltage

DC Convert

Circuit

MOSFET

Q203

PWM

Control IC

Over

Vol tage

Protect

12V

ON/OF

ON/OFF

Control

DIM

CN902

- 17 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 18

4.4 INTRODUCTION OF IC

STUM56AK(U401): integrate ADC, OSD, SCALER, MCU, LVDS, convert analog RGB

into digital and room and shrink scaling output to LCD panel.

PIN Function:

Pin Symbol Description

70 SDO SPI flash serial data output; Input w/5V-tolerant

71 CSZ SPI flash chip select; output

72 SCK SPI flash serial select; output

73 SDI SPI flash serial data input; output

65 DDCA_SDA/RS232_TX DDC data for analog interface; 4mA driving

strength/UART transmitter/GPIO; I/O w/5V-tolrant

66 DDCA_SDA/RS232_RX DDC data for analog interface/UART

transmitter/GPIO;Input w/5V-tolrant

36 DDCD_SDA DDC data for DVI interface; 4mA driving strength;

I/O w/5V-tolerant

37 DDCD_SCL DDC clock for DVI interface; Input w/5V-tolerant

19 RST Chip reset; High reset; Input w/5V-tolerant

22 RSTN Chip reset; Low reset; Input w/5W-toerant

11 VCTRL Regulator control; Output

63 HSYNCO Analog HSYNC input

64 VSYNCO Analog VSYNC input

62 REFP Internal ADC top de-coupling pin

61 REFM Internal ADC bottom de-coupling pin

51 REXT

External resistor 390 ohm to AVDD_DVI

21 PWM1 PWM1; 4mA driving strength; Output

29 PWM0 PWM0; 4mA driving strength; Output

4 BYPASS For External Bypass Capacitor

33 XIN Xin; Crystal Oscillator Input

34 XOUT Xout; Crystal Oscillator Output

44、50 AVDD_DVI

60

52

34

14、67、95、

103、115

13、38、41、

AVDD_ADC

AVDD_PLL

AVDD_MPLL

VDDP Digital Output Power 3.3V

VDDC Digital Core Power 1.8V

DVI Power 3.3V

ADC Power 3.3V

PLL Power 3.3V

MPLL Power 3.3V

47、96、116

AIC1084-33PM (U702): DC power convert, used to 5v convert 3.3v.

LT1117-18(U701): DC power convert, used to 5v convert 3.3v.

- 18 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 19

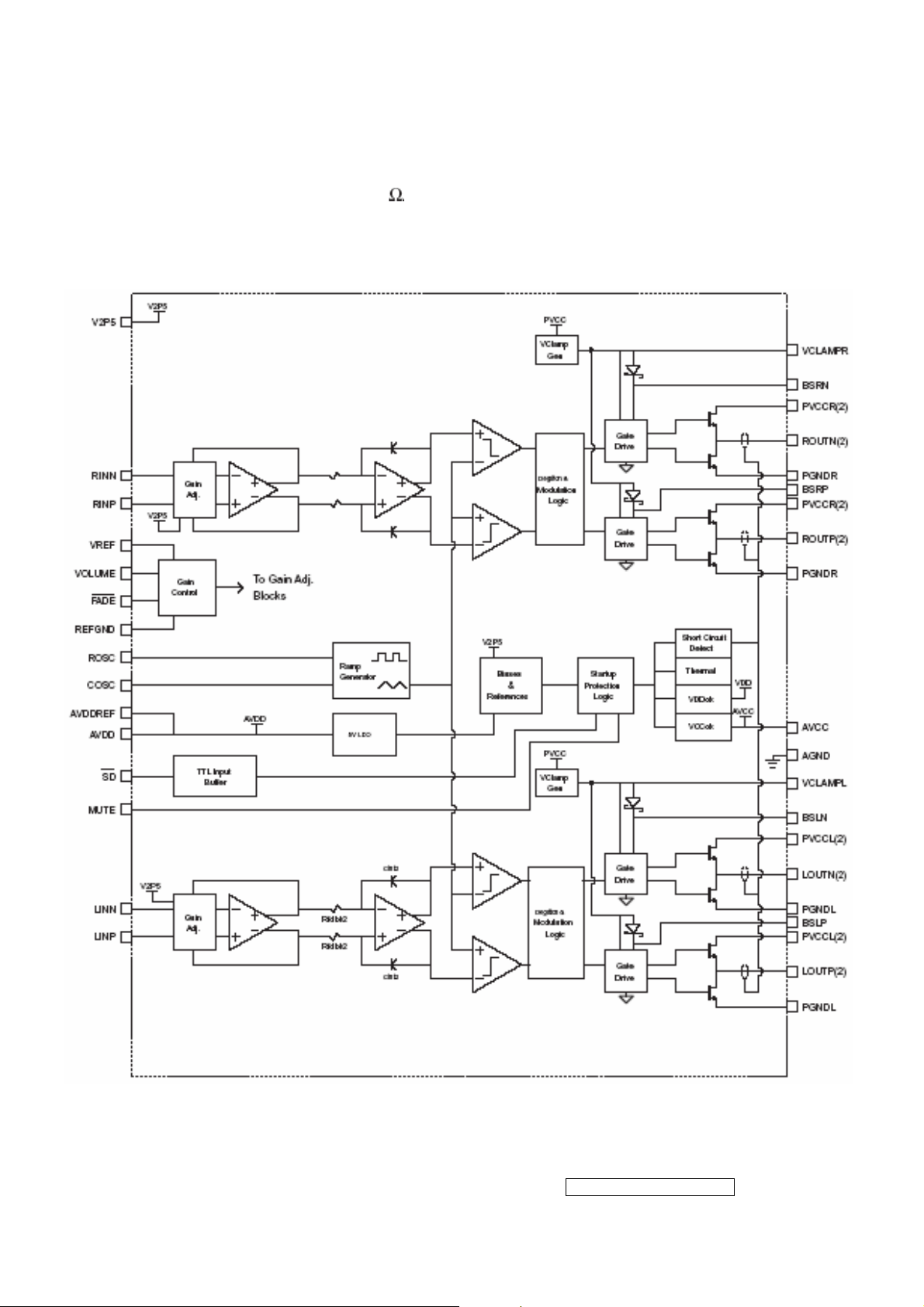

TPA3003D2 (U601): The TPA3003D2 is a audio amplifier IC,3-W efficient, driving

speakers as low as 8

, range of gain from -40dB to 36 dB. The function of

each pin and the inside circuit diagram are as follows:

Circuit Diagram

- 19 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 20

PIN Function

TERMINAL

NO. NAME

AGND 9,10,26 AVcc 33 AVDD 29 O

AVDDREF 7 O

BSLN 13 I/O

BSLP 24 I/O

BSRN 48 I/O

BSRP 37 I/O

COSC 28 I/O

FADE 30 I

LINN 6 I

LINP 5 I

LOUTN 16,17 O

LOUTP 20,21 O

MUTE 34 I

NC 31,32,35 PGNDL 18,19 PGNDR 42,43 -

PVVCCL 14,15 -

PVVCCL 22,23 -

PVCCR 38,39 -

PVCCR 46,47 -

REFGND 12 -

RINP 3 I

RINN 2 I

ROSC 27 I/O

ROUTN 44,45 O

ROUTP 40,41 O

SD 1 I

VCLAMPL 25 VCLAMPR 36 VOLUME 11 I

VREF 8 I

V2P5 4 O

I/O DESCRIPTION

Analog ground for digital/analog cells in core

High-voltage analog power supply (8.5V to 14V)

5-V Regulated output

5-V Reference output-provided for connection to adjacent VREF terminal.

Bootstrap I/O for left channel, negative high-side FET

Bootstrap I/O for left channel, positive high-side FET

Bootstrap I/O for right channel, negative high-side FET

Bootstrap I/O for right channel, positive high-side FET

I/O for charge/discharging currents onto capacitor for ramp generator triangle wave

biased at V2P5

Input for controlling volume ramp rate when cycling SD or during power-up. A logic

low on this pin places the amplifier in fade mode. A logic

high on this pin allows a quick transition to the desired volume setting.

Negative differential audio input for left channel

Positive differential audio input for left channel

Class-D 1/2-H-bridge negative output for left channel

Class-D 1/2-H-bridge positive output for left channel

A logic high on this pin disables the outputs. A low on this pin enables the outputs.

Not internally connected

Power ground for left channel H-bridge

Power ground for right channel H-bridge

Power supply for left channel H-bridge(tied to pins 22 and 23 internally), not

connected to PVCCR or AVcc

Power supply for left channel H-bridge(tied to pins 14 and 15 internally), not

connected to PVCCR or AVcc

Power supply for right channel H-bridge(tied to pins 46 and 47 internally), not

connected to PVCCL or AVcc

Power supply for right channel H-bridge(tied to pins 38 and 39 internally), not

connected to PVCCL or AVcc

Ground for gain control circuitry. Connect to AGND. If using a DAC to control the

volume, connect the DAC ground to this terminal.

Positive differential audio input for right channel

Negative differential audio input for right channel

Current setting resistor for ramp generator. Nominally equal to 1/8*Vcc

Class-D 1/2-H-bridge negative output for right channel

Class-D 1/2-H-bridge positive output for right channel

Shutdown signal for IC (low=shutdown, high=operational). TTL logic levels with

compliance to Vcc.

Internally generated voltage supply for left channel bootstrap capacitors.

Internally generated voltage supply for right channel bootstrap capacitors.

DC voltage that sets the gain of the amplifier.

Analog reference for gain control section.

2.5-V Reference for analog cells, as well as reference for unused audio input when

using single-ended inputs.

- 20 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 21

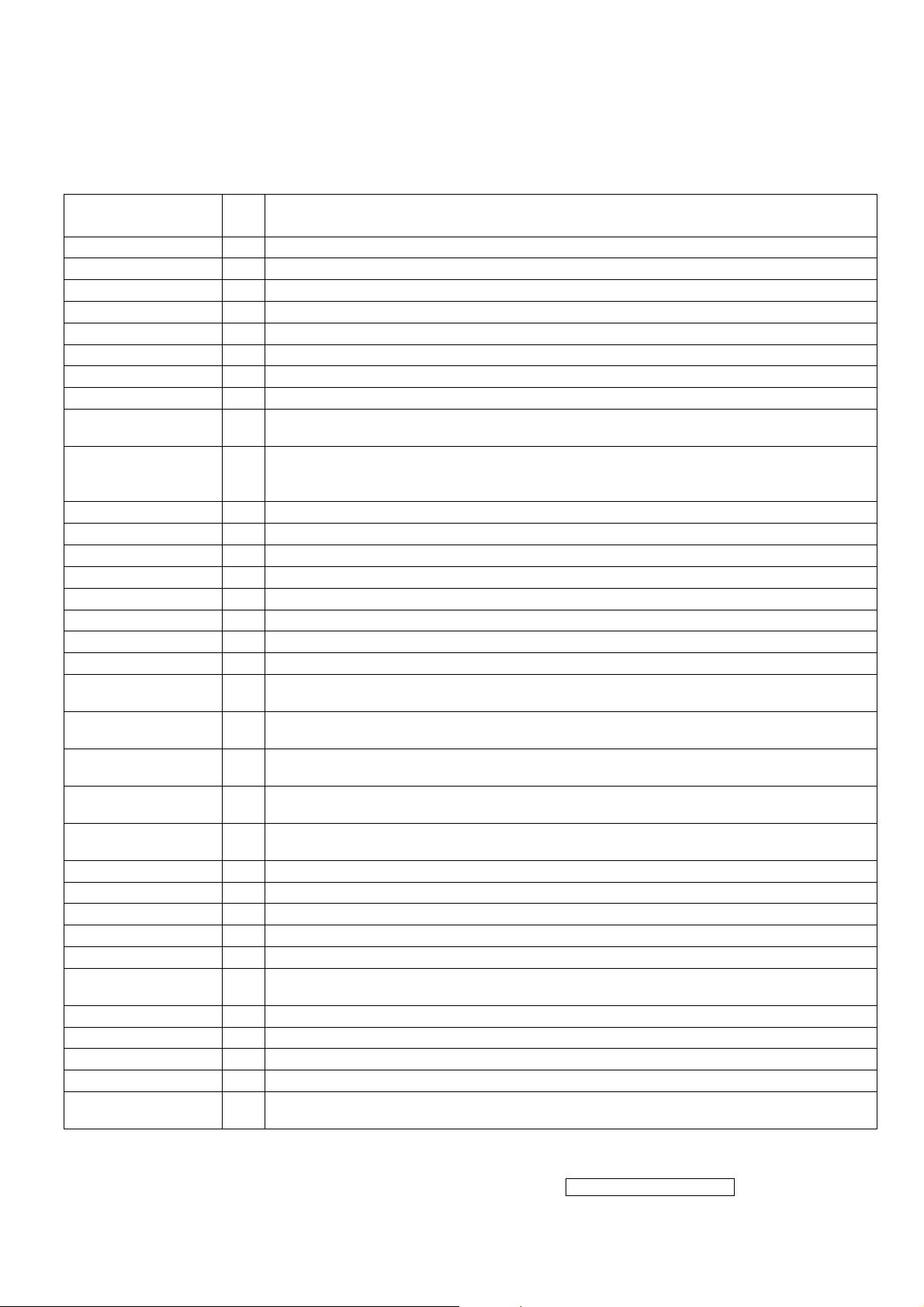

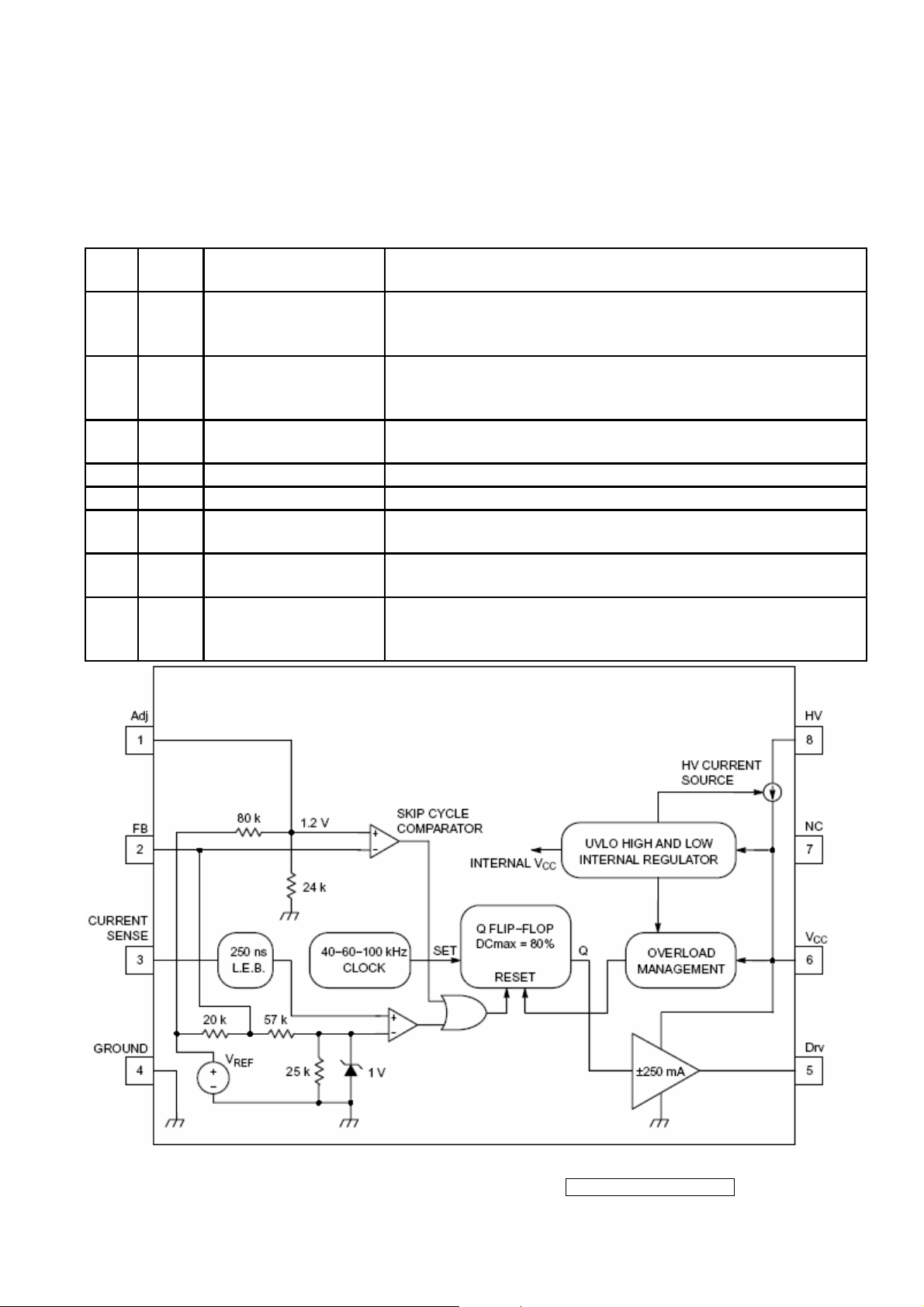

NCP1203D60R2G (IC901): PWM control, high-voltage startup current. The circuit unit

has functions such as over-current protection, over-voltage protection, output

short-circuit protection and etc. The function of each pin and the inside circuit diagram

are as follows:

Pin

No.

Pin

Name

1 Adj

2 FB

3 CS Current sense input

Function Pin Description

Adjust the skipping

peak current

Sets the peak

current setpoint

This pin lets you adjust the level at which the cycle

skipping process takes place. Shorting this pin to ground,

permanently disables the skip cycle feature.

By connecting an optocoupler to this pin, the peak current

setpoint is adjusted accordingly to the output power

demand. Skip cycle occurs when FB falls below Vpin1.

This pin senses the primary current and routes it to the

internal comparator via an L.E.B.

4 GND The IC ground −

5 Drv Driving pulses The driver’s output to an external MOSFET.

6 VCC Supplies the IC

7 NC −

Ensure a clean and

8 HV

lossless startup

sequence

This pin is connected to an external bulk capacitor of

typically 22 F.

This unconnected pin ensures adequate creepage

distance.

Connected to the high−voltage rail, this pin injects a

constant current into the VCC capacitor during the startup

sequence.

- 21 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 22

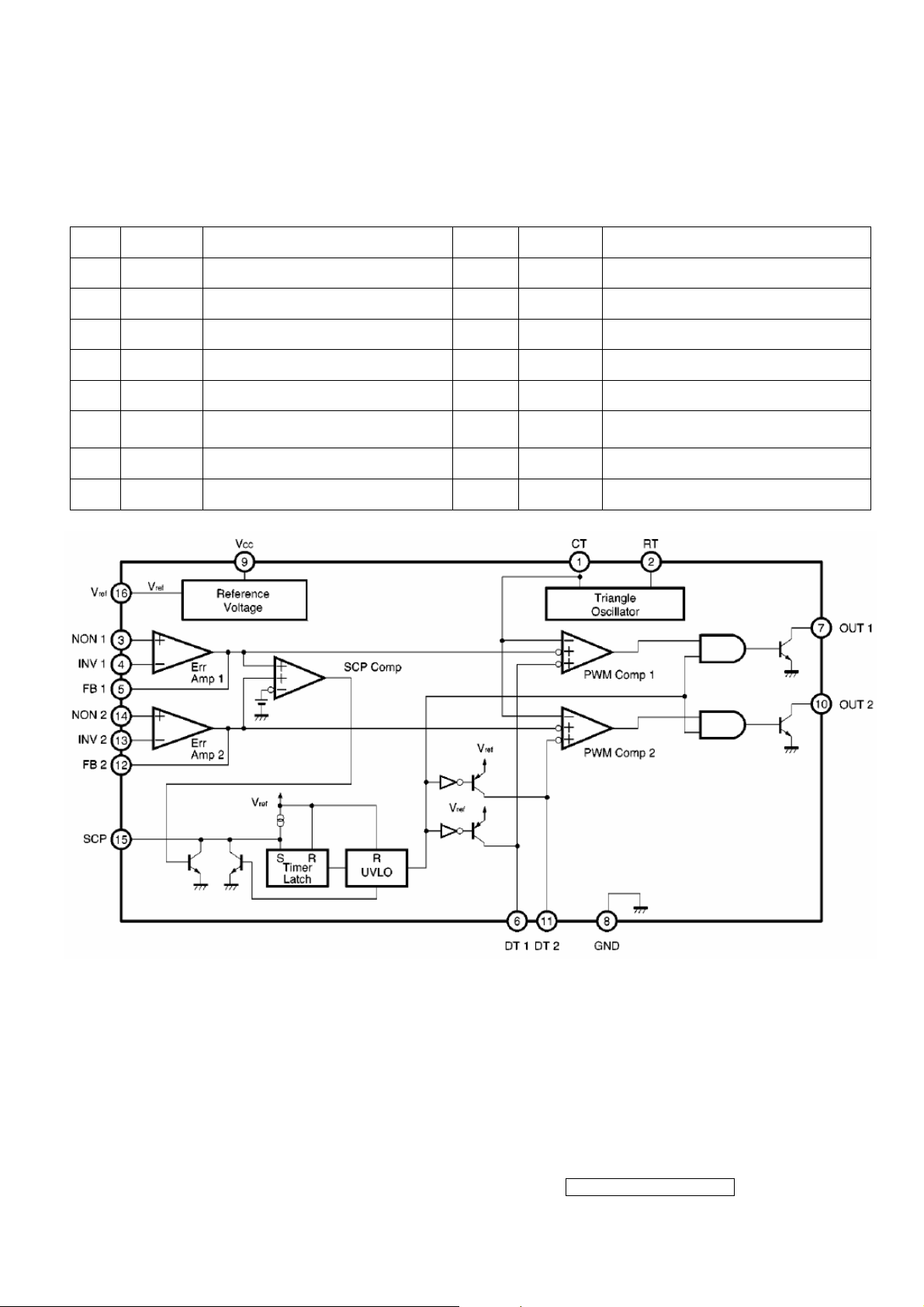

TL1451 (IC201): PWM control, voltage range for working: 3.6~35V, Has such functions

as short-voltage protection, Over-voltage protection, over-current protection and

etc. The function of each pin and the circuit diagram inside are as follows:

Pin Symbol Description Pin Symbol Description

1 CT External timing capacitor 9 VCC Power supply

2 RT External timing resistor 10 2OUT Output 2

3 1IN+ Positive input for error amplifier 1 11 2DTC Output 2 dead time/soft start setting

4 1IN- Positive input for error amplifier 2 12 2FBK Error amplifier 2 output

5 1FBK Error amplifier 1 output 13 2IN+ Positive input for error amplifier

6 1DTC

7 1OUT Output 1 15 SCP Timing latch setting

8 GND Ground 16 REF Reference voltage output (2.5v)

Output 1 dead time/soft start

setting

14 2IN- Positive input for error amplifier

- 22 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 23

5. Adjust Procedure

5.1 ADJUSTMENT CONDITIONS AND PRECAUTIONS

1. Approximately 30 minutes should be allowed for warm up before proceeding.

2. Adjustments should be undertaken only on those necessary elements since most of them

have been carefully preset at the factory.

3. ESD protection is needed before adjustment.

5.2 MAIN ADJUSTMENTS

NO. FUNCTIONS DESIGNATION

1. White Balance Function Key

2. Geometry Function Key

5.3 ALIGNMENT PROCEDURES

Approximately 30 minutes should be allowed for warm up before proceeding

White-Balance adjustment.

1. Adjust of White Balance

1.)How to do the Chroma-7120 MEM .Channel setting

A、Reference to chroma 7120 user guide

B、Use “ SC” key and “ NEXT” key to modify xyY value and use “ID” key to modify the

TEXT description Following is the procedure to do white-balance adjust

2.)Setting the color temp. You want

A、MEM.CHANNEL9 ( 9300 color):

9300 color temp. parameter is Wx = 0.283 ±0.03;Wy = 0.298 ±0.03;

Y = 250 ±20 cd/m

B、MEM.CHANNEL10 ( 6500 color):

6500 color temp. parameter is Wx = 0.313±0.03;Wy = 0.329 ±0.03;

Y = 260 ±20 cd/m

C、MEM.CHANNEL 11 ( 5400 color):

5400 color temp. parameter is Wx = 0.335±0.03;Wy = 0.350 ±0.03;

Y = 250 ±20 cd/m

D、MEM.CHANNEL10 ( SRGB color):

6500 color temp. parameter is Wx = 0.313±0.03;Wy = 0.329 ±0.03;

Y = 220 ±20 cd/m

ViewSonic Corporation

2 ,

2,

2,

2,

- 23 –

Confidential - Do Not Copy VG920

Page 24

3.)Into factory mode of VG720

A、First Power off, then press Switch 2 button along with press Power button will activate

the factory mode, then MCU will do AUTO LEVEL automatically. Meanwhile press

MENU the OSD screen will located at LEFT TOP OF PANEL.

4.)Bias adjustment :

Set the Contrast

Adjust the Brightness

to 70

to 100.

5.)Gain adjustment :

Move cursor to “-F-” and press MENU key

A、Adjust 9300 color-temperature

(1)、Switch the Chroma-7120 to RGB-Mode (with press “MODE” button )

(2)、Switch the MEM. channel to Channel 9 ( with up or down arrow on chroma 7120 )

(3)、The LCD-indicator on chroma 7120 will show x = 0.283 ±0.03, y =0.298 ±0.03,

2

Y = 250 ±20 cd/m

(4)、Adjust the RED of color1 on factory window until chroma 7120 indicator reached

the value R=100

(5)、Adjust the GREEN of color1 on factory window until chroma 7120 indicator reached

the value G=100

(6)、Adjust the BLUE of color1 on factory window until chroma 7120 indicator reached

the value B=100

(7)、Repeat above procedure ( item 4,5,6) until chroma 7120 RGB value meet the

tolerance =100±5

B、Adjust 6500 color-temperature

(1)、Switch the chroma-7120 to RGB-Mode (with press “MODE” button )

(2)、Switch the MEM .channel to Channel 10( with up or down arrow on chroma 7120 )

(3)、The LCD-indicator on chroma 7120 will show x = 0.313 ±0.03, y = 0.329 ±0.03, Y =

2

260 ±20 cd/m

(4)、Adjust the RED of color3 on factory window until chroma 7120 indicator reached

the value R=100

(5)、Adjust the GREEN of color3 on factory window until chroma 7120 indicator reached

the value G=100

(6)、Adjust the BLUE of color3 on factory window until chroma 7120 indicator reached

the value B=100

(7)、Repeat above procedure ( item 4,5,6) until chroma 7120 RGB value meet the

tolerance =100±5

- 24 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 25

C、Adjust 5400 color-temperature

(1) Switch the chroma-7120 to RGB-Mode (with press “MODE” button )

(2)、Switch the MEM .channel to Channel 11( with up or down arrow on chroma 7120 )

(3)、The LCD-indicator on chroma 7120 will show x = 0.335 ±0.03, y = 0.350 ±0.03, Y =

2

250 ±20 cd/m

(4)、Adjust the RED of color3 on factory window until chroma 7120 indicator reached the

value R=100

(5)、Adjust the GREEN of color3 on factory window until chroma 7120 indicator reached

the value G=100

(6)、Adjust the BLUE of color3 on factory window until chroma 7120 indicator reached

the value B=100

(7)、Repeat above procedure ( item 4,5,6) until chroma 7120 RGB value meet the

tolerance =100±5

D、Adjust SRGB color-temperature

(1)、Switch the chroma-7120 to RGB-Mode (with press “MODE” button )

(2)、Switch the MEM .channel to Channel 10( with up or down arrow on chroma 7120 )

(3)、The LCD-indicator on chroma 7120 will show x = 0.313 ±0.03, y = 0.329 ±0.03, Y =

2

220 ±20 cd/m

(4)、Adjust the RED of color3 on factory window until chroma 7120 indicator reached

the value R=100

(5)、Adjust the GREEN of color3 on factory window until chroma 7120 indicator reached

the value G=100

(6)、Adjust the BLUE of color3 on factory window until chroma 7120 indicator reached

the value B=100

(7)、Repeat above procedure ( item 4,5,6) until chroma 7120 RGB value meet the

tolerance =100±5

E、Press reset key and Turn the Power-button “off to on” to quit from factory mode.

2. Geometry

1).Set cross-hatch pattern and preset timing as timing table listed.

2).Change to each mode in turn and wait for the monitor finish auto-alignment and save

press before change to next mode.

3).Until all of modes are adjusted,exit OSD menu and press POWER OFF to exit factory

mode.

- 25 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 26

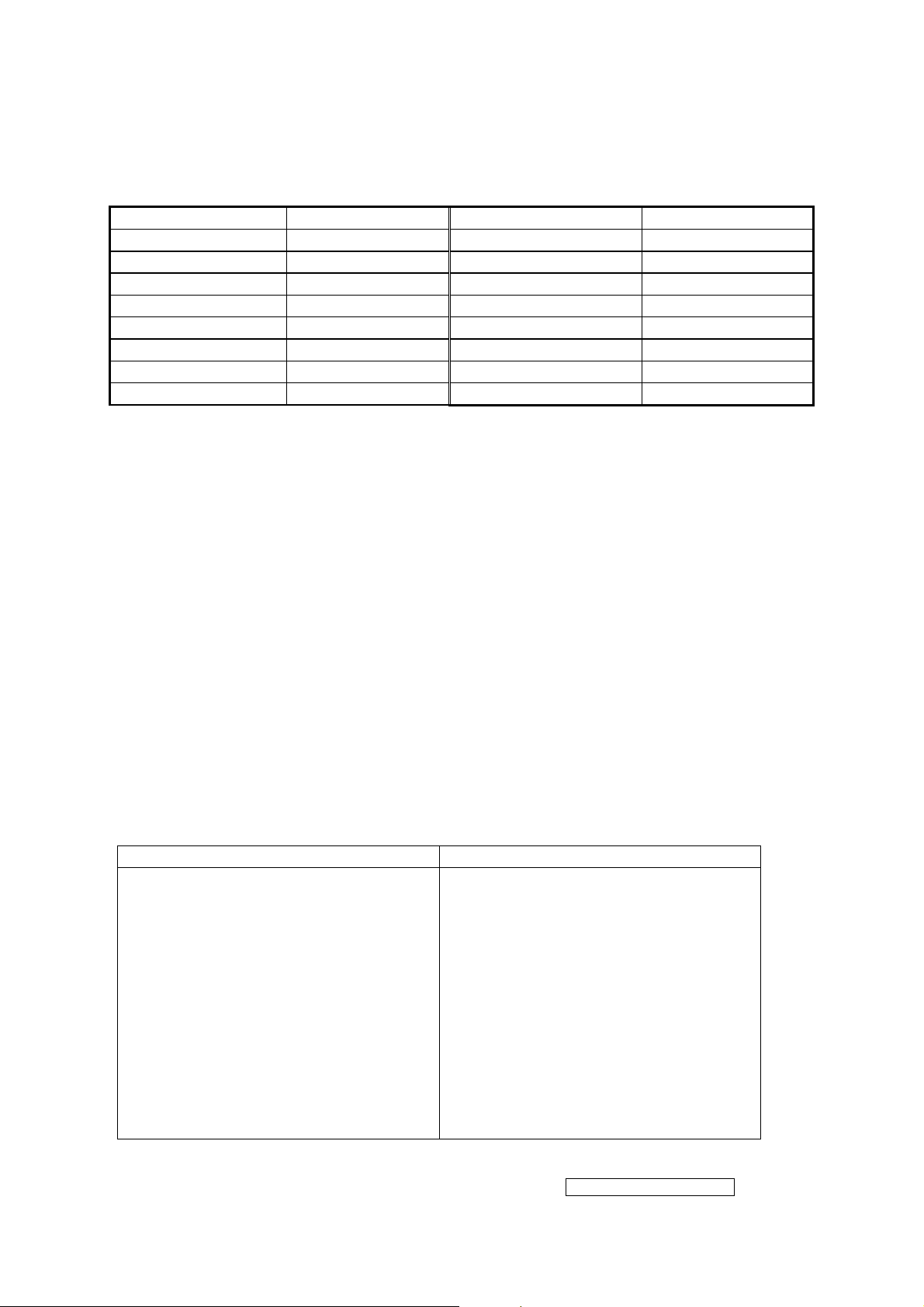

5.4 Factory Defaults

Item Defaults Item Defaults

Contrast 70% Sharpness 33%

Brightness 100% OSD H. Position 50%

Volume 50% OSD V. Position 50%

Balance 50% OSD Time Out 15 Sec

Bass 50% OSD Background On

Treble 50% OSD PIVOT Off

Color Temperature 6500K Resolution Notice Enabled

720x400/640x400 720x400

5.5 Function Test

1 Product: 17” LCD Monitor

2 Test Equipment: Color Video Signal & Pattern (or PC with SXGA resolution and a

sound card)

3 Test Condition: Before function test and alignment, each LCD Monitor should be

warmed up for at least 30 minutes with the following conditions:

(a)In room temperature,

(b) With full-white screen, RGB, and Black

(c) With cycled display modes,

640*480 (H=43.27kHz, V=85Hz)

800*600 (H=53.7kHz, V=85Hz)

1024*768 (H=68.67kHz, V=85Hz)

1280*1024 (H=79.97kHz, V=75Hz)

4 Test Display Modes & Pattern

Compatible Modes

Analog Digital

640 x 350 @ 70Hz, 31.5kHz

640 x 400 @ 70Hz, 31.5kHz

640 x 480 @ 60Hz, 31.5kHz

640 x 480 @ 67Hz, 35.0kHz

640 x 480 @ 72Hz, 37.9kHz

640 x 480 @ 75Hz, 37.5kHz

720 x 400 @ 70Hz, 31.5kHz

800 x 600 @ 56Hz, 35.1kHz

800 x 600 @ 60Hz, 37.9kHz

800 x 600 @ 75Hz, 46.9kHz

800 x 600 @ 72Hz, 48.1kHz

832 x 624 @ 75Hz, 49.7kHz

1024 x 768 @ 60Hz, 48.4kHz

640 x 350 @ 70Hz, 31.5kHz

640 x 400 @ 70Hz, 31.5kHz

640 x 480 @ 60Hz, 31.5kHz

640 x 480 @ 67Hz, 35.0kHz

640 x 480 @ 72Hz, 37.9kHz

640 x 480 @ 75Hz, 37.5kHz

720 x 400 @ 70Hz, 31.5kHz

800 x 600 @ 56Hz, 35.1kHz

800 x 600 @ 60Hz, 37.9kHz

800 x 600 @ 75Hz, 46.9kHz

800 x 600 @ 72Hz, 48.1kHz

832 x 624 @ 75Hz, 49.7kHz

1024 x 768 @ 60Hz, 48.4kHz

- 26 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 27

1024 x 768 @ 70Hz, 56.5kHz

1024 x 768 @ 72Hz, 58.1kHz

1024 x 768 @ 75Hz, 60.0kHz

1280 x 1024 @ 60Hz, 63.4kHz

1280 x 1024 @ 75Hz, 79.97kHz

1280x 720 @ 60Hz, 45kHz

1024 x 768 @ 70Hz, 56.5kHz

1024 x 768 @ 72Hz, 58.1kHz

1024 x 768 @ 75Hz, 60.0kHz

1280 x 1024 @ 60Hz, 63.4kHz

1280 x 1024 @ 75Hz, 79.97kHz

1280x 720 @ 60Hz, 45kHz

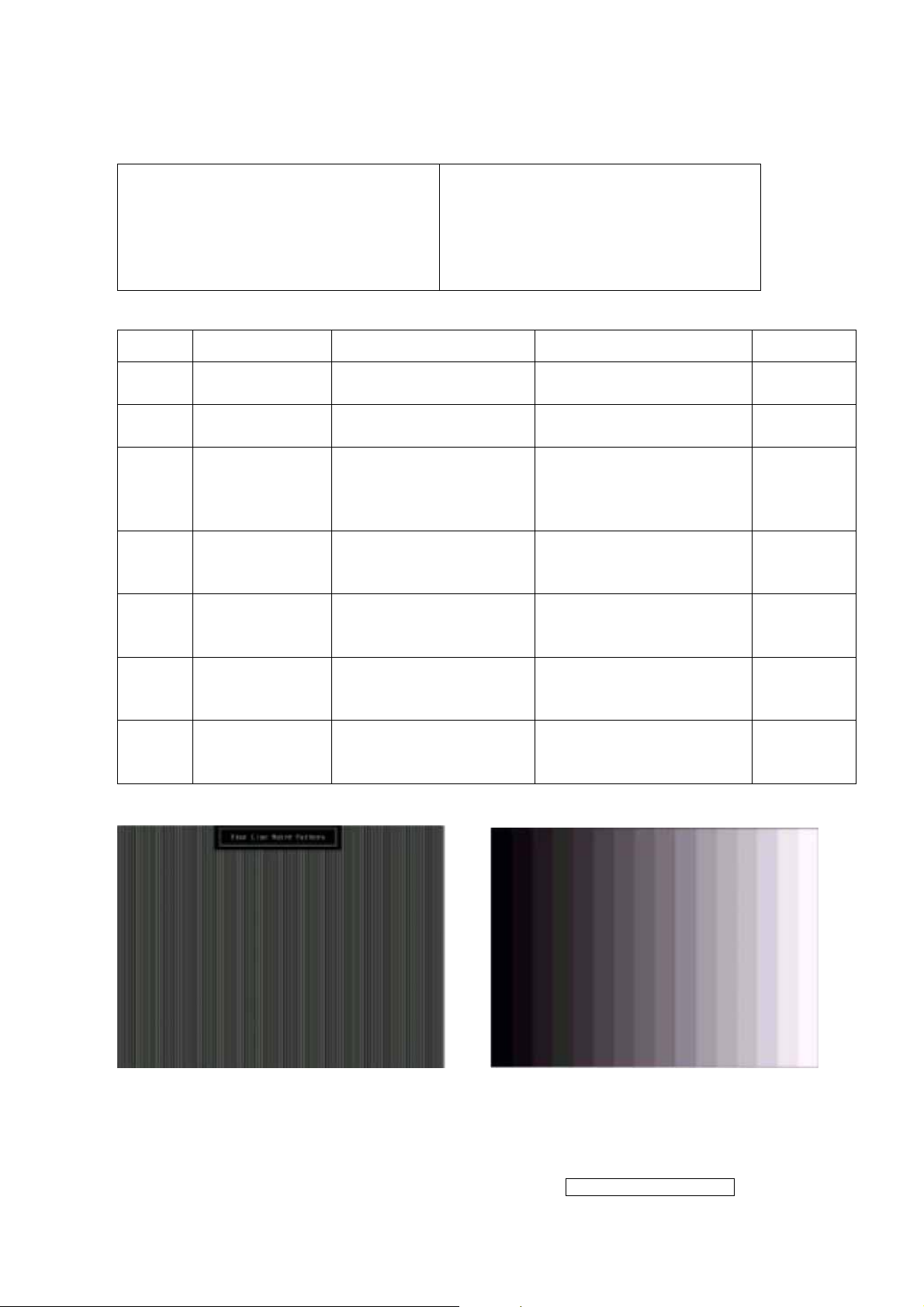

Function Test Display Pattern

Item Test Content Pattern Specification Remark

1

2

3 Boundary

4

Frequency &

Tracking

Contrast/Bright

ness

Fine Line Moire

16 Gray Scale

Horizontal&Vertical

Thickness

RGB Color

Performance

RGB Color Intensities

Screen

5

Uniformity &

Full White

Flicker

6

Dead

Pixel/Line

White Screen & Dark

Screen

7 White Balance White & Black Pattern

Eliminate visual wavy

noise.

16 gray levels sh should

be distinguishable.

Figure 1

Figure 2

Horizontal and Vertical

position of video should

be adjustable to be

Figure 3

within the screen frame.

Contrast of each R, G,

B, color should be

normal.

Should be compliant

with the spec.

Figure

4,5,6

Figure 7

The numbers of dead

pixels should be

Figure 7,8

compliant with the spec.

The screen must have

the pure white and black

Figure 9

pattern, no other color.

Fine Line Morie Pattern (Figure1) Gray Scale Pattern (Figure2)

- 27 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 28

Horizontal & Vertical Thickness Pattern R. Color Pattern (Figure 4)

(Figure 3)

G. Color Pattern (Figure 5) B. Color Pattern (Figure 6)

Full White Pattern (Figure 7) Dark Screen Pattern (Figure 8)

- 28 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 29

Black-White Pattern (Figure 9)

4.3 Function Test and Alignment Procedure

All Modes Reset

You should do “All Mode Reset” (Refer to Chapter III-3. Hot Keys for Function

Controls) first. This action will allow you to erase all end-user’s settings and restore

the factory defaults.

Auto Image Adjust

Please select and enter “Auto Image Adjust” function on Main Menu to see if it is

workable. The “Auto Image Adjust” function is aimed to offer a better screen quality

by built-in ASIC. For optimum screen quality, the user has to adjust each function

manually.

Firmware

Test Pattern: Burn In Mode (Refer to Chapter III-3. Hot Keys for Function Controls)

- Make sure the F/W is the latest version.

DDC

Test Pattern: EDID program

Make sure it can pass test program.

Fine Tune and Sharpness

Test Signal: 1280*1024@60Hz

Test Pattern: Line Moire Pattern

Check and see if the image has noise and focus performs well. Eliminate visual

line bar.

If not, readjust by the following steps:

(a)Select and enter “Fine Tune” function on “Manual Image Adjust” to adjust the

image to eliminate visual wavy noise.

(b)Then, select and enter “Sharpness” function to adjust the clarity and focus of

the screen image.

Boundary

Test Signal: 1280*1024@60Hz

Test Pattern: Horizontal & Vertical Line Thickness Pattern

Check and see if the image boundary is within the screen frame.

If not, readjust by the following steps:

(a)Select and enter “Manual Image Adjust” function on OSD Main Menu.

- 29 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 30

(b)Then, select and enter “Horizontal Size” or “Horizontal/Vertical Position” function

to adjust the video boundary to be full scanned and within screen frame.

White Balance

Test Signal: 640*480@60Hz

Test Pattern: White and Black Pattern

1.5.8 R, G, B, Colors Contrast

Test Signal: 1280*1024@60Hz

Test Pattern: R, G, B, Color Intensities Pattern and 16 Gray Scale Pattern

- Check and see if each color is normal and distinguishable.

- If not, please return the unit to repair area.

Screen Uniformity and Flicker

Test Signal: 1280*1024@60Hz

Test Pattern: Full White Pattern

- Check and see if it is in normal condition.

1.5.10 Dead Pixel and Line

Test Signal: 1280*1024@60Hz

Test Pattern: Dark and White Screen Pattern

- Check and see if there are dead pixels on LCD panel with shadow gauge and

filter film.

- The total numbers and distance of dead pixels should be compliant with the

spec.

Mura

Test Pattern: White, RGB, Black, & Grey

Test Tool: 10% ND Filter

- Check if the Mura can pass 10% ND Filter.

Audio

Test Signal: Voice signal (optional, depend on model)

Test Pattern: liberty

- Make sure there is audio output.

- Make sure that audio function (volume 80%) is working without noise and

resonance.

- Make sure that the sound of right and left speakers are in balance.

Check for Secondary Display Modes

Test Signal:

Analog: 640*350@70Hz; 640*480@60/67/72/75/85Hz;

720*400@70Hz; 800*600@56/60/72/75/85Hz;

832*624@75Hz, 1024*768@60/70/72/75/85Hz;

1280*1024@60/75Hz

Digital: 640*350@70Hz; 640*480@60/72/75/85Hz;

720*400@70Hz; 800*600@56/60/72/75/85Hz;

1024*768@60/70/72/75/85Hz; 1152*870@75Hz,

1280*720@60Hz, 1280*1024@60Hz

- Normally when the primary mode 1280*1024@60Hz is well adjusted and

compliant with the specification, the secondary display modes will also be

compliant with the spec. But we still have to check with the general test pattern to

make sure every secondary is compliant with the specification.

-

- 30 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 31

All Modes Reset

After final QC step, we have to erase all saved changes again and restore the

factory defaults. You should do “All Mode Reset” again.

Power Off Monitor

Turn off the monitor by pressing “Power” button.

5.6 Firmware Upgrade Procedure

When you receive the returned monitor, please check whether the firmware version is

the latest. If not, please do the following procedures to upgrade it to the latest version.

1 Equipment Needed

- VG720/VG920 Monitor

- Fixture for Firmware Upgrade

- Power Adapter (P/N: 47.58201.001) *1 for Fixture

- VGA Cable (P/N: 42.59901.003) *1(Pin 4, 11 should be connected to GND)

- PC (Personal Computer)

- LPT Cable (P/N: 42.59906.001) *1

- Firmware Upgrade Program

- One additional monitor for checking the program execution

- 31 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 32

2 Setup Procedure

2.1 Connect P2 of Fixture with printer port of PC by LPT Cable.

2.2 Connect P1 of Fixture with VG720/VG920 Monitor by VGA Cable.

2.3 Plug Power Adapter to Fixture.

2.4 Connect Power Cord to VG720/VG920 Monitor.

2.5 Connect P3 to the Signal Generator (eg.Chroma2326) for verifying it after the

operation being completed.

2.6 Connect PC to the additional monitor.

JP1:to Power Adapter

P1:to VGA Cable

P2:to LPT Cable

3 Firmware Upgrade Procedure

Step 1. Let VG720/VG920 set to be connected with AC cable and VGA cable.

Step 2.Execute the MSstar ISP tool.

P3:to Signal Generator

- 32 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 33

Step 3. Click “Config” button . Select the Port Type: LPT1 and the Base Addr : 0x378

on “Communication Setting” flame,and then the Speed: 47 on “E2PROM Device

Setting” flame

Step 4. Click “Connect” button. (On this step, if the connection is successful, the “Entry

ISP Mode” Dialog will be showed. If not, the error dialog will be done.)

Step 5. Click “Device” button. Select the “PMC25LV010” or “SST25VF010” viewed on

your set.

- 33 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 34

Step 6. Click “Read” button. Select the object bincode on your corresponding directory.

Step 7. Click “Auto” button. Execute the flashing action by clicking the “Run” button.

Step 8. If the flashing F/W has been completed, “Ok” message will be showed on the

right TextBox.

- 34 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 35

Step 9. Unplug and replug power cord of VG720/VG920 set and then check the OSD

operation and image on srceen.

Step 10. At last, do “Memory Recall.”

3.2 Setup Procedure

3.2.1 Connect P2 and P4 of Fixture with VGA ports of VG720 VG720/VG920by VGA

Cable.

3.2.2 Connect P3 of Fixture with DVI port of VG720 by DVI-DVI Cable.

3.2.3 Connect P1 of Fixture with Printer port of PC by LPT Cable.

3.2.4 Plug Power Adapter to Fixture.

3.2.5 Connect Power Cord to VG720/VG920 Monitor.

3.2.6 Connect PC to the additional monitor.

P3:DVI-DVI Cable

JP1: Power Adapter

P2: VGA Cable

P1:to LTP Cable

- 35 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 36

3.3 DDC Key In Procedure

Sep1.Select and execute DDc Key In program

- 36 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 37

Sep2:Inpute the S/N and execute “Enter”

- 37 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 38

- 38 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 39

Sep3:Key the “Enter” and write the data

- 39 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 40

Sep4:If ddc program OK and show “data compare ok”

- 40 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 41

5.7 Packing For Shipping

- 41 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 42

Packing Part List

ITEM DESCRIPITON PART NUMBER Q’TY

1 CARTON C 44G3943709 1A 1

HANDLE1 50G 600 2 1

2

HANDLE2 50G 600 3 1

3 PE BAG 45G 76 28 V3 1

4 CD MANUAL 70G1701709 4B 1

5 QSG 41G7801709 4A 1

6 EPE COVER 45G 88609 4 1

7 MONITOR T980KA6HKGVWABP 1

8 EPE COVER 45G 88609800 1

9 PE BAG 45G 88626 1 1

44G3943 1 1

10 EPS

44G3943 2 1

11 AUDIO CABLE 89G 173 56507 1

12 POWER CORD 89G402A18N LS 1

13 SIGNAL CABLE 89G 728GAA902 1

14 DVI CABLE 89G1748GAA 11 1

- 42 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 43

6. Troubleshooting Flow Chart

- 43 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 44

7. Recommended Spare Part List

VX920 BOM list(T980KA6HKGVWABP)

Item

ViewSonic

P/N

Ref. P/N Description Location

Universal

number#

Q'ty

1 AUPC980A8P AUPC BOARD 1

2 CBPC980KA6VWP CONVERSION BOARD 1

3 KEPC980KB8SMTP KEY BOARD 1

4 PWPC1942AUV1P POWER BOARD 1

5 7G 1 S 15 WOODEN PALLET 0.025

6 11G 800 2 SPACER SUPPORT (RCM-5) 1

7 11G6054 1 PIN CONNECTOR 4

8 12G 434 2 RUBBER PAD 4

9 12G 437 1 THER MAL PAD 1

10 12G8000 2 FOOT PAD 2

11 15G8004 1 ROLLER PIN 4

12 15G8235 1 MAIN FRAME 1

13 15G8237 1 VESA COVER 1

14 15G8239 1 Kensington bracket 1

15 19G6014 2 塑料打包固定夹 0.2

16 20G 036 1 BASE DIE CASTING 1

17 23G3178709 4A VSC17-LCD FRONT LOGO 1

18 23G3178709 6A BIRD LOGO (E015-006) 1

19 33G4915 KR L FUNCTION BUTTON 1

20 33G4916 1 POWER LENS 0

21 33G4917 KR X ROLLER 4

22 33G4918 KR X CABLE CLIP 2

23 34G1687AKR B BEZEL 1

24 34G1688 KR B REAR COVER 1

25 34G1689AKD B COSMETIC TOP 1

26 34G1690 KD B COSMETIC BOTTOM 1

27 34G1691 KR B VESA COVER 1

28 34G1692 KR B STAND FRONT 1

29 34G1693 KR B STAND REAR 1

30 34G1694 KD B BASE FRONT TOP 1

31 34G1695 KD B BASE FRONT BOTTOM 1

32 34G1696 KR B BASE 1

33 34G1697 KR X SWIVEL COVER 1

34 37G 547 1 HINGE ASS'Y 1

35 40G 190709 1B ID LABEL 1

36 40G 45760819A 机种标签 1

37 40G 459709 1B CARTON LABEL 1

- 44 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 45

38 40G 459709 2B S/N LABEL 1

39 40G 459709 4A H/V WARNING LABEL 1

40 40G 459709 5A HI-POT LABEL FOR 17-LCD 1

41 40G 581 26704 唛头纸 FOR CARTON/PALLET 0.01

42 40G 58162435A MANUAL P/N LABEL 1.05

43 40G 58170918D PALLET LABEL 0.25

44 40G457B709 1A Hg LABEL 1

45 40G581B709 3A 8ms STICKER 1

46 41G7801709 4A QSG 1

47 44G3231 15 EVA WASHER 1

48 44G3943 1 EPS(L) 1

49 44G3943 2 EPS(R) 1

50 44G6002 S 12 PAPER PLATE 0.025

51 44G6002 S 13 PAPER PLATE 0.025

52 44G9003210 CORNER PAPER 0.1

53 45G 76 28 V3 PE BAG 1

54 45G 77 3 TRANSPARENT SHEET 173

55 45G 88609 4 EPE COVER 1

56 45G 88609800 EPE BAG 1

57 45G 88626 1 PE BAG FOR MONITOR 1

58 50G 600 1 W 白色机用打包带 74

59 50G 600 2 HANDLE1 1

60 50G 600 3 HANDLE2 1

61 52G 1185 24 TAPE 65

62 52G 1216 A 铝箔胶带 1

63 52G 2191 D 美纹胶带 75

64 52G6019 1 YELLOW TAPE 5

65 52G6020 5 PROTECT FILM 1

66 52G6022 20 SMALL TAPE 100

67 52G6025 11907 Mylar sheet top 1

68 52G6025 11909 MYLAR BOTTOM 1

69 70G1701709 4B CD MANUAL 1

70 78G 334 5 LCD 内置无源喇叭箱(8欧腜 1

71 85G 713 1 MAIN SHIELD 1

72 89G 173 56507 AUDIO CABLE 1

73 89G 728GAA902 SIGNAL CABLE 1

74 89G 728HAA902 SIGNAL CABLE 0

75 89G1748GAA 11 DVI CABLE 1

76 89G1748HAA 11 DVI SIGNAL CABLE 0

77 89G1748LAA 11 DVI CABLE 0

- 45 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 46

78 89G402A18N IS POWER CABLE 0

79 89G402A18N LS POWER CORD 1

80 95G8014 16921 WIRE HARNESS 16P-11P 3 1

81 95G8018 30915 WIRE HARNESS 1

82 M1G 130 6120 SCREW 4

83 M1G 130 6120 SCREW 2

84 M1G 140 8120 SCREW M4X8 4

85 M1G 140 10120 SCREW M4X10 5

86 M1G 330 4128 SCREW 2

87 M1G1030 6225 SCREW M3X6 1

88 M1G1140 6128 SCREW 1

89 M1G1730 6128 SCREW 4

90 M1G1730 6128 SCREW 3

91 M1G1730 6128 SCREW 2

92 M1G2940 10225 M4*10 4

93 Q1G 130 6 47 SCREW 3

94 Q1G 130 8120 SCREW 3

95 Q1G 130 12120 SCREW 1

96 Q1G 330 6120 SCREW M3X6MM 4

97 Q1G 330 6120 SCREW M3X6MM 2

98 Q1G 330 8120 SCREW 2

99 Q1G1030 10120 M3*10 4

100 Q1G1030 12120 M3*12 2

101 750GLU90N45 12 M190EN04 V5A(SZ)19" LCD 1

102 C 44G3943709 1A CARTON 1

103 AUPC980A8P AUPC BOARD

104 AUPC980A8SMTP AUPC BOARD SMT 1

105 33G3802 4H WAFER 4P RIGHT ANGLE CN603 1

106 33G802414C H WAFER CN602 1

107 51G6002 1 导热胶 0.2

108 67G215B471 3H LOW ESR CAP 470UF 16V 8 C620 1

109 67G305V100 7N GP 10UF50V KME50VB10-M-TP5 C601 1

110 67G305V100 7N GP 10UF50V KME50VB10-M-TP5 C605 1

111 67G305V100 7N GP 10UF50V KME50VB10-M-TP5 C617 1

112 67G305V100 7N GP 10UF50V KME50VB10-M-TP5 C625 1

113 88G 30214K PHONE JACK 5PIN CN601 1

114 90G6119 1 HEATSINK 1

115 AUPC980A8SMTP AUPC BOARD SMT

116 56G 616 6 ID TPA3003D2PF BRG4 TQF U601 1

117 61L0603000 CHIPR 0OHM +-5% 1/10W R602 1

- 46 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 47

118 61L0603102 CHIPR 1KOHM +-5% 1/10W R608 1

119 61L0603103 CHIPR 10KOHM+-5% 1/10W R601 1

120 61L0603103 CHIPR 10KOHM+-5% 1/10W R609 1

121 61L0603103 CHIPR 10KOHM+-5% 1/10W R610 1

122 61L0603124 CHIP 120KOHM 1/10W R604 1

123 61L0603124 CHIP 120KOHM 1/10W R607 1

124 61L0603393 39K OHM 1/10W R611 1

125 61L0603393 39K OHM 1/10W R612 1

126 65G0603101 31 CHIP 100P 50V NPO C612 1

127 65G0603101 31 CHIP 100P 50V NPO C615 1

128 65G0603102 32 CHIP 1000PF 50 X7R C602 1

129 65G0603102 32 CHIP 1000PF 50 X7R C603 1

130 65G0603102 32 CHIP 1000PF 50 X7R C604 1

131 65G0603102 32 CHIP 1000PF 50 X7R C630 1

132 65G0603102 32 CHIP 1000PF 50 X7R C631 1

133 65G0603102 32 CHIP 1000PF 50 X7R C632 1

134 65G0603103 32 0.01UF 50V X7R C607 1

135 65G0603103 32 0.01UF 50V X7R C608 1

136 65G0603103 32 0.01UF 50V X7R C626 1

137 65G0603103 32 0.01UF 50V X7R C629 1

138 65G0603104 12 MLCC C606 1

139 65G0603104 12 MLCC C609 1

140 65G0603104 12 MLCC C618 1

141 65G0603104 12 MLCC C621 1

142 65G0603104 12 MLCC C627 1

143 65G0603104 12 MLCC C628 1

144 65G0603105 12 CHIP CAP 1UF. C610 1

145 65G0603105 12 CHIP CAP 1UF. C611 1

146 65G0603105 12 CHIP CAP 1UF. C613 1

147 65G0603105 12 CHIP CAP 1UF. C614 1

148 65G0603105 12 CHIP CAP 1UF. C616 1

149 65G0603105 12 CHIP CAP 1UF. C619 1

150 65G0603105 12 CHIP CAP 1UF. C623 1

151 65G0603105 12 CHIP CAP 1UF. C624 1

152 65G0603221 32 220PF/50V X7R C622 1

153 71G 56G301 EA CHIP BEAD FB602 1

154 71G 56G301 EA CHIP BEAD FB604 1

155 71G 56G301 EA CHIP BEAD FB610 1

156 71G 56G301 EA CHIP BEAD FB612 1

157 71G 57G301 EA CHIP BEAD 600 OHM 1206 FB605 1

- 47 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 48

158 71G 57G301 EA CHIP BEAD 600 OHM 1206 FB606 1

159 71G 57G601 贴片磁珠 FB601 1

160 71G 57G601 贴片磁珠 FB607 1

161 71G 57G601 贴片磁珠 FB608 1

162 71G 57G601 贴片磁珠 FB609 1

163 715G1566 1 AUDIO 1

164 CBPC980KA6VWP CONVERSION BOARD

165 AIC980KA6VWP MAIN BOARD 1

166 33G801714H H PIN2*7 CN404 1

167 33G801724A H PIN 24P 2.0MM RIGHT ANG CN101 1

168 33G8027 12 WAFER 2*6P 2.0MM R/A CN701 1

169 33G8027 16 WAFER 16PIN 2.0MM DIP CN403 1

170 40G 45762412B CBPC LABEL 1.03

171 51G6002 1 导热胶 0.2

172 67G215L101 4N LOW ESR EC 100UF 25V NC C707 1

173 67G215L101 4N LOW ESR EC 100UF 25V NC C710 1

174 67G215L101 4N LOW ESR EC 100UF 25V NC C712 1

175 67G309V100 3 Electrolytic CAP C408 1

176 67G309V100 3 Electrolytic CAP C717 1

177 67G309V109 3 1UF +-20% 16V C705 1

178 67G309V479 3 4.7UF +-20% 16V C403 1

179 67G309V479 3 4.7UF +-20% 16V C702 1

180 88G 35315F H D-SUB 15PIN CN405 1

181 88G 35315F HJ D-SUB 15PIN CN405 0

182 88G 35424F H DVID CONN 24P FEMALE 90 CN406 1

183 90G6250 1 GP 散热片 1

184 93G 22 53 CRYSTAL 14.31818MHZ HC- X401 1

185 AIC980KA6VWP MAIN BOARD

186 56G 562108 TSUM56AK-LF PQFP-100 U401 1

187 56G 563 7 AIC1084-33PM TO-263 U702 1

188 56G 643 6 IC MICROPROCESSOR MAX81 U406 1

189 56G1133 34 IC M24C02-WMN6TP U404 1

190 56G1133 34 IC M24C02-WMN6TP U405 1

191 56G1133 63AA2 PM25LV010-25SCE U402 1

192 56G1133 74AA2 SST25VF010A-33-4C-SAE S U402 0

193 56G113356A 24LC16B/SNG SOIC-8PIN U403 1

194 57G 417 4 PMBS3904/PLILIPS Q402 1

195 57G 417 4 PMBS3904/PLILIPS Q404 1

196 57G 417 4 PMBS3904/PLILIPS Q701 1

197 57G 417 4 PMBS3904/PLILIPS Q703 1

- 48 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 49

198 57G 417 4 PMBS3904/PLILIPS Q706 1

199 57G 417 6 PMBS3906 PNP Q401 1

200 57G 417 6 PMBS3906 PNP Q403 1

201 57G 417 17 T PZT2907A SOT-223 Q702 1

202 57G 763 1 AO3401L Q704 1

203 61L0603000 CHIPR 0OHM +-5% 1/10W FB410 1

204 61L0603000 CHIPR 0OHM +-5% 1/10W FB411 1

205 61L0603000 CHIPR 0OHM +-5% 1/10W FB412 1

206 61L0603000 CHIPR 0OHM +-5% 1/10W R419 1

207 61L0603000 CHIPR 0OHM +-5% 1/10W R421 1

208 61L0603000 CHIPR 0OHM +-5% 1/10W R431 1

209 61L0603000 CHIPR 0OHM +-5% 1/10W R432 1

210 61L0603000 CHIPR 0OHM +-5% 1/10W R720 1

211 61L0603000 CHIPR 0OHM +-5% 1/10W R721 1

212 61L0603100 CHIPR 10 OHM 1/10W R462 1

213 61L0603100 CHIPR 10 OHM 1/10W R463 1

214 61L0603100 CHIPR 10 OHM 1/10W R464 1

215 61L0603100 CHIPR 10 OHM 1/10W R465 1

216 61L0603100 CHIPR 10 OHM 1/10W R466 1

217 61L0603100 CHIPR 10 OHM 1/10W R467 1

218 61L0603100 CHIPR 10 OHM 1/10W R468 1

219 61L0603100 CHIPR 10 OHM 1/10W R469 1

220 61L0603100 1F CHIP 1KOHM 1/10W 1% R478 1

221 61L0603100 1F CHIP 1KOHM 1/10W 1% R479 1

222 61L0603101 CHIPR 100OHM +-5% 1/10W R411 1

223 61L0603101 CHIPR 100OHM +-5% 1/10W R418 1

224 61L0603101 CHIPR 100OHM +-5% 1/10W R420 1

225 61L0603101 CHIPR 100OHM +-5% 1/10W R427 1

226 61L0603101 CHIPR 100OHM +-5% 1/10W R428 1

227 61L0603101 CHIPR 100OHM +-5% 1/10W R429 1

228 61L0603101 CHIPR 100OHM +-5% 1/10W R441 1

229 61L0603101 CHIPR 100OHM +-5% 1/10W R442 1

230 61L0603101 CHIPR 100OHM +-5% 1/10W R443 1

231 61L0603101 CHIPR 100OHM +-5% 1/10W R445 1

232 61L0603101 CHIPR 100OHM +-5% 1/10W R453 1

233 61L0603101 CHIPR 100OHM +-5% 1/10W R454 1

234 61L0603101 CHIPR 100OHM +-5% 1/10W R455 1

235 61L0603101 CHIPR 100OHM +-5% 1/10W R456 1

236 61L0603101 CHIPR 100OHM +-5% 1/10W R458 1

237 61L0603101 CHIPR 100OHM +-5% 1/10W R704 1

- 49 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 50

238 61L0603102 CHIPR 1KOHM +-5% 1/10W R430 1

239 61L0603102 CHIPR 1KOHM +-5% 1/10W R446 1

240 61L0603102 CHIPR 1KOHM +-5% 1/10W R447 1

241 61L0603102 CHIPR 1KOHM +-5% 1/10W R470 1

242 61L0603102 CHIPR 1KOHM +-5% 1/10W R476 1

243 61L0603102 CHIPR 1KOHM +-5% 1/10W R477 1

244 61L0603102 CHIPR 1KOHM +-5% 1/10W R701 1

245 61L0603103 CHIPR 10KOHM+-5% 1/10W R406 1

246 61L0603103 CHIPR 10KOHM+-5% 1/10W R408 1

247 61L0603103 CHIPR 10KOHM+-5% 1/10W R412 1

248 61L0603103 CHIPR 10KOHM+-5% 1/10W R413 1

249 61L0603103 CHIPR 10KOHM+-5% 1/10W R415 1

250 61L0603103 CHIPR 10KOHM+-5% 1/10W R416 1

251 61L0603103 CHIPR 10KOHM+-5% 1/10W R424 1

252 61L0603103 CHIPR 10KOHM+-5% 1/10W R425 1

253 61L0603103 CHIPR 10KOHM+-5% 1/10W R426 1

254 61L0603103 CHIPR 10KOHM+-5% 1/10W R450 1

255 61L0603103 CHIPR 10KOHM+-5% 1/10W R451 1

256 61L0603103 CHIPR 10KOHM+-5% 1/10W R452 1

257 61L0603103 CHIPR 10KOHM+-5% 1/10W R457 1

258 61L0603103 CHIPR 10KOHM+-5% 1/10W R459 1

259 61L0603103 CHIPR 10KOHM+-5% 1/10W R460 1

260 61L0603103 CHIPR 10KOHM+-5% 1/10W R461 1

261 61L0603103 CHIPR 10KOHM+-5% 1/10W R471 1

262 61L0603103 CHIPR 10KOHM+-5% 1/10W R484 1

263 61L0603103 CHIPR 10KOHM+-5% 1/10W R485 1

264 61L0603103 CHIPR 10KOHM+-5% 1/10W R487 1

265 61L0603103 CHIPR 10KOHM+-5% 1/10W R708 1

266 61L0603103 CHIPR 10KOHM+-5% 1/10W R711 1

267 61L0603103 CHIPR 10KOHM+-5% 1/10W R714 1

268 61L0603103 CHIPR 10KOHM+-5% 1/10W R717 1

269 61L0603103 CHIPR 10KOHM+-5% 1/10W R727 1

270 61L0603121 CHIPR 120 OHM 1/10W R409 1

271 61L0603121 CHIPR 120 OHM 1/10W R414 1

272 61L0603150 1F CHIP 1.5KOHM 1/16W 1% R480 1

273 61L0603202 CHIPR 2KOHM+-5%1/10W R703 1

274 61L0603203 CHIPR 20KOHM +-5% 1/10W R417 1

275 61L0603222 CHIPR 2.2KOHM+-5%1/10W R448 1

276 61L0603222 CHIPR 2.2KOHM+-5%1/10W R449 1

277 61L0603223 CHIPR 22K OHM +-5% 1/10 R405 1

- 50 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 51

278 61L0603390 0F 390OHM +-1% R403 1

279 61L0603392 CHIP 3.9K OHM 1/10W R474 1

280 61L0603392 CHIP 3.9K OHM 1/10W R475 1

281 61L0603471 CHIPR 470OHM+-5%1/10W R437 1

282 61L0603472 CHIP 4.7KOHM +-5% 1/10 R422 1

283 61L0603472 CHIP 4.7KOHM +-5% 1/10 R423 1

284 61L0603472 CHIP 4.7KOHM +-5% 1/10 R705 1

285 61L0603472 CHIP 4.7KOHM +-5% 1/10 R707 1

286 61L0603472 CHIP 4.7KOHM +-5% 1/10 R712 1

287 61L0603472 CHIP 4.7KOHM +-5% 1/10 R725 1

288 61L0603510 CHIP 51OHM 5% 1/10W R702 1

289 61L0603513 CHIP 51K OHM R723 1

290 61L0603560 CHIPR 56 OHM +-5% 1/10W R434 1

291 61L0603560 CHIPR 56 OHM +-5% 1/10W R435 1

292 61L0603560 CHIPR 56 OHM +-5% 1/10W R436 1

293 61L0603750 CHIPR 75OHM+-5%1/10W R438 1

294 61L0603750 CHIPR 75OHM+-5%1/10W R439 1

295 61L0603750 CHIPR 75OHM+-5%1/10W R440 1

296 65G0603104 32 CHIP 0.1UF 50V X7R C401 1

297 65G0603104 32 CHIP 0.1UF 50V X7R C404 1

298 65G0603104 32 CHIP 0.1UF 50V X7R C405 1

299 65G0603104 32 CHIP 0.1UF 50V X7R C406 1

300 65G0603104 32 CHIP 0.1UF 50V X7R C407 1

301 65G0603104 32 CHIP 0.1UF 50V X7R C409 1

302 65G0603104 32 CHIP 0.1UF 50V X7R C410 1

303 65G0603104 32 CHIP 0.1UF 50V X7R C411 1

304 65G0603104 32 CHIP 0.1UF 50V X7R C412 1

305 65G0603104 32 CHIP 0.1UF 50V X7R C413 1

306 65G0603104 32 CHIP 0.1UF 50V X7R C414 1

307 65G0603104 32 CHIP 0.1UF 50V X7R C415 1

308 65G0603104 32 CHIP 0.1UF 50V X7R C416 1

309 65G0603104 32 CHIP 0.1UF 50V X7R C417 1

310 65G0603104 32 CHIP 0.1UF 50V X7R C419 1

311 65G0603104 32 CHIP 0.1UF 50V X7R C420 1

312 65G0603104 32 CHIP 0.1UF 50V X7R C422 1

313 65G0603104 32 CHIP 0.1UF 50V X7R C424 1

314 65G0603104 32 CHIP 0.1UF 50V X7R C425 1

315 65G0603104 32 CHIP 0.1UF 50V X7R C426 1

316 65G0603104 32 CHIP 0.1UF 50V X7R C427 1

317 65G0603104 32 CHIP 0.1UF 50V X7R C428 1

- 51 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 52

318 65G0603104 32 CHIP 0.1UF 50V X7R C429 1

319 65G0603104 32 CHIP 0.1UF 50V X7R C430 1

320 65G0603104 32 CHIP 0.1UF 50V X7R C439 1

321 65G0603104 32 CHIP 0.1UF 50V X7R C440 1

322 65G0603104 32 CHIP 0.1UF 50V X7R C441 1

323 65G0603104 32 CHIP 0.1UF 50V X7R C444 1

324 65G0603104 32 CHIP 0.1UF 50V X7R C445 1

325 65G0603104 32 CHIP 0.1UF 50V X7R C446 1

326 65G0603104 32 CHIP 0.1UF 50V X7R C447 1

327 65G0603104 32 CHIP 0.1UF 50V X7R C448 1

328 65G0603104 32 CHIP 0.1UF 50V X7R C449 1

329 65G0603104 32 CHIP 0.1UF 50V X7R C450 1

330 65G0603104 32 CHIP 0.1UF 50V X7R C451 1

331 65G0603104 32 CHIP 0.1UF 50V X7R C452 1

332 65G0603104 32 CHIP 0.1UF 50V X7R C453 1

333 65G0603104 32 CHIP 0.1UF 50V X7R C454 1

334 65G0603104 32 CHIP 0.1UF 50V X7R C706 1

335 65G0603104 32 CHIP 0.1UF 50V X7R C709 1

336 65G0603104 32 CHIP 0.1UF 50V X7R C711 1

337 65G0603104 32 CHIP 0.1UF 50V X7R C713 1

338 65G0603104 32 CHIP 0.1UF 50V X7R C714 1

339 65G0603104 32 CHIP 0.1UF 50V X7R C715 1

340 65G0603104 32 CHIP 0.1UF 50V X7R C718 1

341 65G0603220 32 Chip Cap 22PF C421 1

342 65G0603220 32 Chip Cap 22PF C423 1

343 65G0603221 32 220PF/50V X7R C443 1

344 65G0603330 32 CHIP 33PF 50V NPO C442 1

345 65G0603473 32 CHIP 47NF 50V X7R C432 1

346 65G0603473 32 CHIP 47NF 50V X7R C433 1

347 65G0603473 32 CHIP 47NF 50V X7R C434 1

348 65G0603473 32 CHIP 47NF 50V X7R C435 1

349 65G0603473 32 CHIP 47NF 50V X7R C436 1

350 65G0603473 32 CHIP 47NF 50V X7R C437 1

351 65G0603473 32 CHIP 47NF 50V X7R C438 1

352 65G0805105 37 CHIP 1UF 50V Y5V C708 1

353 71G 56Z601 2.0X1.2 100M=600OHM FB401 1

354 71G 56Z601 2.0X1.2 100M=600OHM FB402 1

355 71G 56Z601 2.0X1.2 100M=600OHM FB403 1

356 71G 56Z601 2.0X1.2 100M=600OHM FB404 1

357 71G 56Z601 2.0X1.2 100M=600OHM FB405 1

- 52 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 53

358 71G 56Z601 2.0X1.2 100M=600OHM FB406 1

359 71G 56Z601 2.0X1.2 100M=600OHM FB407 1

360 71G 56Z601 2.0X1.2 100M=600OHM FB408 1

361 71G 56Z601 M CHIP BEAD 0805 600OHM FB401 0

362 71G 56Z601 M CHIP BEAD 0805 600OHM FB402 0

363 71G 56Z601 M CHIP BEAD 0805 600OHM FB403 0

364 71G 56Z601 M CHIP BEAD 0805 600OHM FB404 0

365 71G 56Z601 M CHIP BEAD 0805 600OHM FB405 0

366 71G 56Z601 M CHIP BEAD 0805 600OHM FB406 0

367 71G 56Z601 M CHIP BEAD 0805 600OHM FB407 0

368 71G 56Z601 M CHIP BEAD 0805 600OHM FB408 0

369 71G 59B121 贴片磁珠 FB409 1

370 93G 39147SEM ZMM5V6 D414 1

371 93G 39147SEM ZMM5V6 D415 1

372 93G 39147SEM ZMM5V6 D416 1

373 93G 39147SEM ZMM5V6 D426 1

374 93G 39149 ZENER MLL5232B BY FULL D406 1

375 93G 39149 ZENER MLL5232B BY FULL D408 1

376 93G 39149 ZENER MLL5232B BY FULL D409 1

377 93G 39149 ZENER MLL5232B BY FULL D410 1

378 93G 39149 ZENER MLL5232B BY FULL D411 1

379 93G 39149 ZENER MLL5232B BY FULL D412 1

380 93G 64 42 P BAV70 DIODE D407 1

381 93G 64 42 P BAV70 DIODE D413 1

382 93G 6432P LL4148 MINI-MELF/LL-34 D701 1

383 93G 6432P LL4148 MINI-MELF/LL-34 D702 1

384 93G 6433P BAV99 SOT-23 D403 1

385 93G 6433P BAV99 SOT-23 D404 1

386 93G 6433P BAV99 SOT-23 D405 1

387 93G 6433P BAV99 SOT-23 D417 1

388 93G 6433P BAV99 SOT-23 D418 1

389 93G 6433P BAV99 SOT-23 D419 1

390 93G 6433P BAV99 SOT-23 D420 1

391 93G 6433P BAV99 SOT-23 D421 1

392 93G 6433P BAV99 SOT-23 D422 1

393 93G 6433P BAV99 SOT-23 D423 1

394 93G 6433P BAV99 SOT-23 D424 1

395 93G 39S 45 T RLZ36B ZENER DIODE D401 1

396 93G 39S 45 T RLZ36B ZENER DIODE D402 1

397 93G 39S 45 T RLZ36B ZENER DIODE D425 1

- 53 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 54

398 93G1004 4 SCHOTTKY DIODE 1A 40V S D704 1

399 715G1558 1 2 MAIN BOARD 1

400 KEPC980KB8SMTP KEY BOARD

401 33G803411C WAFER 1.0MM SMT 11P CN001 1

402 77G 604 2 TO TACT SWITCH SW001 1

403 77G 604 2 TO TACT SWITCH SW002 1

404 77G 604 2 TO TACT SWITCH SW003 1

405 77G 604 2 TO TACT SWITCH SW004 1

406 77G 604 2 TO TACT SWITCH SW005 1

407 77G 604 2 TO TACT SWITCH SW006 1

408 77G 604 2 TO TACT SWITCH SW007 1

409 77G 604 2 TO TACT SWITCH SW008 1

410 81G 14501 KT KTL-HKBGE33B-TRB LED001 1

411 715G1602 1 KEPC 1

412 PWPC1942AUV1P POWER BOARD

413 PW1942AUV1SMTP MAIN BOARD FOR SMT 1

414 33G8021 2D U CON.2PR/A CN201 1

415 33G8021 2D U CON.2PR/A CN202 1

416 33G8021 2D U CON.2PR/A CN203 1

417 33G8021 2D U CON.2PR/A CN204 1

418 33G8021 2D AC WAFER CN201 0

419 33G8021 2D AC WAFER CN202 0

420 33G8021 2D AC WAFER CN203 0

421 33G8021 2D AC WAFER CN204 0

422 33G8029 3A WAFER 3.96MM CN901 1

423 40G 45762412B CBPC LABEL 1

424 51G 6 4503 RTV 胶 2

425 56G 139 3 PC123FY2 BY SHARP IC902 0

426 56G 139 3A PC123Y22FZOF IC902 1

427 61G 58080 WT NTCR NR901 1

428 61G152M398 64 RES. R918 1

429 63G 10747410S 0.47UF +-10% 250VAC C903 1

430 63G210J3342B2 0.33uF 250V PMS TAIYANG C221 0

431 63G211J334 AB 0.33UF 5% 160V C221 1

432 65G 2K152 5A 1500PE 10% Y5P 2KV C905 1

433 65G 3J1206EM 12PF 5% SL 3KV MURATA C211 1

434 65G 3J1206EM 12PF 5% SL 3KV MURATA C212 1

435 65G 3J1206EM 12PF 5% SL 3KV MURATA C213 1

436 65G 3J1206EM 12PF 5% SL 3KV MURATA C214 1

437 65G 3J1206ET 12PF 5% SL 3KV TDK C211 0

- 54 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 55

438 65G 3J1206ET 12PF 5% SL 3KV TDK C212 0

439 65G 3J1206ET 12PF 5% SL 3KV TDK C213 0

440 65G 3J1206ET 12PF 5% SL 3KV TDK C214 0

441 65G305M1022BJ 1000PF Y2 400V 20% BY J C901 0

442 65G305M1022BJ 1000PF Y2 400V 20% BY J C902 0

443 65G305M1022EM 1000pF Y2 250V 20% BY M C901 1

444 65G305M1022EM 1000pF Y2 250V 20% BY M C902 1

445 65G306M1022BM GP Y1.CAP.001UF 250VAC MUR C935 1

446 65G306M1022BP 1000PF 400VAC/250VAC Y1 C935 0

447 65G306M2222BM GP 2200PF +-20% 250V AC C900 1

448 65G306M2222BP 2200PF Y1 400 20% BY UK C900 0

449 67G215H102 3N KY16VB1000M-1 10*20 C924 0

450 67G215L101 4N LOW ESR EC 100UF 25V NC C906 1

451 67G215L102 3N KY16VB1000M-1 10*20 C924 0

452 67G215L102 3R LOW ESR 1000UF +-20% 16 C924 1

453 67G215L102 4N LOW ESR 1000UF 25V C923 0

454 67G215L102 4N LOW ESR 1000UF 25V C931 0

455 67G215L102 4R 1000UF/25V C923 1

456 67G215L102 4R 1000UF/25V C931 1

457 67G215L470 4N 47UF/25V C909 1

458 67G215L471 4N 470UF25V KY25VB470-M-L C203 0

459 67G215L471 4N 470UF25V KY25VB470-M-L C925 0

460 67G215L471 4R 470UF/25V C203 1

461 67G215L471 4R 470UF/25V C925 1

462 67G215P102 3K LOW ESR EC 1000UF 16V C924 0

463 67G215P102 4K LOW ESR EC 1000UF 25V C923 0

464 67G215P102 4K LOW ESR EC 1000UF 25V C931 0

465 67G215P471 3K LOW ESR EC 470UF 16V C926 0

466 67G215P471 4K LOW ESR EC 470UF 25V C203 0

467 67G215P471 4K LOW ESR EC 470UF 25V C925 0

468 67G215S10115K LOW ESR EC 100uF 450V C904 1

469 67G215S10115N 1000/450PAG450VB100M-L C904 0

470 67G215V102 3N GP KY10VB1000M-L10*16 C924 0

471 67G215V102 3R GP LOW E.S.R 100UF +-20% 1 C924 0

472 67G215Y1014KT LOW ESR EC 100UF 25V C906 0

473 67G215Y4704KT LOW ESR EC 47UF 25V C909 0

474 67G215Y471 3N 470UF 16V KY16VB470M-L C926 0

475 67G215Y4713NV KY16VB470M-CC3 8*15MM C926 0

476 67G215Y4713RV LOW E.S.R 470UF +-20% 1 C926 1

477 73G 174 64 L LINE FILTER LF-004057-1 L902 1

- 55 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 56

478 73G 174 64 LS LINE FILTER L902 0

479 73G 174 64 YS LINE FILTER L902 0

480 73G 253 91 H 阻流圈 L903 0

481 73G 253 91 H 阻流圈 L904 0

482 73G 253 91 L CHOKE BY LI TA L903 1

483 73G 253 91 L CHOKE BY LI TA L904 1

484 73G 253 91 LS CHOKE COIL L903 0

485 73G 253 91 LS CHOKE COIL L904 0

486 73G 253166 L CHOKE L201 0

487 73G 253166 LS CHOCK COIL L201 0

488 73G 253166 YS CHOKE L201 1

489 73L 174 50 LH LINE FILTER L901 1

490 73L 174 50LSH LINE FILTER L901 0

491 80GL17T 28 DN TRANSFORMER PT201 0

492 80GL17T 28 DN TRANSFORMER PT202 0

493 80GL17T 28 YS X'FMR YAO SHENG PT201 1

494 80GL17T 28 YS X'FMR YAO SHENG PT202 1

495 80GL17T 29 L X'FMR PT-004046 T901 1

496 80GL17T 29 V XFMR T901 0

497 80GL17T 29 LS POWER TRANS T901 0

498 93G 50460 13 KBP206G 2A 600V DB901 1

499 93G 50460502 BRIDGE KBP206G 2A 800V DB901 0

500 93G1100 1052T BA159GPT DO-41 DIODE 1A D901 1

501 95G8014 12 35 WIRE HARRNESS CN902 1

502 705G 780 5720P D921/D922 ASS'Y 1

503 705G 780 5721P Q901 ASS'Y 1

504 705G 780 5722P R908 ASS'Y 1

505 705G 780 5725P CN901 ASS'Y 1

506 705G 780 5733P Q203 ASS'Y 1

507 705G 980 88 A1 ASS'Y 1

508 PW1942AUV1SMTP MAIN BOARD FOR SMT

509 PW1942AUV1AIP MAIN BOARD FOR AI 1

510 56G 379 54 NCP1203D60R2G SOIC-8 IC IC901 1

511 56G 608 1 TL1451ACD SOIC-16 IC201 1

512 57G 417 4 PMBS3904/PLILIPS Q204 1

513 57G 417 6 PMBS3906 PNP Q205 1

514 57G 417 12 T 2N3904S-RTK/PS SOT-23 Q204 0

515 57G 417 13 T 2N3906S-RTK/PS SOT-23 Q205 0

516 57G 760 4 DTA144WKA Q202 1

517 57G 760 5 DTC144WKA Q201 1

- 56 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 57

518 57G 760 4C RT1P44HC-T112-1 SC-59BY Q202 0

519 57G 760 5C RT1N44HC-T112-1 SC-59BY Q201 0

520 61L0805000 Chip Resistors 0OHM R208 1

521 61L0805000 Chip Resistors 0OHM R209 1

522 61L0805101 CHIPR 100OHM+-5%1/8W R912 1

523 61L0805102 CHIPR 1K OHM +-5% 1/8W R924 1

524 61L0805102 CHIPR 1K OHM +-5% 1/8W R931 1

525 61L0805102 CHIPR 1K OHM +-5% 1/8W R932 1

526 61L0805103 CHIPR 10KOHM+-5%1/8W R207 1

527 61L0805103 CHIPR 10KOHM+-5%1/8W R917 1

528 61L0805123 CHIP 12K OHM 1/8W R206 1

529 61L0805123 CHIP 12K OHM 1/8W R214 1

530 61L0805123 CHIP 12K OHM 1/8W R231 1

531 61L0805163 CHIP 16KOHM 1/8W R205 1

532 61L0805203 CHIPR 20KOHM +-5% 1/8W R919 1

533 61L0805220 CHIP 22OHM 5% 1/8W R915 1

534 61L0805221 CHIPR 220 OHM +-5% 1/8W R202 1

535 61L0805221 CHIPR 220 OHM +-5% 1/8W R916 1

536 61L0805222 CHIPR 2.2K OHM +-5% 1/8 R910 1

537 61L0805240 1F CHIPR 2.4KOHM +-1% 1/8W R201 1

538 61L0805240 1F CHIPR 2.4KOHM +-1% 1/8W R203 1

539 61L0805240 1F CHIPR 2.4KOHM +-1% 1/8W R933 1

540 61L0805330 2F CHIP 33KOHM 1/8W/1% R929 1

541 61L0805360 1F CHIP 3.6KOHM 1/8W 1% R930 1

542 61L0805362 CHIP 3.6KOHM 1/8W R911 1

543 61L0805471 CHIPR 470 OHM +-5% 1/8W R204 1

544 61L0805471 CHIPR 470 OHM +-5% 1/8W R230 1

545 61L0805472 CHIPR 4.7K OHM +-5% 1/8 R213 1

546 61L0805472 CHIPR 4.7K OHM +-5% 1/8 R914 1

547 61L0805473 CHIPR 47K OHM +-5% 1/8W R210 1

548 61L0805510 2F CHIP 51KOHM 1/8W 1% R232 1

549 61L0805623 CHIPR 62K OHM +-5% 1/8W R212 1

550 61L0805680 CHIP 68OHM 1/8W R909 1

551 61L0805681 CHIP 680OHM 1/8W R229 1

552 61L0805753 75K 1/8W R913 1

553 61L1206000 CHIPR 0OHM+-5% 1/4W F902 1

554 61L1206000 CHIPR 0OHM+-5% 1/4W R925 1

555 61L1206332 CHIP 3.3KOHM 5% 1/4W R903 1

556 61L1206332 CHIP 3.3KOHM 5% 1/4W R904 1

557 61L1206332 CHIP 3.3KOHM 5% 1/4W R905 1

- 57 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 58

558 61L1206334 330K 1/4W R900 1

559 61L1206334 330K 1/4W R901 1

560 61L1206334 330K 1/4W R902 1

561 65G0805102 32 CHIP 1000PF 50V X7R 080 C912 1

562 65G0805104 22 CHIP 0.1UF 25VX7R 0805 C201 1

563 65G0805104 22 CHIP 0.1UF 25VX7R 0805 C202 1

564 65G0805104 22 CHIP 0.1UF 25VX7R 0805 C204 1

565 65G0805104 22 CHIP 0.1UF 25VX7R 0805 C208 1

566 65G0805104 32 CHIP 0.1UF 50V X7R 0805 C907 1

567 65G0805104 32 CHIP 0.1UF 50V X7R 0805 C927 1

568 65G0805104 32 CHIP 0.1UF 50V X7R 0805 C928 1

569 65G0805104 32 CHIP 0.1UF 50V X7R 0805 C929 1

570 65G0805105 22 CHIP 1UF 25V X7R 0805 C205 1

571 65G0805105 22 CHIP 1UF 25V X7R 0805 C210 1

572 65G0805105 22 CHIP 1UF 25V X7R 0805 C223 1

573 65G0805331 31 330PF 50V NPO C207 1

574 65G0805471 31 CHIP 470PF 50V NPO C911 1

575 65G0805474 22 CHIP 0.47UF 25V Y5V 080 C222 1

576 65G0805474 22 CHIP 0.47UF 25V Y5V 080 C932 1

577 93G 60264 B340A DO-214AC D201 0

578 93G 6432S 1N4148W DIODE D210 1

579 93G 6432S 1N4148W DIODE D903 1

580 93G 6432S 1N4148W DIODE D923 1

581 93G 6432S 1N4148W DIODE D924 1

582 93G 6432V DIODE LL4148 GS08 D210 0

583 93G 6432V DIODE LL4148 GS08 D903 0

584 93G 6432V DIODE LL4148 GS08 D923 0

585 93G 6432V DIODE LL4148 GS08 D924 0

586 93G 39S 8 T RLZ11B LLDS ZD201 1

587 93G 39S 25 T RLZ5.1B ROHM ZD902 1

588 93G 39S 25 T RLZ5.1B ROHM ZD905 1

589 93G 39S 38 T PTZ9.1B ROHM ZD903 1

590 93G 39S 40 T RLZ13B ROHM ZD904 1

591 93G 39S 44 T RLZ18B LLDS ZD901 1

592 93G3004 4 DIODE RB050L-40 D201 1

593 PW1942AUV1AIP MAIN BOARD FOR AI

594 6G 31502 1.5MM RIVET 16

595 71G 55 9 T 铁氧体磁珠 J914 1

596 84G 56 1 FUSE 2A 250V BY WICKMAN F901 1

597 93G1020 752T UF4003PT DO-41 DIODE 1A D902 1

- 58 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 59

598 715G1492 1 PWPC 1

599 95G 90 23 TINCOATEDCOPPER J900 1

600 95G 90 23 TINCOATEDCOPPER J901 1

601 95G 90 23 TINCOATEDCOPPER J902 1

602 95G 90 23 TINCOATEDCOPPER J903 1

603 95G 90 23 TINCOATEDCOPPER J906 1

604 95G 90 23 TINCOATEDCOPPER J907 1

605 95G 90 23 TINCOATEDCOPPER J908 1

606 95G 90 23 TINCOATEDCOPPER J909 1

607 95G 90 23 TINCOATEDCOPPER J910 1

608 95G 90 23 TINCOATEDCOPPER J911 1

609 95G 90 23 TINCOATEDCOPPER J912 1

610 95G 90 23 TINCOATEDCOPPER J915 1

611 95G 90 23 TINCOATEDCOPPER J916 1

612 95G 90 23 TINCOATEDCOPPER J917 1

613 95G 90 23 TINCOATEDCOPPER J918 1

614 95G 90 23 TINCOATEDCOPPER J919 1

615 95G 90 23 TINCOATEDCOPPER J921 1

616 61G 17210252T 1KOHM 5% 1/4W R225 1

617 61G 17210252T 1KOHM 5% 1/4W R226 1

618 61G 17210252T 1KOHM 5% 1/4W R227 1

619 61G 17210252T 1KOHM 5% 1/4W R228 1

620 61G 17218252T 1.8KOHM 5% 1/4W R221 1

621 61G 17218252T 1.8KOHM 5% 1/4W R222 1

622 61G 17218252T 1.8KOHM 5% 1/4W R223 1

623 61G 17218252T 1.8KOHM 5% 1/4W R224 1

624 61G 17256152T 560OHM 5% 1/4W R923 1

625 61G175L47052T 47OHM +-5% 1/2W R921 1

626 61G175L47052T 47OHM +-5% 1/2W R922 1

627 65G517K102 5T 1000PF 10% Y5P 500V C922 1

628 67G 2151007NT 10UF 50V C908 1

629 67G 215330 3T 33UF +-20% 50V 105℃ LO C209 1

630 67G215Y1007KT LOW ESR EC10UF 50V C908 0

631 93G 64 1152T DIODE 1N4148 DO-35 D202 1

632 93G 64 1152T DIODE 1N4148 DO-35 D203 1

633 93G 64 1152T DIODE 1N4148 DO-35 D204 1

634 93G 64 1152T DIODE 1N4148 DO-35 D205 1

635 93G 64 1152T DIODE 1N4148 DO-35 D206 1

636 93G 64 1152T DIODE 1N4148 DO-35 D207 1

637 93G 64 1152T DIODE 1N4148 DO-35 D208 1

- 59 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 60

638 93G 64 1152T DIODE 1N4148 DO-35 D209 1

639 56G 158 10 T IC AZ431AZ-AE1 TO-92 IC903 0

640 56G 158 12 KIA431A-AT/P TO-92 IC IC903 1

641 57G 419 PP T 2PC945P Q903 1

642 57G 420 PP T TRANSISTOR 2PA733P Q902 1

643 65G517K102 5T 1000PF 10% Y5P 500V C921 1

644 705G 780 5720P D921/D922 ASS'Y

645 51G 200 1 散热油 2

646 90G6240 2 HEAT SINK 1

647 93G 60236 FMB-26L TO-220 DIODE D922 1

648 93G 60238 DIODE 10A 150V FCH10A15 D921 0

649 93G 60239 DIODE FME-210B TO-220 D921 1

650 93G1506 2 DIODE 15A 60V FMW-2156 D922 0

651 M1G1730 8128 SCREW 2

652 705G 780 5721P Q901 ASS'Y

653 51G 200 1 散热油 2

654 57G 667 30 2SK2645-54MR TO-220F Q901 1

655 57G 724 11 STP9NK65ZFP TO-220FP MO Q901 0

656 90G6240 1 HEAT SINK 1

657 M1G1730 8128 SCREW 1

658 705G 780 5722P R908 ASS'Y

659 61G152M10458G 100K OHM 5% 2W R908 1

660 96G 29 6 SHRINK TUBE UL/CSA 1

661 705G 780 5725P CN901 ASS'Y

662 87G 501 7 RF GP AC SOCKET 1

663 95G 900584 WIRE HARNESS 1

664 95G8021 3 11 HARNESS 100M 1

665 96G 29 6 SHRINK TUBE UL/CSA 1

666 705G 780 5733P Q203 ASS'Y

667 15G6284 1 PLATE 1

668 51G 200 1 散热油 0.2

669 57G 763 12 AOU401L TO-251 Q203 1

670 90G6259 1 HEAT SINK 1

671 AM1G1730 6128 SCREW 1

672 705G 980 88 A1 ASS'Y

673 51G 200 1 散热油 2

674 51G 200 1 散热油 2

675 57G 761 7 TRANSISTOR KTD1691/P Q206 1

676 57G 761 7 TRANSISTOR KTD1691/P Q207 1

677 90G6259 1 HEAT SINK 1

- 60 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 61

678 90G6259 1 HEAT SINK 1

679 M1G1730 8128 SCREW 1

680 M1G1730 8128 SCREW 1

- 61 –

ViewSonic Corporation

Confidential - Do Not Copy VG920

Page 62

8. Exploded Diagram And Spare Parts List

ViewSonic Corporation

- 62 –

Confidential - Do Not Copy VG920

Page 63

ViewSonic Corporation

- 63 –

Confidential - Do Not Copy VG920

Page 64

ViewSonic Corporation

- 64 –

Confidential - Do Not Copy VG920

Page 65

9. Disassemble Process

9.1 Units Disassemble Process

9.1.1 Tools

Glove

Big cross screwdriver

Small cross screwdriver

Prize equipment or abandoned IC card

Screw box

Cushion

Six angle sleeve spanner

9.1.2 Disassemble process

1、 Tide up the worktable, spread straight cushion, put the monitor on it, the front side

adown.(Picture 1)

2、 Disassemble the 4 screws that fix the stand, remove the stand..(Picture 2, 3, 4)

3、 Disassemble the 2 screws of the back cover.(Picture 5)

4、 Use equipment or abandoned IC card to prize up the bezel through the bottom flute,

as showed in the following the picture 6, and rip up the back cover downwards.( as

showed in the following the picture 7,8)

5、 Disassemble the 6 screw M3*6MM through six angle sleeve spanner, showed in the

following picture 9.

6、 Disassemble the 2 fixed screws in the shield, remove the shield as the direction

arrowhead showed, refer to the following picture ,10.