Page 1

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 1

The full-chip PRM-RS Customer Board described in this document is designed for use with the

Remote Sense (RS) family of full-chip PRM

®

regulators, and demonstrates the benefits of

Factorized Power Architecture™. This demonstration board is not designed for installation in enduser equipment. The system demonstrates the use of a PRM Regulator and a VTM

®

Current

Multiplier for general laboratory evaluation only.

Please read this document before setting up a customer demonstration board.

The User Guide is not comprehensive and is not a substitute for common sense and good

practice. For example:

1. When testing electronic products always use approved safety glasses.

2. Provide a strain relief for wires and place the system on the bench in such a way as to prevent

accidental dislodgment from the bench top.

3. Remove power and use caution when connecting and disconnecting test probes and interface

lines to avoid inadvertent short circuits and contact with hot surfaces.

4. Never use a jumper in place of the fuse. Replace the fuse only with its equivalent type

and rating.

5. Never attempt to disconnect the demonstration board from a VTM Customer Board while

power is applied. This system is not designed to demonstrate hot plug capability.

1.0 Introduction

The full-chip PRM-RS Customer Board can be used to demonstrate a stand-alone regulator or in

conjunction with a VTM Customer Board to enable demonstration of a Factorized Power

Architecture (FPA) system. There are many combinations possible using PRM and VTM Customer

Boards, but the focus in this user guide is using one PRM Customer Board and one VTM

Customer Board. The full-chip PRM Customer Board can be configured for local sensing (at the

PRM output), or non-isolated remote sensing (at the VTM module output). The full-chip PRM

Customer Board is nominally configured for local sensing where the voltage feedback circuit

regulates the output voltage of the PRM module. Implementing remote sensing requires

component changes and rework to the board which is detailed in section 8.3.

1.1 Part Numbers and Ratings

Refer to the specific PRM module data sheet for ratings of the device. It is important to remain

within the device limits when testing.

1.2 Contents

The full-chip PRM-RS Customer Board arrives with the following contents:

1. 1 x full-chip PRM-RS Customer Board fully populated

2. 1 x 11mm VI Chip

®

push pin heat sink

3. 2 x VI Chip push pins for heat sink installation

4. 2 x VI Chip push pin heat sink grounding clip

5. 2 x 10 pin male to male headers

Full-chip PRM®-RS Customer Board User Guide

Contents Page

Introduction 1

Features 2

General 2 – 4

Schematic 5

Bill of Material 7

VTM Customer

Boards 8

Testing 10

Modifications 16

Conclusions 19

USER GUIDE | UG:009

For use with PCB part number: 35306

Page 2

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 2

2.0 Features

The full-chip PRM-RS Customer Board has the following features:

1. Input and output lugs for source and load connections

2. Input fuse (appropriately rated)

3. Input capacitor for source decoupling

4. Test points for access to various device pins and circuit voltages

5. Trim pot for adjusting the output voltage set point

6. Voltage regulation, and current sensing circuitry appropriately set for proper operation

7. Recommended output filter inductor

8. Dual output headers (female) for transferring power and signal connections to downstream

VTM

®

Customer Board.

9. Switch for enabling / disabling the device through the PC pin

10. Oscilloscope probe jack for making accurate output voltage measurements

11. Provisions for installing custom VI Chip

®

push pin heat sink with grounding clips (optional,

included with board)

3.0 Board Description

The following section provides a detailed description of the full-chip PRM-RS Customer Board

components and test points.

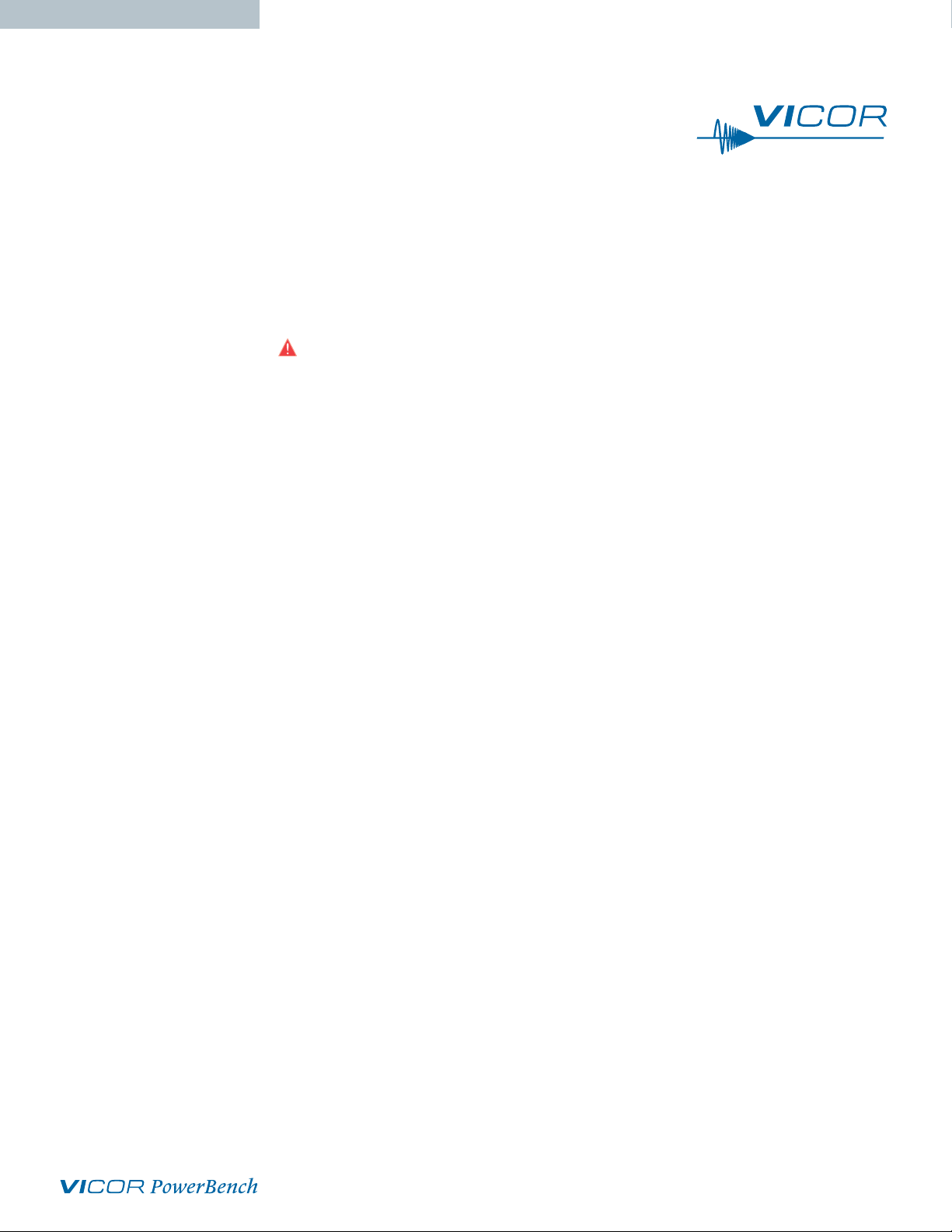

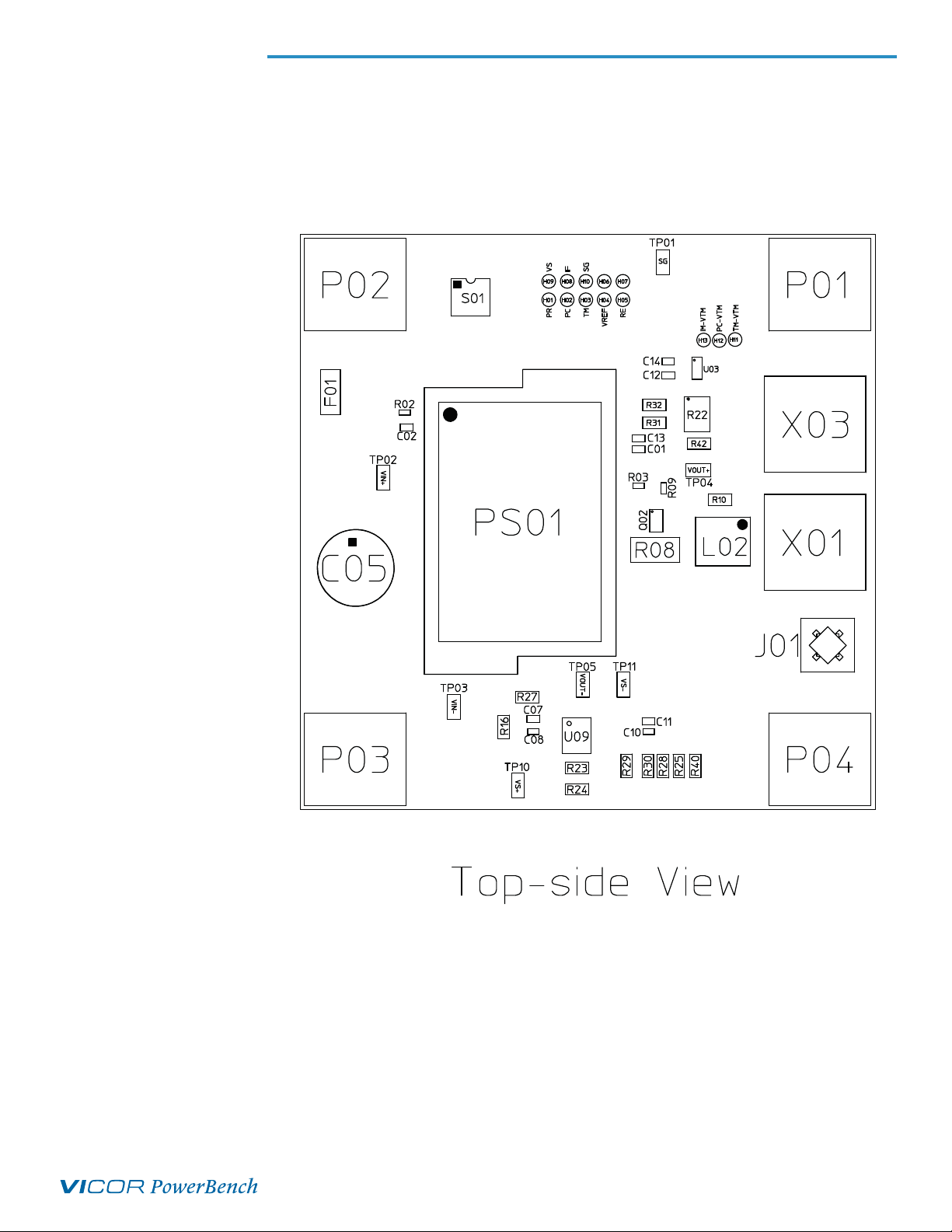

Figure 1

Board Description

Page 3

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 3

3.1 General Components

Refer to Figure 1 and Figure 2:

1. Input Lugs: Sized for #10 hardware. Use these for making connections to the input source.

This board does not contain reverse polarity protection. Check for proper polarity before

applying power.

2. Full-chip PRM-RS module (PS01)

3. Input Fuse (F01): 15 A rated

4. Input Capacitor (C01): 100 µF, 63 V capacitor allows for stable operation with

most input sources.

5. Enable / Disable Switch (S01): Dual switch with the following functionality:

a. S01_1 (Top): Spare switch. Wired to H07 and H06 on the PRM

®

board signal test point

header (#6) to allow for extra functionality if needed. Both positions are open and not

connected anywhere else on the board.

b. S01_2 (Bottom): PC enable switch. When in the right position (ON), the PC pin will be

connected to –IN and the device will be disabled. When in the left position, PC will be

open, and the device will be enabled.

6. Signal Test Point Header: Dual row of plated through hole test points for making measurements

or connections to the signals labeled.

7. VTM

®

Signal Test Point Header: Plated through holes for measuring VTM module signals

returned through connector X03. For use only with VTM Customer Boards containing

dual headers.

8. Output Lugs: Sized for #10 hardware. Use these lugs to connect the output directly to the load

9. Signal Connector (X03): Used to transfer the VTM module PC, IM, TM, and output sense signals

between the PRM and VTM Customer Boards. For use only with VTM Customer Boards

containing dual headers. Refer to Figure 2 for pinout.

10. Power / Signal Connector (X01): Used to transfer power (+/-Out) and VC to downstream VTM

Customer Board when used. For use with all VTM Customer Boards. Refer to Figure 2 for pinout.

11. Output Oscilloscope Probe Jack (J01): Used for making accurate scope measurements of the

output voltage (i.e. ripple). Remove scope grounding lead and insert probe directly into jack

ensuring a good connection between the jack and the probe ground barrel. Do not attempt to

install while power is applied. May not be compatible with all scope probes.

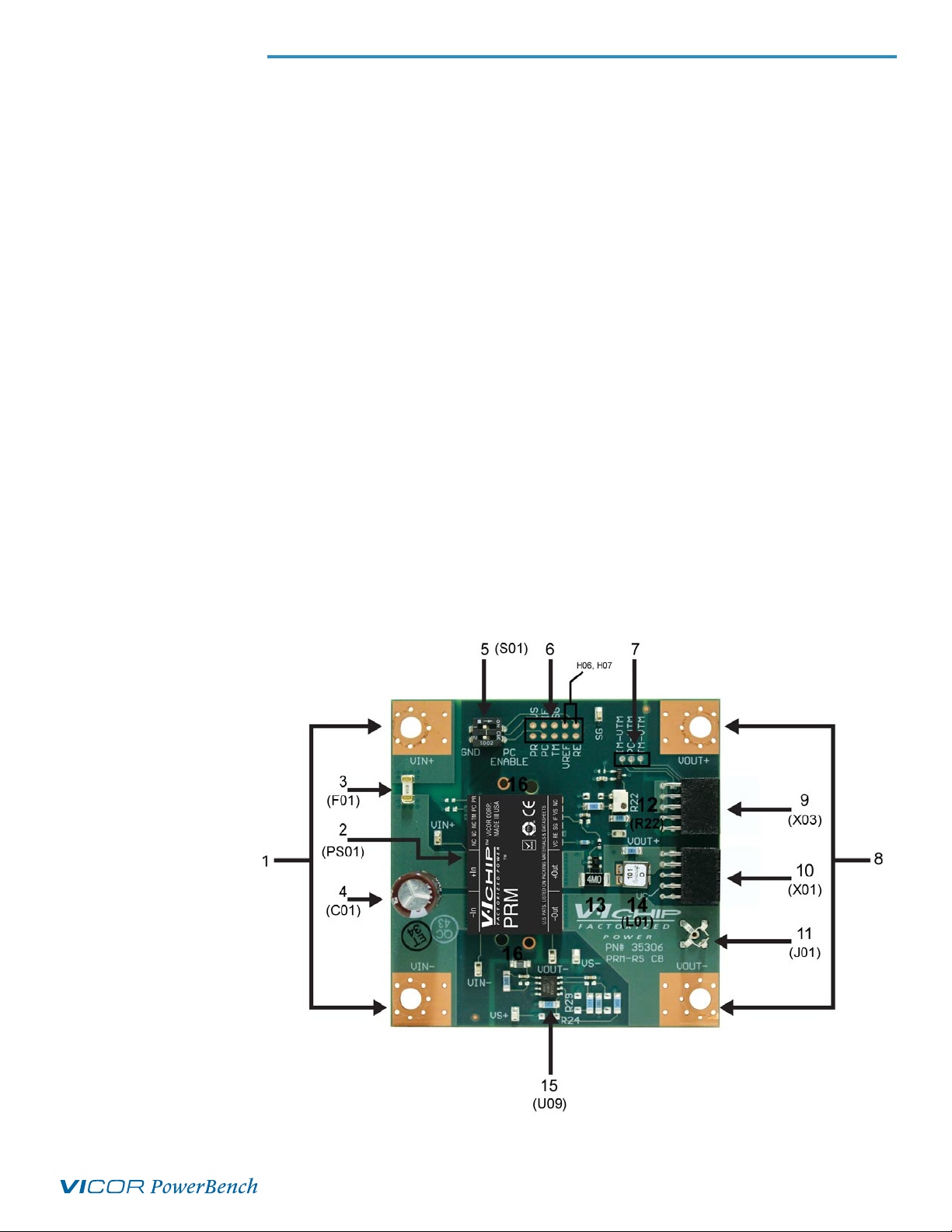

Figure 2

Power / Signal Connectors Pinout,

Front View

-OUT

-OUT

+OUT

-OUT

VC

+OUT

2

+OUT

+OUT

1

VC

-OUT

VS-

VS+

VTM -IN

NC

TM-VTM

NC

PC-VTM

IM-VTM

2

1

Power / Signal Connector (10)

X01

X03

Signal Connector (9)

Page 4

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 4

12. Output Voltage Trim Pot (R22): 11 turn trim pot adjusts the output voltage by increasing or

decreasing the error amplifier reference voltage (V

REF). Turn clockwise to increase the output

voltage, and counterclockwise to decrease the output voltage. Adjustment slot is

1.5 mm (L) x 0.6 mm (W).

13. High Side Current Sense Circuit (R

08, Q02): Current sense shunt and IC monitor the output

current and provide feedback to the IF pin for current limit protection. Gain is typically 200

mV/A, and is set for appropriate current limit set point. IF signal can be monitored at the

Signal Test Point Header (#6) to provide approximate output current measurement, but should

not be used if accurate output current measurements are required (<10% error). Efficiency

measurements should always be performed using an external calibrated shunt.

14. Output Inductor (L01): 0.4 uH inductor provides high AC impedance between PRM

®

and

VTM

®

modules (when used) to prevent high- frequency switching currents from circulating

between devices.

15. Voltage Sense and Error Amplifier (U09A, U09B): Dual op amp provides voltage sensing and

error amplifier function. The customer board is nominally configured for local voltage sensing

at the PRM regulator output. U09B can be re-configured as a differential amplifier to allow for

non-isolated remote sensing at the VTM module output or load. This requires rework as

described in Section 8.3.

16. Push Pin Heat Sink and Grounding Clip Mounting Holes: Use these holes for installing the

optional push pin heat sink and grounding clips included with the board.

Use of a heat sink is highly recommended for appropriate cooling of the PRM regulator.

3.2 Test Points

In addition to the Signal Test Point Headers (#6, #7), there are a number of surface mount test

points on the board with the following functions.

1. V

IN+, VIN- (TP01, TP03): Input voltage test points provide Kelvin connections to the input

leads. Use these test points for measuring the input voltage to avoid error due to interconnect

losses.

2. V

OUT+, VOUT- (TP04, TP05): Output voltage test points provide Kelvin connections to the

output leads. Use these test points for measuring the output voltage to avoid error due to

interconnect losses.

3. Signal Ground (TP01): Signal Ground (SG) test point is the ground reference for all control

circuitry.

4. VS+, VS- (TP10, TP11): +/- sense inputs to the differential amplifier when remote sense is

implemented. When used with a VTM Customer Board, the sense leads may be wired to the

VTM module output voltage through X03 depending on which VTM board is used. If not, a

twisted pair of wires can be used to connect sense leads to the VTM board output from these

test points.

Page 5

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 5

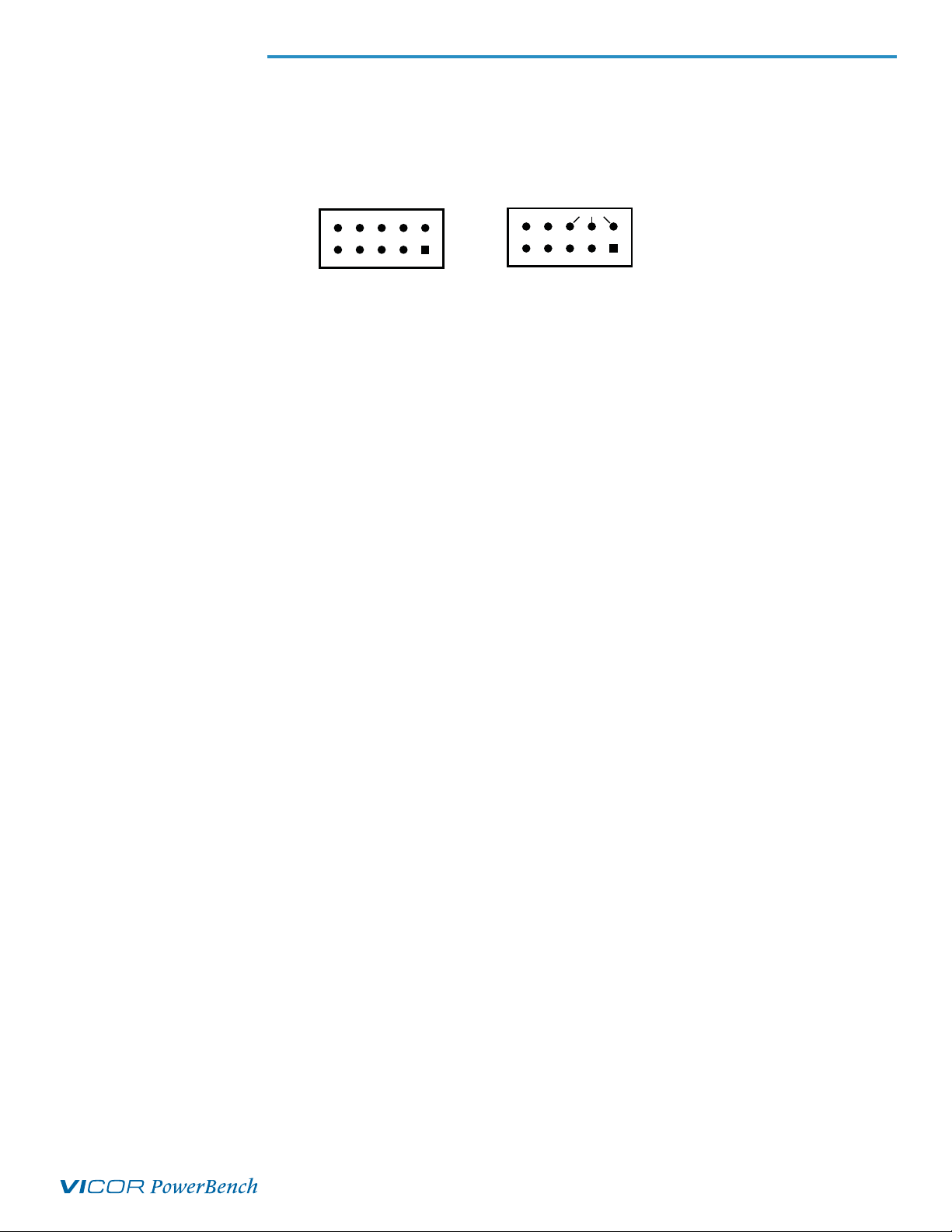

4.0 Schematic, Assembly and Bill of Material (BOM)

4.1 Schematic

Figure 3: Full-chip PRM-RS Customer Board Schematic

P01

TM-VTM

X03

IM-VTM

PC-VTM

H12

H11

H13

12345678910

32770

Vout+

Vout-

J0

VS- VS+

Vvtm_out-

R03

TP01

2

3

S01 SW DIP-2

1

4

H07 H06

H10

H08

VS

H09

TP18

TP13

C01

IF

NC4

15

16

VS

PO

TP16

GND

RE

11

14

12SG13

IM

RE

VC

-RS

TM

PRM

PC

TP19

H05

PC

PR

TP17

H04

1

RE

TM3NC4NC5NC

2

6

Vref

NC2

NC1

TP12

TM

H03

H01

PR

H02

TP15

C02

TP14

NC3

GND

R02

P02

4mR08

TP08

TP04

10

7

TP02

TP06

F01

VIN+

0

8

2

X01

PRMOUT

2512

+OUT

+IN

C05

29207-015

P03

91

7

56

3 4

1

32770

IF

9

–OUT

–IN

8

100u

VIN-

R09

TP09

TP05

TP03

TP07

P04

RE

Q02

OUT

1

0

PS01

FD2

FD1

0.1uH

L02

4

5

V+

HS01

FID UCIA L

FID UCIA L

2

GND

GND

GND

Vout-

4

VIN-

VIN+

3

1206

10

R10

SOT 23_5

VIN-

C07

R16

Vs-

Vs+

VS-

VS+

PRMOUT

TP10

TP11

54.9k

R29

R24

OPEN

OPEN

R40

1.24k

1.24k

R23

R30

GND

6

5

U09B

7

C10

R28

C13

Vref

R25

R31

R42

Vref

2

GND

3

48

U09A

1

R27

0 OHM

VS

GND

C11

R22

10k

C08

R32

1206

OPEN

U03

RE

3

C12

GND

T

IN

OUT2O

SOT 23_3

1

C14

GND

REF3312 Regulator (1.25V)

PR

Page 6

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 6

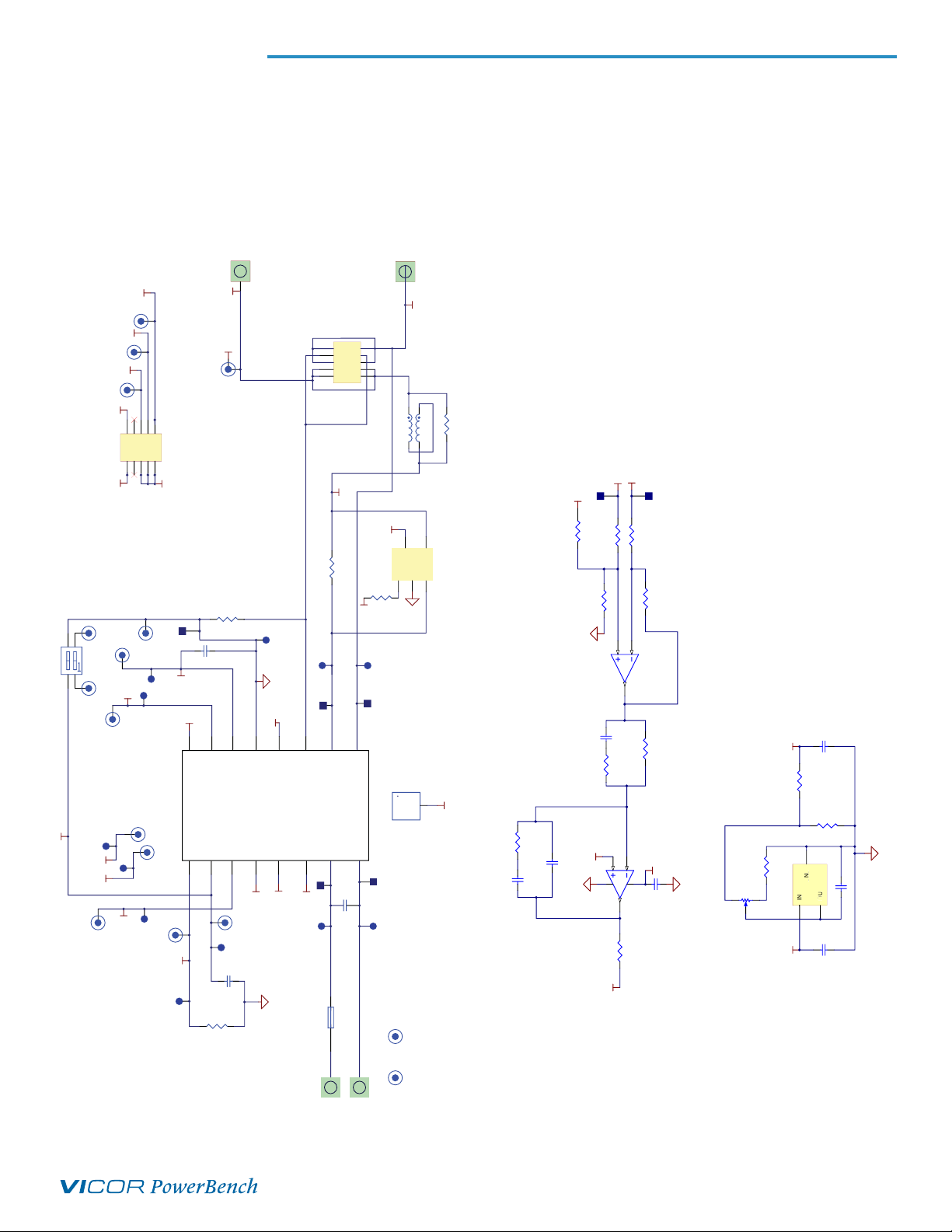

Figure 4

Full-chip PRM-RS

Customer Board

Assembly Drawing

4.2 Assembly Drawing

Page 7

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 7

4.3 Bill of Materials

Ref. Des. Description Manufacturer

Manufacturer Part

Number

C01 Not Applied Not Applied Not Applied

C02 Not Applied Not Applied Not Applied

C05 CAP ALEL 100uF 20% 63 V 0.2 radial U. CHEMI-CON EKME630Ell101MJC5S

C07 CAP X7R 2,200 pF 10% 100 V 0603 Generic Generic

C08 Not Applied Not Applied Not Applied

C10 Not Applied Not Applied Not Applied

C11 CAP X7R 0.01uF 10% 100 V 0603 Generic Generic

C12 CAP X7R 0.10uF 10% 16 V 0603 Generic Generic

C13 CAP X7R 0.22uF 10% 25 V 0603 Generic Generic

C14 Not Applied Not Applied Not Applied

F1 Fuse 15 Amp Fast NANO 451 Littlefuse 0451015.MRL

J01 Jack Vertical Mech Thru Hole Tektronix 131-5031-00

L02 Ind 0.1u/20%/20A dual 3026 Coilcraft SLC7530D-101MLC

PS01 Model Specific Vicor Model Specific

Q02 IC I Sense INA194 SOT23 5 TI INA194

R02 Not Applied Not Applied Not Applied

R03 RES 1K OHM 1W 1/10W 1% 0603 Generic Generic

R08 RES I Sense 4m OHM 1W 1% 2512 Generic Generic

R09 RES 0 OHM Jumper 1A 0603 Generic Generic

R10 RES 10 OHM 1/4W 1% 1206 Generic Generic

R16 RES 24.9K OHM 1/4W 1% 1206 Generic Generic

R22 RES TRIM POT 10K OHM 1/4W 10% SMD Murata PVG5A103C03R00

R23 RES 1.24K OHM 1/4W 1% 1206 Generic Generic

R24 Not Applied Not Applied Not Applied

R25 Not Applied Not Applied Not Applied

R27 RES 0 OHM 1/8W 5% 1206 Generic Generic

R28 RES 1K OHM 1/4W 1% 1206 Generic Generic

R29 Not Applied Not Applied Not Applied

R30 RES 1.24K OHM 1/4W 1% 1206 Generic Generic

R31 RES 10K OHM 1/4W 1% 1206 Generic Generic

R32 Not Applied Not Applied Not Applied

R40 RES 54.9K OHM 1/4W 1% SMD 1206 Generic Generic

R42 RES 4.99K OHM 1/4W 1% 1206 Generic Generic

S01 SW DIP SPST 2 POS C&K SD02H0B

TP01

TP02

TP03

TP04 Test Point, Surface Mount Keystone 5017

TP05

TP10

TP11

U03 IC VREF 1.25V REF3312 SOT23 3 TI REF3312

U09 IC DUAL OPAMP LM6142AIM 8PIN SO National LM6142AIM

X01

X03

CONN 10POS 90° Thru-Hole Female 0.100SPC Sullins PPTC052LJBN-RC

ACCESSORY 1 HS XF 11 mm Full VI Chip®Module Vicor 34074

ACCESSORY 2 Clip Heat Sink Grounding Vicor 33855

ACCESSORY 3 CONN 10POS Header STR M-M 3A/0.100 Sullins PEC05DABN

ACCESSORY 4 Push Pin White 0.063” Vicor 34141

Table 1

Full-chip PRM-RS Customer

Board BOM

Page 8

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 8

5.0 VTM®Customer Boards

The full-chip PRM-RS Customer Board is designed to work with all types of VTM®Customer Boards

to facilitate testing of virtually any PRM

®

/VTM module combination. Note that there are currently two

basic types of VTM Customer Boards. Both board types share many common features, including input

capacitance, output capacitance, and various test points. The main difference between the two board

types is the number of connectors. Before configuring a PRM / VTM board setup, the user should

identify which type of VTM board is being used.

5.1 VTM Customer Board Type A (Single Connector)

The VTM Customer Board Type A contains a single power / signal header designed to mate with

only X01 on the full-chip PRM-RS Customer Board. The VTM module output voltage, and VC

signal are transferred through this header when connected to a PRM Customer Board.

Figure 5

VTM Customer Board Type A

Figure 6

VTM Customer Board Type A

Connector Pinout (Front View)

+IN +IN

+IN

+IN

-IN

-IN

VC

VC

-IN

-IN

VTMTM CUSTOMER BOARD

TYPE A

Power / Signal Connector

Page 9

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 9

5.2 VTM®Customer Board Type B (Dual Connectors)

The VTM Customer Board Type B contains dual connectors designed to mate with both X01 and

X03 on the full-chip PRM-RS Customer Board. The additional connector is used to transfer VTM

module signal pins, as well as the VS+ and VS- signals between boards. The VS+ and VS- signals

are tied directly to the VTM module output and can be used for implementing remote sense as

described in a later section.

Figure 7: VTM Customer Board

Type B

Figure 8: VTM Customer Board

Type B

Connector Pinout (Front View)

VTM -IN

IM-VTM

PC-VTM

TM

VTM

CUSTOMER BOARD

TYPE B

Signal Connector

TM-VTM

NC

NC

VS-

VS+

+IN +IN

+IN

+IN

-IN

-IN

VC

VC

-IN

-IN

VTMTM CUSTOMER BOARD

TYPE B

Power / Signal Connector

Page 10

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 10

6.0 Recommended Test Equipment

The following is a list of recommended test equipment. Output load current, and voltage ratings are

a function of the VTM

®

module selected (if used).

1. DC Power Supply: 0 – 100 V, 500 W minimum.

a. Set Overvoltage Protection (OVP) based on absolute maximum rating of PRM

®

module.

2. Load: Rated appropriately based on output voltage, current, and power requirements. Electronic

load, 0 to 100 V, 130 A minimum recommended.

3. DMM(s).

4. Oscilloscope + Probe(s).

5. Interconnect cables and fastening hardware.

6. Calibrated input and output shunts, appropriately rated.

7. Trim Pot screwdriver

8. Fan

9. Data sheets for requisite PRM and VTM devices used.

10.Safety glasses.

7.0 Push Pin Heat Sink Installation

Each PRM and VTM Customer Board comes with its own heat sink and push pins for installation.

Before testing, it is highly recommended that heat sinks be installed in the appropriate location for

each board. When installing the push pin heat sink, use caution not to exceed the maximum

compressive on the device listed in the data sheet.

8.0 Test Configurations

The full-chip PRM-RS Customer Board is designed to work in a number of different configurations as

described in the following section. The scope of this document is limited to describing a single PRM

Customer Board as a stand-alone or connected to a single VTM Customer Board. Other

configurations may be possible, though they cannot be guaranteed to have stable operation with the

components designed onto the board. If testing is to be performed outside of the recommended

configurations, the design should be evaluated to determine if changes to any of the onboard

components are necessary.

8.1 PRM Board Stand-alone Operation

In this configuration, the PRM module output voltage is sensed through the divider formed by

R40 and R23. U09B is configured as a buffer as illustrated in Figure 9, and provides the sense

voltage to the error amplifier (U09A). R24, and R29 are left open, reserved for differential sensing.

R40 is set to limit the upper trim range based on a maximum reference voltage of 1.25 V.

1.24k

R30

1.24k

R23

Vs-

Vs+

PRMO UT

VS+

VS-

TP10

TP11

R40

R24

R29

6

5

7

U09B

GND

OPEN

OPEN

54.9k

Figure 9: Local Sense

Configuration

Page 11

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 11

8.1.1 PRM®Board Stand-alone Operation Setup

This is the nominal configuration, and requires no rework to implement. If the board has

been modified, restore to its original configuration.

1. Solder test leads to signals on the test point header that will be measured.

2. Connect input source to the input lugs. Verify proper polarity. Set to 0 Volts or OFF before

connecting.

3. Connect output to load using the output lugs. Set load to 0 Amps or OFF.

4. Insert oscilloscope probe into J01 if used.

5. Connect DMM to the output test points (V

OUT+, VOUT-) and to any other signals to be

measured.

6. Set PC Enable Switch (S01_2) to the left position.

7. Apply nominal input voltage.

8. Measure output voltage and verify operation.

9. Use the output voltage trim pot (R

22) to adjust the output to the desired level.

10. Apply 100% load, and verify full load operation.

11. Turn off load and power. Proceed to following sections for detailed test procedure.

8.2 PRM – VTM Board Operation, Local Sense

In this configuration, the PRM and VTM®Customer Boards are connected together to form a

PRM / VTM-pair and regulation is performed at the PRM module output. Load regulation will

be degraded due to the VTM module output resistance. Tighter regulation can be achieved by

implementing non-isolated remote sense as described in Section 8.3.

8.2.1 PRM – VTM Board Local Sense Setup

Local sensing is the nominal configuration of the customer board and requires no rework to

implement. If the board has been modified, restore it to its original configuration.

1. Solder leads to any signals on the test point header to be measured.

2. Identify the type of VTM Customer Board to be used (Type A, or Type B).

a. Type A: Install single male-to-male header to X01 only.

b. Type B: Install dual male-to-male headers on X01 and X03.

3. Connect desired VTM board referring to Figure 11 or Figure 12.

4. Connect input source to the input lugs. Verify proper polarity.

Set to 0 Volts or OFF before connecting.

5. Connect VTM board output to load using the output lugs. Set load to 0 Amps or OFF.

6. Insert oscilloscope probe into VTM board output probe jack.

7. Connect DMM to the VTM board output test points and to any other signals to be measured.

8. Set PC Enable Switch (S01_2) to the left position.

9. Apply nominal input voltage.

10. Measure VTM board output voltage and verify operation.

11. Use the output voltage trim pot (R

22) to adjust the output to the desired level.

a. Do not trim below the minimum input voltage of the VTM module used.

12. Apply 100% load, and verify full load operation.

13. Turn off load and power. Proceed to following sections for detailed test procedure.

Page 12

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 12

8.3.1 PRM – VTM Board, Non-isolated Remote Sense Setup

This is NOT the nominal configuration of the customer board and requires rework to implement.

1. Determine the maximum desired VTM module output trim voltage (R

22 fully clockwise).

2. Use Equation 1 to select the appropriate value for R

24/R29. Obtain the closest 1% standard

value, size 1206 resistors for installation.

3. Remove R

40.

4. Install R

24 and R29 in the appropriate positions

5. Determine the type of VTM Customer Board to be used.

a. Type A:

i. Install single male-to-male header to X01 only.

ii. Connect PRM and VTM Customer Boards together as illustrated in Figure 11.

iii.Connect the VS+ test point to the VTM Board +OUT test point, and VS- test point

to the VTM Board –OUT test point through a twisted pair of wire

b. Type B:

i. Install dual male-to-male headers to X01 and X03

ii. Connect PRM and VTM Customer Boards together as illustrated in Figure 12.

iii.Verify connection from VS+ to VTM +OUT, and VS- to VTM -OUT

6. Connect a jumper between VTM –OUT and VTM –IN

7. Connect input source to the input lugs. Verify proper polarity. Set to 0 Volts or OFF before

connecting.

8. Connect VTM Board output to desired load using the output lugs. Set load to 0 Amps or OFF.

1.24k

R30

1.24k

R23

Vs-

Vs+

PRMO UT

VS+

VS-

TP10

TP11

R40

R24

R29

6

5

7

U09B

GND

OPEN

Figure 10: Remote Sense

Configuration

Equation 1

Where: VOUT_SET(MAX) is the maximum VTM output trim voltage

8.3 PRM®–VTM®Board Operation, Non-isolated Remote Sense

In this configuration, the PRM and VTM Customer Boards are connected together to form a

PRM / VTM pair and regulation is performed at the VTM module output. U09B is configured as a

differential amplifier with a gain set for the appropriate output voltage. R24 and R29 set the gain

and limit the maximum VTM output voltage based on Equation 1 assuming the trim pot (R22) is

fully clockwise.

Page 13

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 13

9. Insert oscilloscope probe into VTM®Board output probe jack.

10. Connect DMM to the VTM board output test points and to any other signals to be measured.

11. Set PC Enable Switch (S0_2) to the left position.

12. Apply nominal input voltage.

13. Measure VTM module output voltage and verify operation.

14. Use the output voltage trim pot (R

22) to adjust the output to the desired level.

a. Do not trim below the minimum input voltage of the VTM module used.

15. Apply 100% load, and verify full load operation.

16. Turn off load and power. Proceed to following sections for detailed test procedure.

Figure 11: Full-chip PRM-RS

Customer Board connection to

VTM Customer Board Type A

Figure 12: Full-chip PRM-RS

Customer Board Connection to

VTM Customer Board Type B

Page 14

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 14

9.0 Test Procedure

Once the board has been setup and verified to be functional, it can now be used to characterize the

behavior, and performance of the selected configuration. Some typical tests are outlined below.

9.1 Efficiency vs. Line / Load (Ambient)

1. Connect input source through calibrated input shunt noting the value. Set to 0 Volts or OFF.

2. Connect output to load through calibrated output shunt noting the value.

Set to 0 Amps or OFF.

3. Connect DMMs to measure input voltage, output voltage, input shunt voltage, and output

shunt voltage. Use Kelvin test points for input, output, and shunt voltage measurements.

4. Turn on fan for cooling. Make sure heat sink is installed.

5. Set PC enable switch to the Left position.

6. Apply desired input voltage and load.

7. Quickly record DMM measurements to avoid heating.

i. GPIB control recommended for simultaneous DMM measurement recording.

8. Turn off input source and load. Allow device to cool to ambient temperature.

9. Repeat for all desired test conditions.

i. GPIB control recommended for line/load sweeps.

10.Use data to calculate efficiency.

9.2 Output Ripple vs. Load

1. Connect input source and load. Set to OFF.

2. Insert oscilloscope probe into output probe jack.

3. Set oscilloscope:

i. AC coupling 1 MΩ, 20 MHz bandwidth.

ii. Time scale: 1 µsec / div

iii. Voltage scale: 200 mV / division

4. Turn on fan for cooling.

5. Apply input voltage.

6. Apply load.

7. Record oscilloscope waveform. Use cursors to measure pk-pk ripple. Adjust scales as necessary.

8. Repeat for all desired conditions.

9.3 Startup Timing, Application of Input

1. Connect input source and load. Set to OFF.

2. Connect oscilloscope probes to V

IN, VOUT, and any other signals to be measured

3. Set scope voltage, and time scales appropriately.

i. 20 msec / div recommended time scale

ii. Trigger on positive edge of V

IN

4. Apply desired startup load

5. Set input source to ramp from 0 to V

IN(NOM).

i. Ensure that the slew rate is within acceptable limits

6. Capture waveform. Adjust scales as necessary.

Page 15

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 15

9.4 PC Enable / Disable Timing

1. Connect input source and load. Set to OFF.

2. Set PC enable switch (S01-2) to the right position to disable the PRM

®

module.

i. PC should be connected to SG.

3. Connect scope probes to PC, V

OUT, and any other signals to be measured.

4. Set scope scales appropriately.

i. 1 msec / div recommended.

ii. Trigger on positive edge of PC.

5. Apply desired startup load.

6. Apply nominal input voltage (V

IN(NOM)).

i. Verify unit is disabled.

7. Move S01_2 to the left position to enable the device.

8. Record Enable waveform. Adjust scales as necessary.

9. Trigger on negative edge of PC.

10.Move S01_2 to the Right position to disable the device.

11.Record Disable waveform. Adjust scales as necessary.

12.Monitor for switch bounce. Repeat measurement or adjust setup as necessary.

9.5 Current Limit

Note: In order for this test to be performed properly, a resistive load must be used. This

includes an electronic load set to constant resistance mode. Be cautious of potential load

interactions when using electronic loads. If the output voltage or current begin to

oscillate, repeat the test with a passive resistive load.

1. Apply input source and load. Set to OFF.

2. If using an electronic load, change to Constant Resistance mode.

3. Connect DMMs to measure V

OUT, IF, and any other signals to be measured.

i. Use electronic load reading, clamp on DC meter to measure approximate output current or

calibrated shunt for more accurate measurement.

4. Set S01_2 to Left position to enable the device.

5. Apply input voltage. Verify output is present.

6. Enable load. Gradually ramp up current (decrease resistance) until current limit threshold is

reached.

i. Current will remain at maximum, output voltage will fold back.

Page 16

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 16

10.0 Advanced Modifications

10.1 Stability, Bandwidth and Transient Response

The nominal compensation of the full-chip PRM-RS Customer Board is set to provide relatively low

bandwidth in order to ensure stability under all of the recommended configurations. The closed

loop frequency response varies as a function of line, load, trim, and output capacitance. Refer to

the PRM

®

module data sheet for a detailed description and AC model. Adding additional

capacitance to the output of the PRM or VTM

®

Customer Board may result in instability. When

testing transient response, it is important for the user to understand that response is a function of

compensation which should be optimized based on the end requirements for best performance. An

example transient response waveform, taken with a passive resistive load, is shown below. As

illustrated, the recovery time is on the order of 180 µsec. It should be noted that with control loop

optimization, faster transient response recovery times are possible.

10.1.1 Compensation Adjustment

The sense and compensation circuit is shown below. Refer to the BOM (4.3) for component

values. If higher bandwidth, faster transient response, and/or operation outside of the

recommended configurations are desired, the user may adjust the compensation, referring to

the appropriate PRM module data sheet for guidelines. This type of tuning is highly recommended

and generally requires the use of a network analyzer to measure the closed loop response.

Stability must be verified across all line, load, and trim conditions. Typically maximum crossover

frequency will occur at full load, and minimum crossover frequency will occur at minimum load.

Examples of closed loop response plots are illustrated below.

Figure 13: Example PRD48BF480T400A00

transient response,

Remote Sense Configuration

Page 17

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 17

Figure 14

Sense and Compensation Components

Figure 15

PRD48BF480T400A00 + V048F480T006-CB

Closed Loop Response, Differential Sense,

48 V

OUT, 0.5 A, Resistive Load

Figure 16

PRD48BF480T400A00 + V048F480T006-CB

Closed Loop Response, Differential Sense,

48 VOUT, 8.3 A, Resistive Load

C07

R16

C08

R40

R24

R29

PRMOUT

TP10

TP11

Vs+

VS+

VS-

Vs-

GND

Vref

PR

R27

0 OHM

48

3

1

U09A

2

C11

VS

GND

R25

C10

7

R28

U09B

GND

5

6

R23

R30

1.24k

1.24k

40

30

GAIN

PHASE

20

10

0

Gain (dB)

-10

-20

-30

-40

100 1000 10000 100000 1000000

Frequency (Hz)

40

30

GAIN

PHASE

20

180

135

90

45

0

-45

Phase (Degrees)

-90

-135

-180

180

135

90

10

0

Gain (dB)

-10

45

0

-45

Phase (Degrees)

-20

-30

-40

100 1000 10000 100000 1000000

-90

-135

-180

Frequency (Hz)

Page 18

UG:009 vicorpower.com Applications Engineering: 800 927.9474 Page 18

10.2 Current Limit Adjustment

The current limit set point is a function of the current sense amplifier gain, the shunt resistor, and

the internal current limit threshold of the PRM

®

module. The onboard current sense IC and shunt

have a typical combined gain of 200 mV/A. The gain of the current sense IC (Q

02) is fixed at 50 V/V,

and the IF current limit threshold is fixed at 2.0 V. The current sense shunt (R

08) can be changed per

Equation 2 in order to adjust the current limit. Once the value has been calculated, obtain the

closest 1% standard value, size 2512 resistor and replace R

08.

10.3 Trim Range Adjustment

The trim range is set by the reference voltage network shown below. The full-chip PRM-RS

Customer Board is nominally configured for a 20 V to 55 V trim range. Any operation outside of

the nominal trim range may require adjustments to the compensation.

Assuming local sense is implemented, the output voltage is defined by Equation 3. Referring to

Figure 17, the output of U

03 is 1.25 V. When R22 is fully clockwise, the U03 output voltage will be

applied directly to V

REF resulting in the maximum reference voltage. This, in combination with the

voltage sense gain will determine the maximum output voltage. As R

22 is turned counter

clockwise, R

22 and R42 form a divider which limits the minimum reference voltage.

In order to change the upper trim range, adjust the voltage sense gain (R

40) based on a maximum

reference voltage of 1.25 V. In order to change the lower trim range, use Equation 3 to determine

the minimum reference voltage required and adjust R

42 appropriately. Before making adjustments

to the trim range, refer to the data sheet to ensure that the device will operate outside of its

rated limits.

V

IF_IL is the IF current limit threshold (2.0 V)

I

LIMIT(SET) is the desired current limit set point

G

CS is the current sense amplifier (QO2) gain (50 V/V)

Equation 2

Equation 3

(local sense only)

Page 19

vicorpower.com Applications Engineering: 800 927.9474 Rev 1.1 Page 19

09/2014

GND

RE Vref

C14

R42

REF3312 Regulator (1.25V)

SOT 23_3

GND

3

IN

1

OUT

2

N

D

I

N

O

U

U03

C12

C13

R31

1206

OPEN

R32

10k

R22

4.99 k

10 k

Figure 17

Reference Circuit

11.0 Conclusion

The full-chip PRM-RS Customer Board is a flexible tool which allows users to implement and perform

basic testing on a very wide range of configurations, including PRM

®

-VTM®module combinations. This

User Guide covers some basic and advanced topics; however, it cannot describe every scenario. If

additional information is required, please contact Vicor Applications Engineering.

Technical advice furnished by Vicor is provided as a free service, with the intent

to facilitate successful implementation of Vicor Products. Vicor assumes

no obligation or liability for the advice given or results obtained.

All such advice given and accepted is at user's risk.

Go to: http://www.vicorpower.com/contact-us for ordering information and application

support.

G

Loading...

Loading...