Page 1

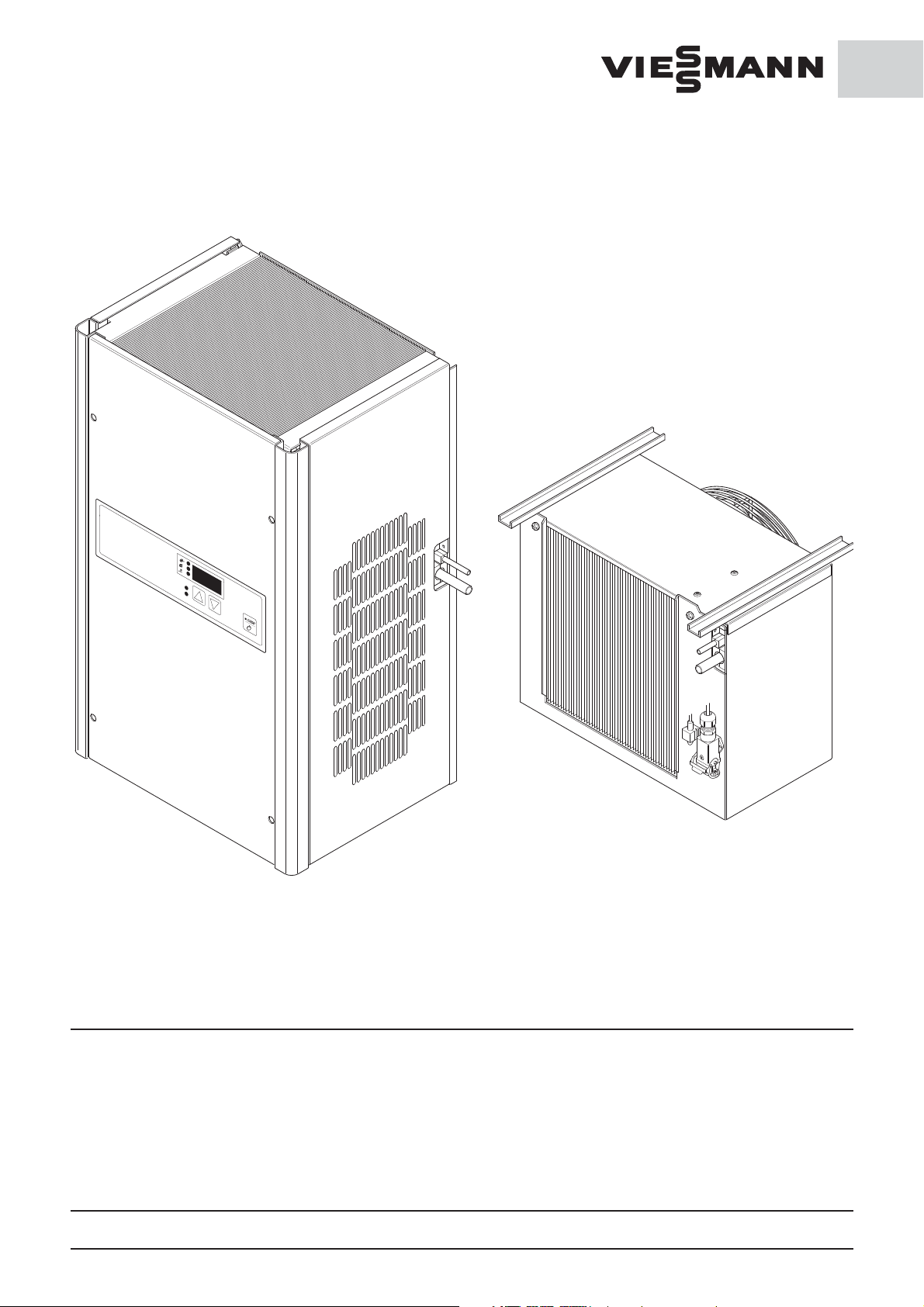

Split refrigeration units

GB

Assembly manual

5237211-09 GB

Please read carefully the following prior to beginning work on the refrigeration unit:

Assembly, maintenance, cleaning and repair may only be Work on the refrigeration unit may only be carried out if the

done by companies specialising in cooling technology. plug is removed from the power supply. Suitable warnings

Technical changes and manipulation are prohibited. must be posted to prevent the refrigeration unit from being

restarted while work is in progress. The regulations of VDE

In case of non-compliance our guarantees are void. 0105 Part 1 - for work on electrical equipment must be

obser ved.

General notice (liability): the details of this technical documents serve for description. Consents regarding the availability of certain features or

regarding a certain purpose always require a special written agreement.

Page No. 5237320-09 GB Right reserved to make technical changes! Version 02.14

Page 2

GB

Table of contents

1. General notes

1.1 Extract from the conditions of guarantee

1.2 Requirements for installation area

1.3 Transport

1.4 Supplied condition

1.5 Unpacking and handling

1.6 Cleaning and maintenance of the refrigeration unit

2. Installation of the refrigeration unit in a Viessmann coldroom

2.1 Assembly of the condensation unit

2.1.1 Drilling diagram for fastening the large condensation unit

2.1.2 Drilling diagram for fastening the small condensation unit

2.2 Assembly of the evaporation unit

2.2.1 Drilling diagram for fastening the large evaporation unit

2.2.2 Drilling diagram for fastening the small evaporation unit

2.3 Installation of pipes

2.4 Installation of electrical cables

2.5 Assembly of the condensate run-off tubing

3. Electrical power supply to the coldroom

3.1 Power supply

3.2 Pre installed socket (Only refrigeration units FS 1800 and FS 2400)

3.3 Connecting the door contact switch

3.3.1 Electronic control SE

3.4 Connecting the alarm

3.5 Connecting remote and central controls

3.6 Connector diagram for electronic control SE

General notice (liability): the details of this technical documents serve for description. Consents regarding the availability of certain features or

regarding a certain purpose always require a special written agreement.

Page No. 5237321-07 GB Contents Right reserved to make technical changes!

Page 3

1. General notes

GB

1.1 Extract from the conditions of guarantee

No guarantee is assumed for damage resulting from

improper use, improper assembly or operation by the

buyer or other parties, natural wear, improper or negligent

handling, or chemical/electro chemical influence, insofar as

this is not our fault, or resulting from in attention to the

assembly, operating and maintenance instructions,

improper alterations or maintenance done by the buyer or

third parties, or as a result of use of parts supplied by other

manufacturers.

1.2 Requirements for installation area / Intended use

For economical operation of the refrigeration unit, the

ambient temperature should be between +5°C to +25°C.

The room must be well ventilated to remove heat

generated. Direct heat radiation on the refrigeration unit

must be avoided. Heating the room must also be avoided,

otherwise the comsumption of electrical power will

increase.

lf installed outdoors, a roof must be provided.

lf ambient temperature is below 10°C an oil heating is to be

installed. Viessmann can supply this as an optional

accessory.

The refrigeration unit is designed to provide free access in

regard to suction and release of air. lf air ducts are required,

these must be designed and installed by a cooling

specialist company.

There must be enough space in front of the suction and air

release vents of the refrigeration unit to guarantee proper

ventilation:

- at least 250 mm in front of all suction and air release

vents

Do not install units in plants where there is a danger

of fire.

According to DIN VDE 0100-482 (VDE 0100 Part 482):

1997-08 these are rooms or places in rooms or out doors

where there is a danger that, depending on the local and

plant conditions, esily flammable materials in dangerous

quantities could be close enough to the electrical

equipment such that higher temperatures or electrical

sparks could cause fire. These could be: work or drying

areas, storerooms, or parts of room, as well as such areas

outdoors, e.g. paper, wood, textile or wood working plants,

hay, straw, jute, and flax storing areas.

- According to BGR 500, chapter 2.35 or local regulations

for operation and maintenance. (qualified staff)

1.3 Transport

Because of the oil in the condenser, the refrigeration

unit may only be transported in a standing position. lf

the unit is to be transported further, only the original

packing may be used.

1.4 Supplied condition

The refrigeration unit is delivered ready for operation,

with wire and plug, packed in a carton.

1.5 Unpacking and handling

- Prior to and during unpacking of the refrigeration

unit, visual inspection must be carried out to check

if any damage occurred during transportation.

- Please inspect for loose parts, dents, scratches,

visible loss of oil, etc.

- During handling, the unit should be gripped only

on the housing or on the frame.

- Prior to disposing of the packing, it should be

inspected for presence of loose parts.

- To process any claims, we require an exact

description of the problem (with picture), as well as

the designation and serial number of the unit.

- To prevent damaging of the unit, it may only be

transported and stored in the position of use. Non

compliance will cause loss of guarantee protection.

General notice (liability): the details of this technical documents serve for description. Consents regarding the availability of certain features or

regarding a certain purpose always require a special written agreement.

Page No. 5237322-06 GB 1 - 1.5 Right reserved to make technical changes!

Page 4

GB

1.6 Cleaning and maintenance of the refrigeration unit

During cleaning the refrigeration unit and the coldroom

should be cut off from the power supply.

Remove the plug from the power supply during such

work and secure against the plug being reinserted, or

switch off the power supply at source and secure

against switching on.

- The cooling unit should be inspected periodically after

beginning operation and, if necessary, cleaned.

Depending on requirements, the intervals between

inspection and cleaning have to be determined.The

cleaning intervals depend on the condition of the

surroundings.

- The condenser and evaporator can be cleaned with a

soft brush, compressed air or, in case of oil residues,

with a high pressure cleaner. Do not use any sharp or

pointed objects. The fins should not be bent or

damaged during cleaning.

By courtesy of intensive contamination with solvents or

outgasing synthetics natural discolorations can appear

on the SilverProtec surface. These are unproblematicly

removable with common purifiers based on oxygen or

with bleaching agents with a reaction time conforming

to the gravity of discoloration. The purifiers Vanish

Oxiaction from Hoffmanns or Sil OXIperfect from Henkel

perform well. Both products are available in trade. For

the cleaning of vertical areas on which the sprayed

purifier would slide down without a reaction time, we

recommend to spray the purifier on a cleaning rag and

then press it slightly on the discoloured spot so that the

rag doesn‘t slip off. Remove the rag after the reaction

time and wipe the treated spot again.

Pay attention to the product information!

General notice (liability): the details of this technical documents serve for description. Consents regarding the availability of certain features or

regarding a certain purpose always require a special written agreement.

Page No. 5237313-01 GB 1.6 Right reserved to make technical changes!

Page 5

2. Installation of a refrigeration unit

in a Viessmann coldroom

2.1 Assembly of the condenser unit

The condenser unit is assembled outside of the coldroom.

The length of the electric cable on the evaporation unit is

15 m, including plug. This is also the maximum distance

between condenser and evaporator.

The minimum distance to the ceiling must be 250 mm to

guarantee proper ventilation

Attention!

This minimum distance must be checked prior to

assembly of the evaporator!

GB

Attention!

The assembly and installation of a split unit must be

done by an approved specialist!

Release the locking screws on the front panel (4).

Remove front panel.

Anchor the evaporation unit on the drill holes provides at

the back of the unit on the wall using the anchoring

material provided.

General notice (liability): the details of this technical documents serve for description. Consents regarding the availability of certain features or

regarding a certain purpose always require a special written agreement.

Page No. 5237323-06 GB 2 - 2.1 Right reserved to make technical changes!

Page 6

GB

2.1.1 Drilling diagram for fastening the large condensation unit

(CS 2000, CS 2800, FS 1400, FS 1800, FS 2400)

Ceiling

Distance to wall 60 mm.

2.1.2 Drilling diagram for fastening the small condensation unit

(CS 0900, CS 1300, FS 0900)

Distance to wall 60 mm

240 mm

Wall

Conections for

refrigerant and electro

min. 60 mm

220 mm

600 mm

420 mm

12 mm

Two drill holes

with 12 mm

lines to the evaporator

Ceiling

427 mm

Two drill holes

with 12 mm

240 mm

12 mm

min.

390 mm

94 mm

250 mm

850 mm

290 mm

min.

250 mm

Wall

Conections for

refrigerant and electro

lines to the evaporator

min. 60 mm

700 mm

94 mm

General notice (liability): the details of this technical documents serve for description. Consents regarding the availability of certain features or

regarding a certain purpose always require a special written agreement.

Page No. 5237334-05 GB 2.1.1 - 2.1.2 Right reserved to make technical changes!

Page 7

2.2 Assembly of the evaporation unit

The evaporator is assembled within the coldroom on the

ceiling.

Using the two drawings 2.2.1 and 2.2.2 four holes are drilled

on the ceiling.

Cut edges should be rust proofed.

Anchor evaporation unit with enclosed plastic scres on the

U-profiles on the coldroom ceiling.

2.2.1 Drilling diagram for large evaporation unit

(CS 2000, CS 2800, FS 1400, FS 1800, FS 2400)

GB

min. 35 min. 80

Distance to wall 140 mm for wall thickness 150 mm.

Distance to wall 230 mm for wall thickness 60 mm.

2.2.2 Drilling diagram for small evaporation unit

(CS 0900, CS 1300, FS 0900)

Distance to wall 165 mm for wall thickness 150 mm.

Distance to wall 255 mm for wall thickness 60 mm.

Exhaust vent

Ceiling

Wall

295 mm

Suction vent

475 mm

Distance to wall 140 - 230 mm

min. 15 min. 15

Exhaust vent

Ceiling

Wall

255 mm

Wall

ø 11 mm

Wall

Suctionvent

381 mm

Distance to wall 165 - 255 mm

General notice (liability): the details of this technical documents serve for description. Consents regarding the availability of certain features or

regarding a certain purpose always require a special written agreement.

Page No. 5237324-06 GB 2.2 - 2.2.2 Right reserved to make technical changes!

ø 11 mm

Page 8

GB

2.3 Installation of conduits

Solder the evaporator to the refrigeration unit at the points

(P and Q) on the refrigeration unit using a suitable copper

pipe with the soldering points on the evaporator.

Test all soldering points for sealing.

The length of the conduit may not exceed 15 m!

Pipe diameter in mm

Unit CS 900 CS 1300 CS 2000 CS 2800

Fluid Conduit (P) 6 6 6 10

Suction Pipe (Q) 10 12 12 16

Unit FS 900 FS 1400 FS 1800 FS 2400

Fluid Conduit (P) 6 10 10 10

Suction Pipe (Q) 12 16 16 16

P

Q

2.4 Laying electrical cables

The electrical cables should be laid along the pipes.

Insert the electrical plug into the proper socket on the

refrigeration unit template.

Attention!

Do not connect electrical power supply until beginning

of operation - Danger!

General notice (liability): the details of this technical documents serve for description. Consents regarding the availability of certain features or

regarding a certain purpose always require a special written agreement.

Page No. 5237325-06 GB 2.3 - 2.4 Right reserved to make technical changes!

Page 9

2.5 Assembly of the condensate run-off tubing

Place plastic ring (D) over the condensate run-off tubing (B).

Insert heating (A) in the condensate run-off tubing (B) which

should be straightened for easier insertion.

GB

D

B

Condensate run-off tubing (B) from inside through hole

(G, ø 31 mm) in the coldroom wall (F). If necessary, a

lubricant can be used.

Condensate run-off tubing (B) on the drain plug (E) of the

evaporation plate.

Cover hole (G) for condensate run-off tubing (B) with the

plastic ring (D).

See separate assembly notes for all split units regarding

pipe drain (H).

D

A

G

B

E

D

B

FH

General notice (liability): the details of this technical documents serve for description. Consents regarding the availability of certain features or

regarding a certain purpose always require a special written agreement.

Page No. 5237326-06 GB 2.5 Right reserved to make technical changes!

Page 10

GB

3. Electrical power supply to coldroom

The refrigeration unit has a pre installed multiple pole socket

for electrical power supply in the coldroom for other

purposes (e.g. lighting, max. 250 Watt).

Attention!

Do not turn on electrical power until operation begins

danger to life!

3.1 Connection

Work on the electrical connections and protective devices

may only be undertaken by a specialist company according

to IEC 364, local regulations and the conditions of the

respective energy supply companies!

Insert plug only in a properly grounded socket.

(AC 230 V ~ 50 Hz)

Connector L1-4 must be removed over 0°C

Power supply

230 V ~, 50 Hz

L1

N

Multiple-pole

plug

Door switch

Pressure

compensator

with heating

(optional)

2

3

1

Distribut

A*

B*

C*

Door frame

heating

optional

2

4

L1

N

3

BK1

BK2

BK3

BK4

5

6

Coldroom

light

max.

60 W

1

Cable foamed into

door frame

BK5

Controls

Switch (2-polig)

with light display

for coldroom

light

Connection diagram for multiple-pole plug electrical power supply for coldroom (Viessmann freezer)

with door contact switch

Connector L1-4 must be removed over 0°C

Power supply

230 V ~, 50 Hz

L1

N

Multiple-pole

plug

Distribut

2

3

1

Door frame

heating

optional

4

2

A*

B*

C*

L1

N

3

BK1

BK2

BK3

BK4

Coldroom

light

1

Cable foamed into

door frame

BK5

max.

60 W

Controls

Pressure

compensator

with heating

(optional)

5

6

Switch (2-polig)

with light display

for Coldroom

light

Connection diagram for multiple-pole plug -

electrical power supply for coldroom (Viessmann freezer)

without door contact switch

Multiple-pole

plug

Connection diagramm for multiple-pole plug - door

contact switch (without electrical power supply for

Door switch

General notice (liability): the details of this technical documents serve for description. Consents regarding the availability of certain features or

regarding a certain purpose always require a special written agreement.

Page No. 5237307-06 GB 3 - 3.1 Right reserved to make technical changes!

Page 11

3.2 Installed plug

(Only refrigeration units FS 1800 and FS 2400)

Release the inside right hand screws on the right side section

(Y), push side section up and remove. Fix CEE plug (Q) on the

reverse side of the floor plate (Z) of the refrigeration unit

with the enclosed screws (J). Insert side section (Y) again,

push down and secure with screws.

Insert CEE coupling ( 5x16 A, AC 400 V 3 ~ 50 Hz) in CEE plug.

GB

Y

T

3.3 Connecting door contact switch

With coldroom door open, the evaporation ventilator should

be switched off. We recommend the installation of a switch

free of potential electricity.

Connection is made via the multiple pole socket on the

refrigeration unit.

In the condition supplied, the unit functions properly

without an external door contact switch.

3.3.1 Electronic control SE

lf a doorswitch is connected to the unit, the sliding switch

on the control must be moved to the position with

doorswitch).The switch can be reached after removing

the front panel.

J

Q

Z

General notice (liability): the details of this technical documents serve for description. Consents regarding the availability of certain features or

regarding a certain purpose always require a special written agreement.

Page No. 5237308-05 GB 3.2 - 3.3.1 Right reserved to make technical changes!

Page 12

GB

3.4 Connecting the alarm contact

The electronic control SE has a potential free alarm contact

to connect to an appropriate alarm (max. 10 A, AC 230 V ~).

The connection is on the back of the plate.

A3

CNCNO

A3

Plate

Contact plan:

Contacts CNC = Opener

Contacts CNO = Close

potential-free

Alarm

AC 10A/230 V

3.5 Connecting remote and central controls

The electronic control SE has a nine pole D Sub plug on the

back of the plate. The serial interface is the connection for

the remote control and can be connected to a central

controlsystem.

General notice (liability): the details of this technical documents serve for description. Consents regarding the availability of certain features or

regarding a certain purpose always require a special written agreement.

Page No. 5237329-05 GB 3.4 - 3.5 Right reserved to make technical changes!

Page 13

Liquely

Vent 1

A8

Condens

A6

Evaproate

Vent

A4

Defro

haeting

A2

Heating

230V / 50 Hz

E1

5 x 1

9 - pol.

D - Sub

ext.

Alarm

A3

Temp.sensor

GB

E2

A8

L1PEN

BN

GNYE

A8

M

~

1

BU

A9

A7

L1PEN

BN

GNYE

A7

BU

Oil

heating

A7

A6

L1PEN

BN

GNYE

A6

M

~

1

BU

P

Multi-Pole

lead

230V / 50 Hz

A5

321

BNBKBU

A5

214

A5

L1PEN

BN

A4

A4

M

1

GNYE

~

BU

A2

L1PEN

BN

GNYE

A2

Pressostat

BU

A1

A1

L1PEN

BK

GNYE

BU

T

BN

A1

Output 230 V/50 Hz

and door contact

E1

L1PEN

BN

GNYE

E1

BU

5 x 1

D - Sub

Socket

Net filter

9 - pol

Serial

interface

A3

CNCNO

A3

Potential-free

Alarm

AC 10A/230 V

E2

2

BN

E2

1

BU

Fuse Box

for FS 1800 SE

and FS 2400 SE

M

For FS 1800 SE and

FS 2400 SE CEE-

pre-installed plug

~

3

3.6 Plus connecting diagram for electronic regulator SE

A1 Plug 230 V / 50 Hz and door contact

A2 defroster heating

A3 Potencial-free alarm contact (s. Ch. 3.4)

A4 Evaporation ventilator

A5 Pressostat

A6 Condenser

A7 Oil heater (Option)

A8 Condenser ventilator

E1 Power supply 230 V / 50 Hz

DIN/

IEC

BK black

BN brown

BU blue

GNYE green/yellow

GB

E2 Coldroom temperature sensor

5 x 1 Option Interface

General notice (liability): the details of this technical documents serve for description. Consents regarding the availability of certain features or

regarding a certain purpose always require a special written agreement.

Page No. 5237330-05 GB 3.6 Right reserved to make technical changes!

and fuse box

Page 14

GB

Viessmann Kältetechnik GmbH

Schleizer Straße 100

95030 Hof/Saale

Germany

Phone +49 (0) 92 81/ 81 4 - 0

Fax +49 (0) 92 81/ 81 4 - 2 69

kaeltetechnik@viessmann.de

www.viessmann-kaeltetechnik.de

Your responsible refrigeration service:

General notice (liability): the details of this technical documents serve for description. Consents regarding the availability of certain features or

regarding a certain purpose always require a special written agreement.

Page No. 00044224-07 GB

Loading...

Loading...