Page 1

Service Manual

ViewSonic VA1912w-2

VA1912wb-2

Model No. VS10866

19” Color TFT LCD Display

(VA1912w-2_VA1912wb-2_SM Rev. 1b Aug. 2006)

ViewSonic 381 Brea Canyon Road, Walnut, California 91789 USA - (800) 888-8583

Page 2

Copyright

Copyright © 2006 by ViewSonic Corporation. All rights reserved. No part of this publication

may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any

language or computer language, in any form or by any means, electronic, mechanical, magnetic,

optical, chemical, manual or otherwise, without the prior written permission of ViewSonic

Corporation.

Disclaimer

ViewSonic makes no representations or warranties, either expressed or implied, with respect to

the contents hereof and specifically disclaims any warranty of merchantability or fitness for any

particular purpose. Further, ViewSonic reserves the right to revise this publication and to make

changes from time to time in the contents hereof without obligation of ViewSonic to notify any

person of such revision or changes.

Trademarks

Optiquest is a registered trademark of ViewSonic Corporation.

ViewSonic is a registered trademark of ViewSonic Corporation.

All other trademarks used within this document are the property of their respective owners.

Revision History

Revision SM Editing Date ECR Number Description of Changes Editor

1a 04/14/2006 Initial Release Jamie Chang

1b 8/09/2006 VS-E060210 Add VA1912wb-2 from VA1912w-2 Jamie Chang

ViewSonic Corporation

i

Confidential - Do Not Copy

VA1912w-2_VA1912wb-2

Page 3

TABLE OF CONTENTS

1. Precautions and Safety Notices 1

2. Specification 3

3. Front Panel Function Control Description 10

4. Circuit Description 16

5. Adjustment Procedure 17

6. Troubleshooting Flow Chart 37

7. Recommended Spare Parts List 45

8. Exploded Diagram and Exploded Parts List 50

9. Block Diagram 52

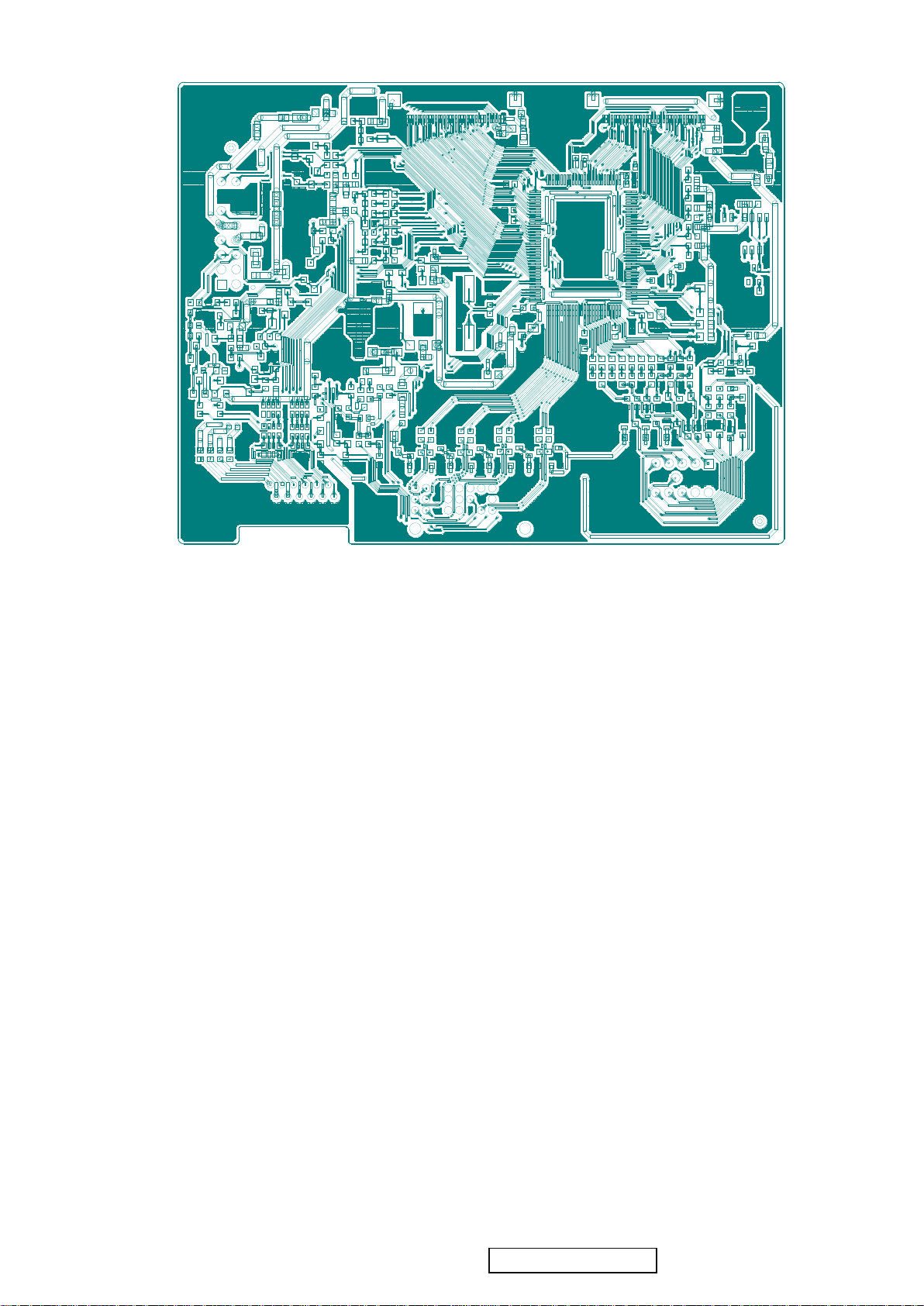

10. Schematic Diagrams 53

11. PCB Layout Diagrams 60

ViewSonic Corporation

ii

Confidential - Do Not Copy

VA1912w-2_VA1912wb-2

Page 4

1. Precautions and Safety Notices

1. Appropriate Operation

(1) Turn off the product before cleaning.

(2) Use only a dry soft cloth when cleaning the LCD panel surface.

(3) Use a soft cloth soaked with mild detergent to clean the display housing.

(4) Use only a high quality, safety approved AC/DC power cord.

(5) Disconnect the power plug from the AC outlet if the product will not be used for a long period of time.

(6) If smoke, abnormal noise, or strange odor is present, immediately switch the LCD display off.

(7) Do not touch the LCD panel surface with sharp or hard objects.

(8) Do not place heavy objects on the LCD display, video cable, or power cord.

(9) Do not use abrasive cleaners, waxes or solvents for your cleaning.

(10) Do not operate the product under the following conditions:

- Extremely hot, cold or humid environment.

- Areas containing excessive dust and dirt.

- Near any appliance generating a strong magnetic field.

- In direct sunlight.

2. Caution

No modification of any circuit should be attempted. Service work should only be performed after you are thoroughly

familiar with all of the following safety checks and servicing guidelines.

3. Safety Check

Care should be taken while servicing this LCD display. Because of the high voltage used in the inverter circuit, the voltage is

exposed in such areas as the associated transformer circuits.

4. LCD Module Handling Precautions

4.1 Handling Precautions

(1) Since front polarizer is easily damaged, pay attention not to scratch it.

(2) Be sure to turn off power supply when connecting or disconnecting input connector.

(3) Wipe off water drops immediately. Long contact with water may cause discoloration or spots.

(4) When the panel surface is soiled, wipe it with absorbent cotton or other soft cloth.

(5) Since the panel is made of glass, it may break or crack if dropped or bumped on hard surface.

(6) Since CMOS LSI is used in this module, take care of static electricity and ensure human earth when handling.

(7) Do not open or modify the Module Assembly.

(8) Do not press the reflector sheet at the back of the module in any direction.

(9) In the event that a Module must be put back into the packing container slot after it was taken out of the container, do

not press the center of the CCFL Reflector edge. Instead, press at the far ends of the CFL Reflector edge softly. Otherwise

the TFT Module may be damaged.

(10) At the insertion or removal of the Signal Interface Connector, be sure not to rotate or tilt the Interface Connector of

the TFT Module.

(11) After installation of the TFT Module into an enclosure (LCD monitor housing, for example), do not twist or bend the

TFT Module even momentarily. When designing the enclosure, it should be taken into consideration that no

bending/twisting forces may be applied to the TFT Module from outside. Otherwise the TFT Module may be damaged.

(12) The cold cathode fluorescent lamp in the LCD contains a small amount of mercury. Please follow local ordinances or

regulations for disposal.

(13) The LCD module contains a small amount of materials having no flammability grade. The LCD module should be

supplied with power that complies with the requirements of Limited Power Source (IEC60950 or UL1950), or an

exemption should be applied for.

(14) The LCD module is designed so that the CCFL in it is supplied by a Limited Current Circuit (IEC60950 or UL1950).

Do not connect the CCFL to a Hazardous Voltage Circuit

ViewSonic Corporation

1

Confidential - Do Not Copy

VA1912w-2_VA1912wb-2

Page 5

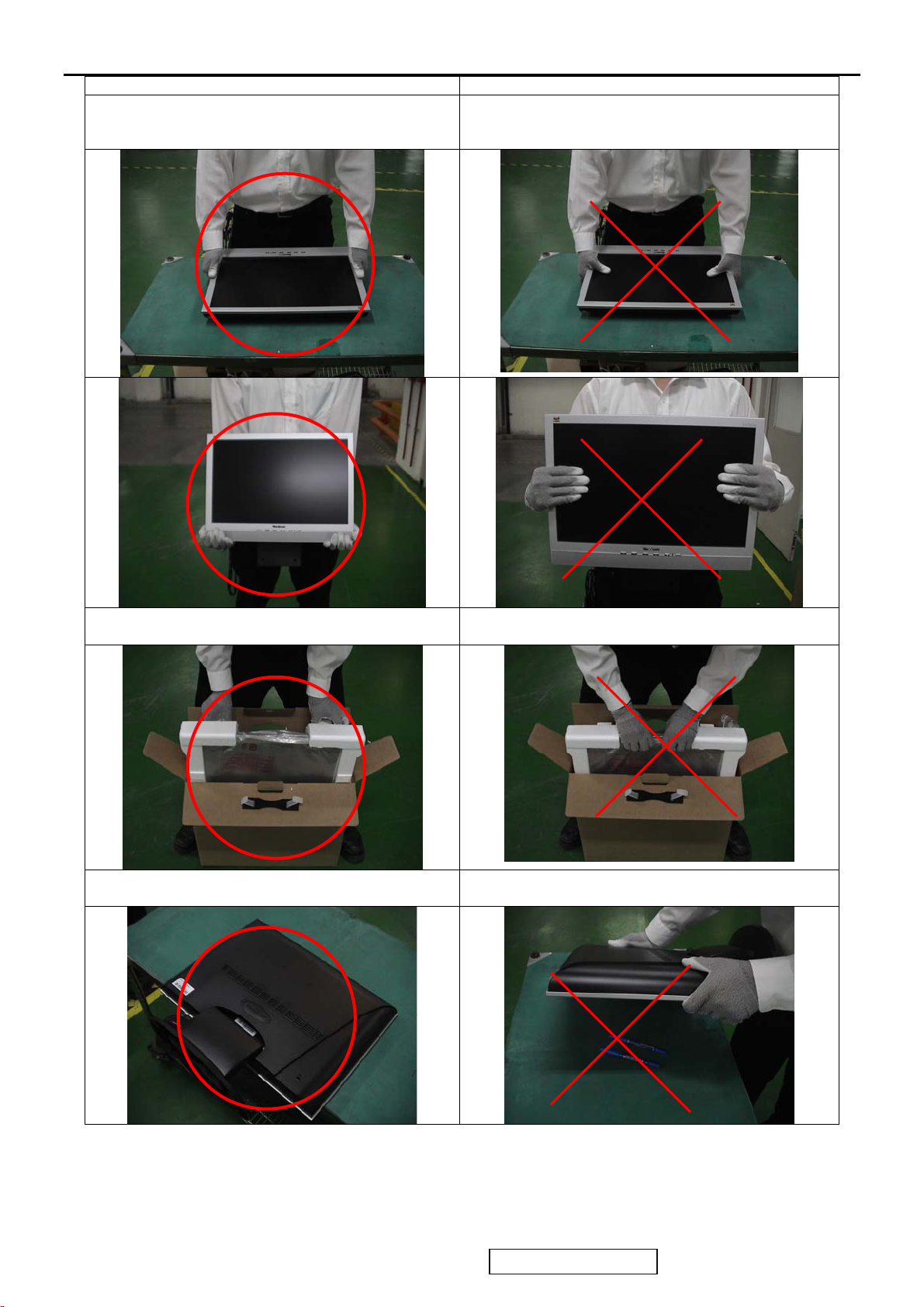

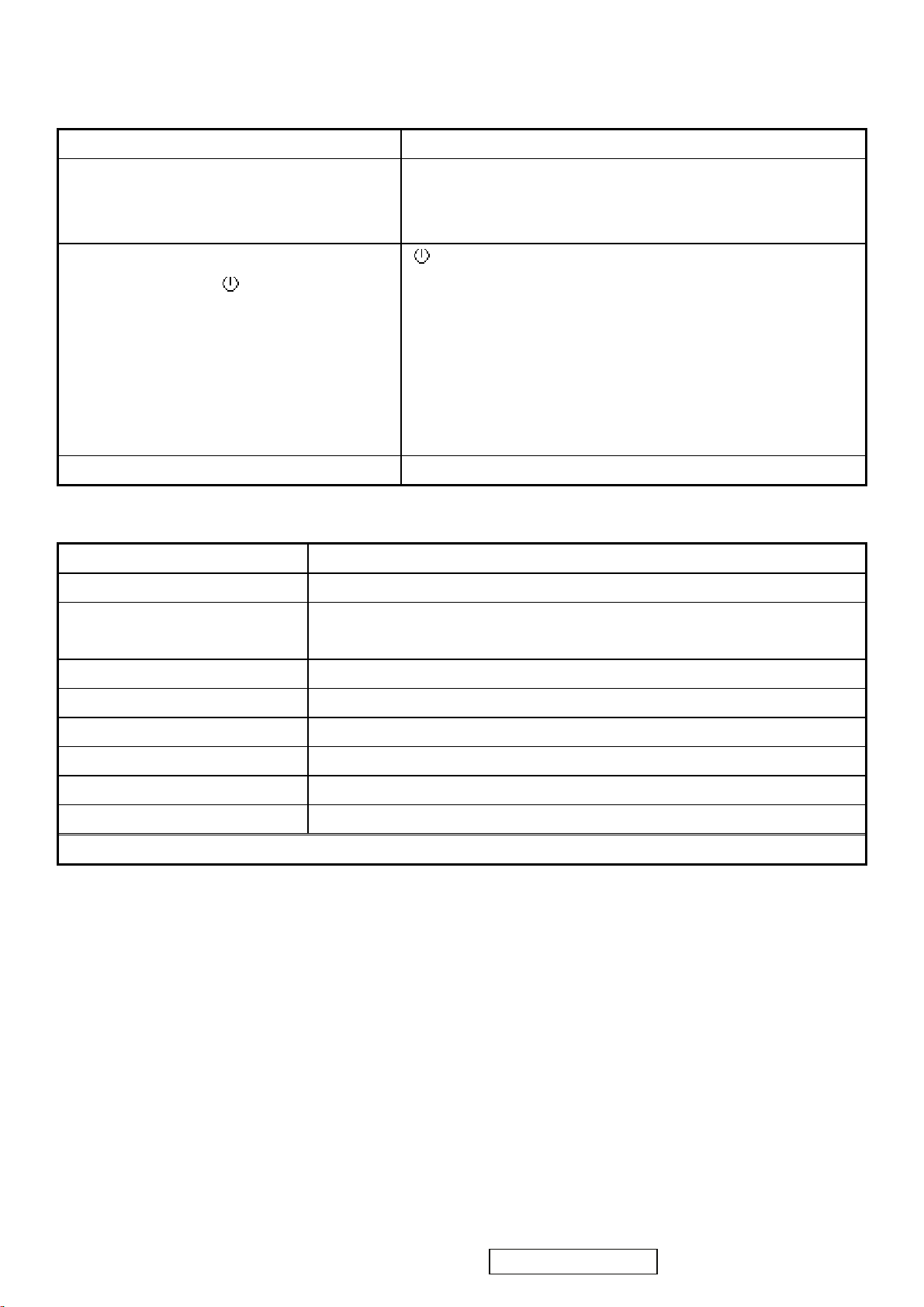

Correct methods : Incorrect Methods :

Only touch the metal-frame of the panel or the front

cover of the monitor.

Do not touch the surface of the polarizer .

Surface of the panel is pressed by fingers & this may

cause “ MURA “

Take out the monitor with cushion Take out the monitor by grasping the LCD panel.

That may cause “ MURA“.

Place the monitor on a clean & soft foam pad . Place the monitor on foreign objects .

ViewSonic Corporation

That could scratch the surface of panel

2

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 6

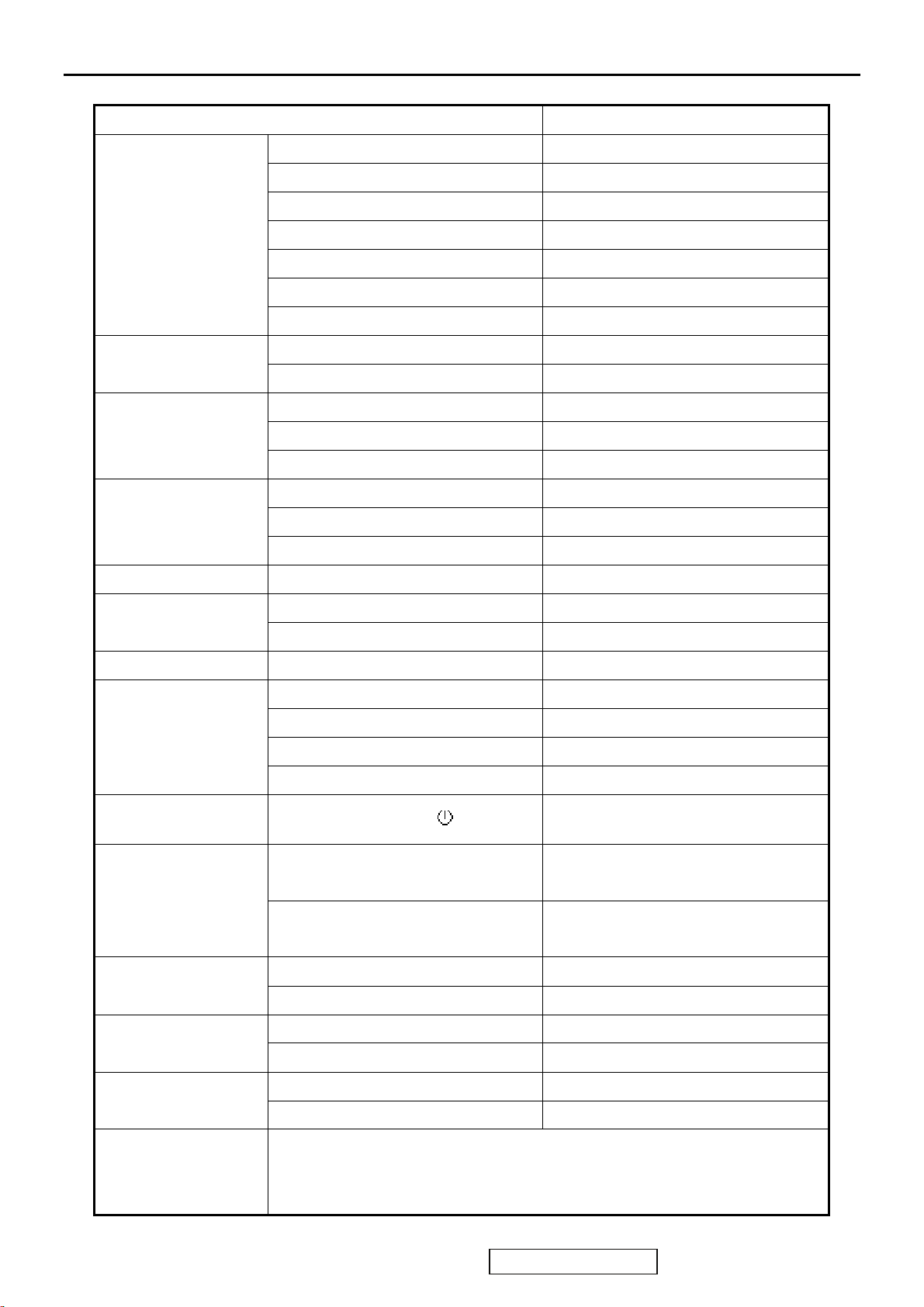

2. Specification

2.1 INSTRUCTION

FEATURES VA1912w-2 / VA1912wb-2

Size 19” wide

Luminance (Typ, cd/㎡) 300 cd/㎡

Contrast Ratio (Typ) 500:1

TFTLCD PANEL

Input Signal

Sync Compatibility

Compatibility

Power Voltage AC 100-240V, 50/60Hz Yes

Power Consumption

Audio Amplifier / Speaker 1.5 W / 2.5W x 2

Colors ( 6 bit + 2 bit FRC) 16.2 M colors

Response Time (Typ) 8 ms

Viewing Angle (H/V) 150 ° / 130 °

Recommend resolution 1440 x 900@60Hz

Analog (75ohms, 0.7/1.0 Vp-p) Yes

Digital No

Separate Sync Yes

Composite Sync No

Sync on Green No

PC Yes

Power Mac Yes

TV Box (NextVision 6) Yes

On Mode(Max / Typ) 36W(max) / 32W(typ)

Active Off Mode (Max) 2W

Tilt ( 20 ° to -5 °)

Swivel No

Ergonomics

Pivot No

Height Adjust No

OSD Control [; X] [ 1 ] [▼] [▲] [ 2 ] [ ] Yes

451 x 391 x 197 (mm)

Physical (W x H x D mm)

17.8 x 15.4 x 7.8 (in)

Dimension

538 x 470 x 158 (mm)

Package (W x H x D mm)

21.2 x 18.5 x 6.2 (in)

Physical (Net kg/lb) 4.5kg (9.9lb)

Weight

Package (Gross Kg/lb) 6.2kg (13.7lb)

Temperature (℉/℃) 41℉-95℉/+5℃-+35℃

Operating Condition

Humidity (%) 20 % - 80 %

Temperature (℉/℃) -4℉-131℉/-20℃-55℃

Storage Condition

Humidity (%) 20 % - 85 %

CB / TCO99 / UL/cUL / FCC-B / ICES 003 / Argentina-TUV/S / NOM / EPA Energy

Ye s

Regulation

ViewSonic Corporation

Star / TUV/Ergo / ISO13406-2 / TUV/GS / CE / GOST-R / SASO / BSMI / PSB /

C-Tick / Korea (MIC) / CCC

3

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 7

2.2 GENERAL SPECTION

Test Resolution & Frequency 1440 x 900 @ 60Hz

Test Image Size Full Size

Contrast and Brightness Controls

2.3 VIDEO INTERFACE

Factory Default:

Contrast = 70%, Brightness = 100%

Analog Input Connector DB-15 (Analog), refer the appendix A

Digital Input Connector N/A

Default Input Connector Defaults to the first detected input

Video Cable Strain Relief Equal to twice the weight of the monitor for five minutes

Video Cable Connector DB-15 Pin out Compliant DDC 2B

Video RGB (Analog)

Video Signals

Video Impedance 75 Ohms (Analog)

Maximum PC Video Signal 950 mV with no damage to monitor

Maximum Mac Video Signal 1250 mV with no damage to monitor

Separate

Sync Signals TTL

DDC 2B Compliant with Revision 1.3

Sync Compatibility Separate Sync

Video Compatibility

Resolution Compatibility

Exclusions Not compatible with interlaced video

Shall be compatible with all PC type computers,

Macintosh computers, and after market video cards

640 x 350*, 640 x 480, 720 x 400* (640 x 400*), 800 x

600, 832 x 624, 1024 x 768, 1152 x 864, 1280 x 768,

1280 x 960, 1280 x 1024, 1440 x 900

* The image vertical size might not be full screen.

But the image vertical position should be at the center.

ViewSonic Corporation

4

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 8

2.4 POWER SUPPLY

Power Supply (Adapter) Part Number: 27-D003247

Input Voltage Range

Input Frequency Range

Short Circuit Protection

Over Current Protection

Leakage Current

Efficiency 80 % TYPICAL AT 100VAC @60HZ

Fuse

Power Dissipation

Max Input AC Current

Inrush Current (Cold Start) 80 A @ 240VAC , 50HZ

Power Supply Cold Start

Power Supply Transient Immunity

Power Supply Line Surge Immunity

90 to 264 VAC

47 to 63 Hertz

OUTPUT CAN BE SHORTED WITHOUT DAMAGE

FUSE 3.15A TYPICAL AT 250 VA C

75 MA (MAX) AT 240VAC / 50HZ

INTERNAL AND NOT USER REPLACEABLE

36 WATT S

1.6 ARMS @ nominal RANGE

SHALL START AND FUNCTION PROPERLY WHEN

UNDER FULL LOAD, WITH ALL COMBINATIONS

OF INPUT VOLTAGE, INPUT FREQUENCY, AND

OPERATING TEMPERATURE

SHALL BE ABLE TO WITHSTAND AN EN61000-4-4

±2KV TRANSIENT TEST WITH NO DAMAGE

Shall be able to withstand ±2KV (L-L) and ±2.3KV

(L-PE) with no damage

Power Supply Missing Cycle Immunity

Power Supply Acoustics

US Type Power Cable

European Type Power Cable

CCC Type Power Cable

Shall be able to function properly, without reset or visible

screen artifacts, when ½ cycle of AC power is randomly

missing at nominal input

The power supply shall not produce audible noise that

would be detectable by the user. Audible shall defined

to be in compliance with ISO 7779 (DIN EN27779:1991)

Noise measurements of machines acoustics. Power

Switch noise shall not be considered

Separate 3-prong NEMA 5-15P type plug. Length =

1.8m. Connects to display.

Color = Black

Schuko CEE7-7 type plug.

Length = 1.8m, Connects to display.

Color = Black

Separate 3-prong type plug.

Length = 1.8m. Connects to display.

PSE Type Power Cable

Power Saving Operation(Method) VESA DPMS Signaling

Power Consumption

Recovery Time

ViewSonic Corporation

Color = Black

Separate 2-prong NEMA 1-15P type plug. Length =

1.8m. Connects to display.

Color = Black

ON Mode < 36 W (max) / 32 W (typ)

ACTIVE OFF < 1 W

ON Mode = N/A, ACTIVE OFF < 5 sec

5

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 9

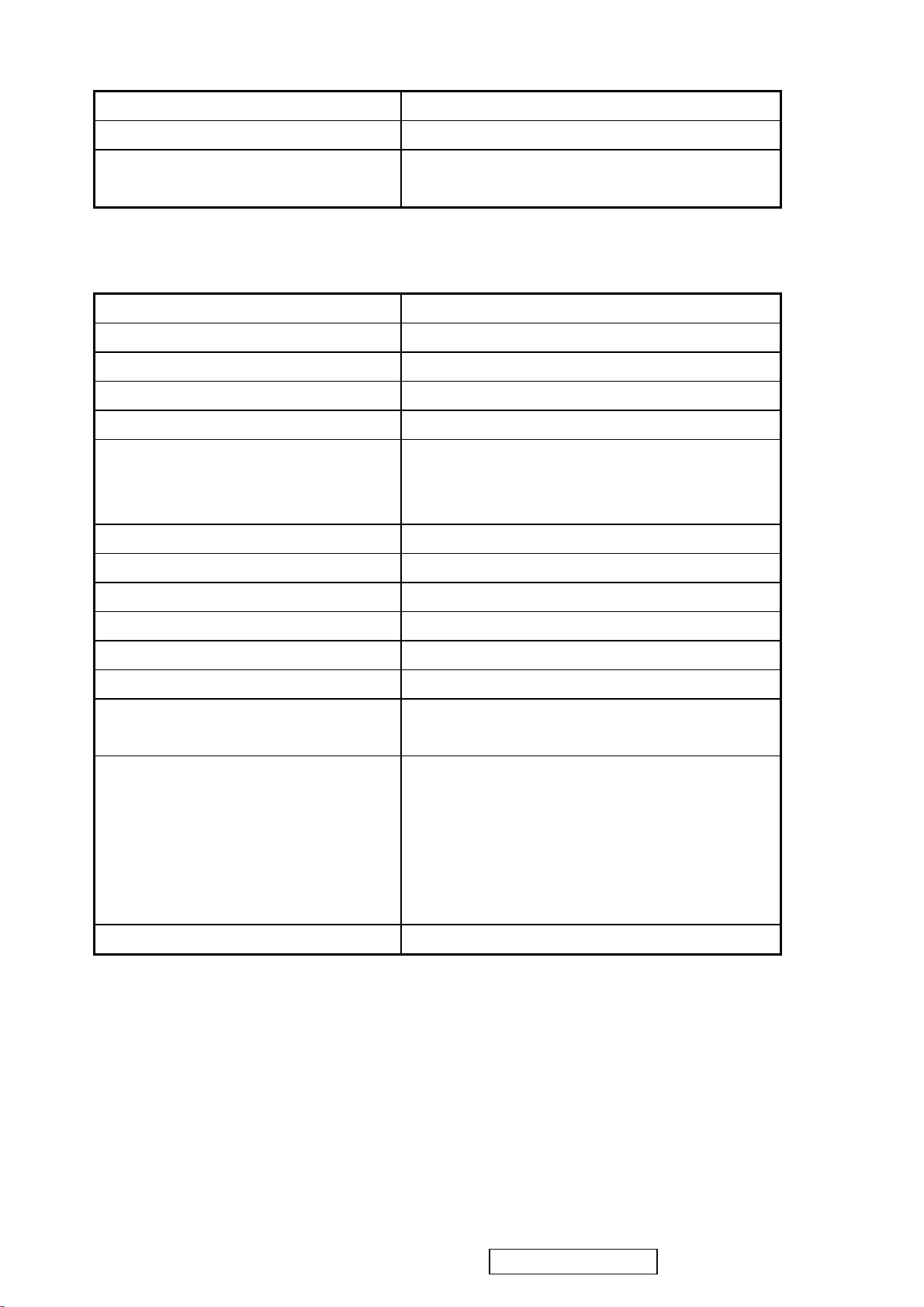

2.5 ELECTRICAL REQUIREMENT

Horizontal / Vertical Frequency

Horizontal Frequency

Vertical Refresh Rate

Maximum Pixel Clock 135 MHz (EDID file is 140MHz)

Sync Polarity Independent of sync polarity.

30 – 82 kHz

50 – 85* Hz.

Timing Table

Item Timing Analog Digital

1 640 x 350 @ 70Hz, 31.5kHz Yes No

2 640 x 4 00 @ 60Hz, 31.5kHz Yes* No

3 640 x 400 @ 70Hz, 31.5kHz Yes No

4 640 x 4 80 @ 60Hz, 31.5kHz Yes No

5 640 x 4 80 @ 67Hz, 35.0kHz Yes No

6 640 x 4 80 @ 72Hz, 37.9kHz Yes No

7 640 x 4 80 @ 75Hz, 37.5kHz Yes No

8 640 x 480 @ 85Hz, 43.27kHz Yes No

9 720 x 4 00 @ 70Hz, 31.5kHz Yes No

10 800 x 600 @ 56Hz, 35.1kHz Yes No

11 800 x 600 @ 60Hz, 37.9kHz Yes No

12 800 x 600 @ 75Hz, 46.9kHz Yes No

13 800 x 600 @ 72Hz, 48.1kHz Yes No

14 800 x 600 @ 85Hz, 53.7kHz Yes No

15 832 x 624 @ 75Hz, 49.7kHz Yes No

16 1024 x 768 @ 60Hz, 48.4kHz Yes No

17 1024 x 768 @ 70Hz, 56.5kHz Yes No

18 1024 x 768 @ 72Hz, 58.1kHz Yes No

19 1024 x 768 @ 75Hz, 60.0kHz Yes No

20 1024 x 768 @ 85Hz, 68.67kHz Yes No

21 1152 x 864@ 75Hz, 67.5kHz Yes No

22 1280 x 1024 @ 60Hz, 63.4kHz Yes No

23 1280 x 1024 @ 75Hz, 79.97kHz Yes No

24 1280x 768 @ 60Hz, 47.78kHz Yes No

25 1280 x 960 @60Hz, 60kHz Yes No

26 1440 x 900 @ 60Hz, 55.96kHz Yes No

*The image vertical size might not be full screen.

Primary Presets

1440 x 900 @ 60Hz

User Presets

Number of User Presets (recognized timings) Available: 10 presets total in FIFO configuration

Changing Modes

● Maximum Mode Change Blank Time for image stability : 3 seconds (Max), excluding “Auto Adjust” time

● Under DOS mode (640 x 350, 720 x 400 & 640 x 400), there is no “Auto Adjust” feature.

● The monitor needs to do “Auto Adjust” the first time a new mode is detected but except the DOS mode 640 x 350, 720 x

400 & 640 x 400.(see section “0-Touch™ Function Actions”)

● While running Change Mode, Auto Adjust or Memory Recall, the image shall blank

ViewSonic Corporation

6

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 10

2.6 FRONT PANEL CONTROLS AND INDICATORS

Front Panel Hardware Controls

Power Switch (Front Head) Power Control, soft Power Switch.

Power LED (Front Head) Green – ON

Orange – Active Off

Dark = Soft Power Switch OFF

Front Panel Controls (Head)

[;X] [ 1 ] [▼] [▲] [ 2 ] [

Reaction Time OSD must fully appear within 0.5s after pushing Button 1

Short Cuts Function from the button(s)

[1] Main Menu

[2] Adjust Contrast / Brightness

[▼] or [▲]

[▼] + [▲] Recall both of Contrast and Brightness to default

[1] + [2] Toggle 720x400 and 640x400 mode when input 720x400 or 640x400 mode

]

To immediately activate Contrast menu. It should be change to Brightness OSD by

push button [2]

[

] Power

[ 1 ] BUTTON 1

[ 2 ] Button 2

[▲] UP ARROW BUTTON

[▼] DOWN ARROW BUTTON

[; X] Audio Mute on/off

Note: Power Button, Button 1 and Button 2 and Mute Button must be

one-shot logic operation. (i.e. there should be no cycling)

[1] + [▼] + [▲] White Balance. (Not shown on user’s guide)

[1] + [▼] Power Lock

[1] + [▲] OSD Lock

[;X] Audio Mute on /off

Remark : All the short cuts function are only available while OSD off

ViewSonic Corporation

7

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 11

Main Menu Controls

Auto Image Adjust*

Contrast/Brightness*

Audio Adjust

Vo l u m e *

4

, Mute*4

1

2*4

Color Adjust

sRGB, 9300K, 6500K(default), 5400, 5000, User Color [R, G, B]

Information

H Frequency, V Frequency, Resolution, Pixel Clock, Serial Number,

Model Number, “www.ViewSonic.com

Manual Image Adjust

H. Size*

1

, H./V. Position*1, Fine Tune*1, Sharpness*3

”

Setup Menu

Language [English, French, German, Spanish, Italian, Finnish, Japanese, Traditional Chinese, Simplified Chinese],

Resolution Notice, OSD Position, OSD Timeout, OSD Background

Memory Recall

1

These functions are not available in Digital Mode

*

2

These functions are not available under sRGB Mode

*

3

These functions are not available under Native Resolution Mode

*

4

These functions setting can be recalled to default by [▼]+[▲]

*

[Remark] Please refer to the detail in the Appendix C

Function descriptions

OSD Lock short cuts function for the buttons

The OSD lock will be activated by pressing the front panel control buttons "(1), & (▲)" for 10 seconds. If the user then tries to

access the OSD by pressing any of the buttons "1", "▼", "▲", "2" a message will appear on the screen for 3 seconds showing

"OSD Locked". The OSD lock will be deactivated by pressing the front panel control buttons "(1), & (▲)" again for 10

seconds.

Note1: When the OSD is locked will lock all functions, including “Volume” and “Mute”

Note 2: Status bar indicating OSD Lock or Unlock is in progress and when complete it will indicate “OSD Locked”

Note 3: OSD Lock should not lock Power Button and Power Lock function

Power Lock short cuts function for the buttons

The power button lock will be activated by pressing the front panel control buttons "(1), & (▼)" for 10 seconds. Locking the

power button means that the user won't be able to turn off the LCD while the power button is locked. If the user presses the

power button while it is locked, a message will appear on the screen for 3 seconds showing "Power Button Locked". It also

means that with the power button locked, the LCD would automatically turn back "On" when power is restored after a power

failure. If the power button is not in the locked mode, then power should return to it's previous state when power is restored

after a power failure. The power button lock will be deactivated by pressing the front panel control buttons "(1), & (▼)" again

for 10 seconds.

Note 1: Status bar indicating Power Button lock or unlock is in progress and when complete it will indicate “Power Button

Locked”

Note 2: Power should only be lockable in the “On State”

Memory Recall Actions

Memory Recall action on the analog and digital mode as below

1. Set the factory defaults as shown in Section 4-8

2. Clean all the mode setting buffer

3. Execute Auto Image Adjust

Note: Memory Recall should have no effect for Language, Power Lock, User Color Settings or Input Priority

Resolution Notice Actions

1. Resolution Notice OSD should show on screen after changing to non-native mode for 30 sec

2. The OSD should disappear after 10 sec or by pushing button [1] or [2]

Resolution Notice function should be disabled when push button [2] under Resolution Notice OSD

0-Touch™ Function Actions

1. Execute Auto Image Adjust when new mode detected, and save the settings to buffer for further use

2. It should be reset by Memory Recall function

(Should not reset by power off, power unplug and others)

ViewSonic Corporation

8

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 12

OSD Auto Save

The OSD shall save new settings when it is turned off by the user or when it times out. There shall not be a separate save

2.7 AUDIO INTERFACE (SPEAKER SPECIFICATION)

Line input connection

Line input signal 1 Vrms

Line input impedance 20k ohms

Maximum power output (Electric)

Signal to Noise Ratio 72 dB

Frequency response 300 TO 20KHZ

Distortion 8%@1kHz

Vibration

3.5 mm stereo jack

1.5W / CH

There should be no audible vibration with volume at 100%. (Input

signal within 1 Vrms)

Screen image

Connector PC99 requirement Audio in

Cable type / length 3.5mm stereo cable / 1.8m length

Audio DPMS

There should be no affect on the screen image stability under any

conditions

Lime Green pantone # 577C

NOTE: THERE IS NO GUARANTEE <1 W POWER

CONSUMPTION IN ACTIVE OFF MODE, WHEN THE AUDIO

CABLE IS CONNECTED

ViewSonic Corporation

9

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 13

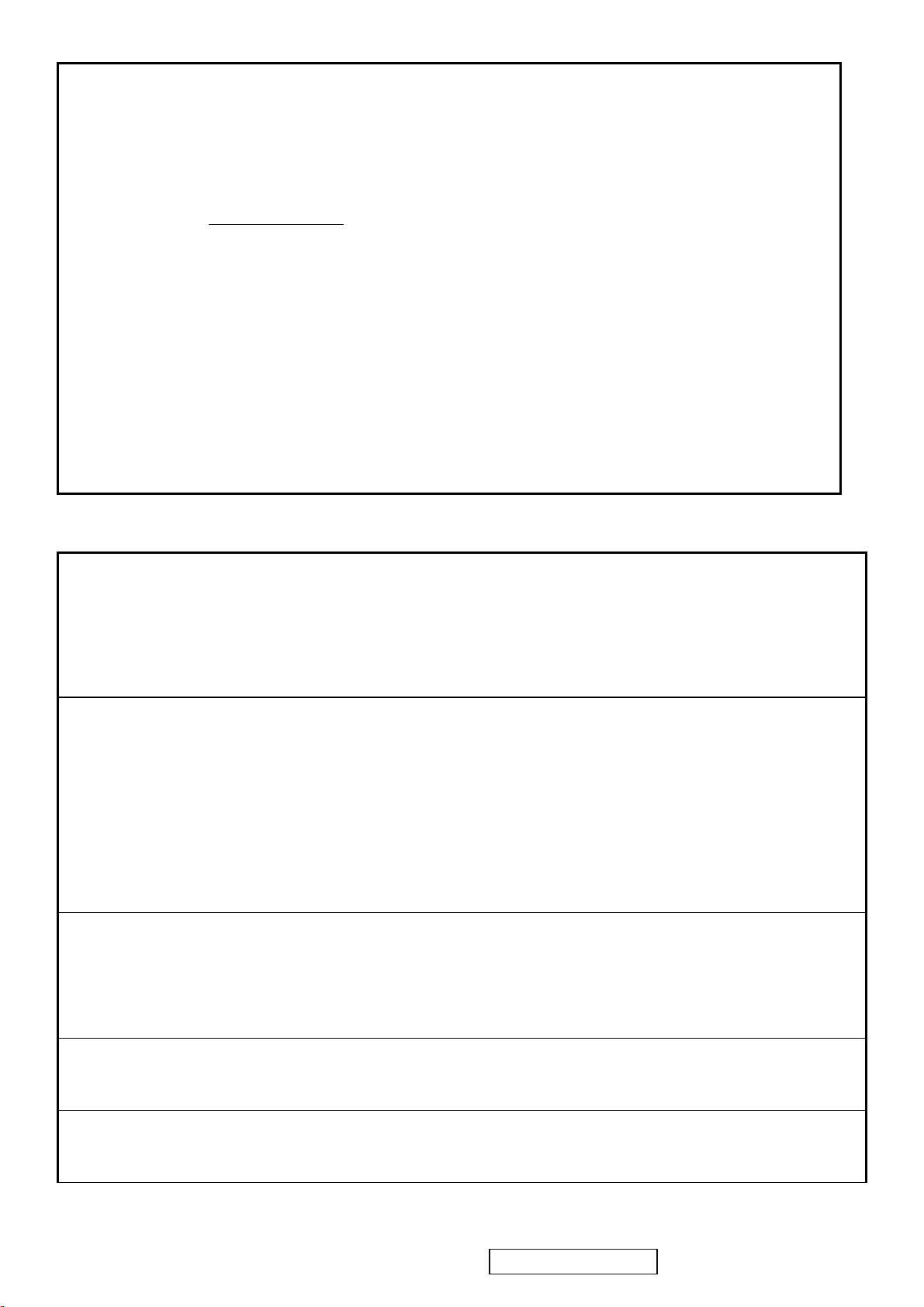

3. Front Panel Function Control Description

Adjusting the Screen Image

Use the buttons on the front control panel to display and adjust the OSD controls which display on the screen. The OSD

controls are explained at the top of the next page and are defined in “Main Menu Controls” on page 10.

ViewSonic Corporation

10

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 14

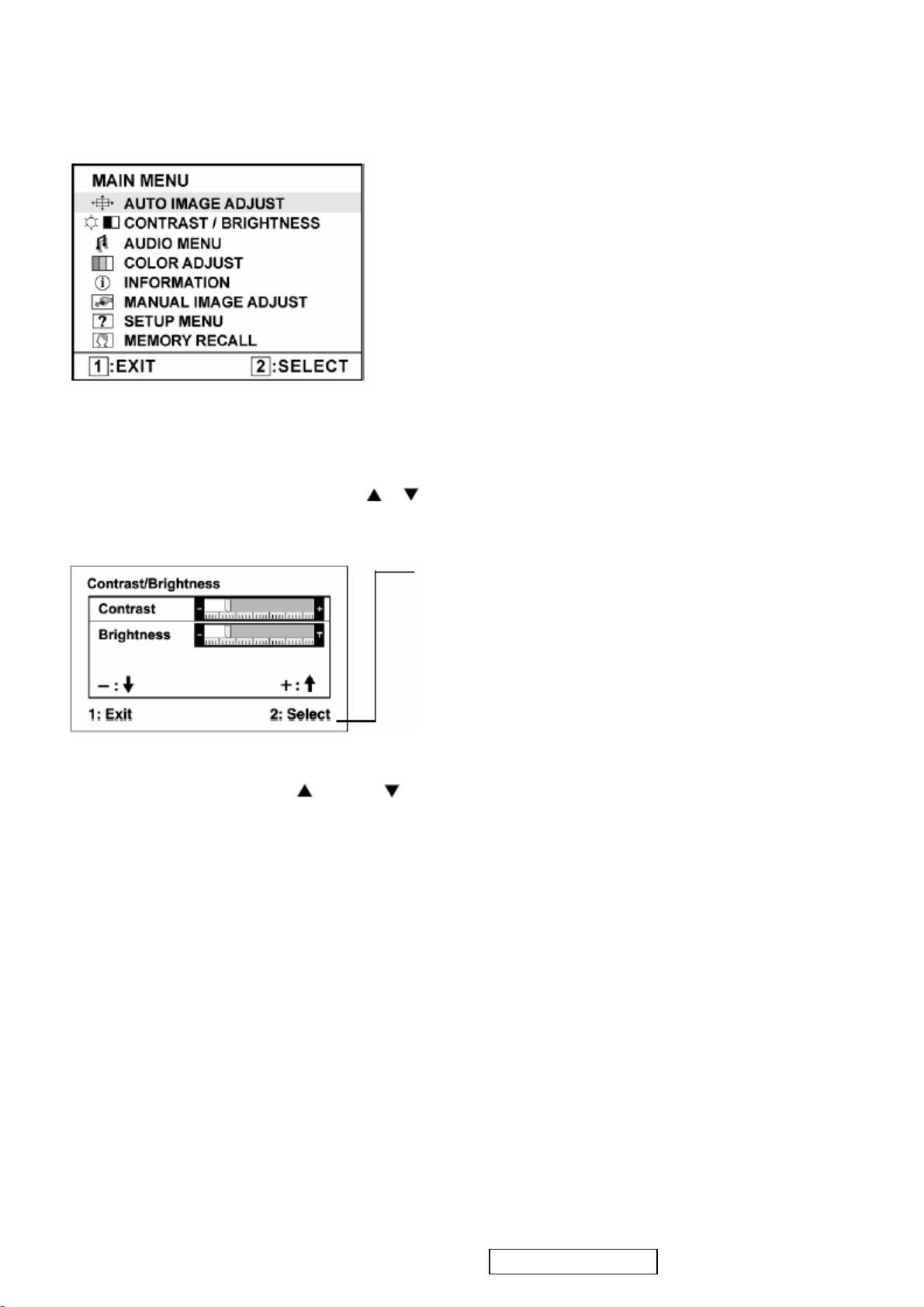

Do the following to adjust the display setting:

1. To display the Main Menu, press button [1].

NOTE: All OSD menus and adjustment screens disappear automatically after about 15 seconds. This is adjustable through the

OSD timeout setting in the setup menu.

2. To select a control you want to adjust, press or to scroll up or down the Main Menu.

3. After the control is selected, press button [2]. A control screen like the one shown below appears.

The command line at the bottom of the control screen tells what to

do next from this screen. You can toggle between control screens,

adjust the selected option, or exit the screen.

4. To adjust the setting, press the up or down buttons.

5.To save the adjustments and exit the menu, press button [1] twice.

The following tips may help you optimize your display:

• Adjust the computer's graphics card so that it outputs a 1440 x 900 @ 60Hz video signal to the LCD display. (Look for

instructions on “changing the refresh rate” in the graphics card's user guide.)

• If necessary, make small adjustments using H. POSITION and V. POSITION until the screen image is completely visible.

(The black border around the edge of the screen should barely touch the illuminated “active area” of the LCD display.)

11

ViewSonic Corporation

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 15

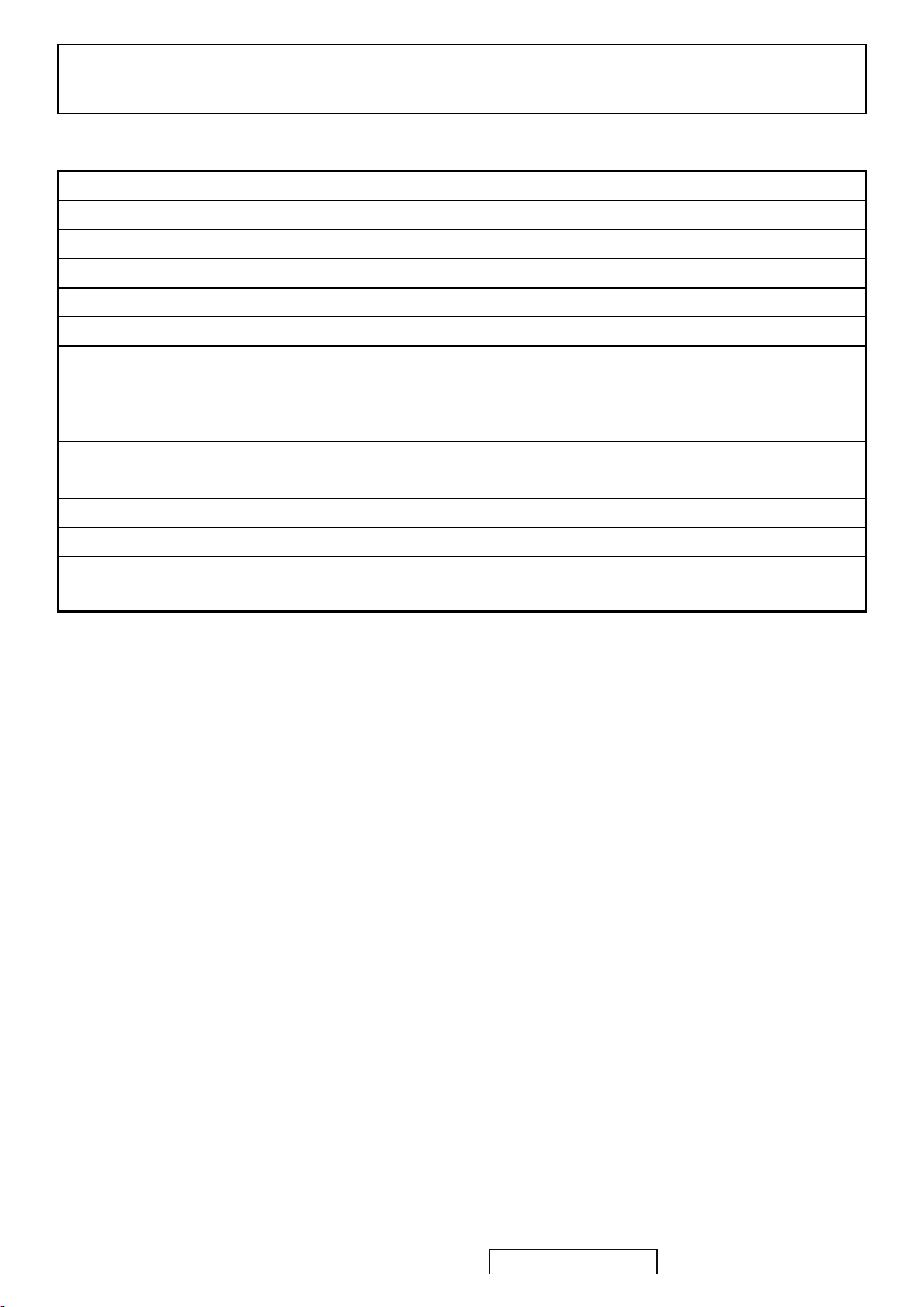

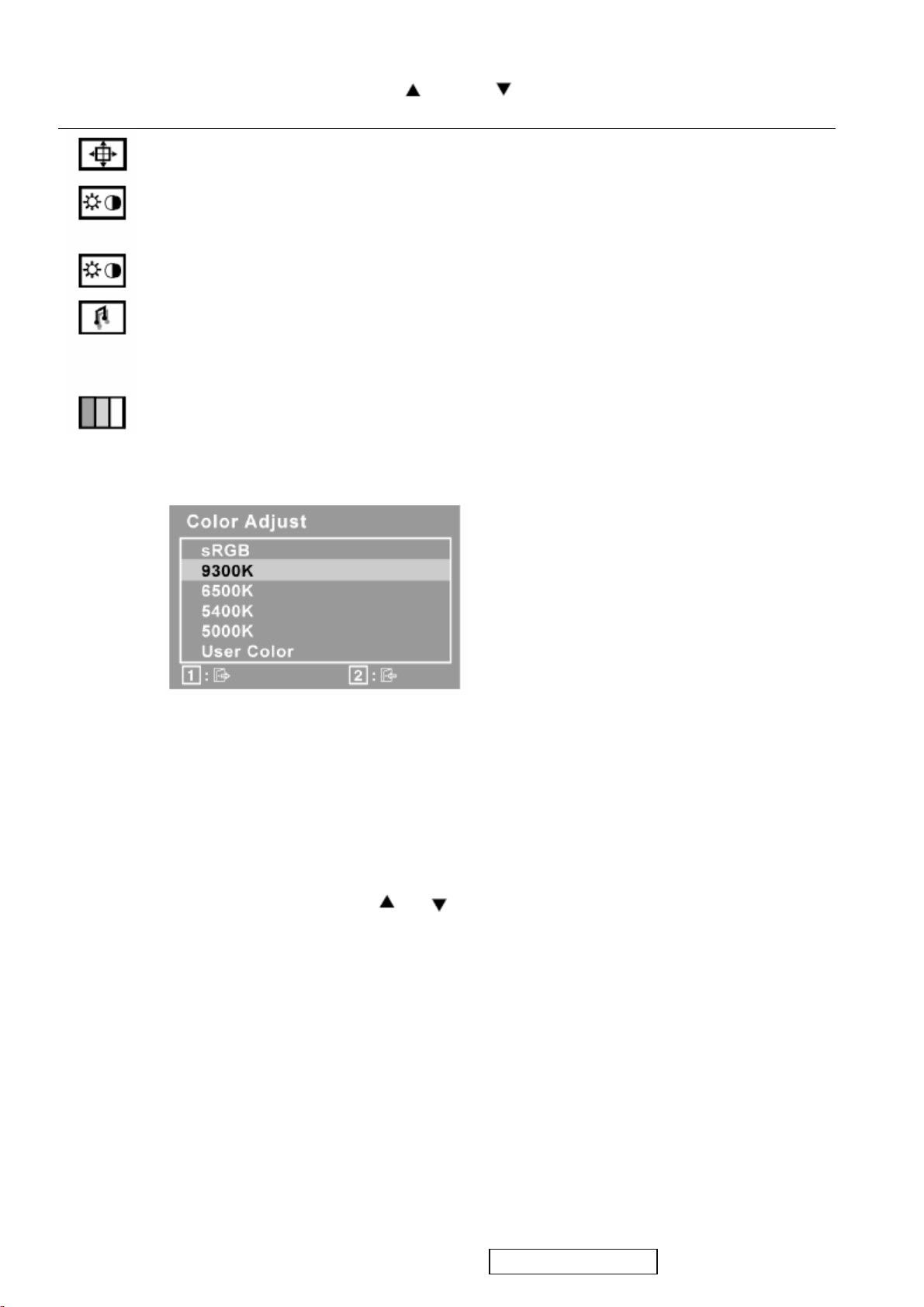

Main Menu Controls

Adjust the menu items shown below by using the up and down buttons.

Control Explanation

Auto Image Adjust sizes and centers the screen image automatically.

Contrast adjusts the difference between the image background (black level) and the foreground (white

level).

Brightness adjusts background black level of the screen image.

Audio Adjust

Volume increases the volume, decreases the volume, and mutes the audio.

Mute temporarily silences audio output.

Color Adjust provides several color adjustment modes, including preset color

temperatures and a User Color mode which allows independent adjustment of

red (R), green (G), and blue (B). The factory setting for this product is 6500K

(6500 Kelvin).

9300K-Adds blue to the screen image for cooler white (used in most office

settings with fluorescent lighting).

6500K-Adds red to the screen image for warmer white and richer red.

5400K-Adds green to the screen image for a darker color.

5000K-Adds blue and green to the screen image for a darker color.

User Color Individual adjustments for red (R), green (G), and blue (B).

1. To select color (R, G or B) press button [2].

2. To adjust selected color, press and . .

Important: If you select RECALL from the Main Menu when the product is set to a Preset Timing

Mode, colors return to the 6500K factory pr

eset.

ViewSonic Corporation

12

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 16

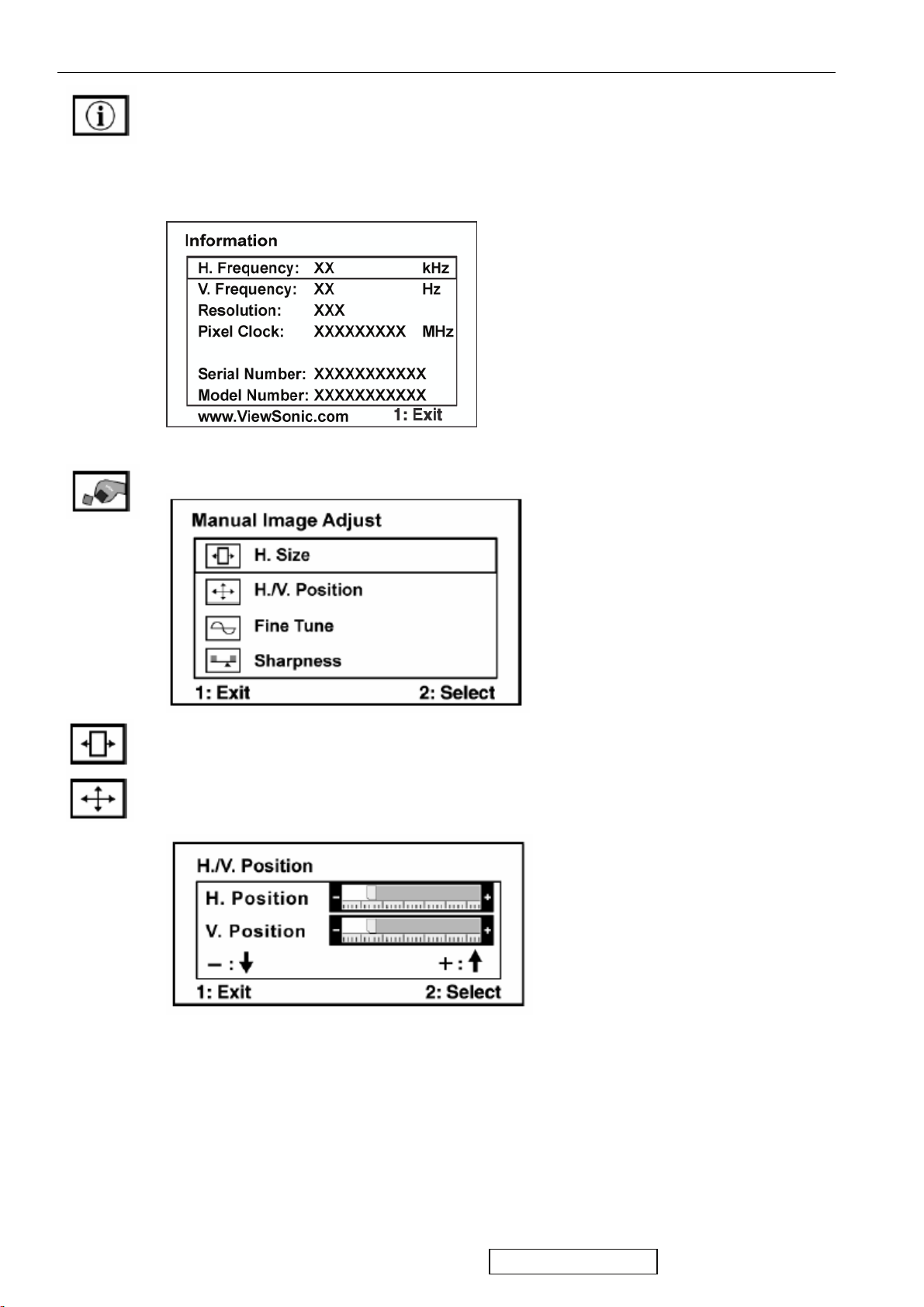

Control Explanation

Information displays the timing mode (video signal input) coming from the graphics card in the

computer, the LCD model number, the serial number, and the ViewSonic® website URL. See your

graphics card’s user guide for instructions on changing the resolution and refresh rate (vertical frequency).

NOTE: VESA 1440 x 900 @ 60Hz (recommended) means that the resolution is 1440 x 900 and the

refresh rate is 60 Hertz.

Manual Image Adjust Sub-menu

H. Size (Horizontal Size) adjusts the width of the screen image.

H./V. Position (Horizontal/Vertical Position) moves the screen image left or right and up or down.

ViewSonic Corporation

13

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 17

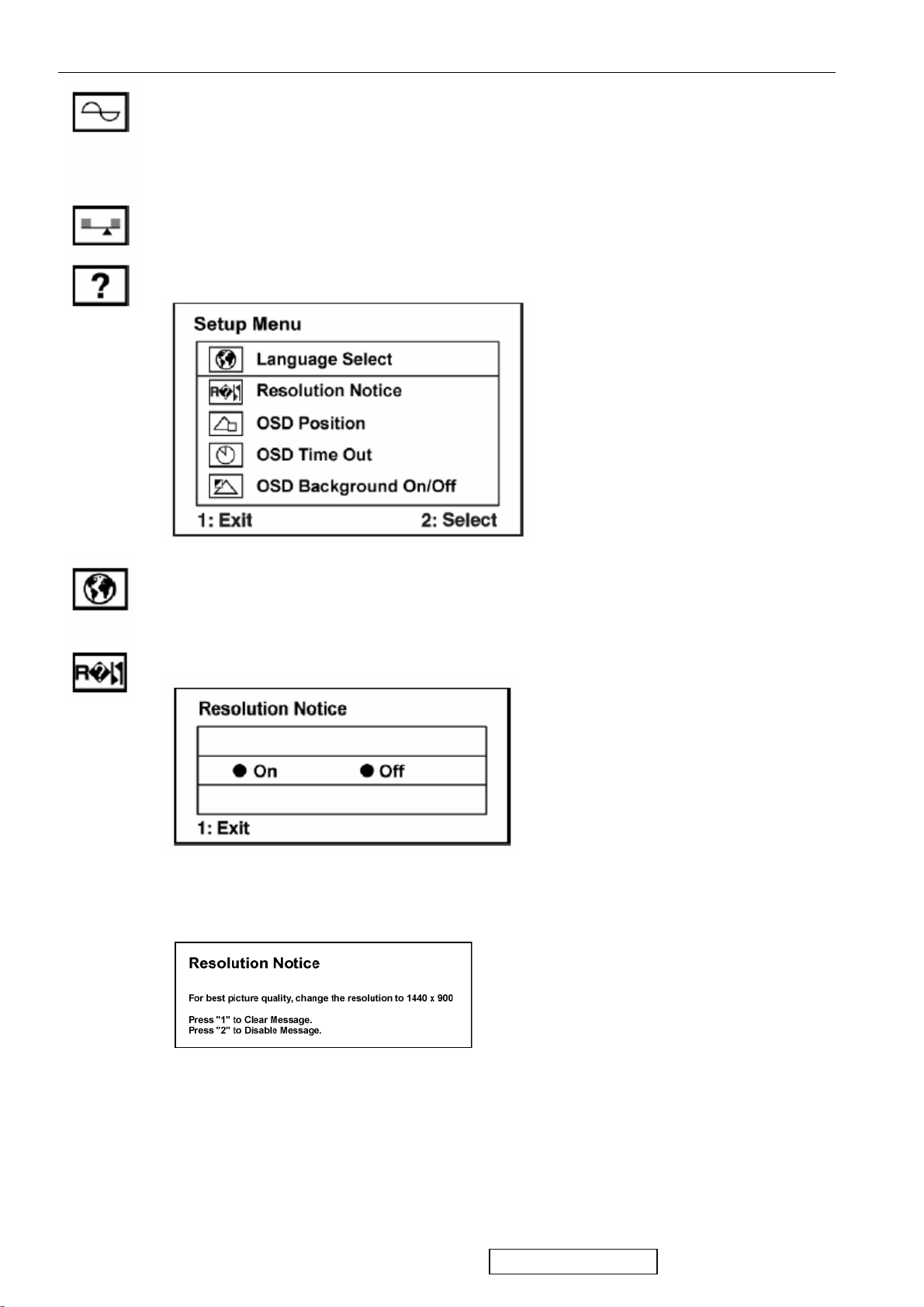

Control Explanation

Fine Tune sharpens the focus by aligning text and/or graphics with pixel boundaries.

NOTE: Try Auto Image Adjust first.

Sharpness adjusts the clarity and focus of the screen image.

Setup Menu displays the menu shown below:

Language Select allows the user to choose the language used in the menus and control screens.

Resolution Notice allows the user to enable or disable this notice.

If you enable the Resolution Notice shown above and your computer is set at a resolution other than 1440

x 900, the following screen appears.

ViewSonic Corporation

14

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 18

Control Explanation

OSD Position allows the user to move the OSD menus and control screens.

OSD Timeout sets the length of time the OSD screen is displayed. For example, with a “30 second”

setting, if a control is not pushed within 30 seconds, the display screen disappears.

OSD Background allows the user to turn the OSD background On or Off.

Memory Recall returns the adjustments back to factory settings if the display is operating in a factory

Preset Timing Mode listed in the Specifications of this manual.

ViewSonic Corporation

15

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 19

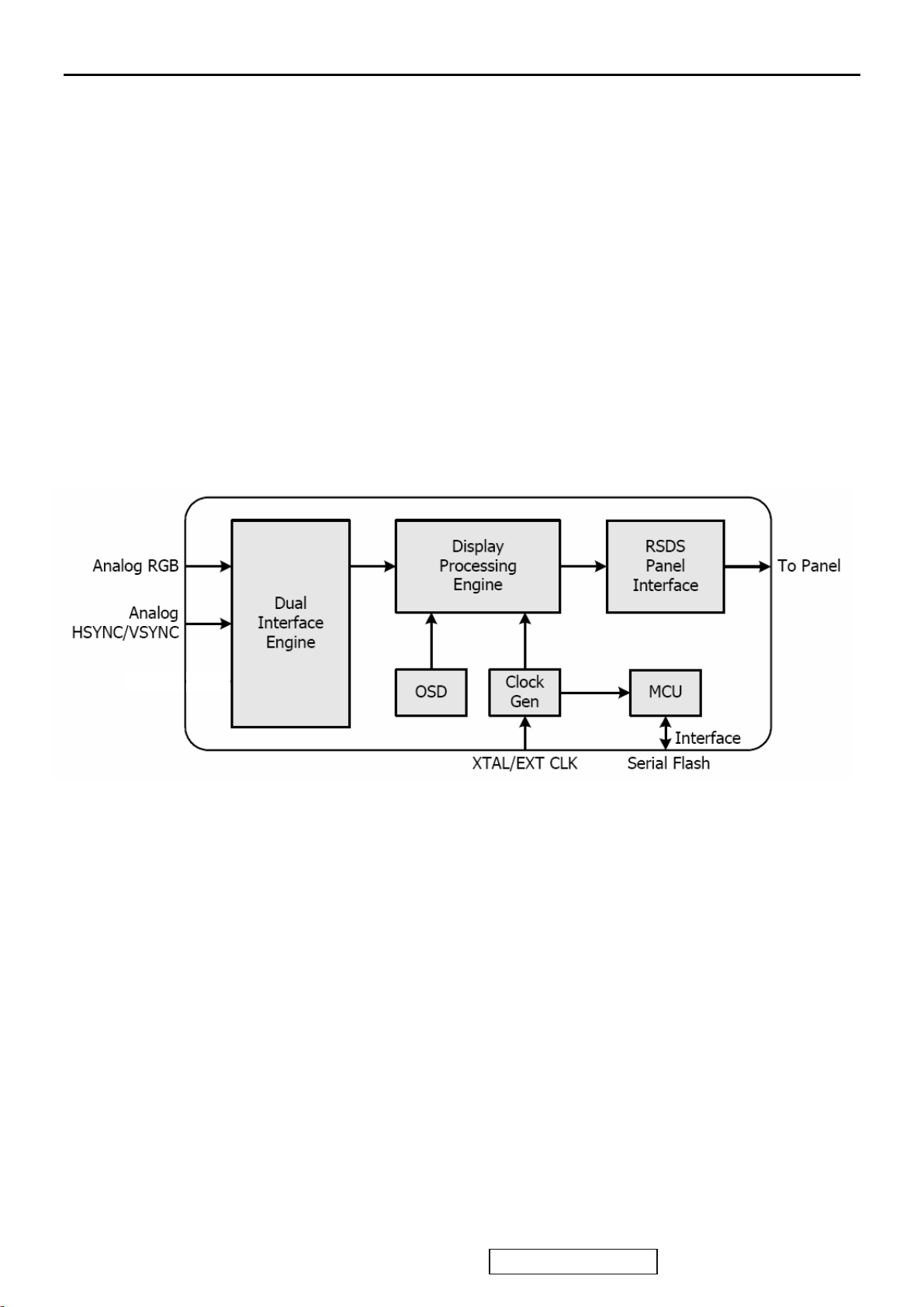

4. Circuit Description

The TSUM17AK is total solution graphics processing IC for LCD monitors with panel resolutions up to SXGA. It is configur ed with

a high-speed integrated triple-ADC/PLL,, a high quality display processing engine, and an integrated output display interface t hat can

support RSDS panel interface format. To further reduce system costs, the TSUM17AK also integrates intelligent power management

control capability for green-mode requirements and spread- spectrum support for EMI management.

The TSUM17AK incorporates the world’s first coherent oversampled RGB graphics ADC in a monitor controller system. The

oversampling ADC samples the input RGB signals at a frequency that is much higher than the signal source pixel rate. This can

preserve details in the video signal that ordinarily would be lost due to input signal jitter or bandwidth limitations in non-o versampled

systems. The TSUM17AK also incorporates a new Dynamic Frame Rate (DFR) generator

panel that preserves the advantages of a fixed output clock rate, while eliminating the output end of frame short-line.

for the digital output video to the display

ViewSonic Corporation

16

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 20

5. Adjustment Procedure

A. Function Test and Alignment Procedure

1. All Modes Reset

You should do “All Model Reset” (Refer to Chap 3. Hot Keys for Function Controls) first. This action will allow

you to erase all end-user’s settings and restore the factory defaults.

2. Auto Image Adjust

The Auto Adjust is aimed to offer a best screen quality by built-in ASIC. For optimum screen quality, the user

has to adjust each function manually.

A.Turn the computer and LCD monitor on.

B. Press the ‘Auto’ button on monitor keypad to Auto Adjust.

C. The LCD monitor will start the Auto Adjust process automatically and run for 10 consecutive seconds, during

which time you will notice the image change.

3. Firmware

Test Patten: Burn in Model (Refer to Chap3. Hot Keys for Function Control)

-Make sure the F/W is the latest version.

4. DCC

Test Patten: EDID program

-Make sure it can pass test program.

5. Window Shut Down

Test Signal: 1280*1024@60Hz

Test Pattern:

Checkered Pattern Every One Pixel (50%Green & 50%Blue)

Inspection Item: Flicker, Mura

6. Window BG

Test Signal: 1280*1024@60Hz

Test Pattern:

Window standard pattern

Inspection Item: Line Defect, Function Defect & Mura

7. 25 Gray

Test Signal: 1280*1024@60Hz

Test Pattern:

Full Screen 25% White (Gray)

Inspection Item: Particle, Line Defect & Mura

8. 50 Gray

Test Signal: 1280*1024@60Hz

Test Pattern:

Full Screen 50% White (Gray)

Inspection Item: Bright Dot, Particle, Line Defect & Mura

9. White Box

Test Signal: 1280*1024@60Hz

Test Pattern:

Window standard pattern

Inspection Item: Particle, Line Defect, Power, Image Remain & Mura

ViewSonic Corporation

17

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 21

10. Black Box

Test Signal: 1280*1024@60Hz

Test Pattern:

Window standard pattern

Inspection Item: Bright Dot, Line Defect & Power

11. RED

Test Signal: 1280*1024@60Hz

Test Pattern:

Full Screen Red

Inspection Item: Bright Dot, Partial & Line Defect

12. Green

Test Signal: 1280*1024@60Hz

Test Pattern:

Full Screen Green

Inspection Item: Bright Dot, Partial & Line Defect

13. Blue

Test Signal: 1280*1024@60Hz

Test Pattern:

Full Screen Green

Inspection Item: Bright Dot, Partial & Line Defect

14. Gray_Scale_0-100_V64

Test Signal: 1280*1024@60Hz

Test Pattern:

Vertical 64 (256) Gray Scale (Right → Left,From 0 to 100% White)

Inspection Item: Line Defect & Function Defect

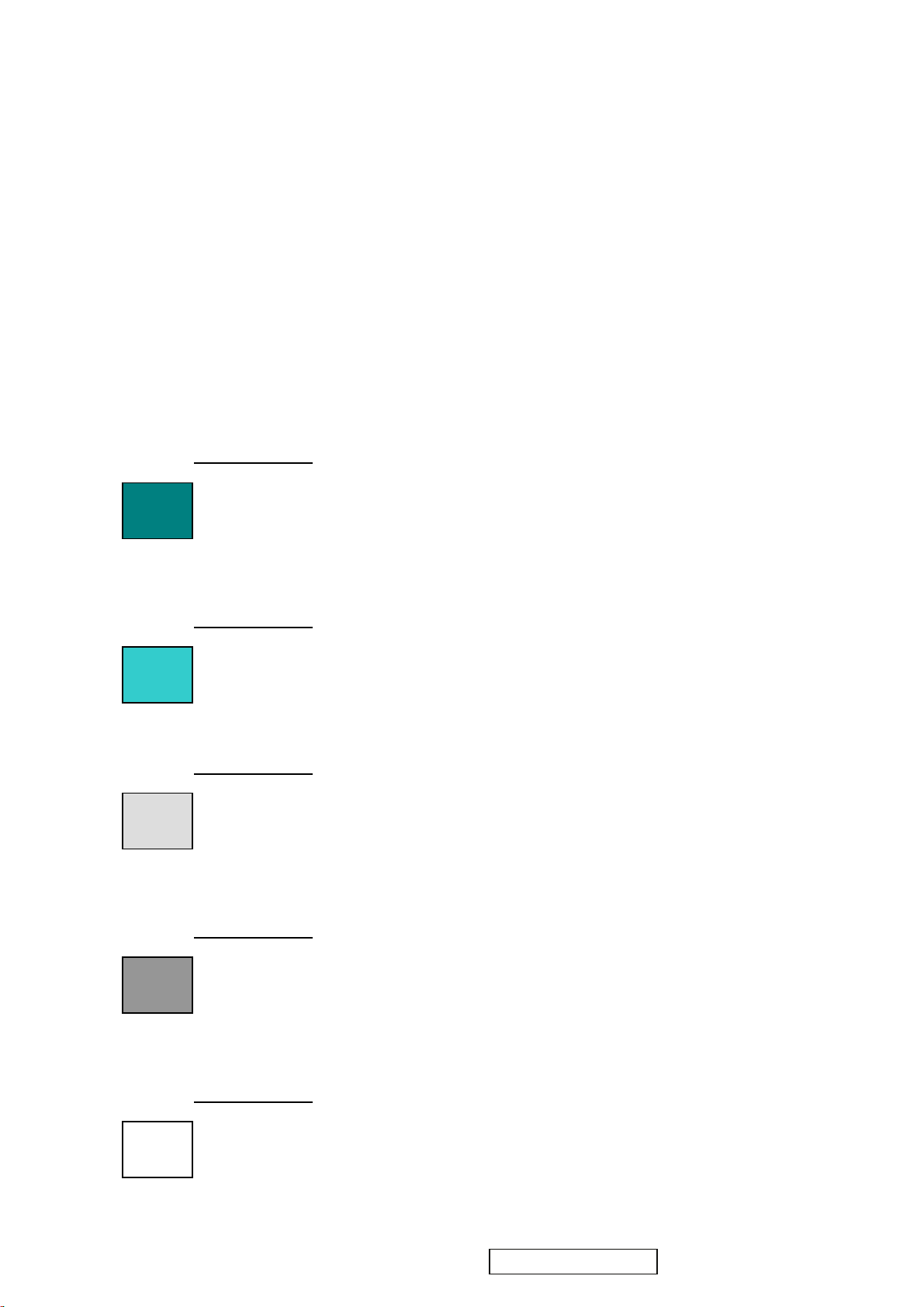

15. Function Test Display pattern

Item Pattern Description Remark

1

2

3

4

5

6

Gray_Scale_0-100_V

Gray_Scale_0-100_H

Vertical 64 (256) Gray Scale (right→left,From 0 to 100% White)

Horizontal 64 (256) Gray Scale (up→down,From 0 to 100% White)

Black Full Screen Black Figure 3

Red Full Screen 50% Red Figure 4

Green Full Screen 50% Green Figure 5

Blue Full Screen 50% Blue Figure6

Figure 1

Figure 2

7

8

White Full Screen White Figure7

Black_Tile Black Tile Under White Background Figure 8

ViewSonic Corporation

18

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 22

Figure 1 Figure 2

Figure 3 Figure 4

Figure 5 Figure 6

Figure 7 Figure 8

ViewSonic Corporation

19

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 23

BIOS update procedure

Mstar ISP Tool User Manual

Setp1:

Take the cable of Print Port to connect Print Port of PC and Print Port of fixture(and EDID burn in the same fixture) to connect

VGA Cable between D-sub of fixture and D-sub of AD Board of monitor,the monitor must be turned on the power。

Step 2 :

Open ISP Tool

ViewSonic Corporation

20

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 24

Step 3 :

Press ”connect” into ISP mode,display the model of Flash,The dialog of figure is displayed “Device Type is Pm25LV512”

then press ”確定”。

Step 4:

Press ”Read” then enter as below figure,then press

If down load BIOS that is successful as below figure then press”確定”。

to down load the program of BIOS (*.bin)。

ViewSonic Corporation

21

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 25

Step 5 :

Press ”Auto” into below figure that display the value of BIOS Checksum below figure is displayed “0x1626” then press ”Run”

to execute the BIOS procedure。

The BIOS procedure is displayed the message ”Verify OK” that the BIOS procedure is successful。

Step 6 :

Press ”Dis Con” then leave the mode of ISP。

ViewSonic Corporation

22

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 26

Step 7:

When select ”ReConnect” and press “Run” then repeat to connect the mode of ISP into next the action of BIOS procedure

ViewSonic Corporation

23

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 27

Packing For Shipping And Disassembly Procedure

Packing For Shipping

1. Packing Procedure

1.1 Paste protection film to protect the monitor. (Figure 1)

1.2 Put the monitor in the PE bag and seal the bag with tape. (Figure 2)

1.3 Put the cushions on the monitor. (Figure 3)

1.4 Place the monitor into the carton and then put all the accessories into the carton. As last, close the carton and seal it with

tape. (Figure 4)

Figure 1

Figure 2

Figure 3

ViewSonic Corporation

Figure 4

24

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 28

Monitor Assembly and Disassembly

1 Separate Stand Assy

1.1 Remove Stand Cover

Step 1 :

Remove the Seat Assy

Step 2 :

Remove the Stand Cover.

Step 3 :

Loose and remove 4 screws

Step4 :

Remove the Stand Assy

Step 5 :

Completed.

ViewSonic Corporation

25

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 29

2 Separate Rear Cover (Rear Case Assy)

Separate Bezel hooks to take Bezel and Rear Cover apart.

Step 1 :

Loose and remove 2 screws.

Step 2 :

Separate Bezel hooks to take

Bezel and Rear Cover apart.

Step 3 :

Remove Rear Cover.

Step 4 :

Completed.

ViewSonic Corporation

26

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 30

3 Remove Power Board and AD Board

3.1 Remove Metal Cover

Step 1 :

Remove FFC from OSD Board.

Step 2 :

Loose and remove 4 screws.

Step 3 :

Lift up LCD module and remove bezel.

Step 4 :

Remove 2 pieces of Backlight wires.

Step 5 :

Remove 2 pieces of Backlight wires.

ViewSonic Corporation

27

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 31

Step 6 :

Loose and remove 2 screws.

Step 7 :

Loose and remove 2 screws.

Step 8 :

Loose and remove 4 screws.

Step 9 :

Remove the PCBA Cover

ViewSonic Corporation

28

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 32

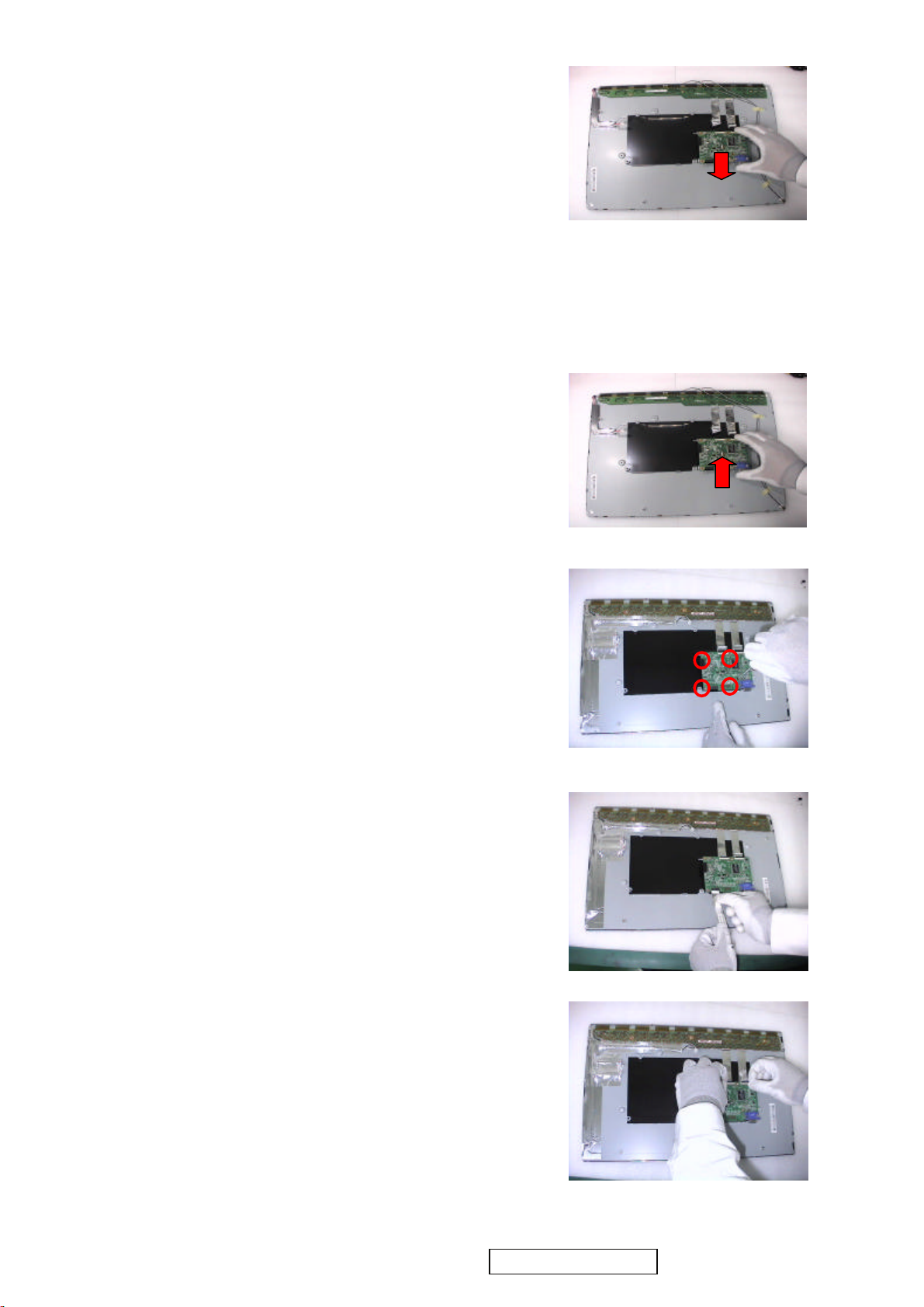

3.2 Remove Power Board and AD Board

Step 1 :

Loose and remove 4 screws.

Step 2 :

Remove Lips Board

Step 3 :

Remove 2 pieces of FFCs.

Step 4 :

Remove the FFC.

Step 5 :

Loose and remove 4 screws.

ViewSonic Corporation

29

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 33

Step 6 :

Remove AD PCBA.

Step7 :

Completed.

4 Change New AD Board and Power Board

Step 1 :

Place new AD Board.

And fasten 4 fixed screws.

Step 2 :

Fasten 4 fixed screws.

Step 3 :

Insert FFC.

ViewSonic Corporation

Step 4 :

Insert 2 pieces of FFCs .

30

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 34

Step 5 :

Insert new Lips Board.

Step 6 :

Fasten 4 fixed screws.

Step 7 :Completed.

ViewSonic Corporation

31

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 35

5. Remove OSD Board

Step 1 :

Separate both Audio Cable.

Step 2 :

Take OSD Board apart.

Step 3:

Completed.

ViewSonic Corporation

32

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 36

6.Change New OSD Board

Step 1 :

Place New OSD Board.

Step 2 :

Insert Audio cable to connectors of

New OSD Board.

Step 3:

Completed.

7. Add Cover to AD PCB Heatsink

Step 1 :

Join the PCB Cover.

Step 2 :

Fasten 4 fixed screws.

ViewSonic Corporation

33

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 37

Step 3 :

Fasten 2 fixed screws

Step 4 :

Fasten 2 fixed screws.

Step 5 :

Insert 2 pieces of Backlight wires.

Step 6 :

Insert 2 pieces of Backlight. wires.

ViewSonic Corporation

Step 7 :

Join LCD module and remove bezel.

34

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 38

Step 8 :

Fasten 4 fixed screws.

Step 9 :

Insert FFC.

Step 10 :

Completed.

8. Rear Assy & Stand Assembly

Step 1 :

Place Rear Cover.

Step 2 :

Fasten 2 fixed screws.

Step 3 :

Place the Stand Assy.

ViewSonic Corporation

35

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 39

Step 4 :

Fasten 4 fixed screws.

Step 5 :

Join the Stand Cover.

Step 6 :

Join the Seat Assy

Step 7 :

Completed.

ViewSonic Corporation

36

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 40

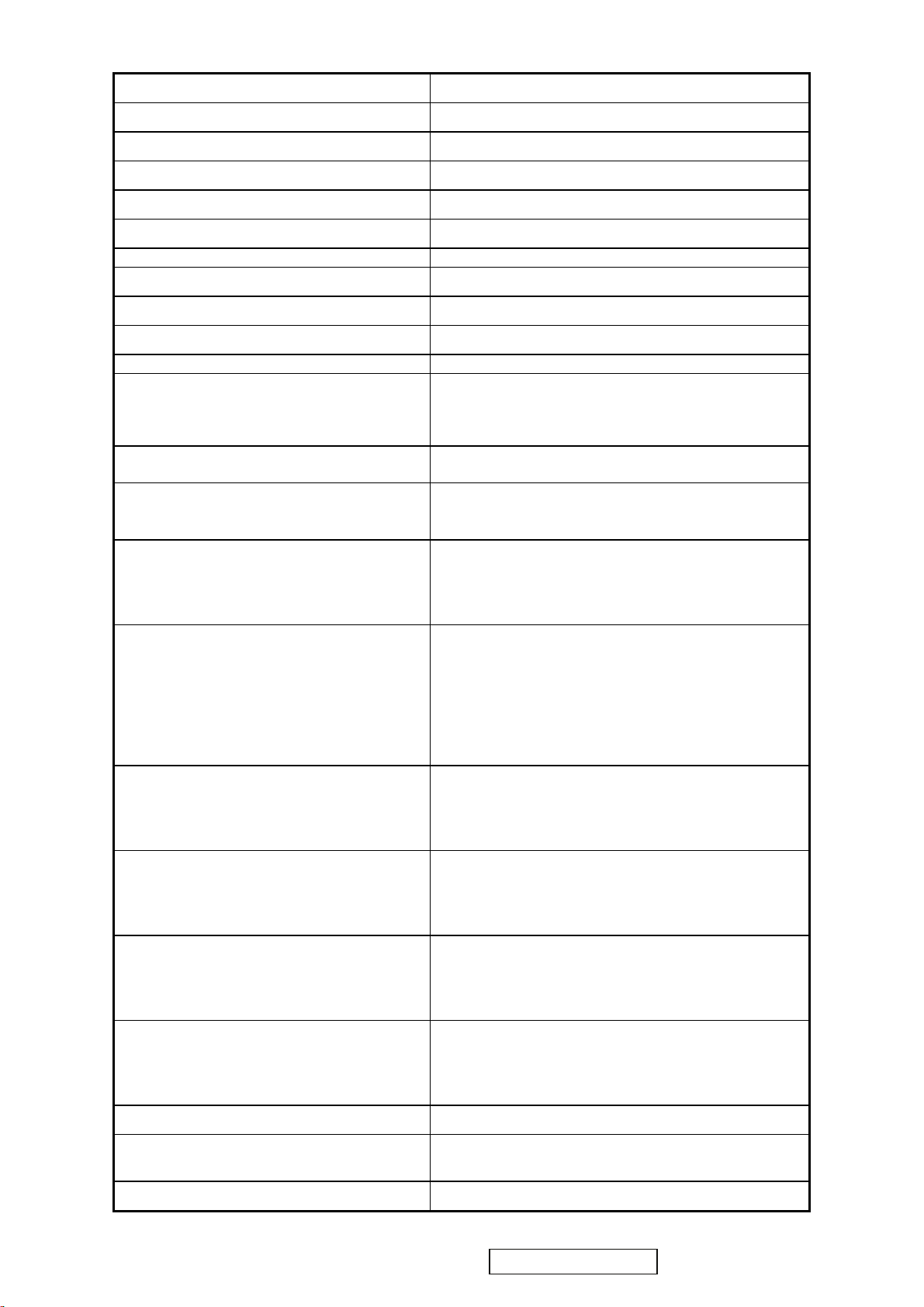

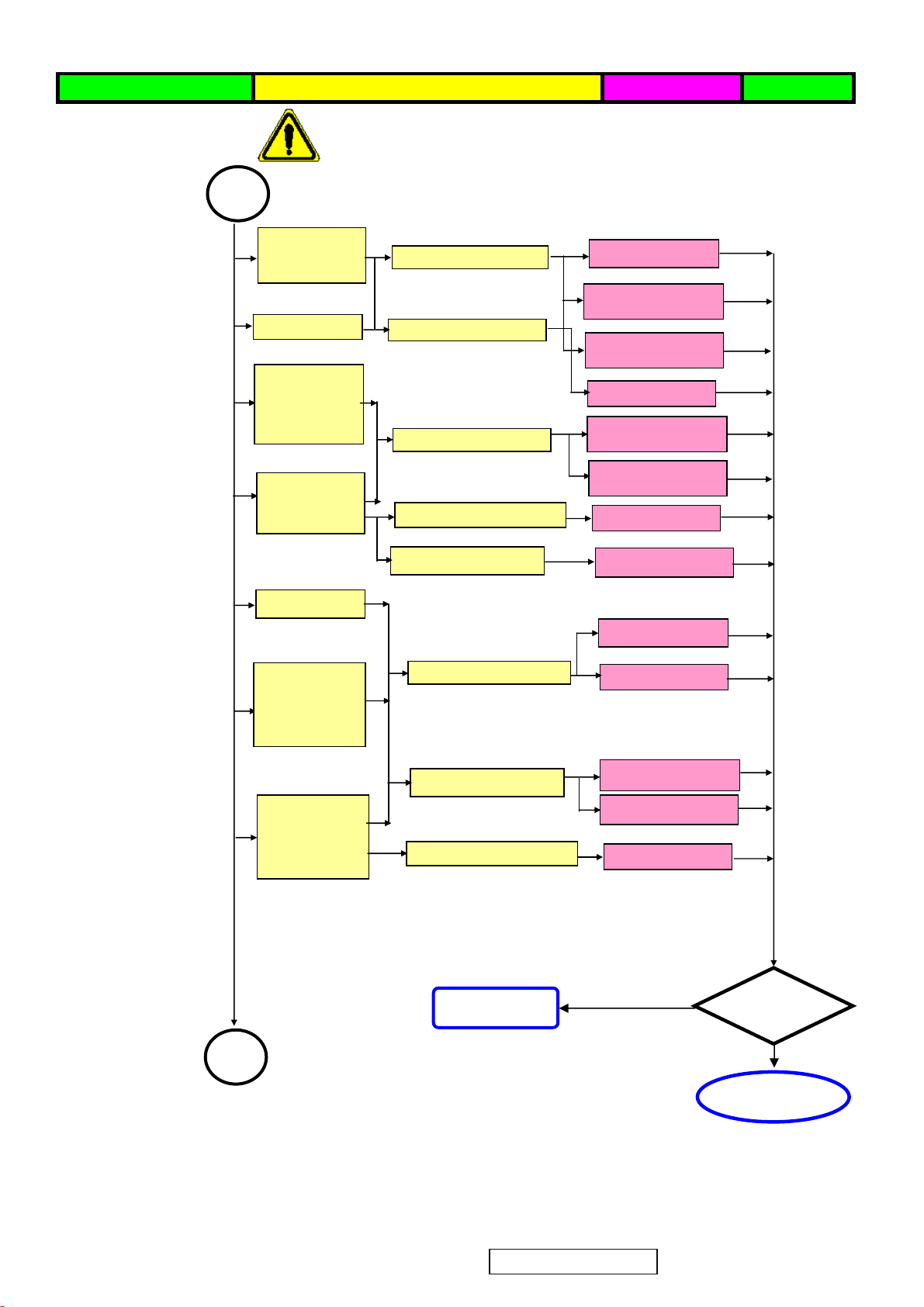

6. Troubleshooting Flow Chart

p

Defect Mode Failure Analysis Repair Testing

Light On Test

※ “ Panel Change” Should be Performed to Level 3 Repair

Flash Dots

Abnormal

Display

Bright Dot

Dark Dot

Backlight

Light Leakage

Mura

Image Sticking

Brightness spot

Particle

Dot Defect

Image Remain

Group Bright

Dots

Others Cosmetics

Check Panel

Panel Change

Defect

NG

Next Ste

A

37

ViewSonic Corporation Confidential - Do Not Copy VA1912w-2_VA1912wb-2

TEST

Completed

Page 41

Defect Mode Failure Analysis Repair Testing

※ “ Panel Change” Should be Performed to Level 3 Repair

A

Display Noise

Power on

Check PCBA

AD/B Change

Display

Abnormal

Power/B Change

Inverter/B Change

Flicker

CNT/B Change

Beat Display

Flicker

Beat Display

Shut Down

Check Panel

Panel Change

Display Wave

Check PCBA

AD/B Change

Power/B Change

CNT/B Change

Check Panel

Panel Change

No Backlight

Check Adapter

Adapter Change

Next Step

NG

TEST

B

Completed

ViewSonic Corporation

38

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 42

p

A

A

A

A

Failure Analysis Repair Testing

※ “ Panel Change” Should be Performed to Level 3 Repair

B

Display White

Out

Check PCB

AD/B Change

Power/B Change

Booting Delay

Brightness

Even

Abnormal

Check PCB

Check PCB

Inverter/B Change

OSD/B Change

Power/B Change

Beat Display

No Backlight

Check Panel

Inverter/B Change

Panel Change

Check Adapter

Adapter Change

No signal

AD/B Change

R.G.B

Display

Abnormal

Check PCB

CNT/B Change

Gray Scale

Display

Abnormal

Check Wire

Check Panel

VGA cable

DVI cable

Panel Change

Next Ste

NG

TEST

C

ViewSonic Corporation

Completed

39

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 43

Defect Mode Failure Analysis Repair Testing

※ “ Panel Change” Should be Performed to Level 3 Repair

C

Horizontal

Line Defect

Vertical

Weak Line

Horizontal

Weak Line

Check PCBA

AD/B Change

Vertical

Band Defect

Check Panel

Panel Change

Horizontal

Band Defect

Power Saving

Display

Abnormal

Check PCBA

AD/B Change

AD/B Change

Peculiar Smell

Check PCBA

Power/B Change

Inverter/B Change

Next Step

NG

TEST

Complete

ViewSonic Corporation

40

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 44

r

g

g

p

Defect Mode Failure Analysis Repair Testing

※ “ Panel Change” Should be Performed to Level 3 Repair

AD/B Change

Power/B Change

Power ON/OFF

Abnormal

No Power

Turn Off

Check PCBA

Check PCBA

Abnormal

CNT/B Change

Inverter/B

OSD/B Change

Check Wire

Check Wire

Check Adapter

OSD Cable

AC Power Change

DC Power CNT

Cable Chan

Adapter Change

e

LED Display

Abnormal

LED Off

LED Dark

Check PCBA

AD/B Change

Power/B Change

Inverter/B

OSD/B Change

LED Abnormal

LED Loss

LED Flicke

Check Wire

OSD Cable

DC Power CNT

Cable Chan

Adapter Change

e

ViewSonic Corporation

NG

Next Ste

41

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

TEST

Completed

Page 45

Defect Mode Failure Analysis Repair Testing

Abnormal BIOS

&OSD

※ “ Panel Change” Should be Performed to Level 3 Repair

OSD Key

Unavailable

OSD Can’t

Input

OSD Can’t

Read

Check PCB

AD/B Change

CNT/B Change

Power/B Change

Inverter/B

OSD/B Change

Abnormal

Louds

peaker

OSD No

Display

OSD Jiggle

OSD Display

Abnormal

Voice Loss

Abnormal

Loud

L/R

Abnormal

Check Wire

Check BIOS

Check PCBA

Check Wire

D-sub cable

OSD cable

VGA cable

DVI cable

BIOS Update

AD/B Change

CNT/B Change

Power/B Change

Inverter/B Change

OSD/B Change

ViewSonic Corporation

No Voice

L/R Same

Volume

Loudspeaker

Noise

Check Loudspeaker

Next Step

42

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

OSD Cable Change

Loudspeaker

Change

NG

Completed

TEST

Page 46

A

p

Defect Mode Failure Analysis Repair Testing

Other Abnormal

Display

※ “ Panel Change” Should be Performed to Level 3 Repair

Display Shut

Down

Check PCB

AD/B Change

Power/B Change

CNT/B Change

Check Panel

Panel Change

Display Flicker

((tapping )

Check PCBA

AD/B Change

CNT/B Change

Check Panel

Panel Change

DVI Signal

Display

Check PCB

AD/B Change

Abnormal

EDID Update

TV Function

Display

Abnormal

Check PCBA

Check Wire

Check Controller

TV /B Change

AV Cable Change

Remote controller

Change

ViewSonic Corporation

NG

Next Ste

43

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

TEST

Complete

Page 47

Trouble Shooting Analysis

Check the information in this section to see if the problems can be solved before requesting repair.

Note:The consumers are only allowed to solve the problems described as below. Any

unauthorized product modification, or failure to follow instructions supplied with the product

will end the warranty immediately.

z No image

Make sure power button is ON.

Check whether the LCD monitor and computer power cords are plugged and whether there is a

supply of power.

z No Signal Input

Check the signal connection between the computer and LCD monitor.

z “Out of Range”

Check the computer image output resolution and frequency and compare the value with the

preset values (Please refer to [Appendix-Display Mode]).

z Fuzzy Image

Adjust Phase.

z Image too bright

Adjust brightness and contrast by OSD.

z Image too dark

Adjust brightness and contrast by OSD.

z Irregular image

Check the signal connection between the computer and LCD monitor.

Perform Auto Adjust.

z Distorted image

Reset the LCD monitor

Take off extra accessories (such as signal extension cord).

z Image is not centered

Use OSD Image Menu to adjust H_Position and V_Position.

Check image size setting.

Perform Auto Adjust.

z Size is not appropriate

Use OSD Image Menu to adjust H_Position and V_Position.

Check image size setting.

Perform Auto Adjust.

z Uneven color

Use OSD Color Menu to adjust color setting.

z Color too dark

Use OSD Color Menu to adjust color setting.

z Dark area distorted

Use OSD Color Menu to adjust color setting.

z White color is not white

Use OSD Color Menu to adjust color setting.

ViewSonic Corporation

44

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 48

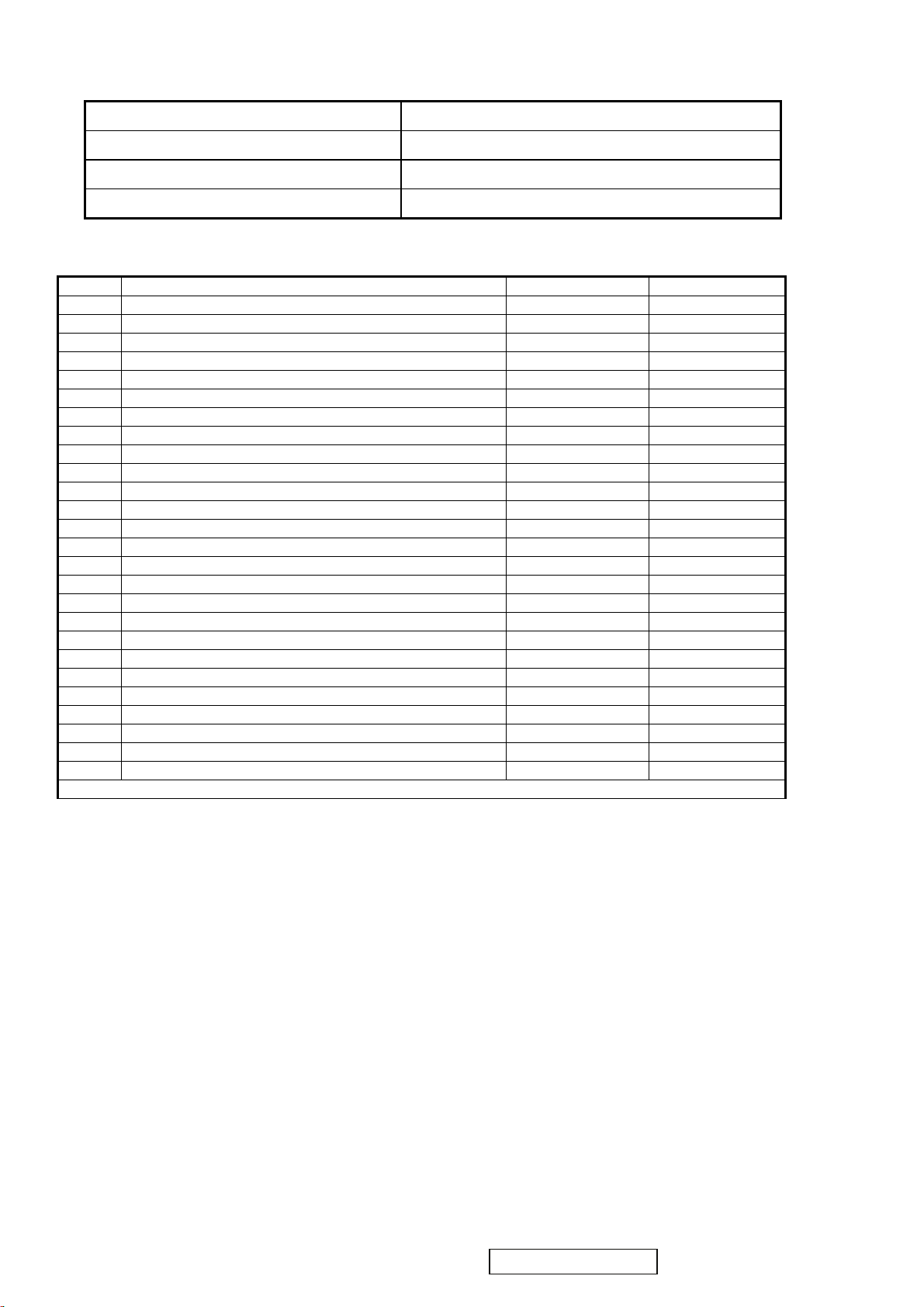

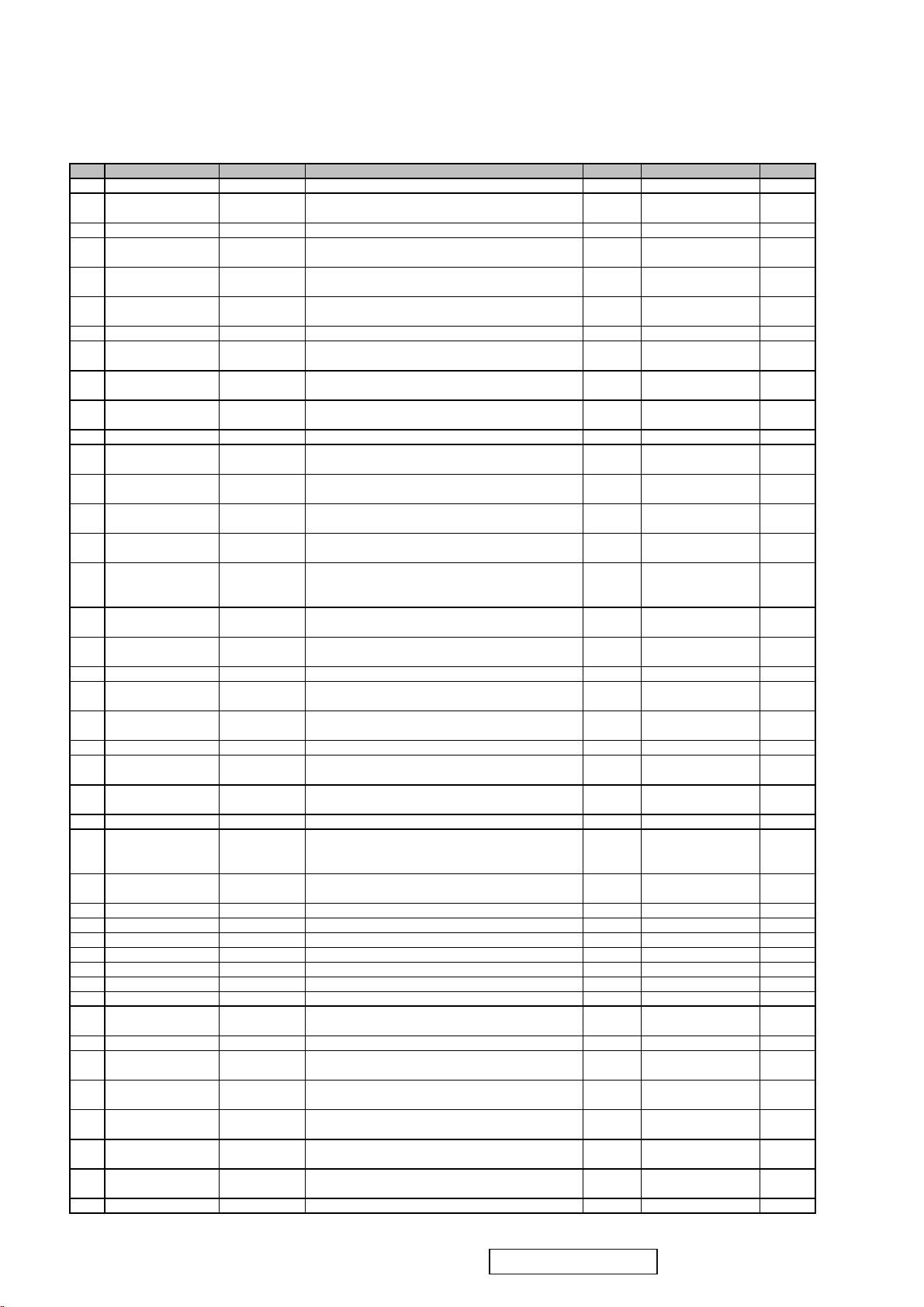

7. Recommended Spare Parts List

m

y

g

(

)

I

gsu_

g

g

n

quip

I

I

_

I

_

I

I

(

)

I

s

g

n

g

I

g

I

_

I

ViewSonic Model Number: VS10866

Serial No. Prefix: Q90

Ite

Accessories:

1

PC Board Assembly:

2

3

4

Cabinets:

5

6 Rear Assy, A190A2-H05, ABS PA757N, Black(J91A11B5), Fuking C-00004282 40-D004257 1

7

8

9 Audio Cable, A150X2, 18AWG, 180cm, Black, JCE, Green I CB-00000544 32F2818004 1

Cables:

10

11 FFC, A190A2-H05, 15 Pins, Tennsure/Young Shin, L=108.5 CB-00004288 32-D004533 1

12 FFC, FFCX816, 36 Pins, Tennsure, package AL_Foil, Green I

Documentation:

13 Label, Pallet Barcode Label, 75x40, A190E2-H03, VSC, Non Green DC-00000586 7741999141 1

14

15

16

Hardware:

17

18 Screw, M3*P1.27*12, φ5.5*2, Steel, Green

19

20

21

Miscellaneous:

22

23 Bag, 570 mmx600 mmx0.13 mm, White, Non Gree

Packing Material:

24

25

26

Power Code, UL, SVT#18/3C, 75C, LP-30B+LS-13, L=1830+/50mm, Black, Linetek, 18AWG, No Ba

PCBA for , A190A2-A02-T, A190A2-A02-H-S1, 1206-04, Rev.04,

ODM, Green II

PCBA for , A190A2-H, A190A2-H-K3, 106-02, Rev.02, USI/ITC,

ODM, Green II

Lips With Audio, DAC-12M030 A, Ver:0F, 5 V/3 A, 12 V/0.7 A,

TYPE, 7 mA, 1710 V, Delta Dongguan_Inverter/Delta

Jian

Bezel Assy, A190A2-H05, ABS PA757N, Silver(Pantone877C),

Fukin

Cover Hinge, A190A2-H05, ABS PA757N, Black(J91A11B5),

Fukin

Seat Assy, A190A2-H05, ABS PA757N, Black(J91A11B5),

Hontech Precisio

Accessory Cable, D-Sub, BLACK, Johnson Components &

E

ments, A150X2, Green

Safety Label for , A190A2-H05, 120 mmx50 mm, Chang Huang,

VSC

VA1912w-2, Green I

Carton Label for , A190A2-H05, 76.2 mmx76.2 mm, Chang Huang,

VSC

VA1912w-2, Green I

MENU for A190E2-H05, Complex, 1C, Yi Ching, VSC_VA1912w2+Caution Card, Green I

SCREW, M3, P=0.5 mm, L=4 mm, Pan Head, Phillips Cross

Recess, Green I

SCREW, M4, P=0.7 mm, L=15 mm, Pan Head, Phillips Cross

Recess, Green I

SCREW, M4, P=0.7 mm, L=8 mm, Round Head, Phillips Cros

Recess, plate color Zn, Screw_with_Washer, Shye Ching/Hama

Naka Moto

SCREW, M4, P=0 mm, L=11.8 mm, Hexagon Stand Off, Socket,

Green I

Tape, Security Tape, OPP, L900xW50x0.045mm, VSC, Non Green M-00000560 7345511002 1

Cushion, A190A2-T05, EPS, WHITE, 450 mmx160 mmx145 mm,

Sin

Home, PS FOAM (Left), Green I

Cushion, A190A2-T05, EPS, WHITE, 450 mmx160 mmx145 mm,

Sin

Home, PS FOAM (Right), Green I

Carton, A190A2-H05, 538 mmx158 mmx470 mm, Chen Ti Paper,

VSC

VA1912w-2, Green I

Remark 1:

Above listed items are examples, supplier can expand the rows to add more necessary items.

Remark 2: All revised RSPLs with newly added items or any change made should be highlighted and correlated with the ECN/ECR approved by ViewSonic Corporation.

RECOMMENDED SPARE PARTS LIST (VA1912W-2)

Description

, Green I

Adaptor, RoHS

awa, head D8, Green I

ECR/ECN ViewSonic P/N Ref. P/N Location Universal number#Q't

A-00000458

B-00005599 35-D005694 1

B-00005600 35-D005166 1

B-00006040 27-D003247 1

C-00004281 40-D004255 1

C-00004284 40-D004250 1

C-00004285 40-D004259 1

CB-00004287 32F3018003 1

CB-00005742 32-D005773 1

DC-00005602 77-D008324 1

DC-00005604 77-D008326 1

DC-00005606

HW-00000554 42A9930008 2000

HW-00000556 42A9990005 2000

HW-00000590 42A9930013 2000

HW-00004042 42-D000649 2000

HW-00006042 42A9940007 2000

P-00000595 7841919921 1

P-00004295 78-D004392 1

P-00004296 78-D004388 1

P-00005607 78-D008325 1

Rev: 1b

32E1818015

AJ0A2T3A25

76-D008373

AJ0A2T3A25

1

1

45

ViewSonic Corporation

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 49

RECOMMENDED SPARE PARTS LIST (VA1912WB-2)

ViewSonic Model Number: VS10866

Serial No. Prefix: QBM Rev: 1a

Item Description ECR/ECN ViewSonic P/N Ref. P/N Location Universal number# Q'ty

1

Accessories:

2 Audio Board (Rev.02) B-00005600 35-D005166 1

PC Board Assembly:

3 Power Supply Board, Ver:0F B-00006039 27-D003247 1

4 Main Board - A190A2-A02-T, A190A2-A02-T-S1,Rev.04 B-00006727 35-D008185 1

5 Front Panel, Bezel Assy C-00004276 40-D004254 1

Cabinets:

6 Back Cover C-00004277 40-D004253 1

7 Cover Hinge C-00004279 40-D004258 1

8 Base Assembly C-00004280 40-D004256 1

9 Audio Cable, A150X2, 18AWG, 180cm, Black CB-00000544 32F2818004 1

Cables:

10 Accessory Cable, D-Sub CB-00004287 32F3018003 1

11 Flat Cable, (FFC, A190A2-H05) CB-00004288 32-D004533 1

12 Flat Cable FFCX816,36 CB-00005742 32-D005773 1

13 Safety Label 120 mmx50 mm Ver.3 DC-00008016 77-D012194 1

Documentation:

14 Carton Label 76.2 mmx76.2 mm DC-00008020 77-D011732 1

15 SN Label 50 mmx25 mm DC-00008021 77-D011737 1

16 User's Guide MENU Complex, 1C DC-00008022 76-D011747 1

17 SCREW, M3, P=0.5 mm, L=4 mm HW-00000553 42A9930008 2000

Hardware:

18 Screw, M3*P1.27*12, φ5.5*2, Steel HW-00000556 42A9990005 2000

19 SCREW, M4, P=0.7 mm, L=15 mm HW-00000590 42A9930013 2000

20 SCREW, M4, P=0.7 mm, L=8 mm HW-00004042 42-D000649 2000

21 SCREW, M4, P=0 mm, L=11.8 mm HW-00006041 42A9940007 2000

22

Miscellaneous:

23 PE Bag, 570 mmx600 mmx0.13 mm P-00000595 7841919921 1

Packing Material:

24 FOAM (Left) P-00004295 78-D004392 1

25 FOAM (Right) P-00004296 78-D004388 1

26 Generic Foam Set P-00001347 30833

27 Generic Box P-00002515 20653

28 Craft Box 538 mmx158 mmx470 mm P-00008015 78-D011688 1

Power Cord 0.75mm2, 3C, A-00002058 32E1818013 1

Tape, Security Tape, OPP, L900xW50x0.045mm M-00000560 7345511002 1

Above listed items are examples, supplier can expand the rows to add more necessary items.

Remark 1:

Remark 2:

All revised RSPLs with newly added items or any change made should be highlighted and correlated with the ECN/ECR approved by ViewSonic Corporation.

This is to eliminate repeated cross checks of each item between this version and prior versions.

ViewSonic Corporation

46

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 50

BOM LIST (VA1912W-2)

ViewSonic Model Number: VS10866

Rev: 1b

Serial No. Prefix: Q90

Item ViewSonic P/N Ref. P/N Description Location Universal number# Q'ty

1 E-00005747 MJ0A10AK01 19" Wide Semi Product,A190A2,1440X900,TN 1

2 N/A 36X8636401 Driver IC,Scan,HX8636APD400(TSMC),300Channel,,RoHS,Green I 3

3 N/A L3J009XXXX 19" wide PS TN Asahi 0.7mm glass Cr BM(Panel Base) 1

4 N/A 74-D002212

5 N/A 74-D002213

6 N/A 73-C000047 ACF,COG,AC-8405Z-23 1.5mmX100M,100000 mmx1.5 mm,COG-ACF,Green I 0.00168

7 N/A 7344191017 ACF,AC-4251FY-16,100M/RL,Green I 0.0044

8 N/A 36-D002378

9 N/A 73-D002676 ACF,PCB,AC-9825R-35,100000 mmx1.5 mm,PCB-ACF,Green I 0.0044

10 N/A 35-D004361 PCBA for ,A190A2-H,A190A2-A02-H-X,1206-01,Rev.01,Green I 1

11 N/A 7349951002 Silicone,TORAY/-9187L,330g 0.4

12 HW-00000533 42A9930008 SCREW,M3,P=0.5 mm,L=4 mm,Pan Head,Phillips Cross Recess,Green I 16

13 HW-00006041 42A9940007 SCREW,M4,P=0 mm,L=11.8 mm,Hexagon Stand Off,Socket,Green I 2

14 N/A 41-D000643 Metal Frame Front,M190A1-L01/A190A2/M190A1-L03,SECC 0.6t,19"wide 1

15 HW-00004042 42-D000649

16 N/A 73-D002886

17 B-00006039 27-D003247

18 N/A 44-D003584 Backlight Unit,A190A2,Green I 1

19 C-00005686 41-D003772 Cover AD Assy,A190A2,SECC,without Dvi-D Hole,Green II 1

20 B-00005599 35-D005694 PCBA for ,A190A2-A02-T,A190A2-A02-H-S1,1206-04,Rev.04,ODM,Green II 1

21 CB-00005742 32-D005773 FFC,FFCX816,36 Pins,package AL_Foil,Green II 2

22 CB-00000544 32F2818004 Audio Cable,A150X2,18AWG,180cm,Black,JCE,Green I 1

23 CB-00004287 32F3018003 Accessory Cable,D-Sub,BLACK,A150X2,Green I 1

24 A-00002058 32E1818013

25 HW-00000590 42A9930013 SCREW,M4,P=0.7 mm,L=15 mm,Pan Head,Green I 4

26 HW-00000555 42A9930014 Screw,M3*P0.5*6,Green I 4

27 HW-00000556 42A9990005 Screw,M3*P1.27*12,φ5.5*2,Steel,Green I 2

28 C-00004284 40-D004250 Cover Hinge,A190A2-H05,ABS PA757N,Black(J91A11B5) 1

29 C-00004282 40-D004257 Rear Assy,A190A2-H05,ABS PA757N,Black(J91A11B5) 1

30 C-00004281 40-D004255 Bezel Assy,A190A2-H05,ABS PA757N,Silver(Pantone877C) 1

31 CB-00004288 32-D004533 FFC,A190A2-H05,15 Pins,L=108.5 1

32 B-00005600 35-D005166 PCBA for ,A190A2-H,A190A2-H-K3,106-02,Rev.02,ODM,Green II 1

33 C-00004283 40-D004252 Stand Assy,A190A2-H05,ABS PA757N,Black(J91A11B5) 1

34 PL-00006048 73-D005900 Panel Protector Film,A190A2-H05,XG-536 T=0.1,With_Print,Green II 1

35 DC-00005602 77-D008324 Safety Label for ,A190A2-H05,120 mmx50 mm,VSC_VA1912w-2,Green II 1

36 N/A 77-D008330 SN Label for ,A190A2-H05,50 mmx25 mm,VSC_VA1912w-2 for China,Green II 1

37 HW-00002076 7841595111 Corner Protector,paper,50 mmx50 mmx1850 mm,Green I 1

38 N/A 7841595191

39 P-00000595 7841919921 Bag,570 mmx600 mmx0.13 mm,White,Non Green 1

40 DC-00000586 7741999141 Label,Pallet Barcode Label,75x40,A190E2-H03,VSC,Non Green 0.021

41 M-00000560 7345511002 Tape,Security Tape,OPP,L900xW50x0.045mm,VSC,Non Green

42 N/A 77-D000114 Customer Label,A170E1-H0G,180 mm,100 mm,Green I 1

43 N/A 77-D000118 Customer Label,A170E1-H0G,130 mm,80 mm,Green I 1

44 N/A 78-D000275 Warranty Card,A170E1-H0G,143 mmx210 mm,VSC_VA712,Green I 1

45 DC-00005603 77-D000576 Carton Label for ,A190E2-H06,20 mmx20 mm,VSC_VA912_for Europe,Green I 1

46 N/A 77-D001323

47 N/A 78-D001492 Pallet,A150X2-T01,Wooden,1150 mmx840 mmx138 mm,Green I 0.02

48 C-00004285 40-D004259 Seat Assy,A190A2-H05,ABS PA757N,Black(J91A11B5) 1

49 P-00004295 78-D004392

50 P-00004296 78-D004388

51 N/A 79-D004425 Shipping Package Information for ,A190A2-H05,ViewSonic 1

52 DC-00005604 77-D008326 Carton Label for ,A190A2-H05,76.2 mmx76.2 mm,VSC_VA1912w-2,Green II 1

53 P-00005607 78-D008325 Carton,A190A2-H05,538 mmx158 mmx470 mm,VSC_VA1912w-2,Green II 1

54 DC-00005605 76-D008375 MENU for A190E2-H05,Complex,1C,VSC_VA1912w-2,CD-ROM,Green II 1

Polarizer,TFT,Degree 135,414 mmx259.7 mmx0.215 mm,NWF-LESEG,M190A1,Green

I

Polarizer,CF,Degree 135,415.84 mmx262.15 mmx0.215 mm,NWFLESEGAGS1,M190A1,Green I

Driver IC,COF,Data,M190A1-L01,HX8018-A050CBAK,Reel,6

bit,432Channel,RoHS,Green I

SCREW,M4,P=0.7 mm,L=8 mm,Round Head,Phillips Cross Recess,plate color

Zn,Screw_with_Washer,head D8,Green I

Conductive Tape,PET+Adhesive,409 mmx58.55 mmx0.05

mm,Mylar_Cover_PcbaX_a190a2,Green I

Lips With Audio,DAC-12M030 A,Ver:0F,5 V/3 A,12 V/0.7 A,I TYPE,7 mA,1710

V,RoHS

Power Cord,CCC,300/500V,0.75mm2,3C,PC-323+COC-01,L=1830+/50mm,Black,Linetek,18AWG,No Bag,Green I

Separator,紙板(AA),1120*820*11mm,A150X2-T01,Non Green

Customer Label for ,A170E1-H0G,15 mmx15 mm,QC Pass Label_VSC_for

China,Green I

Cushion,A190A2-T05,EPS,WHITE,450 mmx160 mmx145 mm,PS FOAM (Left),Green

II

Cushion,A190A2-T05,EPS,WHITE,450 mmx160 mmx145 mm,PS FOAM (Right),Green

II

10

0.025

0.3

1

1

1

1

1

1

1

1

1

ViewSonic Corporation

47

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 51

BOM LIST (VA1912WB-2)

ViewSonic Model Number: VS10866

Rev: 1a

Serial No. Prefix: QBM

Item ViewSonic P/N Ref. P/N Description Location Universal number# Q'ty

1 E-00005747 MJ0A10AK01 19" Wide Semi Product, A190A2, 1440X900, TN 1

2 N/A 36X8636401

3 N/A L3J009XXXX 19" wide PS TN Asahi 0.7mm glass Cr BM(Panel Base) 1

4 N/A 74-D002212

5 N/A 74-D002213

6 N/A 73-C000047

7 N/A 7344191017 ACF, AC-4251FY-16, 100M/RL, Green I 0.0044

8 N/A 36-D002378

9 N/A 73-D002676

10 N/A 35-D004361

11 N/A 7349951002 Silicone, TORAY/-9187L, 330g 0.4

12 N/A PJ0AFT0Q04

13 HW-00000553 42A9930008

14 HW-00006041 42A9940007

15 N/A 41-D000643

16 HW-00004042 42-D000649

17 N/A 73-D002886

18 B-00006039 27-D003247

19 N/A 44-D003584 Backlight Unit, A190A2, Green I 1

20 C-00005686 41-D003772

21 B-00006727 35-D008185

22 CB-00005742 32-D005773 FFC, FFCX816, 36 Pins, package AL_Foil, Green II 2

23 N/A

24 CB-00000544 32F2818004

25 CB-00004287 32F3018003 Accessory Cable, D-Sub, BLACK, A150X2, Green I 1

26 A-00002058 32E1818013

27 N/A PJ0AI15100

28 HW-00000590 42A9930013 SCREW, M4, P=0.7 mm, L=15 mm, Pan Head, Green I 4

29 HW-00000555 42A9930014 Screw, M3*P0.5*6, Green I

30 HW-00000556 42A9990005 Screw, M3*P1.27*12, φ5.5*2, Steel, Green I 2

31 C-00004279 40-D004258 Cover Hinge, A190A2-H05, ABS PA757N, Green I 1

32 C-00004277 40-D004253 Rear Assy, A190A2-H05, ABS PA757N, Green I 1

33 C-00004276 40-D004254 Bezel Assy, A190A2-H05, ABS PA757N, Green I 1

34 CB-00004288 32-D004533 FFC, A190A2-H05, 15 Pins, L=108.5 1

35 B-00005600 35-D005166

36 C-00004278 40-D004251 Stand Assy, A190A2-H05, ABS PA757N, Green I 1

37 PL-00006048 73-D005900

38 DC-00008016 77-D012194

39 DC-00008021 77-D011737

40 HW-00002076 7841595111

41 N/A 7841595191

42 P-00000595 7841919921 Bag, 570 mmx600 mmx0.13 mm, White, Non Green 1

PJ0EACS000

Driver IC, Scan, HX8636APD400(TSMC), 300Channel, ,

RoHS, Green I

Polarizer, TFT, Degree 135, 414 mmx259.7 mmx0.215

mm, NWF-LESEG, M190A1, Green I

Polarizer, CF, Degree 135, 415.84 mmx262.15

mmx0.215 mm, NWF-LESEGAGS1, M190A1, Green I

ACF, COG, AC-8405Z-23 1.5mmX100M, 100000

mmx1.5 mm, COG-ACF, Green I

Driver IC, COF, Data, M190A1-L01, HX8018A050CBAK, Reel, 6 bit, 432Channel, RoHS, Green I

ACF, PCB, AC-9825R-35, 100000 mmx1.5 mm, Hitachi

Chemical(日立化成), PCB-ACF, Green I

PCBA for , A190A2-H, A190A2-A02-H-X, 1206-01,

Rev.01, Green I

Olympic, 19"W, Function BOM, D-sub+Audio, Morning

Star, TSUM17AK

SCREW, M3, P=0.5 mm, L=4 mm, Pan Head, Phillips

Cross Recess, Green I

SCREW, M4, P=0 mm, L=11.8 mm, Hexagon Stand Off,

Socket, Green I

Metal Frame Front, M190A1-L01/A190A2/M190A1L03, SECC 0.6t, 19"wide

SCREW, M4, P=0.7 mm, L=8 mm, Round Head, Phillips

Cross Recess, plate color Zn, Screw_with_Washer, head

D8, Green I

Conductive Tape, PET+Adhesive, 409 mmx58.55

mmx0.05 mm, Mylar_Cover_PcbaX_a190a2, Green I

Lips With Audio, DAC-12M030 A, Ver:0F, 5 V/3 A, 12

V/0.7 A, I TYPE, 7 mA, 1710 V, RoHS

Cover AD Assy, A190A2, SECC, without Dvi-D Hole,

Green II

PCBA for , A190A2-A02-T, A190A2-A02-T-S1, 120805, Rev.04, Green II

Olympic, 19", Accessory BOM, D-sub+Audio, China 3

pin, Black, Power built-in;RoHS

Audio Cable, A150X2, 18AWG, 180cm, Black, JCE,

Green I

Power Cord, CCC, 300/500V, 0.75mm2, 3C, PC323+COC-01, L=1830+/-50mm, Black, Linetek,

18AWG, No Bag, Green I

Olympic, 19"W, ID BOM, D-sub+Audio, China, Black,

VSC, VA1912wb-2

PCBA for , A190A2-H, A190A2-H-K3, 106-02, Rev.02,

ODM, Green II

Panel Protector Film, A190A2-H05, XG-536 T=0.1,

With_Print, Green II

Safety Label for , A190A2-H05, 120 mmx50 mm,

VA1912wb Ver.3, Green II

SN Label for , A190A2-H05, 50 mmx25 mm,

_VA1912wb-2 for Analog for China, Green II

Corner Protector, paper, 50 mmx50 mmx1850 mm, Green

I

Separator, 紙板(AA), 1120*820*11mm, A150X2-T01,

Non Green

3

1

1

0.00168

10

0.0044

1

1

16

2

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

0.025

ViewSonic Corporation

48

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 52

Item ViewSonic P/N Ref. P/N Description Location Universal number# Q'ty

43 DC-00000586 7741999141

44 M-00000560 7345511002

45 N/A 77-D000114

46 N/A 77-D000118 Customer Label, A170E1-H0G, 130 mm, 80 mm, Green I

47 N/A 78-D010933

48 DC-00008020 77-D011732

49 N/A 77-D000114

50 N/A 78-D001492

51 C-00004280 40-D004256 Seat Assy, A190A2-H05, ABS PA757N, Green I 1

52 P-00004295 78-D004392

53 P-00004296 78-D004388

54 N/A 79-D004425

55 P-00008015 78-D011688

56 DC-00008022 76-D011747

Label, Pallet Barcode Label, 75x40, A190E2-H03, VSC,

Non Green

Tape, Security Tape, OPP, L900xW50x0.045mm, VSC,

Non Green

Customer Label, A170E1-H0G, 180 mm, 100 mm, Green

I

Warranty Card, A170E1-H0G, 143 mmx210 mm, VA712

Ver.2, Green II

Carton Label for , A190A2-H05, 76.2 mmx76.2 mm,

VA1912wb-2 for Analog, Green II

Customer Label for , A170E1-H0G, , Green IVA712

Ver.2, Green II

Pallet, A150X2-T01, Wooden, 1150 mmx840 mmx138

mm, Green I

Cushion, A190A2-T05, EPS, WHITE, 450 mmx160

mmx145 mm, PS FOAM (Left), Green II

Cushion, A190A2-T05, EPS, WHITE, 450 mmx160

mmx145 mm, PS FOAM (Right), Green II

Shipping Package Information for , A190A2-H05,

ViewSonic

Carton, A190A2-H05, 538 mmx158 mmx470 mm,

VA1912wb-2 for Analog, Green II

MENU for A190A2-H05, Complex, 1C, VA1912wb-2,

Green II

0.021

0.3

1

1

1

1

1

0.02

1

1

1

1

1

ViewSonic Corporation

49

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 53

8. Exploded Diagram and Exploded Parts List

EXPLODED PARTS LIST (VA1912W-2)

ViewSonic Model Number: VS10866

Rev: 1b

Serial No. Prefix: Q90

Item ViewSonic P/N Ref. P/N Description Q'ty

1 N/A 44-D003584

2 N/A L3J009XXXX

3 N/A

4 HW-00000533 42A9930008

5 B-00006039

6 B-00005599

7 HW-00000533

8 C-00005686

9 C-00004281

10 C-00004282 40-D004257

11 N/A 42A9230001

12 C-00004283 40-D004252

13 C-00004284 40-D004250

14 C-00004285

41-D000643 BACKLIGHT FRONT COVER

27-D003247 POWER PCB ASSY

35-D005694 AD PCB ASSY

42A9930008 SCREW M3*4L

41-D003772 AD COVER

40-D004255 BEZEL ASSY

40-D004259 SEAT ASSY

ViewSonic Corporation

BACKLIGHT UNIT

PANEL ASSY

SCREW M3*4L

REAR ASSY

SCREW D3*8L

STAND ASSY

COVER HINGE

50

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

EXPLODED PARTS LIST (VA1912WB-2)

ViewSonic Model Number: VS10866

Rev: 1a

Serial No. Prefix: QBM

Item ViewSonic P/N Ref. P/N Description Q'ty

1

1

1

2

1

1

7

1

1

1

4

1

1

1

1 N/A 44-D003584 BACKLIGHT UNIT 1

2 N/A L3J009XXXX PANEL ASSY 1

3 N/A 41-D000643 BACKLIGHT FRONT COVER 1

4 HW-00000553 42A9930008 SCREW M3*4L 2

5 B-00006039 27-D003247 POWER PCB ASSY 1

6 B-00005599 35-D005694 AD PCB ASSY 1

7 HW-00000553 42A9930008 SCREW M3*4L 7

8 C-00005686 41-D003772 AD COVER 1

9 C-00004281 40-D004255 BEZEL ASSY 1

10 C-00004282 40-D004257 REAR ASSY 1

11 N/A 42A9230001 SCREW D3*8L 4

12 C-00004283 40-D004252 STAND ASSY 1

13 C-00004284 40-D004250 COVER HINGE 1

14 C-00004285 40-D004259 SEAT ASSY 1

ViewSonic Corporation

Model

Title

Date Rev:

Page 54

PACKING PART LIST ( VA1912W-2 )

ViewSonic Model Number: VS10866

Rev: 1b

Item ViewSonic P/N Ref. P/N Location Q'ty

1 N/A

2 P-00000595

3 P-00004295

4 P-00004296

5 N/A

6 N/A

7 N/A

8 CB-00004287

9 CB-00000544

10 N/A

11 N/A

12 N/A

13 N/A

14 C-00004285

15 N/A

VA1912W-2

7841919921

78-D004392

78-D004388

Different region

(refer to BOM)

Different region

(refer to BOM)

Different region

(refer to BOM)

32F3018003

32F2818004

N/A

Different region

(refer to BOM)

Different region

(refer to BOM )

Different region

(refer to BOM)

40-D004259

Different region

(refer to BOM)

LCD Monitior 1

PE Foam Bag 1

PS Foam (Left) 1

PS Foam(Right) 1

Carton 1

Power Cord 1

Power Cord 1

Monitor Cable 1

Audio Cable 1

DVI Cable (N/A) 1

Menu (Quick Setup) 1

Menu (CD-ROM) 1

Warranty Registration card 1

Seat 1

Customer Label 1

PACKING PART LIST ( VA1912WB-2 )

ViewSonic Model Number: VS10866

Rev: 1a

Item ViewSonic P/N Ref. P/N DESCRIPTION Q'ty

1 N/A

2 P-00000595

3 P-00004295

4 P-00004296

5 N/A

6 N/A

7 N/A

8 CB-00004287

9 CB-00000544

10 N/A

11 N/A

12 N/A

13 N/A

14 C-00004285

15 N/A

VA1912W-2

7841919921

78-D004392

78-D004388

Different region

(refer to BOM)

Different region

(refer to BOM)

Different region

(refer to BOM)

32F3018003

32F2818004

N/A

Different region

(refer to BOM)

Different region

(refer to BOM )

Different region

(refer to BOM)

40-D004259

Different region

(refer to BOM)

LCD Monitior 1

PE Foam Bag 1

PS Foam (Left) 1

PS Foam(Right) 1

Carton 1

Power Cord 1

Power Cord 1

Monitor Cable 1

Audio Cable 1

DVI Cable (N/A) 1

Menu (Quick Setup) 1

Menu (CD-ROM) 1

Warranty Registration card 1

Seat 1

Customer Label 1

ViewSonic Corporation

51

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

Page 55

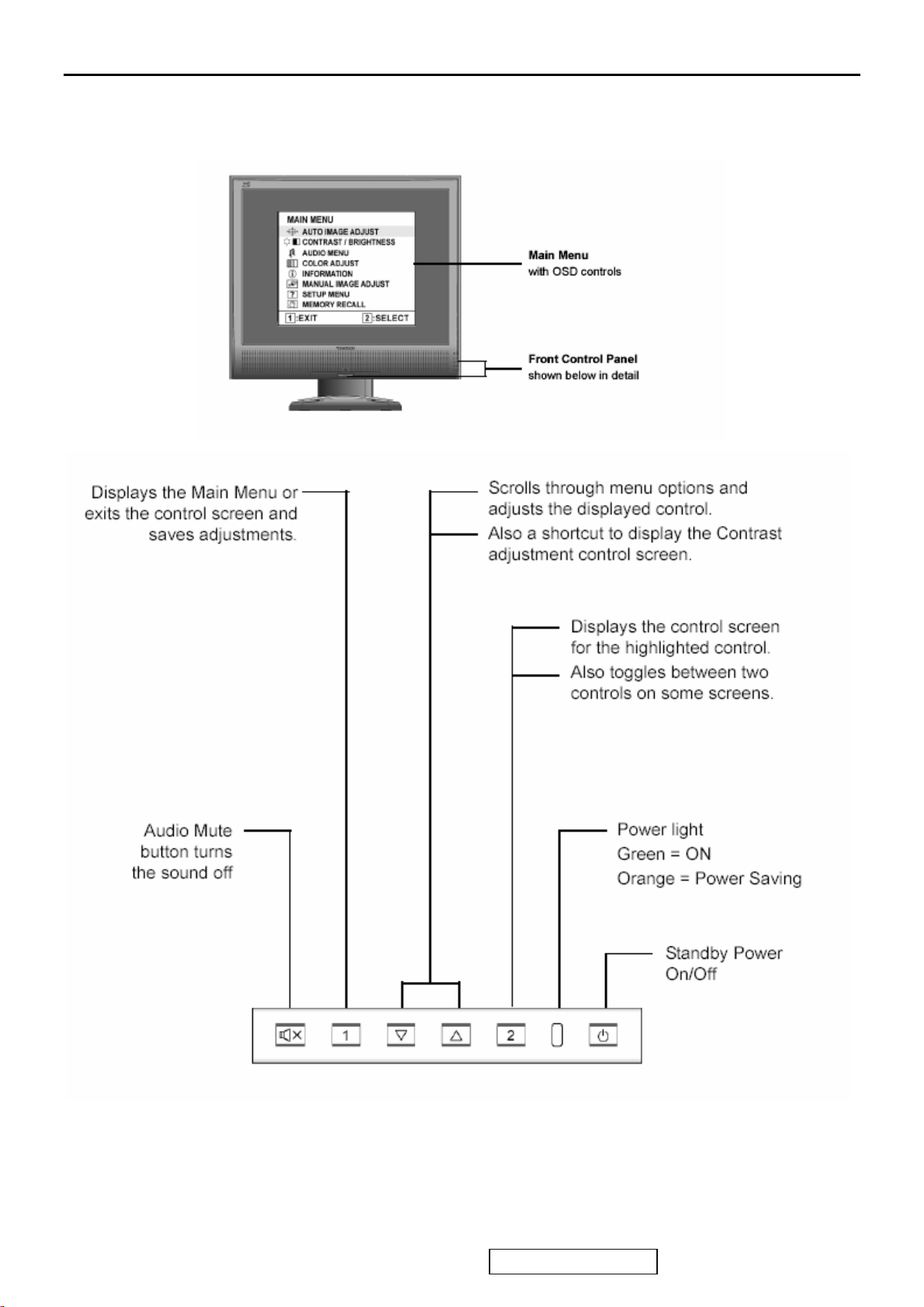

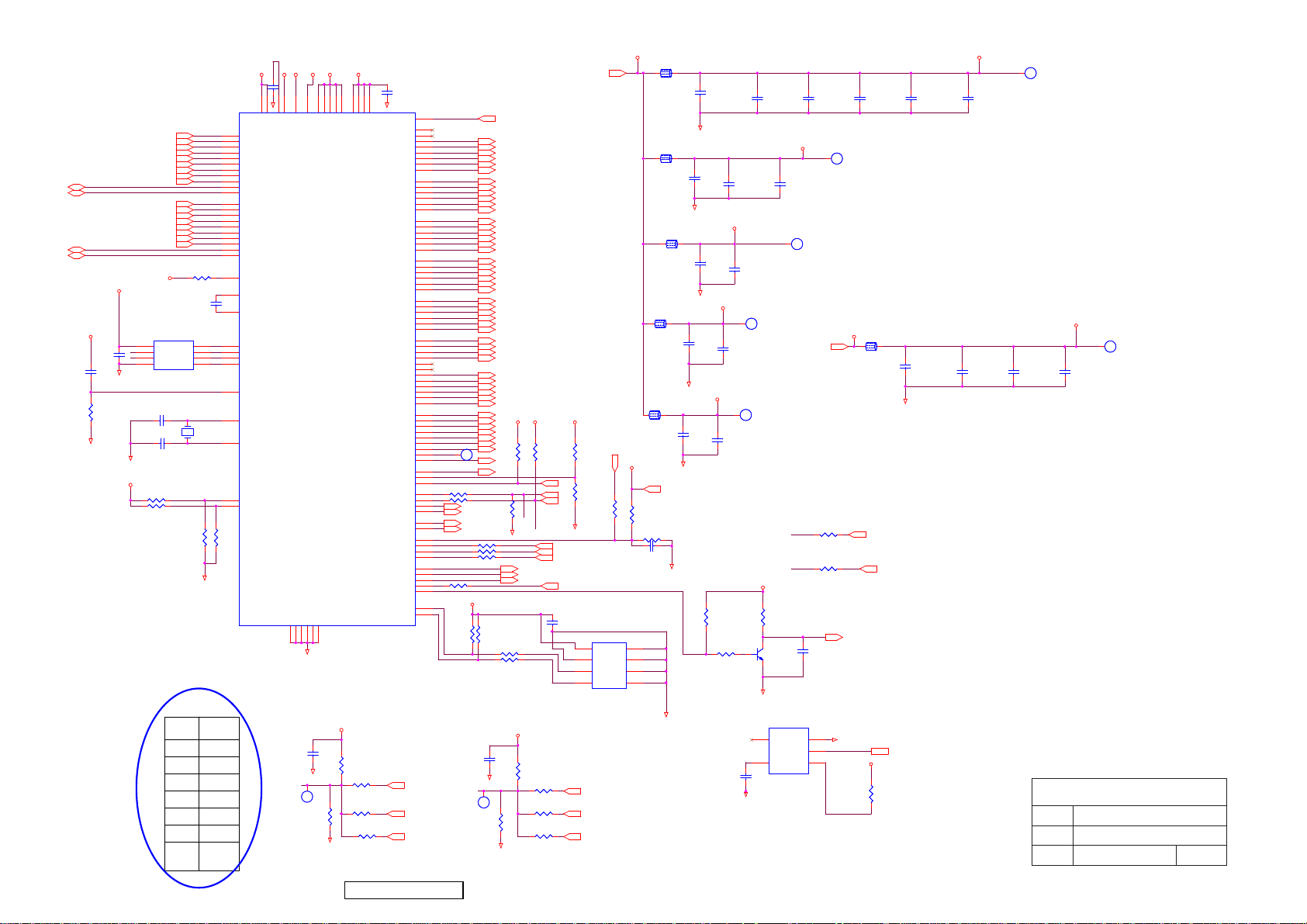

9. Block Diagram

D-sub

Analog Video

OSD Key Pad / Audio Out

Main Board

LDO

DC-5V

DC-12V

Speaker

3.3V

5V

LCD Module

12V

Signal

AC Power

Audio In

LIPS

Backlight

ViewSonic Corporation

52

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

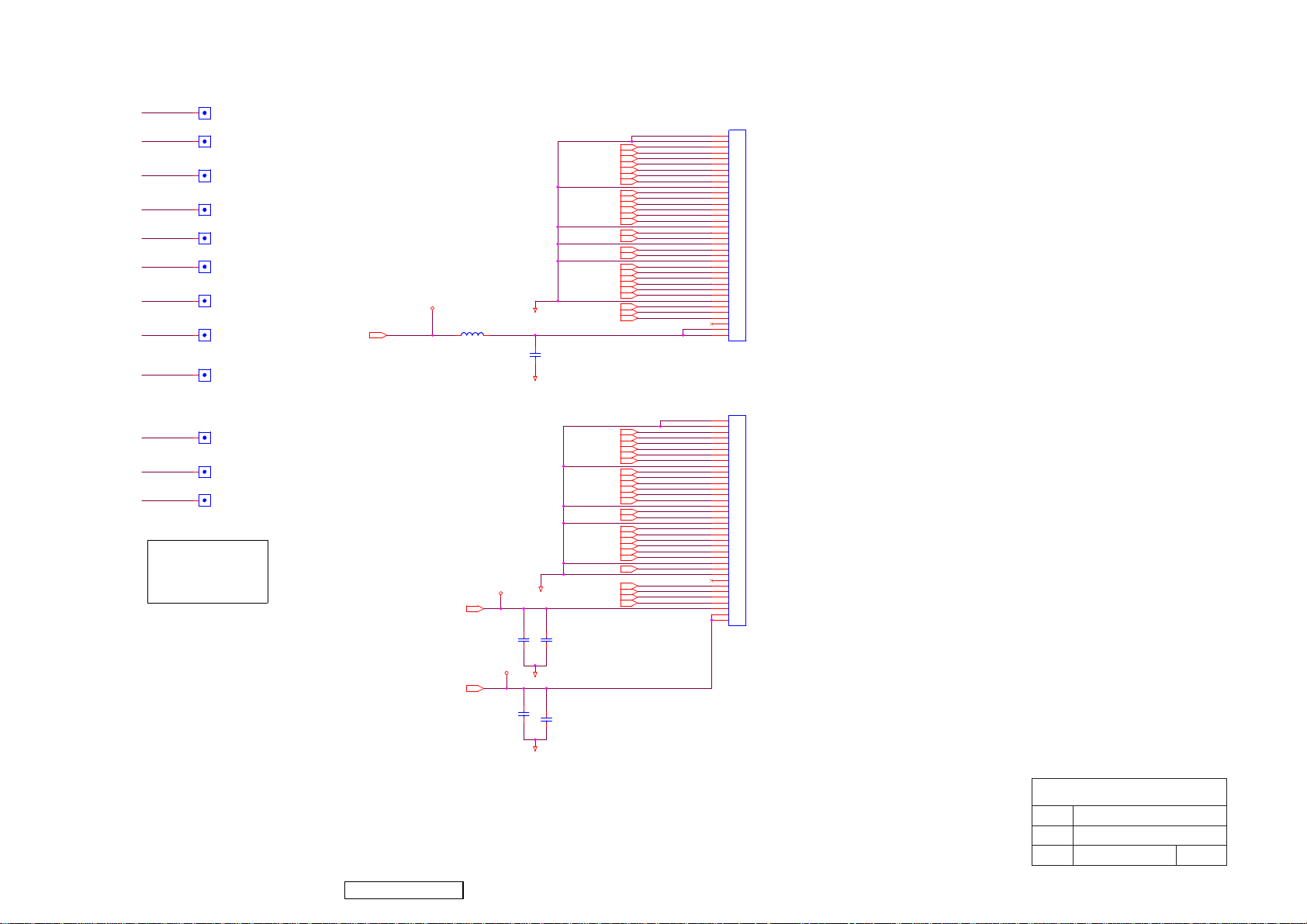

Page 56

B1

OSD

B2

INVERTER I/F

LED_OR

LED_GL

TURBO

MENU

LEFT

RIGHT

AUTO

POWER

V33C

AUDIOR-

AUDIOR+

AUDIOL-

AUDIOL+

AUDIOL+

AUDIOL-

AUDIOR+

AUDIOR-

AUD_DET

VOL_ADJ

AUDIO_ON

LED_GL

AUDIOR-

AUDIOR+

AUDIOL-

AUDIOL+

AUD_DET

VOL_ADJ

LED_OR

LED_GL

TURBO

MENU

LEFT

RIGHT

AUTO

POWER

V5A_ESD

VGA_5V

DVI_5V

V5A

B3

V5A

VGA_5V

V5A_ESD

B4

V5A_ESD

V5A

DVI_5V

B5

V5A

DVI_5V

VGA_5V

POWER

VGA

DVI

V33C

V33C

DSUB_DET

DDCA_DAT

DDCA_CLK

GNDR

GNDG

GNDB

HSYNC

VSYNC

DDCD_CLK

DDCD_DAT

CLK+

CLK-

VCTRL

Vref

V18C

V33P

V12A

B6

DSUB_DET

SOG

DDCA_DAT

DDCA_CLK

RIN

GNDR

GIN

GNDG

BIN

GNDB

HSYNC

VSYNC

DDCD_CLK

DDCD_DAT

R+

RG+

GB+

BCLK+

CLK-

LED_OR

LED_GL

TURBO

MENU

LEFT

RIGHT

AUTO

POWER

AUDIO_ON

INV_ON/OFF

DCDC_ON/OFF

PANEL_ON/OFF

VCM_PWM

VOL_ADJ

INV_ADJ

AUD_DET

DVI_5V

VCTRL

V12A

V18C

V33C

Vref

V5A

SCALER

DSUB_DET

SOG

RIN

GIN

BIN

R+

R-

G+

G-

B+

B-

V33P V33P

V18C

SOG

DDCA_DAT

DDCA_CLK

RIN

GNDR

GIN

GNDG

BIN

GNDB

HSYNC

VSYNC

DDCD_CLK

DDCD_DAT

R+

RG+

GB+

BCLK+

CLK-

AUDIO_ON

INV_ON/OFF

DCDC_ON/OFF

PANEL_ON/OFF

VCM_PWM

VOL_ADJ

INV_ADJ

AUD_DET

Vref

BR2N

BR2P

BR1N

BR1P

BR0N

BR0P

BG2N

BG2P

BG1N

BG1P

BG0N

BG0P

BB2N

BB2P

BB1N

BB1P

BB0N

BB0P

FR2N

FR2P

FR1N

FR1P

FR0N

FR0P

FG2N

FG2P

FG1N

FG1P

FG0N

FG0P

FB2N

FB2P

FB1N

FB1P

FB0N

FB0P

FCKN

FCKP

FSTH

BCKN

BCKP

BSTH

STB

POL

CPV

STV

GVOFF

OE

BR2N

BR2P

BR1N

BR1P

BR0N

BR0P

BG2N

BG2P

BG1N

BG1P

BG0N

BG0P

BB2N

BB2P

BB1N

BB1P

BB0N

BB0P

FR2N

FR2P

FR1N

FR1P

FR0N

FR0P

FG2N

FG2P

FG1N

FG1P

FG0N

FG0P

FB2N

FB2P

FB1N

FB1P

FB0N

FB0P

FCKN

FCKP

FSTH

BCKN

BCKP

BSTH

STB

POL

CPV

STV

OE

GVOFF

VCM_PWM

PANEL_ON/OFF

DCDC_ON/OFF

V12A

V5A

B8

PANEL_INTERFACE

BR2N

BR2P

BR1N

BR1P

BR0N

BR0P

BG2N

BG2P

BG1N

BG1P

BG0N

BG0P

BB2N

BB2P

BB1N

BB1P

BB0N

BB0P

FR2N

FR2P

FR1N

FR1P

FR0N

FR0P

FG2N

FG2P

FG1N

FG1P

FG0N

FG0P

FB2N

FB2P

FB1N

FB1P

FB0N

FB0P

FCKN

FCKP

FSTH

BCKN

BCKP

BSTH

STB

POL

CPV

STV

OE

GVOFF

VCM_PWM

PANEL_ON/OFF

DCDC_ON/OFF

V12A

V33P

V5A

V5A

V33C

V12A

INV_ON/OFF

INV_ADJ

ViewSonic Corporation

V12A

INV_ON/OFF

INV_ADJ

53

Confidential - Do Not Copy VA1912w-2_VA1912wb-2

ViewSonic Corporation

Model

Title

System Diagram

Date Rev:

Page 57

DDCA_DAT

DDCA_CLK

DDCD_DAT

DDCD_CLK

VCC33

V5A

WP

C90

C90

WP

0603/100n/25V/7

0603/100n/25V/7

C80

C80

R116

R116

GND

GND

0603/10K/5%

0603/10K/5%

GND

VCC33

R118 R0603/OPENR118 R0603/OPEN

R119 R0603/OPENR119 R0603/OPEN

need to modify, the SAR is

6 bits and the max voltage

is 1.8V

1206/10u/16V/X/PbF

1206/10u/16V/X/PbF

ViewSonic Corporation

RIN

GNDR

GIN

GNDG

SOG

BIN

GNDB

HSYNC

VSYNC

R+

RG+

GB+

B-

CLK+

CLK-

R124 0603/390R/1%R124 0603/390R/1%

AVDD

0603/100n/25V/7

0603/100n/25V/7

U2

8

SDO

VDD

7

CE#

HOLD#

3

WP#

SCK

VSS4SDI

Pm25LV512U2Pm25LV512

C94 0603/22p/50V/NC94 0603/22p/50V/N

C93 0603/22p/50V/NC93 0603/22p/50V/N

RIGHT

POWER

AUTO

LEFT

MENU

TURBO

RIGHT

+LEFT

+POWER

U1

U1

RIN

59

GNDR

58

GIN

56

GNDG

55

SOG

57

BIN

54

GNDB

53

HSYNC

63

VSYNC

64

DDCA_DAT

65

DDCA_CLK

66

R+

39

R-

40

G+

42

G-

43

B+

45

B-

46

CLK+

48

CLK-

49

DDCD_DAT

36

DDCD_CLK

37

51

62

C91

C91

61

70

2

71

1

72

6

73

5

19

32

Y1

Y1

14.31818MHz

14.31818MHz

33

102

104

R114

R114

R115

R115

0603/10K/5%

0603/10K/5%

0603/10K/5%

0603/10K/5%

GND

VOLTAGEPIN

1.77V

1.24V

0.47V

1.77V

1.24V

0.47V

SR1(1.77) SR2(0.93)

C68

C68

0603/100n/25V/7

0603/100n/25V/7

44

50

34

4

GND

RIN0P

AVDD_DVI

AVDD_DVI

RIN0N

AVDD_MPLL

GIN0P

GIN0N

SOGIN0

BIN0P

BIN0N

HSYNC0

VSYNC0

DDCA_SDA/RS232_Tx

DDCA_SCL/RS232_Rx

RX2P

RX2N

RX1P

RX1N

RX0P

RX0N

RXCKP

RXCKN

DDCD_SDA

DDCD_SCL

REXT

REFP

REFM

SDO

SCZ

SCK

SDI

RST

XIN

XOUT

MODE[0]

MODE[1]

SAR11 SAR11

0603/10M/5%/RoHS/OPEN

0603/10M/5%/RoHS/OPEN

VDDCVDPPAVDDVPLLVDVI VMPLL

C92

C92

0603/100n/25V/7

12

97

117

68

GND

VCTRL

VDDC

VDDC

VDDC

NC/LVACKP/NC

NC/LVACKM/NC

VDD_OTP

RA1P/LVA2P/RA2

RA1N/LVA2M/RA3

RA2P/LVA1P/RA4

RA2N/LVA1M/RA5

RA3P/LVA0P/RA6

RA3N/LVA0M/RA7

GA1P/NC/GA2

GA1N/NC/GA3

GA2P/NC/GA4

GA2N/NC/GA5

GA3P/LVA3P/GA6

GA3N/LVA3M/GA7

BA1P/NC/BA2

BA1N/NC/BA3

BA2P/NC/BA4

BA2N/NC/BA5

BA3P/NC/BA6

BA3N/NC/BA7

RB1P/NC/RB2

RB1N/NC/RB3

RB2P/NC/RB4

RB2N/NC/RB5

RB3P/NC/RB6

RB3N/NC/RB7

GB1P/NC/GB2

GB1N/NC/GB3

GB2P/NC/GB4

GB2N/NC/GB5

GB3P/NC/GB6

GB3N/NC/GB7

CLKAP/LVB3P/LHSYNC

CLKAN/LVB3M/LVSYNC

CLKBN/LVBCKM/LDE

NC/LVB2P/NC

NC/LVB2M/NC

BB1P/LVB1P/BB2

BB1N/LVB1M/BB3

BB2P/LVB0P/BB4

BB2N/LVB0M/BB5

BB3P/NC/BB6

BB3N/NC/BB7

GPIO_P22

GPIO_P23

GPIO_P03

GPIO_P16/PWM2

GPIO_P15/PWM0

PWM2/GPIO_P24

GPIO_P27/PWM1

GPIO_P12

PWM1/GPIO_P25

GPIO_P00/SAR1

GPIO_P01/SAR2

GPIO_P02/SAR3

GPIO_P06

GPIO_P07

PWM0/GPIO_P26

GPIO_P13

GPIO_P14

DDCROM_SCL

DDCROM_SDA

R127

R127

0603/20K/1%/OPEN

0603/20K/1%/OPEN

R128

R128

R67

R67

R134

R134

0603/3.3K/1%/OPEN

0603/3.3K/1%/OPEN

0603/100n/25V/7

11

107

108

109

110

111

112

113

114

98

99

100

101

105

106

89

90

91

92

93

94

9

10

15

16

17

18

2

3

5

6

7

8

118

119

120

121

122

123

124

125

126

127

128

1

80

ESP

81

OSP

88

GPO0

87

GPO1

86

GPO2

85

GPO3

84

GPO4

83

GPO5

82

GPO6

75

74

26

35

69

78

79

20

21

22

RSTN

23

24

25

27

28

29

30

31

77

76

LEFT

MENU

TURBO

FB0N

FB0P

FB1N

FB1P

FB2N

FB2P

FG0N

FG0P

FG1N

FG1P

FG2N

FG2P

FR0N

FR0P

FR1N

FR1P

FR2N

FR2P