ViewSonic VCDTS23125 Service manual

Service Manual

ViewSonic E70f+SB-3

Model No. VCDTS23125

17” Digital Controlled Color Monitor

ViewSonic

(E70f+SB-3_SM_832 Rev. 1a – May 2004)

381 Brea Canyon Road, Walnut, California 91789 USA - (800) 888-8583

Copyright

Copyright

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, electronic, mechanical, magnetic, optical, chemical,

manual or otherwise, without the prior written p ermission of ViewSonic Corporation.

Disclaimer

ViewSonic makes no representations or warranties, either expressed or implied, with respect to the

contents hereof and specifically disclaims any warranty of merchantability or fitness for any particular

purpose. Further, ViewSonic reserves the right to revis e this publication and to make changes from time

to time in the contents hereof without obligation of ViewSonic to notify any person of such revision or

changes.

Trademarks

Optiquest is a registered trademark of ViewSonic Corporation.

ViewSonic is a registered trademark of ViewSonic Corporation.

All other trademarks used within this document are the property of their respective owners.

2004 by ViewSonic Corporation. All rights reserved. No part of this publication may be

¤

Revision History

Revision Date Description Of Changes Approval

1a 05/13/04 Initial Release DCN- 4412 Angela Lu

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

i

TABLE OF CONTENTS

1. Precautions and Safety Notices

2. Specification

3. Front Panel Function Control Description

4. Circuit Description

5. Adjusting Procedure

6. Trouble Shooting Flow Chart

7. Recommended Spare Parts List

8. Exploded Diagram And Spare Parts List

9. Block Diagram

10. Schematic Diagrams

11. PCB Layout Diagrams

1

3

21

25

28

38

43

52

60

61

74

ViewSonic Corporation Confidential -Do Not Copy 70f+SB-3 E

ii

1. Precautions And Safety Noticess

WA RN I N G!

This service information is designed for experience repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service

a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians.

Any attempt to service or repair the product or products dealt within this service information by anyone else

could result in serious injury or death.

1. CAUTION

No modification of any circuit should be attempted. Service work should only be performed after you are thoroughly

familiar with all of the following safety checks and servicing guide lines.

2. SAFETY CHECK

Care should be taken while servicing this CRT display because of the high voltage used in the deflection circuits.

These voltages are exposed in such areas as the associated flyback and yoke circuits.

3. FIRE & SHOCK HAZARD

3-1 Insert an isolation transformer between the CRT display and AC power line before servicing the chassis.

3-2 In servicing pay attention to original lead dress especially in the high voltage circuit. If a short circuit is found,

replace all parts which have been overheated as a result of the short circuit

3-3 All the protective devices munt be reinstalled per original design.

3-4 Soldering must be inspected for possible cold solder joints, frayed leads, damaged insulation, solder splashes or

sharp solder points. Be certain to remove all foreign material.

4. LEAKAGE CURRENT COLD CHECK

4-1 Unplug the AC cord and connect a jumper between the two prongs on the plug.

4-2 Turn the CRT display power switch “on”.

4-3 Measure the resistance value with an ohmmeter between the jumpered AC plug and each exposed metallic part

on the CRT display such as the metal frame, screwheads, control shafts, etc. When the exposed metallic part has

a return path to the chassis, the reading should be 1.8 megohm minimum

.

.

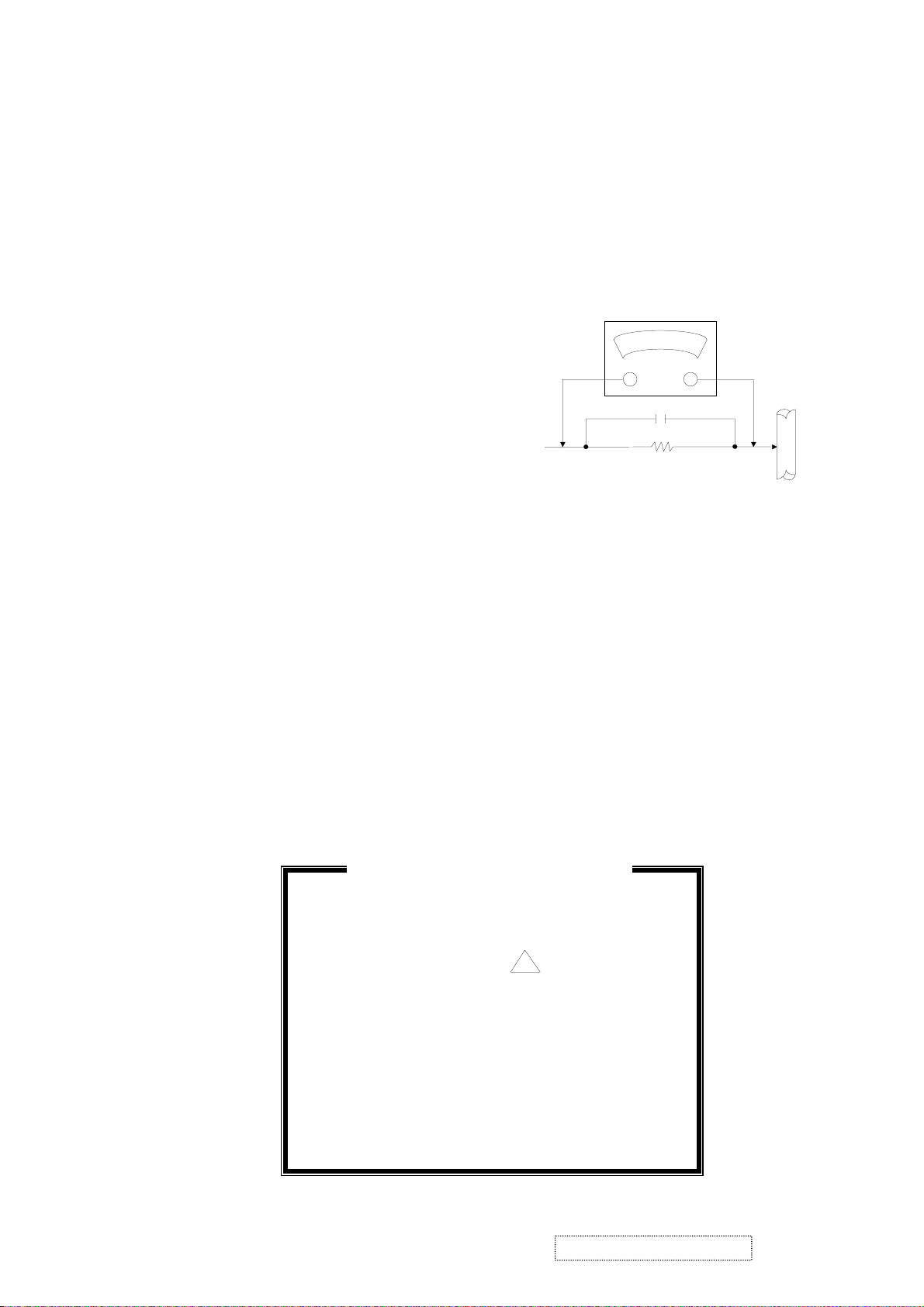

5. LEAKAGE CURRENT HOT CHECK

5-1 Plug the AC cord directly into the AC outlet. Do not use an isolation transformer during this check.

5-2 Connect a 1500 ohm, 10 watt resistor, paralleled by a 0.15uF capacitor between each exposed metallic part and

a good earth ground (as shown in Fig.1).

5-3 Use an AC voltmeter with 1000 ohm/volt or more sensitivity and measure the AC voltage across the

combination 1500 ohm resistor and 0.15uF capacitor.

ViewSonic Corporation Confidential -Do Not Copy 70f+SB-3 E

1

5-4 Move the resistor connection to each exposed metallic part and measure the voltage.

5-5 Reverse the polarity of the AC plug in the AC outlet and repeat the above measurement.

5-6 Voltage measured must not exceed 7.5 volt RMS, from any exposed metallic part to ground A leakage current

tester may be used in the above hot check, in which case any current measured must not exceed 5.0 milliamp. In

the case of a measurement exceeding the 5.0 milliamp value, a rework is required to eliminate the chance of

shock hazard.

NoteΚ High voltage is present when this CRT display is operating. Always discharge the anode of the picture

tube to the display chassis to prevent shock hazard.

TO

INSTRUMENT'S

EXPOSED

METAL PARTS

6. IMPLOSION PROTECTION

Picture tubes are equipped with an integral implosion protection system, but care should be taken to avoid damage and

scratching during installation. Use only Panasonic replacement picture tubes.

7. X-RADIATION

WA RN I NG ΚThe only potential source of X-Radiation is the picture tube. However when the high voltage circuit is

operating properly there is no possibility of X-Radiation problem. The basic precaution which must be exercised is to

keep the high voltage at the following factory-recommended level.

NoteΚΚΚΚ It is important to use an accurate periodically calibrated high voltage meter.

AC VOLTMETER

(EARTH

GROUND)

0.15ӴF

1500 Ө 10W

Fig. 1

7-1 The procedure for adjusting high voltage is shown on page 27.

7-2 If can not be adjust 25.0 KV at immediate service is required to prevent the possibility of premature

component failure.

7-3 To prevent X-Radiation possibility it is essential to use the specified picture tube.

IMPORTANT SAFETY NOTICE

There are special components used in this CRT displays

which are important for safety. These parts are identified

by the international symbol

diagram and on the replacement parts list. It is essential

that these critical parts should be replaced with

manufacture’s specified parts to prevent X-RADIATION,

shock, fire, or other hazards. Do not modify the original

design or this will void the original parts and labor

guarantee.

!

on the schematic

ViewSonic Corporation Confidential -Do Not Copy 70f+SB-3 E

2

2. Specification

A. GENERAL

1. ALLSPECIFICATION MUST BE MET OVER LINE VOLTAGE RANGE OF 90VACTO 264VAC 50HZ/ 60HZ, UNLESS OTHERWISE

SPECIFIED.

o

2. OPERATING TEMPERATURE RANGE IS 0

3. THE MONITOR MUST BE OPERATIONAL IN AN USABLE STATE WITHIN 30 SECONDS AFTER TURN-ON.

4. ALL SIGNAL LEVELS ARE MEASURED ASSUMING TERMINATION AT THE MONITOR'S INPUT JACKS OR IN ITS

CHARACTERISTIC IMPEDANCE.

AN AMBIENT LIGHTING LEVEL OF 400 TO 600 LUX IS ASSUMED WHEN SETTING BRIGHTNESS FOR RASTER

5.

EXTINCTION THRESHOLD.

6. ALL PURITY RELATED SPECIFICATIONS MUST BE MET WITHOUT EXTERNAL DEGAUSSING.

7. ALL CONTROLS MUST HAVE EXCESS RANGE (NO CONTROL MAY BE LEFT AT AN END STOP WHEN PROPER

ALIGNMENT IS COMPLETED).

THE MONITOR IS NOT REQUIRED TO MEET SPECS DURING THE FOLLOWING BUT MUST TOLERATE, WITHOUT

8.

DAMAGE TO THE CRT OR CIRCUITS, ANY SEQUENCY OR COMBINATION OF POWER ON AND OFF, SIGNAL ON

AND OFF, ERRATIC, WRONG FREQUENCY OR NOISY INPUTS WHILE AT ANY POSSIBLE UNPLUGGING OF POWER

OR SIGNAL, SETTINGS OF USER ACCESSIBLE CONTROLS. LIKEWISE, THE MONITOR SHOULD SURVIVE EXTENDED

PERIODS OF OPERATION WITH LINE VOLTAGE REDUCED BELOW THE SPECIFIED MINIMUM.

9. AN ISOLATION TRANSFORMER SHOULD BE USED WHEN PERFORMING ALIGNMENT AND TESTS. PORTIONS OF

THE POWER SUPPLY BOARD ARE HOT GROUND. THE REMAINING BOARDS ARE COLD GROUND.

10. DISCHARGE OF CRT ANODE SHOULD BE DONE ONLY TO CRT GROUND STRAP.

11. GEOMETRIC MEASUREMENT IS ASSUMED TO BE MAKING ALONG A STRAIGHT SURFACE WITH A FLAT RULE OR

TEMPLATE.

C TO 40oC WITH A RELATIVE HUMIDITY OF 10% OR LESS TO 90%.

B. INSTRUMENT ALIGNMENT

1. DEFLECTION PRESETS

CONTROL POTS VR101, VR401, VR403, FOCUS VR ARE SET AT MIDDLE POINT. SCREEN VR SET TO MIN.

2. POWER SUPPLY ALIGNMENT

2.1 INPUT VGA 640X480 SIGNAL CROSSHATCH PATTERN & BEAM CURRENT SET AT 0uA.

2.2 ADJUST VR101 UNTIL DC=105V0.3V AT TP201

2.3 ADJUST G2 UNTILL PICTURE VISIBLE.

2.4 ADJ VR403 UNTIL VOLTAGE AT TP208 = 63.0V 0.3V.

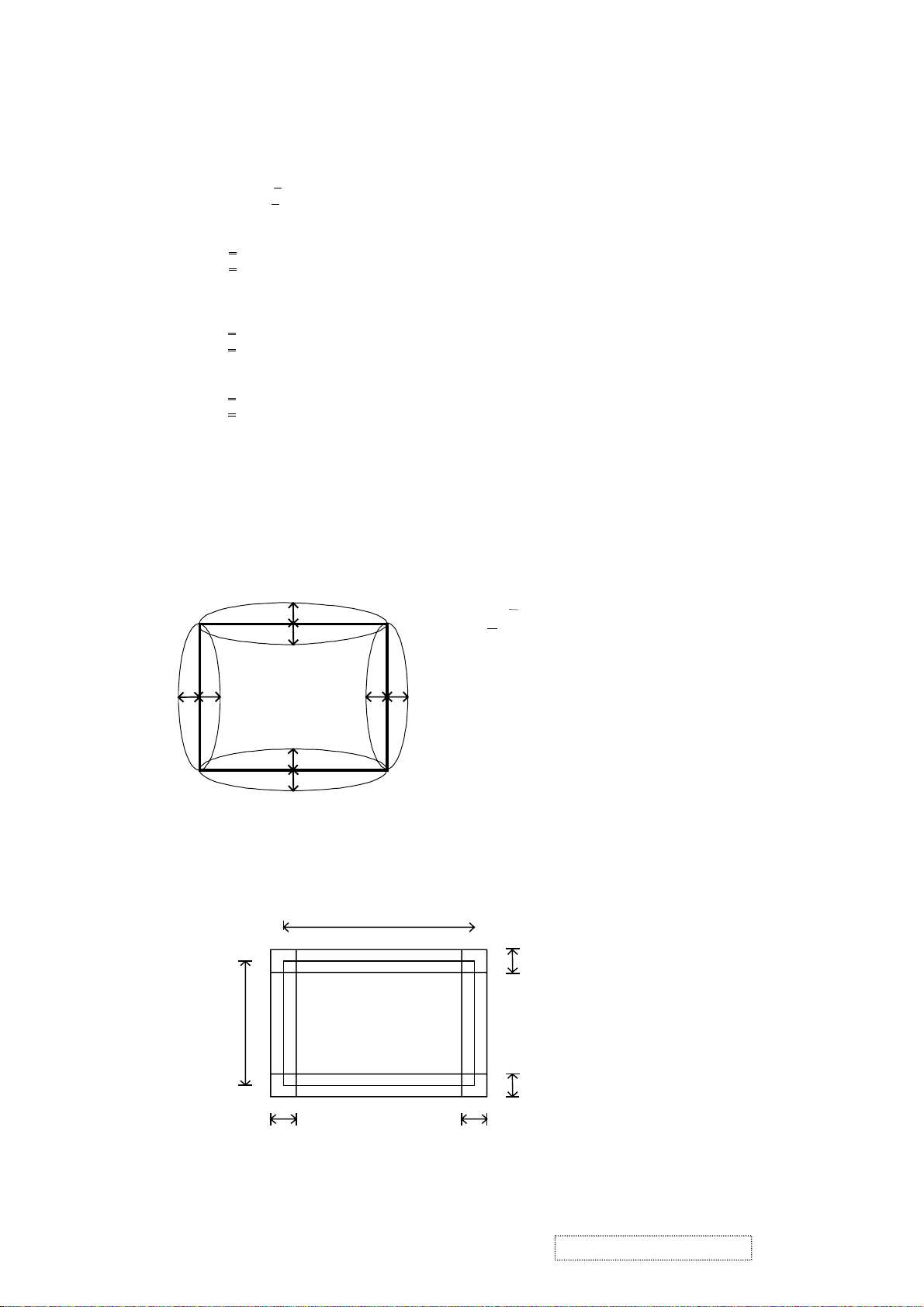

3. SIZE & GEOMETRY ADJUSTMENT

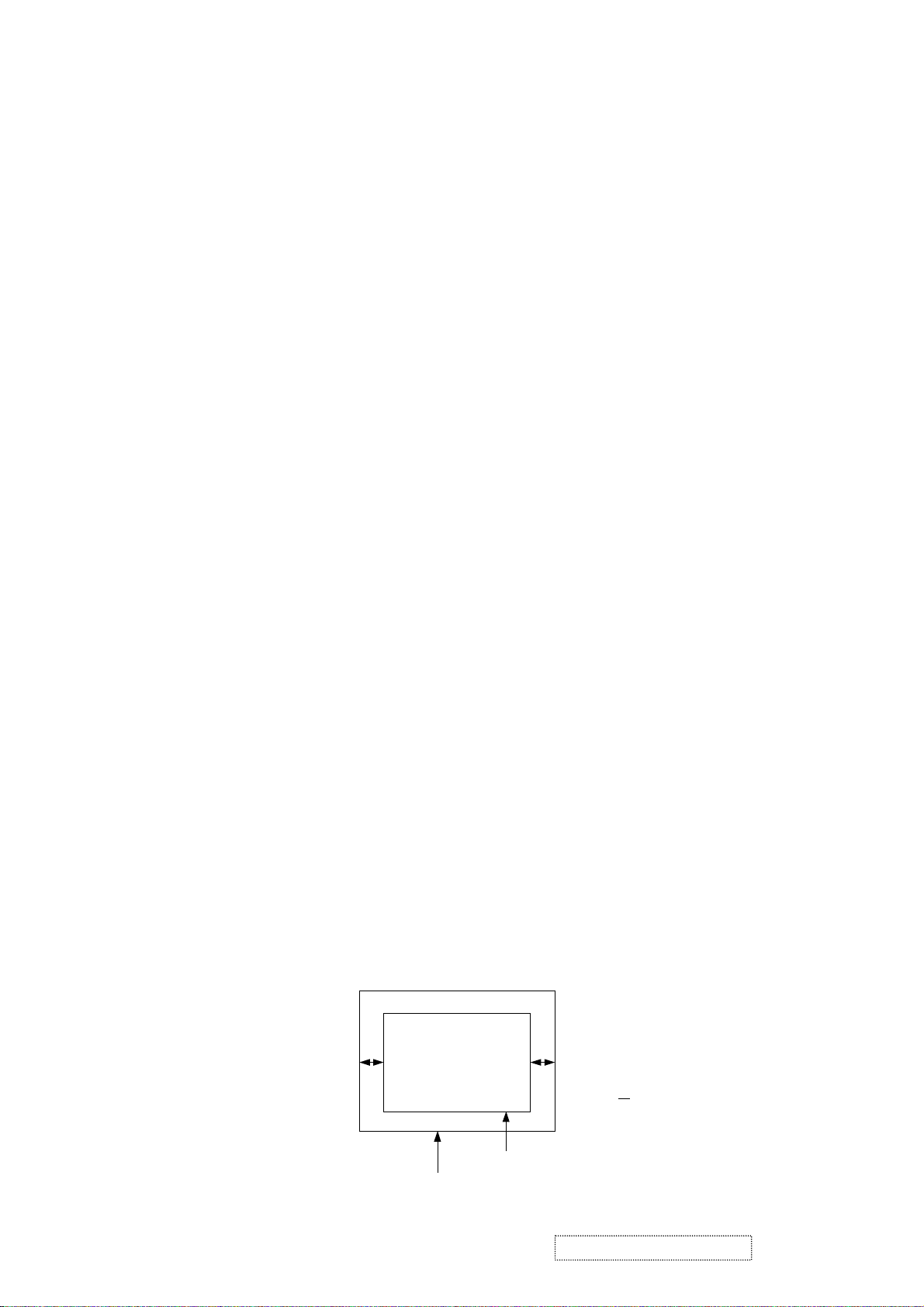

3.1 RASTER CENTERING

3.1.1 INPUT CROSSHATCH PATTERN AT 60KHZ 1024*768 MODE.

3.1.2 ADJUSTCONTRAST TO 10FL, ADJUST SCREEN JUST RASTER VISIBLE.

3.1.3 ADJUST VR401 TO CENTER RASTER ON SCREEN SUCH THAT THE HORIZONTAL DISTANCE

FORM THE MIDPOINT OF THE LEFT DISPLAY EDGE TO THE LEFT BEZEL EDGE IS WITHIN

2MM. OF THE DISTANCE FROM MIDPOINT OF THE RIGHT BEZEL EDGE.

A

B

I A-B I < 2mm

BEZEL

RASTER

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

3

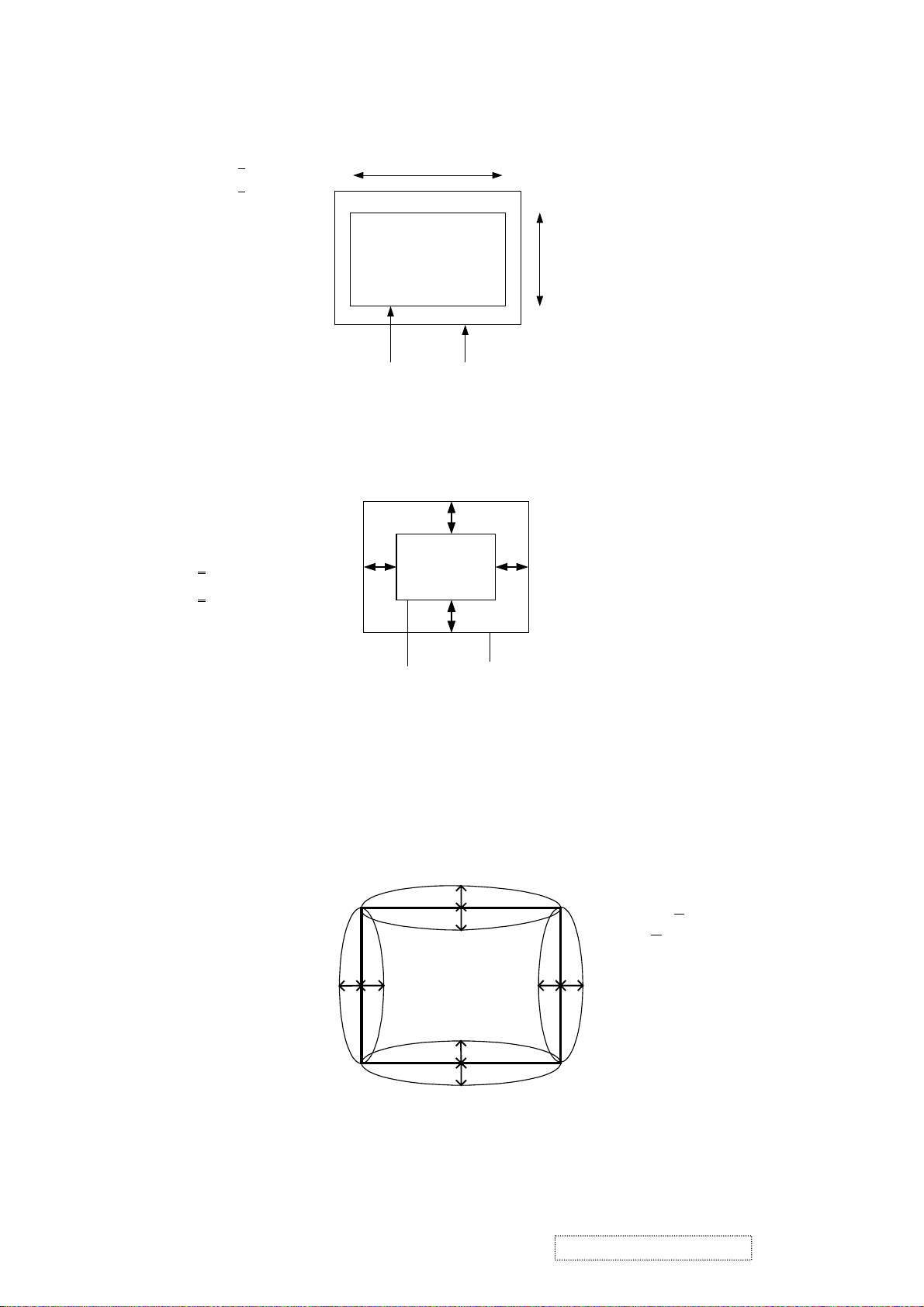

3.2 PICTURE SIZE

INPUT MODE 1-12 SIGNAL ADJUST V-SIZE, H-SIZE TO ACHIEVE.

H-SIZE: 310mm. +

2mm.

V-SIZE: 230mm. + 2mm.

3.3 PICTURE POSITION

INPUT MODE 1-12 ADJUST V-POSITION, H-POSITION SUCH THAT THE PICTURE IS CENTERED WITH THE

SCREEN

A – B I <

I

C – D I <

I

2mm.

2mm.

A

310mm

PICTURE

230mm

BEZEL

C

B

D

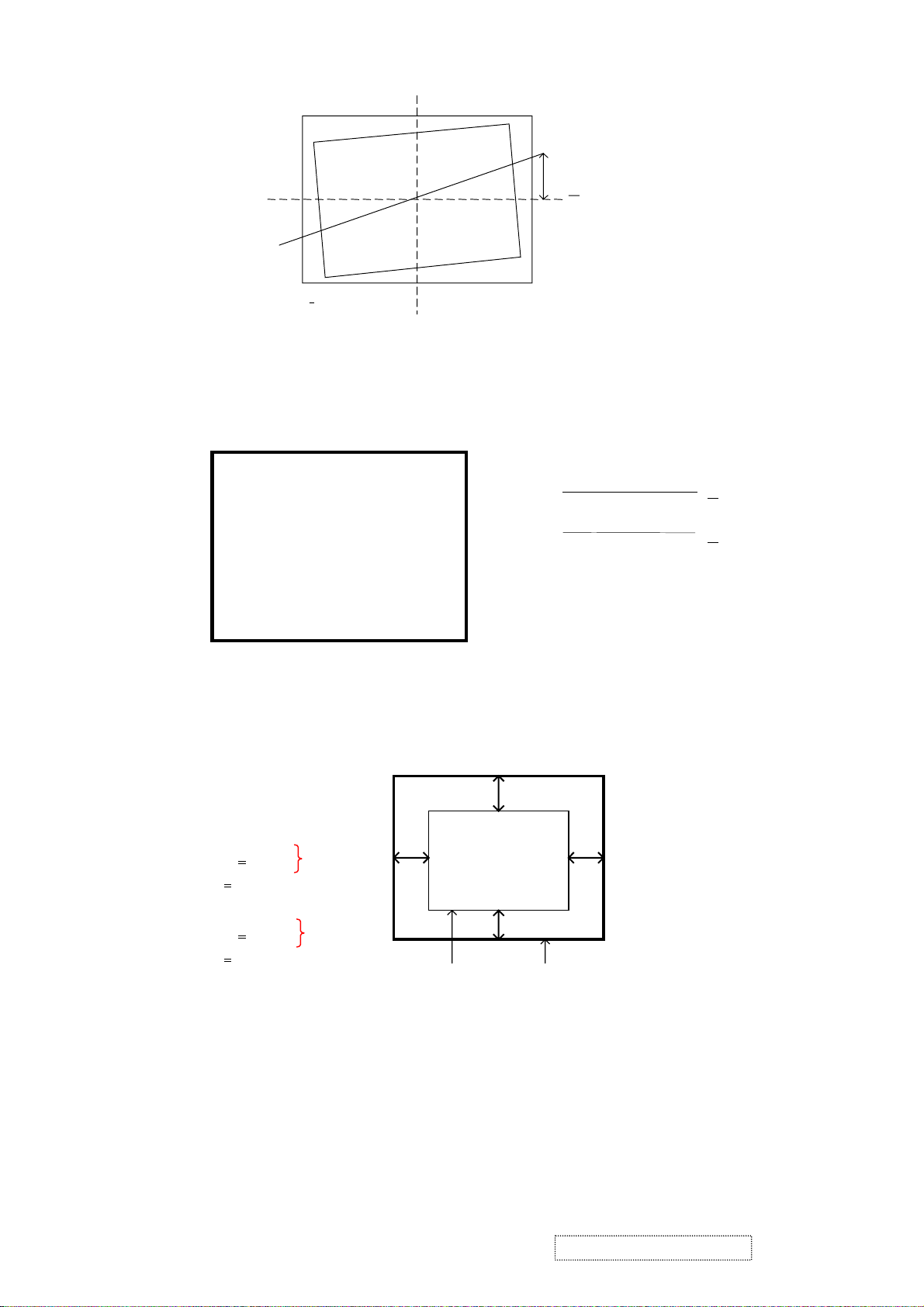

3.4 GEOMETRY ADJUSTMENT

3.4.1 INPUT MODE 1-12.

3.4.2 PINCUSHION AND BARREL DISORTION

A

PICTURE

C'

A' BB'

D'

BEZEL

C

D

PI N CU SION < 1 m m ( A ,B,C ,D)

BA RR EL < 1 m m ( A ,B ,C,D)

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

4

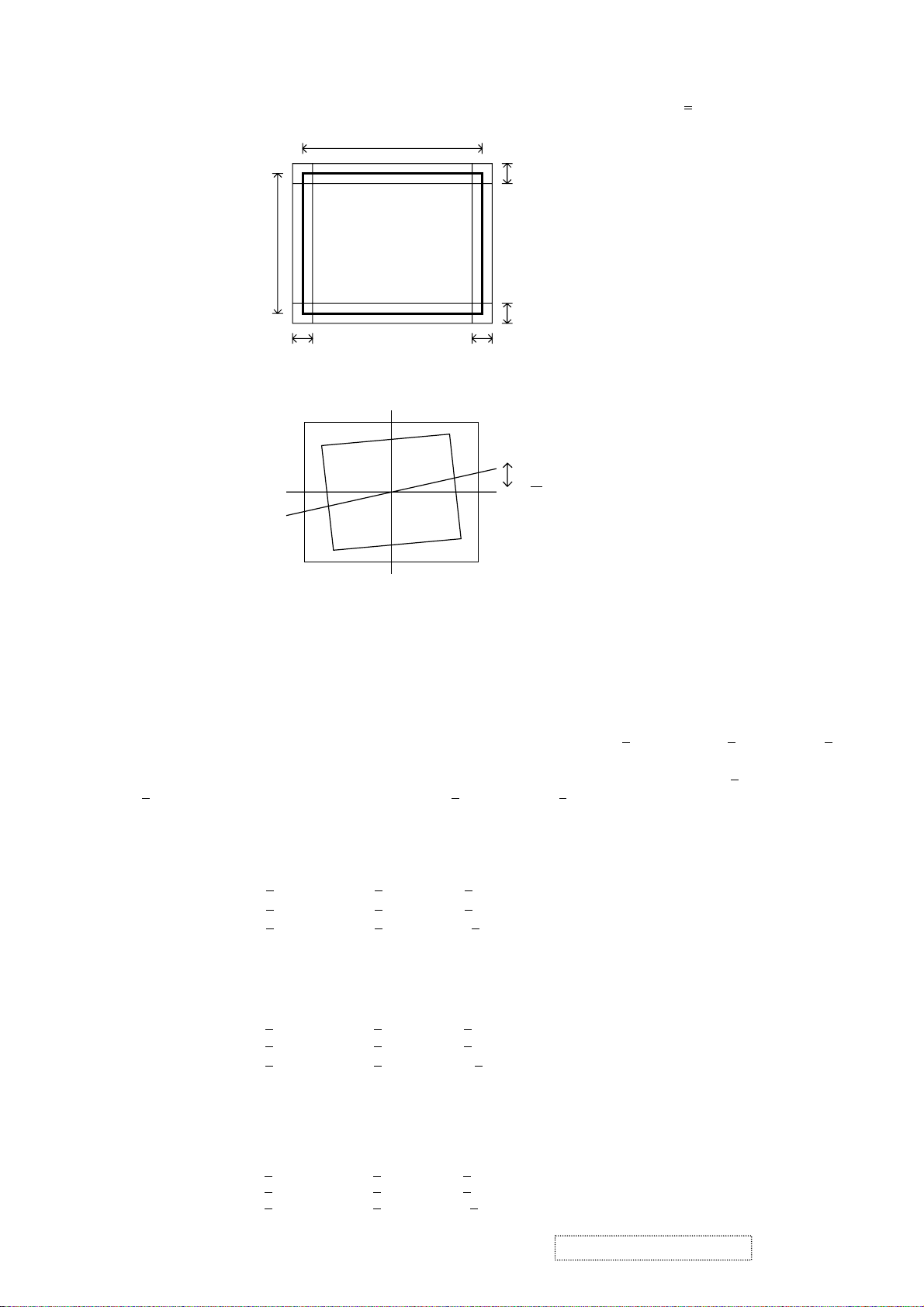

3.4.3 TRAPEZOID AND PARALLEOGRAM DISTROTION TRAPEZOID / PARALLEOGRAM < 1.5mm.

310mm

1.5mm

230mm

1.5mm

1.5mm1.5mm

3.4.4 ROTATE ADJUSTMENT

230mm

310mm

h < 1m m

4. VIDEO ALIGNMENT / FUNCTION MEMORY RECALL

4.1 INPUT 1024x768 69KHZ FULL BLACK PATTERNS.

4.2 SET CONTRAST 0%, BRIGTHNESS 100%, RGB CUT OFF 0%, RGB DRIVER 50%, TURN THE G2 (SCREEN) KNOB

TO OBTAIN RASTER LIGHT O/P ABOUT 0.25FL.

4.3 BASE ON x, y READING, FIX THE STRONG GUN CUT OFF TO 130, THEN ADJUST THE OTHER TWO GUN AND

SCREEN KNOB TO MEET FOLLOWING CHROMATICALLY 9300

0.2FL, STORE THE ADJUSTMENT OF 9300oK, THEN BASE ON x, y READING, FIX THE STRONG GUN AND G2,

ADJUST THE OTHER GUN TO MEET FOLLOWING CHROMATICALLY SPEC 6500

0.003, Y = DON’T CARE 5000OKÆ x = 0.346+ 0.003, y = 0.359 + 0.003, Y = DON’T CARE

+

O

KÆx =0.283 + 0.003, y =0.297 + 0.003, Y = 0.5 +

O

KÆ x = 0.313+ 0.003, y = 0.329

4.4 ADJUST BRIGHTNESS TO 50%, CONTRAST 100%

4.5 APPLY 70mm x 70mm GREEN WINDOW PATTERN, ADJUST G-DRIVER TO OBTAIN GREEN WINDOW PATTERN

LIGHT O/P ABOUT 30FL (9300OK)

APPLY WHITE WINDOW PATTERN, ADJUST R-DRIVER, B-DRIVER TO MEET FOLOWING CHROMATICALLY SPEC.

9300OKÆ x = 0.283 + 0.003, y = 0.297 + 0.003, Y = 45+ 2FL. For TEXT/SPREADSHEET mode

O

KÆ x = 0.283 +

9300

O

KÆ x = 0.283 + 0.003, y = 0.297 + 0.003, Y = 150+ 4FL. For VIDEO/MOVIE/DVD mode

9300

0.003, y = 0.297 + 0.003, Y = 85+ 3FL. For GRAPHIC/GAME mode

4.6 APPLY 70mm x 70mm GREEN WINDOW PATTERN, ADJUST G-DRIVER TO OBTAIN GREEN WINDOW PATTERN

LIGHT O/P ABOUT 30FL (6500OK)

4.7 APPLY WHITE WINDOW PATTERN, ADJUST R-DRIVER, B-DRIVER TO MEET FOLLOWING CHROMATICALLY

SPEC.

O

KÆ x = 0.313 + 0.003, y = 0.329 + 0.003, Y = 45+ 2FL For TEXT/SPREADSHEET mode

6500

O

6500

KÆ x = 0.313 + 0.003, y = 0.329 + 0.003, Y = 85+ 3FL For GRAPHICS/GAME mode

O

6500

KÆ x = 0.313 + 0.003, y = 0.329 + 0.003, Y = 130 + 4FL For VIDEO/MOVIE/DVD mode

4.8 APPLY 70mm x 70mm GREEN WINDOW PATTERN , ADJUST G-DRIVER TO OBTAIN GREEN WINDOW

PATTERN LIGHT O/P ABOUT 30FL (5000OK)

4.9 APPLY WHITE WINDOW PATTERN, ADJUST R-DRIVER,B-DRIVER TO MEET FOLLOWING

CHROMTICALLY SPEC

O

5000

5000

5000

KÆ x = 0.346 + 0.003, y = 0.359 + 0.003, Y = 45+ 2FL For TEXT/SPREADSHEET mode

O

KÆ x = 0.346 + 0.003, y = 0.359 + 0.003, Y = 85+ 3FL For GRAPHICS/GAME mode

O

KÆ x = 0.346 + 0.003, y = 0.359 + 0.003, Y = 130+ 4FL For VIDEO/MOVIE/DVD mode

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

5

4.10 APPLY FULL WHITE PATTERN

4.11 ADJUST OSD ABL TO OBTAIN LIGHT O/P = 30+1FL FOR ALL MODE

4.12 APPLY FULL WHITE PATTERN ADJUST CONTRAST FROM 30FL TO 10FL AND CHECK THE CHROMATICALLY

MEET FOLLOWING SPEC.

x (AT CONTRST, 30) –x (AT CONTRST, 25.75) I < 0.007.

I

y (AT CONTRST, 30) –y (AT CONTRST, 25.75) I < 0.003.

I

x (AT CONTRST, 10) –x (AT CONTRST, 25.75) I < 0.007.

I

y (AT CONTRST, 10) –y (AT CONTRST, 25.75) I < 0.006.

I

4.13 FUNCTION “ALL MODE RESET.

PUSH BUTTON “1” AND POWER SWITCH ON, THE PICTURE SHOULD RESTORE TO THAT OF FACTORY MODE.

4.14 USER COLOR MUST BE DEFAULTED AS 9300OK.

5. FOCUS ADJUSTMENT.

5.1 APPLY SIGNAL ALL “ME” PATTERN AT 1024*768 69K MODE.

5

.2 SET BRIGHTNESS 50% CONTRAST 100%.

5.3 SET FOCUST CONTROL FOR BEST FOCUS.

C. INSTRUMENT TEST

6. TEST PRESETS.

6.1 BRIGHTNESS SET 50%, CONTRST SET 100%.

6.2 INPUT FULL WHITE PATTERN.

6.3 WARM-UP - ALLOW 30 MINUTES WARM-UP PRIOR TO TEST.

7. POWER SUPPLY TEST

7.1 INPUT CHARACTERISTICS

7.1.1 INPUT VOLTAGE RANGE: 90V

7.1.2 INPUT FREQUENCY RANGE: 50HZ TO 60HZ.

7.1.3 MAX. INPUT AC CURRENT: 2A, LOW LINE INPUT, FULL LOAD.

7.1.4 INRUSH CURRENT: LESS THAN 30A FOR ½ CYCLE AT 110V, 50A FOR ½ CYCLE AT 240V, AT COLD

STRART.

7.1.5 EFFICIENCY: 70% MIN AT 110V LINE INPUT FULL LOAD.

7.2 OUTPUT CHARACTERISTICS:

7.2.1 STATIC OUTPUT CHARACTERISTICS:

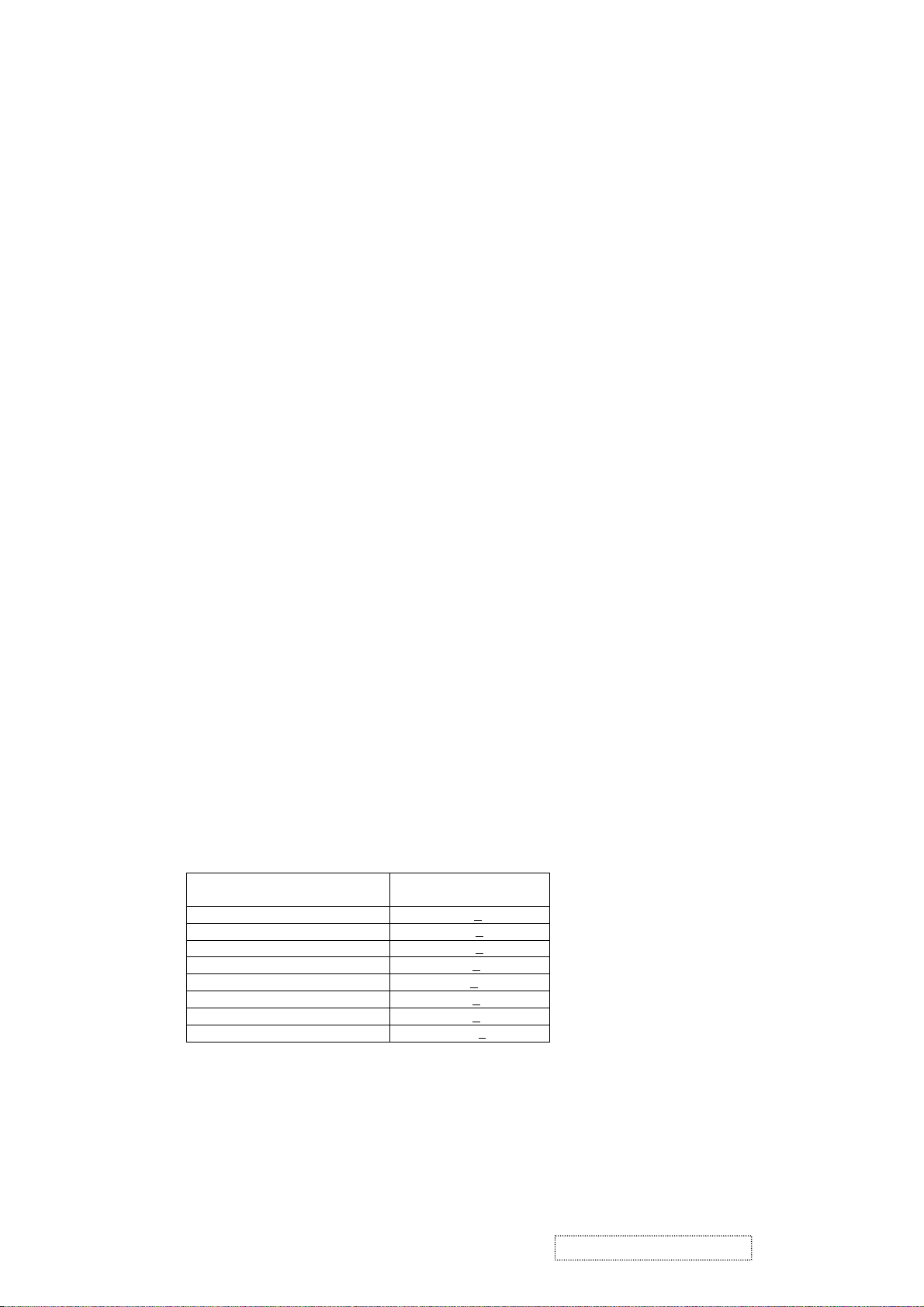

MEASUREMENT

POINT

TP201 105 V + 3%

TP202 46.5 V + 5%

TP203 13.5 V + 5%

TP204 7.5 V + 5%

TP205 12 V + 5%

TP206 6.3 V + 5%

TP207 5.5 V + 5%

TP208 -13.5 V + 5%

7.3 DIELECTRIC WITHSTAND VOLTAGE:

7.3.1 PRIMARY TO SECONDARY: 2545VDC

7.3.2 PRIMARY TO SAFETY GROUND: 2545VDC FOR 1 SEC.

7.3.3 LEAKAGE CURRENT: 0.75mA. MAXIMUM AT 110/220VAC

AC TO 264 VAC, SINGLE PHASE.

OUTPUT

VOLTAGE

FOR 1 SEC.

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

6

8. GEOMETRICAL TESTS

A

A

8.1 SIZE

8.1.1 APPLY FULL WHITE PATTERN AT ALL MODES.

8.1.2 PICTURE SIZE:

H-SIZE: 310mm +

V-SIZE: 230mm +

8.1.3 BRIGHTNESS ATABILITY

H-SIZE: <

V-SIZE: <

2mm.

2mm.

NOTE: MIN. LIGHT OUTPUT TO MAX. LIGHT OUTPUT.

8.1.4 AC POWER VOLTAGE STABILITY.

H-SIZE: <

V-SIZE: <

2mm

2mm

8.1.5 THERMAL STABILITY (SIZE VARIATION)

H-SIZE: <

V-SIZE: <

2mm.

2mm.

NOTE: TEMP. 0

8.2 GEOMETRY

8.2.1 APPLY SIGNAL D AT EACH MODE.

8.2.2 PINCUSION AND BARREL DISTROTION

3mm.

3mm.

o

C~ 40

o.

C

PINCUSION < 2mm (A,B,C,D)

BARREL < 1.5mm (A,B,C,D)

C'

'BB'

D'

D

8.2.3 TRAPEZOID AND PARALLOGRAM DISTROTION

310mm

230mm

2mm

2mm

2mm

2mm

TRAPEZOI D < 2 .0 mm ( A,B,C,D)

PARAL L ELOGRAM <2.0 mm ( A,B,C,D)

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

7

8.2.4 PICTURE TILT.

V

230mm

310mm

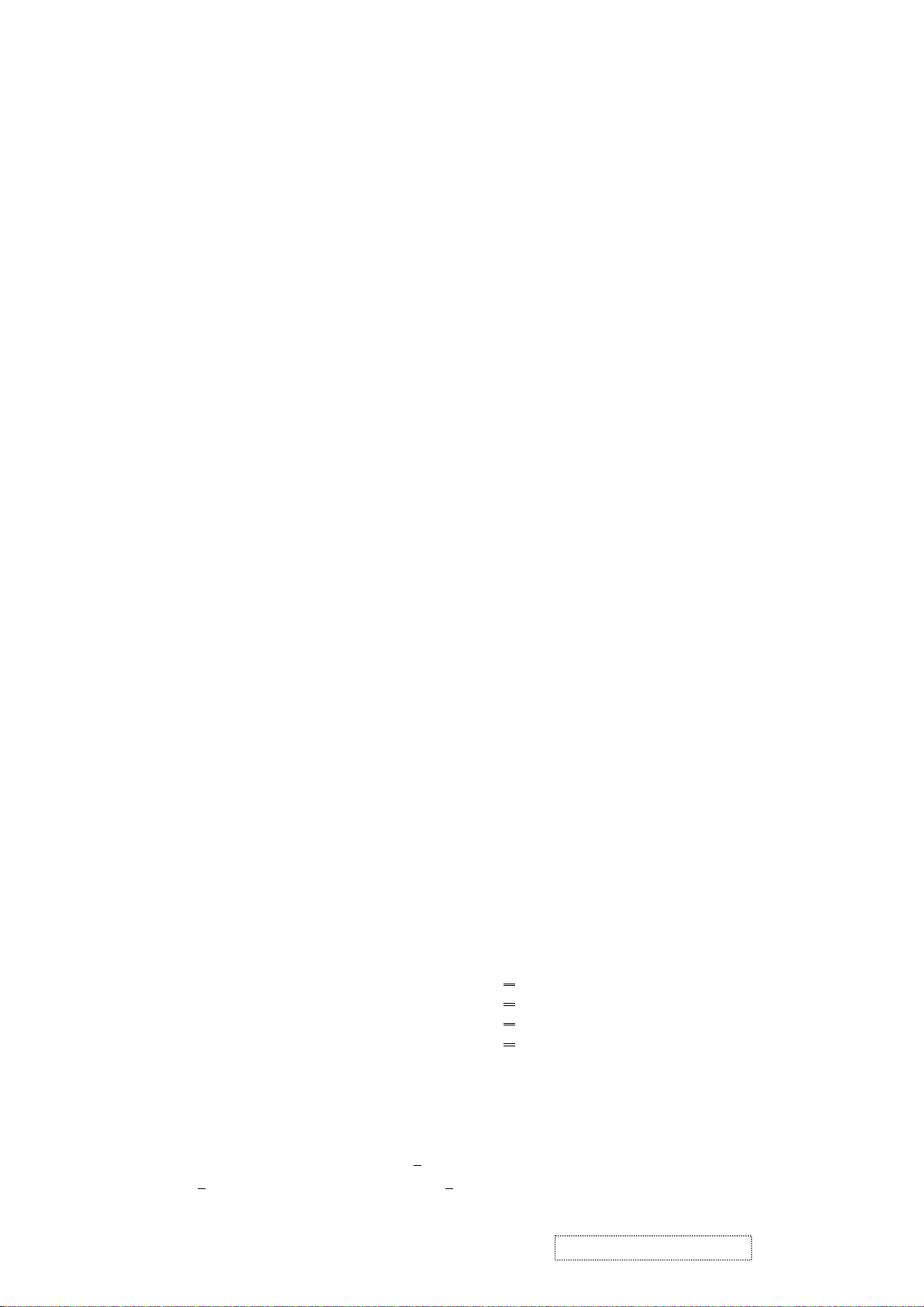

8.3 LINEARITY

APPLY SIGNAL D AT ALL MODE, INPUT CROSS-HATCH PATTERN

h<

2mm

8.4 CENTERING (WITH MAGNETIC FIELD)

8.4.1 APPLY SIGNAL D AT ALL MODES.

8.4.2 PICTURE POSITION

A – B I <

I

I C – D I <

A – B I <

I

I C – D I <

3mm.

3mm.

4mm.

4mm.

Prima

Other

H-Linearity: (Hmax-Hmin)*10 0%

(Hmax+Hmin)

-Linearity:

(Vmax-Vmin)*100%

+

C

A

D

PICTURE

B

BAZEL

<

Primary

4%

Primary

4%

<

5% Oth ers

d

9. HORIZONTAL SWEEP

9.1 PULL-IN RANGE

9.1.1 APPLY SIGNAL D WITH A HORIZONTAL FREQUENCY OF 30KHZ MODE, MONITOR MUST BE

9.1.2 APPLY SIGNAL D WITH A HORIZONTAL A HORIZONTAL FREQUENCY OF 70KHZ MODE,

MONITOR MUST BE IN SYNC.

IN SYNC.

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

8

10. VERTICAL SWEEP.

10.1 VERTICAL PULL-IN RANGE.

10.1.1 APPLY SIGNAL D MODE: VGA (CHG fv = 50Hz)

10.1.2 OBSERVE THAT PICTURE LOCKS UP IN SYNC.

10.1.3 APPLY SIGNAL D MODE: 69K (CHG fv = 160HZ), MONITOR MUST BE IN SYNC.

11. CRT VOLTAGES / REGULATION / POWER

11.1 FILAMENT MEASUREMENT

11.1.1 APPLY SIGNAL A (FLAT WHITE FIELD) AT VGA MODE.

11 1 2 SET CONTRAST TO 30 FLS AND BRIGHTNESS TO THRESHOLD OF RASTER

11.1.3 MEASURE HEATER VOLTAGE AT 6.3V AND VOLTAGE MUST BE 6.3 +

11.2 NORMAL HIGH VOLTAGE

11.2.1 APPLY SIGNAL A (FULL WHITE PATTERN) AT VGA MODE.

11.2.2 SET BRIGHTNESS 0%, CONTRAST 0%.

11.2.3 MEASURE HIGH VOLTAGE MUST BE 26 1KV.

11.2.4 APPLY SIGNAL A AT 69KHZ MODE

11.2.4. REPEAT STEP 11.2.2 THROUGH 11.2.3 THE HIGH VOLTAGE MEASURED MUST BE

11.3 HIGH VOLTAGE REGULATION

11.3.1 SET BRIGHTNESS 100%, CONTRAST 100%.

11.3.2 SET BEAM CURRENT TO MAXIMUM.

11.3.3 MEASURE HIGH VOLTAGE AT ANODE CAP.

11.3.4 SUBTRACT VALUE OBTAINED 11.3.3 FROM VALUE OBTAINED IN 11.2.3 THE RESULTS MUST BE

1.5KV MAXIMUM.

0.3V.

26 ± 1KV.

11.4 POWER CONSUMPTION

11.4.1 APPLY SIGNAL A (FULL WHITE FIELD) AT 69K MODE.

11.4.2 SET BRIGHTNESS 50%, CONTRAST 100%, PRESET SIZE.

11.4.3 POWER CONSUMPTION MUST BE LESS THAN 75WATTS.

12. CRT PARAMETERS

12.1 PURITY

12.1.1 INPUT FULL WHITE PATTERN AT 69KHZ MODE, SET BRIGHTNESS 50%,&CONTRAST 100% .

12.1.2 NO COLORED STAINS MAYBE VISIBLE WHEN APPLYING FULL WHITE PATTERN

12.2 DEGAUSSING

12.2.1 BEFORE SWITCHING ON THE DEGAUSSING , THE PTC101 MUST BE COLD, INTERNAL

DEGAUSSING MUST BE CAPABLE OF ACTIVATION 10 MINUTES OR LESS AFTER ANY PREVIIOUS

ACTIVATION.

12.2.2 APPLY THE SIGNAL WITH FULL WHITE PATTERN, REMOVE ALL MAGNETIC MATERIAL WITHIN

HALF A METER OF THE APPARATUS, THEN SWITCH ON THE DEGAUSSING, THE DEGAUSSING

SHOULD BE WELL.

12.3 CONVERGENCE

12.3.1 APPLY A CROSSHATC-HATCH SIGNAL. AT 69KHZ

12.3.2 WITH INSTRUMENT FACING EAST, CONVERGENCE WITHIN A CIRCLE EQUAL TO

THE DIAMETER OF THE VERTICAL HEIGHT MUST BE A ZONE 0.25mm, B ZONE 0.30mm C ZONE

0.35mm.

12.4 FOCUS

12.4.1 APPLY SIGNAL E (ALL “ ME “ PATTERN) AT 1024x768 85Hz MODE.

14.4.2 ADJUST CONTRAST FOR AN AREA OF LUMINANCE OF 28FL.

12.4.2 FOCUS MUST BE SET SUCH THAT INDIVIDUAL CHARACTER CAN BE DISTINGUISHED OVER

THE ENTIRE DISPLAY AREA.

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

9

12.5 MOIRE PATTERNING

12.5.1 FOCUS MUST BE ADJUSTED AS 12.4.

12.5.2 APPLY A FULL WHITE PATTERN SIGNAL.

12.5.3 ADJUST BRIGHTNESS CONTROL FOR A RASTER JUST AT THE THRESHOLD OF EXTINCTION.

12.5.4 AS THE CONTRAST CONTROL IS ROTATED TO ACHIEVE ANY DISPLAY INTENSITY

PRIMARY MODE: NO MOIRE PATTERN MAY BE VISIBLE.

OTHER MODE: A AREA ON MOIRE VISIBLE, B AREA HAS SLIGHT MOIRE.

12.6 BRIGHTNESS UNIFORMITY

12.6.1 APPLY A FLAT WHITE FIELD SIGNAL.AT 1024 * 768 85Hz MODE.

12.6.2 BRIGHTNESS VARIATION DUE TO CRT CHARACTERISTICS MUST BE MONOTONIC FROM THE

DISPLAY CENTER TO ANY DISPLAY EDGE, WITH THE DISPLAY CENTER AT 20 FEET LAMBENT

THE MAXIMUM CENTER TO CENTER LIGHT FALL OFF SHOULD BE NO MORE THAN 25% OF THE

AVERAGE OF THE FOUR CORNERS AND WITH NO ONE CORNER MORE THAN 25% LESS THAN

THAT OF THE CENTER .

12.7 ARCING CORONA

12.7.1 NO MORE THAN 2 ARCS ARE PERMITTED DURING AN 8 HOURS PERIOD OF NORMAL

OPERATION. INCLUDING ARCS INDUCED BY TURN-ON AND TURN-OFF.

12.7.2 NO ARCING OR CORONA MAY OCCUR BETWEEN METAL PARTS AT ANY TIME INCLUDING

TURN-ON AND TURN-OFF.

13. X-RAY PROTECTION TEST

13.1 SHUTDOWN CIRCUIT CHECKS.

13.1.1 INPUT VGA 31.5KHZ SIGNAL, PATTERN: SIGNAL A.

13.1.2 SET BRIGHTNESS 50%, CONTRAST 100%.

13.1.3 WHEN THE ZD405 PARALLEL WITH 27K RESISTOR, THE MOITOR MUST BE SHUTDOWN AND NO SPOT.

13.1.4 TURN POWER OFF, AFTER TURN ON AGAIN, MONITOR MUST BE OPERATED NORMAL.

AT 12 FL

NOTE: THIS TEST MUST BE PERFORMED ON ALL SETS BEFORE THE BACKCOVER IS INSTALLED.

14. VIDEO TEST

14.1 WHITE BALANCE CHORMATICITY & COLOR TRACKING & AVERAGE LIGHT O/P

(TEXT/SPEADSHEET MODE)

14.1.1 APPLY SIGNAL 69KHz/ 85KHz, PATTERN: FULL WHITE PATTERN.

14.1.2 SET BRIGHTNESS 50%, CONTRAST 100%

6500°Ko x = 0.313 ± 0.012; y = 0.329 ± 0.012

5000°Ko x = 0.349 ± 0.012; y = 0.359 ± 0.012

| x (AT CONTRAST, 30) – x (AT CONTRAST, 25.75) |

| x (AT CONTRAST, 25.75) – x (AT CONTRAST, 10) |

14.2 CONTRAST RANGE

14.1 .3 SET ULTRABRITE FUNCTION TO TEXT/SPEADSHEET MODE.

14.1.3 COLOR TEMPERATURE MUST BE:

9300°Ko x = 0.283 ± 0.012; y = 0.297 ± 0.012

14.1.4 LIGHT OUTPUT MUST BE BETWEEN 28-32 FL.

14.1.5 COLOR TRACKING ERROR ( ONLY 9300°K )

14.1.6 APPLY FULL WHITE PATTERN ADJUST CONTRAST FROM 30FL TO 10FL AND CHECK THE

CHROMATICALLY MEET FLOWING SPEC.

| y (AT CONTRAST, 30) – y (AT CONTRAST, 25.75) |

| y (AT CONTRAST, 25.75) – y (AT CONTRAST, 10) |

14.2.1 APPLY SIGNAL 69KHZ/ 85Hz, PATTERN: 70x70mm WINDOW BLOCK.

14.2.2 SET BRIGHTNESS 50%.

o

14.2.3 SET COLOR TEMPERATURE 9300

14.2.4 WITH CONTRAST AT MAXIMUM, 45 +

85+5 FL FOR GRAPHICS/GAME MODE 150+5 FL FOR VIDEO/MOVIE/DVD MODE

K

3FL FOR TEXT SPREADSHEET MODE

0.007.

0.003.

0.007.

0.006.

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

10

14.3 BRIGHTNESS RANGE

14.3.1 NO VIDEO INPUT, SET CONTRAST 0%, BRIGHTNESS 100%

14.3.2 RASTER LIGHT O/P 0.3 –0.8FL.

14.4 LUMINANCE LINEARITY

14.4.1 APPLY SIGNAL B MODE: VGA480.

14.4.2 SET BRIGHTNESS TO THRESOLD OF RASTER EXTINCTION.

14.4.3 ALL STAIRSTEPS MUST BE DISCERNIBLE FROM EACH OTHER FOR ANY CONTRAST SETTING

WHERE THE BRIGHTEST BAR IS VARIED BETWEEN 5 TO 20 FL BY ADJUST CONTRAST CONTROL.

14.5 TEMPERATURE STABILITY

14.5.1 APPLY SIGNAL A MODE: VGA480.

14.5.2 SET BRIGHTNESS TO THRESHOLD OF RASTER EXTINCTION AND CONTRAST TO PRODUCE 25FL AT

o

C.

25

14.5.3 LUMINANCE MUST NOT CHANGE MORE THAN 5FL OVER A TEMPERATURE RANGE

OF 10

o

14.6 BANDWIDTH RESOLUTION

14.6.1 APPLY SIGNAL D MODE: 69KHZ / 85HZ.

14.6.2 OBSERVE THAT VERTICAL LINES AND HORIZONTAL LINES WHILE SET BRIGHTNESS CONTROL AT

DETECT POSITION AND CONTRAST CONTROL AT ANY SETTING.

14.7 VIDEO RISE TIME / FALL TIME.

14.7.1 INPUT FULL WHITE PATTERN AT 69KHz/85Hz

14.7.2 MEASURE VIDEO RISE & FALL TIMES AT EACH CATHODE WITH A LOW CAPACITANCE 100X PROBE

AND 150MHZ MINIMUM BW OSCILLOSCOPE.

14.7.3 ADJUST CONTRAST TO CATHODE OUTPUT 40V.

14.7.4 RISE AND FALL TIMES MUST BE AS FOLLOWS: 10% TO 90% <

8.5 ns.

C TO 40oC.

15. FACTORY PRESET:

15.1 BURN-IN MODE CANCELLATION:

TO PUSH “

AND SYNC INPUT IN ORDER TO LET MONITOR POWER ON, MEANWHILE WITH RELEASEING “

” AND “ ” KEY FIRST, AND THEN PUSH POWER SWITCH WITHOUT RELEASE “ ” AND “ ” KEY

” AND “ ”KEY,

BURN-IN MODE WILL BE CANCELLED.

15.2 CONTRAST: 100

15.3 BRIGHTNESS: 50

o

15.4 COLOR: 9300

K

15.5 POWER SWITCH: POWER OFF

16. POWER MANAGEMENT TESTS.

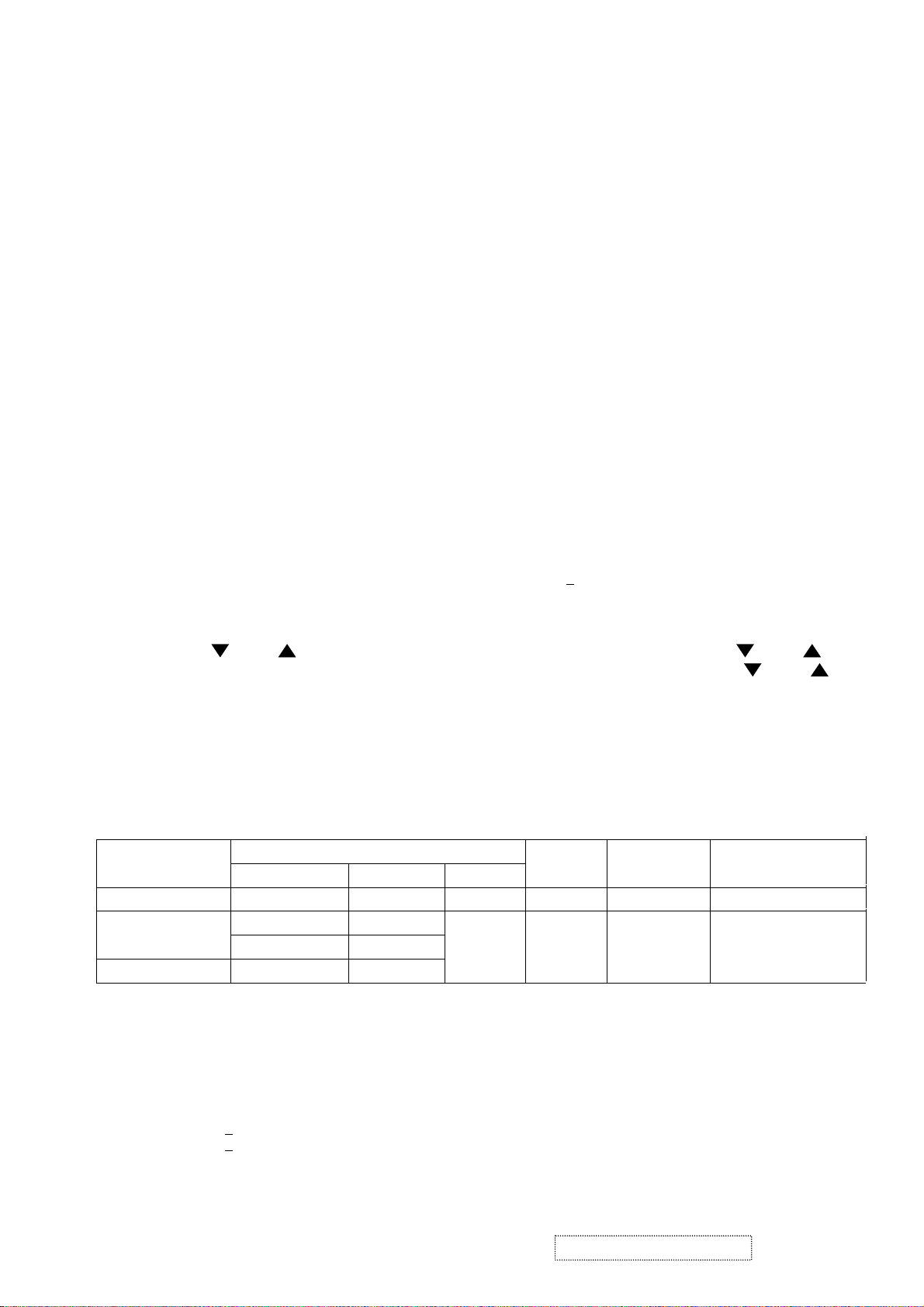

16.1 POWER CONSUMPTIONS TEST TABLE:

MODE

SYNC PULSE

HORIZONTAL VERTICAL VIDEO

POWER LED RECOVERY TIME

(SEC)

NORMAL ON YES YES YES <75w GREEN -

POWER SAVING

NO YES

YES NO

BLANK

<5w AMBER <10

POWER SAVING NO NO

17. AUTO SIZING FUNCTION

17.1 INPUT ALL USER MODE AND CROSS PATTERN

17.2 PRESS THE AUTO SIZING KEY , THE PICTURE WILL BE MUTE AROUND 2~4 sec , THEN PICTURE WILL BE IN THE

CENTER OF THE MONITOR AND PICTURE CAN’T OVER THE FRONT BEZEL.

17.3 The PICTURE SIZE ARE AS FOLLOWING :

H-SIZE : 310 +

V-SIZE : 230 +

5 mm

5 mm

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

11

17.4 THE PICTURE POSITION ARE AS FOLLOWING .

A-B ~d 10mm

~

C-D ~d 10mm

~

A

PICTURE

C

B

D

BAZEL

17.5 INPUT ALL PRESET MODE AND CROSS PATTERN,

17.6 PRESS THE AUTO SIZING KEY, THE PICTURE WILL BE MUTE AROUND 1~2 sec , THEN PICTURE WILL BE IN THE

PRESET CONDITION ( SAME AS RECALL )

17.7 DIAGNOSTIC MESSAGE TEST.

17.7.1 AS 10KHZ <H <29KHZ OR H >73KHZ ; And 30HZ <V <48HZ OR V>160HZ.

THE OSD SHOW:

17.7.2 AS NO H-SYNC (H<10KHZ).

17.7.3 AS NO V-SYNC (V<10KHZ).

17.7.4 AS NO H-SYNC AND V-SYNC (H<10 AND V<10KHZ).

17.7.5 AS DISCONNECTED SIGNAL CABLE OR PC IS OFF.

THE OSD SHOW:

After 20 seconds

18. DDC TEST: CONNECTS SIGNAL CABLE INTO DDC TESTER TO PROGRAM EDID DATA SAVED IN IC303

18.1 THE EDID DATA SAVED IN IC302 SHOULD BE SAME AS SPECIFIED IN APPENDIX-D

18.2 EACH PRODUCTION UNIT SHOULD HAVE IT’S OWN SERIAL NEMBER, WEEK OF MANUFACTURE.

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

12

19. X-RAY RADIATION TEST.

19.1 NORMAL HIGH VOLTAGE

19.1.1 APPLY FULL BLACK PATTERN AT 640x480/ 60HZ MODE.

19.1.2 SET CONTRAST 0%, BRIGHTNESS 0%.

19.1.3 MEASURE HIGH VOLTAGE MUST BE 26KV +

19.1.4 APPLY FULL BLACK PATTERN AT 1024x768 / 85HZ MODE.

19.1.5 REPEAT STEP 19.1.3

19.2 HIGH VOLTAGE REGULATION

19.2.1 APPLY FULL WHITE PATTERN AT 1024x768/ 85HZ MODE.

19.2.2 SET CONTRAST 100%, BRIGHTNESS 100%, MEASURE HV.

19.2.3 SET CONTRAST 0%, BRIGHTNESS 0%, MEASURE HV.

19.2.4 COMPARE THE DIFFERENCE BETWEEN ITEM 19.2.2. & 19.2.3, THE VOLTAGE REGULATION

SHOULD BE LESS THAN 1.5KV.

19.3 HOLD-DOWN TEST

19.3.1 APPLY FULL BLCAK PATTERN AT 640x480/ 60HZ MODE.

19.3.2 SET CONTRAST 100%, BRIGHTNESS 50%.

19.3.3 ZD405 IS PARALLELED WITH 27K RESISTOR, THE MONITOR MUST BE SHUTDOWN.

19.3.4 TURN OFF, REMOVE PARALLELED RESISTOR, THEN TURN ON AGAIN, MONITOR MUST

BE OPERATED NORMALLY.

19.4 FAULT TEST.

19.4.1 APPLY FULL WHITE PATTERN AT 1024x768/ 85HZ MODE.

19.4.2 SET CONTRAST 0%, BRIGHTNESS 50%.

19.4.3 ADJUST VR403 TO MAXIMUM POSITION.

19.4.4 ADJUST FBT SCREEN VR, LET BEAM CURRENT BE 9uA, MEASURING THE H.V AND

X-RADIATION.

19.4.5 THE H.V. SHOULD BE UNDER 29KV AND X-RADIATION SHALL BE LESS THAN 0.1Mr/HR.

19.4.6 THE NORMAL ADJUST SHOULD BE RECOVERED AFTER THIS TEST IS FINISHED.

1KV.

19.5 X-RAY RADIATION TEST.

19.5.1 TO SIMULATE S-RAY PROTECTION CIRCUIT: USE 18K, 5% RESISTOR TO PARALLED WITH

19.5.2 CONTROL VR403 TO SET AT MINIMUM POINT.

19.5.3 APPLY FULL WHITE PATTERN AT 1024x768/ 85HZ MODE.

19.5.4 ADJUST CONTRAST/BRIGHTNESS SETTING BACK AND FROTH TO GET A BEAM CURRENT

AT 50uA, 200uA, 400uA RESPECTIVELY.

19.5.5 ADJUST VR403 TO GET H.V. GRADUALLY UNIT THIS TESED SET IS AT THE THERSHOLD

OF SHUTDOWN BUT STILL WORKING.

19.5.6 RECORD THE HIG VOLTAGE OF THERSHOLD AT 50uA, 400uA, THE H.V. SHALL BE LESS

THAN 31KV.

19.5.7 USE TVX-1A/ 1B/ 2000 AND RF/D TO MEASURE THE X-RADIATION AT THE POSITION OF

TOP, BOTTOM, RIGHT, LEFT, FRONT AND BACK SIDE OF THE MONITOR, THEN WRITE

DOWN THE READINGS AT EACH SIDE OF THE TESED UNIT.

19.5.8 THE X-RAY RADIATION SHALL BE LESS THAN 0.1Mr/hr.

19.5.9 THE NORMAL CONDITION SHOULD BE RECOVERED AFTER ALL TEST ITEMS ARE

FINISHED.

D: CHASSIS ALIGNMENT / TEST SPECIFICATION.

1. POWER SUPPLY ALIGNMENT: INPUT SIGNAL: VGA480 CROSS-HATCH PATTERN/

1.1 ADJUST VR101 UNTIL DC=75V0.3V AT TP201

1.2 ADJ VR403 UNTIL VOLTAGE AT TP208 = 63.0V 0.3V.

2. MEASURE

TP201 = 105 V ± 5%

TP202 = 46.5 V ± 5%

TP203 = 13.5 V ± 5%

TP204 = 7.5 V ± 5%

TP205 = 12 V ± 5%

TP206 = 6.3 V ± 5%

TP207 = 5.5 V ± 5%

TP208 =-13.5 V ± 5%

R476

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

13

3. VIDEO BOARD FUNCTION TEST & PRE-ALIGNMENT.

3.1 INPUT SIGNAL: 10.24x768 75HZ.

3.1.1 PUSH R.G.B BIAS BOTTOMS, OBSERVE THAT THE RASTER MUST CHANGE WITH COLOR R.G.B

RESPECTIVELY.

3.1.2 PUSH R.G.B DRIVE BOTTOMS, OBSERVE THAT THE ACTIVE MUST CHANGE WITH COLOR R.G.B

RESPECTIVELY.

3.2 CONTRAST & BRIGHTNESS

3.2.1 PUSH KEY “ ” TO DISPLAY BRIGHTNESS OR PUSH KEY “ ” TO DISPLAY CONTRAST ICON ON

3.2.2 PUSH “MENU: KEY SELECTION CONTRAST AND BRIGHTNESS.

3.2.3 PUSH KEY “ ” OR“ ”KEY CHECK CONTRAST AND BRIGHTNESS FUNCTION.

4. MAIN BOARD FUCTION TEST

4.1 BASIC FUNCTION

4.1.1 PUSH “MENU”KEY, SELCT H-SIZE, H-POSITION, V-SIZE, V-POSITION, ZOOM

4.1.2 PUSH KEY “

4.2 GEOMETRY FUNCTION CHECK

4.2.1 PUSH “MENU” KEY, SELECTION PINCUSHION, PINBALANCE, TRAPESOID, PARALLELOGRAM & ROTATE

FUNCTION.

4.2.2 PUSH KEY “

ROTATE FUNCTION.

4.3 HV TEST

4.3.1 HV MEASURE AT VGA MODE SHOULD BE 26 +

4.3.2 HV MEASURE AT 60K MODE SHOULD BE 26 +

” OR“ ”KEY RECHECK H-SIZE, H-POSITION, V-SIZE, V-POSITION, ZOOM

” OR“ ”KEY CHECK PINCUSHION, PINBALANCE, TRAPEZOID, PARALLELOGRAM &

OSD.

1KV AT MAX. BEAM

1KV AT MAX. BEAM

4.4 X-RAY PROTECTION TEST

4.4.1 WHEN THE R455 PARALLEL WITH 27K RESISTOR, THE MONITOR MUST BE SHUTDOWN AND NO SPOT

4.4.2 TURN POWER OFF, AFTER TURN ON AGAIN, MONITOR MUST BE OPERATED NORMAL

E. RELIABILITY SPECIFICATION:

1. ENVIRONMENT TEST.

1.1 TEMPERATURE:

OPERATING: 0

STORAGE: -40

1.2 HUMIDITY:

OPERATING: 5% TO 95% RELATIVE HUMIDITY (NON-CONDENSING)

STORAGE: 5% TO 95% RELATIVE HUMIDITY (NON-CONDENSING)

1.3 ALTITUDE:

OPERATING: -400METERS TO +3000 METERS.

STORAGE : -400 METERS TO +12000METERS.

2. TRASPORTATION TEST.

2.1 VIBRATION: THE UNIT SHALL BE DESIGNED TO SURVIVE THE FOLLOWING VIBRATION TEST.

VIBRATION FREQUENCY : 5~250Hz.

ACCELERATION : 1.0G.

SWEEP TIME : 1OCT/MIN.

TEST TIME : 60MIN PER AXIS.

2.2 DROP TEST: THIS TEST EVALUATES THE UNIT AGAINST THE AFFECT OF DROPS ENCOUNTERED DURING THE

PROCESS OF TRANSPORTATION.

2.2.1 DROP SEQUENCE.

A. BOTTOM CORNER.

B. THE TREE RADIATING EDGES FROM THAT CORNER.

C. SIX FLAT SURFACES OF THE PACKAGE.

2.2.2 DROP HEIGHT: 76.2CM.

2.2.3 ACCEPTANCE CRITERIA

THE MONITOR SHALL HAVE NO DEGRADATION IN MECHANICAL OR FUNCTION PERFORMANCE ERROE

AFTER BEGIN SUBJECTED THERE TESTS.

o

C to 40oC (OUTSIDE OF ENCLOSURE)

o

c to 60oC.

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

14

3. ELECTRONIC DISCHARGE (E.S.D).

3.1 AIR DISCHARGE:

15KV: NO UNRECOVERABLE DAMAGE IS ALLOWED.

3.2 CONTROL DISCHARGE:

9KV: NO UNRECOVERABLE DAMAGE IS ALLOWED.

4. ARCING TEST.

A DIRECT PATH TO THE EXTERNAL AQUADAG GROUND FOR CRT ARCING CURRENTS SHALL BE PROVIDEED THROUGH

SPARK GAPS OR ALTERNATE DEVICE SUCH THAT NO DAMAGE OCCURS TO THE CRT OR THE MONITOR CIRCUITRY.

5. POWER LINE DISTURDANCE (P.L.D).

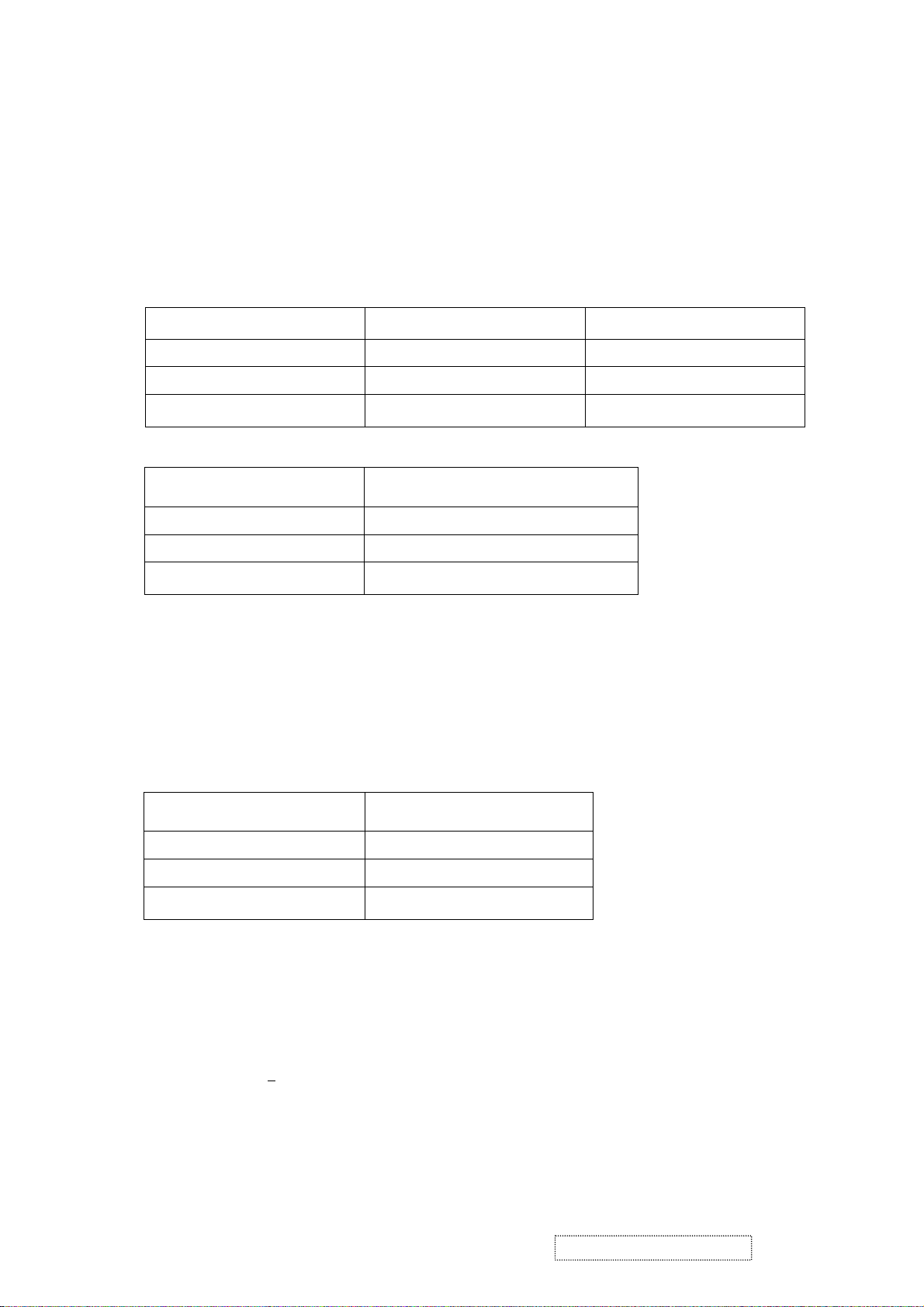

THE UNIT SHALL NOT COMPONENTS FAILURES OR FUNCTION ERROR UNDER THE FOOLOWING CONDITIONS.

TEST#1

FLUCTUATION RANGE NOMINAL LINE –30% NOMINAL LINE-100%

FLUCTUATION TIEM 3 CYCLES 1 CYCLES

INTERVAL 100 CYCLES 100 CYCLES

TEST PERIOD 5 CYCLES 5 CYCLES

TEST#2

FLUCTUATION RANGE NOMINAL LINE –15%/ -15%

FLUCTUATION TIEM 1 MINUTE

INTERVAL 1 MINUTE

TEST PERIOD 10 MINUTES.

NO. SIGN OF FAULTS OR MALFUNCTIONS SHALL BE OBSERVED UNDER THE ABOVE TEST CONDITIONS.

5.1 AC LINE NOISE TEST.

THE TEST EVALUATES THE OPERATION OF THE AGAINST AC LINE VOLTAGE.

5.1.1 TEST EQUIPMENT

A. AC LINE NOISE SIMULATOR (INS-410).

B. ISOLATION TRANSFORMER.

5.1.2 TEST METHOD.

APPLIED VOLTAGE + 1KV

PULSE WIDTH 50ns, 100ns, 400ns, 800ns

APPLIED PHASE 0 360 VIBRABLE

APPLIED TIME 1 MINUTE

NO SIGN OFF FAULTS OR MALFUNCTIONS SHALL BE OBSERVED.

6. RELIABILITY

THE MEAN TIME BETWEEN FAILURE (MTBF) WILL BE GREATER THAN 20000 HOURS WHEN OPERATION A

TEMPERATURE OF 25

O

C CALCUTION SHALL BE PER MIL-HDBK-217F WITH GROUND BEGIN.

7. BURN-IN

A> AC LINE: 110V/ 60HZ OR 230V / 50HZ.

B> TEMPERATURE: 25 +

C> BRUN-IN TIME: 24 HOURS.

5OC.

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

15

F. REGULATORY REQUIREMENT:

1. SAFETY

1.1 UL

THE MONITOR SHALL BE APPROVED TO UL STANDARD UL1950.

1.2 CSA

THE MONITOR SHALL BE CERTIFIED TO CSA STANDARD CSA-CS22.2. NO.950.

1.2 TUV: 60950

1.3 IEC STANDARD: IEC60950

1.4 THE MONITOR SHALL MEET THE REQUIREMENTS AS FOLLOWS:

A) FCC RULES PART 15 SUBPART J FOR CLASS B.

B) CE: EN55022, EN55024

1.5 ERGONMICS

A) MPRII.

B) TUV/GS.

C) TCO99 (OPTION).

1.6 DIELECTRIC STRENGTH TEST:

THE MONITOR SHALL WITHSTAND A 2545 VDC / 3 SEC.

BETWEEN PRIMARY AND SECONDARY.

BETWEEN PRIMARY AND PROTECTIVE EARTHLING.

1.7 LEAKAGE CURRENT:

THE MAXIMUM CURRENT FLOWING IN THE FRAME / GROUND CONDUCTOR SHALL BE LESS THAN 0.75mA AT

110 / 240

VAC.

1.8 X-RADIATION:

ALL MONITORS MUST COMPLY WITH THE DHHS REGULATIONS CONCERNING X- RADIATION. THAT IS A

FAILURE CONDITION MUST BE SIMULATED THAT WOULD PRODUCE THE WORST CASE X-RAYS SHOULD NOT

MEASURE MORE THAN 0.5 MR / HR (MILLIRONTGEN PER HOUR) AT A DISTANCE OF TWO-INCHES ANYWHERE,

AROUND THE MONITOR.

G. APPENDIX:

APPEDNDIX A:

ALL SIGNALS MUST BE AVAILABLE WITH CHROMA 2135, 2250.

SIGNAL A FULL WHITE PATTERN.

SIGNAL B STAIRSTEP: 16 GRAY LEVELS INCLUDING BLACK AND WHITE ASCENDING FROM LEFT TO RIGHT IN

EQUAL PIXEL WIDTHS.

SIGNAL C COLOR BARS: EIGHT 100 PIXEL WIDE BARS.

SIGNAL D CROSSHATCH: 12 * 16 SQUARES.

SIGNAL E ACTIVE DISPLAY CONTAINS ALL CHARATERS “ME” ON WHITE BACKGROUND.

SIGNAL F 70mm x 70mm FIELD OF WHITE CENTERED IN THE MIDDLE OF THE SCREEN.

APPENDIX B:

TIMING OF INPUT SIGNALS. INPUT LEVEL SPECIFICATION.

A.INPUT LEVEL

ANALOG VIDEO

R.G.B: 0.7V ± 3DB

COMPOSITE SYNC

LOW (0) 0.00V MIN. 0.65V MAX.

HIGH (1) 2.40V MIN. 5.50V MAX

!

APPENDIX C: MAGNETIC FIELD

!

! !!!!!OPSUI!BNFSJDB!!!;!CI!>!361!,

EUROPE :BH=250+

ASIA :BH=400+

AUSTRALIA : BH = 270 +

CHINADOMESTIC :BH=340+

10MG, BV = 270 + 10 MG.

!21NH-!CW!>!561!,!21!NH/!

10MG, BV = 450 + 10 MG.

10MG, BV = -570 + 10 MG.

10MG, BV = 360 + 10 MG.

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

16

APPENDIX D:

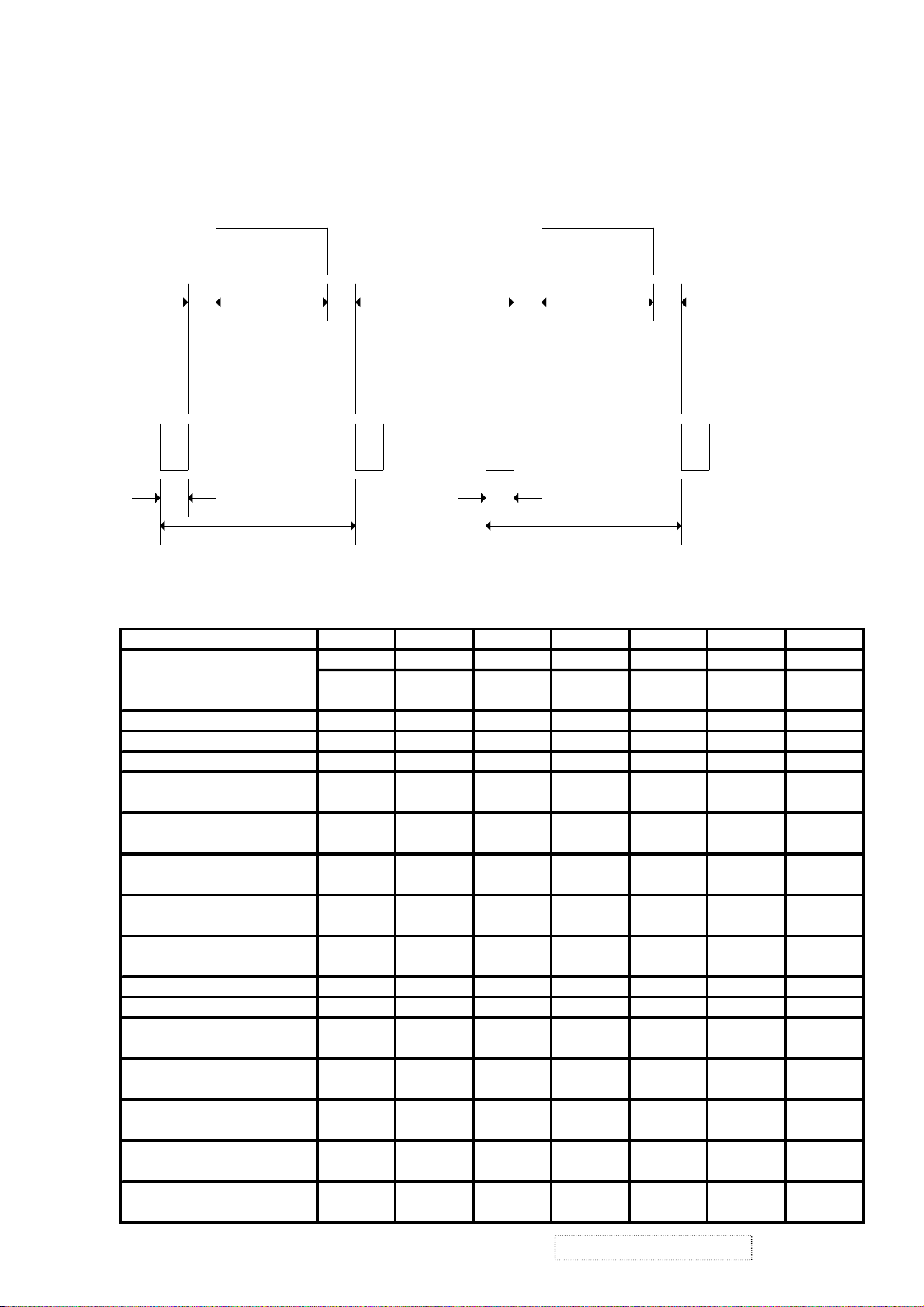

TIMING OF INPUT SIGNALS.

Vertical

R

Video

Horizontal

Video

D

CE

QS

Sync Sync

B

A

P

O

Sync Polarity : Positive / Negative

PRESET TIMING CHART.

MODE NO.

123456

VGA VGA MAC VESA VESA VESA MAC

MODE NAME

640

X

640

X

640

X

640

X

640

X

800

400 480 480 480 480 600 624

PIXEL CLOCK (MHZ)

HORIZONTAL FREQ (KHZ)

25.175 25.175 30.240 31.500 36.000 49.557

31.469 31.469 35.00 37.50 43.269 46.875 49.717

SYNC . POLARITY -----+

A H.TOTAL (us)

(PIXELS) (

B H.SYNC (us)

(PIXELS) (96)(

C H.BACK PORCH (us)

(PIXELS) (48)(

D H.ACTIVE (us)

(PIXELS) (

E H.FRONT PORCH (us)

(PIXELS) (16)(

VERTICAL FREQ (HZ)

31.778 31.778 28.571 26.667 23.111 21.333 20.115

)(

800

)(

800

)(

864

)(

840

)(

832

1056

3.813 3.813 2.116 2.032 1.556 1.616 1.118

)(

96

)(

64

64

)(

)(

56

1.907 1.907 3.175 3.810 2.222 3.232 3.911

)(

48

)(

96

120

)(

)(

80

160

25.422 25.422 21.164 20.317 12.778 16.162 14.528

)(

640

)(

640

)(

640

)(

640

)(

640

800

0.636 0.636 2.116 0.508 1.556 0.323 0.558

)(

16

)(

64

16

)(

)(

56

70.089 59.940 66.667 75.00 85.008 75 74.53

SYNC . POLARITY + ----+

O V.TOTAL (ms)

(LINES) (

P V.SYNC (ms)

(LINES) (2)(

Q V.BACK PORCH (ms)

(LINES) (35)(

R V.ACTIVE (ms)

(LINES) (

S V.FRONT PORCH (ms)

(LINES) (12)(

14.268 16.684 15.000 13.333 11.764 13.333 13.417

)(

449

)(

525

)(

525

)(

500

)(

509

625

0.064 0.064 0.086 0.080 0.069 0.064 0.06

)(

2

)(

3

)(

3

)(

3

1.112 1.048 1.114 0.427 0.578 0.448 0.784

)(

33

)(

39

16

)(

)(

25

12.711 15.254 13.714 12.800 11.093 12.812

)(

400

)(

480

)(

480

)(

480

)(

480

600

0.381 0.381 0.086 0.026 0.023 0.021 0.021

)(

10

)(

3

)(

1

)(

1

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

17

X

)(

)(

80

)(

)(

)(

16

)(

)(

3

)(

21

)(

)(

1

832

.

27

1152

64

224

832

32

667

3

39

.

552

624

1

X

)

)

)

)

)

)

)

)

)

MODE NO.

(64)

(96)

(96)

(

)

(96)

(

)

(

)

(

)

(

)

(

)

MODE NAME

PIXEL CLOCK (MHZ)

HORIZONTAL FREQ (KHZ)

SYNC. POLARITY

A H.TOTAL (us)

(PIXELS)

B H.SYNC (us)

(PIXELS)

C H.BACK PORCH (us)

(PIXELS)

D H.ACTIVE (us)

(PIXELS)

E H.FRONT PORCH (us)

(PIXELS)

VERTICAL FREQ(HZ)

SYNC. POLARITY

O V.TOTAL (ms)

(LINES)

P V.SYNC (ms)

(LINES)

Q V.BACK PORCH (ms)

(LINES)

R V.ACTIVE (ms)

(LINES)

S V.FRONT PORCH (ms)

(LINES)

8 9 10 11 12

VESA VESA MAC VESA VESA

800 X 1024 X 1024 X 1280 X 1024 X

600 768 768 1024 768

56.25 78.75 80.000 108.000 94.500

53.674 60.023 60.241 63.981 68.677

++-++

18.631 16.66 16.600 15.630 14.561

(1048 ) (1312 ) (1328 ) (1688 ) (1376 )

1.138 1.219 1.2 1.037 1.016

112

2.702 2.235 2.2 2.296 2.201

(152 ) (176) (176) (248 ) (208 )

14.222 13.003 12.8 11.852 10.836

800

1024

1024

1280

1024

0.569 0.23 0.4 0.444 0.508

(32 ) (16 ) (32 ) (48 ) (48 )

85 75.029 74.927 60.200 85.000

++-++

11.756 13.328 13.346 16.661 11.765

(631 ) (800 ) (804 ) (1066 ) (808 )

0.056 0.05 0.05 0.047 0.044

(3) (3) (3) (3) (3)

0.503 0.466 0.498 0.594 0.524

(27) (28) (30) (38 ) (36 )

11.179 12.795 12.749 16.005 11.183

(600 ) (768 ) (768 ) (1024 ) (768 )

0.019 0.017 0.05 0.016 0.015

(1) (1) (3) (1) (1)

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

18

USER TIMING CHART

MODE NO.

1234567

IBM VESA VESA VESA VESA VESA IBM

MODE NAME

720

X

640

X

640

X

800

X

800

X

800

X

1024

400 480 350 600 600 600 768

PIXEL CLOCK (MHZ)

HORIZONTAL FREQ (KHZ)

SYNC. POLARITY

A H.TOTAL (us)

(PIXELS)

B H.SYNC (us)

(PIXELS)

C H.BACK PORCH (us)

(PIXELS)

D H.ACTIVE (us)

(PIXELS)

E H.FRONT PORCH (us)

(PIXELS)

VERTICAL FREQ(HZ)

SYNC. POLARITY

O V.TOTAL (ms)

(LINES)

P V.SYNC (ms)

(LINES)

Q V.BACK PORCH (ms)

(LINES)

R V.ACTIVE (ms)

(LINES)

S V.FRONT PORCH (ms)

(LINES)

34.381 31.500 31.500 36.000 40 50 44.9

37.048 37.861 37.861 35.156 37.879 48.077 35.522

+-+++++

26.992 26.413 26.413 28.444 26.420

.

828

.

151

928 832 832 1024 1056 1040 1264

2.094 1.27 2.032 2.000 3.22

.

43

.

92

72 40 64 72 128 120 176

3.025 4.064 3.048 3.556 2.21

.

28 1.247

104 128 96 128 88 64 56

20.942 20.317 20.317 22.222 20 16 22.806

720 640 640 800 800 800 1024

0.931 0.762 1.016 0.667 1 1.12 0.178

32 24 32 24 40 56 8

88.000 72.809 85.080 56.250 60.317 72.188 86.958

+- -++++

11.364 13.735 11.754 17.778 16.579 13.853 11.5

421 520 445 625 628 666 408

0.081 0.079 0.079 0.057 0.106 0.125 0.113

3332464

0.459 0.739 1.585 0.626 0.607 0.478 0.563

17 28 60 22 23 23 20

0.797 12.678 9.244 17.067 15.84 12.48 10.81

400 480 350 600 600 600 384

0.027 0.237 0.845 0.028 0.026 0.77 0.014

1 9 32 1 1 37 0

SCANTYPE INTERLACED NO NO NO NO NO NO YES

X

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

19

MODE NO.

8 9 10 11 12 13

VESA VESA VESA VESA VESA VESA

MODE NAME

1024

X

1024

X

1280

X

1152

X

640

X

720

768 768 960 864 400 400

PIXEL CLOCK (MHZ)

HORIZONTAL FREQ (KHZ)

SYNC. POLARITY

A H.TOTAL (us)

(PIXELS)

B H.SYNC (us)

(PIXELS)

C H.BACK PORCH (us)

(PIXELS)

D H.ACTIVE (us)

(PIXELS)

E H.FRONT PORCH (us)

(PIXELS)

VERTICAL FREQ(HZ)

SYNC. POLARITY

O V.TOTAL (ms)

(LINES)

P V.SYNC (ms)

(LINES)

Q V.BACK PORCH (ms)

(LINES)

R V.ACTIVE (ms)

(LINES)

S V.FRONT PORCH (ms)

(LINES)

75.000 65.000 108.000 108 31.535

56.476 48.36 60.000 67.537

.

861 37.927

--++--

17.707 20.677 16.667 14.815 26.413 26.366

1328 1344 1800 1600 832 936

1.813 2.092 1.037 1.185 2.032 2.028

136 136 112 128 64 72

1.92 2.462 2.889 2.37 3.048 3.042

144 160 312 256 96 108

13.653 15.754 11.852 10.667 20.317 20.282

1024 1024 1280 1152 640 720

0.32 0.369 0.889 0.593 1.016 1.014

24 24 96 64 32 36

70.069 60.004 60.000 75 85.08 85.039

- -++++

14.272 16.666 16.667 13.333 11.754 11.759

806 806 1000 900 445 446

0.106 0.124 0.05 0.044 0.079 0.079

663333

0.513 0.60

.

60

.

474 1.083 1.107

29 29 36 32 41 42

13.599 15.88 16.000 12.810

.

665 10.546

768 768 960 864 400 400

0.053 0.062 0.017 0.015 0.026 0.026

331111

SCANTYPE INTERLACED NO NO NO NO NO NO

X

.

5

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

20

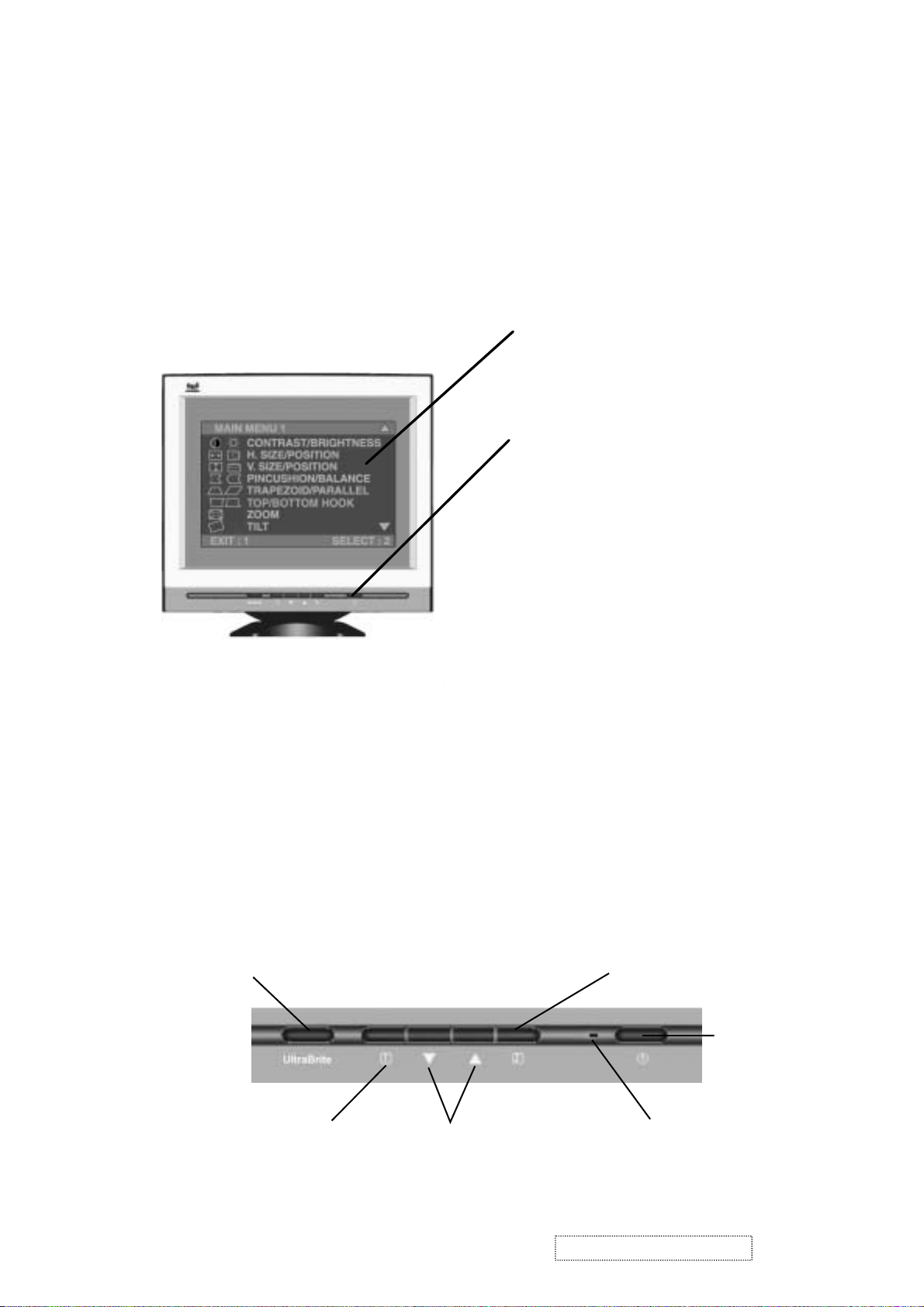

3. Front Panel Function Control Description

Adjusting the Screen Image

Use the buttons on the monitor control panel to adjust the OnView® controls.

1 Press [1] to display the Main Menu.

NOTE: OnView controls disappear after 15 seconds.

2 Press ▲ or ▼ to highlight an option.

3 Press [2].

4 Press ▲ or ▼ to adjust the setting.

5 Press [1] twice to save and exit.

Main Menu

Control panel

Switches between Normal, UltraBrite 3x and UltraBrite 5x modes:

"NORMAL: TEXT/SPREADSHEET":

When selected, this brightness level setting

displays a standard CRT brightness of 120

nits for text and spreadsheet applications.

"ULTRABRITE 3x: GRAPHICS/GAME":

When selected, this UltraBrite™ setting

displays up to 300 nits of brightness for

optimum display performance of graphics

applications and games .

"ULTRABRITE 5x: VIDEO/MOVIE/DVD":

When selected, this UltraBrite™ setting

displays up to 500 nits of brightness for

optimized display performance of video applications.

Displays the highlighted

option or toggles

between options

Power button

Displays the Main

Menu or exits and

saves

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Scrolls through

options or adjusts

settings

21

Power light:

green = on

orange = power save

Loading...

Loading...