Page 1

ViewSonic Pro8400

Model No. VS13647

DLP Projector

(Pro8400 SM Rev. 1a Feb. 2011)

ViewSonic 381 Brea Canyon Road, Walnut, California 91789 USA - (800) 888-8583

Service Manual

Page 2

Copyright

Copyright© 2010 by ViewSonic Corporation. All rights reserved. No part of this publication may be

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, electronic, mechanical, magnetic, optical, chemical,

manual or otherwise, without the prior written permission of ViewSonic Corporation.

Disclaimer

ViewSonic makes no representations or warranties, either expressed or implied, with respect to the contents

hereof and specifically disclaims any warranty of merchantability or fitness for any particular purpose. Further,

ViewSonic reserves the right to revise this publication and to make changes from time to time in the contents

hereof without obligation of ViewSonic to notify any person of such revision or changes.

Trademarks

Optiquest is a registered trademark of ViewSonic Corporation.

ViewSonic is a registered trademark of ViewSonic Corporation.

All other trademarks used within this document are the property of their respective owners.

Revision History

Revision SM Editing Date ECR Number Description of Changes Editor

1a GG02/22/11 Sophia Kao

Confidential - Do Not Copy

ViewSonic Corporation

All content on this SM had approved by PE, Charles

Pro8400

i

Page 3

Table of Contents

1 System Introduction ................................................................ ................................ .............. 1

1.1 Technical Specification ..................................................................................................1

1.2 Location of Features, Controls, and I/O ........................................................................ 2

1.3 Pro8400 Lamp Specification ..........................................................................................9

1.4 Pro8400 System Block Diagram .................................................................................12

2 Firmware (PixelWorks) Upgraded Flow ................................................................ .............. 13

2.1 Setup Tool/Equipment ..................................................................................................13

2.2 Upgrading Procedure ...................................................................................................13

3 Machine Disassembly and Replacement ................................ ................................ ............ 14

3.1 Tools ...............................................................................................................................14

3.2 Disassembly Procedure ...............................................................................................15

3.3 Assembly FAN Module.................................................................................................23

3.4 Disassembly Lamp Module ..........................................................................................24

4 Troubleshooting and Verifying the Repair ................................ ................................ ........... 25

4.1 Troubleshooting ............................................................................................................25

4.2 Verifying the Repair ......................................................................................................32

5 Adjustment / Alignment Procedure ................................ ................................ ...................... 38

5.1 Color Wheel Index Adjustment ....................................................................................38

5.2 ADC Calibration ............................................................................................................39

5.3 Keystone Adjustment ....................................................................................................41

6 Connector Information ................................ ................................ ................................ ........ 42

6.1 Main Board ................................ ....................................................................................42

6.2 The backside of Main Board ........................................................................................42

6.3 Ballast Board .................................................................................................................43

6.4 Power Board..................................................................................................................44

7 FRU (Field Replaceable Unit) List ................................ ................................ ...................... 45

7.1 Mechanical Drawing .....................................................................................................46

7.2 Packing drawing ............................................................................................................48

8 Maintenance ................................................................ ................................ ....................... 51

Appendix A: RS-232 Command and Configuration ................................................................ .... 52

Appendix B: IR Control Code ................................................................................................ .....54

Appendix C: How to reset the Lamp Hours ................................................................ ................ 55

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

ii

9 Recommended Spare Parts List ................................................................. ........................ 56

Page 4

1 System Introduction

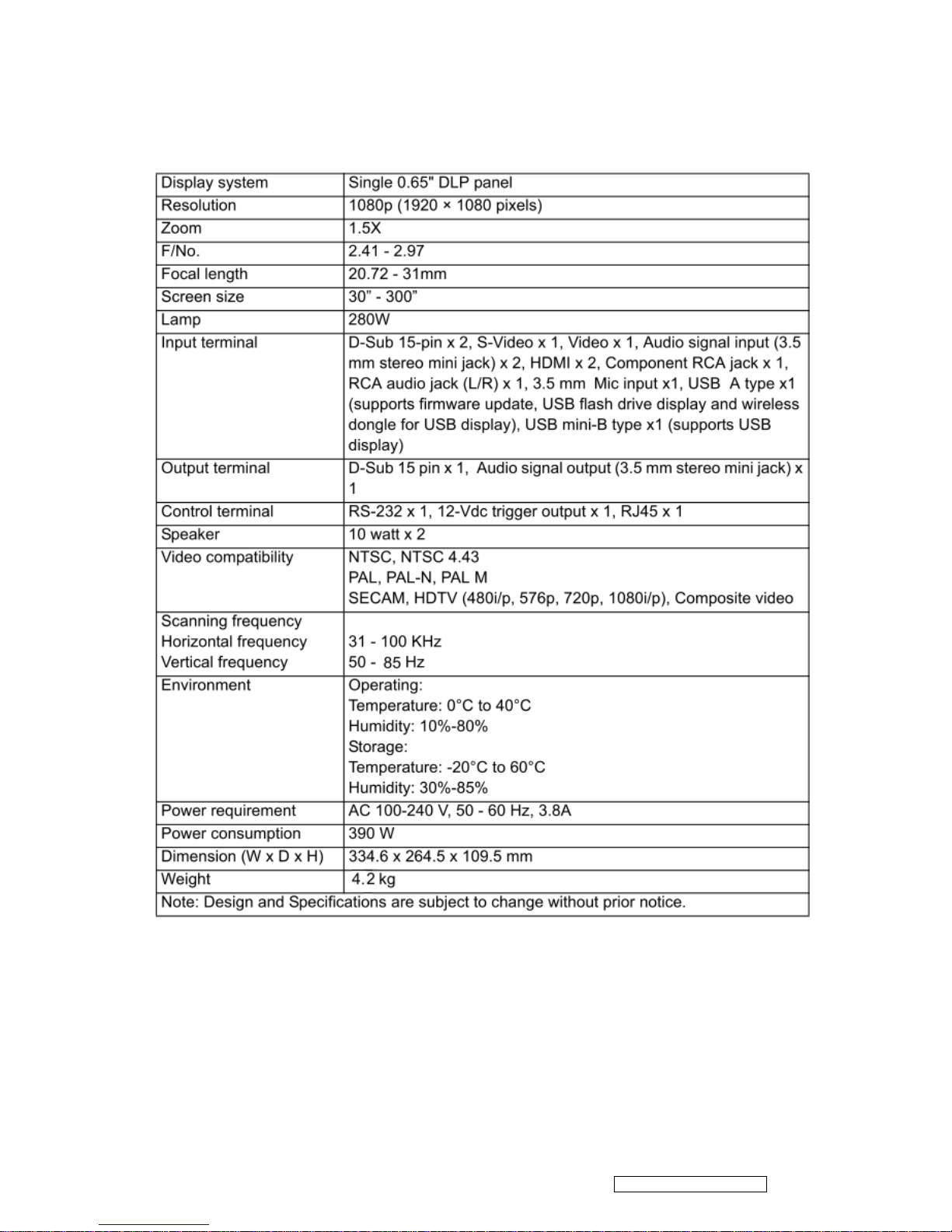

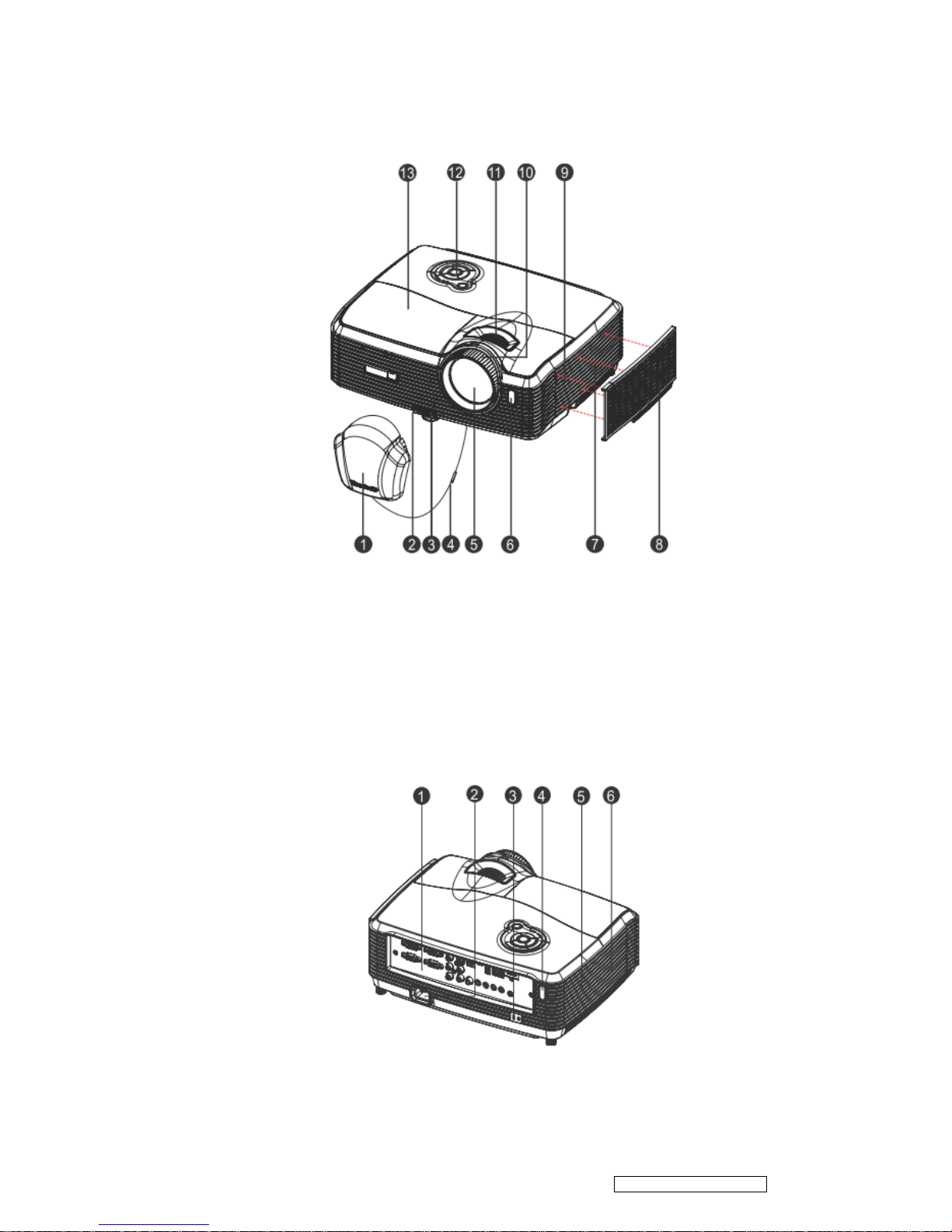

1.1 Technical Specification

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

1

Page 5

1.2 Location of Features, Controls, and I/O

A. Projector overview

Front View

1. Lens cap 8. Filter cover

2. Elevator button 9. Speaker

3.Elevator foot 10.Focus ring

4. Lens cap strap 11.Zoom ring

5. Projection lens 12.Control panel

6. Front IR remote control sensor 13.Lamp cover

7. Ventilation holes (intake)

Real View

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

2

Page 6

1. Connection ports 2. AC power socket

3. Kensington lock 4. Rear IR remote control sensor

5. Speaker 6. Ventilation holes (exhaust)

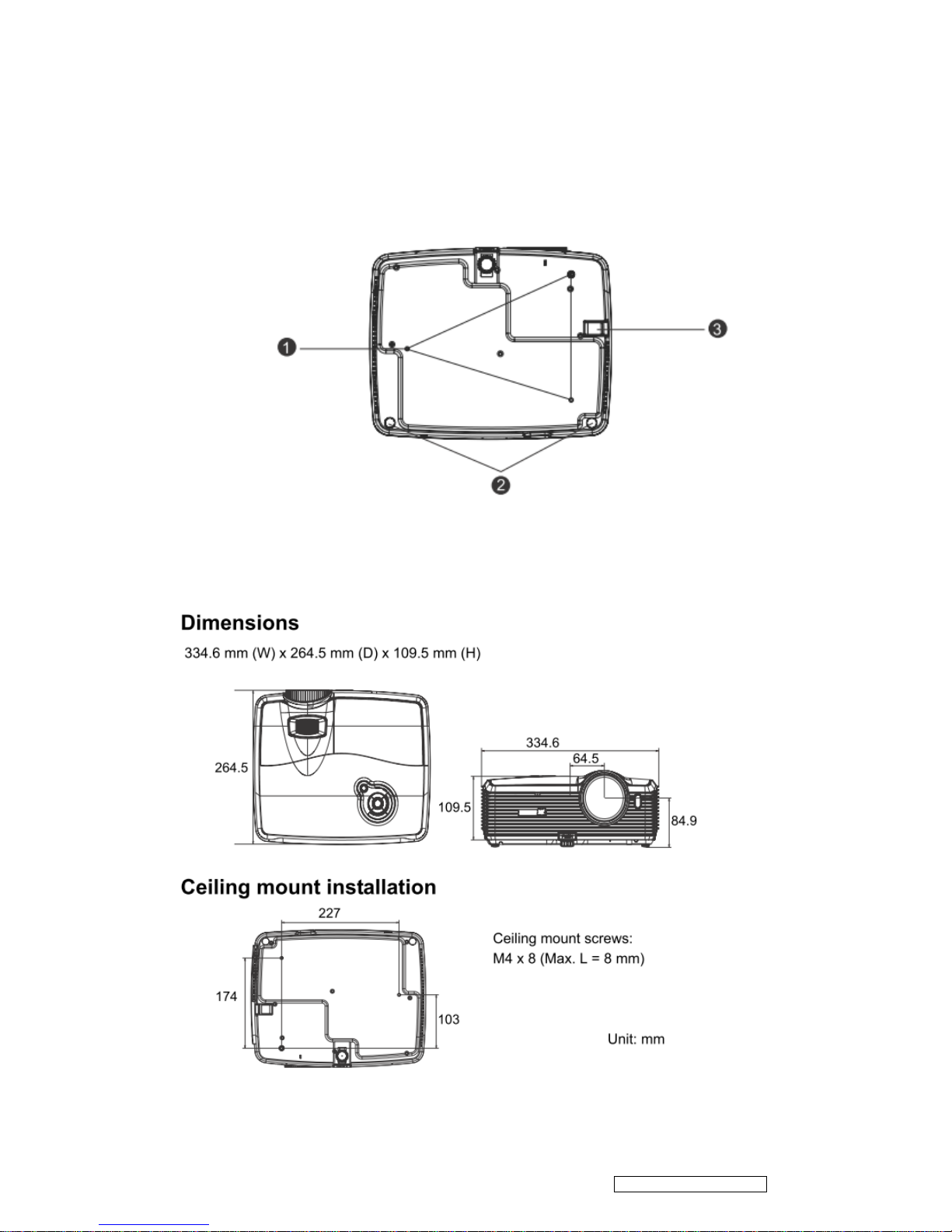

Bottom View

1. Ceiling mount (M4*8)

2. Tilt-adjustment feet

3. Security bar

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

3

Page 7

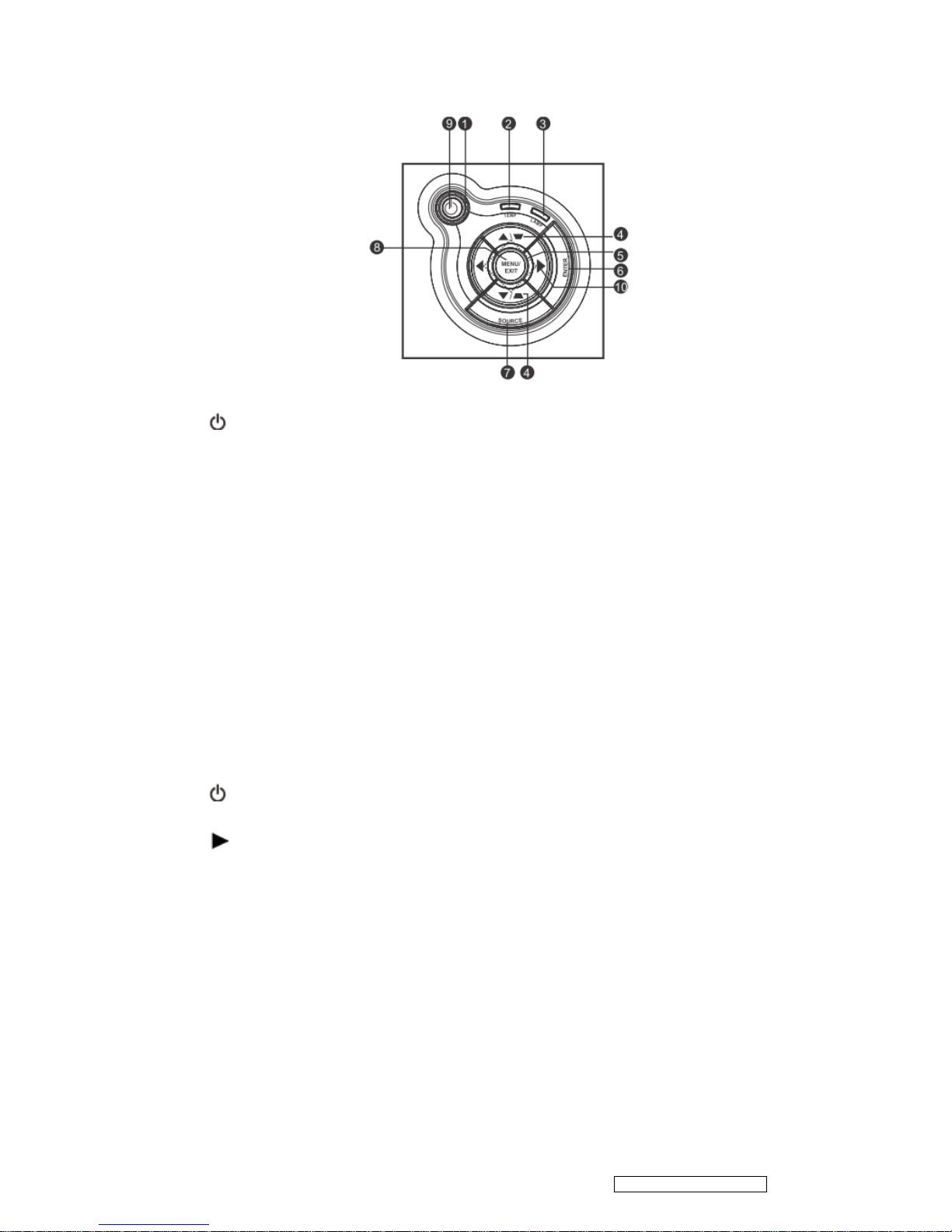

B. Button function and LED indicator

LED

1. Power (Power LED indicator)

2. TEMP (Temperature LED indicator)

3. LAMP (Lamp LED indicator)

Button function

4. Keystone/Arrow keys /Up, /Down)

Manually correct distorted images resulting from an angled projection.

5. Four directional buttons

Use four directional buttons to select items or make adjustments to your selection.

6. ENTER

Enter to sub-menu and confirm the menu selecti on.

7. SOURCE

Display the source selection bar .

8. MENU/EXIT

Display or exit the on -screen display menus.

9. Power

Turn the projector on or off.

10. Right/Panel key

Activate panel key lock.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

4

Page 8

C. Connection ports

1. RS232

When operating th e projector via a computer, connect this to the controlling computer's

RS-232C port.

2. Monitor Out

Connect to a computer display, etc.

3. Component (Y Cb/Pb Cr/Pr)

Connect Y Cb/Pb Cr/Pr output from video equipment to this jack.

4. S-Video

Connect S-Video output from video equipment to this jack.

5. USB B

USB display supports computer connection via USB mini -B type to A type cable.

6. USB A

This connector supports firmware update , USB flash drive display and wireless dongle for USB

display.

7. LAN

For LAN display/ network control and web server .

8. HDMI 1

Connect HDMI output from video equipment to this jack.

9. HDMI 2

Connect HDMI output from video equipment to this jack .

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

5

Page 9

10. DC 12V Out

12V DC out

11. MIC in

Microphone input jack.

12. Audio Out

Connect to a speaker or other audio input equipment.

13. Audio 2

Connect an audio output from video equipment or computer to this jack.

14. Audio 1

Connect an audio output from video equipment or computer to this jack.

15. Audio 3 (L/R)

Connect an audio o utput from video equipment to this jack.

16. Video

Connect composite video output from video equipment to this jack.

17. Computer in 2

Connect image input signal (analog RGB or component) to this jack.

18. Computer in 1

Connect image input signal (analog RGB or component) to this jack.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

6

Page 10

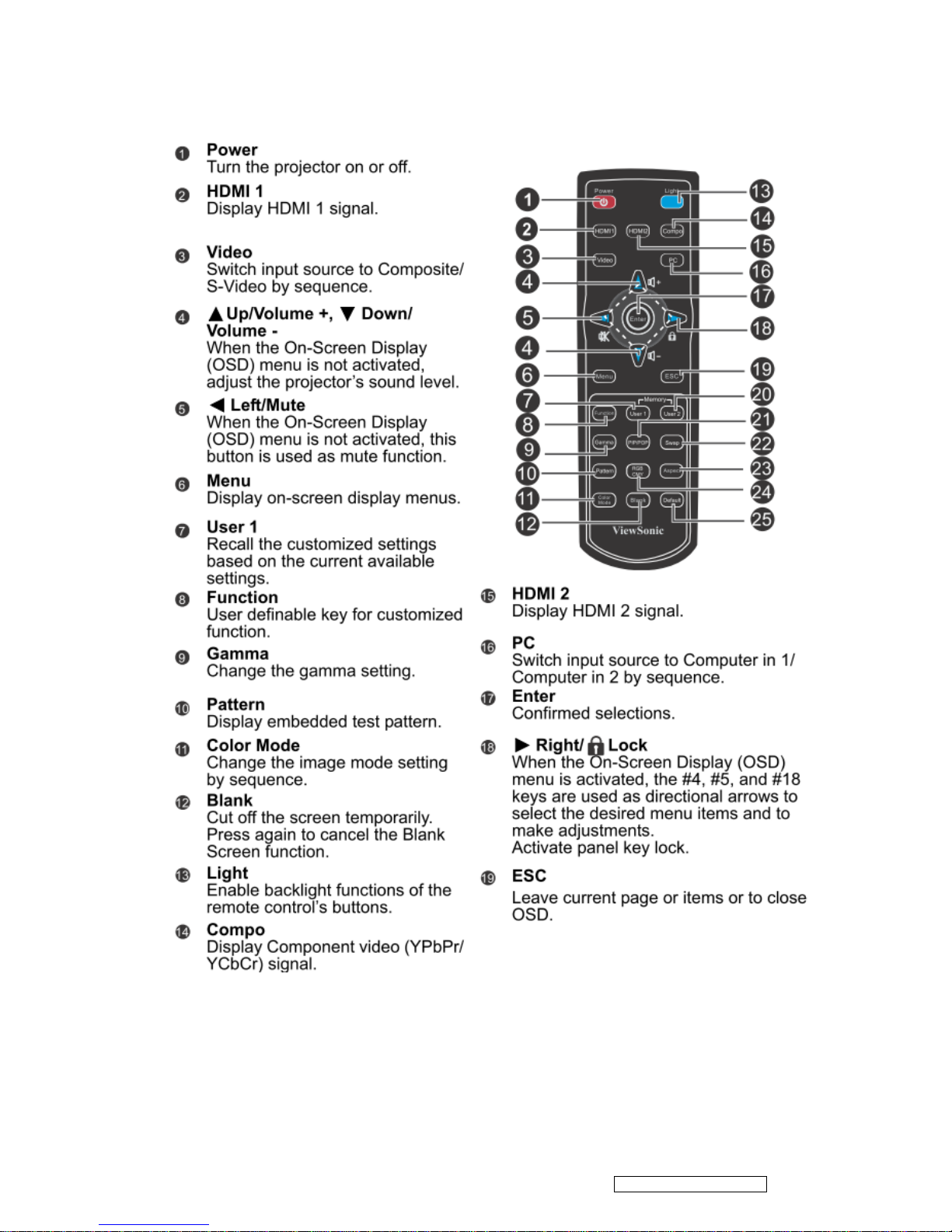

D. Remote Control

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

7

Page 11

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

8

Page 12

1.3 Pro8400 Lamp Specification

Product Scope

The product is a lamp system consisting of a short arc burner within a reflector and electronic lamp

driver.

Type lamp P-VIP 280/0.9 E20.8e

Identcode : A 737 57A (FC, non-grinding)

Type driver PT VIP O3 TOP 280W unipro AS

Identcode : A 741 73B (lock type,Gen5,VC, unipro)

The lamp must be operated with the OSRAM lamp driver only.

Initial Characteristics

nominal tolerance

Input Voltage 380V DC 250…400V DC

Standby(non-operating) min. 120V DC

Max. slew rate of input voltage

During switch on 30Vμs

Input Current 0.8A

Max. input voltage ripple 30Vpp@ 100/120Hz

Max. input current ripple 1Arms@40 -300kHz

Input Wattage max.308W @280W lamp wattage

Input Wattage standby operation 1,7W typical 2.5W max.

Output Wattage

nominal 280W 3%

4

DIM mode 230W 3%

4

controlled by UART 230W…280W in step with of 1/128 of nominal power

Output current limitation 4.6A(RMS) 5%

Ignition pulse typ.2.5kVpeak symm. 2.1…3.5 kVpeak

Ignition Phase Duration typ.3.5s max.6 s

Enable-Disable-Enable Cycle 15 s minimum

Acoustic sound pressure level typical acoustic sound pressure level tbd dB(A) at 25cm

measuring distance; measured in steady state lamp

operation

5

Acoustic sound power level typical acoustic sound power level tbd dB(A) acc. to EN

ISO 3744; measured in steady state lamp operation

5

Switch-off lamp voltage 140V 5V

Cooling method forced air cooling at1.5 m/s minimum

Thermal Protection Tc1 switch point 955

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

9

Page 13

Safety Protections The lamp connections are not mains isolated, The lamp

can be switched on via the Start Control Input signal(SCI).

A Flag Output signal indicates if the lamp has lit rightly. The

Start Control Input and the Flag Output are mains isolated.

Note:

4

Measured at real lamp load. Deviations will occur on all kind of artificial loads (e.g.

resistor)

5

Measured with RGB waveform. Customer generated UNISHAPE waveforms can lead to

noise deviation.

Attention for handling

Do not touch the lamp until it has cooled completely, because the lamp is very hot

during operation and immediately after turned off.

The lamp has to be fixed firmly to the base or socket.

Turn off the power supply during maintenance.

Do not hold the lamp except outer surface of the reflector.

Wear protective gloves and eyeglasses when handling the lamp.

Any unusual shock or vibration to the lamp should be avoided.

The lamp contains the mercury. Its breakage might cause mercury to flow out of the

reflector. Please manage provision at the customer’s product.

Do not pull the lead wire and plug by more than 24.5N.

Please be careful of handling the lamp because it is made of glass.

Please notice for keeping or handling the lamp, because there is a projection of this

lamp with reflector ahead.

Do not touch the bulb and the mirror area of the reflector.

Attention for use

Do not close or cover the lamp with any flammable stuff.

During operation, the lamp is under extremely high pressure. Please manage

provision at the customer ’s product to prevent fragments of bulb and mercury from

flowing out of it. If the lamp bursts in case of an emergency, the sound will be

occurred.

Lamp operation should be with the specified lamp driver and the system ONLY.

Do not look at the lamp directly during operations.

Do not expose your skin directly. We recommend to you to put on something for

protection for your skin. For example, long sleeve shirt, gloves, glassed and so on.

Do not modify the lamp and never use a lamp tha t has been modified.

Any unusual shock or vibration to the lamp should be avoided during operation.

Do not use any broken lamps.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

10

Page 14

Dispose of used lamps according to your local instruction.

Do not turn on the lamp while the system is opened.

The lamp contains mercury. If the lamp bursts during operation ventilate the area

sufficiently to avoid inhaling harmful mercury fumes.

Use the lead below 200

C to prevent a deterioration of cladding clad of the

fluorocarbon resin.

The lead wire insulation clad shouldn ’t touch the reflector.

Exchange the lamp that has already passed the life time immediately.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

11

Page 15

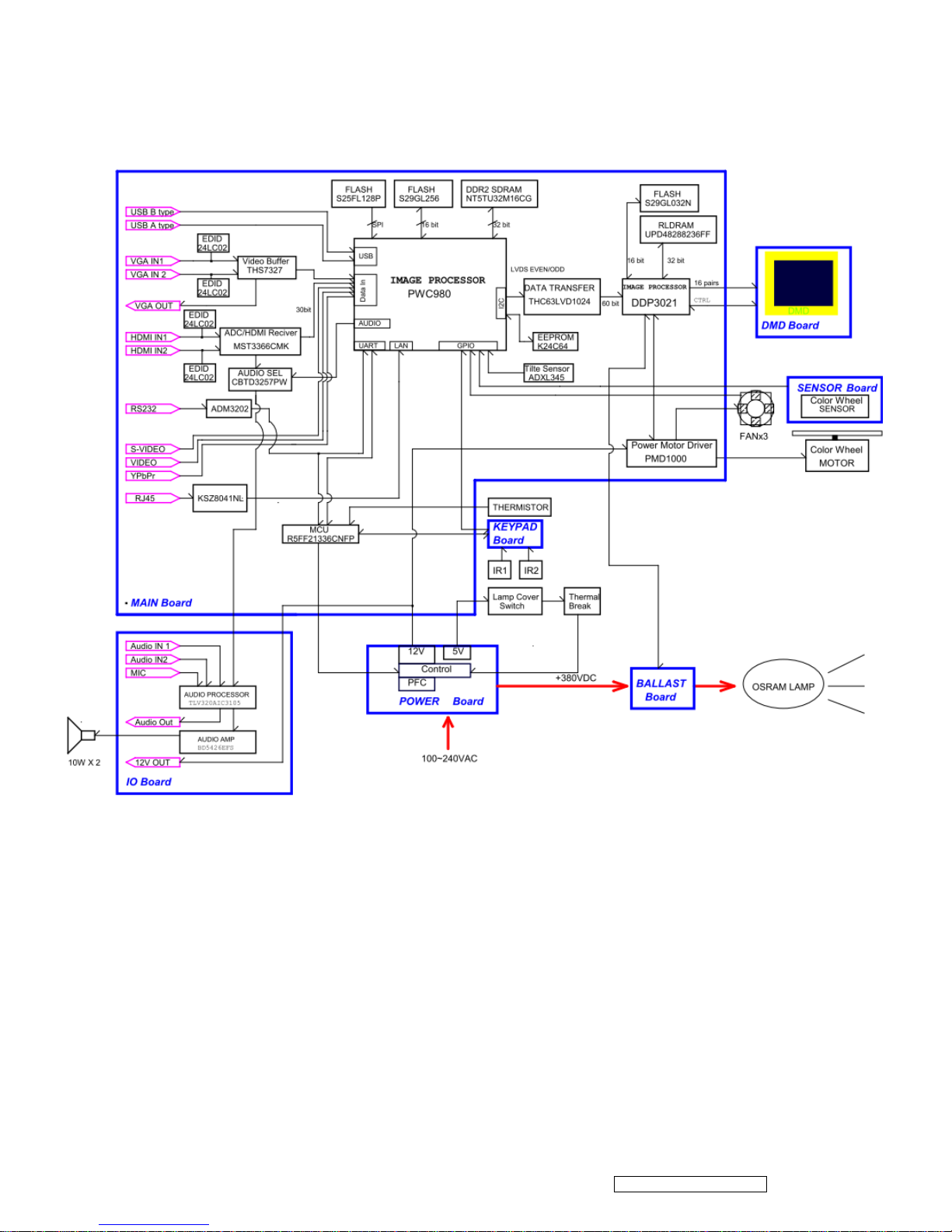

1.4 Pro8400 System Block Diagram

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

12

Page 16

2 Firmware (PixelWorks) Upgraded Flow

This chapter provides the information regarding relevant equipments and upgrading

procedure for f irmware upgrade.

Note:

Please check the firmware and composer version before any f irmware upgrade procedures.

During firmware download period, please do not shut down PC or projector , this will cause flash

memory’s damage. And need to return the unit t o manufacturer for flash memory recovery.

2.1 Setup Tool/Equipment

USB Disk

Power Cord

2.2 Upgrading Procedure

1) Give power supply to switch projector on.

2) Insert the USB Disk into the projector (copy the upgrading F/W document into it firstly.)

3) Enter the engineering mode.

4) Press Menu to exit.

5) Select the next item of “Language” to enter the upgrading mode . (“Language” is a hiding item

that can be seen only after entering the engineering mode and then exit successfully.)

6) Press button to select ”USB Upgrader”, and then press right button to search FW

document.

7) After finding the FW document, move highlight bar to ” Start Upgrade”.

8) Press right button to start upgrade procedure.

9) When complete the procedure, projector will turn off automatically. Unplug the power cord.

1

2

3

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

13

Page 17

3 Machine Disassembly and Replacement

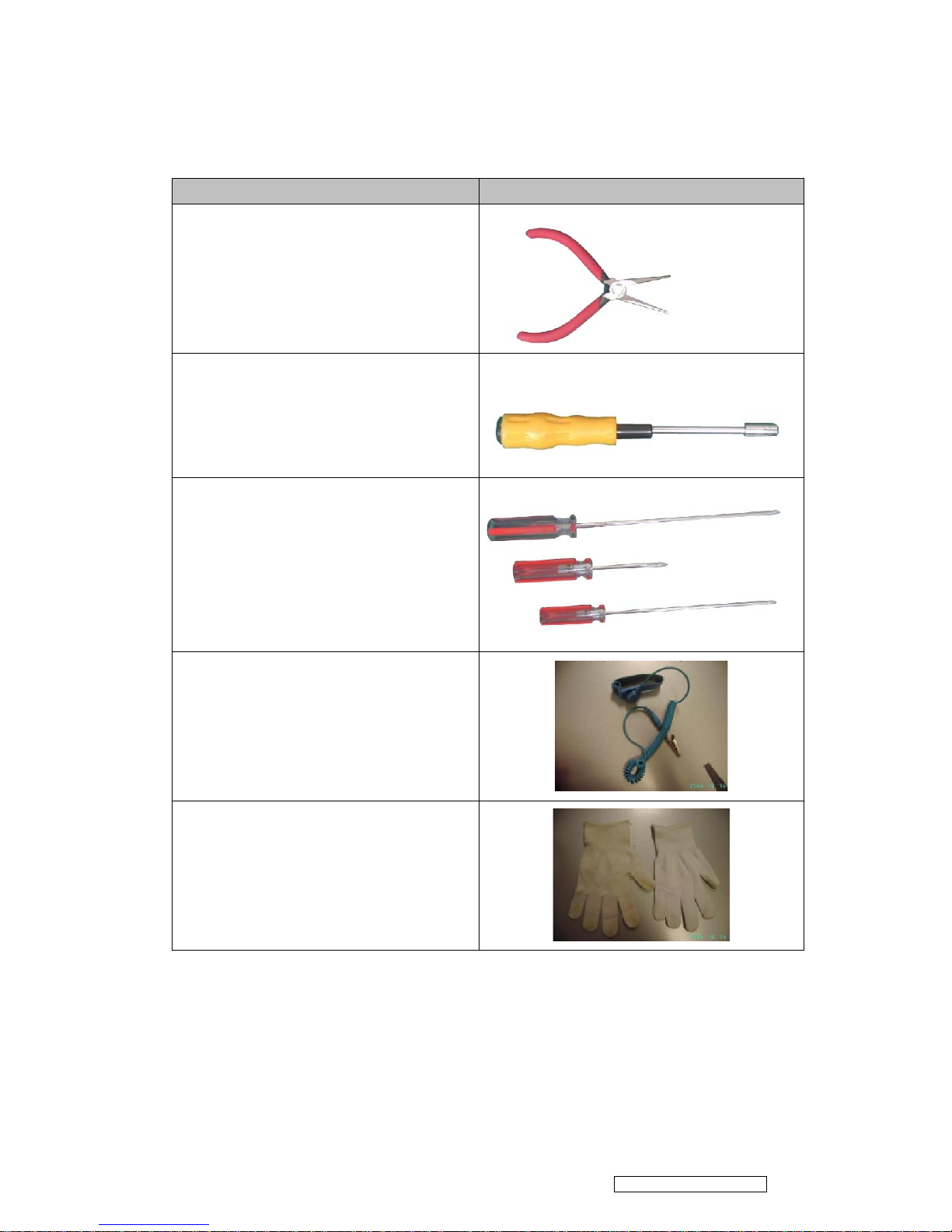

3.1 Tools

Item Photo

Long Nose Nipper

Hex Sleeves 5mm

Screw Bit(+):107

Screw Bit(+):101

Screw Bit(+):102

Anti-static wrist strap

Anti-static wrist gloves

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

14

Page 18

3.2 Disassembly Procedure

Warning

Put on the Static Electricity Ring when starting for repair.

Repair Environment suggest in Clean -room class 10000. Do not remove Optical

Engine or DMD panel outside the clean room. Please return the optical engine to

supplier if your repair condition can not meet the requirement.

While screwing or unscrewing screws, please keep the screwdriver straight. Keeping

screwdriver inclined will damage the screw holes.

Please turn off the power befo re replacing any parts.

Please wait for the projector lamp cooling down and turn off the power before changing

it. Never touch or hit the lamp module when replacing the lamp.

When you replace the projector lamp, never touch the new lamp with your bare hands.

The invisible residue left by the oil on your hands may shorten the lamp life. Use

lint-free gloves or finger cots are recommended.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

15

Page 19

Step Figure Description

1

Press the power button to

shutdown the projector and

disconnect the power cord.

If the lamp is hot, please do not

start any procedure until the

projector lamp cools down.

Flip the projector and remove

the lens cover.

2

1. Flip the projector on the table.

2. Remove the screws

J1635-A010-0A*8 on the Bottom

cover as shown.

3

Rotate the Focus Ring by

forward sequence to take it off

from the unit.

J1635-A010-0A*8

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

16

Page 20

Step Figure Description

4

1. Disconnect the FFC cable

between top cover and main

board.

2. Raise the Top Cover carefully.

Note: Don’t allow to scratch

surface of the lens.

To avoid scratching, it would

better paste some film on it for

protection before raising the Top

Cover.

5

1. Remove four screws to lift up

the keypad board.

6

1. Remove all screws as shown

to remove the IO cover.

FFC Cable

J1635-3720-0A *4

J1635-C230-00*4

J1635-A632-01*2P0P35-2500-00*8

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

17

Page 21

Step Figure Description

7

1. Remove the three screws on

the metal sheet of Main Board.

2. Remove the metal sheet of

Main Board.

8

1. Show you what the connector

should be.

2. Remove all wires. (Including

the two fan modules.)

3. Remove two screws on the

Main Board.

4. Remove the Main Board.

9

1. Remove three screws as

shown.

2. Remove the three wires on

the audio board.

3. Remove the audio board.

P2535-7300-0A *3

P2535-7300-0A *2

P2535-7300-0A*3

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

18

Page 22

Step Figure Description

10

1. Loosen the two screws as

shown.

11

1. Loosen the two screws as

shown.

2. Remove the metal sheet of

Ballast.

Note

Note: 2 wires have been

connected to Ballast.

Disconnect these 2 wires before

remove the metal sheet.

J1635-3185-00

To La m p

To Power Board

J1635-3623-0A

J1635-D110-0A*2

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

19

Page 23

Step Figure Description

12

Release the four pillars by Long

Nose Nipper to remove the

Ballast.

13

1. Remove four screws on the

optical engine.

2. Remove the optical engine

module carefully.

14

1. Loosen all screws of the two

speakers and then remove them

away.

2. Loosen the screws on the

Power Board and then remove

the Power module from Bottom

Cover.

J1635-A491-0A*4

P2535-7300-0A*4

J1635-D420-0A

J1635-2045-00*4

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

20

Page 24

Step Figure Description

15

Loosen the two screws and

remove the lamp module from

optical engine.

Note: Those screws are

included in the Lamp module.

16

1. Loosen the two screws on

the OE Fan.

2. Remove the Fan.

3. Loosen the four screws on

DMD Board.

4. Remove the heat sink and

DMD Board.

17

Loosen one screw to remove

the metal sheet.

J1635-3660-0A *2

P2535-7300-0A *4

P2535-7300-0A

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

21

Page 25

Step Figure Description

18

Loosen the three screws to

remove the protective cover of

color wheel.

19

Loosen the two screws to

remove the color wheel module

gently.

20

1. Loosen the two screws on

the Zoom Ring.

2. Remove the Zo om Ring.

J1635-3188-00 *2

J1635-0780-0A *3

P5K35-0220-00 *2

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

22

Page 26

Step Figure Description

21

1. Loosen the four screws on

the Lens.

2. Remove the Lens carefully.

3.3 Assembly FAN Module

Step Figure

Description

1

Assemble Fan1(J2394-0143-01) and

Fan2 (J2394-0144-00 ):

1. Paste the Fan Pad (P4E38-1070-00)

on the middle of it.

2. Paste the Fan Sponge*4

(P4G38-1180-00) on the top and

bottom of it as picture shown.

P0335-7010-01*4

Fan Pad

Fan1 Fan2

Fan Sponge*4

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

23

Page 27

3.4 Disassembly Lamp Module

As the projector operates over time, the brightness of the projector lamp gra dually decreases

and the lamp becomes more susceptible to breakage. We recommend replacing the lamp if a

warning message is displayed.

Note:

The lamp is extremely hot right after turning off the projector. If you touch the lamp, you

may scald your finger. When you replace the lamp, wait for at least 45 minutes for the

lamp to cool down.

Wear protective gloves and eyeglasses when fixing or detaching the lamp.

Do not operate the lamp in proximity to paper, cloth, or other combustible material nor

cover it with such materials.

1. Turn off the projector.

2. If the projector is installed in a ceiling mount, remove it.

3. Unplug the power cord.

4. Loosen the screw in the side of the lamp cover and remove the cover.

5. Remove the screws from the lamp module, raise the handle, an d lift out the module.

6. Insert the new lamp module into the projector and tighten the screws.

7. Replace the lamp cover and tighten the screw.

8. Turn on the projector. If the lamp does not turn on after the warm-up period, try reinstalling the

lamp.

9. Reset the lamp hour. Refer to the “Information” menu.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

24

Page 28

4 Troubleshooting and Verifying the Repair

This chapter provides technicians with electronic background how to maintain the product.

Moreover, you can get the appropriate operation to solve some complicated probl ems of

component repairing and professional problems.

4.1 Troubleshooting

Warning

Do not directly look into the lens to avoid eyesight damages.

The projector is equipped with ventilation holes (intake) and ventilation holes (exhaust). Do

not block or place anything near these slots, or internal heat build -up may occur, causing

picture degradation or damage to the projector.

Confirm Software and hardware

(1) Confirm FW version is the latest.

How to enter Engineering Mode?

-Open the Main menu and move the color bar to “Information” item, and then move down

the color bar to “Equivalent Lamp Hours” item, press the direction key following the actions

below:

Right once, left twice, right once; then you will enter the Engineering Mode. )

Note: This FW version is just for reference.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

25

Page 29

(2) Confirm LED indicator

Note: Swapping modules that may be defective with others known to be good is generally an ideal way to

find the module responsible for the problem. A failure symptom is rarely caused by more than one module,

so you will not usually need to replace more than one to correct a particular failure. Whatever main board,

ballast, IR board, power board, lamp module or optical engine are all suitable to check by swapping

modules.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

26

Page 30

Power Source Troubleshooting:

No Power

Source after

turning on

Replace AC

socket

Replace power

board or reinstall

Replace keypad

and FFC

Replace

power board

Replace

main board

OK

OK

OK

OK

NG

NG

NG

NG

Check 7 pin

Power output

Check

Safety Switch

Check AC socket

and connector

Check LED and

keypad FFC

Fan failure after

turning on

Reconnect fan

Replace fan

Replace

Main board

NG

NG

NG

OK

OK

Check

Main board

Check

Fan

Check fan

connection

Check

Fuse

OK

Replace fuse

NG

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

27

Page 31

Fail to light up

Refer to LED

indicator and follow

indicative actions

Replace

Lamp Module

Replace

Power board

Replace

Ballast

Replace

Main board

OK

OK

OK

OK

OK

NG

NG

NG

NG

NG

Check

Main board

Check Ballast

Check

Lamp life

Check LED

indication

Check PWR 380V

output

Replace

CW module

NG

Check CW

Rotation while power

on

No Volume

Replace

Speaker

Replace

Audio board

NG

NG

OK

Check

Audio board

Check

Speaker

Check

Main board

Replace

Main board

NG

OK

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

28

Page 32

Signal Troubleshooting

Computer

No Signal

Turn on

Source

Replace

Cable

Replace

Main board

OK

OK

NG

NG

NG

Check

Output signal

Check

Cable

Check

Source

Video

No Signal

Turn on

Source

Replace

Cable

NG

NG

NG

OK

OK

Check

Cable

Check

Source

Check

Main board

Replace

Main board

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

29

Page 33

Image abnormal

Adjust

Input signal

Replace

Main board

Replace

Optical Engine

OK

OK

OK

NG

NG

NG

Check

Optical Engine

Check input

cable and signal

setting

Power on

again and reset

OSD

Check

Main board

Color abnormal

Adjust

Input signal

Adjust Color

Wheel Index

Replace

Main board

NG

NG

NG

OK

OK

Check

Main board

Check Color

Wheel Index

Check input

cable and signal

setting

Replace

Optical Engine

OK

NG

Check

Optical Engine

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

30

Page 34

Operation Function Troubleshooting

Remote Control

Failure

Replace

Battery

Replace

Remote Control

Replace

IR

Replace

Main board

OK

OK

OK

NG

NG

NG

NG

Check

Main board

Check

Remote Control

Check

Battery Level

Check

IR

Button Failure

Replace Keypad

and FFC

Replace

Main board

NG

NG

OK

Check

Main board

Check

Keypad and FFC

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

31

Page 35

4.2 Verifying the Repair

After repairing projector (Dissembling and assembling projector), Repair center should verify

the quality of repaired unit.

(1) Check Logo

Check Logo is correct after power on projector.

(2) Signal test (Each I/O can functio n normally)

Connect all connector to the jacks one after the other to check whether each channel can

project normally.

I/O port Monitor In (VGA)

Test Equipment

Standard Pattern generator (Ex. Quantum data)

Signal format

1920*1080 60Hz

I/O port Video

Test Equipment

Standard Pattern generator (Ex. Quantum data) or DVD player

Signal format

NTSC

I/O port S-Video

Test Equipment

Standard Pattern generator or DVD player

Signal format

480i

I/O port USB

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

32

Page 36

Test Equipment

PC and Remote controller

Test method

1. Connect PC (laptop) VGA output to projector.

Set PC (laptop) output signal to projector

2. Connect projector USB to PC.

Press remote controller page up/down to scroll presentation file up and

down (ex Microsoft office series)

I/O port Audio input

Test Equipment

Connect audio input to audio output of DVD player

Signal format

480i

I/O port HDMI

Test Equipment

HDMI source device

Signal format

1080p

(3) Operation test

Buttons operation

Button description Test criteria

Power button

1. Mechanical motion (Up & Down) should be free from getting stuck

when pressing the button

2. Press “power” button and projector will switch on

Menu

1. Mechanical motion (Up & Down) should be free from getting stuck

when pressing the button.

2. Press Menu button can make projector function normally.

4-way button

1. Mechanical motion (Up & Down) should be free from getting stuck

when pressing the 4-way button.

2. Press 4-way button can be used to scroll through OSD (On -

Screen Display) menus and make adjustments.

Source

1. Mechanical motion (Up & Down) should be free from getting stuck

when pressing the button

2. Press Source button manually selects an input source

Foot adjuster operation

Foot adjuster. Test criteria

Foot adjuster button

Foot adjusters should stretch downward smoothly by pressing the foot

adjuster buttons on the two sides

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

33

Page 37

Zoom ring and Focus ring

Ring Test criteria

Zoom ring

Mechanical motion of rotating Zoom ring to the end of right and left by

hand should be free from getting stuck.

Focus ring

The feeling of rotating Focus ring to the end of right and left by hand

should free from seizing

(4) Image Quality

Projected image size: 60 inches (diagonal length)

Zoom ring: Adjust zoom ring to wide (Maximum projection size)

VGA

I/O port

Monitor In (VGA)

Test Equipment

Standard Pattern generator (Ex. Quantum data)

Signal format

1920*1080 60Hz

Projected image size

60” in diagonal length

Test Pattern

Test criteria

ANSI Brightness

Apparent color strip, bend and streak

corner on the projected image are not

allowable.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

34

Page 38

Extreme Gray-Scale

--0 represents full black, 255 represents full

white.

--Distinguishing the gray from black at the

value of 32 and the gray from white at the

value of 239 easily are acceptable.

Circular Geometry, Cross hatch and

Dots

1. The four lines of outer frame should

not only be existent but also

distinguishable.

2. The dots in the square should be

distinguishable.

Scaled Text ( Resolution)

1. Rotate Zoom ring to wide mode

(Maximum projected image)

2. Fix projector to set diagonal length of

projected image to 60”.

3. Adjust focus ring to make resolution of

4 corners and center are balanced.

4. Check the characters should be

recognized easily.

5. Rotate Zoom ring to tele mode

(Minimum projected image)

6. Adjust focus ring to make resolution of

4 corners and center are balanced.

7. Check the characters should be

recognized easily.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

35

Page 39

INFOCOMM SMPTE 133

1. The intervals of center thin white and

black bars should be distinct.

2. The squares around the small circle in

the center show the transition of full

white to full black.

S-Video

I/O port

S-Video

Test Equipment

Standard Pattern generator (Ex. Quantum data)&DVD player

Signal format

480i

Criteria

No apparent color deviation on the projected image

Video

I/O port

Video

Test Equipment

Standard Pattern generator (Ex. Quantum data)&DVD player

Criteria

No apparent color deviation on the projected image

HDMI

I/O port

HDMI

Test Equipment

HDMI source device

Signal format

1080p

Criteria

No apparent color deviation on the projected image nor abnormal

voice.

(5) Resolution

I/O port

VGA

Test Equipment

PC

Test Method

1. Rotate Zoom ring to wide mode (Maximum projected image)

2. Fix projector to set diagonal length of projected image to 60 ”.

3. Adjust focus ring to make resolution of 4 corners and center

are balanced.

4. Check the characters should be recognized easily.

5. Rotate Zoom ring to tele mode (Minimum projected image)

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

36

Page 40

6. Adjust focus ring to make resolution of 4 corners and center

are balanced.

7. Check the characters should be recognized easily.

(6) Front and Rear infrared sensor

Device

Front and Rear infrared

Test Equipment

Remote controller

Test method

1. Cover front sensor and operate remote controller to test rear

sensor

2. Cover rear sensor and operate remote controller to test front

sensor

(7) Brightness measurements

Test items

Brightness measurements

Test Equipment

Chroma automatic system (The alternative is CL -200)

Test method

Measure 9 points

Criteria

Marketing spec 20% off

(8) Cosmetic standard for repaired projector

Follow cosmetic standard for repair center.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

37

Page 41

5 Adjustment / Alignment Procedure

5.1 Color Wheel Index Adjustment

(1) Open the image of 256-level RGB.

(2) Enter the engineering Mode, and then move down the color bar to “CW Index” item.

(3) Press the button (right or left) to adjust the value of CW Index.

(4) Notice the changing of color till the RGB colors are distinguishable.

NOTE:

1. The CW Index of each CW is not a ll the same.

2. Adjusting the CW Index till the R, G, B colors are distinguishable will be fine.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

38

Page 42

5.2 ADC Calibration

(1)Open the image of Gray16.

(2) Enter the engineering Mode, and then move down the color bar to “ADC Calibration” item.

(3) Press right button to execute ADC Calibration. C olor deviation is unacceptable.

If the screen blinks once, and then back to search signal and at last search out the image of

Gray16, this indicates the calibration is successful.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

39

Page 43

(4) Open the image of SMPTEbar.

(5) Move down the color bar to “YPbPr Cal. /Th. Lamp” item.

(6) Press right button to execute YPbPr Calibration. Color deviation is unacceptable.

If the screen blinks once, and then back to search signal and at last search out the image of

SMPTEbar, this indicates the calibration is successful.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

40

Page 44

5.3 Keystone Adjustment

(1) At horizontal platform, adjust the projector foot to make platform level.

(2) And then enter the engineering mode, and then move down the color bar to “Keystone Cal.”

item.

(3) Press right button to adjust.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

41

Page 45

6 Connector Information

This section provides each connector location on boards and function of each board. They will

be useful for your detecting the defective boards.

6.1 Main Board

Connector Description

No1 Connect to DMD Board

6.2 The backside of Main Board

No1

No2

No4

No6

No8

No9

No10

No11 No12

No3

No5

No7

No1

No13

No14

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

42

Page 46

Connector Description

No 1 Keypad control

No 2 FAN1

No 3 Color Wheel Sensor

No 4 Color Wheel control

No 5 /

No 6 Ground

No 7 Optical Engine Fan

No 8 Ignite signal connected to Ballast

No 9 Thermal switch

No 10 Main Board Power Supply

No 11 FAN2

No 12 Safety switch

No 13 Audio Board

No 14 /

6.3 Ballast Board

Connector Description

No 1 Lamp power supply

No 2 Ignite signal connected to Main board

No 3 High Voltage Power supply

No1

No2

No3

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

43

Page 47

6.4 Power Board

Connector Description

No 1 380V output for ballast

No 2 12V/5V output for Main board and Audio board

No1

No2

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

44

Page 48

7 FRU (Field Replaceable Unit) List

Introduction

This section is a list of all the FRU removal . Following the FRU table of contents is an enlarged

view of the entire projector, which shows the primary FRUs in the projector.

When working on the projec tor, use appropriate anti-static precautions such as anti -static mats,

wrist straps and grounded work surfaces. Failure to do this can destroy static -sensitive

components and make the product inoperable.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

45

Page 49

7.1 Mechanical Drawing

4. IO Cover

1. Lamp Cover

2. Top Cover

3. Filter Cover

5. Main Board

7. Audio Board

6. Lens Cover

8. Lamp Module

9. Optical Engine

10. Left Speaker

15. Right Speaker

14. Fan2

16. B-IR Board

13. Lens Frame

12. F-IR Board

11. Fan1

17. Ballast

18. Power Board

19. Bottom Cover

20. Rear Foot

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

46

Page 50

ViewSonic Model Number: VS13647

Rev:1a

Item ViewSonic P/N Ref. P/N Description

Q’ty

1

C-00010583

P7U84-4520 Lamp Cover 1

2

C-00010758

P7W84-4500 Top Cover 1

3

C-00010588

P7U34-4620-00 Filter Cover 1

4

C-00010759

P7W84-4530 IO Cover 1

5

B-00010911

P7W84-7100 Main Board 1

6

C-00010589

P7U34-4540-99 Lens Cover 1

7

B-00010813

P7W47-3100 Audio Board 1

8

RLC-059

P7U84-2400 Lamp Module 1

9

E-00010674

P7W84-2200 Optical Engine 1

10

E-00010441

J2413-0111-00 Left Speaker 1

11

M-00008759

J2394-0143-01 Fan1 1

12

B-00008158

P3747-5101 F-IR Board 1

13

C-00010587

P7U34-4610-00 Lens Frame 1

14

M-00008760

J2394-0144-00 Fan2 1

15

E-00010440

J2413-0108-00 Right Speaker 1

16

B-00010719

P7U47-5101 B-IR Board 1

17

B-00010720

P7U84-9000 Ballast 1

18

B-00010717

P7U84-8100 Power Board 1

19

C-00010585

P7U84-4510 Bottom Cover 1

20

M-00008767

P7U38-1540-00 Rear Foot 2

EXPLODED PARTS LIST (Pro8400)

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

47

Page 51

7.2 Packing drawing

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

48

Page 52

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

49

Page 53

ViewSonic Model Number: VS13647

Rev:1a

Item ViewSonic P/N Ref. P/N Description

Q'ty

1

n/a

P7W38-5000-00 UL LB 1

2

n/a

J4238-R815-01 SERIAL LB 1

3

n/a

P2838-5001-00 WARNING LB 1

4

n/a

P1638-5007-00 LB 1

5

n/a

P1638-5010-00 LB 1

6

n/a

P1238-R504-00 LB 1

7

n/a

J4039-0082-00 BB BAG 1

8

P-00010782

P7U39-7004-00 EPE 1

9

n/a

P7U39-3000-00 POUCH 1

10

DC-00010799

P7W39-4000-00 QG 1

11

DC-00010800

P7W39-A000-00 CD 1

12

n/a

J2491-0008-02 BATTERIES 1

13

P-00008410

J4039-R157-01 PE.BAG 1

14

P-00010781

P7U39-7003-00 EPE-LEFT 1

15

P-00010780

P7U39-7002-00 EPE-RIGHT 1

16

P-00010870

P7W39-6000-00 CARTON 1

17

n/a

J4238-5006-00 LB 1

PACKING PART LIST (Pro8400)

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

50

Page 54

8 Maintenance

The projector needs proper maintenance. You should keep the lens clean as dust, dirt or spots

will project on the screen and diminish image q uality. If any other parts need replacing, contact

your dealer or qualified service personnel. When cleaning any part of the projector, always

switch off and unplug the projector first.

Warning:

Never open any of the covers on the projector. Dangerous electrical v oltages inside the projector

can cause severe injury. Do not attempt to service this product yourself. Refer all servicing to

qualified service personnel.

Cleaning the Lens

Gently wipe the lens with lens cleaning paper. Do not touch the lens with your hand s.

Cleaning the Projector Housing

Gently wipe with a soft cloth. If dirt and stains are not easily removed, use a soft cloth damped

with water, or water and neutral detergent, and wipe dry with a soft, dry cloth.

Cleaning the Filter Cover

The filter cover, which is located at the side of the projector, should be cleaned after every 100

hours of use. If it is not cleaned periodically, it can become clogged with dust and prevent the

projector from being ventilated properly. This can cause over heating and damage the projector.

To clean the filter cover:

1. Switch the projector off and unplug the AC power

cord from the wall socket.

2. Remove the filter cover as the

illustration shown.

3. Clean the filter cover.

To clean the filter cover, you are advised to use a

small vacuum cleaner designed for computers

and other office equipment.

If the filter cover is torn, replace it.

4. Replace the filter cover.

5. Attach the filter cover.

6. Plug the power back into the projector.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

51

Page 55

Appendix A: RS-232 Command and Configuration

Baud Rate: 19200 Parity Bit: none

Data Bit: 8 Stop Bit: 1 Assign Port: COM1

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

52

Page 56

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

53

Page 57

Appendix B: IR Control Code

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

54

Page 58

Appendix C: How to reset the Lamp Hours

(1) Press “Menu” button to open the Main menu.

(2) Move color bar to “Information” item.

(3) Move down the color bar to “ Equivalent Lamp Hours Reset” item.

(4) Press “enter” button to enter sub-menu.

(5) Press left button to select “yes” to reset Lamp Hours.

(6)Then the Lamp Hours would reset to 0 hours.

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

55

Page 59

ViewSonic Model Number:VS13647

Serial No. Prefix:S8E

Rev.: 1a

Item Categor

y

Part Name Description ECR/ECNViewSonic P/

N

Ref. P/N Remar

k

1 LAM

P

LAMP_MODULE_280W_SPARE PART_VPD-X7000_ROH

S

RLC-059 P7U84-240

0

If Q'ty = 1000, price = 80

2 Remote Controlle

r

REMOTE CONTROL_VIEWSONIC_VPD-W6004_WITHOUT/B_ROH

S

A-00008988

J8947-0310-00

3 Power Cord POWER CORD (AUSTRALIA).

_

(SAA)YP-35/YC-12_YUNG LI_ROH

S

A-00008060

J2552-0053-00

4 Power Cord POWER CORD(CHINA).

_

YP-03/YC-12_YUNG LI_ROH

S

A-00008056

J2552-0106-00

5 Power Cord POWER CORD(EUROPE).

_

YP-22/YC-12_YUNG LI_ROH

S

A-00008057

J2552-0107-00

6 Power Cord POWER CORD(UK).

_

YP-61/YC-12_YUNG LI_ROH

S

A-00008058

J2552-0108-00

7 Power Cord POWER CORD (SOUTH AFRICA).

_

YP-80/YC-12_YUNG LI_ROH

S

A-00008233

J2552-0056-01

8 Power Cord POWER CORD(USA).

_

UL(YP-12/YC-12)_YUNG LI_ROH

S

A-00008059

J2552-0109-00

9 Power Cord POWER CORD (ARGENTINA)

_

SP-852+IS-14_I-SHENG_ROH

S

A-00008585

J2552-0263-00

10 Si

g

nal Cable HDMI 19P TO 19P CABLE_L1800_VIEWSONIC_P2650-05_PAN_ROH

S

CB-00008572

J2552-0171-00

11 RS232 Cabl

e

DB9P TO DB9P CABLE_L1500_P35251A-05_PAN_ROH

S

CB-00009062

J2552-0208-00

12 Adapter VGA-15P-6P CABLE

_

P4724-08_PAN_ROH

S

CB-00008906

J2552-0212-00

13 Si

g

nal Cable VGA-15P CABLE_P3842-06_PAN_ROH

S

CB-00008710

J2552-0072-03

14 Main Board MAIN

_

DIP_PCB_ASY_SPARE PARTS_VPD-W6002_ROH

S

B-00010911

P7W84-7100

15

Power Boar

d

POWER BOARD_SPARE PARTS_VPD-X7000_ROH

S

B-00010717

P7U84-810

0

16

Ke

y

Pa

d

KEYPAD_DIP_PCB_ASY_VPD-W6001_ROH

S

B-00010718

P7U47-710

0

17

IR Boar

d

FIR_DIP_PCB_ASY_PD-X702_ROHS (Front IR

)

B-00008158 P3747-5101

18

IR Boar

d

REAR IR_DIP_PCB_ASY_VPD-W6001_ROHS (Rear IR

)

B-00010719 P7U47-5101

19

Ballast

OSRAM-BALLAST-280W

_

SPARE PART_VPD-X7000_ROH

S

B-00010720

P7U84-900

0

20

I/O Boar

d

AUDIO_DIP_PCB_ASY_VPD-W6002_ROH

S

B-00010813

P7W47-3100

21

DMD Boar

d

DMD_DIP_PCB_ASY_VPD-W6002_ROH

S

B-00010814

P7W47-6100

22

Sensor Boar

d

CW SENSOR_DIP_PCB_ASY_VPD-W6002_ROHS (CW Sensor Board

)

B-00010723 P7W47-5100

23 Lamp Cove

r

LAMP COVER_SPARE PARTS_VPD-X7000_ROH

S

C-00010583 P7U84-452

0

24 Top Cove

r

TOP COVER_SPARE PARTS_VPD-W6002_ROH

S

C-00010758 P7W84-4500

25

Bottom Cove

r

BOTTOM COVER_SPARE PARTS_VPD-X7000_ROH

S

C-00010585 P7U84-451

0

26

I/O Cove

r

I/O COVER_SPARE PARTS_VPD-W6002_ROH

S

C-00010759 P7W84-4530

27

Lens Cove

r

LENS-FRAME-BOTTOM_VPD-X7000_05000-0050-00_NO PAINTING_ROH

S

C-00010587 P7U34-4610-0

0

28

Filter Cove

r

FILTER-HOLDER_VPD-X7000_05000-0050-00_NO PAINTING_ROH

S

C-00010588 P7U34-4620-0

0

29

Lens Cove

r

LENS-COVER_VPD-X7000_05000-0050-00_FOR PAINTING_ROH

S

C-00010589 P7U34-4540-99

30 Wire

FFC CABLE

_

A20200C3344NB_ENTERY_0.5PITCH_20PIN_L200MM_ROHS(keypad board to MB

CB-00009764 J2591-0140-00

31 Wire

FFC CABLE

_

A20110D3344NB_ENTERY_0.5PITCH_20PIN_L110MM_ROHS(audio board to MB

)

CB-00009765 J2591-0139-00

32 Wire

WIRE CON-CON

_

1102003-344_MSK_4PIN_L100MM_1571#28_ROHS(B-IR board to MB

)

CB-00009766

J2595-0518-00

33 Wire

WIRE CON-CON

_

1102003-345_MSK_4PIN_L260MM_1571#28_ROHS(F-IR board to MB

)

CB-00009767

J2595-0519-00

34 Wire

WIRE SW-CON

_

1102003-201_MSK_2PIN_L25MM_1007#26_ROHS (Lamp door switch

)

CB-00009768

J2595-0344-00

35 Wire

WIRE CON-CON

_

1102003-200_MSK_10+4PIN-2*8PIN_L115/185MM_1007#24/#26_ROHS(power board to MB an

d

CB-00009769

J2595-0342-00

36 Wire

WIRE CON-CON

_

1102003-187_MSK_5PIN_L150MM_1571#28_ROHS(ballast to MB

)

CB-00009770

J2595-0328-00

37 Wire

WIRE TERMINAL-CON

_

103AP-110330-10N001_SEMITEC_ROH

S

CB-00009771

J2595-0489-00

38 Wire

WIRE CON-THERMAL FUSE

_

01800171R_AVERTRONICS_ROHS(thermal switch

)

CB-00009772

J2595-0343-00

39 Wire

WIRE CON-CON

_

1102003-98_MSK_2PIN_L140MM_1015#22_ROHS(power board to ballast

)

CB-00008469

J2595-0218-00

40 Wire

TERMINAL WIRE

_

1102003-239_MSK_1PIN_L70MM_BLACK_1015#16_ROH

S

CB-00009773

J2596-0016-00

41 Wire

WIRE LAMP-BALA

(

MPD-X5501)_01800167R_AVERTRONICS_2PIN_L185MM_3239V#20_ROHS(Ballast to Lam

p

CB-00009774

J2595-0336-00

42 Wire

WIRE CON-CON 1102003-182 MSK 4PIN L120MM 1571#28 ROHS

(

color wheel to main board

)

CB-00009053

J2595-0325-00

43

Q

ucik Start Guide

(QS

QG_

VIEWSONIC_VPD-W6002_GLOBAL_ROH

S

DC-00010799

P7W39-4000-00

44 User's Guide (DVD R

O

CD ROM_VIEWSONIC_VPD-W6002_GLOBAL_ROH

S

DC-00010800

P7W39-A000-00

45

Label / Sticke

r

CARTON LB_VIEW SONIC_PJ557D_GLOBAL_ROHS(for China

)

DC-00008672 P0N38-5013-00

46

O

p

tical Engine OPTICAL ENGINE_SPARE PART_WITHOUT LAMP_VPD-W6002_ROH

S

E-00010674 P7W84-2200

47

Color Wheel

COLORWHEEL

_

SPARE PARTS_VPD-X7000_ROH

S

E-00010436 P7U84-260

0

48 Lens LENS ASY_SPARE PARTS_VPD-X7000_ROH

S

E-00010437 P7U84-620

0

49 DMD Chip DMD-ATYPE-0.65-1080P_VPD-W6004_ROH

S

E-00010529 P7Y84-7010

50 Li

g

ht Pipe LIGHT TUNNEL_BPD-W6102_ROH

S

E-00010530 P8D84-7620

51 Speake

r

SPEAKER_P52KUG06X-7JS1_VECO_ROHS (Right

)

E-00010440 J2413-0108-00

52 Speake

r

SPEAKER_P52KUG06X-7JS2_VECO_ROHS (Left

)

E-00010441 J2413-0111-00

53 Screw HEXAGON-HEAT-BOLT

_

TPD-X570_00_ROH

S

HW-00009484P0P35-2500-00

54 Screw SCREW

_TP_4_10_A_

2.5_D=6.8_WH-ZN_NONE_ROH

S

HW-00009485 J1635-A010-0

A

55 Screw SCREW_M_3_5_A_1.5_D=4.5_BLACK_NONE_ROH

S

HW-00009486J1635-A342-00

56 Screw SCREW

_TP_3_8_A_2_

D=5.3_BLACK_NONE_ROH

S

HW-00009487J1635-A632-01

57 Screw SCREW

_M_3_5_A_2_

D=5.3_BLACK_NONE_ROH

S

HW-00009488 J1635-C230-00

58 Screw SCREW-MB-670H

_

EMS-DX540_01_NO PAINTING_ROH

S

HW-00009489P2535-7300-0

A

59 Screw SCREW-WASHER_TP_3_6_D_2.6_D=8.5_ZN_NONE_SUS_ROH

S

HW-00009490J1635-3623-0

A

60 Screw SCREW_M_2.0_3.5_E_0.5_D=4.0_WH-ZN_NONE_ROH

S

HW-00009491 J1635-3185-00

61 Screw SCREW

_M_3_5_E_1_

D=6_WH-ZN_NL_ROH

S

HW-00009492J1635-D110-0

A

62 Screw SCREW-WASHER_TP_2_4_D_1_D=3.2_ZN_NONE_SUS_ROH

S

HW-00009493

J1635-3720-0

A

63 Fan FAN-3000_EE92251S1_3PIN_SUNON_ROHS (Left

)

M-00008759 J2394-0143-01

64 Fan FAN-3400

_

EF92251BX_3PIN_SUNON_ROHS (Right

)

M-00008760 J2394-0144-00

65 Fan SLEEVE FAN

_

MF50201V1_SUNON_ROHS (Lamp

)

M-00008761 J2394-0145-01

66

S

pong

e FAN-FILTER_VPD-X7000_ROH

S

M-00008764

P7U38-1650-0

0

67

S

pong

e FAN-FILTER-LOWER_VPD-X7000_ROH

S

M-00008765

P7U38-1670-0

0

68

S

pong

e

FAN SPONGE

_

MPD-X5501_ROHS (Fan sponge

)

M-00008766 P4G38-1180-00

69 Pa

d

FAN PAD_TPD-X5500_ROH

S

M-00008390 P4E38-1070-00

70

Rin

g

ZOOM-RING_VPD-X7000_05002-2019-00_FOR PAINTING_ROH

S

M-00008762 P7U34-4580-99

71

Rin

g

FOCUS-RING_VPD-X7000_05002-2019-00_NO PAINTING_ROH

S

M-00008763 P7U34-4570-99

72 Foo

t

RUBBER-FOOT_VPD-X7000_ROH

S

M-00008767 P7U38-1540-0

0

73 Carton CARTON_VIEWSONIC_VPD-W6002_GLOBAL_ROH

S

P-00010870 P7W39-6000-00

74 Foa

m

EPE_NO_VPD-X7000_LEFT_ROH

S

P-00010780 P7U39-7002-0

0

75 Foa

m

EPE_NO_VPD-X7000_RIGHT_ROH

S

P-00010781 P7U39-7003-0

0

76 Foa

m

EPE_NO_VPD-X7000_TOP_ROH

S

P-00010782 P7U39-7004-0

0

77 Plastic Ba

g

PE BAG._NO BRAND_298MM*190MM_ROH

S

P-00008794 J4039-R184-01

78 Plastic Ba

g

PE BAG._NO BRAND_GLOBAL_ROH

S

P-00008410 J4039-R157-01

Remark 1:

Above listed items are examples, supplier can expand the rows to add more necessar

y

items.

Remark 2:

N

otice: 1. For some special parts, some photos for identification purpose may be asked by reques

t

2. For all internal cables, there must be some wordings on the "Description" column about where the cable is used (connecting to which two parts)

3. All internal cables/wires should be put in the "Cables" cate

gory

4. All external cables should be put in the "Accessories" categor

y

5. Parts relationship (Main/Second source or 1/2/3/4) should be added in the "Compatibility" column

6. If an

y

part for certain product isn't listed in the form, supplier/PE can add it themselves and keep the part name unified.

Hardware:

[Screw, Bracket,

Hinge]

PC Board

Assembly: [All

PCBA]

Accessories:

[Adapter, Remote

Controller, Power

Cord, External

Cables]

Electronic

Components:

[Optical Engine,

Speaker, Color

Wheel]

Cabinets:

[Front Bezel, All

Covers, Base

Assembly]

Cables: [All

internal

Cables/wires]

RECOMMENDED SPARE PARTS LIST (PRO8400-1W)

Miscellaneous:

[Switch, Fan,

Rubber Foot,

Logo]

Packing Material:

[Box, Foam, Bags]

Documentation:

[Quick Start

All revised RSPLs with newly added items or any change made should be highlighted and correlated with the ECN/ECR approved by ViewSonic Corporation. This is to eliminate repeated cross checks of

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

56

9 Recommended Spare Parts List

Page 60

* Reader’s Response*

Dear Readers:

Thank you in advance for your feedback on our Service Manual, which allows continuous improvement

of our products. We would appreciate your completion of the Assessment Matrix below, for return to

ViewSonic Corporation.

Assessment

A. What do you think about the content of this Service Manual?

Unit Excellent Good Fair Bad

1. System Introduction

2. Firmware Upgraded Flow

3. Machine Disassembly and Replacement

4. Troubleshooting and Verifying the Repair

5. Adjustment / Alignment Procedure

6. Connector Information

B.

Are you satisfied with this Service Manual?

Item Excellent Good Fair Bad

1. Service Manual Content ʳʳʳʳ

2. Service Manual Layout ʳʳʳʳ

3. The form and listing ʳʳʳʳ

C. Do you have any other opinions or suggestions regarding this service manual?

Reader’s basic dada:

Name: ʳ Title: ʳ

Company: ʳ

Add: ʳ

Tel: ʳ Fax: ʳ

E-mail: ʳ

After completing this form, please return it to ViewSonic Quality Assurance in the USA at facsimile

1-909-839-7943.

7. FRU (Field Replaceable Unit) List

8. Maintenance

9. Recommended Spare Parts List

Confidential - Do Not Copy

ViewSonic Corporation

Pro8400

57

Loading...

Loading...