Page 1

Model No. VCDTS23125

17” Digital Controlled Color Monitor

Service Manual

ViewSonic E70f+SB-3

ViewSonic

381 Brea Canyon Road, Walnut, California 91789 USA - (800) 888-8583

(E70f+SB-3_SM_832 Rev. 1a – May 2004)

Page 2

Copyright

Copyright

¤

2004 by ViewSonic Corporation. All rights reserved. No part of this publication may be

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, electronic, mechanical, magnetic, optical, chemica l,

manual or otherwise, without the prior written permission of ViewSonic Corporation.

Disclaimer

ViewSonic makes no representations or warranties, either expressed or implied, with respect to the

contents hereof and specifically disclaims any warranty of merchantability or fitness for any particular

purpose. Further, ViewSonic reserves the right to revise this publication and to make changes from time

to time in the contents hereof without obligation of ViewSonic to notify any person of such revision or

changes.

Revision History

Revision Date Description Of Changes Approval

1a 05/13/04 Initial Release DCN- 4412 Angela Lu

Trademarks

ViewSonic is a registered trademark of ViewSonic Corporation.

All other trademarks used within this document are the property of their respective owners.

Optiquest is a registered trademark of ViewSonic Corporation.

i

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 3

TABLE OF CONTENTS

2. Specification

3. Front Panel Function Control Description

4. Circuit Description

6. Trouble Shooting Flow Chart

9. Block Diagram

10. Schematic Diagrams

7. Recommended Spare Parts List

1. Precautions and Safety Notices

5. Adjusting Procedure

8. Exploded Diagram And Spare Parts List

11. PCB Layout Diagrams

1

3

21

25

28

38

43

52

60

61

74

ii

ViewSonic Corporation Confidential -Do Not Copy 70f+SB-3 E

Page 4

WA RN I N G!

This service information is designed for experience repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service

a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians.

Any attempt to service or repair the product or products dealt within this service information by anyone else

could result in serious injury or death.

1. CAUTION

No modification of any circuit should be attempted. Service work should only be performed after you are thoroughly

familiar with all of the following safety checks and servicing guide lines.

2. SAFETY CHECK

Care should be taken while servicing this CRT display because of the high voltage used in the deflection circuits.

These voltages are exposed in such areas as the associated flyback and yoke circuits.

3. FIRE & SHOCK HAZARD

3-1 Insert an isolation transformer between the CRT display and AC power line before servicing the chassis.

3-2 In servicing pay attention to original lead dress especially in the high voltage circuit. If a short circuit is found,

replace all parts which have been overheated as a result of the short circuit

.

3-3 All the protective devices munt be reinstalled per original design.

3-4 Soldering must be inspected for possible cold solder joints, frayed leads, damaged insulation, solder splashes or

sharp solder points. Be certain to remove all foreign material.

4. LEAKAGE CURRENT COLD CHECK

4-1 Unplug the AC cord and connect a jumper between the two prongs on the plug.

4-2 Turn the CRT display power switch “on”.

4-3 Measure the resistance value with an ohmmeter between the jumpered AC plug and each exposed metallic part

on the CRT display such as the metal frame, screwheads, control shafts, etc. When the exposed metallic part has

a return path to the chassis, the reading should be 1.8 megohm minimum

.

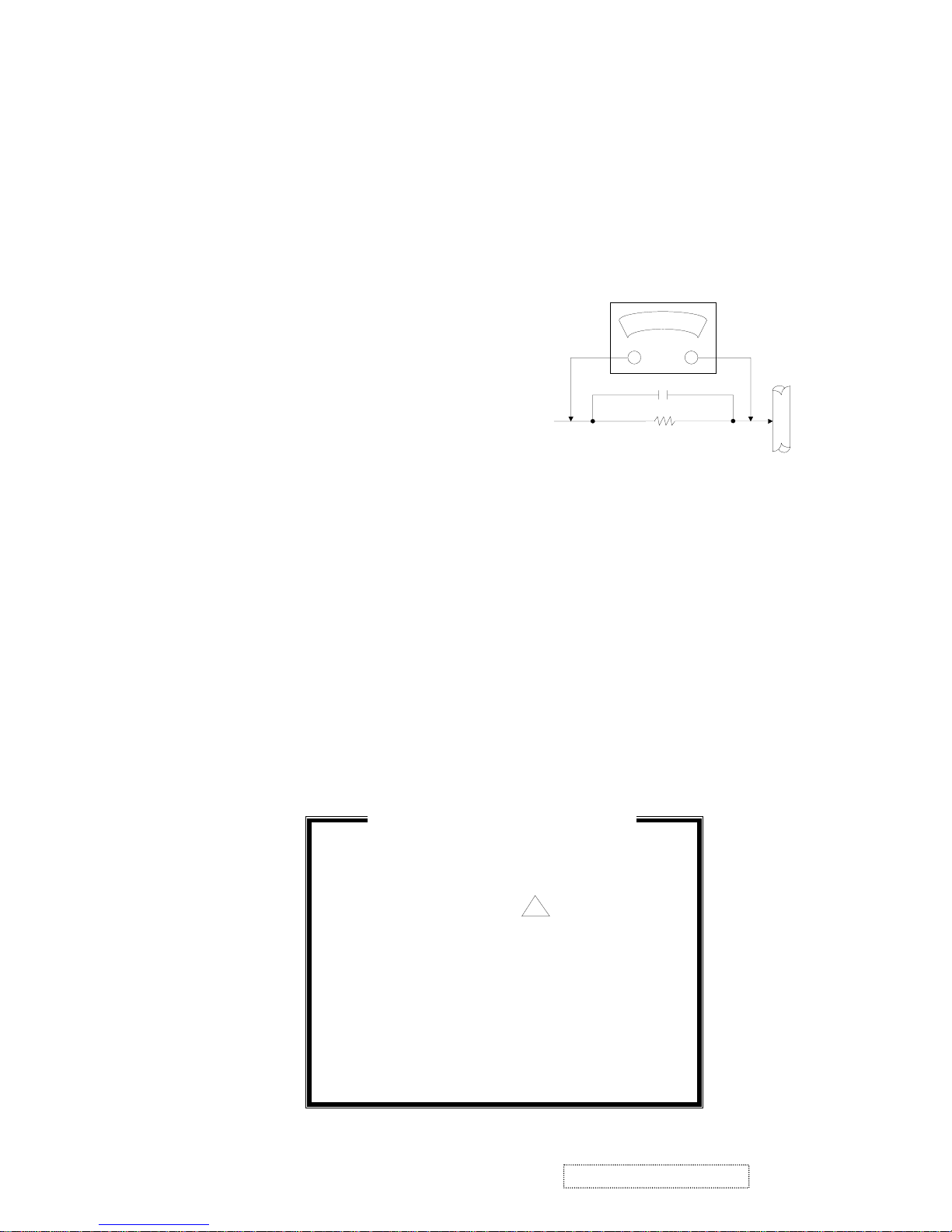

5. LEAKAGE CURRENT HOT CHECK

5-1 Plug the AC cord directly into the AC outlet. Do not use an isolation transformer during this check.

5-2 Connect a 1500 ohm, 10 watt resistor, paralleled by a 0.15uF capacitor between each exposed metallic part and

a good earth ground (as shown in Fig.1).

5-3 Use an AC voltmeter with 1000 ohm/volt or more sensitivity and measure the AC voltage across the

combination 1500 ohm resistor and 0.15uF capacitor.

1. Precautions And Safety Noticess

1

ViewSonic Corporation Confidential -Do Not Copy 70f+SB-3 E

Page 5

5-4 Move the resistor connection to each exposed metallic part and measure the voltage.

5-5 Reverse the polarity of the AC plug in the AC outlet and repeat the above measurement.

5-6 Voltage measured must not exceed 7.5 volt RMS, from any exposed metallic part to ground A leakage current

tester may be used in the above hot check, in which case any current measured must not exceed 5.0 milliamp. In

the case of a measurement exceeding the 5.0 milliamp value, a rework is required to eliminate the chance of

shock hazard.

NoteΚ High voltage is present when this CRT display is operating. Always discharge the anode of the picture

tube to the display chassis to prevent shock hazard.

AC VOLTMETER

TO

INSTRUMENT'S

EXPOSED

METAL PARTS

1500 Ө 10W

0.15ӴF

Fig. 1

(EARTH

GROUND)

6. IMPLOSION PROTECTION

Picture tubes are equipped with an integral implosion protection system, but care should be taken to avoid damage and

scratching during installation. Use only Panasonic replacement picture tubes.

7. X-RADIATION

WA RN I NG ΚThe only potential source of X-Radiation is the picture tube. However when the high voltage circuit is

operating properly there is no possibility of X-Radiation problem. The basic precaution which must be exercised is to

keep the high voltage at the following factory-recommended level.

NoteΚΚΚΚ It is important to use an accurate periodically calibrated high voltage meter.

7-1 The procedure for adjusting high voltage is shown on page 27.

7-2 If can not be adjust 25.0 KV at immediate service is required to prevent the possibility of premature

component failure.

7-3 To prevent X-Radiation possibility it is essential to use the specified picture tube.

IMPORTANT SAFETY NOTICE

There are special components used in this CRT displays

which are important for safety. These parts are identified

by the international symbol

!

on the schematic

diagram and on the replacement parts list. It is essential

that these critical parts should be replaced with

manufacture’s specified parts to prevent X-RADIATION,

shock, fire, or other hazards. Do not modify the original

design or this will void the original parts and labor

guarantee.

2

ViewSonic Corporation Confidential -Do Not Copy 70f+SB-3 E

Page 6

A. GENERAL

1. ALLSPECIFICATION MUST BE MET OVER LINE VOLTAGE RANGE OF 90VAC TO 264VAC 50HZ/ 60HZ, UNLESS OTHERWISE

2. OPERATING TEMPERATURE RANGE IS 0

o

C TO 40oC WITH A RELATIVE HUMIDITY OF 10% OR LESS TO 90%.

3. THE MONITOR MUST BE OPERATIONAL IN AN USABLE STATE WITHIN 30 SECONDS AFTER TURN-ON.

4. ALL SIGNAL LEVELS ARE MEASURED ASSUMING TERMINATION AT THE MONITOR'S INPUT JACKS OR IN ITS

CHARACTERISTIC IMPEDANCE.

5.

AN AMBIENT LIGHTING LEVEL OF 400 TO 600 LUX IS ASSUMED WHEN SETTING BRIGHTNESS FOR RASTER

EXTINCTION THRESHOLD.

6. ALL PURITY RELATED SPECIFICATIONS MUST BE MET WITHOUT EXTERNAL DEGAUSSING.

7. ALL CONTROLS MUST HAVE EXCESS RANGE (NO CONTROL MAY BE LEFT AT AN END STOP WHEN PROPER

ALIGNMENT IS COMPLETED).

8.

THE MONITOR IS NOT REQUIRED TO MEET SPECS DURING THE FOLLOWING BUT MUST TOLERATE, WITHOUT

DAMAGE TO THE CRT OR CIRCUITS, ANY SEQUENCY OR COMBINATION OF POWER ON AND OFF, SIGNAL ON

AND OFF, ERRATIC, WRONG FREQUENCY OR NOISY INPUTS WHILE AT ANY POSSIBLE UNPLUGGING OF POWER

OR SIGNAL, SETTINGS OF USER ACCESSIBLE CONTROLS. LIKEWISE, THE MONITOR SHOULD SURVIVE EXTENDED

PERIODS OF OPERATION WITH LINE VOLTAGE REDUCED BELOW THE SPECIFIED MINIMUM.

9. AN ISOLATION TRANSFORMER SHOULD BE USED WHEN PERFORMING ALIGNMENT AND TESTS. PORTIONS OF

THE POWER SUPPLY BOARD ARE HOT GROUND. THE REMAINING BOARDS ARE COLD GROUND.

10. DISCHARGE OF CRT ANODE SHOULD BE DONE ONLY TO CRT GROUND STRAP.

11. GEOMETRIC MEASUREMENT IS ASSUMED TO BE MAKING ALONG A STRAIGHT SURFACE WITH A FLAT RULE OR

TEMPLATE.

2. Specification

SPECIFIED.

B. INSTRUMENT ALIGNMENT

1. DEFLECTION PRESETS

CONTROL POTS VR101, VR401, VR403, FOCUS VR ARE SET AT MIDDLE POINT. SCREEN VR SET TO MIN.

2. POWER SUPPLY ALIGNMENT

2.1 INPUT VGA 640X480 SIGNAL CROSSHATCH PATTERN & BEAM CURRENT SET AT 0uA.

2.2 ADJUST VR101 UNTIL DC=105V0.3V AT TP201

2.3 ADJUST G2 UNTILL PICTURE VISIBLE.

2.4 ADJ VR403 UNTIL VOLTAGE AT TP208 = 63.0V 0.3V.

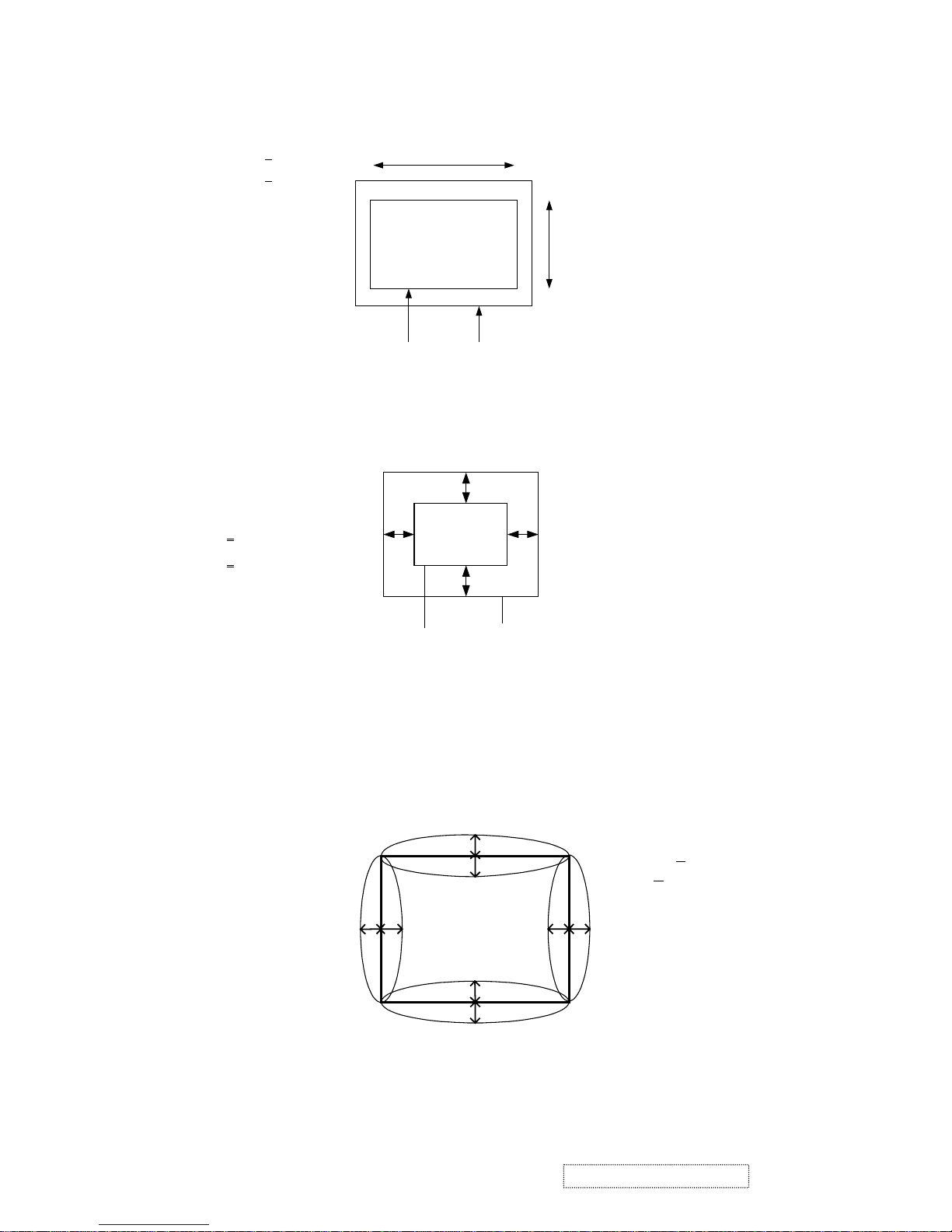

3. SIZE & GEOMETRY ADJUSTMENT

3.1 RASTER CENTERING

3.1.1 INPUT CROSSHATCH PATTERN AT 60KHZ 1024*768 MODE.

3.1.2 ADJUSTCONTRAST TO 10FL, ADJUST SCREEN JUST RASTER VISIBLE.

3.1.3 ADJUST VR401 TO CENTER RASTER ON SCREEN SUCH THAT THE HORIZONTAL DISTANCE

FORM THE MIDPOINT OF THE LEFT DISPLAY EDGE TO THE LEFT BEZEL EDGE IS WITHIN

2MM. OF THE DISTANCE FROM MIDPOINT OF THE RIGHT BEZEL EDGE.

A

B

BEZEL

RASTER

I A-B I < 2mm

3

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 7

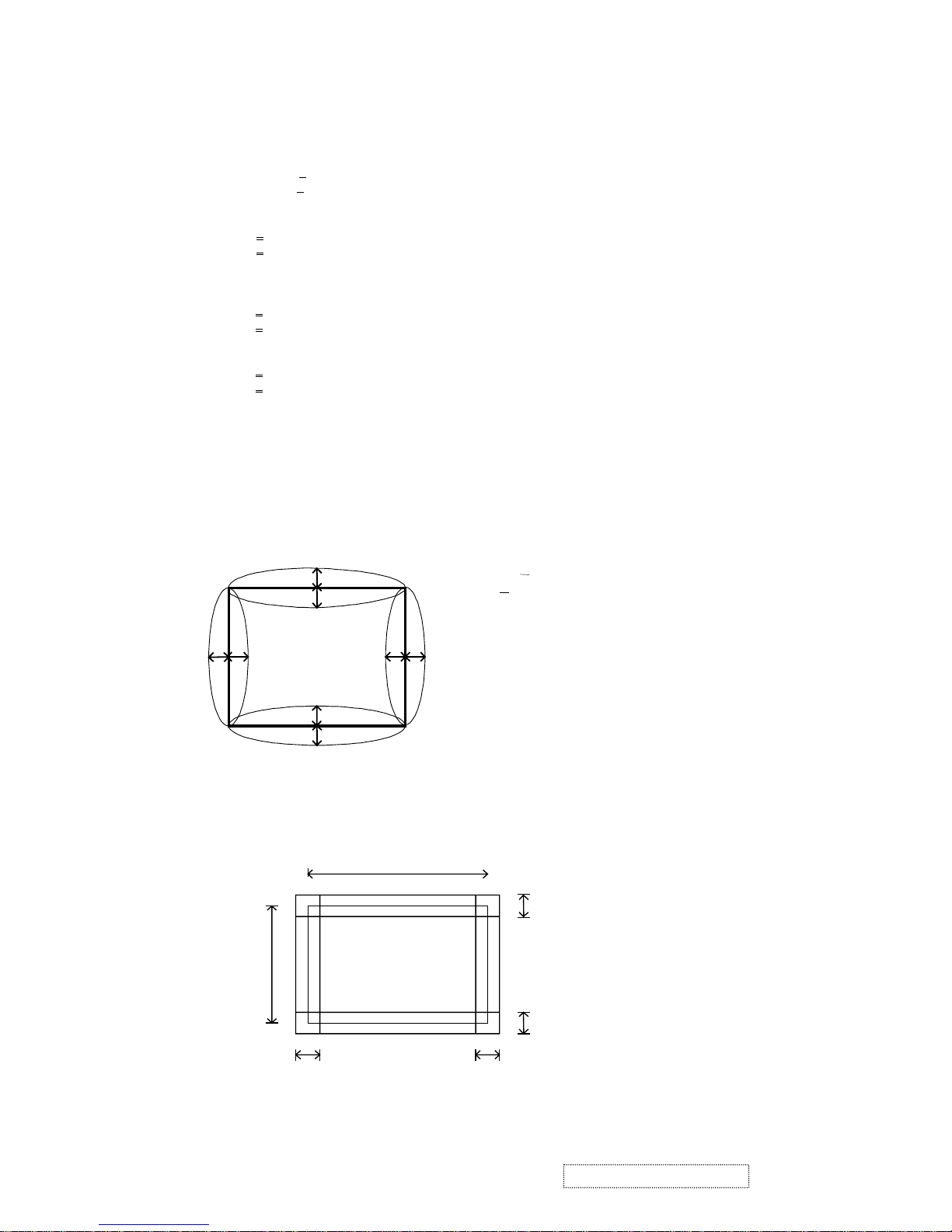

3.2 PICTURE SIZE

INPUT MODE 1-12 SIGNAL ADJUST V-SIZE, H-SIZE TO ACHIEVE.

H-SIZE: 310mm. +

2mm.

V-SIZE: 230mm. + 2mm.

230mm

310mm

BEZEL

PICTURE

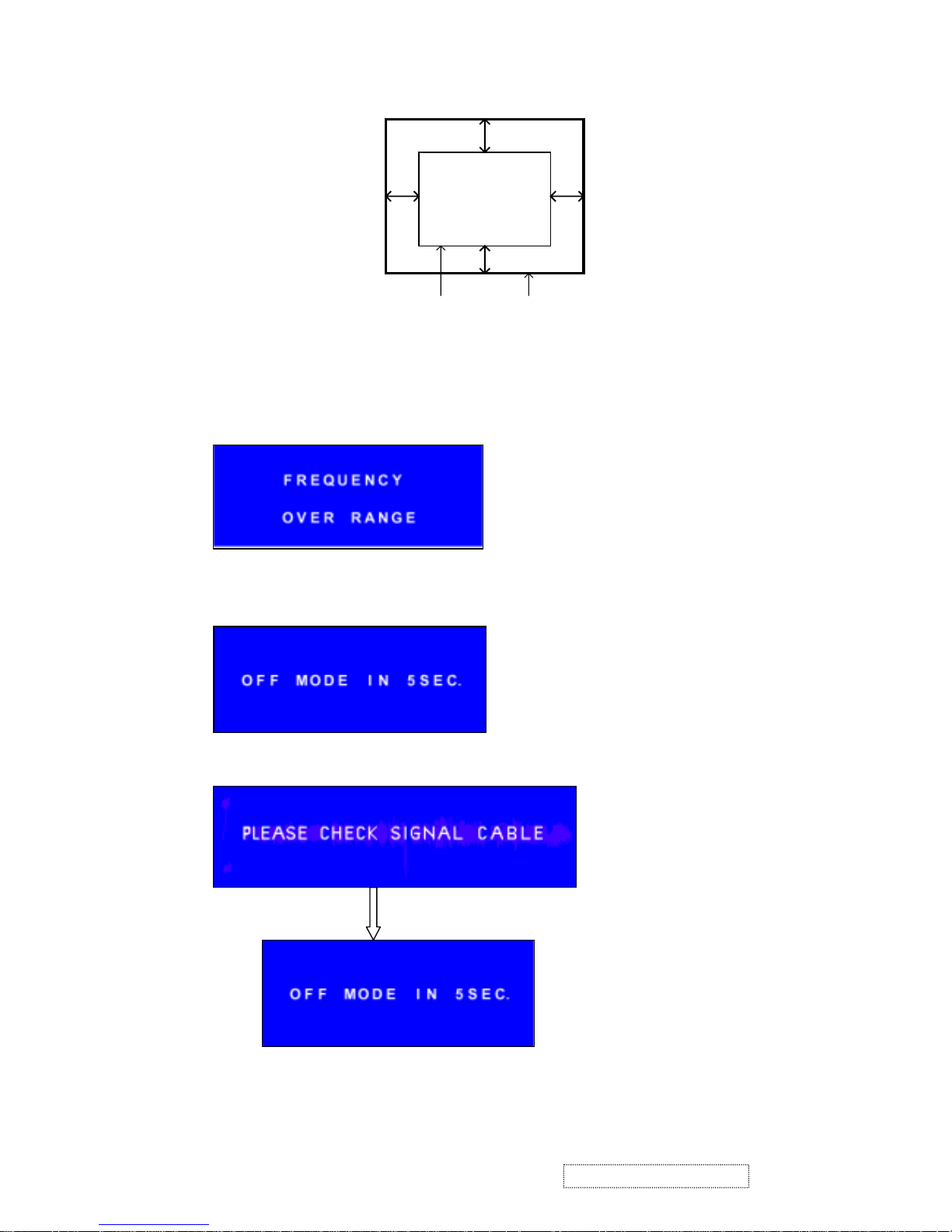

3.3 PICTURE POSITION

INPUT MODE 1-12 ADJUST V-POSITION, H-POSITION SUCH THAT THE PICTURE IS CENTERED WITH THE

SCREEN

I

A – B I <

2mm.

I

C – D I <

2mm.

3.4 GEOMETRY ADJUSTMENT

3.4.1 INPUT MODE 1-12.

3.4.2 PINCUSHION AND BARREL DISORTION

BEZEL

PICTURE

A

B

D

C

A

A' BB'

C'

C

D'

D

PI N C US I O N < 1 m m ( A ,B,C ,D)

BA RR E L < 1mm ( A ,B ,C,D)

4

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 8

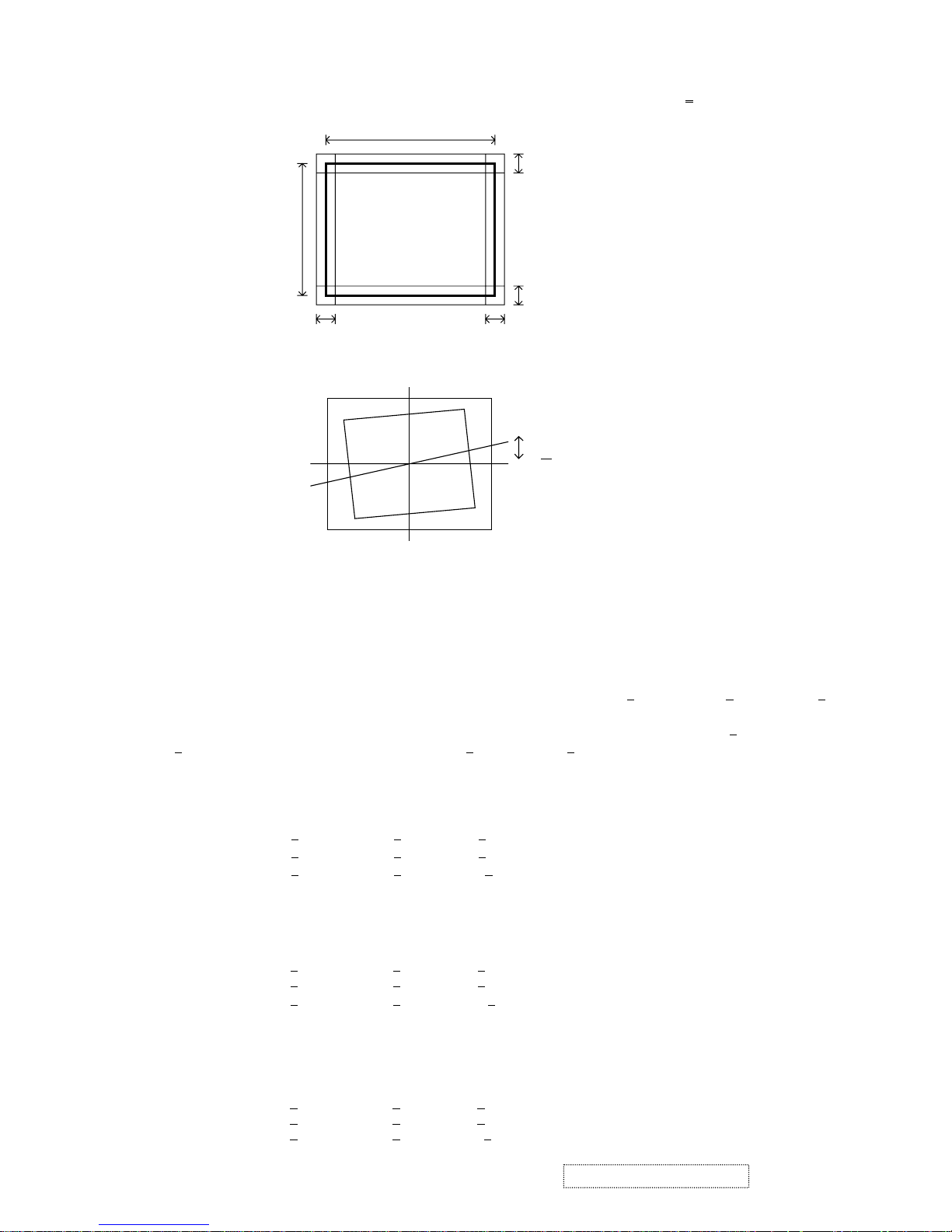

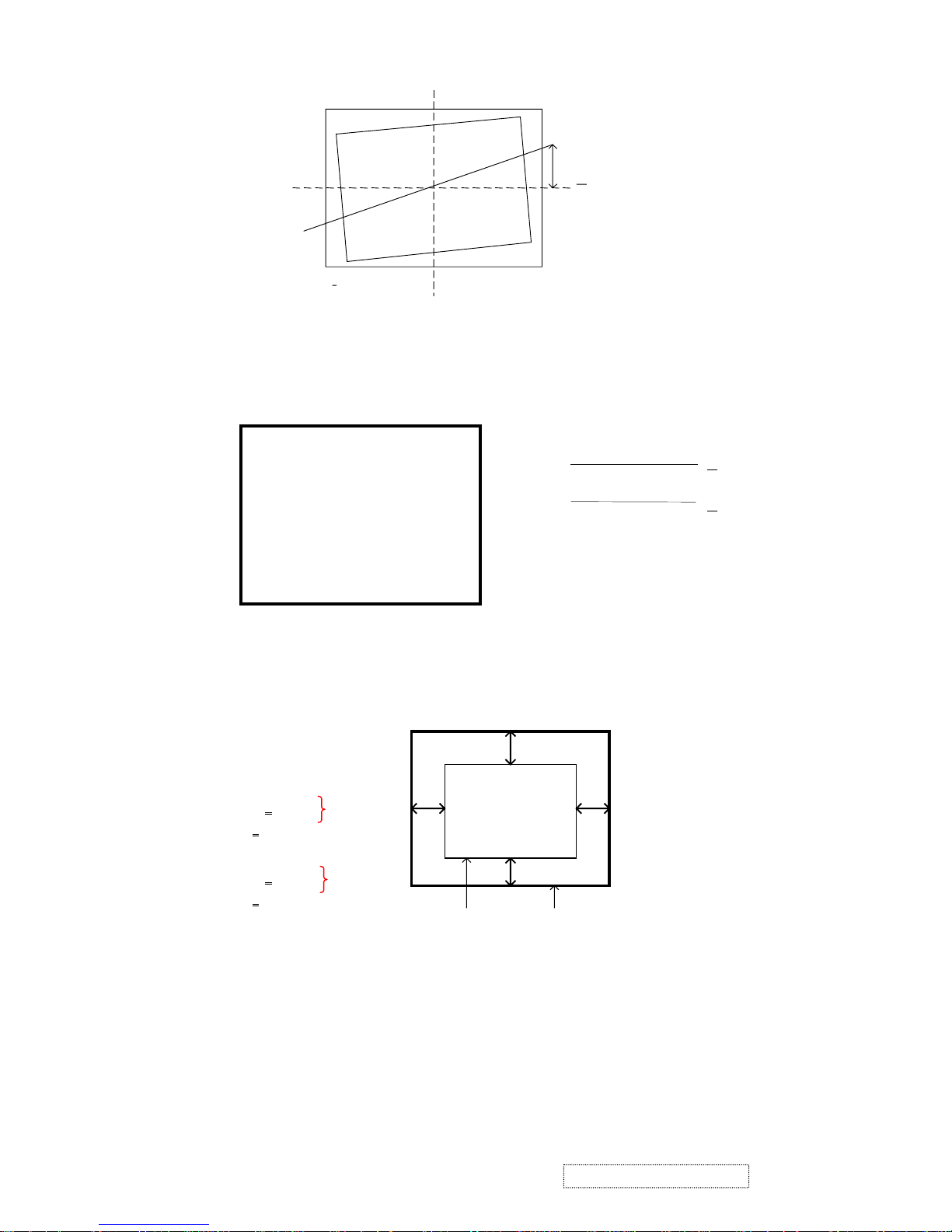

3.4.3 TRAPEZOID AND PARALLEOGRAM DISTROTION TRAPEZOID / PARALLEOGRAM < 1.5mm.

3.4.4 ROTATE ADJUSTMENT

4. VIDEO ALIGNMENT / FUNCTION MEMORY RECALL

4.1 INPUT 1024x768 69KHZ FULL BLACK PATTERNS.

4.2 SET CONTRAST 0%, BRIGTHNESS 100%, RGB CUT OFF 0%, RGB DRIVER 50%, TURN THE G2 (SCREEN) KNOB

TO OBTAIN RASTER LIGHT O/P ABOUT 0.25FL.

4.3 BASE ON x, y READING, FIX THE STRONG GUN CUT OFF TO 130, THEN ADJUST THE OTHER TWO GUN AND

SCREEN KNOB TO MEET FOLLOWING CHROMATICALLY 9300

O

KÆx =0.283 + 0.003, y =0.297 + 0.003, Y = 0.5 +

0.2FL, STORE THE ADJUSTMENT OF 9300oK, THEN BASE ON x, y READING, FIX THE STRONG GUN AND G2,

ADJUST THE OTHER GUN TO MEET FOLLOWING CHROMATICALLY SPEC 6500

O

KÆ x = 0.313+ 0.003, y = 0.329

+

0.003, Y = DON’T CARE 5000OKÆ x = 0.346+ 0.003, y = 0.359 + 0.003, Y = DON’T CARE

4.4 ADJUST BRIGHTNESS TO 50%, CONTRAST 100%

4.5 APPLY 70mm x 70mm GREEN WINDOW PATTERN, ADJUST G-DRIVER TO OBTAIN GREEN WINDOW PATTERN

LIGHT O/P ABOUT 30FL (9300OK)

APPLY WHITE WINDOW PATTERN, ADJUST R-DRIVER, B-DRIVER TO MEET FOLOWING CHROMATICALLY SPEC.

1.5mm

1.5mm

1.5mm1.5mm

230mm

310mm

h < 1m m

230mm

310mm

9300OKÆ x = 0.283 + 0.003, y = 0.297 + 0.003, Y = 45+ 2FL. For TEXT/SPREADSHEET mode

9300

O

KÆ x = 0.283 +

0.003, y = 0.297 + 0.003, Y = 85+ 3FL. For GRAPHIC/GAME mode

9300

O

KÆ x = 0.283 + 0.003, y = 0.297 + 0.003, Y = 150+ 4FL. For VIDEO/MOVIE/DVD mode

4.6 APPLY 70mm x 70mm GREEN WINDOW PATTERN, ADJUST G-DRIVER TO OBTAIN GREEN WINDOW PATTERN

LIGHT O/P ABOUT 30FL (6500OK)

4.7 APPLY WHITE WINDOW PATTERN, ADJUST R-DRIVER, B-DRIVER TO MEET FOLLOWING CHROMATICALLY

SPEC.

6500

O

KÆ x = 0.313 + 0.003, y = 0.329 + 0.003, Y = 45+ 2FL For TEXT/SPREADSHEET mode

6500

O

KÆ x = 0.313 + 0.003, y = 0.329 + 0.003, Y = 85+ 3FL For GRAPHICS/GAME mode

6500

O

KÆ x = 0.313 + 0.003, y = 0.329 + 0.003, Y = 130 + 4FL For VIDEO/MOVIE/DVD mode

4.8 APPLY 70mm x 70mm GREEN WINDOW PATTERN , ADJUST G-DRIVER TO OBTAIN GREEN WINDOW

PATTERN LIGHT O/P ABOUT 30FL (5000OK)

4.9 APPLY WHITE WINDOW PATTERN, ADJUST R-DRIVER,B-DRIVER TO MEET FOLLOWING

CHROMTICALLY SPEC

5000

O

KÆ x = 0.346 + 0.003, y = 0.359 + 0.003, Y = 45+ 2FL For TEXT/SPREADSHEET mode

5000

O

KÆ x = 0.346 + 0.003, y = 0.359 + 0.003, Y = 85+ 3FL For GRAPHICS/GAME mode

5000

O

KÆ x = 0.346 + 0.003, y = 0.359 + 0.003, Y = 130+ 4FL For VIDEO/MOVIE/DVD mode

5

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 9

4.10 APPLY FULL WHITE PATTERN

4.11 ADJUST OSD ABL TO OBTAIN LIGHT O/P = 30+1FL FOR ALL MODE

4.12 APPLY FULL WHITE PATTERN ADJUST CONTRAST FROM 30FL TO 10FL AND CHECK THE CHROMATICALLY

MEET FOLLOWING SPEC.

I

x (AT CONTRST, 30) –x (AT CONTRST, 25.75) I < 0.007.

I

y (AT CONTRST, 30) –y (AT CONTRST, 25.75) I < 0.003.

I

x (AT CONTRST, 10) –x (AT CONTRST, 25.75) I < 0.007.

I

y (AT CONTRST, 10) –y (AT CONTRST, 25.75) I < 0.006.

4.13 FUNCTION “ALL MODE RESET.

PUSH BUTTON “1” AND POWER SWITCH ON, THE PICTURE SHOULD RESTORE TO THAT OF FACTORY MODE.

4.14 USER COLOR MUST BE DEFAULTED AS 9300OK.

5. FOCUS ADJUSTMENT.

5.1 APPLY SIGNAL ALL “ME” PATTERN AT 1024*768 69K MODE.

5

.2 SET BRIGHTNESS 50% CONTRAST 100%.

5.3 SET FOCUST CONTROL FOR BEST FOCUS.

C. INSTRUMENT TEST

6. TEST PRESETS.

6.1 BRIGHTNESS SET 50%, CONTRST SET 100%.

6.2 INPUT FULL WHITE PATTERN.

6.3 WARM-UP - ALLOW 30 MINUTES WARM-UP PRIOR TO TEST.

7. POWER SUPPLY TEST

7.1 INPUT CHARACTERISTICS

7.1.1 INPUT VOLTAGE RANGE: 90V

AC TO 264 VAC, SINGLE PHASE.

7.1.2 INPUT FREQUENCY RANGE: 50HZ TO 60HZ.

7.1.3 MAX. INPUT AC CURRENT: 2A, LOW LINE INPUT, FULL LOAD.

7.1.4 INRUSH CURRENT: LESS THAN 30A FOR ½ CYCLE AT 110V, 50A FOR ½ CYCLE AT 240V, AT COLD

STRART.

7.1.5 EFFICIENCY: 70% MIN AT 110V LINE INPUT FULL LOAD.

7.2 OUTPUT CHARACTERISTICS:

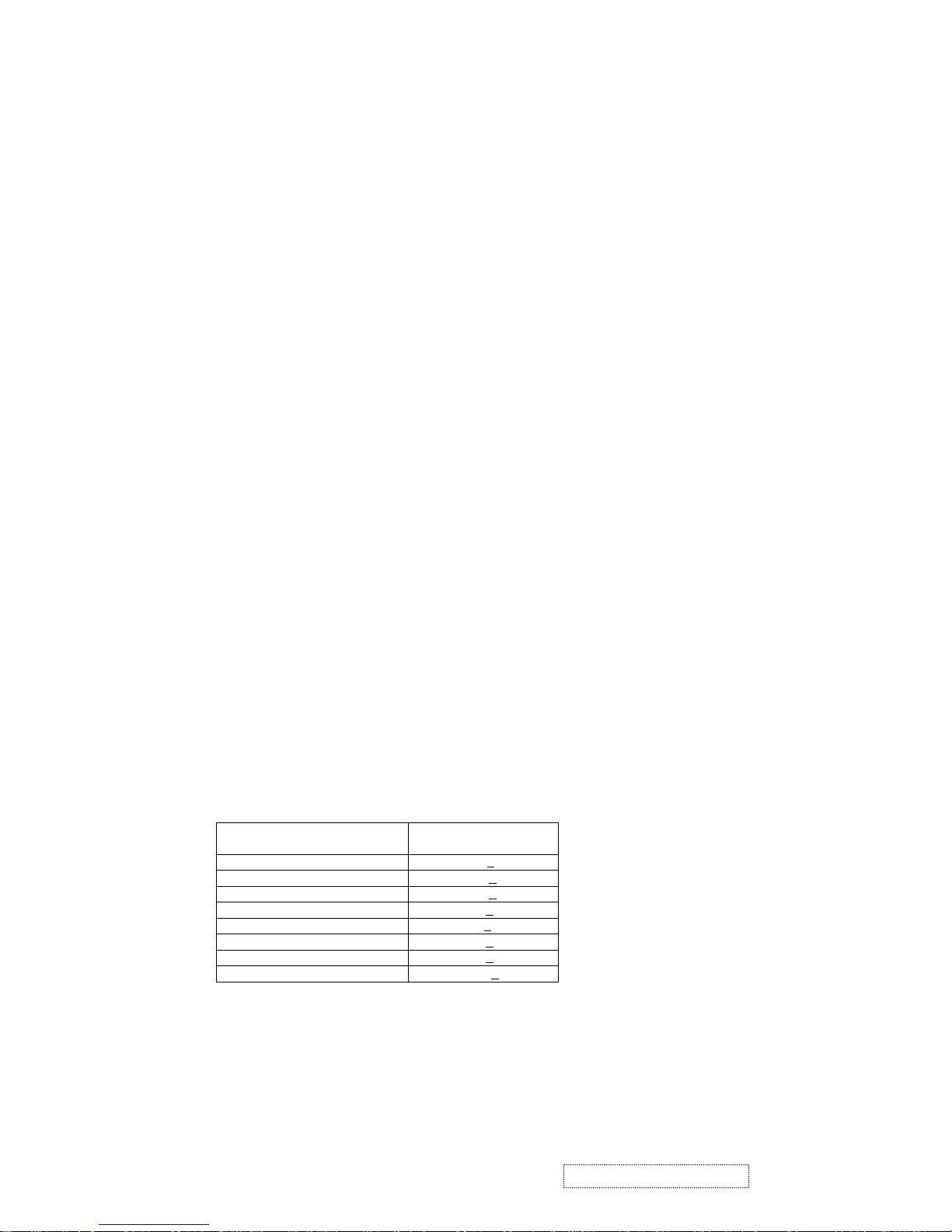

7.2.1 STATIC OUTPUT CHARACTERISTICS:

MEASUREMENT

POINT

OUTPUT

VOLTAGE

TP201 105 V + 3%

TP202 46.5 V + 5%

TP203 13.5 V + 5%

TP204 7.5 V + 5%

TP205 12 V + 5%

TP206 6.3 V + 5%

TP207 5.5 V + 5%

TP208 -13.5 V + 5%

7.3 DIELECTRIC WITHSTAND VOLTAGE:

7.3.1 PRIMARY TO SECONDARY: 2545VDC

FOR 1 SEC.

7.3.2 PRIMARY TO SAFETY GROUND: 2545VDC FOR 1 SEC.

7.3.3 LEAKAGE CURRENT: 0.75mA. MAXIMUM AT 110/220VAC

6

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 10

8. GEOMETRICAL TESTS

8.1 SIZE

8.1.1 APPLY FULL WHITE PATTERN AT ALL MODES.

8.1.2 PICTURE SIZE:

H-SIZE: 310mm +

3mm.

V-SIZE: 230mm +

3mm.

8.1.3 BRIGHTNESS ATABILITY

H-SIZE: <

2mm.

V-SIZE: <

2mm.

NOTE: MIN. LIGHT OUTPUT TO MAX. LIGHT OUTPUT.

8.1.4 AC POWER VOLTAGE STABILITY.

H-SIZE: <

2mm

V-SIZE: <

2mm

8.1.5 THERMAL STABILITY (SIZE VARIATION)

H-SIZE: <

2mm.

V-SIZE: <

2mm.

NOTE: TEMP. 0

o

C~ 40

o.

8.2 GEOMETRY

8.2.1 APPLY SIGNAL D AT EACH MODE.

8.2.2 PINCUSION AND BARREL DISTROTION

8.2.3 TRAPEZOID AND PARALLOGRAM DISTROTION

A

A

'BB'

C'

C

D'

D

PINCUSION < 2mm (A,B,C,D)

BARREL < 1.5mm (A,B,C,D)

310mm

230mm

2mm

2mm

2mm

2mm

PARAL L EL OGRAM <2.0mm (A,B,C,D)

TRAPEZOID < 2 .0 mm ( A,B,C,D)

7

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 11

8.2.4 PICTURE TILT.

2mm

230mm

310mm

h<

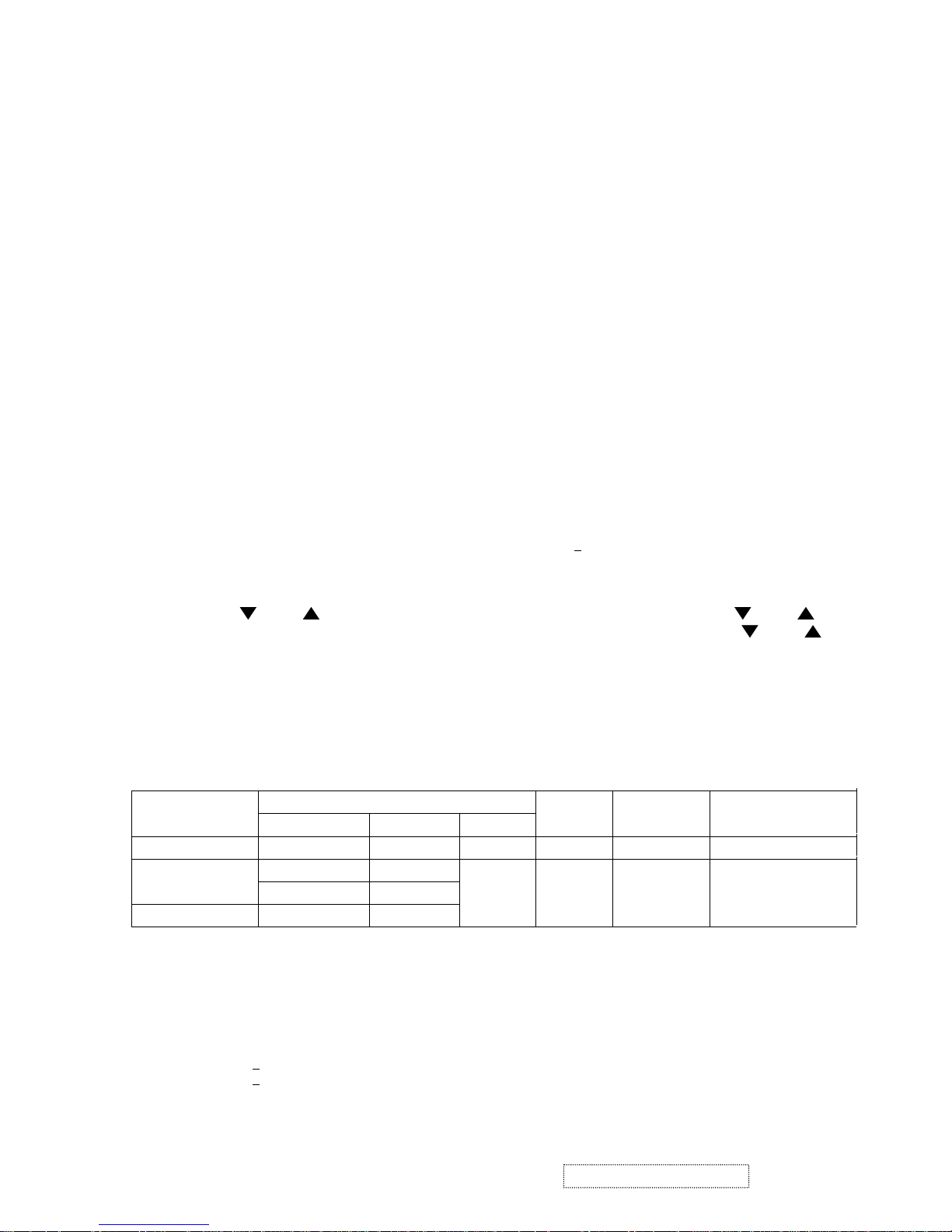

8.3 LINEARITY

APPLY SIGNAL D AT ALL MODE, INPUT CROSS-HATCH PATTERN

8.4 CENTERING (WITH MAGNETIC FIELD)

8.4.1 APPLY SIGNAL D AT ALL MODES.

8.4.2 PICTURE POSITION

I

A – B I <

3mm.

I C – D I <

3mm.

I

A – B I <

4mm.

I C – D I <

4mm.

H-Linearity: (Hmax-Hmin)*10 0%

(Hmax+Hmin)

V

-Linearity:

(Vmax-Vmin)*100%

+

<

4%

<

4%

Primary

Primary

d

5% Oth ers

C

D

B

A

PICTURE

BAZEL

Prima

Other

9. HORIZONTAL SWEEP

9.1 PULL-IN RANGE

9.1.1 APPLY SIGNAL D WITH A HORIZONTAL FREQUENCY OF 30KHZ MODE, MONITOR MUST BE

IN SYNC.

9.1.2 APPLY SIGNAL D WITH A HORIZONTAL A HORIZONTAL FREQUENCY OF 70KHZ MODE,

MONITOR MUST BE IN SYNC.

8

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 12

10. VERTICAL SWEEP.

10.1 VERTICAL PULL-IN RANGE.

10.1.1 APPLY SIGNAL D MODE: VGA (CHG fv = 50Hz)

10.1.2 OBSERVE THAT PICTURE LOCKS UP IN SYNC.

10.1.3 APPLY SIGNAL D MODE: 69K (CHG fv = 160HZ), MONITOR MUST BE IN SYNC.

11. CRT VOLTAGES / REGULATION / POWER

11.1 FILAMENT MEASUREMENT

11.1.1 APPLY SIGNAL A (FLAT WHITE FIELD) AT VGA MODE.

11 1 2 SET CONTRAST TO 30 FLS AND BRIGHTNESS TO THRESHOLD OF RASTER

11.1.3 MEASURE HEATER VOLTAGE AT 6.3V AND VOLTAGE MUST BE 6.3 +

0.3V.

11.2 NORMAL HIGH VOLTAGE

11.2.1 APPLY SIGNAL A (FULL WHITE PATTERN) AT VGA MODE.

11.2.2 SET BRIGHTNESS 0%, CONTRAST 0%.

11.2.3 MEASURE HIGH VOLTAGE MUST BE 26 1KV.

11.2.4 APPLY SIGNAL A AT 69KHZ MODE

11.2.4. REPEAT STEP 11.2.2 THROUGH 11.2.3 THE HIGH VOLTAGE MEASURED MUST BE

26 ± 1KV.

11.3 HIGH VOLTAGE REGULATION

11.3.1 SET BRIGHTNESS 100%, CONTRAST 100%.

11.3.2 SET BEAM CURRENT TO MAXIMUM.

11.3.3 MEASURE HIGH VOLTAGE AT ANODE CAP.

11.3.4 SUBTRACT VALUE OBTAINED 11.3.3 FROM VALUE OBTAINED IN 11.2.3 THE RESULTS MUST BE

1.5KV MAXIMUM.

11.4 POWER CONSUMPTION

11.4.1 APPLY SIGNAL A (FULL WHITE FIELD) AT 69K MODE.

11.4.2 SET BRIGHTNESS 50%, CONTRAST 100%, PRESET SIZE.

11.4.3 POWER CONSUMPTION MUST BE LESS THAN 75WATTS.

12. CRT PARAMETERS

12.1 PURITY

12.1.1 INPUT FULL WHITE PATTERN AT 69KHZ MODE, SET BRIGHTNESS 50%,&CONTRAST 100% .

12.1.2 NO COLORED STAINS MAYBE VISIBLE WHEN APPLYING FULL WHITE PATTERN

12.2 DEGAUSSING

12.2.1 BEFORE SWITCHING ON THE DEGAUSSING , THE PTC101 MUST BE COLD, INTERNAL

DEGAUSSING MUST BE CAPABLE OF ACTIVATION 10 MINUTES OR LESS AFTER ANY PREVIIOUS

ACTIVATION.

12.2.2 APPLY THE SIGNAL WITH FULL WHITE PATTERN, REMOVE ALL MAGNETIC MATERIAL WITHIN

HALF A METER OF THE APPARATUS, THEN SWITCH ON THE DEGAUSSING, THE DEGAUSSING

SHOULD BE WELL.

12.3 CONVERGENCE

12.3.1 APPLY A CROSSHATC-HATCH SIGNAL. AT 69KHZ

12.3.2 WITH INSTRUMENT FACING EAST, CONVERGENCE WITHIN A CIRCLE EQUAL TO

THE DIAMETER OF THE VERTICAL HEIGHT MUST BE A ZONE 0.25mm, B ZONE 0.30mm C ZONE

0.35mm.

12.4 FOCUS

12.4.1 APPLY SIGNAL E (ALL “ ME “ PATTERN) AT 1024x768 85Hz MODE.

14.4.2 ADJUST CONTRAST FOR AN AREA OF LUMINANCE OF 28FL.

12.4.2 FOCUS MUST BE SET SUCH THAT INDIVIDUAL CHARACTER CAN BE DISTINGUISHED OVER

THE ENTIRE DISPLAY AREA.

9

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 13

12.5 MOIRE PATTERNING

12.5.1 FOCUS MUST BE ADJUSTED AS 12.4.

12.5.2 APPLY A FULL WHITE PATTERN SIGNAL.

12.5.3 ADJUST BRIGHTNESS CONTROL FOR A RASTER JUST AT THE THRESHOLD OF EXTINCTION.

12.5.4 AS THE CONTRAST CONTROL IS ROTATED TO ACHIEVE ANY DISPLAY INTENSITY

AT 12 FL

PRIMARY MODE: NO MOIRE PATTERN MAY BE VISIBLE.

OTHER MODE: A AREA ON MOIRE VISIBLE, B AREA HAS SLIGHT MOIRE.

12.6 BRIGHTNESS UNIFORMITY

12.6.1 APPLY A FLAT WHITE FIELD SIGNAL.AT 1024 * 768 85Hz MODE.

12.6.2 BRIGHTNESS VARIATION DUE TO CRT CHARACTERISTICS MUST BE MONOTONIC FROM THE

DISPLAY CENTER TO ANY DISPLAY EDGE, WITH THE DISPLAY CENTER AT 20 FEET LAMBENT

THE MAXIMUM CENTER TO CENTER LIGHT FALL OFF SHOULD BE NO MORE THAN 25% OF THE

AVERAGE OF THE FOUR CORNERS AND WITH NO ONE CORNER MORE THAN 25% LESS THAN

THAT OF THE CENTER .

12.7 ARCING CORONA

12.7.1 NO MORE THAN 2 ARCS ARE PERMITTED DURING AN 8 HOURS PERIOD OF NORMAL

OPERATION. INCLUDING ARCS INDUCED BY TURN-ON AND TURN-OFF.

12.7.2 NO ARCING OR CORONA MAY OCCUR BETWEEN METAL PARTS AT ANY TIME INCLUDING

TURN-ON AND TURN-OFF.

13. X-RAY PROTECTION TEST

13.1 SHUTDOWN CIRCUIT CHECKS.

13.1.1 INPUT VGA 31.5KHZ SIGNAL, PATTERN: SIGNAL A.

13.1.2 SET BRIGHTNESS 50%, CONTRAST 100%.

13.1.3 WHEN THE ZD405 PARALLEL WITH 27K RESISTOR, THE MOITOR MUST BE SHUTDOWN AND NO SPOT.

13.1.4 TURN POWER OFF, AFTER TURN ON AGAIN, MONITOR MUST BE OPERATED NORMAL.

NOTE: THIS TEST MUST BE PERFORMED ON ALL SETS BEFORE THE BACKCOVER IS INSTALLED.

14. VIDEO TEST

14.1 WHITE BALANCE CHORMATICITY & COLOR TRACKING & AVERAGE LIGHT O/P

(TEXT/SPEADSHEET MODE)

14.1.1 APPLY SIGNAL 69KHz/ 85KHz, PATTERN: FULL WHITE PATTERN.

14.1.2 SET BRIGHTNESS 50%, CONTRAST 100%

14.1 .3 SET ULTRABRITE FUNCTION TO TEXT/SPEADSHEET MODE.

14.1.3 COLOR TEMPERATURE MUST BE:

9300°Ko x = 0.283 ± 0.012; y = 0.297 ± 0.012

6500°Ko x = 0.313 ± 0.012; y = 0.329 ± 0.012

5000°Ko x = 0.349 ± 0.012; y = 0.359 ± 0.012

14.1.4 LIGHT OUTPUT MUST BE BETWEEN 28-32 FL.

14.1.5 COLOR TRACKING ERROR ( ONLY 9300°K )

14.1.6 APPLY FULL WHITE PATTERN ADJUST CONTRAST FROM 30FL TO 10FL AND CHECK THE

CHROMATICALLY MEET FLOWING SPEC.

| x (AT CONTRAST, 30) – x (AT CONTRAST, 25.75) |

0.007.

| y (AT CONTRAST, 30) – y (AT CONTRAST, 25.75) |

0.003.

| x (AT CONTRAST, 25.75) – x (AT CONTRAST, 10) |

0.007.

| y (AT CONTRAST, 25.75) – y (AT CONTRAST, 10) |

0.006.

14.2 CONTRAST RANGE

14.2.1 APPLY SIGNAL 69KHZ/ 85Hz, PATTERN: 70x70mm WINDOW BLOCK.

14.2.2 SET BRIGHTNESS 50%.

14.2.3 SET COLOR TEMPERATURE 9300

o

K

14.2.4 WITH CONTRAST AT MAXIMUM, 45 +

3FL FOR TEXT SPREADSHEET MODE

85+5 FL FOR GRAPHICS/GAME MODE 150+5 FL FOR VIDEO/MOVIE/DVD MODE

10

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 14

14.3 BRIGHTNESS RANGE

14.3.1 NO VIDEO INPUT, SET CONTRAST 0%, BRIGHTNESS 100%

14.3.2 RASTER LIGHT O/P 0.3 –0.8FL.

14.4 LUMINANCE LINEARITY

14.4.1 APPLY SIGNAL B MODE: VGA480.

14.4.2 SET BRIGHTNESS TO THRESOLD OF RASTER EXTINCTION.

14.4.3 ALL STAIRSTEPS MUST BE DISCERNIBLE FROM EACH OTHER FOR ANY CONTRAST SETTING

WHERE THE BRIGHTEST BAR IS VARIED BETWEEN 5 TO 20 FL BY ADJUST CONTRAST CONTROL.

14.5 TEMPERATURE STABILITY

14.5.1 APPLY SIGNAL A MODE: VGA480.

14.5.2 SET BRIGHTNESS TO THRESHOLD OF RASTER EXTINCTION AND CONTRAST TO PRODUCE 25FL AT

25

o

C.

14.5.3 LUMINANCE MUST NOT CHANGE MORE THAN 5FL OVER A TEMPERATURE RANGE

OF 10

o

C TO 40oC.

14.6 BANDWIDTH RESOLUTION

14.6.1 APPLY SIGNAL D MODE: 69KHZ / 85HZ.

14.6.2 OBSERVE THAT VERTICAL LINES AND HORIZONTAL LINES WHILE SET BRIGHTNESS CONTROL AT

DETECT POSITION AND CONTRAST CONTROL AT ANY SETTING.

14.7 VIDEO RISE TIME / FALL TIME.

14.7.1 INPUT FULL WHITE PATTERN AT 69KHz/85Hz

14.7.2 MEASURE VIDEO RISE & FALL TIMES AT EACH CATHODE WITH A LOW CAPACITANCE 100X PROBE

AND 150MHZ MINIMUM BW OSCILLOSCOPE.

14.7.3 ADJUST CONTRAST TO CATHODE OUTPUT 40V.

14.7.4 RISE AND FALL TIMES MUST BE AS FOLLOWS: 10% TO 90% <

8.5 ns.

15. FACTORY PRESET:

15.1 BURN-IN MODE CANCELLATION:

TO PUSH “

” AND “ ” KEY FIRST, AND THEN PUSH POWER SWITCH WITHOUT RELEASE “ ” AND “ ” KEY

AND SYNC INPUT IN ORDER TO LET MONITOR POWER ON, MEANWHILE WITH RELEASEING “

” AND “ ”KEY,

BURN-IN MODE WILL BE CANCELLED.

15.2 CONTRAST: 100

15.3 BRIGHTNESS: 50

15.4 COLOR: 9300

o

K

15.5 POWER SWITCH: POWER OFF

16. POWER MANAGEMENT TESTS.

16.1 POWER CONSUMPTIONS TEST TABLE:

SYNC PULSE

MODE

HORIZONTAL VERTICAL VIDEO

POWER LED RECOVERY TIME

(SEC)

NORMAL ON YES YES YES <75w GREEN -

NO YES

POWER SAVING

YES NO

POWER SAVING NO NO

BLANK

<5w AMBER <10

17. AUTO SIZING FUNCTION

17.1 INPUT ALL USER MODE AND CROSS PATTERN

17.2 PRESS THE AUTO SIZING KEY , THE PICTURE WILL BE MUTE AROUND 2~4 sec , THEN PICTURE WILL BE IN THE

CENTER OF THE MONITOR AND PICTURE CAN’T OVER THE FRONT BEZEL.

17.3 The PICTURE SIZE ARE AS FOLLOWING :

H-SIZE : 310 +

5 mm

V-SIZE : 230 +

5 mm

11

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 15

17.4 THE PICTURE POSITION ARE AS FOLLOWING .

~

A-B ~d 10mm

~

C-D ~d 10mm

17.5 INPUT ALL PRESET MODE AND CROSS PATTERN,

17.6 PRESS THE AUTO SIZING KEY, THE PICTURE WILL BE MUTE AROUND 1~2 sec , THEN PICTURE WILL BE IN THE

PRESET CONDITION ( SAME AS RECALL )

C

D

B

A

PICTURE

BAZEL

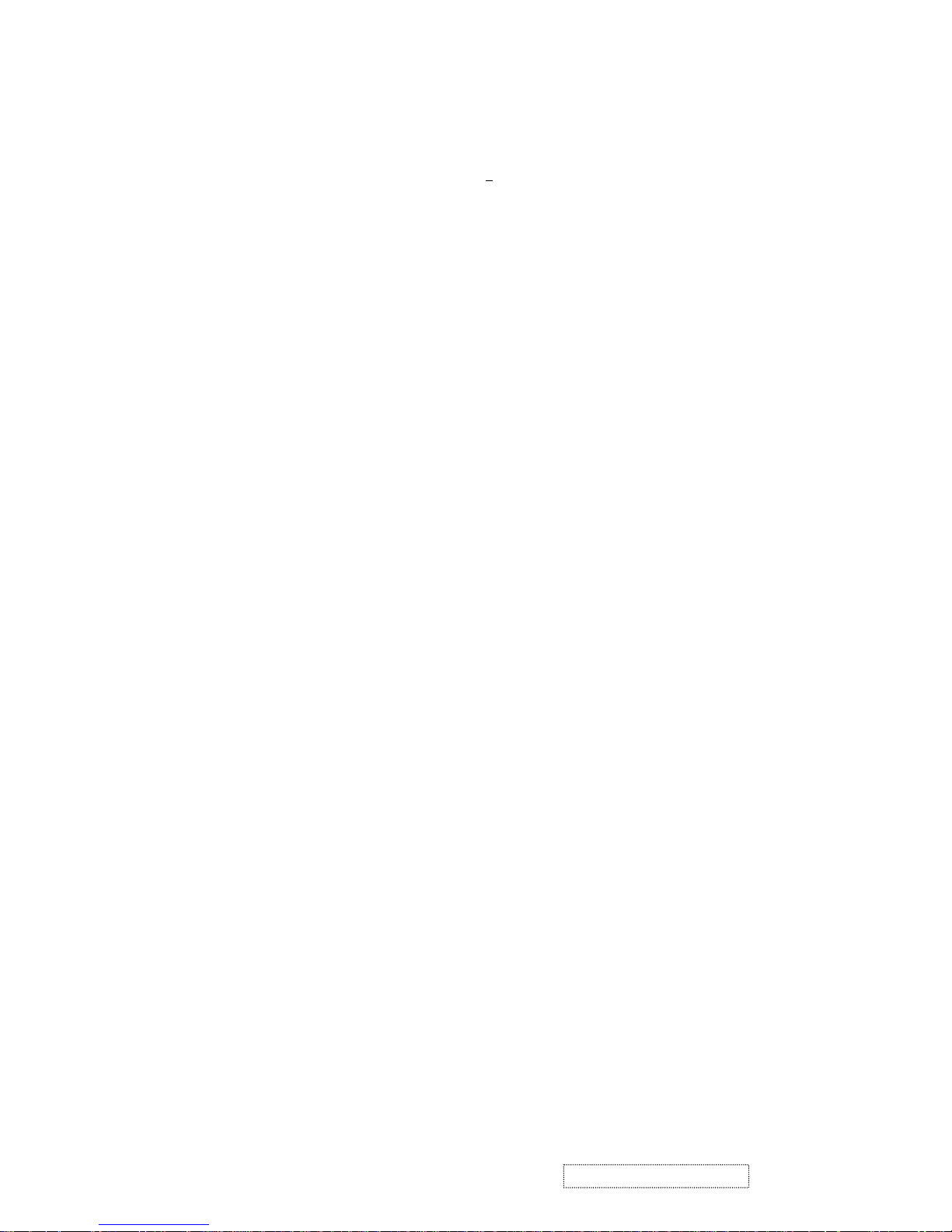

17.7 DIAGNOSTIC MESSAGE TEST.

17.7.1 AS 10KHZ <H <29KHZ OR H >73KHZ ; And 30HZ <V <48HZ OR V>160HZ.

THE OSD SHOW:

17.7.2 AS NO H-SYNC (H<10KHZ).

17.7.3 AS NO V-SYNC (V<10KHZ).

17.7.4 AS NO H-SYNC AND V-SYNC (H<10 AND V<10KHZ).

17.7.5 AS DISCONNECTED SIGNAL CABLE OR PC IS OFF.

THE OSD SHOW:

After 20 seconds

18. DDC TEST: CONNECTS SIGNAL CABLE INTO DDC TESTER TO PROGRAM EDID DATA SAVED IN IC303

18.1 THE EDID DATA SAVED IN IC302 SHOULD BE SAME AS SPECIFIED IN APPENDIX-D

18.2 EACH PRODUCTION UNIT SHOULD HAVE IT’S OWN SERIAL NEMBER, WEEK OF MANUFACTURE.

12

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 16

19. X-RAY RADIATION TEST.

19.1 NORMAL HIGH VOLTAGE

19.1.1 APPLY FULL BLACK PATTERN AT 640x480/ 60HZ MODE.

19.1.2 SET CONTRAST 0%, BRIGHTNESS 0%.

19.1.3 MEASURE HIGH VOLTAGE MUST BE 26KV +

1KV.

19.1.4 APPLY FULL BLACK PATTERN AT 1024x768 / 85HZ MODE.

19.1.5 REPEAT STEP 19.1.3

19.2 HIGH VOLTAGE REGULATION

19.2.1 APPLY FULL WHITE PATTERN AT 1024x768/ 85HZ MODE.

19.2.2 SET CONTRAST 100%, BRIGHTNESS 100%, MEASURE HV.

19.2.3 SET CONTRAST 0%, BRIGHTNESS 0%, MEASURE HV.

19.2.4 COMPARE THE DIFFERENCE BETWEEN ITEM 19.2.2. & 19.2.3, THE VOLTAGE REGULATION

SHOULD BE LESS THAN 1.5KV.

19.3 HOLD-DOWN TEST

19.3.1 APPLY FULL BLCAK PATTERN AT 640x480/ 60HZ MODE.

19.3.2 SET CONTRAST 100%, BRIGHTNESS 50%.

19.3.3 ZD405 IS PARALLELED WITH 27K RESISTOR, THE MONITOR MUST BE SHUTDOWN.

19.3.4 TURN OFF, REMOVE PARALLELED RESISTOR, THEN TURN ON AGAIN, MONITOR MUST

BE OPERATED NORMALLY.

19.4 FAULT TEST.

19.4.1 APPLY FULL WHITE PATTERN AT 1024x768/ 85HZ MODE.

19.4.2 SET CONTRAST 0%, BRIGHTNESS 50%.

19.4.3 ADJUST VR403 TO MAXIMUM POSITION.

19.4.4 ADJUST FBT SCREEN VR, LET BEAM CURRENT BE 9uA, MEASURING THE H.V AND

X-RADIATION.

19.4.5 THE H.V. SHOULD BE UNDER 29KV AND X-RADIATION SHALL BE LESS THAN 0.1Mr/HR.

19.4.6 THE NORMAL ADJUST SHOULD BE RECOVERED AFTER THIS TEST IS FINISHED.

19.5 X-RAY RADIATION TEST.

19.5.1 TO SIMULATE S-RAY PROTECTION CIRCUIT: USE 18K, 5% RESISTOR TO PARALLED WITH

R476

19.5.2 CONTROL VR403 TO SET AT MINIMUM POINT.

19.5.3 APPLY FULL WHITE PATTERN AT 1024x768/ 85HZ MODE.

19.5.4 ADJUST CONTRAST/BRIGHTNESS SETTING BACK AND FROTH TO GET A BEAM CURRENT

AT 50uA, 200uA, 400uA RESPECTIVELY.

19.5.5 ADJUST VR403 TO GET H.V. GRADUALLY UNIT THIS TESED SET IS AT THE THERSHOLD

OF SHUTDOWN BUT STILL WORKING.

19.5.6 RECORD THE HIG VOLTAGE OF THERSHOLD AT 50uA, 400uA, THE H.V. SHALL BE LESS

THAN 31KV.

19.5.7 USE TVX-1A/ 1B/ 2000 AND RF/D TO MEASURE THE X-RADIATION AT THE POSITION OF

TOP, BOTTOM, RIGHT, LEFT, FRONT AND BACK SIDE OF THE MONITOR, THEN WRITE

DOWN THE READINGS AT EACH SIDE OF THE TESED UNIT.

19.5.8 THE X-RAY RADIATION SHALL BE LESS THAN 0.1Mr/hr.

19.5.9 THE NORMAL CONDITION SHOULD BE RECOVERED AFTER ALL TEST ITEMS ARE

FINISHED.

D: CHASSIS ALIGNMENT / TEST SPECIFICATION.

1. POWER SUPPLY ALIGNMENT: INPUT SIGNAL: VGA480 CROSS-HATCH PATTERN/

1.1 ADJUST VR101 UNTIL DC=75V0.3V AT TP201

1.2 ADJ VR403 UNTIL VOLTAGE AT TP208 = 63.0V 0.3V.

2. MEASURE

TP201 = 105 V ± 5%

TP202 = 46.5 V ± 5%

TP203 = 13.5 V ± 5%

TP204 = 7.5 V ± 5%

TP205 = 12 V ± 5%

TP206 = 6.3 V ± 5%

TP207 = 5.5 V ± 5%

TP208 =-13.5 V ± 5%

13

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 17

3. VIDEO BOARD FUNCTION TEST & PRE-ALIGNMENT.

3.1 INPUT SIGNAL: 10.24x768 75HZ.

3.1.1 PUSH R.G.B BIAS BOTTOMS, OBSERVE THAT THE RASTER MUST CHANGE WITH COLOR R.G.B

RESPECTIVELY.

3.1.2 PUSH R.G.B DRIVE BOTTOMS, OBSERVE THAT THE ACTIVE MUST CHANGE WITH COLOR R.G.B

RESPECTIVELY.

3.2 CONTRAST & BRIGHTNESS

3.2.1 PUSH KEY “ ” TO DISPLAY BRIGHTNESS OR PUSH KEY “ ” TO DISPLAY CONTRAST ICON ON

OSD.

3.2.2 PUSH “MENU: KEY SELECTION CONTRAST AND BRIGHTNESS.

3.2.3 PUSH KEY “ ” OR“ ”KEY CHECK CONTRAST AND BRIGHTNESS FUNCTION.

4. MAIN BOARD FUCTION TEST

4.1 BASIC FUNCTION

4.1.1 PUSH “MENU”KEY, SELCT H-SIZE, H-POSITION, V-SIZE, V-POSITION, ZOOM

4.1.2 PUSH KEY “

” OR“ ”KEY RECHECK H-SIZE, H-POSITION, V-SIZE, V-POSITION, ZOOM

4.2 GEOMETRY FUNCTION CHECK

4.2.1 PUSH “MENU” KEY, SELECTION PINCUSHION, PINBALANCE, TRAPESOID, PARALLELOGRAM & ROTATE

FUNCTION.

4.2.2 PUSH KEY “

” OR“ ”KEY CHECK PINCUSHION, PINBALANCE, TRAPEZOID, PARALLELOGRAM &

ROTATE FUNCTION.

4.3 HV TEST

4.3.1 HV MEASURE AT VGA MODE SHOULD BE 26 +

1KV AT MAX. BEAM

4.3.2 HV MEASURE AT 60K MODE SHOULD BE 26 +

1KV AT MAX. BEAM

4.4 X-RAY PROTECTION TEST

4.4.1 WHEN THE R455 PARALLEL WITH 27K RESISTOR, THE MONITOR MUST BE SHUTDOWN AND NO SPOT

4.4.2 TURN POWER OFF, AFTER TURN ON AGAIN, MONITOR MUST BE OPERATED NORMAL

E. RELIABILITY SPECIFICATION:

1. ENVIRONMENT TEST.

1.1 TEMPERATURE:

OPERATING: 0

o

C to 40oC (OUTSIDE OF ENCLOSURE)

STORAGE: -40

o

c to 60oC.

1.2 HUMIDITY:

OPERATING: 5% TO 95% RELATIVE HUMIDITY (NON-CONDENSING)

STORAGE: 5% TO 95% RELATIVE HUMIDITY (NON-CONDENSING)

1.3 ALTITUDE:

OPERATING: -400METERS TO +3000 METERS.

STORAGE : -400 METERS TO +12000METERS.

2. TRASPORTATION TEST.

2.1 VIBRATION: THE UNIT SHALL BE DESIGNED TO SURVIVE THE FOLLOWING VIBRATION TEST.

VIBRATION FREQUENCY : 5~250Hz.

ACCELERATION : 1.0G.

SWEEP TIME : 1OCT/MIN.

TEST TIME : 60MIN PER AXIS.

2.2 DROP TEST: THIS TEST EVALUATES THE UNIT AGAINST THE AFFECT OF DROPS ENCOUNTERED DURING THE

PROCESS OF TRANSPORTATION.

2.2.1 DROP SEQUENCE.

A. BOTTOM CORNER.

B. THE TREE RADIATING EDGES FROM THAT CORNER.

C. SIX FLAT SURFACES OF THE PACKAGE.

2.2.2 DROP HEIGHT: 76.2CM.

2.2.3 ACCEPTANCE CRITERIA

THE MONITOR SHALL HAVE NO DEGRADATION IN MECHANICAL OR FUNCTION PERFORMANCE ERROE

AFTER BEGIN SUBJECTED THERE TESTS.

14

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 18

3. ELECTRONIC DISCHARGE (E.S.D).

3.1 AIR DISCHARGE:

15KV: NO UNRECOVERABLE DAMAGE IS ALLOWED.

3.2 CONTROL DISCHARGE:

9KV: NO UNRECOVERABLE DAMAGE IS ALLOWED.

4. ARCING TEST.

A DIRECT PATH TO THE EXTERNAL AQUADAG GROUND FOR CRT ARCING CURRENTS SHALL BE PROVIDEED THROUGH

SPARK GAPS OR ALTERNATE DEVICE SUCH THAT NO DAMAGE OCCURS TO THE CRT OR THE MONITOR CIRCUITRY.

5. POWER LINE DISTURDANCE (P.L.D).

THE UNIT SHALL NOT COMPONENTS FAILURES OR FUNCTION ERROR UNDER THE FOOLOWING CONDITIONS.

TEST#1

FLUCTUATION RANGE NOMINAL LINE –30% NOMINAL LINE-100%

FLUCTUATION TIEM 3 CYCLES 1 CYCLES

INTERVAL 100 CYCLES 100 CYCLES

TEST PERIOD 5 CYCLES 5 CYCLES

TEST#2

FLUCTUATION RANGE NOMINAL LINE –15%/ -15%

FLUCTUATION TIEM 1 MINUTE

INTERVAL 1 MINUTE

TEST PERIOD 10 MINUTES.

NO. SIGN OF FAULTS OR MALFUNCTIONS SHALL BE OBSERVED UNDER THE ABOVE TEST CONDITIONS.

5.1 AC LINE NOISE TEST.

THE TEST EVALUATES THE OPERATION OF THE AGAINST AC LINE VOLTAGE.

5.1.1 TEST EQUIPMENT

A. AC LINE NOISE SIMULATOR (INS-410).

B. ISOLATION TRANSFORMER.

5.1.2 TEST METHOD.

APPLIED VOLTAGE + 1KV

PULSE WIDTH 50ns, 100ns, 400ns, 800ns

APPLIED PHASE 0 360 VIBRABLE

APPLIED TIME 1 MINUTE

NO SIGN OFF FAULTS OR MALFUNCTIONS SHALL BE OBSERVED.

6. RELIABILITY

THE MEAN TIME BETWEEN FAILURE (MTBF) WILL BE GREATER THAN 20000 HOURS WHEN OPERATION A

TEMPERATURE OF 25

O

C CALCUTION SHALL BE PER MIL-HDBK-217F WITH GROUND BEGIN.

7. BURN-IN

A> AC LINE: 110V/ 60HZ OR 230V / 50HZ.

B> TEMPERATURE: 25 +

5OC.

C> BRUN-IN TIME: 24 HOURS.

15

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 19

F. REGULATORY REQUIREMENT:

1. SAFETY

1.1 UL

THE MONITOR SHALL BE APPROVED TO UL STANDARD UL1950.

1.2 CSA

THE MONITOR SHALL BE CERTIFIED TO CSA STANDARD CSA-CS22.2. NO.950.

1.2 TUV: 60950

1.3 IEC STANDARD: IEC60950

1.4 THE MONITOR SHALL MEET THE REQUIREMENTS AS FOLLOWS:

A) FCC RULES PART 15 SUBPART J FOR CLASS B.

B) CE: EN55022, EN55024

1.5 ERGONMICS

A) MPRII.

B) TUV/GS.

C) TCO99 (OPTION).

1.6 DIELECTRIC STRENGTH TEST:

THE MONITOR SHALL WITHSTAND A 2545 VDC / 3 SEC.

BETWEEN PRIMARY AND SECONDARY.

BETWEEN PRIMARY AND PROTECTIVE EARTHLING.

1.7 LEAKAGE CURRENT:

THE MAXIMUM CURRENT FLOWING IN THE FRAME / GROUND CONDUCTOR SHALL BE LESS THAN 0.75mA AT

110 / 240

VAC.

1.8 X-RADIATION:

ALL MONITORS MUST COMPLY WITH THE DHHS REGULATIONS CONCERNING X- RADIATION. THAT IS A

FAILURE CONDITION MUST BE SIMULATED THAT WOULD PRODUCE THE WORST CASE X-RAYS SHOULD NOT

MEASURE MORE THAN 0.5 MR / HR (MILLIRONTGEN PER HOUR) AT A DISTANCE OF TWO-INCHES ANYWHERE,

AROUND THE MONITOR.

G. APPENDIX:

APPEDNDIX A:

ALL SIGNALS MUST BE AVAILABLE WITH CHROMA 2135, 2250.

SIGNAL A FULL WHITE PATTERN.

SIGNAL B STAIRSTEP: 16 GRAY LEVELS INCLUDING BLACK AND WHITE ASCENDING FROM LEFT TO RIGHT IN

EQUAL PIXEL WIDTHS.

SIGNAL C COLOR BARS: EIGHT 100 PIXEL WIDE BARS.

SIGNAL D CROSSHATCH: 12 * 16 SQUARES.

SIGNAL E ACTIVE DISPLAY CONTAINS ALL CHARATERS “ME” ON WHITE BACKGROUND.

SIGNAL F 70mm x 70mm FIELD OF WHITE CENTERED IN THE MIDDLE OF THE SCREEN.

APPENDIX B:

TIMING OF INPUT SIGNALS. INPUT LEVEL SPECIFICATION.

A.INPUT LEVEL

ANALOG VIDEO

R.G.B: 0.7V ± 3DB

COMPOSITE SYNC

LOW (0) 0.00V MIN. 0.65V MAX.

HIGH (1) 2.40V MIN. 5.50V MAX

APPENDIX C: MAGNETIC FIELD

!

!

! !!!!!OPSUI!BNFSJDB!!!;!CI!>!361!,

!21NH-!CW!>!561!,!21!NH/!

EUROPE :BH=250+

10MG, BV = 450 + 10 MG.

ASIA :BH=400+

10MG, BV = 270 + 10 MG.

AUSTRALIA : BH = 270 +

10MG, BV = -570 + 10 MG.

CHINADOMESTIC :BH=340+

10MG, BV = 360 + 10 MG.

16

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 20

APPENDIX D:

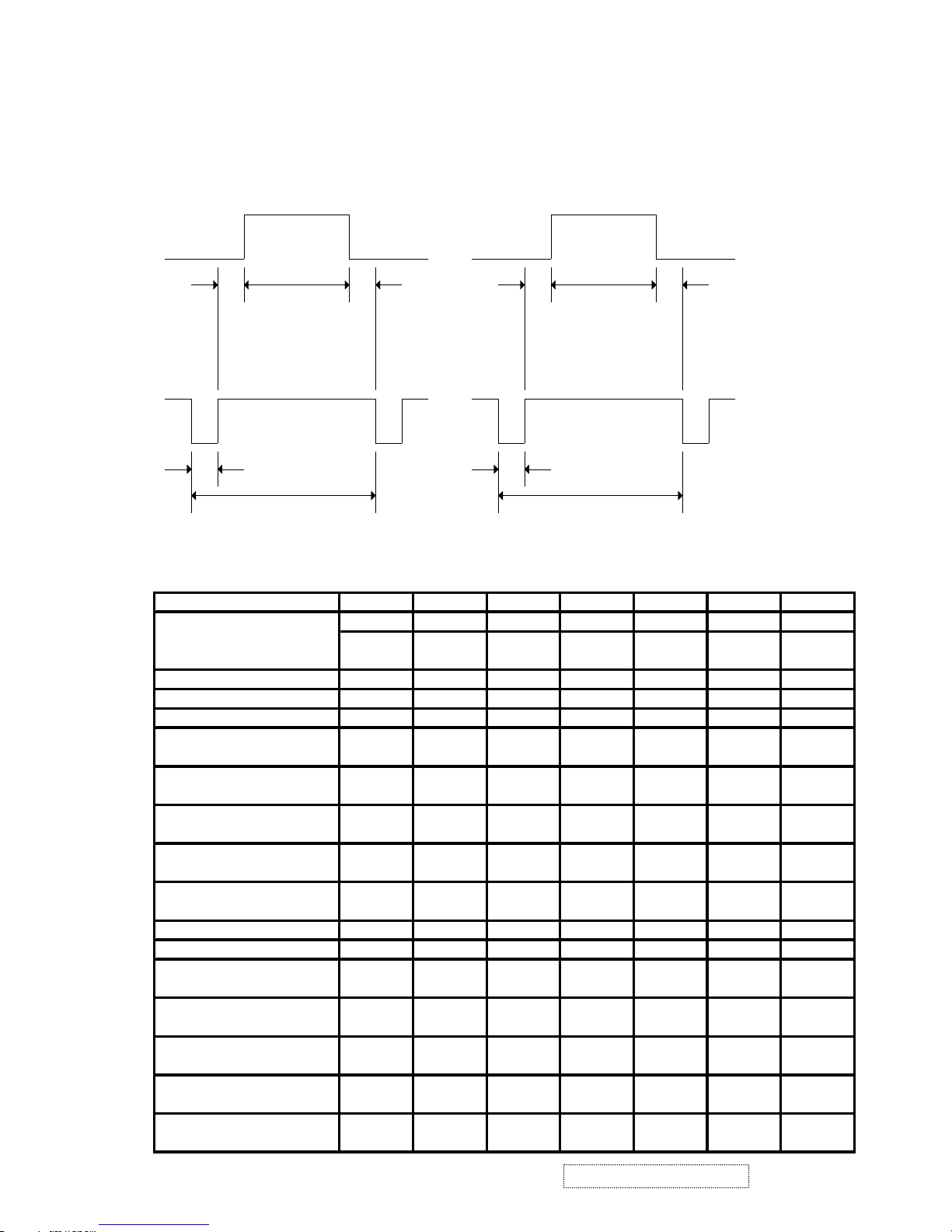

TIMING OF INPUT SIGNALS.

Video

D

CE

A

B

Video

R

QS

O

P

Sync Sync

Horizontal

Vertical

Sync Polarity : Positive / Negative

PRESET TIMING CHART.

MODE NO.

123456

VGA VGA MAC VESA VESA VESA MAC

MODE NAME

640

X

640

X

640

X

640

X

640

X

800

X

832

X

400 480 480 480 480 600 624

PIXEL CLOCK (MHZ)

25.175 25.175 30.240 31.500 36.000 49.557

.

27

HORIZONTAL FREQ (KHZ)

31.469 31.469 35.00 37.50 43.269 46.875 49.717

SYNC . POLARITY -----+

A H.TOTAL (us)

31.778 31.778 28.571 26.667 23.111 21.333 20.115

(PIXELS) (

800

)(

800

)(

864

)(

840

)(

832

)(

1056

)(

1152

)

B H.SYNC (us)

3.813 3.813 2.116 2.032 1.556 1.616 1.118

(PIXELS) (96)(

96

)(

64

)(

64

)(

56

)(

80

)(

64

C H.BACK PORCH (us)

1.907 1.907 3.175 3.810 2.222 3.232 3.911

(PIXELS) (48)(

48

)(

96

)(

120

)(

80

)(

160

)(

224

)

D H.ACTIVE (us)

25.422 25.422 21.164 20.317 12.778 16.162 14.528

(PIXELS) (

640

)(

640

)(

640

)(

640

)(

640

)(

800

)(

832

)

E H.FRONT PORCH (us)

0.636 0.636 2.116 0.508 1.556 0.323 0.558

(PIXELS) (16)(

16

)(

64

)(

16

)(

56

)(

16

)(

32

)

VERTICAL FREQ (HZ)

70.089 59.940 66.667 75.00 85.008 75 74.53

SYNC . POLARITY + ----+

O V.TOTAL (ms)

14.268 16.684 15.000 13.333 11.764 13.333 13.417

(LINES) (

449

)(

525

)(

525

)(

500

)(

509

)(

625

)(

667

)

P V.SYNC (ms)

0.064 0.064 0.086 0.080 0.069 0.064 0.06

(LINES) (2)(

2

)(

3

)(

3

)(

3

)(

3

)(

3

)

Q V.BACK PORCH (ms)

1.112 1.048 1.114 0.427 0.578 0.448 0.784

(LINES) (35)(

33

)(

39

)(

16

)(

25

)(

21

)(

39

)

R V.ACTIVE (ms)

12.711 15.254 13.714 12.800 11.093 12.812

.

552

(LINES) (

400

)(

480

)(

480

)(

480

)(

480

)(

600

)(

624

)

S V.FRONT PORCH (ms)

0.381 0.381 0.086 0.026 0.023 0.021 0.021

(LINES) (12)(

10

)(

3

)(

1

)(

1

)(

1

)(

1

)

17

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 21

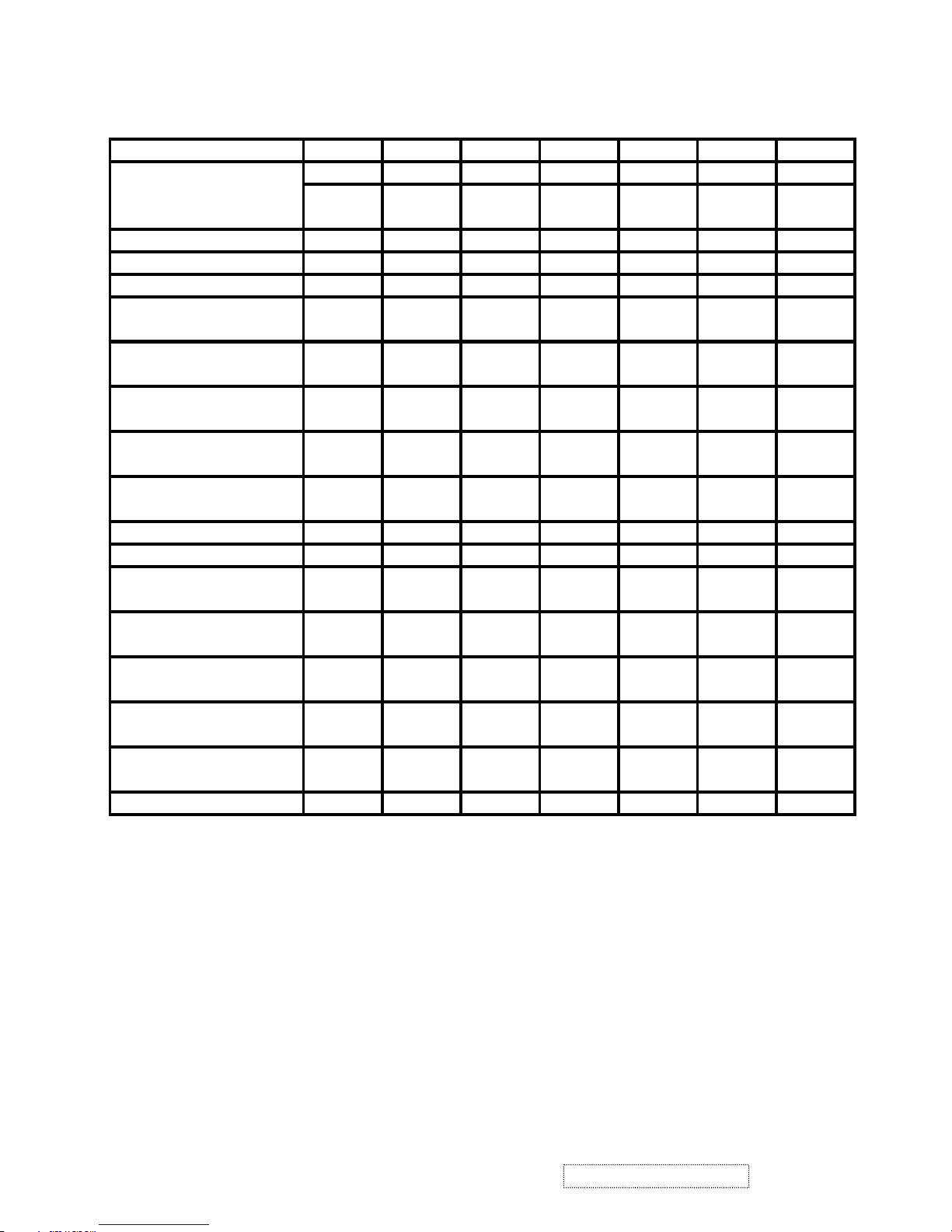

MODE NO.

8 9 10 11 12

VESA VESA MAC VESA VESA

MODE NAME

800 X 1024 X 1024 X 1280 X 1024 X

600 768 768 1024 768

PIXEL CLOCK (MHZ)

56.25 78.75 80.000 108.000 94.500

HORIZONTAL FREQ (KHZ)

53.674 60.023 60.241 63.981 68.677

SYNC. POLARITY

++-++

A H.TOTAL (us)

18.631 16.66 16.600 15.630 14.561

(PIXELS)

(1048 ) (1312 ) (1328 ) (1688 ) (1376 )

B H.SYNC (us)

1.138 1.219 1.2 1.037 1.016

(PIXELS)

(64)

(96)

(96)

(

112

)

(96)

C H.BACK PORCH (us)

2.702 2.235 2.2 2.296 2.201

(PIXELS)

(152 ) (176) (176) (248 ) (208 )

D H.ACTIVE (us)

14.222 13.003 12.8 11.852 10.836

(PIXELS)

(

800

)

(

1024

)

(

1024

)

(

1280

)

(

1024

)

E H.FRONT PORCH (us)

0.569 0.23 0.4 0.444 0.508

(PIXELS)

(32 ) (16 ) (32 ) (48 ) (48 )

VERTICAL FREQ(HZ)

85 75.029 74.927 60.200 85.000

SYNC. POLARITY

++-++

O V.TOTAL (ms)

11.756 13.328 13.346 16.661 11.765

(LINES)

(631 ) (800 ) (804 ) ( 1066 ) (808 )

P V.SYNC (ms)

0.056 0.05 0.05 0.047 0.044

(LINES)

(3) (3) (3) (3) (3)

Q V.BACK PORCH (ms)

0.503 0.466 0.498 0.594 0.524

(LINES)

(27) (28) (30) (38 ) (36 )

R V.ACTIVE (ms)

11.179 12.795 12.749 16.005 11.183

(LINES)

(600 ) (768 ) (768 ) ( 1024 ) (768 )

S V.FRONT PORCH (ms)

0.019 0.017 0.05 0.016 0.015

(LINES)

(1) (1) (3) (1) (1)

18

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 22

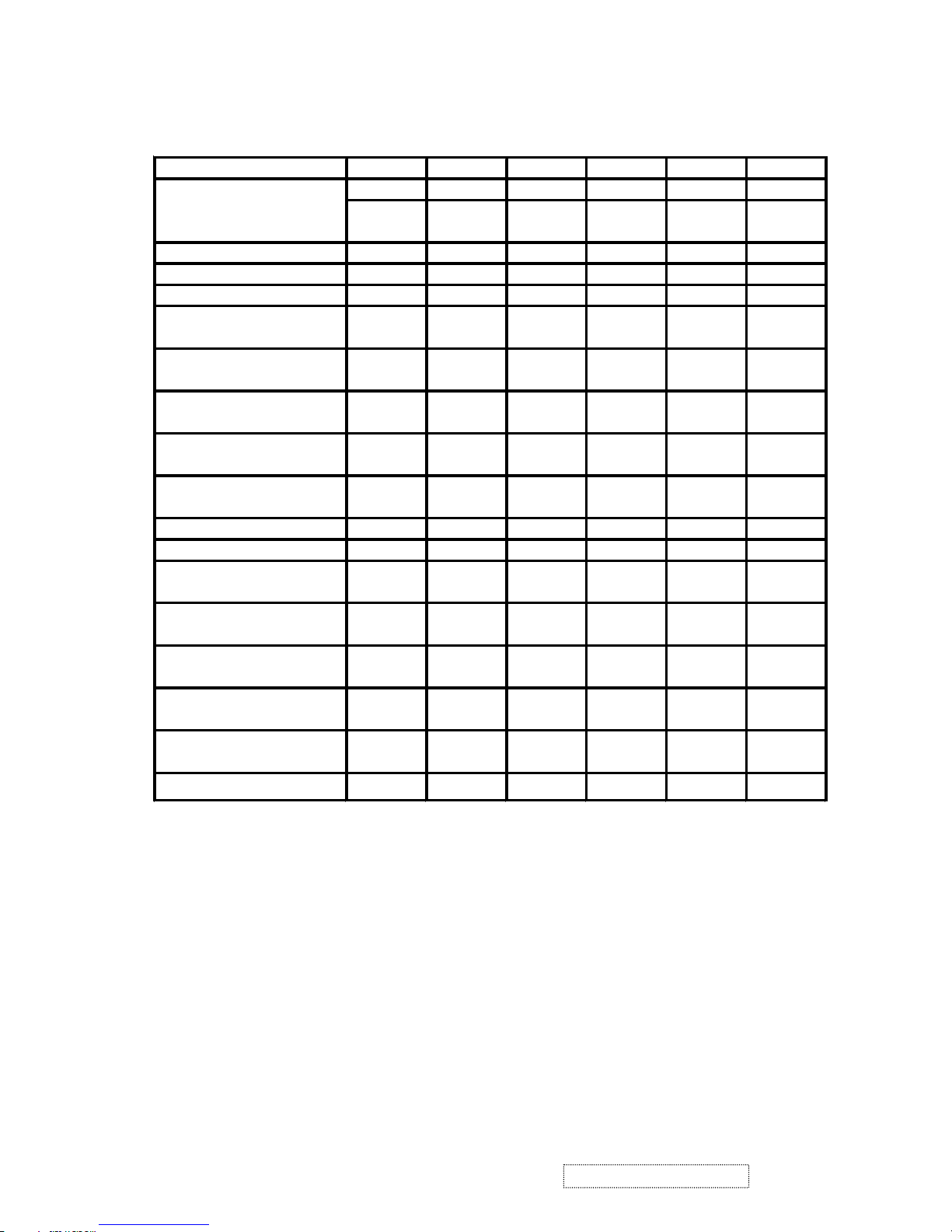

USER TIMING CHART

MODE NO.

1234567

IBM VESA VESA VESA VESA VESA IBM

MODE NAME

720

X

640

X

640

X

800

X

800

X

800

X

1024

X

400 480 350 600 600 600 768

PIXEL CLOCK (MHZ)

34.381 31.500 31.500 36.000 40 50 44.9

HORIZONTAL FREQ (KHZ)

37.048 37.861 37.861 35.156 37.879 48.077 35.522

SYNC. POLARITY

+-+++++

A H.TOTAL (us)

26.992 26.413 26.413 28.444 26.420

.

828

.

151

(PIXELS)

928 832 832 1024 1056 1040 1264

B H.SYNC (us)

2.094 1.27 2.032 2.000 3.22

.

43

.

92

(PIXELS)

72 40 64 72 128 120 176

C H.BACK PORCH (us)

3.025 4.064 3.048 3.556 2.21

.

28 1.247

(PIXELS)

104 128 96 128 88 64 56

D H.ACTIVE (us)

20.942 20.317 20.317 22.222 20 16 22.806

(PIXELS)

720 640 640 800 800 800 1024

E H.FRONT PORCH (us)

0.931 0.762 1.016 0.667 1 1.12 0.178

(PIXELS)

32 24 32 24 40 56 8

VERTICAL FREQ(HZ )

88.000 72.809 85.080 56.250 60.317 72.188 86.958

SYNC. POLARITY

+- -++++

O V.TOTAL (ms)

11.364 13.735 11.754 17.778 16.579 13.853 11.5

(LINES)

421 520 445 625 628 666 408

P V.SYNC (ms)

0.081 0.079 0.079 0.057 0.106 0.125 0.113

(LINES)

3332464

Q V.BACK PORCH (ms)

0.459 0.739 1.585 0.626 0.607 0.478 0.563

(LINES)

17 28 60 22 23 23 20

R V.ACTIVE (ms)

0.797 12.678 9.244 17.067 15.84 12.48 10.81

(LINES)

400 480 350 600 600 600 384

S V.FRONT PORCH (ms)

0.027 0.237 0.845 0.028 0.026 0.77 0.014

(LINES)

1 9 32 1 1 37 0

SCANTYPE INTERLACED NO NO NO NO NO NO YES

19

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 23

MODE NO.

8 9 10 11 12 13

VESA VESA VESA VESA VESA VESA

MODE NAME

1024

X

1024

X

1280

X

1152

X

640

X

720

X

768 768 960 864 400 400

PIXEL CLOCK (MHZ)

75.000 65.000 108.000 108 31.535

.

5

HORIZONTAL FREQ (KHZ)

56.476 48.36 60.000 67.537

.

861 37.927

SYNC. POLARITY

--++--

A H.TOTAL (us)

17.707 20.677 16.667 14.815 26.413 26.366

(PIXELS)

1328 1344 1800 1600 832 936

B H.SYNC (us)

1.813 2.092 1.037 1.185 2.032 2.028

(PIXELS)

136 136 112 128 64 72

C H.BACK PORCH (us)

1.92 2.462 2.889 2.37 3.048 3.042

(PIXELS)

144 160 312 256 96 108

D H.ACTIVE (us)

13.653 15.754 11.852 10.667 20.317 20.282

(PIXELS)

1024 1024 1280 1152 640 720

E H.FRONT PORCH (us)

0.32 0.369 0.889 0.593 1.016 1.014

(PIXELS)

24 24 96 64 32 36

VERTICAL FREQ(HZ)

70.069 60.004 60.000 75 85.08 85.039

SYNC. POLARITY

- -++++

O V.TOTAL (ms)

14.272 16.666 16.667 13.333 11.754 11.759

(LINES)

806 806 1000 900 445 446

P V.SYNC (ms)

0.106 0.124 0.05 0.044 0.079 0.079

(LINES)

663333

Q V.BACK PORCH (ms)

0.513 0.60

.

60

.

474 1.083 1.107

(LINES)

29 29 36 32 41 42

R V.ACTIVE (ms)

13.599 15.88 16.000 12.810

.

665 10.546

(LINES)

768 768 960 864 400 400

S V.FRONT PORCH (ms)

0.053 0.062 0.017 0.015 0.026 0.026

(LINES)

331111

SCANTYPE INTERLACED NO NO NO NO NO NO

20

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 24

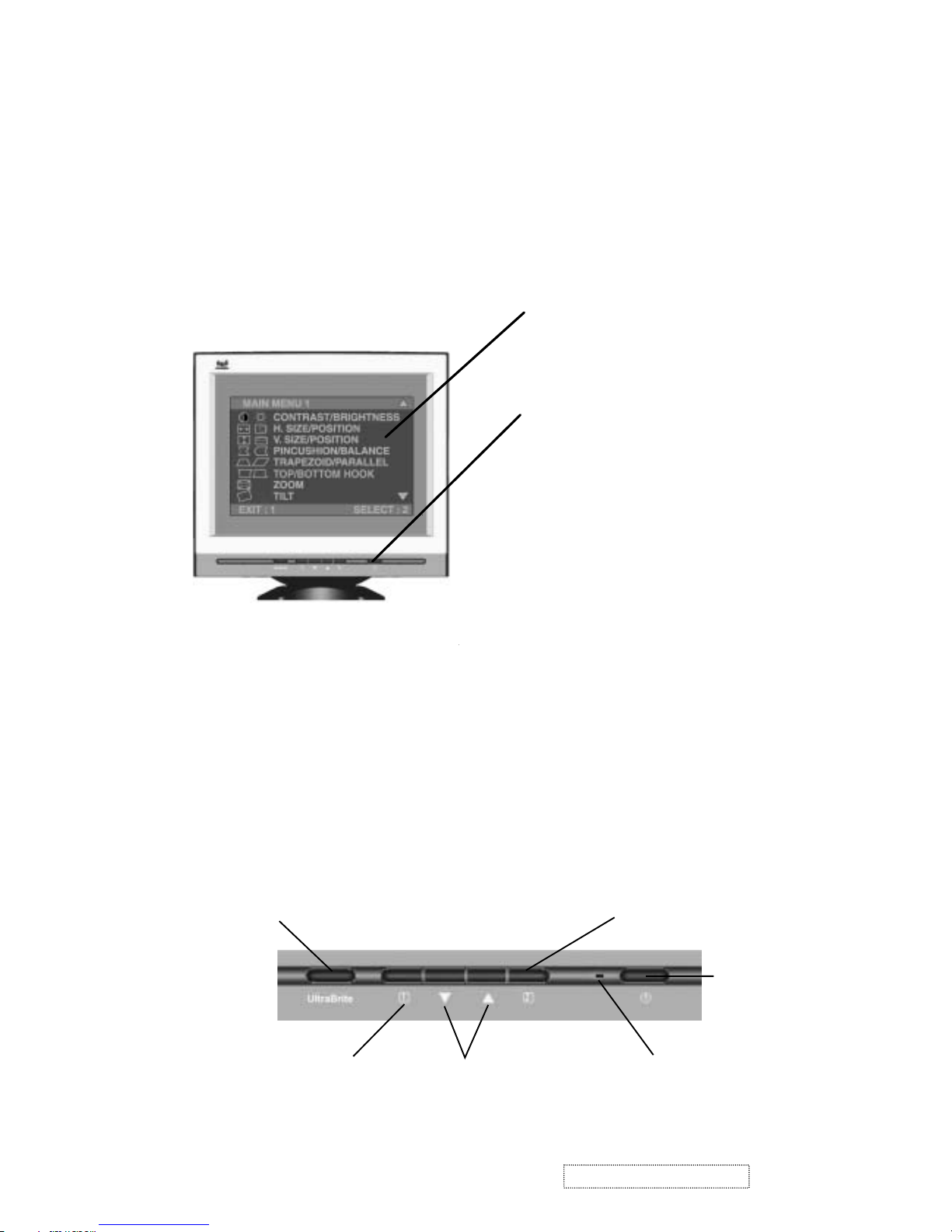

Adjusting the Screen Image

Use the buttons on the monitor control panel to adjust the OnView® controls.

1 Press [1] to display the Main Menu.

NOTE: OnView controls disappear after 15 seconds.

2 Press ▲ or ▼ to highlight an option.

3 Press [2].

4 Press ▲ or ▼ to adjust the setting.

5 Press [1] twice to save and exit.

Main Menu

Control panel

Displays the Main

Menu or exits and

saves

Power button

Scrolls through

options or adjusts

settings

Power light:

green = on

orange = power save

Switches between Normal, UltraBrite 3x and UltraBrite 5x modes:

"NORMAL: TEXT/SPREADSHEET":

displays a standard CRT brightness of 120

"ULTRABRITE 3x: GRAPHICS/GAME":

displays up to 300 nits of brightness for

applications and games .

"ULTRABRITE 5x: VIDEO/MOVIE/DVD":

displays up to 500 nits of brightness for

When selected, this brightness level setting

nits for text and spreadsheet applications.

When selected, this UltraBrite™ setting

optimum display performance of graphics

When selected, this UltraBrite™ setting

optimized display performance of video applications.

Displays the highlighted

option or toggles

between options

3. Front Panel Function Control Description

21

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 25

Menu Options

Control Explanation

Contrast adjusts the difference between the image background

(black level) and the foreground (white level).

Brightness adjusts the background black level of the screen

image.

Horizontal Position moves the screen image left or right.

Horizontal Size adjusts width of the screen image.

Vertical Position moves the screen image up or down.

Vertical Size adjusts the height of the screen image.

Pincushion curves the vertical sides of the screen image.

Pin Balance curves the vertical edges of the screen image to the

left or right.

Trapezoid adjusts the top and bottom of the screen image until

they have equal length.

Parallelogram slants the vertical edges of the screen image until

they are parallel.

Top Hook

adjusts the top corners of the screen image.

Bottom Hook

adjusts the bottom corners of the screen image.

22

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 26

Tilt rotates the entire screen image.

Degauss removes the build-up of magnetic fields that can cause

irregular colors to appear around the edges of screen images.

There are two ways to degauss the display: automatically by

turning the monitor on, or manually by selecting the Degauss

control from the menu.

With Degauss selected from the menu, press button [2] to

degauss the monitor manually.

Important: Do not degauss repeatedly. Doing so can be harmful

to the display. Wait at least 20 minutes before selecting this

control again.

Language allows you to choose from among several languages

for the menus and control screens: English, French, German,

Italian, and Spanish.

OSD Position allows you to move the on-screen menus and

control screens.

Control Explanation

Zoom

expands and contracts the entire screen image.

H/V Moire reduces interference patterns that appear as ripples,

waves, or unwanted background color textures.

Interference patterns of this type are most noticeable when

viewing images having closely spaced lines or finely detailed

patterns.

Input Level

displays the voltage level of the video signal.

Note: the default selection is 0.7V.

ViewMatch® Color

provides several color options: preset color

temperatures and User Color which allows you to adjust red (R),

green (G), and blue (B). The factory setting for this product is

9300K (9300°Kelvin).

9300K — Adds blue to the screen image for cooler white (used

in most office settings with fluorescent lighting).

6500K — Adds red to the screen image for warmer white and

richer red.

5000K — Adds blue and green to the screen image for a darker

color.

User Color — Individual adjustments for red, green, and blue.

23

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 27

Memory Recall returns adjustments to the original factory

settings if the display is operating in a Preset Timing Mode. (See

the table at the bottom of page 10.)

Exception: This control does not affect changes made with the

User Color control.

Viewmeter

®

displays information regarding the current input

signal coming from the graphics card of the computer. See

Setting the Timing Mode on page 5.

Control Explanation

automatically adjusts horizontal and vertical size

and position of the screen image.

Auto Sizing

24

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 28

A. Power supply.

1. Power supply.

1-1. Primary side:

1.1.1 The raw DC voltage is built on C101 from AC line voltage through EMI filter, and bridge rectifier (CR101),

then composes with main transformer (T101), switching MOSFET (Q101) and PWM IC (IC101) to form a DC-DC

voltage converter by fly-back switching topology,which means that the power energy is pumped up at primary

winding of transformer during duty “ON” cycle, then transfer the stored energy to primary side, and voltage

regulated by IC101 using way of pulse width modulation.

The IC101 starts up through some components composed of R103, R104, R105, Q102 and ZD101 to build up VCC

voltage at pin7, and supplied by transformer once secondary voltage is established.

IC101 have to work synchronously with horizontal sync by feeding fly-back pulse through C112.

1.1.2 R120, C108 and D113 composed a soft-start circuit to prevent over-stress occurred during power start.

1.1.3 The TP201: 75V voltage can be adjusted through VR101.

1.1.4 IC102, Q216, R204,R228 is 2W circuit in the power saving mode.

1-2. Secondary side

:

Each raw of DC voltage output from T101.

1.1.5 TP201 voltage output from T101 pin12 and is rectified by D202, C201.

1.1.6 TP202 voltage output from T101 pin1 1and is rectified by D203, C202.

1.1.7 TP203 voltage output from T101 pin17 and is received by D205, C205.

1.1.8 TP204 voltage output from T101 pin18 and is rectified by D206, C206.

1.1.9 TP205 voltage output from TP203 is rectified by Q206, ZD201 and D208.

1.1.10 TP207 voltage output from TP204 and is rectified by Q210, ZD202 and D209.

1.1.11 TP209 voltage output from T101 pin10 and is rectified by D207, C207.

2. Power saving.

The EPA power management state as follows:

State SUS Pd Power consummation LED

Normal H H 100% Green

Power saving

L L

d 2W

Amber

SUS = IC301 (MCU) pin 21 output.

PD = IC301 (MCU) pin17 output.

In the power saving mode, no output from Q206 (12V) and Q208 (6.3V)

.

3. Degauss.

When the power is on and when press manual degauss, IC301 pin20 output high level voltage to turn on Q201, RL101 and

activate Degauss.

4. Rotation.

IC301 pin18 PWM to rotation circuit, Q211 and Q213 control flow of current of Rotation coil, when the bases of C215

Increase from 0 to 14V, as Q211 will turn on gradually, the current startsfrom 14V to 7V via Rotate coil.

When C215decrease from 14V to 0V, the current will change from 7V to GND.

4. Circuit Description

B. Micro (IC301).

1. HS/VS Processor.

HS/VS input pin41 (HS), pin42 (VS), IC301 individually to work on frequency, polarity, process of H+V and power

saving, then output horizo ntal sync (pin34) and vertical sync (pin33) o f positive polarity to IC401 TDA9113 pin1, pin2.

2. PWM Control.

The PWM control of IC301 is pin29 (Brightness), pin19 (DAC ABL), and pin18 (Rotation), the PWM output via R,

C after rectified may

control each function

.

25

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 29

3. Power saving / Mute / LED control.

IC301 pin17, pin21 are power saving control pin, the condition of power saving and mode change, pin16 will

change from Low to Hi and active Mute function.

Normal Active

Mute L H

SUS / PD H L (Power saving)

IC301 pin21ΰSUSαfunction as LED control, the mode is as listed:

Power on Power saving Over range freq.

Pin21 Hi Low Low

4. CS control (CS1 ~ CS3).

To count H-SYNC by the output frequency, then output the cumulating as listed:

Freq. CS1 CS2 CS3

< 30K 0 0 0

30K~34K 0 0 0

34K~36.5K 1 0 0

36.5K~41K 1 0 1

41K~45K 0 1 0

45K~52K 0 1 1

52K~62K 1 1 0

62K~ 71K 1 1 1

5. Key Control: IC301 pin37~pin40 function as DAC switch input to control OSD display function.

Pin37 : 2.

Pin38 : Ϧ.

Pin39 : ϯ.

Pin40 : 1.

6. I

2

C Bus.

IC301 have two groups I

2

C bus to control IC302 E2PROM , IC401, Auto aliment, IC601, IC603,

and IC604.

C. Deflectioncontrol.

1. Auto SYNC deflection control and B+ control circuit horizontal and vertical sync through IC401 TDA9113 transmit.

Deflection controller IC401 TDA9113:

1-1 The control O/P (V-position,H-position, V-size, H-size, Pincushion, Pin-Balance, Trapezoid, Parallelogram,

moire) are use I

2

C control.

1-2 SYNC input:

H-sync (pin1) (From IC301 pin34).

V-sync (pin2) (From IC301 pin33).

1.3 Output:

a. B

+

Driver (pin28).

b. H-Driver (pin26).

c. EW-Driver (pin24).

d. V-focus (pin32).

e. V -out (pin23).

1-4 Horizontal.

a. H-sync inputs through pin1, then take a HFLY pulse from FBT pin5 to IC401 for AFC to make pin26 H-Driver

output at the same time.

b. Pin6 and pin8 (C429, R471) control horizontal hold in range.

1-5 Vertical.

a. V-sync outputs from MCU IC301 pin32 to IC401 pin2, then than smite from pin23, pin13, to IC501 KA2142

pin7, pin10.

b. IC401 pin23, outputs to vertical hold in range is controlled by pin22 (C508).

1-6 B

+

control.

Take a pulse from FBT pin5 and accumulates to become a DC voltage via D423, C437, then transformed by

VR403 to a conjunction to IC401 pin15 (#5V) outputs pulse by pin28 via Q202 to boost converter circuit.

26

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 30

1-7 Vertical deflection.

a. IC401 pin23 (vertical saw-tooth wave) and pin13 (REF.8V) output to IC501 KA2142

pin7 and pin10, then IC501 pin6 make vertical deflection output to adjust vertical size & position.

b. Vertical blank: IC501 pin4 take a blanking pulse, after passing Q501 buffer can supply video blanking signal.

1-8 Boost converter.

The Booster con verter mainly composes of Q202, L201, capacitor C204 and rectifier diode D204. IC401 pin28 B

+

driver output via Q204, Q205, Q202 to driver Booster converter and provide a DC-voltage to provide B+ H-output

circuit use, As H-freq. Change, IC401 pin28 B

+

-driver will change its output; Booster converter will also change

the B+ it provides, H-freq. will varies from 30K ~ 70KHz, B+ will varies from 63V ~ 160V.

1-9 X-RAY radiation protection.

D. Horizontal output.

1. Horizontal driver circuit.

The output of IC401 pin26 H-Driver connect to Q402 H-Driver transistor makes Q402 active ON/OFF function,

push H-output Q401to reach secondary via induction of T402 . For T402 is a transformer of reduced voltage and

converted pole, Q401 will be turn off when Q402 is on, on the contrary, when Q402 is turn off and Q401 will be on.

2. Horizontal output circuit.

Horizontal output circuit is composed by Q401, T401, D401, C401 and C416, H-Driver circuit output via T402 to

switch Q401 ON/OFF to output saw tooth wave and make DY able to control the circuit scanning of elections in

the CRT. L403, L404, C414, C415, and C417 modify Horizontal linearity switching individually Dai RL401,

Q414, and Q416.

3. EW-Pincushion and width control circuit.

The voltage across C420 can be varied in accordance with vertical parabolic waveform and DC voltage, which is

generated by two stage drive Q411, Q412, Q409. The peak yoke current is increased in proportion to the voltage

across C414, as the voltage across C420 is decreased for compensating the pincushion effect.

The parabolic waveform and DC voltage are generated from IC401 pin24.

FBT pin5 output one pulse to pass through ZD405 and C444 integration DC voltage, and through D418 to IC401

pin25, when anode voltage abnormal increase, FBT pin5 and IC401 pin25 voltage to be increased, too. As IC401

IC401 X-RAY protection circuit immediately active, H-Driver, B-Driver and V-OUT no output.

The X-RAY radiation protection circuit used in this monitor is a latching type the monitor will shown down and

continue until turn-off the monitor with power switch.

pin25 # 8V,

E.Video.

1. Video amplifier (IC601).

1-1 The video amplifier module is composed of three amplifiers for Red, Green, Blue channel.

1-2 The video input signal is fed to the video preamplifier IC601 pin6 Red, pin7 Green, pin5 Blue through AC coupling

capacitor C602, C603, C601.

1-3 The clamping pulse comes from IC301 pin34.

1-4 IC602 (IC602) output amplifier for B, R, G channel respectively.

1-5 The PWM control to IC603 (IC603) is pin6 (B cut-off), pin7 (R cut-off), and pin8 (G

cut-off), the PWM output via R, C after rectified may control R / G / B cut-off.

2. On screen display (IC604).

2-1 IC604 is a on screen display generator, pin7 fo r H-sync input, pin12 for V- sync input.

2-2 The IC604 is controlled by IC301 via SCL (pin12), SDA (pin11).

2-3 The OSD signal is output from pin17 (r), pin16 (g), pin15 (b) and OSD BLK to IC601 pin4, pin2, pin1, and pin3.

2-4 The IC601 output R, G, B into the OSD IC ( IC604 ) for the auto sizing function.

3. Auto beam limit CRT (ABL CRT).

When beam current pass through R448 over 400uA, the voltage build at base of Q418 will be low enough to turn on

Q418, then the voltage of pin22 of IC601 will be pulled down accordingly to reduce the video preamplifier gain output.

4. Brightness control.

Brightness is controlled by varying the DC voltage of G1 with the IC301 PIN29 (PWM).

5. Blanking CRT.

5-1 IC501 pin3 vertical blanking pulse is fed to the base of Q501, The blanking pulse O/P is coupled to G1 by C507.

5-2 Horizontal blanking pulse are fed to IC601 pin24 and let video O/P amp cut off during the period of horizontal

retrace, while mode change, IC301 pin16 will pull high to turn off. The G1 voltage will down to –180V then CRT

will cut off the video output.

27

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 31

A. General.

1. ALL SPECIFICATION MUST BE MET OVER LINE VOLTAGERANGE OF 90 VAC TO 264VAC 50HZ/ 60HZ, UNLESS OTHERWISE

SPECIFIED.

2. OPERATING TEMPERATURE RANGE IS 0

o

C TO 40oC WITH A RELATIVE HUMIDITY OF 10% OR LESS TO 90%.

3. THE MONITOR MUST BE OPERATIONAL IN AN USABLE STATE WITHIN 30 SECONDS AFTER TURN-ON.

4. ALL SIGNAL LEVELS ARE MEASURED ASSUMING TERMINATION AT THE MONITOR'S INPUT JACKS OR IN ITS CHARACTERISTIC

IMPEDANCE.

5. ANAMBIENT LIGHTING LEVEL OF 400 TO 600 LUX IS ASSUMED WHEN SETTING BRIGHTNESS FOR RASTER EXTINCTION

THRESHOLD.

6. ALL PURITY RELATED SPECIFICATIONS MUST BE MET WIT HOUT EXTERNAL DEGAUSSING.

7. ALL CONTROLS MUST HAVE EXCESS RANGE (NO CONTROL MAY BE LEFT AT AN END STOP WHEN PROPER ALIGNMENT IS

COMPLETED).

8. THE MONITOR IS NOT REQUIRED TO MEET SPECS DURING THE FOLLOWING BUT MUST TOLERATE, WITHOUT DAMAGE TO

THE CRT OR CIRCUITS, ANY SEQUENCY OR COMBINATION OF POWER ON AND OFF, SIGNALON AND OFF, ERRATIC,WRONG

FREQUENCY OR NOISY INPUTS WHILE AT ANY POSSIBLE UNPLUGGING OF POWER OR SIGNAL, SETTINGS OF USER ACCESSIBLE

CONTROLS. LIKEWISE, THE MONITOR SHOULD SURVIVE EXTENDED PERIODS OF OPERATION WITH LINE VOLTAGE REDUCED

BELOW THE SPECIFIED MINIMUM.

9. AN ISOLATION TRANSFORMER SHOULD BE USED WHEN PERFORMING ALIGNMENT AND TESTS. PORTIONS OFTHE POWER

SUPPLY BOARD ARE HOT GROUND. THE REMAINING BOARDS ARE COLD GROUND.

10. DISCHARGE OF CRT ANODE SHOULD BE DONE ONLY TO CRT GROUND STRAP.

11 .

GEOMETRIC MEASUREMENT IS ASSUMED TO BE MAKING ALONG A STRAIGHT SURFACE WITH A FLAT RULE OR TEMPLATE.

5. Adjusting Procedure

28

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 32

B. Instrument alignment.

1. Defection presets.

Control pots VR101, VR401, VR403 Focus VR are set at middle point, screen VR set to MIN.

2. Power adjustment.

2.1 Input crosshatch pattern at 31K 640×480, beam current set at 0µA.

2.2 Adjust VR101 until DC = 75V0.3V at TP201.

2.3 Adjust VR403 until voltage at TP208 = 63V0.3V for LG CRT.

63.5V0.3V for SDI CRT.

3. Size & Geometry Adjustment.

3.1 Raster Centering.

3.1.1 Input cross hatch pattern at 60K 1024*768 Hz mode.

3.1.2 Adjust contrast to 10FL, adjust screen just raster visible.

3.1.3 Adjust VR401 to center raster on screen such that the horizontal distance from the midpoint of the left

display edge to the left bezel edge is within 2mm of the distance from the midpoint of the right display

edge to the right bezel edge.

3.2 Picture size.

Input mode 1 ~ 12 signal adjust V-size, H-size to achieve.

H-sizeΚ310mm2mm.

V-sizeΚ230mm2mm.

3.3 Picture position.

Input mode 1~12 adjust V-position, H-position such

that the picture is centered with the screen.

3.4 Geometry adjustment.

3.4.1 Input mode 1~12.

3.4.2 Pincushion and barrel distortion.

3.4.3 Trapezoid and parallelogram distortion trapezoid

/ parallelogramЉ1.5mm.

3.4.4 Rotate adjustment.

h¡Ø 1m

m

310m

m

230m

m

Rotation

AB

Bezel

Raste

r

A-B

Raster center

2mm

Bezel

Picture

D

AB

C

¡ýA - B¡ý¡Ø 2m

m

¡ýC - D¡ý¡Ø 2m

m

Picture position

Bezel

Picture

310m

m

230m

m

Picture size

AA' BB'

C

C'

D

D'

Pinchshion

ู

1mm (A’,B’,C’,D’ )

Barrel

ู

1mm (A,B,C,D)

Pincushion / Barrel distortion

29

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 33

4. Video alignment / function memory reset.

4.1 INPUT 1024x768 69KHZ FULL BLACK PATTERNS.

4.2 SET CONTRAST 0%, BRIGTHNESS 100%, RGB CUT OFF 0%, RGB DRIVER 50%, TURN THE G2 (SCREEN) KNOB TO OBTAIN

RASTER LIGHT O/P ABOUT 0.25FL.

4.3 BASE ON x, y READING, FIX THE STRONG GUN CUT OFF TO 130, THEN ADJ UST THE OTHER TWO GUN AND SCREEN KNOB TO

MEET FOLLOWING CHROMATICALLY 9300

O

KÆx =0.283 + 0.003, y =0.297 + 0.003, Y = 0.5 + 0.2FL, STORE THE ADJUSTMENT OF

9300

o

K, THEN BASE ON x, y READING, FIX THE STRONG GUN AND G2, ADJUST THE OTHER GUN TO MEET FOLLOWING

CHROMATICALLY SPEC 6500

O

KÆ x = 0.313+ 0.003, y = 0.329 + 0.003, Y = DON’T CARE 5000OKÆ x = 0.346+ 0.003, y = 0.359 +

0.003, Y = DON’T CARE

4.4 ADJUST BRIGHTNESS TO 50%, CONTRAST 100%

4.5 APPLY 70mm x 70mm GREEN WINDOW PATTERN, ADJUST G-DRIVER TO OBTAIN GREEN WINDOW PATTERN LIGHT O/P ABOUT

30FL (9300

O

K)

4.6 APPLYWHITE WINDOW PATTERN, ADJUST R-DRIVER, B-DRIVER TO MEET FOLOWING CHROMATICALLY SPEC.

9300

O

KÆ x = 0.283 + 0.003, y = 0.297 + 0.003, Y = 45+ 2FL. For TEXT/SPREADSHEET mode

9300

O

KÆ x = 0.283 + 0.003, y = 0.297 + 0.003, Y = 85+3FL. For GRAPHIC/GAME mode

9300

O

KÆ x = 0.283 + 0.003, y = 0.297 + 0.003, Y = 150+ 4FL. For VIDEO/MOVIE/DVD mode

4.7 APPLY 70mm x 70mm GREEN WINDOW PATTERN, ADJUST G-DRIVER TO OBTAIN GREEN WINDOW PATTERN LIGHT O/P ABOUT

30FL (6500

O

K)

4.8 APPLY WHITE WINDOW PATTERN, ADJUST R-DRIVER, B-DRIVER TO MEET FOLLOWING CHROMATICALLY SPEC.

6500

O

KÆ x = 0.313 + 0.003, y = 0.329 + 0.003, Y = 45+ 2FLFor TEXT/SPREADSHEET mode

6500

O

KÆ x = 0.313 + 0.003, y = 0.329 + 0.003, Y = 85+3FL For GRAPHICS/GAME mode

6500

O

KÆ x = 0.313 + 0.003, y = 0.329 + 0.003, Y = 130 +4FL For VIDEO/MOVIE/DVD mode

4.9 APPLY 70mm x 70mm GREEN WINDOW PATTERN , ADJUST G-DRIVER TO OBTAIN GREEN WINDOW

PATTERN LIGHT O/P ABOUT 30FL (5000

O

K)

4.10 APPLY WHITE WINDOW PATTERN, ADJUST R-DRIVER,B-DRIVER TO MEET FOLLOWING

CHROMTICALLY SPEC

5000

O

KÆ x = 0.346 + 0.003, y = 0.359 + 0.003, Y = 45+2FL For TEXT/SPREADSHEET mode

5000

O

KÆ x = 0.346 + 0.003, y = 0.359 + 0.003, Y = 85+3FL For GRAPHICS/GAME mode

5000

O

KÆ x = 0.346 + 0.003, y = 0.359 + 0.003, Y = 130+4FL For VIDEO/MOVIE/DVD mode

4.11 APPLY FULL WHITE PA TTERN

4.12 ADJUST OSD ABL TO OBTAIN LIGHT O/P = 30+1FL FOR ALL MODE

4.13 APPLY FULL WHITE PATTERN ADJUST CONTRAST FROM 30FL TO 10FL AND CHECK THE CHROMATICALLY MEET FOLLOWING

SPEC.

I

x (AT CONTRST, 30) –x (AT CONTRST, 25.75) I < 0.007.

I

y (AT CONTRST, 30) –y (AT CONTRST, 25.75) I < 0.003.

I

x (AT CONTRST, 10) –x (AT CONTRST, 25.75) I < 0.007.

I

y (AT CONTRST, 10) –y (AT CONTRST, 25.75) I < 0.006.

4.14 FUNCTION “ALL MODE RESET.

PUSH BUTTON “1” AND POWER SWITCH ON, THE PICTURE SHOULD RESTORE TO THAT OF FACTORY MODE.

4.15 USER COLOR MUST BE DEFAULTE D AS 9300OK.

5.

Focus adjustment.

5.1 APPLY SIGNAL ALL “ME” PATTERN AT 1024*768 69K MODE.

5.2 SET BRIGHTNESS 50% CONTRAST 100%.

5.3 SET FOCUST CONTROL FOR BEST FOCUS.

30

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 34

C. PCB defined.

SW301

SW302

SW303

SW304

IC401

IC301

IC302

P401

VR401VR403

LED301

IC501

T401

WP603

SW101

VR101 IC101

C101

T101

X101

Adjust raster center

Adjust TP201=77V

IC303

Q409

Q202

Q401D401

P301

Q101

WP602

IC602

IC604

IC601

IC603

P603

P602P601

31

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 35

D. Service mode brief Description.

Connect sync cable first

1. Push ϭ2 & ϯ key and turn on monitor, enter burn-in mode then power off;

2. Push ϭ1 & Ϧ key and turn on monitor, enter service mode as below

32

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 36

33

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 37

34

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 38

35

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 39

Other :

1. Super Bri ghtness OSD Expression(looply-select by pressing hot-key on the front panel)

2. Monitor in DPMS mode~show below OSD 5 seconds

3. H-sync or V-sync is out of pull-in range~show below OSD 25 seconds

H: 30kHz-72kHz, +/- 1.5kHz

V: 50Hz~160Hz, +/- 1Hz

36

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 40

4. Signal cable disconnected~show below OSD 20 seconds,( then show OFF MODE IN 5 SEC.)

5. if moniotr is in the state in which OSD can be opened,

press key 1 and about 10 seconds, show OSD LOCK,then OSD is locked and can't be opened

6. if moniotr is in the state in which OSD is locked

press key 1 and about 10 seconds, show OSD UNLOCK, then OSD can be opened again

37

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 41

1. Power supply is defective.

No power or power

abnormal

Power indicator

LED don't light

Is F101 normal?

Is CR101, NTC

101 normal?

Is IC101 normal?

Is Q101 or R111,

R112 normal?

Check horizontal

and vertical circuit

Replace F101

Replace CR101,

NTC 101

Replace IC101

Replace Q101 or

R111, R112

Does the power

indictor LED light

once and the go out?

Check horizontal circuit

and power on again

Is the power indicator

LED light normally?

Check vertical circuit and

power on again

Is the LED normal?

Check video circuit

Are TP201~TP209

voltage normal?

Check D202, D203,

D205, D206, D207, Q203,

Q206, Q208, Q210

Is the T101 normal?

Replace T101

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

Yes

No

No

Yes

No

No

Yes

6. Trouble Shooting Flow Chart

38

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 42

2. Horizontal deflection circuit is defective.

The horizontal deflection

circuit is defective

Is the voltage on terminal

TP202=45V?

Is the power supply

circuit normal?

Is the pin1 waveform of

IC401 normal?

Is the pin28 waveform of

IC401 normal?

Is the pin26 waveform of

IC401 normal?

Is the waveform of Q402

"collector" normal?

Is the waveform of Q401

"BASE" normal?

Is the diode modulatic

circuit normal?

Is the voltage on terminal

TP201=75V?

Check power supply

circuit

Check H.sync input

Q402 is defective

Horizontal drive is

defective T402, Q401,

T401

Diode modulation circuit is

defictive C401, D401,

C413, C414, C415, C417,

Q409, C416

No

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

0.8Vp-p

45Vp-p

1.4Vp-p

12Vp-p

4.6Vp-p

fH

CRT is defictive

No

Check booster convertor

circuit Q202, Q204, Q205

Check IC401 pin26

normal?

39

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 43

3. The raster don’t appear.

The raster don't appear

Is the C425= -200V

normal?

Does the CRT heater

glow red?

Does the entire screen

light up?

Turn the FBT screen

clockwise

FBT is defective

R457, D420 are defective

Is the voltage at the heater

pin9 of CRT socket

normal?

D206,Q208 are

defective

Heater voltage

approx. 6.3V

Video circuit Q419, Q420

IC301 pin29 brightness

control are defective

No

Yes

Yes

No

Yes

No

No

40

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 44

4. Vertical deflection is defective.

Vertical is defective

The picture is one

horizontal line

Is the waveform pin2 of

IC401 normal?

Check the dflection Yoke

Is the waveform at pin6

of IC501 normal?

Check V-sync of IC301

pin33 or signal cable

Is the IC501 pin2=14V

pin5=-12V?

Is the waveform of IC401

pin13, pin23 normal?

Check power supply 14V,

-12V

IC401 is defective

5Vp-p

45Vp-p

Yes

Yes

No

No

No

Yes

No

41

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 45

5. Video is defective.

No video display

Does the entire screen

light up?

Are the voltage on heater,

G1,G2 of CRT socket

normal?

Are the waveform of the

terminal BK,RK,GKof

CRT socket normal?

Are the waveform at the

pin18, pin19, pin20 of

IC601?

Are the input waveform

at P601 pin1, pin3, pin5

normal?

The CRT is defective.

The raster don't appear.

Check the signal cable or

computer

IC601 its buffer or its drive

circuit. (clamping pulse,blanking

pulse, is defective)

Video optput circuit defective

IC602 pin1, pin2, pin3

CRT drive circuit is defective

heater, power supply circuit

D206, G1, G2, FBT , IC603 and

its drive circuit

Turn up the screen control

and check whether the raster

appear.

0.7Vp-p

Heater: 6.3VDC

G1: -65V

G2: 550V

Yes

Yes

No

No

No

No

Yes

Yes

No

Yes

3Vp-p

72Vp-p

42

ViewSonic Corporation Confidential-Do Not Copy 70f+SB-3E

Page 46

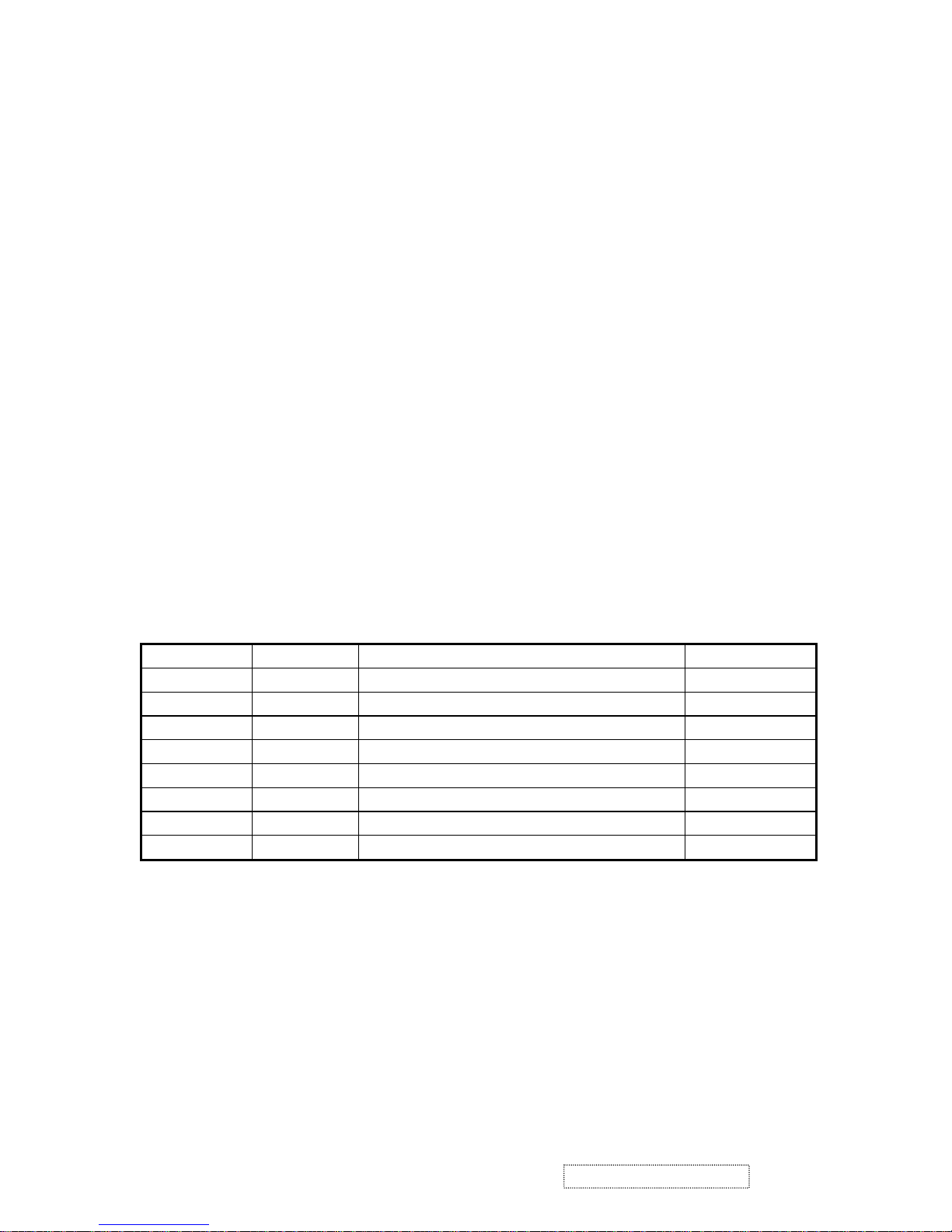

Item Reference P/N ViewSonic P/N

escr. of revision(s)

24b 720840115 E-RL-0414-0106

emoved from RSP

L

24c 720840115 E-RL-0414-0123 Added to RSPL

27b 736000026 E-YK-0413-0060

emoved from RSP

L

27c 736000026 E-X-0415-0134 Added to RSPL

44b 3080421200 A-VC-0101-0344

emoved from RSP

L

44c - 95(see below) (see below) Added to RSPL

Item Revision History ViewSonic P/N Reference P/N Description Location Universal number# Lead time

1 E-IC-0401-0985 2510005310 IC PWM 8PIN IC101 UC3843BN 4 WEEKS

2 E-IC-0401-2852 2610185342 IC EEPROM 8K 8PIN IC302 M24C08BN6 4 WEEKS

3 E-IC-0401-2275 2530095106 IC DEFLECTION PROCESSOR SDIP-32P IC401 TDA9113 4 WEEKS

4 E-IC-0401-2730 2530026104 IC VERT DEFLECTION SIP-10P IC501 KA2142 4 WEEKS

5 E-IC-0401-2393 2530159004 IC RGB VIDEO PRE-AMP 24PIN IC601 LM1269 4 WEEKS

6 E-IC-0401-4003 2530159104 IC WB AMP DRIVER RGB CRT TO-220-9P IC602 LM2460TA 4 WEEKS

7 E-IC-0401-4004 2500165111 IC 120V TRIPLE BIAS CLAMP DIP-8P IC603 LM2479NA 4 WEEKS

8 E-IC-0401-2731 2530211226 IC MASK OSD CONTROLLER DIP-20P IC604 NT68295-90049 4 WEEKS

9 E-Q-0402-0156 242017400006 FET 600V 6A 1.25ohm TO-220F Q101 2SK2545 2 WEEKS

10 E-Q-0402-1453 210106300017 TR 350V 0.5A TO-92 30-200 Q102 2N6517TA 2 WEEKS

11 E-Q-0402-1432 242016350517 FET 250V 8.1A 0.45ohm TO-220F Q202 IRFS634B 2 WEEKS

12 E-Q-0402-1588 211162030006 TR -40V -3A 2-8H1A 120-240 Q203 2SA1359-Y 2 WEEKS

13 E-Q-0402-1455 211102500117 TR -50V -0.15A TO-92 200-240 Q205 KSA1015GRTA 2 WEEKS

14 E-Q-0402-1454 210231010011 TR 20V 1A TO-92MOD 120-240 Q206 2SD468CTZ 2 WEEKS

15 E-Q-0402-1452 210057920017 TR 750V 12A TO-3PF 10 Q401 FJAF6812TU 2 WEEKS

16 E-Q-0402-1206 210233510011 TR 80V 1A TO-92MOD 100-200 Q402 2SD667CTZ 2 WEEKS

17 E-Q-0402-0888 211106000106 TR -300V -0.05A TO-92 40 Q404 BF421(TPE2) 2 WEEKS

18 E-Q-0402-1451 210013030006 TR 60V 3A 2-10R1A 100-320 Q409 2SD2012 2 WEEKS

19 E-Q-0402-1208 211105700006 TR -250V -0.05A 2-5F1B 50 Q419 BF423(TPE2) 2 WEEKS

20 E-Q-0402-1207 210105700006 TR 250V 0.05A TO-92 50 Q501 BF422(TPE2) 2 WEEKS

21 E-R-0405-6645 190204200 RES FUSING MF 1/2W .1 J R114 RF50ST52A0.1OHMJ 2 WEEKS

22 E-R-0405-0923 190200400 RES FUSING MF 1/2W .22 J SMALL R457 RFS12JR220A520NH 2 WEEKS

23 E-RL-0414-0074 720060701 RELAY 240VAC/12VDC 5A DPST TV4 RL101 OSA-SS-212DM5 2 WEEKS

24b Removed 04/19/04 E-RL-0414-0106 720840115 RELAY 125VAC/12VDC 10A SPDT RL401 833H-1C-C 2 WEEKS

24c Added 04/19/04 E-RL-0414-0123 720840115 RELAY 125VAC/12VDC 10A SPDT RL401 833H-1C-C 2 WEEKS

25 E-T-0408-0519 2801427200 X'FMR SMT 250uH J T101 SMT-35RV-315T 2 WEEKS

26 E-FBT-0406-0237 2850008610 FBT 17" 70KHZ 1.24mH T401 CF1803DE2700 2 WEEKS

27b Removed 04/19/04 E-YK-0413-0060 736000026 RESONATOR 12.00MHZ +/-0.1% 2P 10*10 Y301 ZTA12.00MX010 2 WEEKS

27c Added 04/19/04 E-X-0415-0134 736000026 RESONATOR 12.00MHZ +/-0.1% 2P 10*10 Y301 ZTA12.00MX010 2 WEEKS

28 A-PC-0106-0150 3090107600 AC POWER CORD L1800 BLACK P-model 2 WEEKS

29 A-PC-0106-0254 3090130400 AC POWER CORD L1800 BLACK P-model to pc 2 WEEKS

30 M-LB-0813-0925 3201969100 LABEL ID 65*75 E70F+ P-model 2 WEEKS

31 PL-TB-0717-0148 3360318700 SWIVEL ABS EP32 S7SB1EL 2 WEEKS

32 C-BS-0303-0397 3360425000 BASE ABS 41 S7SB1EL 2 WEEKS

33 C-BC-0302-0525 3368214601 R/C ASSY J770SCM03C S7RB1AT 2 WEEKS

34 M-MS-0808-7805 3360506500 LED LENS PMMA NAT Y0-487 S7FB2AT 2 WEEKS

35 PL-NB-0707-0196 3360625100 POWER KNOB ABS 41 S7PFB1AT 2 WEEKS

36 PL-FK-0709-0120 3360728400 FUNCTION KEY ABS 41 S7PFB1AT 2 WEEKS