Page 1

Installation Instructions

for use by heating contractor

Vitodens 200-W, Series B2HB

Models 45, 57

Wall-mounted, gas-fired condensing boiler

For operation with natural gas and liquid propane gas

Heating input: 32 to 199 MBH

9 to 58 kW

VITODENSr 200-W

H

5680 493 - 05 12/2015

Product may not be exactly as shown

IMPORTANT

Read and save these instructions

for future reference.

Please file in Service Binder

Page 2

Safety

Vitodens 200-W B2HB 45, 57 Installation

Safety, Installation and Warranty Requirements

Please ensure that these instructions are read and understood before commencing installation. Failure to comply with

the instructions listed below and details printed in this manual can cause product/property damage, severe personal

injury, and/or loss of life. Ensure all requirements below are understood and fulfilled (including detailed information

found in manual subsections).

Product documentation

Read all applicable documentation before commencing

installation. Store documentation near boiler in a

readily accessible location for reference in the future

by service personnel.

For a listing of applicable literature,

please see section entitled “Important

Regulatory and Safety Requirements”.

Warranty

Information contained in this and

related product documentation must

be read and followed. Failure to do

so renders the warranty null and void.

Licensed professional heating contractor

The installation, adjustment, service and maintenance

of this equipment must be performed by a licensed

professional heating contractor.

Please see section entitled

“Important Regulatory and Installation

Requirements”.

Contaminated air

Air contaminated by chemicals can cause by-products

in the combustion process, which are poisonous to

inhabitants and destructive to

Viessmann equipment.

For a listing of chemicals which

cannot be stored in or near the

boiler room, please see subsection

entitled “Mechanical room” in the

“Installation Instructions”.

Advice to owner

Once the installation work is complete, the heating

contractor must familiarize the system operator/

ultimate owner with all equipment, as well as safety

precautions/requirements, shutdown procedure, and

the need for professional service annually before the

heating season begins.

WARNING

Installers must follow local regulations with respect to

installation of carbon monoxide detectors. Follow the

Viessmann maintenance schedule of the boiler contained

in this manual.

Operating and Service Documentation

It is recommended that all product documentation such as

parts lists, operating and service instructions be handed

over to the system user for storage. Documentation is to

be stored near boiler in a readily accessible location for

reference by service personnel.

22

Carbon monoxide

Improper installation, adjustment, service and/or

maintenance can cause flue products to flow into

living space. Flue products contain poisonous carbon

monoxide gas.

For information pertaining to the

proper installation, adjustment, service

and maintenance of this equipment to

avoid formation of carbon monoxide,

please see subsection entitled

“Mechanical room” and “Venting

requirements” in the “Installation Instructions”.

Fresh air

This equipment requires fresh air for

safe operation and must be installed

ensuring provisions for adequate

combustion and ventilation air exist.

For information pertaining to the

fresh air requirements of this product,

please see subsection entitled

“Mechanical room” in the “Installation

Instructions”.

Equipment venting

Never operate boiler without an installed venting

system. An improper venting system can cause

carbon monoxide poisoning.

For information pertaining to

venting and chimney requirements,

please see section entitled “Venting

Connection”. All products of

combustion must be safely vented

to the outdoors.

WARNING

This boiler requires fresh air for safe operation and must

be installed with provisions for adequate combustion

and ventilation air (in accordance with local codes and

regulations of authorities having jurisdiction).

Do not operate this boiler in areas with contaminated

combustion air. High levels of contaminants such as

dust, lint or chemicals can be found at construction

sites, home renovations, in garages, workshops, in dry

cleaning/laundry facilities, near swimming pools and in

manufacturing facilities.

Contaminated combustion air will damage the boiler

and may lead to substantial property damage, severe

personal injury and/or loss of life. Ensure boiler/burner is

inspected and serviced by a qualified heating contractor

at least once a year in accordance with the Service

Instructions of the boiler.

5680 493 - 05

Page 3

Vitodens 200-W B2HB 45, 57 Installation

Safety, Installation and Warranty Requirements

Safety

Fiberglass wool and ceramic fiber materials

WARNING

Inhaling of fiberglass wool and/or ceramic fiber

materials is a possible cancer hazard. These materials

can also cause respiratory, skin and eye irritation.

The state of California has listed the airborne fibers of

these materials as a possible cancer hazard through

inhalation. When handling these materials, special care

must be applied.

Suppliers of ceramic fiber products recommend the

following first aid measures:

- Respiratory tract (nose and throat) irritation:

If respiratory tract irritation develops, move the person

to a dust free location.

- Eye irritation: If eyes become irritated, flush immediately

with large amounts of lukewarm water for at least 15

minutes. Eyelids should be held away from the eyeball

to ensure thorough rinsing. Do not rub eyes.

- Skin irritation: If skin becomes irritated, remove soiled

clothing. Do not rub or scratch exposed skin. Wash area

of contact thoroughly with soap and water. Using

a skin cream or lotion after washing may be helpful.

- Gastrointestinal irritation: If gastrointestinal tract

irritation develops, move the person to a dust free

environment.

Suppliers of fiberglass wool products recommend the

following precautions be taken when handling these

materials:

- Avoid breathing fiberglass dust and contact with

skin and eyes.

- Use NIOSH approved dust/mist respirator.

- Wear long-sleeved, loose fitting clothing, gloves

and eye protection.

- Wash work clothes separately from other clothing.

Rinse washer thoroughly.

- Operations such as sawing, blowing, tear-out and

spraying may generate airborne fiber concentration

requiring additional protection.

First aid measures

- If eye contact occurs, flush eyes with water to remove

dust. If symptoms persist, seek medical attention.

- If skin contact occurs, wash affected areas gently

with soap and warm water after handling.

WARNING

Appliance materials of construction, products of

combustion and the fuel contain alumina, silica, heavy

metals, carbon monoxide, nitrogen oxides, aldehydes

and/or other toxic or harmful substances which can

cause serious injury or loss of life and which are

known to the State of California to cause cancer,

birth defects and other reproductive harm. Always

use proper safety clothing, respirators and equipment

when servicing or working nearby the appliance.

About these Installation Instructions

Take note of all symbols and notations intended to draw attention to potential hazards or important product

information. These include “WARNING”, “CAUTION”, and “IMPORTANT”. See below.

Warnings draw your attention to the presence of

WARNING

Indicates an imminently hazardous situation which,

if not avoided, could result in loss of life, serious injury

or substantial product/property damage.

CAUTION

Indicates an imminently hazardous situation which,

if not avoided, may result in minor injury or product/

property damage.

IMPORTANT

potential hazards or important product information.

Cautions draw your attention to the presence of

potential hazards or important product information.

Helpful hints for installation, operation or maintenance

which pertain to the product.

This symbol indicates that additional, pertinent

information is to be found.

This symbol indicates that other instructions must

be referenced.

5680 493 - 05

3

Page 4

Table of Contents

Vitodens 200-W B2HB 45, 57 Installation

Page

Safety

General Information

Set-up

Safety, Installation and Warranty Instructions................2

Product documentation.............................................2

Warranty................................................................2

Licensed professional heating contractor....................2

Contaminated air....................................................2

Advice to owner......................................................2

Carbon monoxide.....................................................2

Fresh air................................................................2

Equipment venting...................................................2

About these Installation Instructions..........................3

Important Regulatory and Installation Requirements........5

Codes.......................................................................5

Instructing the system user......................................5

Initial start-up..........................................................5

Working on the equipment.......................................5

Technical literature..................................................5

For installations on the Commonwealth of

Massachusetts........................................................6

CSD-1 field testing of high limit switches..................6

Applicability..............................................................8

Product Information....................................................8

Multi boiler system..................................................8

Mechanical Room.....................................................9

Before Set-up........................................................10

Minimum Clearances.................................................10

Recommended minimum service clearances..............10

Boiler Connections

Preparing the Connections.........................................11

Wall Mounting.........................................................13

Fitting the wall mounting bracket............................13

Installing the wall mounting bracket.........................13

Installation of mounting bracket on

brick/concrete wall................................................13

Boiler mounting bracket and frame...........................14

Installation on wood studs......................................14

Installation on metal studs....................................14

Frame Mounting....................................................16

Models B2HB 45, 57 Frame Mounting....................17

Connections............................................................18

Connecting power..................................................18

Boiler venting........................................................18

Proper piping practice.............................................18

Gas shut-off valve connection.................................18

Gas connection and piping......................................19

Gas piping pressure test.........................................20

Heating water connections......................................20

DHW storage tank information.................................21

Making the DHW connections...............................21

Accessing the control unit connections.....................22

Routing the connecting cables.................................24

Connecting DHW sensor.........................................25

Setting altitude parameters.....................................25

Control base.........................................................26

External accessory connection box..........................27

Condensate connection........................................28

4

5680 493 - 05

Page 5

Vitodens 200-W B2HB 45, 57 Installation

Table of Contents

Page

Boiler Connections (continued)

Control Connections

Safety Connections and Pressure Testing.....................29

Installing boiler safety devices.................................29

Low water cut-off..................................................30

Performing a boiler pressure test.............................30

Waterside Flow........................................................30

Waterside flow (primary circuit)...............................30

Installation Examples.................................................32

General.................................................................32

Clearances............................................................32

System Layout 1-9...................................................33

Alternative DHW Connection....................................42

Boiler in Heating/Cooling............................................43

Boiler in heating/cooling application..........................43

Boiler with Low Water Cut-off..................................44

Boiler with low water cut-off (remote-mounted

field supplied)........................................................44

Venting Connection.................................................42

Electrical Connections..............................................43

Power supply connection of accessories...................43

Connection of accessories.......................................43

Overview of Electrical Connections,

Models B2HB 45 and 57...........................................44

Additional Information

Accessing the X3 Plug..............................................48

Connecting the Low-loss Header Sensor......................48

Connecting the Outdoor Temperature Sensor..............49

External 0-10 Volt Signal Connection.........................50

24 VAC Thermostat Connection...............................51

LON Module..........................................................52

Installing the LON module to the boiler

control board.........................................................52

Connecting the LON module cable...........................52

Accessory Kit..........................................................53

Accessory kit connections for heating circuit

with mixing valve..................................................53

Closing the Control Unit............................................53

Closing the control cover .......................................52

Closing the External Accessory Connection Box............53

Reinstalling the Front Enclosure Panel..........................55

Instructing the system user.....................................55

Technical Data.........................................................57

Installation Fittings....................................................59

Lighting and Operating Instructions.............................60

5680 493 - 05

5

Page 6

General Information

Important Regulatory and Installation Requirements

Codes

The installation of this unit shall be in accordance with

local codes or, in the absence of local codes, use CAN/

CSA-B149.1 or .2 Installation Codes for Gas Burning

Appliances for Canada. For U.S. installations use the

National Fuel Gas Code ANSI Z223.1. Always use latest

editions of codes.

In Canada all electrical wiring is to be done in accordance

with the latest edition of CSA C22.1 Part 1 and/or local

codes. In the U.S. use the National Electrical Code ANSI/

NFPA 70. The heating contractor must also comply with

both the Standard for Controls and Safety Devices for

Automatically Fired Boilers, ANSI/ASME CSD-1, and

the Installation Code for Hydronic Heating Systems,

CSA B214-01, where required by the authority having

jurisdiction.

Instructing the system user

The installer of the system is responsible to ensure the

system operator/ultimate owner is made familiar with the

system functioning, its activation, and its shut-down.

Initial start-up

Initial start-up must be performed by a qualified heating

contractor. Proper completion of the Maintenance Record

by the heating contractor is also required.

Working on the equipment

The installation, adjustment, service, and maintenance

of this boiler must be done by a licensed professional

heating contractor who is qualified and experienced in

the installation, service, and maintenance of hot water

boilers. There are no user serviceable parts on the boiler,

burners, or control.

Ensure main power supply to equipment, the heating

system, and all external controls has been deactivated.

Close main gas supply valve. Take precautions in all

instances to avoid accidental activation of power during

service work.

The following topics must be covered:

Proper system operation sequence.

Explain the equipment.

Demonstrate an emergency shut-down, what to do and

what not.

Explain that there is no substitute for proper maintenance

to help ensure safe operation.

The Maintenance Record is located in the Service

Instructions

Please carefully read this manual prior to attempting startup, maintenance or service. Any warranty is null and void

if these instructions are not followed.

For information regarding other Viessmann System

Technology componentry, please reference documentation

of the respective product.

We offer frequent installation and service seminars to

familiarize our partners with our products. Please inquire.

Technical literature

Literature for the Vitodens boiler:

- Technical Data Manual

- Installation Instructions

- Service Instructions

- Operating Instructions and User’s Information Manual

- Instructions of other Viessmann products utilized and

installed

- Installation codes mentioned in this manual

The completeness and functionality of field supplied

electrical controls and components must be verified by

the heating contractor. These include low water cutoffs, flow switches (if used), staging controls, pumps,

motorized valves, air vents, thermostats, etc.

Leave all literature at the installation site and advise the

system operator/ultimate owner where the literature can

be found. Contact Viessmann for additional copies.

This product comes with several safety instruction labels

attached.

Do not remove!

Contact Viessmann immediately if replacement labels are

required.

Vitodens 200-W B2HB 45, 57 Installation

6

5680 493 - 05

Page 7

Vitodens 200-W B2HB 45, 57 Installation

General Information

Important Regulatory and Installation Requirements (continued)

For installations on the Commonwealth of Massachusetts, the following modifications to NFPA-54 chapter 10 apply:

Excerpt from 248 CMR 5-08:

2(a) For all side-wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in

part for residential purposes, including those owned or operated by the Commonwealth and where the sidewall exhaust vent

termination is less than (7) feet above finished grade in the area of the venting, including but not limited to decks and

porches, the following requirements shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of the side-wall horizontal vented gas

fueled equipment, the installing plumber or gasfitter shall observe that a hard wired carbon monoxide detector with an

alarm and battery back-up is installed on the floor level where the gas equipment is to be installed. In addition, the

installing plumber or gasfitter shall observe that a battery operated or hard wired carbon monoxide detector with an

alarm is installed on each additional level of the dwelling, building or structure served by the side-wall horizontal vented

gas fueled equipment. It shall be the responsibility of the property owner to secure the services of qualified licensed

professional for the installation of hard-wired carbon monoxide detectors.

a. In the event that the side-wall horizontally vented gas fueled equipment is installed in a crawl space or an attic, the

hard-wired carbon monoxide detector with alarm and battery back-up may be installed on the next adjacent floor level.

b. In the event that the requirements of this subdivision can not be met at the time of completion of installation, the owner

shall have a period of thirty (30) days to comply with the above requirements; provided, however, that during said thirty

(30) day period, a battery operated carbon monoxide detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as required in accordance with the above

provisions shall comply with NFPA 720 and be ANSI/UL 2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be permanently mounted to the exterior of the building at a minimum

height of eight (8) feet above grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled

heating appliance or equipment. The sign shall read, in print size no less than one-half (1/2) inch in size, “GAS VENT

DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the side-wall horizontally vented gas fueled equipment shall not approve

the installation unless, upon inspection, the inspector observes carbon monoxide detectors and signage installed in

accordance with the provisions of 248 CMR 5.08(2)(a) 1 through 4.

(b) EXEMPTIONS: The following equipment is exempt from 248 CMR 5.08(2)(a) 1 through 4:

1. The equipment listed in Chapter 10 entitled “Equipment Not Required To Be Vented” in the most current edition

of NFPA 54 as adopted by the Board; and

2. Product Approved side-wall horizontally vented gas fueled equipment installed in a room or structure separate from the

dwelling, building or structure used in whole or in part for residential purposes.

CSD-1 Field Testing of High Limit Switches for Vitodens boilers – where required by law.

As per ASME Boiler and Pressure Vessel Code, section IV, subsection HG-613 TEMPERATURE CONTROL requirements, Vitodens

200-W hot water boilers are protected from over-temperature by two temperature-operated controls. These temperature control

devices conform to Standards for Limit Controls, and are accepted by CSA, a nationally recognized testing agency. Each boiler

is equipped with a manual reset high temperature limit control and a temperature control that will cut off fuel supply when the

system water temperature reaches a preset operating temperature. VIESSMANN IS NOT RESPONSIBLE FOR ANY DAMAGES

THAT THE FOLLOWING TEST PROCEDURE MAY RESULT IN BY OVERHEATING THE SYSTEM.

The Vitodens 200 boilers are equipped with flow switches or sensors that when activated enable the burner to operate.

The fixed high limit, when tripped, produces a fault that will require manual reset of the boiler control.

Fixed High Limit fault simulation #1:

- Ensure that the boiler and boiler pump are in normal operating condition (pump output sÖ is the boiler pump).

- Remove the cover from the back of the boiler control allowing access to the boiler control plugs.

- Under the extended menu (in the Operating manual), select ‘Test mode’ then ‘flue gas test ON’ and press ‘OK’.

- The boiler/burner will start a firing cycle and will gradually go into high fire mode.

- Once the burner ignites, disconnect the boiler pump plug sÖ from the boiler control board (gently with pliers).

Note: For boiler models equipped with flow switches (only boiler sizes 19 to 100), it may be required that flow switches be

jumpered during testing.

- Observe the boiler temperature on the control display.

- The temperature will gradually rise as more heat is put into the boiler heat exchanger. The burner will then shut off.

- The boiler temperature should continue to rise and once it reaches 210ºF (99ºC) the manual reset high limit safety switch

will trip electronically generating an F2 fault.

- Should the limit temperature not be reached during the test, repeat the test with the following additional step;

- two minutes after the burner shuts off, energize the boiler pump for a maximum of 1 second (by plugging in boiler pump plug sÖ).

Fixed High Limit fault simulation #2:

- Close the boiler valve and jumper across the flow switch.

- Run the boiler at high fire and it will shut down by the coding card (in B2TB models, set coding address 06 to maximum) but

should continue to steady increase the boiler temperature until the fixed high limit is tripped.

- Once the fixed high limit is tripped, slowly open the boiler valve to safely cool the boiler down.

5680 493 - 05

7

Page 8

General Information

Applicability

CAUTION

The boiler serial number must be provided when ordering

replacement parts. Some replacement parts are not

reverse compatible with previous versions of the Vitodens

200-W B2HB boiler.

IMPORTANT

When ordering replacement parts, provide either the

16-digit boiler serial number (on the bar code label) or

the 12-digit ASME/NB serial number, located as shown

underneath boiler front enclosure panel. Refer to page 15

for instructions on how to remove front enclosure panel.

NG and LPG

Model No. B2HB 45

Serial No. 7454703 jjjjjjjjj

Model No. B2HB 57

Serial No. 7454704 jjjjjjjjj

Vitodens 200-W B2HB 45, 57 Installation

Product Information

Natural gas-fired wall-mounted condensing heating boiler

for weather-responsive operation in closed loop, forced

circulation hot water heating systems for space heating

and domestic hot water (DHW) production.

Models B2HB 45 and 57 are for operation with natural

gas. For a fuel conversion to liquid propane gas

refer to the service instructions for details.

Boiler model must be selected based on an accurate heat

loss calculation of the building. Ensure boiler model is

compatible with connected radiation.

Vitodens 200-W, B2HB series boilers are factory-tested

and calibrated. Further gas valve adjustments are not

typically required during field start-up.

Product may not be exactly as shown

A Inox-Radial heat exchanger made from stainless steel

– for high operational reliability and a long service life.

Large heating output in the smallest of spaces

B Modulating MatriX cylinder burner for extremely

clean combustion and quiet operation

C Variable speed combustion fan for quiet and

economical operation

D Gas and water connections

E Digital boiler control unit

Multi boiler system

In connection with the installation of a multi boiler system

observe the installation instructions of the multi boiler

system accessories.

8

5680 493 - 05

Page 9

Vitodens 200-W B2HB 45, 57 Installation

General Information

Mechanical Room

During the early stages of designing a new home, we recommend that proper consideration be given to constructing a

separate mechanical room dedicated to the gas- or oil-fired heating equipment and domestic hot water storage tank(s).

The boiler must be located in a heated indoor area, near a floor drain, and as close as possible to a wall. Whenever

possible, install the boiler near an outside wall so that it is easy to duct the venting system to the boiler.

Locate the boiler on a wall capable of supporting 210 lb. (95 kg) [the weight of the boiler filled with water]. Ensure

that the boiler location does not interfere with the proper circulation of combustion and ventilation air of other fuel

burning equipment within the mechanical room (if applicable).

The maximum room temperature of the mechanical room where the boiler is located must not exceed 104ºF (40ºC).

Installation area conditions

WARNING

Incorrect ambient conditions can lead to damage to the

heating system and put safe operation at risk.

H Ensure ambient temperatures are higher than 32°F

(0°C) and lower than 104°F (40°C).

H Prevent the air from becoming contaminated by

halogenated hydrocarbons (e.g. as contained in paint

solvents or cleaning fluids) and excessive dust (e.g.

through grinding or polishing work). Combustion air

for the heating process, and ventilation of the boiler

room must be free of corrosive contaminants. To that

end, any boiler must be installed in an area that has no

chemical exposure. The list to the right indicates the

main, currently known sources.

H Avoid continuously high levels of humidity (e.g. through

frequent drying of laundry).

H Never close existing ventilation openings.

WARNING

If you notice fire coming from the appliance, call the fire

department immediately! Do not attempt to extinguish

the fire unless qualified to do so.

IMPORTANT

The service life of the boiler’s exposed metallic surfaces,

such as the casing and fan housing, is directly influenced

by proximity to damp and salty marine environments. In

such areas, higher concentration levels of chlorides from

sea spray, coupled with relative humidity, can lead to

degradation of the exposed metallic surfaces mentioned

above. Therefore, it is imperative that boilers installed

in such environments not be installed using direct vent

systems which draw outdoor air for combustion. Such

boilers must be installed using room air dependent vent

systems; i.e. using room air for combustion. The indoor

air will have a much lower relative humidity and, hence,

potential corrosion will be minimized.

Sources of combustion and ventilation air contaminants

Areas likely to contain contaminants:

H New building construction

H Swimming pools

H Remodelling areas, hobby rooms

H Garages with workshops

H Furniture refinishing areas

H Dry cleaning/laundry areas and establishments

H Auto body shops

H Refrigeration repair shops

H Metal fabrication plants

H Plastic manufacturing plants

H Photo processing plants

H Beauty salons

Products containing contaminants:

H Chlorine-type bleaches, detergents and cleaning

solvents found in household laundry rooms

H Paint and varnish removers

H Hydrochloric acid, muriatic acid

H Chlorine-based swimming pool chemicals

H Spray cans containing chlorofluorocarbons

H Chlorinated waxes and cleaners

H Cements and glues

H Refrigerant leaks

H Calcium chloride used for thawing

H Sodium chloride used for water softening salt

H Permanent wave solutions

H Adhesives used to fasten building products and other

similar items

H

Antistatic fabric softeners used in clothes dryers

Boiler operation in marine environments (damp, salty

coastal areas)

WARNING

Fire causes a risk of burns and explosion!

H Shut down the boiler

H Close fuel shut-off valves

H Use a tested fire extinguisher, class ABC.

5680 493 - 05

9

Page 10

Set-up

Before Set-up

Before placing boiler in its installation location, ensure all

necessary accessories are installed.

Minimum Clearances

Vitodens 200-W B2HB 45, 57 Installation

CAUTION

The boiler must be installed in such a way that gas

ignition system components are protected from water

(spraying, splashing, etc.) during boiler operation and

service.

Recommended minimum service clearances

For typical Vitodens installations, Viessmann recommends

installing the boiler with the clearances shown in the

illustration on the left.

Note: The 12 in. (305 mm) side clearance specified is

only recommended to be able to view the boiler

certified rating plate, decal and also accommodate

the PRV installation kit.

Note: The Vitodens 200-W, B2HB boiler has passed the

zero inches vent clearance to combustibles testing

requirements dictated by the boiler Harmonized

Standard ANSI Z21.13. CSA 4.9 (latest edition)

and therefore is listed for zero clearance to

combustibles when vented with a single-wall

special venting system (AL-29-4C material) or

UL/ULC-listed CPVC/PPs gas vent material. The

zero inches vent clearance to combustibles for

the Vitodens 200-W, B2HB boiler supercedes the

clearance to combustibles listing that appears on

the special venting system label.

If the pressure relief valve is rotated 90º facing forward

by using an extension between the tee and the boiler

connection, then this clearance can be reduced to b in.

This b in. clearance is only required to be able to remove

the boiler’s front cover and view the rating plate attached

to it, if needed.

This reduced clearance is also used in Vitodens multiple

boiler installation system as described in

the multiple boiler installation instructions.

The Vitodens 200-W, B2HB boiler is approved for closet

and alcove installation with the following clearances to

combustibles.

Table 1 Clearances

Top Front Rear Left Right Vent pipe

00 AL CL0000

AL = Alcove

CL = Closet

See the Vitodens 200-W B2HB Venting

System Installation Instructions for details.

10

5680 493 - 05

Page 11

Vitodens 200-W B2HB 45, 57 Installation

Preparing the Connections

*1 DHW

Connections

(Field Supplied)

Boiler Connections

Use an approved pipe sealant or teflon tape when

connecting the following installation fittings.

This section constitutes an overview only! Refer to

subsequent sections for detailed information on individual

piping connections.

Legend

DR Boiler heating return for domestic hot water production

DS Boiler heating supply for domestic hot water production

BD Boiler Drain

BF Boiler Fill

BR Boiler Return

BS Boiler Supply

GC Gas Connection

PRV Pressure Relief Valve

*1 See page 40 for alternate DHW connection.

*2 Discard when using the multi-boiler distribution

manifold

5680 493 - 05

11

Page 12

Boiler Connections

Preparing the Connections (continued)

Vitodens 200-W B2HB 45, 57 Installation

This section constitutes an overview only! Refer to

subsequent sections for detailed information on individual

piping connections.

Use an approved pipe sealant or teflon tape when

connecting the following installation fittings.

IMPORTANT

The maximum ambient temperature must not exceed

104ºF (40ºC).

Note: When preparing gas, water and electrical

connections in the field, see section entitled

“Wall Mounting” on page 13, 14 and 15 of this

manual for information regarding the installation

of the wall mounting bracket.

1. Heating water connections and gas connection to

be made in the field. See illustration and connectionspecific section for details.

2. See subsection entitled “Electrical Connections”

for details regarding power supply to the Vitodens

200-W B2HB boiler.

Legend

A Boiler Supply

B Gas Connection, 1” NPTF

C Boiler Return

D Recommended height (single boiler system)

E Condensate drain

12

5680 493 - 05

Page 13

Vitodens 200-W B2HB 45, 57 Installation

Wall Mounting

Boiler Connections

Fitting the wall mounting bracket

Following are the installation instructions for the mounting

bracket on each material. See the instructions applicable

to your installation requirements.

Installing the wall mounting bracket

The Vitodens 200-W B2HB can be wall-mounted on a

concrete wall.

Note: The enclosed screws and rawl plugs are only

suitable for concrete. For other construction

materials, use bolts and anchors that are suitable

for 210 lb (95 kg) loads.

Installation of mounting bracket on brick/concrete wall

1. Drill holes 7 31/64 in. (12 mm).

2. Install rawl plugs and screw mounting bracket

to wall.

3. Ensure the mounting bracket is level.

CAUTION

Whichever mounting method is used, ensure that the

bracket is tightly and securely fastened to wall. Failure

to secure boiler properly could cause boiler to loosen,

posing a severe safety hazard.

5680 493 - 05

13

Page 14

Boiler Connections

Wall Mounting (continued)

Vitodens 200-W B2HB 45, 57 Installation

Boiler mounting bracket

Install the boiler mounting bracket to the wall studs.

Ensure the mounting bracket is level.

To mount on wood or metal studs a cross bar or frame

may be required as reinforcement. The wall and studs

must be capable of supporting a minimum of 210 lb.

(95 kg).

For construction materials, use fixings that are suitable

for 210 lb (95 kg) loads.

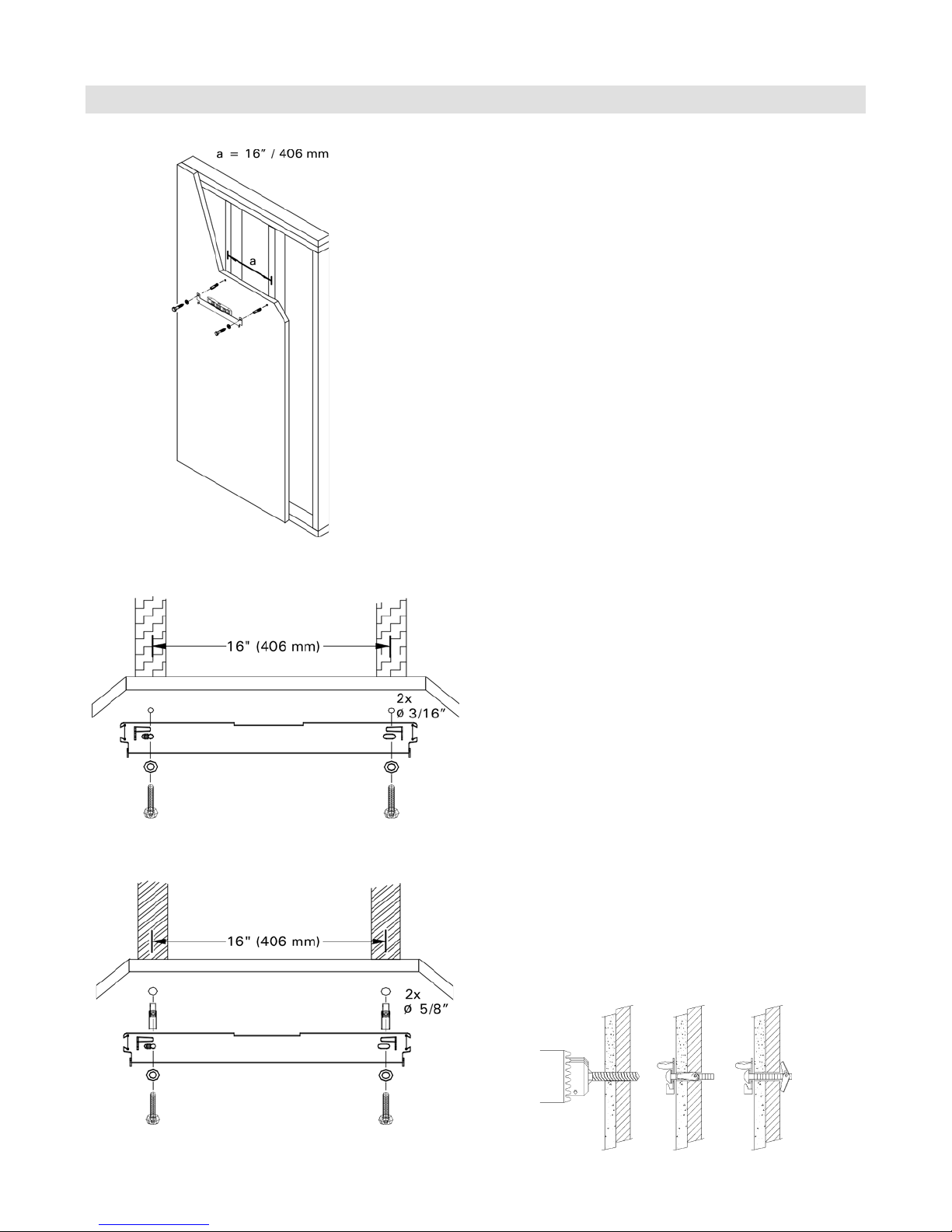

Installation on wood studs

Install mounting bracket on wood studs as per illustration.

Drill 3/16” pilot holes to insert mounting bolts. Ensure that

holes are located in the center of each wood stud. Secure

with bolts to wooden studs as shown.

Installation on metal studs

install mounting bracket on metal studs as per illustration.

Drill f” pilot holes to insert anchors. Ensure that holes are

located in the center of each metal stud. Use appropriate

fasteners to mount to metal studs (not supplied). Secure

with bolts to metal studs as shown. Ensure the mounting

bracket is level.

14

5680 493 - 05

Page 15

Vitodens 200-W B2HB 45, 57 Installation

Wall Mounting (continued)

Boiler Connections

1. Remove the external accessories connection box

cover.

2. Loosen the screws at the bottom of the boiler

(do not remove completely).

3. Remove the front encloser panel (lift up and pull

away from the boiler).

4. Mount boiler onto the mounting bracket.

5. Adjust the levelling screws to ensure the boiler

is level. Place the round bubble level on top of the

boiler to verify.

Note: For draining of the condensate (see page 26).

6. Install supplied installation fittings as per layout on

page 11.

CAUTION

The boiler must be level both vertically and horizontally

to ensure proper draining of the condensate.

5680 493 - 05

15

Page 16

Boiler Connections

Frame Mounting

Vitodens 200-W B2HB 45, 57 Installation

The boiler stand is used for free-standing installation of a

single boiler within the mechanical room.

When using the boiler stand, ensure that the stand is

securely fastened to the floor (recommended concrete

expansion anchors are Hilti model KB-TZ e x 4 or

equivalent.

The Vitodens 200-W, model B2HB does not come with

a mounting template. The wall location for the frame,

mounting bracket and all vents must be field calculated.

Boiler mounting bracket and frame

1. Attach the wall mounting bracket (supplied with the

boiler) to the boiler mounting frame using the supplied

hardware. Ensure that the wall mounting bracket is

level.

2. Move the rack into position and secure to the floor

(and to the wall if needed).

16

5680 493 - 05

Page 17

Vitodens 200-W B2HB 45, 57 Installation

Models B2HB 45, 57 Frame Mounting

Boiler Connections

1. Remove the external accessories connection box

cover.

2. Loosen the screws at the bottom of the boiler

(do not remove completely).

3. Remove the front encloser panel (lift up and pull

away from the boiler).

4. Mount boiler onto the mounting bracket and ensure

the boiler is securely mounted. Then install the

holding bracket to the frame on top of the boiler.

5. Adjust the levelling screws to ensure the boiler

is level.

6. Connect the boiler to the installation fittings.

CAUTION

The boiler must be level both vertically and horizontally

to ensure proper draining of the condensate.

5680 493 - 05

17

Page 18

Boiler Connections

Connections

Vitodens 200-W B2HB 45, 57 Installation

Connecting power

The Vitodens 200-W boiler has a external accessories

connection box installed, which requires a 120VAC/12A

power supply. Refer to the wiring diagram (see page 44).

Boiler venting

The Vitodens 200-W B2HB boiler comes with a pre-installed

vent pipe adaptor.

Run venting system, single-wall or coaxial, through the

side wall or the roof, taking the shortest possible route

and at a rising angle (min. 3º).

WARNING

Remove outer gasket if single wall (boiler room air

dependant) venting system is used.

2 imperfect threads

Leave 2 threads bare

Manual gas shutoff

Closed

Open

Proper piping practice

Support piping by proper suspension method. Piping

must not rest on or be supported by boiler. Use moderate

amount of dope.

Gas shut-off valve connection

1. Make gas connections in accordance with codes

CAN/CSA B149.1 and .2 or National Fuel Gas Code

ANSI Z223.1/NFPA 54, as well as local codes.

2. Connect gas shutoff valve to the boiler gas

connection.

3. Once connected close gas shutoff valve on boiler.

See following page for details on gas

connection and piping.

18

5680 493 - 05

Page 19

Vitodens 200-W B2HB 45, 57 Installation

Connections (continued)

Boiler Connections

Gas connection and piping

1. Refer to current CAN/CSA B149.1 and .2 or National

Fuel Gas Code ANSI Z223.1/NFPA 54, as well as

local codes for gas piping requirements and sizing.

Pipe size to the boiler must be determined based on:

- pipe length

- number of fittings

- type of gas

- maximum input requirements of all gas appliances

in the residence.

IMPORTANT

Design piping layout in such a way that piping does not

interfere with serviceable components.

2. Before connecting boiler to gas line, install ground

joint union, capped drip leg and a manual equipment

shutoff valve as shown. Valves must be listed by a

nationally recognized testing agency. Make boiler gas

connection as shown.

3. Perform gas piping pressure test as described in the

following subsection.

Legend

A Gas connection 7 1 in. (NPT)

B Accessible manual gas shutoff valve

C Ground joint union

D Drip leg

IMPORTANT

Max. gas supply pressure: 14 “w.c.

4. Identify shutoff valves as such with a tab and

familiarize operator / ultimate owner of boiler with

these valves.

See Vitodens 200-W B2HB Service Instructions

for applicable system coding information.

WARNING

The gas supply piping must be leak tested before placing

the boiler in operation.

CAUTION

Ensure that gas piping is large enough for all appliances in

the residence. No noticeable gas pressure drop in the gas

line must occur when any unit (or combination of units)

lights or runs.

IMPORTANT

Regarding operation with LPG, we recommend the

installation of an external safety solenoid valve when

installing the boiler in rooms below ground level.

5680 493 - 05

19

Page 20

Boiler Connections

Connections (continued)

Vitodens 200-W B2HB 45, 57 Installation

Gas piping pressure test

When performing the gas piping pressure test, ensure the

following requirements are met.

WARNING

Never check for gas leaks with an open flame.

WARNING

Exposing boiler gas pressure regulator and gas valve to

extreme pressures renders warranty null and void.

IMPORTANT

½ psig = 14 “w.c.

1. Isolate the boiler from the gas supply piping system

using the individual manual shutoff valve during

pressure tests equal to or less than ½ psig (14 “w.c.)

2. The boiler and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of ½ psig (14 “w.c.)

3. Perform leak test.

Use approved liquid spray solution for bubble test.

Ensure that no liquid is sprayed on any electrical

components, wires or connectors. Do not allow

leak detection fluid to contact gas valve regulator

or regulator vent opening.

4. Correct any and all deficiencies.

5. Remove air from gas line.

Heating water connections

1. Thoroughly flush heating system (particularly before

connecting the boiler to an existing system).

2. Connect boiler to the heating system.

Max. operating pressure: 4 bar (60 psig)

Test pressure: 6 bar (90 psig)

IMPORTANT

Damage resulting from pressure exceeding those values

stated is not covered by Viessmann warranty.

3. Connect field supplied nipples and tees as shown

for DHW supply and return.

*1 DHW

Connections

(Field Supplied)

20

Legend

DR Boiler heating return for domestic hot water production

DS Boiler heating supply for domestic hot water production

BD Boiler Drain

BF Boiler Fill

BR Boiler Return

BS Boiler Supply

GC Gas Connection

PRV Pressure Relief Valve

*1 See page 40 for alternate DHW connection.

*2 Discard when using the multi-boiler distribution

manifold

IMPORTANT

Apply sufficient amount of thread sealant (supplied) when

making the connections.

5680 493 - 05

Page 21

Vitodens 200-W B2HB 45, 57 Installation

Connections (continued)

Boiler Connections

DHW storage tank information

The DHW water tank sensor is required when using a

stand-alone DHW storage tank with the Vitodens 200-W

B2HB heating boiler. It comprises the sensor only required

for the connection of a stand-alone tank. All other

required piping connections are field supplied.

See Vitodens 200-W B2HB Service Instructions

for applicable system coding information.

IMPORTANT

Apply sufficient amount of thread sealant (supplied) when

making the connections.

Making the DHW connections

1. With a Vitocell 100 and 300 series tanks locate the

DHW temperature sensor well and install the

DHW temperature sensor % using the installation

instructions provided with the DHW storage tanks.

IMPORTANT

Follow the Installation Instructions supplied with the

Viessmann DHW storage tank when mounting and

securing DHW tank temperature sensor %.

WARNING

If a DHW storage tank other than a Viessmann Vitocell

100 or 300 tank is used, the installer must verify proper

operation of the Viessmann DHW tank temperature

sensor with original manufacturer of the tank. Viessmann

strongly recommends the installation of a temperature

tempering valve in the DHW supply line.

5680 493 - 05

21

Page 22

Boiler Connections

Connections (continued)

Vitodens 200-W B2HB 45, 57 Installation

Accessing the control unit connections

1. Remove both screws from the junction box cover

and set screws aside.

2. Loosen both retaining screws as shown (do not

remove).

22

3. Pull the external accessory connection box forward

until the retaining screws are clear of the guides (built

into the rails).

4. Swing the external accessory connection box down.

5680 493 - 05

Page 23

Vitodens 200-W B2HB 45, 57 Installation

Connections (continued)

Boiler Connections

5. Tilt the bottom of the external accessory connection

box cover forward.

6. Pull the cover up to clear the locating pins and out

to remove, then set aside.

7. Slide both sides of the programming unit cover closed.

8. Release the hinged hooks located on both sides of

the control unit.

9. To open hinged cover, lift cover and then fold down

the control unit.

10. Release locking tabs as shown.

11. Remove cover.

5680 493 - 05

23

Page 24

Boiler Connections

Connections (continued)

Vitodens 200-W B2HB 45, 57 Installation

12. Route all connecting cables to the appropriate areas

and secure the cables to the control base using

existing strain reliefs as shown.

CAUTION

When running and securing connecting cables on site,

ensure that the maximum permissible temperatures of

the cables are not exceeded.

Electronic modules can be damaged by

electrostatic discharges. Before commencing

work, touch grounded objects (such as heating

or water pipes) to discharge static loads.

Legend

A Low voltage connections

B 120V connections

C Internal extension

D Main PCB

E Communication module (accessory)

F Cable grommet for power cable

% Plugs for connecting the DHW temperature

sensor to the cable harness

Routing the connecting cables

Note: If connecting cables touch hot components they will

be damaged. When routing and securing connecting

cables on site, ensure that the maximum permissible

temperatures for these cables are not exceeded.

Remove the existing cable grommet when using larger

wire (cable) size [up to

cable with the cable grommet plugged into the lower

casing section (orange).

9/16 in. (7 14 mm)]. Secure the

24

5680 493 - 05

Page 25

Vitodens 200-W B2HB 45, 57 Installation

Connections (continued)

Field Connection

Connection

X9 Connector

(boiler control board)

Boiler Connections

Connecting DHW sensor

1. Attach the DHW sensor to the quick connect plugs

provided from the boiler control board (see page 24).

Install DHW tank temperature sensor

as described in the Vitocell Installation

Instructions supplied with the DHW

storage tank.

Setting altitude parameters

In the factory default setting, the boiler is equipped to

operate in altitudes of up to 5,000 ft. (1,500 m).

Altitude can be set using coding address 93 (in coding

level 2 General).

See Vitodens 200-W B2HB Service Instructions

for applicable system coding information.

5680 493 - 05

25

Page 26

Boiler Connections

Connections (continued)

Vitodens 200-W B2HB 45, 57 Installation

Control base

Note: See wiring diagram on page 44 for connection to

the external accessory connection box.

DHW

TEMPERATURE

SENSOR

OUTDOOR

TEMPERATURE

SENSOR

26

5680 493 - 05

Page 27

Vitodens 200-W B2HB 45, 57 Installation

Connections (continued)

ACCESSORIES

(ie VITOTROL

REMOTE OR

MIXING VALVE)

0-10V INPUT

Boiler Connections

External accessory connection box

Note: See wiring diagram on page 44 for connection

to the control base.

120/1/60 12 AMP

POWER SUPPLY WITH

DISCONNECT AND

PROTECTION

PUMP

5680 493 - 05

27

Page 28

Boiler Connections

Connections (continued)

Condensate Connection for Vitodens

200-W, models B2HB 45, 57

Legend

A Retaining clip

B Siphon trap

C Flexible discharge tubing

D Flexible discharge tubing

Vitodens 200-W B2HB 45, 57 Installation

Condensate connection

The Vitodens 200-W B2HB boiler comes with a builtin condensate trap. An external trap is not required

when connecting the field drain to flexible discharge

tubing. Discharge tubing (field supplied) must be of 1 in.

diameter.

Use CPVC, PVC or other material approved by codes

listed below.

The drain pipe and fittings must conform to ANSI

standards and ASTM D1785 or D2846. CPVC or PVC

cement and primer must conform to ASTM D2564 or

F493. In Canada use CSA or ULC listed schedule 40

CPVC or PVC drain pipe, fittings and cement.

If the condensate outlet of the Vitodens 200-W B2HB

boiler is lower than the drain, a condensate pump must be

installed. Select a pump which is approved for condensing

boiler applications. To avoid condensate spillage, select

a pump with an overflow switch. The drain connection

must terminate into an open or vented drain as close to

the boiler as possible to prevent siphoning of the boiler

drain.

1. Install the condensate drain pipe with a suitable

gradient. Pull the condensate hose so far out of the

boiler that no unnecessary bends are created inside

the boiler. Check tightness of siphon connection.

Condensate installation example:

Air gap

IMPORTANT

As shipped, the flexible discharge tubing E will be found

to be pushed up inside the boiler housing. Ensure the

condensate drain pipe is pulled down and positioned to

allow the condensate to properly drain.

2. Discharge condensate from the boiler into the vented

drainage system, either directly or (if required) via a

neutralization unit (accessory).

Installation Instructions of Neutralization Unit

(if applicable)

IMPORTANT

Pipe ventilation must take place between the siphon trap

and the neutralization unit (if applicable).

IMPORTANT

Do not connect the drain pipe from any other appliance,

such as water softener backwash pipe, to Vitodens

condensate drain pipe.

3. Ensure the condensate discharge tubing is vented

to the atmosphere prior to being plumbed into the

neutralization unit.

28

5680 493 - 05

Page 29

Vitodens 200-W B2HB 45, 57 Installation

Safety Connections and Pressure Testing

Legend

A Reducing tee, 1½ in. x 1½ in. x ¾ in.

B Nipple, length 1½ in. x 2½ in. (field supplied)

C Isolation valve, 1½ in. (field supplied)

D Nipple, length 3½ in. x ¾ in.

E Tee ¾ in.

F Nipple, length 1½ in. x ¾ in.

G Pressure relief valve, ¾ in. NPT

H Drain valve connection, ¾ in.

Minimum connection diameters:

Pressure relief valve.........................¾ in.

Discharge pipe................................¾ in.

Piping to precharged expansion tank..(field supplied)

Boiler Connections

Installing boiler safety devices

1. Remove loosely pre-assembled combination pressure

relief valve and drain valve assembly.

2. Apply sufficient amount of pipe sealant to both ends

of all pipe fittings B,D,F and H and install onto

tees A, and E.

3. Install pressure relief valve G and isolation valve

C and tighten.

4. Install discharge pipe on pressure relief valve in such

a way that...

- the end of the pipe is not threaded.

- the pressure relief discharge pipe extends to a floor

drain and ends approximately 6 in. (150 mm) above

the drain.

Ensure that...

- there is no shutoff valve installed in the discharge pipe.

- discharge pipe diameter is not reduced.

- discharge is not piped to outdoors.

IMPORTANT

Install the (approved) factory supplied pressure relief

valve.

Removal of air from the system must occur via use of air

vent(s) in the system supply. To ensure the boiler can be

purged of all air, ensure supply/return water lines do not

contain restrictive piping where air could be trapped.

WARNING

Do not install an isolation valve between boiler and

pressure relief valve.

The discharge pipe for the pressure relief valve must

be oriented to prevent scalding of attendants.

Pipe pressure relief valve discharge pipe close to floor

drain. Never pipe discharge pipe to the outdoors.

5680 493 - 05

29

Page 30

Boiler Connections

Safety Connections and Pressure Testing (continued)

Vitodens 200-W B2HB 45, 57 Installation

Low water cut-off

A low water cut-off may be required by local codes. If

boiler is installed above radiation level, a low water cut-off

device of approved type (field supplied) must be installed

in all instances. Do not install an isolation valve between

boiler and low water cut-off.

WARNING

Exposing the boiler to pressures and temperatures in

excess of those listed will result in damages, and will

render warranty null and void.

Max. operating pressure...............4 bar (60 psig)

Testing pressure..........................6 bar (90 psig)

Max. boiler water temperature......210ºF (99ºC)

Performing a boiler pressure test

The boiler must be leak tested before being placed in

operation. Before boiler is connected to piping or electrical

power supply, it must be hydrostatically pressure tested.

1. After installing safety devices (see previous page),

install temporary cap on ¾ in. x 2 in. nipple.

2. Cap supply and return connections.

3. Connect ½ in. garden hose to boiler fill valve at

the bottom of the boiler and fill boiler slowly until

pressure gage indicates max. 8 bar (120 psig).

4. Maintain pressure for 15 minutes. During time of

pressure testing, do not leave boiler unattended.

5. Inspect all pipe joint connections and safety devices

with a flashlight for leaks. A lower manometer

reading than 8 bar (120 psig) usually indicates loss

of water due to leakage. All leaks must be repaired.

6. After 15 minutes, release water pressure from boiler

by opening boiler drain valve slowly, remove caps

from supply and return connections as well as ¾ in.

cap from 2 in. nipple, and install pressure relief valve

immediately instead of ¾ in. cap.

7. After boiler has passed pressure test, proceed with

the installation.

Waterside Flow

Waterside flow (primary circuit)

The Vitodens 200-W, B2HB is designed for closed loop,

forced circulation hot water heating systems only.

Use standard friction loss method for pipe sizing. Observe

boiler maximum and minimum flow rate limitations.

If system flow rate exceeds boiler maximum flow rate

(as stated above), falls below the minimum flow rate

or if system flow rate is unknown, Viessmann strongly

recommends the installation of a low-loss header.

Once the low-loss header is connected, the built-in lowloss header logic of the Vitodens 200-W boiler ensures

the required t across the system through the sensory

communication between the low-loss header and the

boiler.

An alternative method may be used, such as primary

secondary piping using closely spaced tees. A low-loss

header offers additional benefits not provided by a pair

of closely spaced tees. Viessmann therefore strongly

recommends and prefers the use of a low-loss header

over closely spaced tees. Refer to the Technical Data

manual for low-loss header information.

30

5680 493 - 05

Page 31

Vitodens 200-W B2HB 45, 57 Installation

Boiler Connections

Waterside Flow (continued)

Pressure drop (primary circuit) for

Vitodens 200-W, B2HB 45 - 57

For sizing an on-site circulation system.

Max. flow rate: 14.3 GPM (3,250 L/H)

Boiler max. flow rate 14.3 GPM (3250 L/h)

Model B2HB 45 1 boiler 2 boilers 3 boilers 4 boilers 5 boilers 6 boilers 7 boilers 8 boilers

Output (NG/LPG)

MBH 149 298 447 596 745 894 1043 1192

t for NG/LPG

20º F (11º C) rise GPM

(L/h)

25º F (14º C) rise GPM

(L/h)

30º F (17º C) rise GPM

(L/h)

35º F (19.5º C) rise GPM

(L/h)

40º F (22º C) rise GPM

(L/h)

14.9

(3384)

11.9

(2707)

9.9

(2256)

8.5

(1934)

7.5

(1692)

29.8

(6768)

23.8

(5415)

19.9

(4512)

17.0

(3868)

14.9

(3384)

44.7

(10152)

35.8

(8122)

29.8

(6768)

25.5

(5801)

22.4

(5076)

59.6

(13536)

47.7

(10829)

39.7

(9024)

34.1

(7735)

29.8

(6768)

74.5

(16920)

59.6

(13536)

49.7

(11280)

42.6

(9669)

37.3

(8460)

89.4

(20305)

71.5

(16244)

59.6

(13536)

51.1

(11603)

44.7

(10152)

104.3

(23689)

83.4

(18951)

69.5

(15792)

59.6

(13536)

52.2

(11844)

119.2

(27073)

95.4

(21658)

79.5

(18048)

68.1

(15470)

59.6

(13536)

Boiler max. flow rate 14.3 GPM (3250 L/h)

Model B2HB 57 1 boiler 2 boilers 3 boilers 4 boilers 5 boilers 6 boilers 7 boilers 8 boilers

Output (NG/LPG)

MBH 185 370 555 740 925 1110 1295 1480

t for NG/LPG

20º F (11º C) rise GPM

(L/h)

25º F (14º C) rise GPM

(L/h)

30º F (17º C) rise GPM

(L/h)

35º F (19.5º C) rise GPM

(L/h)

40º F (22º C) rise GPM

(L/h)

5680 493 - 05

18.5

(4202)

14.8

(3361)

12.3

(2801)

10.6

(2401)

9.3

(2101)

37.0

(8403)

29.6

(6723)

24.7

(5602)

21.1

(4802)

18.5

(4202)

55.5

(12605)

44.4

(10084)

37.0

(8403)

31.7

(7203)

27.8

(6303)

74.0

(16807)

59.2

(13446)

49.3

(11205)

42.3

(9604)

37.0

(8403)

92.5

(21009)

74.0

(16807)

61.7

(14006)

52.9

(12005)

46.3

(10504)

111.0

(25210)

88.8

(20168)

74.0

(16807)

63.4

(14406)

55.5

(12605)

129.5

(29412)

103.6

(23530)

86.3

(19608)

74.0

(16807)

64.8

(14706)

148.0

(33614)

118.4

(26891)

98.7

(22409)

84.6

(19208)

74.0

(16807)

31

Page 32

Boiler Connections

Installation Examples

General

The schematics on the following pages are to be seen

as guidelines only. They further do not display all system

varieties, safety devices, or concepts possible. Specific

system layouts may be further discussed with the local

Viessmann sales representative office.

Clearances

A minimum of 2 in. (51 mm) circumferential clearance

from non-insulated hot water pipes to combustible

construction must be maintained. In cases where the

pipes are insulated with pipe insulation of appropriate

and sufficient thickness and insulation values, the above

clearance may be reduced to 0 in. (refer to local gas

codes).

CAUTION

For underfloor heating applications, an additional

immersion or strap-on aquastat must be installed in the

low temperature underfloor loop (downstream of the

mixing valve) to de-energize the pump and/or boiler

to prevent overheating. High water temperatures can

damage concrete slabs.

IMPORTANT

The examples on the following pages depict possible

piping layouts of the Vitodens 200-W B2HB boiler

equipped with Viessmann System Technology.

For boiler and tank combinations, please install only

feasible combinations listed in the Viessmann Price List.

Please note that the following examples are simplified

conceptual drawings only!

Piping and necessary componentry must be field verified.

A low water cut-off (LWCO) must be installed where

required by local codes.

Proper installation and functionality in the field is the

responsibility of the heating contractor.

Vitodens 200-W B2HB 45, 57 Installation

WARNING

If a DHW storage tank other than a Viessmann Vitocell

100 or 300 tank is used, the installer must verify proper

operation of the Viessmann DHW tank temperature

sensor with the original manufacturer of the tank.

Viessmann strongly recommends the installation of a

temperature tempering valve in the DHW supply line.

IMPORTANT

DHW supply and return piping between boiler DHW

connections and the Viessmann DHW tank connections,

shall be a minimum of 1¼ in. pipe size. This will ensure

the residual head of the field supplied pump is fully utilized

to overcome the resistance of the DHW heat exchanger

coil and to provide sufficient water flow to the boiler heat

exchanger.

In non-Viessmann DHW tank applications, perform, in

addition to the above, accurate calculations for DHW

tank coil pressure drop versus boiler pump (field supplied)

residual head to ensure sufficient water flow to the boiler

heat exchanger. Failure to heed the above instructions

may cause boiler short-cycling and inadequate DHW

supply.

Note: In the following piping layout examples all pumps

are field supplied.

32

5680 493 - 05

Page 33

Vitodens 200-W B2HB 45, 57 Installation

System Layout 1

Vitodens 200-W, B2HB with a direct-connected heating circuit

Boiler Connections

Legend

A Vitodens 200-W B2HB boiler with

Vitotronic 200, HO1B outdoor reset control

B Outdoor temperature sensor !

C Vitotrol remote (optional)

D Heating circuit

E Heating circuit pump

F DHW circulating pump sA

G DHW storage tank

H DHW tank temperature sensor %

I Expansion tank

J Flow check valve

K DHW recirculation pump

L Temperature and pressure relief valve

M Pressure relief valve

* Function based on coding of address 33

5680 493 - 05

20

28/20 *

Installation of ...

■ radiator heating circuit (high-temp. circuit)

■ DHW production

... with the following flow conditions:

The flow rate of the heating circuit is less than the

maximum possible water flow rate of the Vitodens 200-W

B2HB boiler (see page 31 for maximum water flow rate of

boiler).

The use of a low-loss header is strongly recommended if

the maximum water flow rate in the application concerned

exceeds the values shown in the applicable table on page

31, or if the system flow rates are unknown.

The low-loss header is available as accessory part.

See following pages for installation examples with a lowloss header.

IMPORTANT

DHW circulating pump F must pump into the Vitodens

200-W boiler (as illustrated).

33

Page 34

Boiler Connections

System Layout 2

Vitodens 200-W, B2HB with one heating circuit and low-loss header

Vitodens 200-W B2HB 45, 57 Installation

Legend

A Vitodens 200-W B2HB boiler with

Vitotronic 200, HO1B outdoor reset

control

B Outdoor temperature sensor !

C Vitotrol remote (optional)

D Heating circuit

E Boiler pump 20

F DHW circulating pump sA

G DHW storage tank

H DHW tank temperature sensor %

I Expansion tank

J Temperature and pressure relief valve

K DHW recirculation pump 28/20 *

L Low-loss header

M Pressure relief valve

N Viessmann temperature sensor for

low-loss header ?

O Heating circuit pump 28/20 *

* Function based on coding of address 33

34

Installation of ...

■ radiator heating circuit (high-temp. circuit)

■ DHW production

... with the following flow conditions:

The flow rate of the heating circuit is greater than the

maximum possible water flow rate of the Vitodens

200-W B2HB boiler (see page 31 for maximum water

flow rate of boiler).

The use of a low-loss header is strongly recommended

if the maximum water flow rate in the application

concerned exceeds the values shown on page 31,

or if the system flow rates are unknown.

The low-loss header is available as accessory part.

IMPORTANT

Please note location of expansion tank.

DHW circulating pump F must pump into the Vitodens

200-W B2HB boiler (as illustrated).

5680 493 - 05

Page 35

Vitodens 200-W B2HB 45, 57 Installation

System Layout 3

Vitodens 200-W, B2HB with...

- DHW storage tank

- one heating circuit with mixing valve and system separation

Boiler Connections

Legend

A Vitodens 200-W B2HB boiler with

Vitotronic 200, HO1B outdoor reset

control

B Outdoor temperature !

C Vitotrol remote (optional)

D Underfloor heating circuit

E Mixing valve temperature sensor ?

F Pressure relief valve

G Plate heat exchanger for system

separation

H Accessory kit for heating circuit with

mixing valve

I DHW circulating pump sA

J DHW storage tank

K DHW tank temperature sensor %

L Expansion tank

M DHW recirculation pump 28/20 *

N Temperature and pressure relief valve

O Flow check valve

P Heating circuit pump 20

Q Heating circuit pump

* Function based on coding of address 33

IMPORTANT

DHW circulating pump must pump I into the Vitodens

200-W B2HB boiler (as illustrated).

5680 493 - 05

Installation of ...

■ underfloor heating circuit with 3-way mixing valve

and system separation (low-temp. circuit)

■ DHW production

... with the following flow conditions:

The flow rate of the heating circuit is less than the

maximum possible water flow rate of the Vitodens

200-W B2HB boiler.

See page 31 for maximum water flow rate of the Vitodens

200-W B2HB boilers. The use of a low-loss header is

recommended if the system water flow rate is unknown.

The low-loss header is available as accessory part.

See following pages for installation examples with a

low-loss header.

IMPORTANT

System separation is required of underfloor heating

systems employing non-oxygen diffusion barrier tubing.

All components on the secondary side of the heat

exchanger must be made of corrosion-resistant materials.

IMPORTANT

Sizing of field-supplied pump P is critical for proper

boiler operation in this system layout. See page 31 for the

supply head pressure drop of the boiler. An undersized

pump may cause short-cycling and/or improper operation

of the boiler. Viessmann STRONGLY recommends using a

low-loss header and a boiler pump in this system layout.

35

Page 36

Boiler Connections

System Layout 4

Vitodens 200-W, B2HB with...

- DHW storage tank

- one direct-connected heating circuit

- one heating circuit with a mixing valve

Vitodens 200-W B2HB 45, 57 Installation

Legend

A Vitodens 200-W B2HB boiler with

Vitotronic 200, HO1B outdoor reset

control

B Outdoor temperature sensor !

C Vitotrol remote (optional)

D Under floor heating circuit

E Radiator heating circuit

F Heating circuit pump

G Mixing valve temperature sensor ?

H Accessory kit for heating circuit with mixing valve

I Domestic hot water storage tank

J DHW tank temperature sensor %

K Expansion tank

L Temperature and pressure relief valve

M Pressure relief valve

N DHW recirculation pump 28/20 *

O Boiler pump 20

P DHW circulating pump sA

* Function based on coding of address 33

IMPORTANT

DHW circulating pump P must pump into the Vitodens

200-W B2HB boiler (as illustrated).

36

Installation of different heating circuits...

■ radiator heating circuit (high-temp. circuit)

■ under floor heating circuit with 3-way mixing valve

(low-temp. circuit)

■ DHW production

... with the following flow conditions:

1. The water flow rate (output) of the radiator heating

circuit is at least 30% greater than that of the under

floor heating circuit.

2. The total flow rate of the two heating circuits is

less than the maximum possible water flow rate of

the Vitodens 200-W B2HB boiler (see page 31 for

max. water flow rate).

The use of a low-loss header is strongly

recommended if the maximum water flow rate in the

application concerned exceeds the values shown on

page 31, or if the system flow rates are unknown.

The low-loss header is available as accessory part.

See following pages for additional installation examples

with a low-loss header.

The 3-way mixing valve, built-in to achieve the lowtemperature level of the under floor heating circuit, is

controlled by an accessory kit for a heating circuit with

mixing valve.

5680 493 - 05

Page 37

Vitodens 200-W B2HB 45, 57 Installation

System Layout 5

Vitodens 200-W, B2HB with...

- DHW storage tank

- one heating circuit with mixing valve

- one heating circuit without mixing valve

- low-loss header

Boiler Connections

Legend

A Vitodens 200-W B2HB boiler with

Vitotronic 200, HO1B outdoor reset control

B Outdoor temperature sensor !

C Vitotrol remote (optional)

D Under floor heating circuit

E Radiator heating circuit

F Boiler circuit pump 20

G Mixing valve temperature sensor ?

H Kit for heating circuit with mixing valve

I Domestic hot water storage tank

J DHW tank temperature sensor %

K Expansion tank

L Temperature and pressure relief valve

M Pressure relief valve

N DHW recirculation pump 28/20 *

O DHW circulating pump sA

P Heating circuit pump

Q Low-loss header

R Viessmann temperature sensor for low-loss header ?

S Heating circuit pump 28/20 *

* Function based on coding of address 33

5680 493 - 05

Installation of different heating circuits...

■ radiator heating circuit (high-temp. circuit)

■ under floor heating circuit with 3-way mixing valve

(low-temp. circuit)

■ DHW production

... with the following flow conditions:

The total flow rate of the two heating circuits is greater

than the maximum possible water flow rate of the

Vitodens 200-W B2HB boiler (see page 31 for maximum

water flow rate of boiler).

The use of a low-loss header is strongly recommended.

The low-loss header is available as accessory part.

The 3-way mixing valve, built-in to achieve the lowtemperature level of the under floor heating circuit, is

controlled by an accessory kit for a heating circuit with

mixing valve.

IMPORTANT

DHW circulating pump O must pump into the Vitodens

200-W B2HB boiler (as illustrated).

37

Page 38

Boiler Connections

System Layout 6

Vitodens 200-W, B2HB with...

- DHW storage tank

- one heating circuit without a mixing valve

- two heating circuits with a mixing valve

- low-loss header

Vitodens 200-W B2HB 45, 57 Installation

Legend

A Vitodens 200-W B2HB boiler with