Page 1

FlatPAC-EN™ and FlatPAC-EN MI

EN Compliant Autoranging Switchers

FlatPAC-EN/EN MI Design Guide

Design Guide

and

“Quick Install” Instructions

www.vicorpower.com

Rev. 2/2012 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474

Page 2

TABLE OF CONTENT

Overview of Product...........................................................................................................................3

Part Numbering...................................................................................................................................3

Mechanical Considerations.................................................................................................................4

FlatPAC-EN/EN MI Do’s and Don’ts................................................................................................4

Technical Description.........................................................................................................................5

Configuration Layout drawing...........................................................................................................6

Quick Install Instructions....................................................................................................................7

Mechanical Drawings.........................................................................................................................10

Output connector information............................................................................................................11

Connector Kit listing..........................................................................................................................12

Interface Connections.........................................................................................................................13

RS 232 Microcontroller......................................................................................................................14

Specifications.......................................................................................................................... ..........18

Output vs. AC & DC Voltage Graphs . .............................................................................................20

Thermal Curves..................................................................................................................................22

Current Share Boards.........................................................................................................................26

Pg 2 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 2/2012

FlatPAC-EN/EN MI Design Guide

Page 3

FlatPAC-EN™ and FlatPAC-EN MI

EN Compliant Autoranging Switcher

Overview

The FlatPAC-EN/EN MI is an ultra low profile switching power supply that provides up to 500 Watts from up to 4

isolated outputs. It operates on either 115 or 230 Vac nominal (47-63 Hz), or 250-380 Vdc. It can be populated

with either VI-200/VI-J00 or Maxi/Mini/Micro Vicor converters. The use of these converters gives the FlatPACEN/EN MI the inherent power flexibility typical of all Vicor products. With dimensions of 1.4" H (35,6mm) x 5.0"

W (127mm) x 9.2" L (233,7mm), the FlatPAC-EN/EN MI provides a power density greater than 7W/in

3

. It is facto-

ry configured to meet user output requirements. Note: The FlatPAC-EN/EN MI does not have an internal fan.

The MI version is a rugged chassis designed specifically for COTS and harsh environment applications

Using the PowerBench configurator tool available on vicorpower.com, anybody can now configure a FlatPAC-EN

(and other Westcor power supplies) online.

Standard Features

• Power Factor Correction (passive): Power Factor (Typical) 0.70 (>75% Load)

• Input Voltage: 90-132/180-264 Vac1, 47-63 Hz, or 250-380 Vdc

• Maximum Power Output: 500W (105/190Vac min.)

425W for EN61000-3-2 compliance

• Up to 4 isolated user specifiable outputs

• Conducted EMI: FCC Class A EN 55022 Class A

FCC Class B EN 55022 Class B

Mil-STD 461 may require external filter

• Harmonic Attenuation to EN61000-3-2/A14

2

• Compliant to EN61000-4-4 (Electrical Fast Transient/Burst) and EN61000-4-5 (Surge Immunity)

• MI version meets Mil-STD 810 for Shock and Vibration with extended temp range

• MI version also available with -40C temp rating

• Efficiency (typical) > 70%

• Autosense

3

• RS-232 microcontroller interface

• Output overcurrent protection on all outputs

• Size: 1.4" H (35,6mm) x 5.0" W (127,0mm) x 9.2" L (233,7mm)

• Safety Agency Approvals: cURus, cTUVus, CE Mark

1

Derates to 260W@90Vac, 400W @ 180 Vac.

2

For output power ≤ 425W, not to exceed an input current of 3.33 A rms at 230 Vac, 50 Hz.

3 This feature is implemented in all converter slots (except with Micro modules). Autosense allows automatic local sensing

when remote sense connections are not made. The FlatPAC-EN/EN MI will operate in remote sense mode when remote

sense connections are made. Refer to page 16 for more information on Autosense.

Optional Features

• Current Share Board for unit to unit power sharing - See page 26 and page 27

• Connector kits (# 19-130044)

• Conformal coating available on select MI models - contact factory

• -40oC Operation, Mil-STD 810 Shock and Vibration (MI rugged chassis only)

Part Numbering

FlatPAC-EN/EN MI FLx1-x2 x3 -xxxx (-x4)(-x5)x

1

Number of outputs

e.g. FL4-13-6544 x

2

Number of VI-200/VI-J00 modules

x

3

Number of Maxi/Mini/Micro modules

xxxx Sequential number assigned by Westcor

(-x4) Optional Factory assigned: G - RoHS

(-x5) Optional versions

Note: x5= MI for rugged chassis, = MC for rugged chassis with conformal coating

Rev. 2/2012 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Pg. 3

FlatPAC-EN/EN MI Design Guide

Page 4

Mechanical Considerations

The FlatPAC-EN/EN MI is mounted on the bottom surface using standard 8-32 or 4 mm screws (cannot be mounted from the front.)

Maximum allowable torque is 5 in. lbs.,. The maximum penetration for mounting holes A1, A2, A3 and A4 is

0.125 in. (3mm) and for mounting holes B1, B2, C1 and C2 is 0.250 in. (6mm). The minimum recommended

mounting holes are as follows:

1. For standard mounting (forced air cooling), use A1, A2, A3, A4 mounting holes.

2. For standard mounting (conduction cooling), use A1, A2, A3, A4, B1 and B2 mounting holes.

3. For a Vicor 2 Up FlatPAC retrofit replacement, use C1 and C2 as these two are identical to the recommended

mounting holes on the FlatPAC.

For increased ruggedness, additional mounting holes can be used to secure the power supply.

The FlatPAC-EN/EN MI does not have an internal fan. It can be either conduction or convection cooled (same

model).

Avoid excessive bending of output power cables after they are connected to the output terminals. For high-current

outputs, use cable ties to support heavy cables and minimize mechanical stress on connectors. Be careful not to

short-out to neighboring outputs. The maximum torque recommended on output nuts is 10 in. lbs.

For applications that require vibration levels above MIL-STD-810E, minimum integrity test, a shock absorbing

mount design is required.

FlatPAC-EN/EN MI Do’s and Don’ts

• Do not exceed an operating case temperature of 90oC. To prevent an overtemperature condition, an external

fan may be required.

• Run the output (+/–) power cables next to each other to minimize inductance.

• Always turn the power supply off before disconnecting input or output wires.

• When using the remote sense feature, the +Out and -Out load wires should never be disconnected while the

supply is operating. Failing to do so could damage the power supply.

• Do not attempt to repair or modify the power supply in any manner as this action will void the warranty. In

the event of problems, contact Customer Service at 1-800-735-6200.

• Insert proper fault protection at power supply input terminals (i.e., a fuse). Refer pg 13 for more information.

• Use proper size wires to avoid overheating and excessive voltage drop.

• Output voltages over 60Vdc, whether from individual modules or series arrays, are considered as hazardous

secondary outputs under UL 60950. Appropriate care must be taken in design implementation of the supply.

Pg 4 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 2/2012

FlatPAC-EN/EN MI Design Guide

Identical mounting

holes (C1 & C2)

to Vicor's

2 UP FlatPAC

C1

C2

A1

B1

B2

A3

A4

Page 5

Technical Description

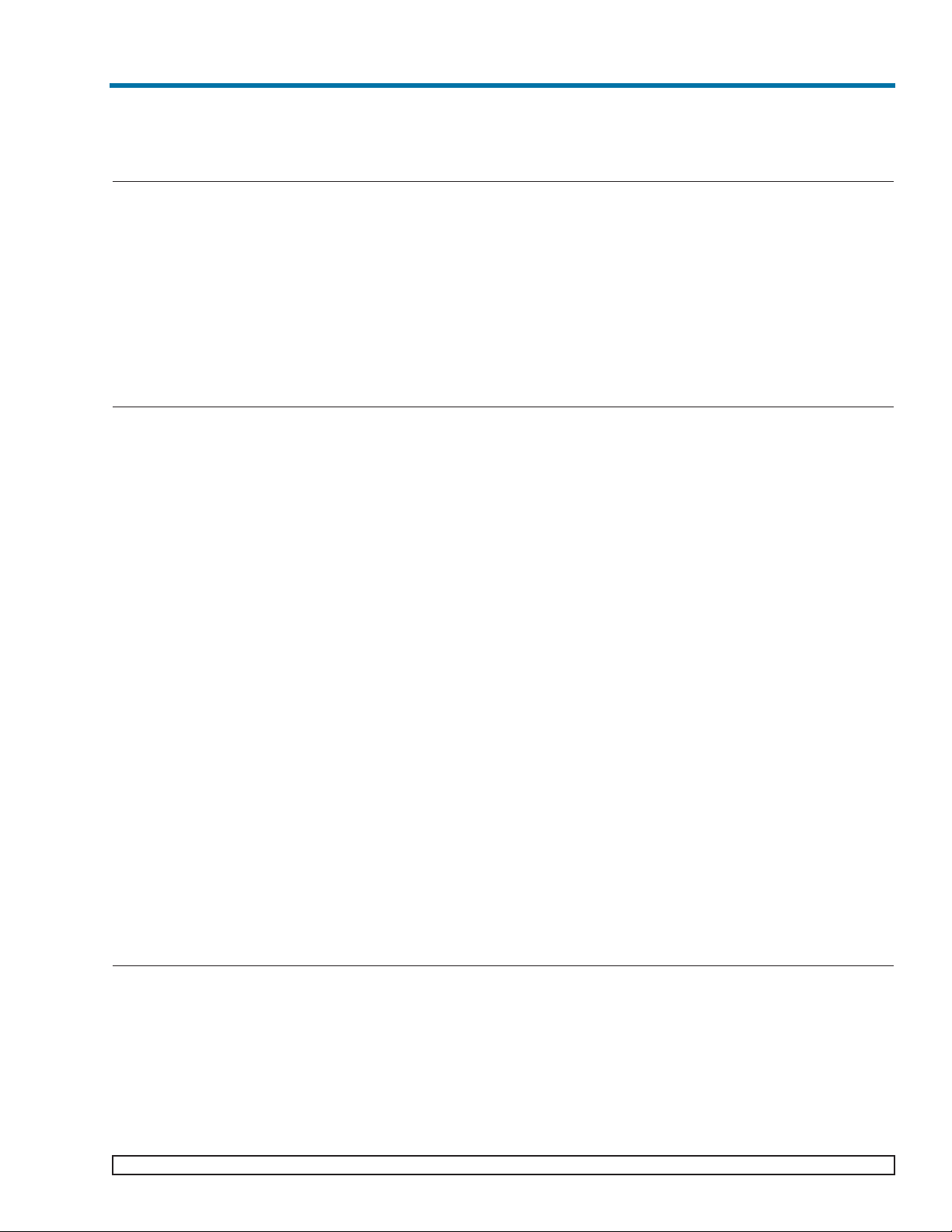

The FlatPAC-EN/EN MI consists of an off-line single phase autoranging front end, EMI filter, customer interface,

power supply control circuit, associated housekeeping circuits, a MiniHAM module and a selection of Vicor’s VI200/VI-J00 and/or Maxi/Mini/Micro DC-DC converters.

The MiniHAM was specifically designed for EN compliance using passive filtering. Unlike active PFC solutions,

the MiniHAM generates no EMI, greatly simplifying and reducing system noise filtering requirements. It is also

considerably smaller and more efficient than active alternatives and improves the unit’s MTBF. It will provide harmonic current compliance at 230Vac input up to 425W of output power. Input AC mains voltage is applied to input

connector MBJ1 (see page 7) and the input current is passed through an EMI filter designed to meet conducted

noise limit of EN 55022, Classes A and B specifications (certain configurations meet EN55022 Class B. Consult

Factory.)

At start-up, the microcontroller verifies that the input voltage is within the specified operating range. Once this

occurs, the microcontroller closes the safety relay and puts the autoranging front-end in the correct mode (closing

or opening the Doubler relay). The autoranging front-end has two modes, the doubler mode (90Vac - 132Vac) or

bridge rectifier mode (180Vac-264Vac, 250Vdc-380Vdc). Inrush current is limited by a PTC thermistor. The PTC

is shunted out (by closing the Inrush relay) when the output voltage has charged up the bus capacitors within the

specified range (205Vdc-390Vdc). Approximately 1 second after the application of the input voltage, the bus voltage is within operating limits and the AC OK signal asserts to a TTL "1", indicating the input power is OK. After

AC OK is asserted high, the user can now control the power outputs.

Output voltage conversion is achieved by Vicor’s 300Vin family of Zero-Current-Switching (ZCS) DC-DC converters. These are forward converters in which the main switching element switches at zero current. This patented

topology has a number of unique attributes: low switching losses; high frequency operation, resulting in reduced

size for magnetics and capacitors; excellent line and load regulation; wide adjustment range for output; low

EMI/RFI emission and high efficiencies.

At initial power-up, all outputs are disabled to limit the inrush current and to allow the DC bus potential to settle

to the correct operating level. A low-power transformer flyback circuit converts the high voltage DC bus into regulated low voltage to power the internal housekeeping circuits as well as the auxiliary +5Vs located in the interface

connector.

An output Enable/Disable function is provided to control Vicor’s DC-DC converters. If the Enable/Disable control

pin is pulled low, the modules output is disabled. The nominal delay associated for an output to come up when

measured from release of the Enable/Disable pin is 9-12 ms. The General Shutdown function controls all outputs

simultaneously and works in a similar manner.

Rev. 2/2012 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Pg. 5

FlatPAC-EN/EN MI Design Guide

Page 6

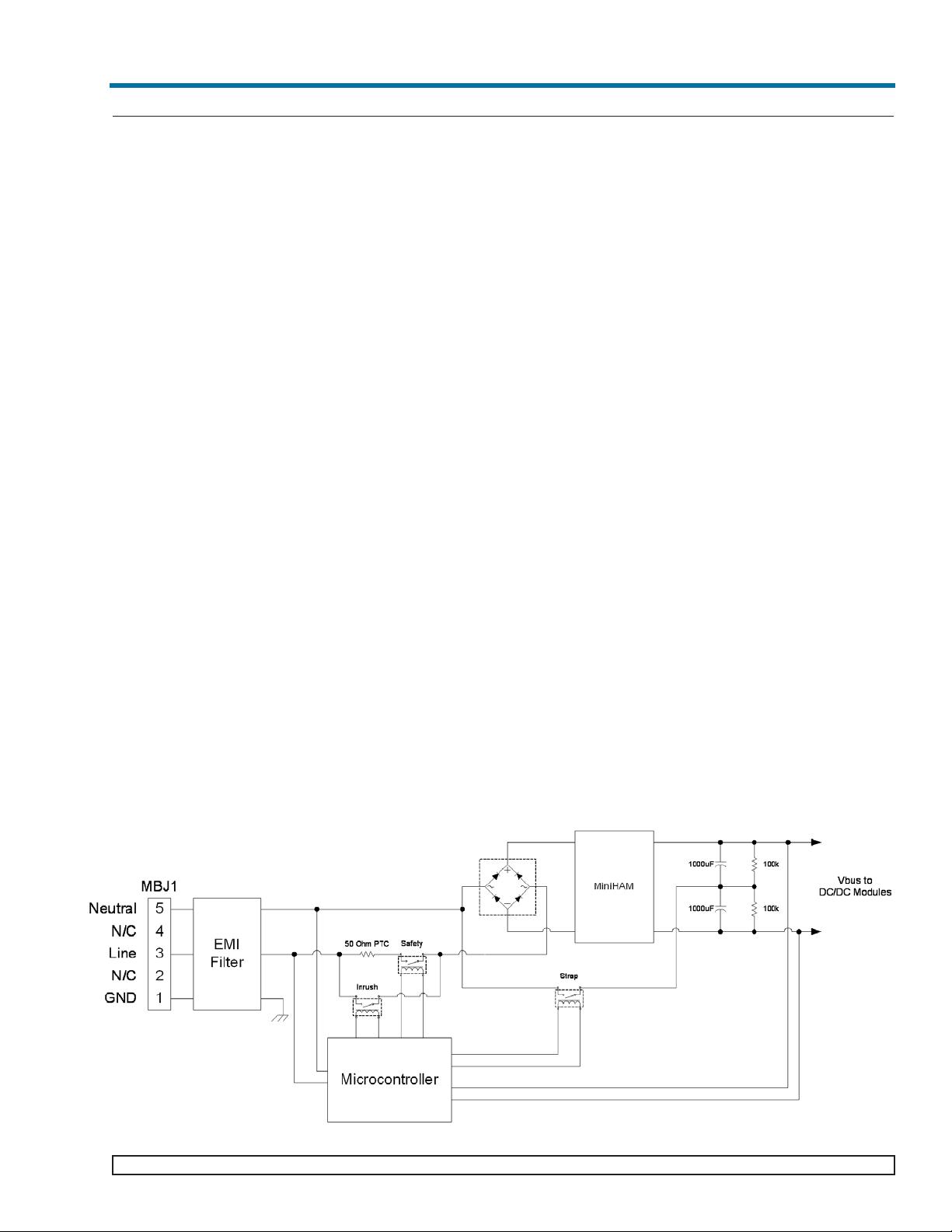

FlatPAC-EN/EN MI Configuration Layout

Pg 6 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 2/2012

FlatPAC-EN/EN MI Design Guide

CBJ1

Interface Conn.

M2

VI-200

Maxi

M1

VI-J00

or

Mini

MBJ1

Input Conn.

MiniHAM

CBJ1

Interface Conn.

MBJ1

Input Conn.

M2

Micro

M1

Micro

M3

Micro

MiniHAM

M4

VI-J00

or

Mini

CBJ1

Interface Conn.

M1

VI-J00

or

Mini

MBJ1

Input Conn.

MiniHAM

M2

VI-J00

or

Mini

M3

VI-J00

or

Mini

Single or Dual Outputs

(Stud Connectors)

Single, Dual orTriple Outputs

(Two 18 pin Molex Connectors)

Single, Dual, Triple or Quadruple Outputs

(Two 18 pin Molex Connectors)

For a single output configuration,

either M1or M2 is used

(assumes either a full brick

and/or half brick is used)

(assumes only half bricks are used)

Note: The type of output connector a FlatPAC-EN has depends on which modules are used. E.g. if a two output configuration uses

two half bricks (instead of a full brick and half brick) this two output configuration will have the 18 pin molex connectors,

not stud connectors.

(assumes only half and/or

quarter bricks are used)

Page 7

FlatPAC-EN/EN MI “Quick Install” Instructions (For mechanical drawings, see page 10)

Mounting the FlatPAC-EN/EN MI

• Mount the FlatPAC-EN on the bottom (cannot be mounted from the front).

• For standard mounting (forced air cooling), use A1, A2, A3, A4 mounting holes.

For standard mounting (conduction cooling), use A1, A2, A3, A4, B and B2

mounting holes.

• For a Vicor 2 Up FlatPAC retrofit replacement, use C1 and C2 as these

two are identical to the mounting holes on the FlatPAC.

• For increased ruggedness, use additional mounting holes to secure the power

supply.

• Use #8-32 or 4mm mounting screws. For mounting holes A1, A2, A3 and

A4, the maximum penetration should not exceed 0.125 in. (3mm). For mounting holes B1, B2, C1 and C2, do not exceed maximum penetration of 0.250 in.

(6 mm).

* The maximum allowable torque is 5 in. lbs.,

Input Connections

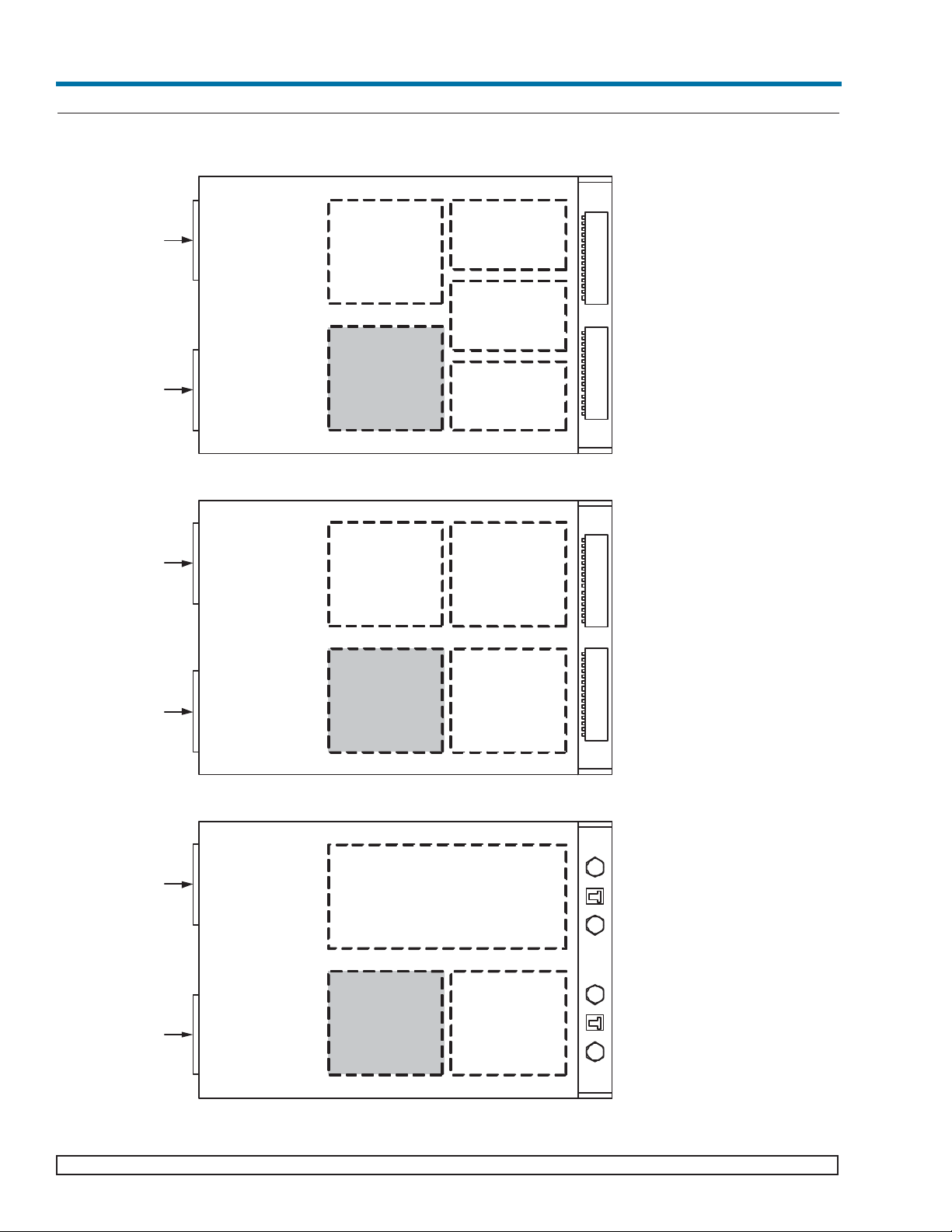

Input Power MBJ1

• Apply input AC power connector MBJ1 using a maximum torque of 5 in. lbs

• Place a fuse or circuit breaker in the input line for safety requirements

(9A).

• Use Molex mating receptacle 39-01-4051, terminals 39-00-0090 and crimp

tool Molex # 11-01-0199.

Output Connections (Refer to page 6 for more information on configuration

layout and output connector type)

Note: The type of output connector a FlatPAC-EN has depends on which modules are

used. Also, outputs with molex connectors are limited to 9A/pin (27A per output).

Power Connections

Installing power connectors on outputs with 10-32 stud connectors (only full

and/or half bricks used):

• Install #10 ring lugs on output studs

* The right stud is positive and the left stud is the return when viewed from the

output end.

• Remove the nut and place ring lug over output stud.

• Replace and tighten the nut to a torque of 10 inch pounds. Do Not Over-

Tighten Nuts.

Installing power connectors on outputs with 18 pin Molex connectors (only

half bricks used):

• The output M1 slot accepts either a Mini or a Junior module. J2-7, J2-8, J216 are positive, while pins J2-9, J2-17 and J2-18 are the returns.

• J2-1, J2-2, J2-3, J2-4, J2-5, J2-10, J2-11, J2-12 and J2-14 are not connected.

• The output M2 slot accepts either a Mini or a Junior module. J3-7, J3-8,

and J3-16 are positive while pins J3-9, J3-17 and J3-18 are the returns.

• The output M3 slot accepts either a Mini or a Junior module. J3-1, J3-10,

J11 are positive while pins J3-2, J3-3, J3-12 are the returns.

• For this 18 pin housing, use Molex mating receptacle #39-01-2180 with #3900-0039 terminals.

• Attach 18-24 AWG stranded wire using Molex tool #11-01-0197.

• Note: The molex connectors are limited to 9A/pin (27A per output)

Rev. 2/2012 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Pg. 7

FlatPAC-EN/EN MI Design Guide

MBJ1

N/C

N/C

L1

L2/N

GND

OUTPUTS M2 & M3

OUTPUT M1

18 PIN MOLEX OUTPUT CONNECTOR

J2

J3

1

18

9

10

1

9

10

18

PIN DESCRIPTION

1 N/C

2 N/C

3 N/C

4 N/C

5 N/C

6 TRIM M1

7 +V OUT M1

8 +V OUT M1

9 -V OUT M1

PIN DESCRIPTION

10 N/C

11 N/C

12 N/C

13 + SENSE M1

14 N/C

15 - SENSE M1

16 +V OUT M1

17 - V OUT M1

18 - V OUT M1

J2

PIN DESCRIPTION

1 +V OUT M3

2 -V OUT M3

3 -V OUT M3

4 + SENSE M3

5 - SENSE M3

6 TRIM M2

7 +V OUT M2

8 +V OUT M2

9 -V OUT M2

PIN DESCRIPTION

10 +V OUT M3

11 +V OUT M3

12 -V OUT M3

13 + SENSE M2

14 TRIM M3

15 - SENSE M2

16 +V OUT M2

17 - V OUT M2

18 - V OUT M2

J3

A3

C1

B1

Identical mounting

holes (CI & C2) to Vicor's

2 UP FlatPAC

A1

A4

C2

B2

A2

STUD OUTPUT CONNECTORS

-

J1

OUTPUT M1

10-32 STUDS

+

M1

-

J2

OUTPUT M2

+

Page 8

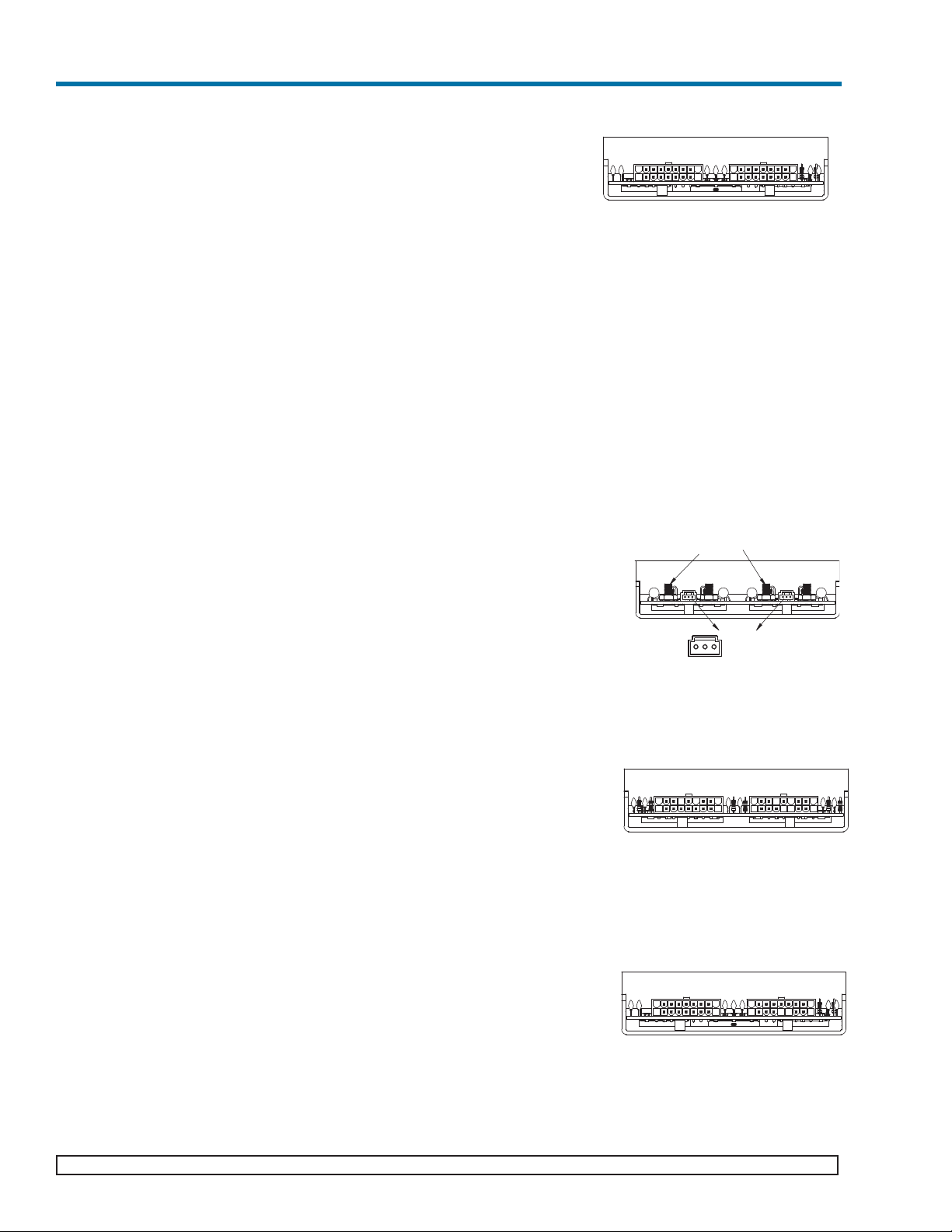

Installing power connectors on outputs with 18 pin Molex connectors

(only half and/or quarter bricks used):

• The output M1 slot only accepts a Micro module. J2-7, J2-8, J2-13 and

J2-16 are positive, while pins J2-9, J2-15, J2-17 and J2-18 are the

returns.

• The output M2 slot only accepts a Micro module. J2-1, J2-4, J2-10, J211 are positive, while pins J2-2, J2-3, J2-5 and J2-12 are the returns.

• The output M3 slot only accepts a Micro module. J3-7, J3-8, J3-13

and J3-16 are positive, while pins J3-9, J3-15, J3-17 and J3-18 are the

returns.

• The output M4 slot only accepts either a Mini or a Junior module. J3-1,

J3-10 and J3-11 are positive while pins J3-2, J3-3, and J3-12 are the

returns.

• For this 18 pin housing, use Molex mating receptacle #39-01-2180 with

#39-00-0039 terminals.

• Attach 18-24 AWG stranded wire using Molex tool #11-01-0197

• Note: The molex connectors are limited to 9A/pin (27A per output)

See page 11 for detailed diagrams of output connections.

Sense Connections

The FlatPAC-EN/EN MI is shipped with Autosense installed (For more informa-

tion on Autosense, refer to page 16)

Sense Connections for stud outputs (only full and/or half bricks used):

• For Remote Sense, connect Remote Sense wires to Remote Sense/Trim Pin

Access Connector J1 or J2 for single output and J1/J2 for dual outputs.

* Connector pins J1-2 and J2-2 are the + Senses and J1-3 and J2-3 are

the -Senses.

• Use Molex mating receptacle #50-57-9403 with #16-02-0103 terminals.

• Attach terminals to 24-30 AWG stranded twisted pair wire using Molex tool #

11-01-0208.

• Attach opposite end of sense lines to their respective outputs to point where

regulation is desired. Verify that sense lines are not cross-connected.

Sense Connections on 18 pin molex output connectors (only half bricks used):

• If Remote Sense is desired, connect Remote Sense wires to the sense lines of

Connector J2 for output 1 and J3 for outputs 2 and 3.

* For Output M1, J2- 13 is the +Sense and J2-15 is the -Sense.

* For Output M2, J3-13 is the +Sense and J3-15 is the -Sense.

* For Output M3, J3-4 is the +Sense and J3-5 is the -Sense.

• Use Molex mating receptacle #39-01-2180 with #39-00-0039 terminals.

• Attach 18-24 AWG stranded twisted pair wire using Molex tool #11-01-

0197.

Sense Connections on 18 pin output connectors (only half and/or quarter bricks

used):

• If Remote Sense is desired (available only on output M4), connect Remote

Sense wires to sense lines of Connector J3

* Remote Sense is NOT available for Micro modules and hence is not

available on outputs M1, M2 and M3.

* On output M4, J3- 4 is the +Sense and J3-5 is the -Sense.

• Use Molex mating receptacle #39-01-2180 with #39-00-0039 terminals.

• Attach 18-24 AWG stranded twisted pair wire using Molex tool #11-01-0197

Pg 8 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 2/2012

FlatPAC-EN/EN MI Design Guide

OUTPUTS M1 & M2

OUTPUTS M3 & M4

18 PIN MOLEX OUTPUT CONNECTORS

J2

J3

PIN DESCRIPTION

1 +V OUT M2

2 -V OUT M2

3 -V OUT M2

4 +V OUT M2

5 - VOUT M2

6 TRIM M1

7 +V OUT M1

8 +V OUT M1

9 -V OUT M1

PIN DESCRIPTION

10 +V OUT M2

11 +V OUT M2

12 -V OUT M2

13 + VOUT M1

14 TRIM M2

15 - VOUT M1

16 +V OUT M1

17 - V OUT M1

18 - V OUT M1

PIN DESCRIPTION

1 +V OUT M4

2 -V OUT M4

3 -V OUT M4

4 + SENSE M4

5 - SENSE M4

6 TRIM M3

7 +V OUT M3

8 +V OUT M3

9 -V OUT M3

PIN DESCRIPTION

10 +V OUT M4

11 +V OUT M4

12 -V OUT M4

13 + VOUT M3

14 TRIM M4

15 - VOUT M3

16 +V OUT M3

17 - V OUT M3

18 - V OUT M3

1

9

10

18

1

9

10

18

OUTPUT M1

OUTPUT M2

10-32 STUDS

+

M2

J2

-

M1

-

J1

+

STUD OUTPUT CONNECTORS

1

2

3

1 Trim Pin

2 + Remote Sense

3 - Remote Sense

Pin

OUTPUTS M2 & M3

OUTPUT M1

18 PIN MOLEX OUTPUT CONNECTORS

J2

J3

J2-13 + SENSE M1

J2-15 - SENSE M1

J3-4 + SENSE M3

J3-5 - SENSE M3

J3-13 + SENSE M2

J3-15 - SENSE M2

1

18

9

10

1

9

10

18

+S

-S

+S

-S

+S

-S

OUTPUTS M1 & M2

OUTPUTS M3 & M4

18 PIN OUTPUT CONNECTORS

J2

J3

M4 accepts 1 Mini or 1

Junior

J3-4 + SENSE M4

J3-5 - SENSE M4

1

9

10

18

1

9

10

18

M1, M2, M3 accept Micro modules

No sense connections are available

for Micro modules

+S

-S

Page 9

Trim Connections

Trim Connections on stud output connectors (when full and/or half brick

used) :

• For output M1, J1-1 provides Trim Access

• For output M2, J2-2 provides Trim Access

• Use Molex mating receptacle #50-57-9403 with #16-02-0103 terminals.

• Attach 24-30 AWG stranded wire using Molex tool #11-01-0208.

Trim Connections for 18 pin Molex output connectors (when half bricks

used):

• For output M1, J2-6 provides Trim access

• For output M2 and M3, J3-6 and J3-14 provides Trim access respectively.

• Use Molex mating receptacle #39-01-2180 with #39-00-0039 terminals.

• Attach 18-24 AWG stranded wire using Molex tool #11-01-0197.

Trim Connections for 18 pin Molex output connectors (when half and/or

quarter bricks used):

• For outputs M1 and M2, J2-6 and J2-14 provide Trim access respectively.

• For outputs M3 and M4, J3-6 and J3-14 provide Trim access respectively.

• Use Molex mating receptacle #39-01-2180 with #39-00-0039 terminals.

• Attach 18-24 AWG stranded wire using Molex tool #11-01-0197.

Interface Connections

• CBJ1-1 is Signal Ground and CBJ1-3 is AC OK.

• CBJ1-4 is the Transmit and CBJ1-5 is the Receive functions for the RS-232

command protocol.

+

• CBJ1-4 thru 9 are Enable/Disable,CBJ1-10 is General Shutdown and CBJ312 is +5VS.

• For the FlatPAC-EN, CBJ1-2 and CBJ1-11 are not connected.

• Use Molex mating receptacle #50-57-9412 with #16-02-0097 cinch pins.

• Attach 24-30 AWG stranded wire using Molex tool #11-01-0209.

+

These functions are part of the RS-232 Command Protocols. See page 14 for

detailed information .

Rev. 2/2012 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Pg. 9

FlatPAC-EN/EN MI Design Guide

1

2

3

1 Trim Pin

2 + Remote Sense

3 - Remote Sense

Pin

OUTPUT M1

OUTPUT M2

10-32 STUDS

+

M2

J2

-

M2

M1

-

J1

+

TRIM: STUD OUTPUT CONNECTORS

OUTPUTS M2 & M3

OUTPUT M1

18 PIN MOLEX OUTPUT CONNECTORS

J2

J3

J2-6 TRIM M1

J3-6 TRIM M2

J3-14 TRIM M3

1

18

9

10

1

9

10

18

T

T

T

OUTPUTS M1 & M2

OUTPUTS M3 & M4

18 PIN MOLEX OUTPUT CONNECTORS

J2

J3

J2-6 TRIM M1

J2-14 TRIM M2

J3-6 TRIM M3

J3-14 TRIM M4

1

9

10

18

1

9

10

18

T

T

T

T

PIN DESCRIPTION

CBJ1-1 SGND

CBJ1-2 N/C

CBJ1-3 ACOK

CBJ1-4 TX

CBJ1-5 RX

CBJ1-6 E/D-4

CBJ1-7 E/D-3

CBJ1-8 E/D-2

CBJ1-9 E/D-1

CBJ1-10 GSD

CBJ1-11 N/C

CBJ1-12 +5VS

Page 10

FlatPAC-EN/EN MI Mechanical Drawings

Pg 10 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 2/2012

FlatPAC-EN/EN MI Design Guide

1

CB J1 (12 PIN)

MBJ1

1

9.53.38 215.908.500

12.70.50

101.604.000

4X #8-32 x .125 OR M4 x 3mm MAX LG

FROM OUTSIDE OF POWER SUPPLY

CUSTOMER MOUNTING HOLES

138.435.450

147.965.825

5.56.219

115.894.563

AIR

FLOW

CUSTOMER MOUNTING HOLES

4X #8-32 x .250 OR M4 x 6mm MAX LG

FROM OUTSIDE OF POWER SUPPLY

OUTPUTS M1 & M2

OUTPUTS M3 & M4

J2

J3

OUTPUT M2 & M3

OUTPUT M1

J2

J3

OUTPUT M1

OUTPUT M2

+

M2

J2

-

M2

M1

M1

-

J1

+

PIN 1

N/C

N/C

L1

L2/N

GND

0.77.03

35.591.40

233.699.20

C1

C2

MATING CONNECTOR:

HOUSING: MOLEX (50-57-9412)

SOCKET CRIMP 24-30 AWG: MOLEX (16-02-0097)

CRIMP TOOL: MOLEX (11-01-0209)

2

3

CBJ1 E/D INTERFACE CONNECTOR

4

PIN REF DESCRIPTION

CBJ1-1 SGND SIGNAL GROUND

CBJ1-2 N/C N/C

CBJ1-3 ACOK AC POWER OK

CBJ1-4 TX TRANSMIT

CBJ1- 5 RX RECEIVE

CBJ1-6 E/D-4 ENABLE/DISABLE

CBJ1-7 E/D-3 ENABLE/DISABLE

CBJ1- 8 E/D-2 ENABLE/DISABLE

CBJ1-9 E/D-1 ENABLE/DISABLE

CBJ1-10 GSD GENERAL SHUTDOWN

CBJ1-11 N/C N/C

CBJ1-12 +5VS +5V@300mA

3

2

1

REFERENCE DESIGNATION

NOTES: UNLESS OTHERWISE SPECIFIED

MB MOTHER BOARD

CB CONTROL BOARD

CONNECTOR PART NUMBERS SPECIFIED ARE MOLEX OR EQUIVALENT

A COMPLETE SET OF MATING CONNECTORS CAN BE PURCHASED FROM WESTCOR BY SPECIFYING

CONNECTOR KIT P/N 19-130044.

4

CBJ4 AND CBJ5 ARE PART OF THE RS-232 MICROCONTROLLER FUNCTIONS. SEE PAGE 12 INFORMATION.

5

FOR A VICOR 2 UP FLATPAC RETROFIT, USE MOUNTING HOLES C1 AND C2. SEE PAGE 4 OR 7 FOR MOUNTING DETAILS.

5

5

MATING CONNECTOR:

HOUSING: MOLEX (39-01-4051)

SOCKET CRIMP 16 AWG: MOLEX (39-00-0090)

CRIMP TOOL: MOLEX (11-01-0199)

MBJ1 A/C INPUT

2

3

Measurement tolerances are

Fractions +/- 1/32

Decimals .xx +/- .01

.xxx +/- .005

Angles +/- 1/2

o

Note: The type of output connector a FlatPAC-EN has

depends on which modules are used.

See page 11 for detailed

output connection information

Page 11

Rev. 2/2012 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Pg. 11

FlatPAC-EN/EN MI Design Guide

Output Connectors for FlatPAC-EN/EN MI

2

3

4

5

6

7

8

11

12

13

14

15

16

17

1

10

9

18

MATING CONNECTOR:

18 PIN HOUSING: MOLEX (39-01-2180)

TERMINAL FEM CRIMP 18-24 AWG: MOLEX (39-00-0039)

USE CRIMP TOOL: MOLEX (11-01-0197)

10-32 OUTPUT STUDS

- SENSE

3

SxJ2 REMOTE SENSE/TRIM

PIN CONNECTOR

1

2

TRIM

+ SENSE

MATING CONNECTOR:

HOUSING: MOLEX (50-57-9403)

TERMINAL FEM CRIMP 24-30 AWG: MOLEX (16-02-0103)

USE CRIMP TOOL: MOLEX (11-01-0208)

B. 18 PIN MOLEX CONNECTORS - when configured only with half bricks

A. STUD OUTPUT CONNECTOR - when configured with full brick and/or half brick

-V OUT

+V OUT

C. 18 PIN MOLEX CONNECTORS - when configured with half and/or quarter bricks

Refer to page 6 to review configuration layout of FlatPAC-EN

MATING CONNECTOR:

18 PIN HOUSING: MOLEX (39-01-2180)

TERMINAL FEM CRIMP 18-24 AWG: MOLEX (39-00-0039)

USE CRIMP TOOL: MOLEX (11-01-0197)

2

3

4

5

6

7

8

11

12

13

14

15

16

17

1

10

9

18

10 N/C

11 N/C

12 N/C

13 + SENSE M1

14 N/C

15 - SENSE M1

16 +V OUT M1

17 -V OUT M1

18 -V OUT M1

PIN DESCRIPTION

1 N/C

2 N/C

3 N/C

4 N/C

5 N/C

6 TRIM M1

7 +V OUT M1

8 +V OUT M1

9 -V OUT M1

Outputs M1

10

+V OUT M3

11

+V OUT M3

12

-V OUT M3

13

+ SENSE M2

14

TRIM M3

15

- SENSE M2

16

+V OUT M2

17

-V OUT M2

18

-V OUT M2

PIN DESCRIPTION

1

+V OUT M3

2

-V OUT M3

3

-V OUT M3

4

+ SENSE M3

5

- SENSE M3

6

TRIM M2

7

+V OUT M2

8

+V OUT M2

9

-V OUT M2

Outputs M2 and M3

OUTPUT M2 & M3

OUTPUT M1

3

1 +V OUT M2

2 -V OUT M2

3 -V OUT M2

4 +V OUT M2

5 -V OUT M2

6 TRIM M1

7 +V OUT M1

8 +V OUT M1

9 -V OUT M1

Outputs M1 and M2

10 +V OUT M2

11 +V OUT M2

12 -V OUT M2

13 +V OUT M1

14 TRIM M2

15 -V OUT M1

16 +V OUT M1

17 - V OUT M1

18 - V OUT M1

1

+V OUT M4

2

-V OUT M4

3

-V OUT M4

4

+SENSE M4

5

-SENSE M4

6

TRIM M3

7

+V OUT M3

8

+V OUT M3

9

-V OUT M3

Outputs M3 and M4

10

+V OUT M4

11

+V OUT M4

12

-V OUT M4

13

+V OUT M3

14

TRIM M4

15

-V OUT M3

16

+V OUT M3

17

- V OUT M3

18

- V OUT M3

OUTPUTS M1 & M2

OUTPUTS M3 & M4

J2

Note: The type of output connector a FlatPAC-EN has depends on which modules are used. E.g. if a two output configuration uses two half bricks

(instead of a full brick and half brick) this two output configuration will have the 18 pin molex connectors, not stud connectors.

(Note: The Molex connectors are limited to 9A/pin (27A/output)

(Note: The Molex connectors are limited to 9A/pin (27A/output)

Page 12

FlatPAC-EN - Connector Kit listing

Connector Kit 19-130044 - Available for purchase from Westcor

Pg 12 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 2/2012

FlatPAC-EN/EN MI Design Guide

Page 13

Rev. 2/2012 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Pg. 13

FlatPAC-EN/EN MI Design Guide

Interface Connections

Chassis Input Power Terminals (MBJ1)

Input AC power is applied through connector MBJ1 using Molex mating connector 39-01-4051. Use 16 AWG

wire with Molex Socket Pin 39-00-0090 and Crimp Tool 11-01-0199.

A fault clearing device, such as a fuse or circuit breaker, with a maximum 9A rating at the power supply input is

required for safety agency compliance. It should be sized to handle the start-up inrush current of 14Apkrms at

either 115 Vac or 230 Vac.

Output Power Connections

There are two types of output power terminals available in the FlatPAC-EN. Each slot has one of the following

configurations: either 10-32 plated steel bolts or an 18 pin Molex connector (The type of output connector a

FlatPAC-EN has depends on which modules are used. See page 6 and 11. Molex connectors are limited to 9A/pin,

27A per output) The positive polarity of the stud output termination is the right bolt when viewed from the output

end. Each power output is isolated, so outputs of positive or negative polarity can be configured through proper

selection of the output reference terminal.

In order to minimize parasitic cable inductance and reduce EMI, the output power cables should be routed in close

proximity to one another, and large current loops should be avoided. To avoid excessive voltage drop, do not

undersize power cables, especially for high current outputs. Do not bulk input AC wires with the output wires

because this can couple output noise into the input wires which can increase EMI. Excessive cable inductance

coupled with large capacitive loading can introduce instability in switching power supplies. This problem can be

avoided with proper system design. Consult Vicor’s Applications Engineering Department for assistance with

applications that use long cable lengths and excessive load capacitance.

User Interface Connections

Signal Ground (CBJ1-1)

Signal Ground on CBJ1-1 is an isolated secondary ground reference for all CBJ1 interfacing signals. This is not

the same as Earth Ground on input power connector MBJ1.

MATING CONNECTOR:

HOUSING: MOLEX (39-01-4051)

SOCKET CRIMP 16 AWG: MOLEX (39-00-0090)

CRIMP TOOL: MOLEX (11-01-0199)

MBJ1 A/C INPUT

MBJ1

N/C

N/C

L1

L2/N

GND

Figure 2: Input Power Terminal MBJ1

2

3

4

5

6

7

8

11

12

13

14

15

16

17

1

10

9

18

1 N/C

2 N/C

3 N/C

4 N/C

5 N/C

6 TRIM M1

7 +V OUT M1

8 +V OUT M1

9 -V OUT M1

10 N/C

11 N/C

12 N/C

13 + SENSE M1

14 N/C

15 - SENSE M1

16 +V OUT M1

17 - V OUT M1

18 - V OUT M1

PIN DESCRIPTION PIN DESCRIPTION

10-32 OUTPUT STUDS

TRIM

1

J1/J2 SENSE/TRIM

PIN CONNECTOR

3

2

- SENSE

+ SENSE

B. 18 PIN MOLEX OUTPUT CONNECTOR

A. STUD OUTPUT

J2 (18 PIN OUTPUT, SENSE

AND TRIM PIN CONNECTOR)

-V OUT

+V OUT

Outputs M2 and M3 (Using 2 Minis or 2 Juniors)

1 +V OUT M3

2 -V OUT M3

3 -V OUT M3

4 + SENSE M3

5 - SENSE M3

6 TRIM M2

7 +V OUT M2

8 +V OUT M2

9 -V OUT M2

10 +V OUT M3

11 +V OUT M3

12 -V OUT M3

13 + SENSE M2

14 TRIM M3

15 - SENSE M2

16 +V OUT M2

17 - V OUT M2

18 - V OUT M2

PIN DESCRIPTION PIN DESCRIPTION

J3 (18 PIN OUTPUT, SENSE

AND TRIM PIN CONNECTOR)

J2/J3

2

3

4

5

6

7

8

11

12

13

14

15

16

17

1

10

9

18

Outputs M3 and M4 (Using 1 Micro

and 1 Mini or 1 Junior)

1 +V OUT M4

2 -V OUT M4

3 -V OUT M4

4 + SENSE M4

5 - SENSE M4

6 TRIM M3

7 +V OUT M3

8 +V OUT M3

9 -V OUT M3

10 +V OUT M4

11 +V OUT M4

12 -V OUT M4

13 + VOUT M3

14 TRIM M4

15 - VOUT M3

16 +V OUT M3

17 - V OUT M3

18 - V OUT M3

PIN DESCRIPTION PIN DESCRIPTION

J3 (18 PIN OUTPUT, SENSE

AND TRIM PIN CONNECTOR)

1 +V OUT M2

2 -V OUT M2

3 -V OUT M2

4 +V OUT M2

5 - VOUT M2

6 TRIM M1

7 +V OUT M1

8 +V OUT M1

9 -V OUT M1

10 +V OUT M2

11 +V OUT M2

12 -V OUT M2

13 + VOUT M1

14 TRIM M2

15 - VOUT M1

16 +V OUT M1

17 - V OUT M1

18 - V OUT M1

PIN DESCRIPTION PIN DESCRIPTION

J2 (18 PIN OUTPUT, SENSE

AND TRIM PIN CONNECTOR)

J2/J3

Output M1 (Using 1 Mini or 1 Junior)

Outputs M1 and M2 (Using 2 Micros)

B. 18 PIN MOLEX OUTPUT CONNECTOR

(Note: The Molex connectors are limited to 9A/pin (27A/output)

Figure 3: Output Power Connections

Page 14

AC OK (CBJ1-3)

AC OK is an active high TTL compatible signal and provides a status indication of the AC input power. It is on pin

CBJ1-3 and is capable of sinking 16 mA maximum. This signal switches to a TTL "1" when the high voltage bus

exceeds low-line condition during turn-on. Upon loss of input power, the bus voltage will drop, causing the AC

OK signal to go low. Typically, a 2.5ms holdup time is provided for a 500W load following the loss of the AC OK

signal.

TRANSMIT/RECEIVE RS-232 Command Protocol (CBJ1-4 and CBJ1-5)

The FlatPAC-EN/EN MI incorporates a microprocessor for communicating status and allowing user control. A

suitable Terminal Emulator must be used to communicate with this circuit. A free emulator can be downloaded

from the vicor website at www.vicorpower.com (FlatPAC-EN page). Operation in the remote mode requires commanding the Power Supply to be a slave via the RS-232 interface.

Operating Modes

The FlatPAC-EN has two operating modes, Remote and Manual, which can be set using the RS-232 interface feature. The operating mode setting is stored in a non-volatile EEPROM and requires an REON or REOFF command

in order to switch modes. The default mode setting from the factory is in Manual mode. The FlatPAC-EN has an

operating mode indicator LED, which is viewable through the left side vent hole nearest the CBJ1 E/D Interface

Connector. When this LED is ON, the power supply is operating in Remote Mode.

Communications Protocol

The protocol is an ASCII character stream that will be sent back and forth between the power supply and the user.

The FlatPAC-EN/EN MI in the remote mode will be considered a slave in that it will only respond to commands

and requests and will not initiate conversations. Communications are half-duplex in that only the FlatPAC-EN/EN

MI receiver or transmitter may be active at one time. The unit will reply to all commands or requests with a

defined response followed by a carriage return and line feed character pair (CR/LF). The user must wait for the

reply from the FlatPAC-EN before issuing the next command or request. The data bytes will have a format of 1

start bit, 8 data bits, 1 stop bit and no parity at 9600 Baud.

Commands, Status Requests and Module Replies

All commands and requests will have a reply. The reply will be one of the following character strings followed by

a CR/LF character pair. "OK"- Issued when a command has been received and acted upon and the command has no

return data associated with it. "Inv Command"- Issued when an unrecognized command has been received or a

command cannot be executed at this time. "Inv Range"- Issued when a command argument is not within a valid

range.

The following is the list of commands and their definitions. All commands must be followed with a CR/LF character pair.

PUP - Power Up

This command starts the automatic turn on timed sequence for the modules. If a Power Down sequence is active at

the time this command is received, a reply of "Inv Command" is returned; otherwise "OK" is returned.

PDN - Power Down

This command starts the automatic turn off timed sequence for the modules. This command can be given at any

time and will cancel any uncompleted automatic power up sequences. "OK" is returned.

EMO - Emergency Off

This command turns all modules off. If either a Power Up or Power Down sequence is active at the time, it will be

terminated immediately. A response of "OK" is returned.

Pg 14 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 2/2012

FlatPAC-EN/EN MI Design Guide

Figure 4: LED Indicator

Output

Connections

CBJ1

Interface

Connector

LED Indicator inside

Page 15

TON1, TON2, TON3, TON4 - Turn On commands for modules 1, 2, 3, or 4.

These commands turn on the module identified by the trailing digit. If an automatic sequence is in effect at the

time this command is received, a reply of "Inv Command" is returned; otherwise "OK" is returned.

TOFF1, TOFF2, TOFF3, TOFF4 - Turn Off commands for modules 1, 2, 3, or 4.

These commands turn off the module identified by the trailing digit. If an automatic sequence is in effect at the

time this command is received, a reply of "Inv Command" is returned; otherwise "OK" is returned.

SDON1, SDON2, SDON3, SDON4 - Set Delay On Time for modules 1, 2, 3 or 4.

These commands set the associated time delays for the DC-DC converters to be activated via "PC" pin release.

There is an additional delay of up to 7ms inherent in the DC-DC converters. These commands are entered with a

trailing argument. The valid range of the argument is from 1 to 255 and is in 10 millisecond increments. The effective range of delay then becomes 10 to 2550 milliseconds or 0.01 to 2.55 seconds. Out of range arguments are

replied to with an "Inv Range" message; otherwise "OK" is returned. The delay times are effective and run concurrent from either power up of the unit or from receipt of the Power Up command. If these commands are entered

without an argument then the unit will report the present settings of these variables.

SDOFF1, SDOFF2, SDOFF3, SDOFF4 - Set Delay Off Time for modules 1, 2, 3, or 4.

These commands set the associated time delays for the DC-DC converters to be deactivated via "PC"pin release.

These commands are entered with a trailing argument. The valid range of the argument is from 1 to 255 and is in

10 millisecond increments. The effective range of delay then becomes 10 to 2550 milliseconds or 0.01 to 2.55 seconds. Out of range arguments are replied to with an "Inv Range" message; otherwise "OK" is returned. The delay

times are effective and run concurrent from either receipt of the Power Down command or from an error condition

with the unit. If these commands are entered without an argument then the unit will report the present settings of

these variables.

BV - Bus Voltage Readback

This command returns the current Bus Voltage reading.

MS - Module Status

This command returns the module status as shown: MS=X1 X2 X3 X4 X5

X1 indicates the status of module output 1.

X2 indicates the status of module output 2.

X3 indicates the status of module output 3.

X4 indicates the status of module output 4.

A "1" indicates the output is up/on and ok and a "0" indicates the output is down/off.

X5 indicates the status of the power supply Bus. A "1" indicates BUS OK and a "0" indicates BUS NOT OK.

SN - Serial Number

This command returns the serial number as set by factory (available only on request.)

REON - Remote Mode ON

This command put the power supply into the slave mode. In this mode the power supply will only respond when

commanded.

REOFF - Remote Mode OFF

This command put the power supply into the manual mode. In this mode the power supply will only respond to the

following commands via the RS-232 interface: REON, SN, SDON1, SDON2, SDON3, SDON4, BV, MS, HST.

HST - Heat Sink Temperature

This command returns Temperature of the Heat Sink in degrees Celsius. Heat Sink Temperature is measured frequently and stored into EEPROM memory. Upon loss of power last measured value in stored in EEPROM.

Rev. 2/2012 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Pg. 15

FlatPAC-EN/EN MI Design Guide

Page 16

Pg 16 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 2/2012

FlatPAC-EN/EN MI Design Guide

Enable/Disable Mode (CBJ1-8 and CBJ1-9)

The Enable/Disable control pins allow outputs to be sequenced either on or off. CBJ1-4 through CBJ1-9 are the

control pins for outputs 1 through 4. The Enable/Disable pins should be pulled low to less than 0.7V with respect

to Signal Ground to disable the outputs. They will source 9mA maximum. These pins should be open circuited or

allowed to exceed 4.5V when enabled. Do not apply more than 5V to these inputs.

The correspondence between a module and its E/D line as seen from the output end of the power supply goes from

left to right.

General Shutdown /GSD (CBJ1-10)

The GSD control pin on CBJ1-10 allows simultaneous shutdown of all outputs. This pin must be pulled down to

less than 0.7V, and will source 9mA maximum to shut down all outputs. The GSD pin should be open circuited or

allowed to exceed 4.5V when not in use, or when the outputs are to be enabled. Do not apply more than 5V to this

input at any time. Normal open circuit voltage is 1.5 to 4V with respect to Signal Ground.

Auxiliary Vcc +5V/300mA (CBJ1-12)

The Vcc on CBJ1-12 is an auxiliary 5V regulated power source. It is +5 Vdc +/–5% with respect to Signal Ground

and can supply 300 mA maximum. It is capable of withstanding a short, but shorted user interface functionality

will be lost.

+Sense/ –Sense ( J2) (Not applicable when using BatMod current source.)

The sense lines for the outputs are shipped from the factory with Autosense. Autosense provides the user with

automatic sensing of the outputs. With Autosense, the FlatPAC-EN/EN MI will automatically operate in a Remote

Sense mode when the Remote Sense connections are made. But in the event that the Remote Sense is not connected or needed, no Local Sense selection is necessary - simply hook up the outputs and the FlatPAC-EN will automatically operate in Local Sense mode. To check if an output has the Autosense feature, measure the impedance

from the + Out to + Sense and - Out to - Sense pins. If the impedance is 5 ohms, then the output has Autosense

and does not require local sense jumpers. When using the remote sense feature, the +Out and -Out load wires

should never be disconnected while the supply is operating. Failing to do so could damage the power supply.

In the local sense mode (Remote Sense lines not connected), the power supply will regulate the output at the output

terminals. The voltage appearing at the load may drop slightly due to voltage drop in the power cables. If it is necessary to compensate for voltage drop along the output power cables, the output can be trimmed up or configured

for Remote Sense. Use stranded twisted pair 24-30 AWG wire for the Remote Sense lines. Remote Sense can compensate for a voltage drop of up to 0.5V, or 0.25V on each leg.

The Sense connector for outputs with stud connectors is a 3 pin connector providing the +Sense connection on J1/

J2-2 and the - Sense connection on J1/J2-3. The Sense connector for outputs with 18 pin Molex connectors is provided on the 18 pin output connector that also provides the output and trim connections. See page 11 for details.

Note: Remote sense is not available for output configurations using the Micro modules.

Figure 5: Enable/Disable Mode

Figure 6: Auxiliary Vcc

A TTL "1" applied to the base of the transistor turns

output OFF. Pin 1 (or Pin 7 for GSD) is pulled Low

with respect to Signal Ground.

Enable/Disable Control

TTL "1" (OFF)

TTL "0" (ON)

Enable/Disable Output 1

1

0

General Shutdown

Signal Ground

J1

FlatPAC-EN

Vcc

5

1

7

4

CBJ1

CBJ1-12

CBJ1-1

Auxiliary Vcc

Signal Ground

78M05

+5V/300 mA

0.1 µF

Page 17

Rev. 2/2012 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Pg. 17

FlatPAC-EN/EN MI Design Guide

External Trim (Not applicable when using BatMod current source)

The Trim pin can be used for external control of the output voltage. Trim connections on single and dual output

connector for output M1 is J1-1 while for output M2 is J2-2. Trim connections on triple output connectors for output M1 is J2-6, for output M2 is J3-6, and for output M3 is J3-14. Trim connections for quadruple output connectors on outputs M1 and M2 is J2-6 and J2-14 respectively, and for outputs M3 and M4 is J3-6 and J3-14 respectively. A 10% increase to the trim pin voltage will result in a 10% increase in output voltage. Reducing the trim

pin voltage by 10% will result in a 10% decrease in output voltage.

OUTPUT MODULE V

ref

R

TH

VI-200/VI-J00 ≥3.3V 2.5V 10kΩ

VI-200/VI-J00 <3.3V 0.97V 3.88kΩ

Maxi/Mini/Micro (Predefined) 1.23V 1kΩ

Maxi/Mini/Micro (Userdefined) 1.23V Consult Factory

Table 1. Module Internal Reference Voltages and Thevenin Resistances.

Example:

±10% trim adjust on a 12V nominal output.

Figure 8 shows a typical variable trim circuit. Using a 10k trimpot (R7), the resistor values for R6 and R8 can be

calculated as follows:

V

1

= V

ref

+ 10% = 2.75V Given: V

ref

= 2.5V (see Table 1)

I

R5

= (2.75V - V

ref

)/RTH= (2.75V - 2.5V)/10kΩ = 25μA Given: RTH= 10kΩ (see Table 1)

Setting the bottom limit:

V

R6

= 2.5V - 10% = 2.25V

And since I

R5

= IR6= 25μA,

R6 = V

R6/IR6

= 2.25V/25μA = 90kΩ

V2= V1+ VR6= 2.75V + 2.25V = 5V

I

R7

= V2/R7 = 5V/10kΩ = 500μA

I

R8

= IR7+ IR6= 525μA

V

R8

= (V

nom

+10%) - V2= 13.2V - 5V = 8.2V Given: V

nom

= 12V

R8 = V

R8/IR8

= 8.2V/525μA = 15.62kΩ

Consult Applications Engineering when trimming outputs below 5V.

Load

+Out

+Sense

-Sense

-Out

Use 24-30 AWG

Twisted Pair Wires

Figure 7: Remote Sense

Figure 8: External Trim

Note: Trimming up by more than 15%

may induce over voltage protection.

(Remote Sense)

Use 24-30 AWG

R8

+

V

2

R7

-

Twisted Pair Wires

Load

Use 24-30 AWG

Twisted Pair Wires

To Error

Amplifier

+Out

R1

+Sense

R2

Trim

+

RTH

R5

V1

-

R3

Ref

V

R4

R6

-Sense

-Out

Page 18

Specifications (Typical at 25°C, nominal line and 75% load, unless otherwise specified)

GENERAL

Number of Outputs 1-4

Modules VI-200/VI-J00, VE-200/VE-J00: Maxi/Mini/Micro

Efficiency Typically > 70%

Safety Agency Approvals cURus – UL 60950-1, CSA 60950-1

cTUVus – EN 60950-1, UL 60950-1, CSA 60950-1

CE Mark – Low Voltage Directive, 73/23/EEC amended by 93/68/EEC

Vibration Mil-STD 810 Minimum Integrity (MI chassis only)

Shock Mil-STD 810 40G Functional Shock (MI chassis only)

Maximum Output Power Up to 500 Watts; 425 Watts for EN 61000-3-2/A14 compliance

(not to exceed input current of 9A) (105/190 Vac minimum input)

INPUT

Input 90-132/180-264 Vac 47-63Hz

250-380 Vdc

Inrush Current 14 A pk@ 115 Vac and 230 Vac

Line/Load Regulation

VI200/VI-J00:± 0.2% max.10% to full load; ± 0.5% max. No load to 10% load

Line Regulation* Maxi/Mini/Micro:± 0.20% max. to 0.3% max LL to HL, Full Load

Ride Through Time 500W 400W

@ 115Vac (typical) 12ms 15ms

@ 230Vac (typical) 16ms 18ms

Harmonic Distortion EN61000-3-2 A/14 (For output power ≤ 425W or input current not

in excess of 3.33 A rms at 230 Vac, 50 Hz.)

Conducted EMI FCC and EN 55022 Class A

(certain configurations meet EN 55022 Class B)

Mil-STD 461 may require external filter - contact factory

Power Factor >.70

Transient Burst Immunity EN61000-4-4

Surge Immunity EN61000-4-5

Voltage Dips EN61000-4-11

Dielectric Withstand Primary to Chassis GND = 1,500 V

RMS

Primary to Secondary = 3,000 VRMS

Secondary to Chassis GND = 500 VRMS

* See Vicor module specifications. A preload may be necessary for modules trimmed down below 90% of normal output voltage.

OUTPUT

VI-200/VI-J00 Modules

Parameter MIN. TYP. MAX. UNITS NOTES

Setpoint Accuracy* 0.5 1 % of Vnom

Load/line Regulation ±0.2 % 10% to Full Load

Load/line Regulation ±0.5 % Load to 10%

Temperature Regulation 0.01 0.02 %/°C Over rated temp.

Long Term Drift 0.02 %/K hours

Output Ripple & Noise:

VI/E-200 100 mV p-p See module design guide

VI/E-J00 100 mV p-p for exact specifications

Voltage Trim Range

VI-200/VI-J00 Slots 50-110 % V out ± 10% on 10-15 Vout

Total Remote Sense Compensation 0.5 Volts Autosense. See pg.14

OVP Set Point

1

115 125 135 %Vout Recycle Power

Current Limit 105 115 125 % of I max Auto Recovery

Short Circuit Current 20 (105

2

) 130 %

Overtemperature Limiting Not available on VI-J00

*

For special and adjustable voltages, maximum setpoint accuracy is 2% of Vnom.

1

131% Nominal for Booster Modules. No OVP for VI-J00

2 VI-J00 modules only.

Pg 18 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 2/2012

FlatPAC-EN/EN MI Design Guide

Page 19

Rev. 2/2012 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Pg. 19

FlatPAC-EN/EN MI Design Guide

OUTPUT (CONT’D.)

Maxi/Mini/Micro Modules

Parameter

MIN. TYP. MAX. UNITS NOTES

Setpoint Accuracy* ±0.5 ±1 % of V

NOM

Load Regulation ±0.01 % of V

NOM

See module design guide for e

exact specifications.

Temperature Regulation 0.002 0.005 %/°C -20 to 100°C

Long Term Drift 0.02 %/K hours

Output Ripple and noise:

Maxi 75 mV p-p See module design guide

Mini 100 mV p-p for exact output ripple

Micro 125 mV p-p specifications.

Voltage Trim Range

Maxi/Mini/Micro Slots

10-110 % Vout Preload may be required.

Total Remote Sense Compensation 0.5 Volts Autosense. See pg 14

OVP Set Point 112 135 % of V

out

Recycle power

Current Limit 102 115 135 % of I max Auto Recovery

Overtemperature Limiting Not available

* For special, adjustable voltages and 48Vdc outputs, maximum setpoint accuracy is 2% of Vnom.

Note: See individual module datasheets for specific module specifications.

ENVIRONMENTAL

Storage Temperature -40°C to +100°C

Operating Temperature

Ambient air (see derating curves) -20°C to +70°C (MI -40°C to +70°C)

Case Temperature -20°C to +90°C (MI -40°C to +90°C)

(75° for full size VI-200 module)

Specific temperature data on all module configurations can be obtained by contacting Applications Engineering.

Altitude Derate 2.6% total output power for each 1,000 ft to a maximum

operating altitude of 15,000 ft. Non-operating storage maximum

altitude is 40K.

Humidity 0 to 95% non condensing

Product Weight 3.4 lbs. (1,5 kg)

Dimensions 1.4" H (35,6mm) x 5.0" W (127,0mm) x 9.20" L (233,7mm)

Warranty** 2 years limited warranty. See vicorpower.com for complete warranty

statement.

** Opening, repairing or modifying the unit will void the warranty. If you have any problem with the power supply, please

contact Customer Service at 1-800-735-6200. If the unit needs to be returned for inspection/analysis, an RMA number will

be issued. All units must have a RMA number prior to return.

Page 20

Output Power Derating

Pg 20 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 2/2012

FlatPAC-EN/EN MI Design Guide

Page 21

Output Power Derating -continued

All module configurations: The FlatPAC-EN/EN MI or an individual output may be limited by module power limitations.

1. One cannot exceed the output power rating of the FlatPAC-EN regardless of the module capability.

2. Also see Output Power vs. Input Voltage charts on page 21.

3. Please note that FlatPAC-EN configurations that uses Molex outputs connectors are limited to 9A/pin (27A per output).

This is a Molex connector limitation, NOT a module power limitation. Westcor’s online configuration tool (VSPOC) will

not provide a FlatPAC-EN/EN MI solution for requirements that exceed the 27A limitation.

Rev. 3/2009 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Pg. 20

FlatPAC-EN/EN MI Design Guide

Page 22

Thermal Curves for FlatPAC-EN/EN MI

Pg 22 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 2/2012

FlatPAC-EN/EN MI Design Guide

Page 23

Thermal Curves for FlatPAC-EN/EN MI - continued

Rev. 2/2012 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Pg. 23

FlatPAC-EN/EN MI Design Guide

Page 24

Thermal Curves for FlatPAC-EN/EN MI - continued

Pg 24 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 2/2012

FlatPAC-EN/EN MI Design Guide

Page 25

Thermal Curves for FlatPAC-EN/EN MI - continued

Rev. 2/2012 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Pg. 25

FlatPAC-EN/EN MI Design Guide

Page 26

Pg 26 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 2/2012

FlatPAC-EN/EN MI Design Guide

Current Share Boards - Optional Feature

"Current sharing" also known as Load Sharing, is the

ability to divide the output current evenly across all

active power supplies. This greatly reduces stresses

on each power supply and allows them to run cooler,

resulting in higher reliability. Standard "current sharing" techniques typically utilize shunt resistors or

Hall Effect devices to measure the current from each

power supply. Power shunt resistors continually dissipate power and require cooling especially when

dealing with high output currents of >100Amps. Hall

Effect devices measure magnetic fields generated by

current flowing through a conductor and, although

they dissipate no power, they tend to be large and

expensive.

First developed by Westcor Engineering for paralleling MegaPAC supplies, the Box-to-Box Current

Share Board or CSB allows two or more Vicor power

supplies to current share by utilizing the inherent voltage

drop produced in the negative output return cable. This

eliminates the need for additional shunt resistors or

expensive Hall Effect devices and provides a simple 5

wire connection method to achieve a +/-1mV accuracy

between the Negative Output power rails. This accuracy

translates to a 1% current sharing if there is a total of

100mV conductional voltage drop in the negative return

path.

Constructed as a current source to drive the Trim pin of

a Vicor module, the design uses an accurate comparator

circuit to monitor the power returns. In addition, the circuit is unidirectional and can only trim an output voltage

up. The benefit is that only the supply that is supporting

less current is adjusted up. This action balances the currents to the load by matching the output voltages of the

supplies. In the case of one supply failing, the circuit

will attempt to trim the failed supply only. This will

leave the remaining functional supply alone to provide

power to the load at its nominal voltage. Thus the circuit

also offers simple redundancy. In addition, because CSB

functions as a current source, the Trim outputs (T1 and

T2) of the CSB can be placed in parallel to create a summing node. This allows current sharing between more

than two supplies by paralleling the T2 output of one

CSB circuit with the T1 output of the next CSB.

Please note: The CSB is not intended for use in Hotswap

Applications.

Requirements:

1. For proper operation, the power supplies being paralleled should be enabled at the same time.

2. -Out conductors must be of equal length and wire

gauge.

Separate -Out conductors must be used from each supply

to the load, or the use of a "Y" connection to a common

point

must be used as shown in figure 1. Each leg of the "Y"

must have a minimum of a few millivolts of drop in order

for proper operation. 50mV to 100mV of drop will provide from 5% to 1% accuracy.

3. -V1 and -V2 for all Box-to-Box circuits must be connected directly at the negative output power studs or terminals to achieve accurate current sharing.

4. D* can be added if redundancy is needed. If redundancy is not required, D* can be replaced with direct

wire connections.

5. When using D*, the Power input should be connected

on the cathode side of the paralleling diodes as shown

above.

6. Terminate Sense Leads either locally or remotely as

shown in figure 1.

7. For paralleling more than 2 supplies consult factory

for assistance.

Figure 1. CSB Interconnect Example

Supply # 1

5V @ 120A

+OUT

+S

-OUT

-S

TRIM

Supply # 2

5V@120A

+OUT

+S

-OUT

-S

TRIM

T1

-V1

T2

-V2

Power

+VOUT

-VOUT

D*

D*

CSB02

Black

White

Brown

Yellow

Red

Page 27

Current Share Boards - Optional Feature (contd)

Specifications:

1. Power: 2-50Vdc at 5mA maximum.

2. Accuracy: +/- 1mV between -Vout connections.

3. Output current when not trimming up: +/- 1uA (VI-200/J00), +/-5uA (Maxi/Mini/Micro ).

4. Use 4 non-plated through holes with standoffs for mounting.

5. CSB01 MUST be used for current sharing VI-200/VI-J00 converters

6. CSB02 MUST be used for current sharing Maxi/Mini/Micro converters

***PLEASE NOTE, THE CSB IS NOT INTENDED FOR HOTSWAP APPLICATIONS***

Contact your Regional Applications Engineer at 1-800-927-9474 for additional information.

Rev. 2/2012 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Pg. 27

FlatPAC-EN/EN MI Design Guide

Figure 3. Cable Drawing

P1

24.0" +/- 1.0"

Powe r

T1

-V1

T2

-V2

Red, 22 AWG

Yellow, 22 AWG

Brown, 22 AWG

White, 22 AWG

Black, 22 AWG

12

34

56

1.74"

(44.2mm)

0.12"

(3.0mm)

1.500"

(38.1mm)

0.12"

(3.0mm)

0.900"

(22.9mm)

1.14"

(29.0mm)

0.13" (3.3mm) Dia Non

Plated thru hole 4

places

Molex CT43045F surface mountable

connector. .390" height above board.

Pin Description

1 Power

2T1

3 -V1

4T2

5 -V2

6

No Connection

J1 Pinout

Figure 2. Mechanical Drawing

Page 28

Notes

Pg 28 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 2/2012

FlatPAC-EN/EN MI Design Guide

Page 29

FlatPAC-EN/EN MI Design Guide

VICOR GLOBAL OFFICES

For more information about this or other Vicor products, or for assistance with component-based power system design,

contact the Vicor office nearest you. Vicor's comprehensive line of power solutions includes modular, high-density DCDC converters and accessory components, configurable power supplies, and custom power systems. Westcor, a

division of Vicor, designs and builds, configurable power supplies incorporating Vicor’s high density DC-DC converters

and accessory components. Westcor’s product line includes:

LOPAC FAMILY:

• PFC MicroS • PFC Micro • PFC Mini

MEGAPAC FAMILY:

• PFC MegaPAC • PFC MegaPAC-EL (Low Noise) • PFC MegaPAC MI (Rugged)

• PFC MegaPAC (Low Noise/High Power) • Mini MegaPAC • Autoranging MegaPAC

• 4kW MegaPAC • 4kW MegaPAC-EL (Low Noise) • ConverterPACs

OTHERS:

• FlatPAC-EN PFC FrontEnd

MilCOTS (MI) versions available for the PFC MegaPAC, PFC Mini, PFC Micro/MicroS and FlatPAC-EN products

Information furnished by Vicor is believed to be accurate and reliable. However, no responsibility is assumed by Vicor for its use. No license is granted by implication or otherwise under any patent or patent rights of Vicor. Vicor components are not designed to be used in applications, such as life support systems, wherein a failure or malfunction could result in injury or death. All sales are subject to Vicor's Terms and Conditions of Sale, which are

available upon request.

Specifications are subject to change without notice. The latest data is available on the Vicor website at vicorpower.com

_________________________________________________________________________________________________

www.vicorpower.com

USA

Vicor Corporation,

Corporate Headquarters

25 Frontage Road

Andover, MA 01810

Tel: 800-735-6200,

Tel: 978-470-2900

Fax: 978-475-6715

Vicor Corporation

377 E. Butterfield Road

Suite 201

Lombard, IL 60148

Tel: 630-769-8780

Fax: 630-769-8782

Vicor, Westcor Division

560 Oakmead Parkway

Sunnyvale, CA 94085

Tel: 408-522-5280

Fax: 408-774-5555

EUROPE

Vicor France Vicor Germany

Tel: 33-1-3452-1830 Tel: +49-89-962439-0

Free Phone Free Phone

France Only: Germany Only:

0800 419 419 0800 018 29 18

Fax: 33-1-3452-2830 Fax: +49-89-962439-39

Email: vicorfr@vicr.com Email: vicorde@vicr.com

Vicor Italy Vicor U.K.

Tel: +39-02-2247-2326 Tel: +44-1276-678-222

Free Phone Italy Only: Free Phone UK Only:

800-899-677 0800-980-8427

Fax: +39-02-2247-3166 Fax: +44-1276-681-269

Email: vicorit@vicr.com Email: vicoruk@vicr.com

ASIA-PACIFIC

Vicor Hong Kong

Tel: +852-2956-1782

Fax: +852-2956-0782

Vicor Japan Co., Ltd.

Tel: 81-3-5487-3880

Fax: 81-3-5487-3885

© Vicor Corporation 2012

Loading...

Loading...