Page 1

Technical Data Manual

Model Nos. and pricing: see Price List

VVVVIIIITTTTOOOOCCCCEEEELLLLLLLL111100000000----BBBB

Dual coil domestic hot water storage tank

79 and 119 USG / 300 and 450 ltr

Product may not be exactly as shown

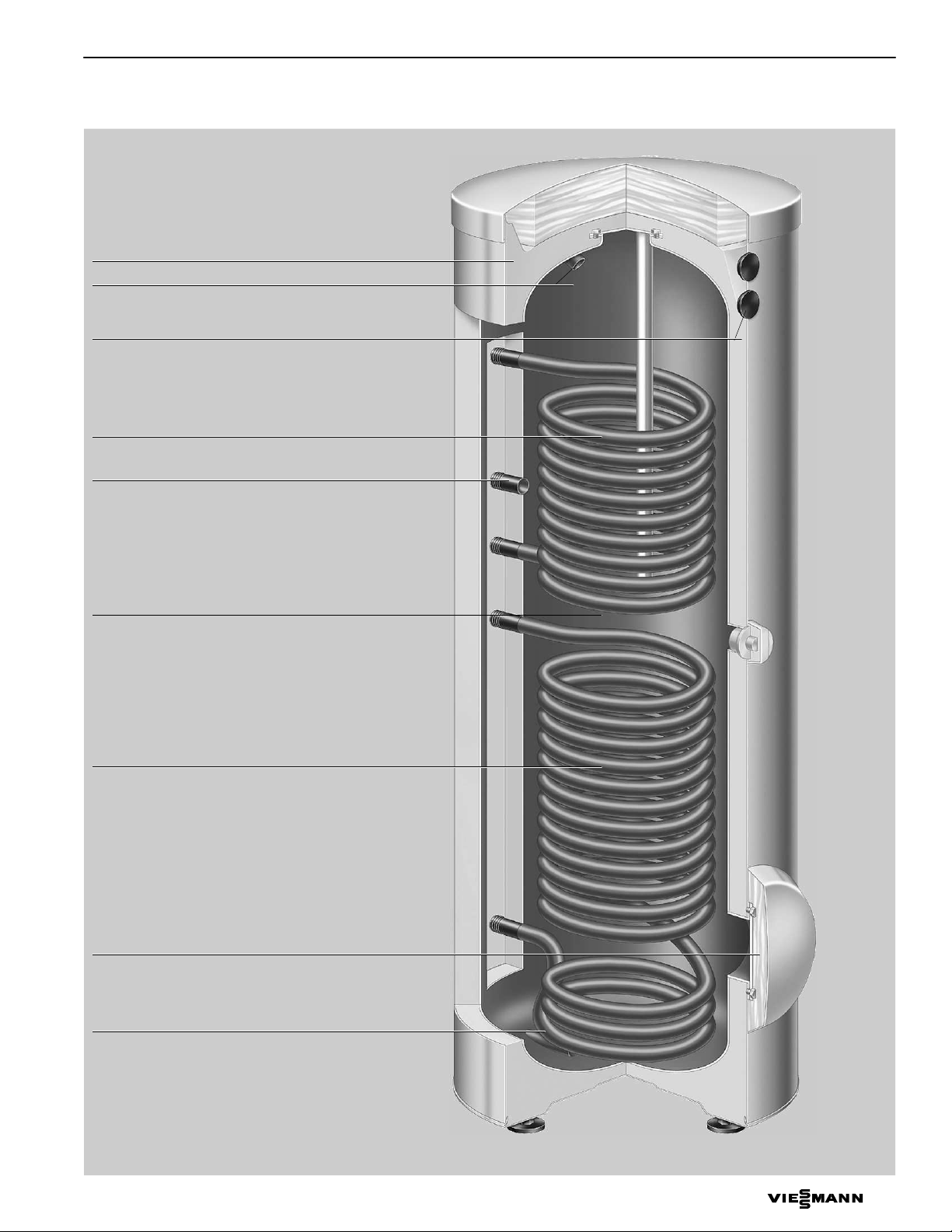

Vitocell 100-B

CVB Series

Vertical indirect-fired dual coil domestic hot water storage tank

made of steel with Ceraprotect enamel coating

One heat exchanger coil facilitates heat transfer from the solar

collectors to domestic hot water, a second heat exchanger coil

allows reheating of the water content by the hot water heating

boiler.

5285 656 - 01 03/2014

This tank version is not suitable

for steam heating applications.

Page 2

Product Information

5

2

8

5

6

5

6

-

0

1

Product Information

Domestic hot water storage tank of corrosion

protected steel with built-in insulation made

of PUR Foam.

Fully hygienic, efficient and economical

domestic hot water production by solar

collectors and a hot water heating boiler.

Heat from the solar collectors is transferred

to the domestic hot water via the lower

tank coil.

Benefits at a glance:

H Corrosion-resistant tank with Ceraprotect

enamel coating ensures a long service life.

Additional cathode protection is provided

by a magnesium anode.

H The entire water content is heated by a

coiled 1”/25 mm diameter steel heat

exchanger surface which extends to the

bottom of the tank.

H Large heat exchanger surfaces allow fast

and even heating of the entire water

content, guaranteeing a high level of

domestic hot water comfort.

H Increased energy savings thanks to highly

effective, foamed-in-place HCFC-free

insulation keeping standby losses at a

minimum.

H Two thermometers to show the DHW

temperature at the top of the tank and at

the midpoint of the tank.

H The Vitocell-B 100 119 USG / 450 L

capacity tank is supplied with removable

soft PET insulation for easier handling.

H For dual-mode DHW heating with solar

panels in conjunction with a boiler. The

solar energy gathered by the solar panels

is transferred to the DHW by the lower

indirect coil. For mono-mode DHW heating

with a boiler or heat pump - both indirect

coils can be connected in series.

H Certified to CSA Low Lead Content

Certification Program;

including US Safe Drinking Water Act,

NSF/ANSI 372 as well as other applicable

US State requirements.

2 VITOCELL 100-B

Page 3

Highly effective foamed-in-place

5

2

8

5

6

5

6

-

0

1

hard PUR foam insulation (HCFC free, 79 USG / 300 ltr)

or soft PET insulation (119 USG / 450 ltr)

Domestic hot water

Two thermometers

Upper coildomestic hot water is reheated by boiler

Recirculation tapping

Product Information

Cross-Section

Steel domestic hot water tank

with Ceraprotect enamel

Lower coil connection for solar connectors

Inspection port/

cleanout opening

Domestic cold water / drain

VITOCELL 100-B 3

Page 4

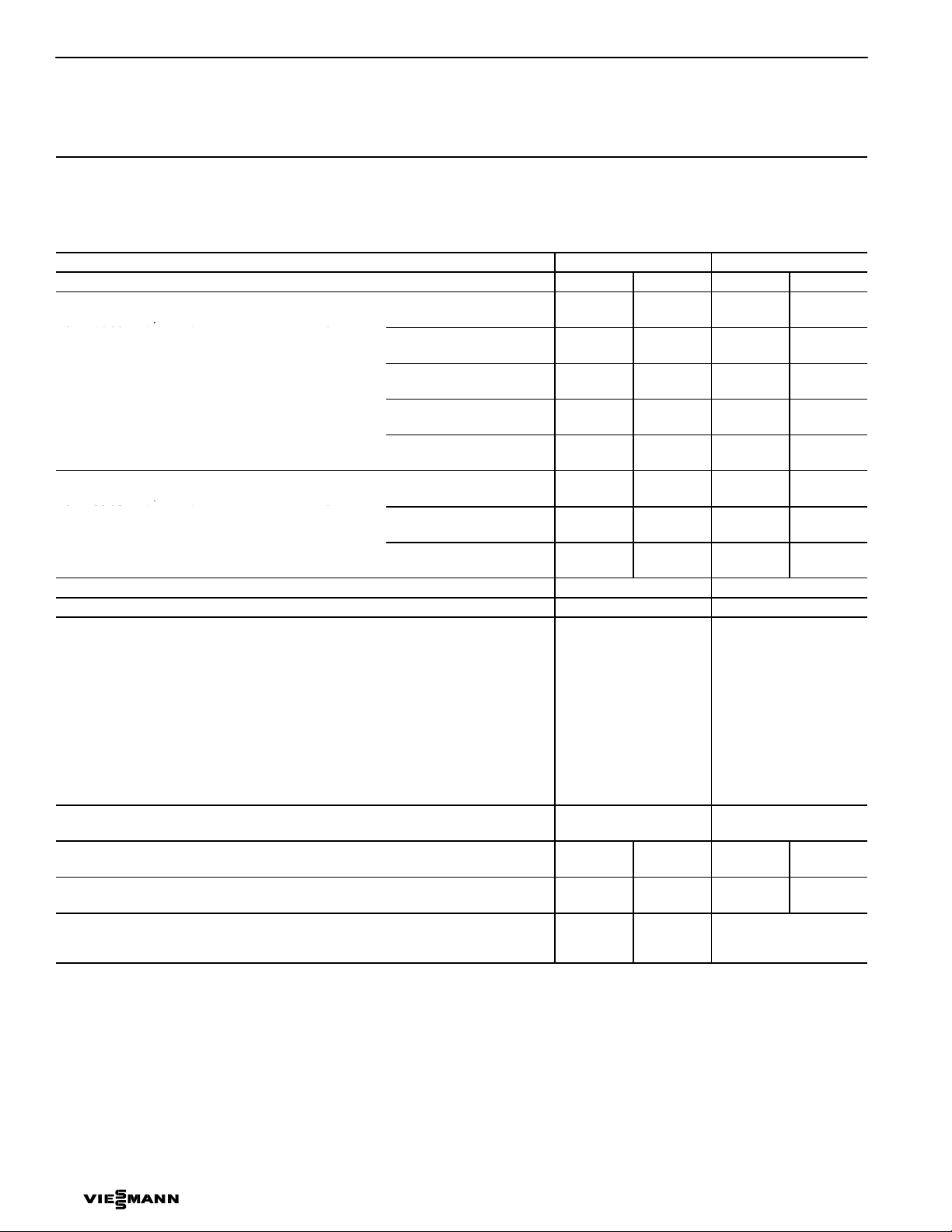

Technical Data

withaDHWtemperatureincreasefrom50to113ºF/

withaDHWtemperatureincreasefrom50to140ºF/

"

5

2

8

5

6

5

6

-

0

1

Technical Data

For DHW production in conjunction with heating boilers, Suitable for heating systems with:

and heating systems without low limit for dual coil operation H max. working pressure on heat exchanger side up to 150 psig at

Storage capacity USG / ltr 79 / 300 119 / 450

Coil upper

Recovery rate

*3

with a DHW temperature increase from 50 to 113 ºF/

10 to 45 ºC and a supply water temperature of

Recovery rate

*3

.. . .. .

with a DHW temperature increase from 50 to 140 ºF/

10 to 60 ºC and a supply water temperature of

......

Insulation Hard PUR Foam Soft PET insulation

Standby losses

Overall dimensions with insulation

*4

*5

320°F/160°C

H max. working pressure on DHW water side of up to 150 psig at

210°F/99°C

H max. testing pressure on DHW side of 300 psig

194ºF/90ºC

176ºF/80ºC

158ºF/70ºC

140ºF/60ºC

122ºF/50ºC

194ºF/90ºC

176ºF/80ºC

158ºF/70ºC

MBH / kW

GPH / ltr/h

MBH / kW

GPH / ltr/h

MBH / kW

GPH / ltr/h

MBH / kW

GPH / ltr/h

MBH / kW

GPH / ltr/h

MBH / kW

GPH / ltr/h

MBH / kW

GPH / ltr/h

MBH / kW

GPH / ltr/h

106 / 31

201 / 761

89 / 26

169 / 640

68 / 20

129 / 491

51 / 15

97 / 368

38 / 11

71 / 270

79 / 23

104 / 395

68 / 20

91 / 344

51 / 15

68 / 258

*1

344 / 1302

286 / 1081

214 / 811

150 / 566

117 / 442

205 / 774

154 / 584

104 / 395

lower

181 / 53

151 / 44

113 / 33

79 / 23

62 / 18

154 / 45

116 / 34

79 / 23

*2

160 / 47

305 / 1154

136 / 40

259 / 982

102 / 30

195 / 737

143 / 540

104 / 393

123 / 36

164 / 619

102 / 30

136 / 516

100 / 378

MBH/24 h 7.8 9.5

upper

75 / 22

55 / 16

75 / 22

*1

454 / 1720

376 / 1425

292 / 1106

208 / 786

156 / 589

241 / 911

200 / 756

150 / 567

lower

239 / 70

198 / 58

153 / 45

109 / 32

82 / 24

181 / 53

151 / 44

113 / 33

*2

Overall width (∅)

Overall depth

Overall height

Tilt height including insulation

Tilt height excluding insulation

Weight

Tank with insulation

Heat exchanger coil liquid content USG

Heat exchanger area ft.

Connections Coils ∅” (male thread)

Domestic cold/hot water ∅” (male thread)

Recirculation ∅” (male thread)

*1

The upper coil is designated for connection to a hot water heating boiler or a heat pump.

*2

The lower coil is designated for connection to solar collector panels or heat pumps.

*3

When planning for the recovery rate as stated or calculated, allow for the corresponding circulation pump.

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

lbs

kg

ltr

2

2

m

1.6

9.7

0.9

1”

1”

1”

25

633

28

705

68¾

1746

70½

1792

-

-

352

160

6

10

16.1

1.5

2.6

2.3

9

15

1.4

1”

1”

1”

The stated recovery rate is only achieved when the rated output of the boiler is equal to or greater than that stated under “Recovery

rate”.

*4

Measured values are based on a room temperature of 68°F / 20 ºC and a domestic hot water temperature of 149°F / 65 ºC and can vary

by 5 %.

*5

For other dimensions, see illustration and table on page 5.

33½

850

36

918

77

1955

731/

1860

452

205

3.3

12.5

20.5

1.9

1¼”

-

-

8

1”

1”

For information regarding other Viessmann System Technology componentry, please reference documentation of the respective product.

4 VITOCELL 100-B

Page 5

79 USG / 300 ltr Tank

5

2

8

5

6

5

6

-

0

1

MA

TH

IO

h

Ø k

a

DCW/D

Y

SCR

TPV

BWS

RT

BWR

SCS

b

DHW

*1

Technical Data

Legend

Section A-B

*1

SW1

SW2

Total height

g

f

e

c

d

Total depth

IO Inspection and cleanout opening

D Drain

BWR Boiler water return (upper coil)

SCR Solar collector return (lower coil) or

BWS Boiler water supply (upper coil)

SCS Solar collector supply (lower coil) or

DCW Domestic cold water

SW1*1Sensor well for tank temperature

SW2 Sensor well for the lower

DHW Domestic hot water

RT Recirculation tapping

Total width

TPV Temperature and pressure relief

MA Protective magnesium anode

*1

boiler return

boiler supply

sensor of boiler control at BWS

level

thermometer at SCS level

valve

For solar heating systems Viessmann

recommends placement of the DHW tank

temperature sensor of the solar control in

the solar collector return (SCR). This

requires a brass elbow with sensor well

included in the accessory pack.

The DHW tank temperature sensor of the

boiler control is placed in the SW1 sensor

well (see installation example on page 8).

DHW tank temperature sensor

in solar heating applications

79 USG / 300 ltr

DHW tank temperature sensor for

solar application (included with

Solar control)

Brass elbow with sensor well

(accessory pack)

Solar collector return connection

Storage

capacity

a

b

c

d

e

f

g

h

k

USG /

ltr

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

79 /

300

3

76

10¼

260

34½

875

39

995

43¾

1115

53¼

1355

63

1600

13

333

4

101

VITOCELL 100-B 5

Page 6

Technical Data

5

2

8

5

6

5

6

-

0

1

119 USG / 450 ltr Tank

TH

MA

h

k

DHW

BWS

RT

BWR

SCS

SCR

a

*1

c

b

DCW/D

Legend

Section A-B

SW1

*1

IO Inspection and cleanout opening

D Drain

BWR Boiler water return (upper coil)

SCR Solar collector return (lower coil) or

boiler return

BWS Boiler water supply (upper coil)

SCS Solar collector supply (lower coil) or

boiler supply

SW2

g

f

e

d

Total height

DCW Domestic cold water

SW1*1Sensor well for tank temperature

sensor of boiler control at BWS

level

SW2 Sensor well for the lower

thermometer at SCS level

DHW Domestic hot water

RT Recirculation tapping

TPV Temperature and pressure relief

valve

MA Protective magnesium anode

Total width

*1

For solar heating systems Viessmann

recommends placement of the DHW tank

temperature sensor of the solar control in

Total depth

the solar collector return (SCR). This

requires a brass elbow with sensor well

included in the accessory pack.

The DHW tank temperature sensor of the

boiler control is placed in the SW1 sensor

well (see installation example on page 8).

DHW tank temperature sensor

in solar heating applications

119 USG / 450 ltr

Storage

capacity

a

C

b

c

d

e

f

DHW tank temperature sensor for solar

application (included with solar control

unit)

g

h

Brass elbow with sensor well

(accessory pack)

k

Solar collector return connection

USG /

ltr

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

119 /

450

4 ¼

107

13¾

349

363/

924

1044

483/

1230

567/

1444

70 ¼

1784

165/

422

100

8

41

8

8

8

4

6 VITOCELL 100-B

Page 7

Technical Data

5

2

8

5

6

5

6

-

0

1

Pressure drop on heating water side Domestic hot water pressure drop

of a single coil

“ w.c.

mbar

40 100

32 80

24 60

20 50

16 40

12 30

400

320

240

200

160

120

“w.c.

mbar

C

80

40

32

24

20

16

12

8

4

3.2

2.4

2

1.6

1.2

Pressure drop

9 2 000

13 3 000

18 4 000

22 5 000

2.2 500

2.6 600

3.5 800

4.4 1 000

26 6 000

ltr/h

31 7 000

44 10000

GPM

Waterflow

8 20

4 10

3.2 8

2.4 6

2 5

1.6 4

1.2 3

0.8 2

0.4 1

Pressure drop

2.2 500

3.5 800

4.4 1 000

2.6 600

Waterflow

79 USG / 300 ltr

ltr/h

9 2 000

13 3 000

18 4 000

22 5 000

GPM

119 USG / 450 ltr

Upper indirect coil, 300 ltr capacity

Lower indirect coil, 300 ltr and upper

indirect coil, 450 ltr capacity

Lower indirect coil, 450 ltr capacity

Domestic hot water draw rate

Storage tank contents heated to 140ºF / 60ºC, boiler not reheating

Storage capacity USG

ltr

Domestic hot water draw

Water with t = 140ºF / 60ºC (constant)

USG

ltr

Percentage tank volume 37% 50%

VITOCELL 100-B 7

79

300

32

110

119

450

53

220

Page 8

Standard Equipment/Product Installation

5

2

8

5

6

5

6

-

0

1

Standard Equipment

Vitocell 100-B (79 USG / 300 ltr

capacity) DHW Tank

DHW tank made from steel with

Ceraprotect enamel coating.

–

2 welded sensor wells for DHW tank

temperature sensor, i.e. aquastat, and

the thermometer

–

adjustable leveling bolts

–

protective magnesium anode

–

fitted thermal insulation made from

hard PUR foam

–

threaded elbow with sensor well

The color of the epoxy-coated sheet

metal casing is Vitosilver.

The following are packed separately and

attached to the crate:

–

1 brass elbow with sensor well

–

1 Loctite package

–

1 temperature and pressure relief valve

–

2 thermometers °F / °C

–

7 brass adaptors (1”)

–

1 brass tee (1”)

–

1 brass hex bushing (1”x¾”)

–

1 brass cap (1”)

Product Installation

Vitocell 100-B (119 USG / 450 ltr

capacity) DHW Tank

DHW tank made from steel with

Ceraprotect enamel coating.

–

2 welded sensor wells for DHW tank

temperature sensor, i.e. aquastat, and

the thermometer

–

protective magnesium anode

–

fitted thermal insulation made from soft

PET insulation, packed separately

–

threaded elbow with sensor well

–

adjustable leveling bolts

–

protective magnesium anode

The color of the plastic-coated thermal

insulation is Vitosilver.

The following are packed separately and

attached to the crate:

–

5 brass adaptors (1”)

–

2 brass adaptors (1¼”)

–

1 Loctite package

–

1 temperature and pressure relief valve

–

1 brass tee (1¼”)

–

1 brass elbow with sensor well

–

1 brass cap

–

2 thermometers °F / °C

–

1 plug (R1½”)

Domestic hot water connection

Domestic hot water supply

DHW recirculation line

DHW recirculation pump

Spring-loaded flow check valve

Discharge pipe

Pressure and temperature relief valve

Shut-off valve

Drain

Domestic cold water supply lines

Backflow preventer

Domestic cold water inlet

Precharged expansion tank

(required where backflow preventer is

installed; check local plumbing codes

and requirements)

Thermostatic mixing valve/anti-scald

valve for solar applications (field

supplied)

WARNING

Due to the potentially high DHW

temperatures generated by the solar

heating system, the domestic hot

water temperature must be limited to a

maximum of 140°F/60°C by installing

a mixing device, e.g. a thermostatic

mixing valve. The mixing device does

not completely eliminate the risk of

scalding at the tap. The installation of a

mixing tap is required.

8 VITOCELL 100-B

Page 9

Installation example

5

2

8

5

6

5

6

-

0

1

System Design Guidelines

Solar collector

Vitocell 100-B

Filling valve

Solar-Divicon (pumping station)

Recirculation pump

Anti-scald tempering valve

HC Heating circuit

B Oil/Gas-fired boiler

DCW Domestic cold water

DHW Domestic hot water

T&P Temperature and pressure relief valve

VITOCELL 100-B 9

Page 10

System Design Guidelines

5

2

8

5

6

5

6

-

0

1

Sensor wells

The sensor wells are welded into the DHW

tank.

Ø7/8” / 21 mm

Ø5/8” / 16 mm

8” / 200 mm

Sensor wells for solar operation

For solar heating systems, Viessmann

recommends placement of the DHW tank

temperature sensor in the solar collector

return. This requires installation of a a brass

elbow with sensor well included in the

accessory pack.

c

b

e

d

Dimension 79/300 119/450

a

b

c

d

e

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

a

6 1/4

160

5.9

150

7/8”

22

¼

6.5

1

/

3

8

8.7

220

7.9

210

7/8”

22

6.5

1

¼

Temperature and pressure

relief valve

A temperature and pressure relief valve

(T&P relief valve) is supplied with the tank.

The heating contractor must install the

valve on each tank in a method meeting

code requirements. If local codes require a

different relief valve, substitute the

manufacturer’s supplied valve. The tank is

approved for 150 psig. Maximum operating

pressure is 150 psig.

The T&P relief valve supplied with the tank

is tested under ANSI Z21.22 Code for Relief

Valves and Automatic Gas Shut-off Devices

for Hot Water Supply Systems.

Backflow preventers

Where backflow preventers are required, a

domestic water expansion tank installation

is recommended in the cold water inlet

piping before the cold water enters the

Vitocell. For the backflow device, observe

local plumbing codes and regulations.

Watts Model

40XL-8

ASME pressure

steam rating

CSA temperature

steam rating

Relief

temperature

Inlet thread

Outlet thread

/

3

8

150 psig

(US and Canada)

1438 MBH

205 MBH

210ºF (99ºC)

¾” male

¾” female

Warranty excerpt

Our warranty for domestic hot water tanks

states that the water to be heated must be

of drinking (potable) water quality and that

any water treatment equipment in use must

function correctly.

Viessmann accepts no responsibility for

damage howsoever caused and reserves the

right to withdraw the product warranty if the

product has been improperly installed or

misapplied by the installer, contractor or end

user. In order to qualify for product warranty,

strict adherence to the installation and

service manuals must be assured. In the

event that Viessmann non-approved

components are utilized, Viessmann reserves

the right to withdraw all expressed or implied

warranties without written notice.

The water to be heated with the Vitocell

must be drinking (potable) water quality. If

the tank is used to heat other media, the

warranty will be null and void. Damage

resulting from excessive pressure or

temperature is clearly not the responsibility

of Viessmann.

The amount of chloride and sulfate

acceptable to the tank is limited. In areas

where high concentrations of chloride and

sulfate are present in drinking water, please

consult Viessmann for directions.

For full warranty details, please read the

product warranty card.

Heating water supply temperature

over 230ºF / 110ºC

These operating conditions require the

installation of an additional safety high limit

into the DHW storage tank, preventing the

domestic hot water temperature from rising

above 203 ºF/ 95 ºC. A domestic hot water

tempering valve must be used.

10 VITOCELL 100-B

Page 11

VITOCELL 100-B 11

5

2

8

5

6

5

6

-

0

1

Page 12

5

2

8

5

6

5

6

-

0

1

Printed on environmentally friendly

(recycled and recyclable) paper.

12 VITOCELL 100-B

Technical information subject to change without notice.

Loading...

Loading...