VICOR FL48-100150, FL5-100100, FL48-200500, FL48-200250, FL48-200150 Datasheet

...

Rev. 4/2003 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474

FlatPAC-EN Design Guide

Design Guide

and

“Quick Install” Instructions

www.vicorpower.com

FlatPAC-EN™

EN Compliant Autoranging Switcher

TABLE OF CONTENT

Overview of Product...........................................................................................................................3

Part Numbering...................................................................................................................................3

Mechanical Considerations.................................................................................................................4

FlatPAC-EN Do’s and Don’ts.............................................................................................................4

Technical Description.........................................................................................................................5

Configuration Layout drawing...........................................................................................................6

Quick Install Instructions....................................................................................................................7

Mechanical Drawings.........................................................................................................................10

Interface Connections.........................................................................................................................11

RS 232 Microcontroller......................................................................................................................12

Batmod Current Source......................................................................................................................16

In-line Filter........................................................................................................................................16

Specifications.......................................................................................................................... ..........17

Output vs. AC & DC Voltage Graphs . .............................................................................................19

Thermal Curves..................................................................................................................................21

Current Share Boards.........................................................................................................................23

Pg. 2 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 4/2003

FlatPAC-EN Design Guide

FlatPAC-EN™

EN Compliant Autoranging Switcher

Overview

The FlatPAC-EN is an ultra low profile switching power supply that provides up to 500 Watts from up to 4 isolated

outputs. It operates on either 115 or 230 Vac nominal (47-63 Hz), or 250-380 Vdc. The two-output version contains 1 full brick and 1 half brick. The three-output version contains 3 half bricks. And the four-output version contains 1 half brick and 3 quarter bricks.

The use of these converters gives the FlatPAC-EN the inherent power flexibility typical of all Vicor products.

With dimensions of 1.4" H (35,6mm) x 5.0" W (127mm) x 9.2" L (233,7mm), the FlatPAC-EN provides a power

density greater than 7W/in

3

.

It is factory configured to meet user output requirements. Note: The FlatPAC-EN

does not have an internal fan.

Standard Features

• Power Factor Correction (passive): Power Factor (Typical) 0.70 (>75% Load)

• Input Voltage: 90-132/180-264 Vac1, 47-63 Hz, or 250-380 Vdc

• Maximum Power Output: 500W (105/190Vac min.)

425W for EN61000-3-2 compliance

• Up to 4 isolated user specifiable outputs

• Conducted EMI: FCC Class A EN 55022 Class A

FCC Class B EN 55022 Class B

*(may require optional in-line filter. Contact Factory.)

• Harmonic Attenuation to EN61000-3-2/A14

2

• Compliant to EN61000-4-4 (Electrical Fast Transient/Burst) and EN61000-4-5 (Surge Immunity)

• Rugged: Meets MIL-STD-810E, Category 10 for vibration

• Efficiency (typical) > 70%

• Autosense

3

• RS-232 microcontroller interface

• Output overcurrent protection on all outputs

• Size: 1.4" H (35,6mm) x 5.0" W (127,0mm) x 9.2" L (233,7mm)

• Safety Agency Approvals: CE Marking,

CTÜVUS, CULUS

1

Derates to 260W@90Vac, 400W @ 180 Vac.

2

For output power ≤ 425W, not to exceed an input current of 3.33 A rms at 230 Vac, 50 Hz.

3 This feature is implemented in all converter slots. Autosense allows automatic local sensing when remote sense connec-

tions are not made. The FlatPAC-EN will operate in remote sense mode when remote sense connections are made. Refer to

page 14 for more information on Autosense.

Optional Features

• Extended Temperature Range Version

• Current Share Board for unit to unit power sharing - See page 23 and page 24

• Connector kits (# 19-130044)

• In-line Filter - see page 16

• Low leakage version

Part Numbering

FlatPAC-EN FLx1-x2 x3 -xxx (-x4)x1Number of outputs

e.g. FL4-13-501 x

2

Number of 1st Gen VI-200 & VI-J00 modules

x

3

Number of 2nd Gen Maxi, Mini and Micro modules

xxx Sequential number assigned by Westcor

(x4) Optional versions

E - Extended Temperature Range Version

LL - Low Leakage version

Rev. 4/2003 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Pg. 3

FlatPAC-EN Design Guide

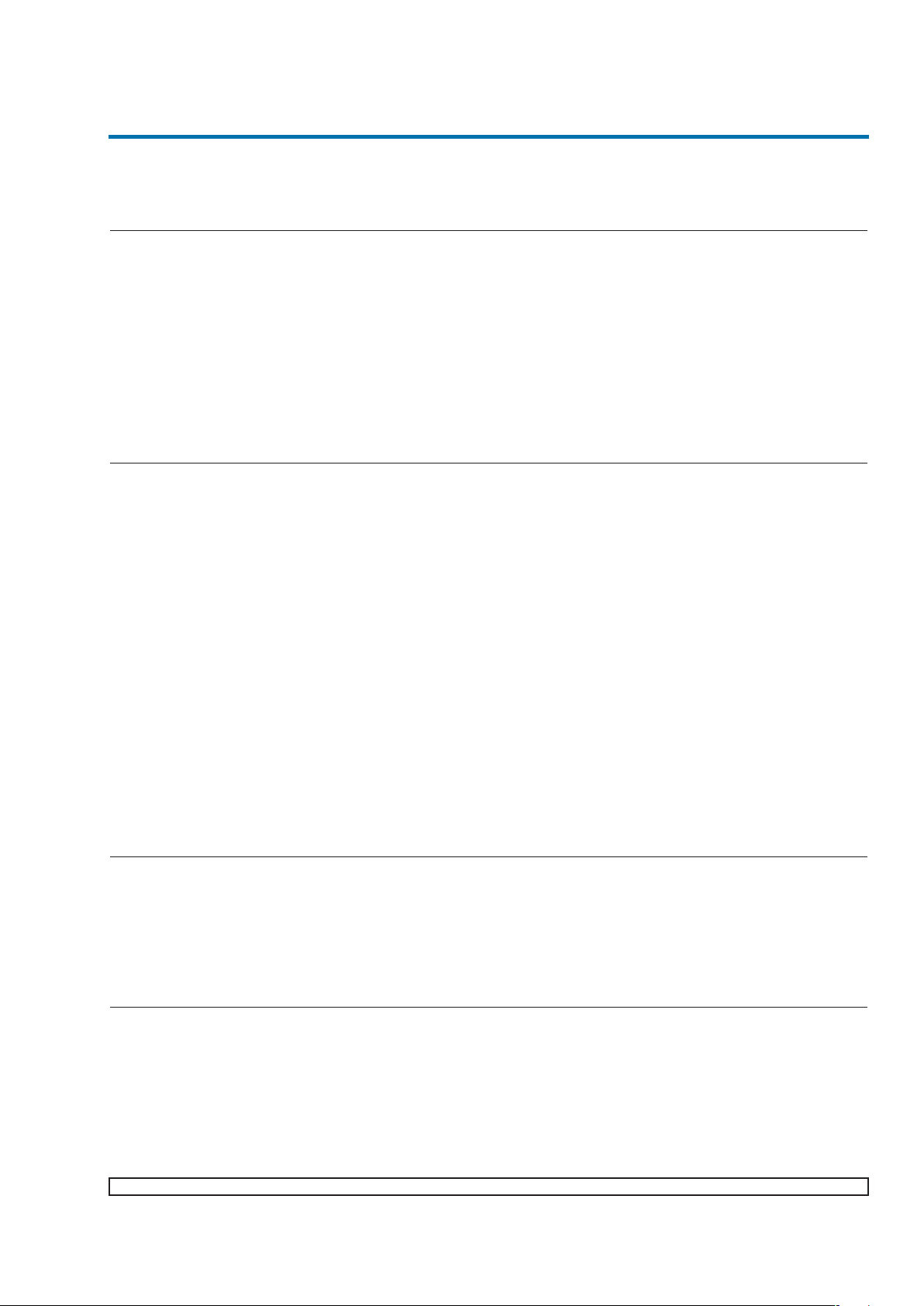

Mechanical Considerations

The FlatPAC-EN is mounted on the bottom surface using standard 8-32 or 4 mm screws (cannot be mounted from

the front.)

Maximum allowable torque is 5 in. lbs.,. The maximum penetration for mounting holes A1, A2, A3 and A4 is 0.125

in. (3mm) and for mounting holes B1, B2, C1 and C2 is 0.250 in. (6mm). The minimum recommended mounting

holes are as follows:

1. For standard mounting (forced air cooling), use A1, A2, A3, A4 mounting holes.

2. For standard mounting (conduction cooling), use A1, A2, A3, A4, B1 and B2 mounting holes.

3. For a Vicor 2 Up FlatPAC retrofit replacement, use C1 and C2 as these two are identical to the recommended

mounting holes on the FlatPAC.

For increased ruggedness, additional mounting holes can be used to secure the power supply.

The FlatPAC-EN does not have an internal fan. It can be conduction or convection cooled (same model).

Avoid excessive bending of output power cables after they are connected to the output terminals. For high-current

outputs, use cable ties to support heavy cables and minimize mechanical stress on connectors. Be careful not to

short-out to neighboring outputs. The maximum torque recommended on output nuts is 10 in. lbs.

For applications that require vibration levels above MIL-STD-810E, a shock absorbing mount design is required.

FlatPAC-EN Do’s and Don’ts

• Do not exceed an operating case temperature of 90oC. To prevent an overtemperature condition, an external

fan may be required.

• Run the output (+/–) power cables next to each other to minimize inductance.

• Do not attempt to repair or modify the power supply in any manner as this action will void the warranty. In

the event of problems, contact Westcor’s Customer Service Department at 1-800-797-5678 or (408) 522-5280.

• Insert proper fault protection at power supply input terminals (i.e., a fuse).

• Use proper size wires to avoid overheating and excessive voltage drop.

Pg. 4 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 4/2003

FlatPAC-EN Design Guide

Identical mounting

holes (C1 & C2)

to Vicor's

2 UP FlatPAC

C1

C2

A1

A2

B1

B2

A3

A4

Technical Description

The FlatPAC-EN consists of an off-line single phase autoranging front end, EMI filter, customer interface, power

supply control circuit, associated housekeeping circuits, a MiniHAM module and a selection of Vicor’s 1st

Generation (VI-200 and VI-J00) and/or 2nd Generation (Maxi, Mini and Micro) DC-DC converters.

The MiniHAM was specifically designed for EN compliance using passive filtering. Unlike active PFC solutions,

the MiniHAM generates no EMI, greatly simplifying and reducing system noise filtering requirements. It is also

considerably smaller and more efficient than active alternatives and improves the unit’s MTBF. It will provide harmonic current compliance at 230Vac input up to 425W of output power. Input AC mains voltage is applied to input

connector MBJ1 (see page 6) and the input current is passed through an EMI filter designed to meet conducted

noise limit of EN 55022, Classes A and B specifications. Certain configurations may require Westcor’s optional

external in-line filter to meet EN 55022 Class B.

At start-up, the microcontroller verifies that the input voltage is within the specified operating range. Once this

occurs, the microcontroller closes the safety relay and puts the autoranging front-end in the correct mode (closing

or opening the Doubler relay). The autoranging front-end has two modes, the doubler mode (90Vac - 132Vac) or

bridge rectifier mode (180Vac-264Vac, 250Vdc-380Vdc). Inrush current is limited by a PTC thermistor. The PTC

is shunted out (by closing the Inrush relay) when the output voltage has charged up the bus capacitors within the

specified range (205Vdc-390Vdc). Approximately 1 second after the application of the input voltage, the bus voltage is within operating limits and the AC OK signal asserts to a TTL "1", indicating the input power is OK. After

AC OK is asserted high, the user can now control the power outputs.

Output voltage conversion is achieved by Vicor’s 300Vin family of Zero-Current-Switching (ZCS) DC-DC converters. These are forward converters in which the main switching element switches at zero current. This patented

topology has a number of unique attributes: low switching losses; high frequency operation, resulting in reduced

size for magnetics and capacitors; excellent line and load regulation; wide adjustment range for output; low

EMI/RFI emission and high efficiencies.

At initial power-up, all outputs are disabled to limit the inrush current and to allow the DC bus potential to settle

to the correct operating level. A low-power transformer flyback circuit converts the high voltage DC bus into regulated low voltage to power the internal housekeeping circuits as well as the auxiliary +5Vs located in the interface

connector.

An output Enable/Disable function is provided to control Vicor’s DC-DC converters. If the Enable/Disable control

pin is pulled low, the modules output is disabled. The nominal delay associated for an output to come up when

measured from release of the Enable/Disable pin is 9-12 ms. The General Shutdown function controls all outputs

simultaneously and works in a similar manner.

Rev. 4/2003 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Pg. 5

FlatPAC-EN Design Guide

Figure 1. FlatPAC-EN Architecture

1000uF

1000uF

MiniHAM

100k

100k

1

2

3

4

5

Microcontroller

Safety

Inrush

Strap

GND

N/C

Line

N/C

Neutral

MBJ1

Vbus to

DC/DC Modules

50 Ohm PTC

EMI

Filter

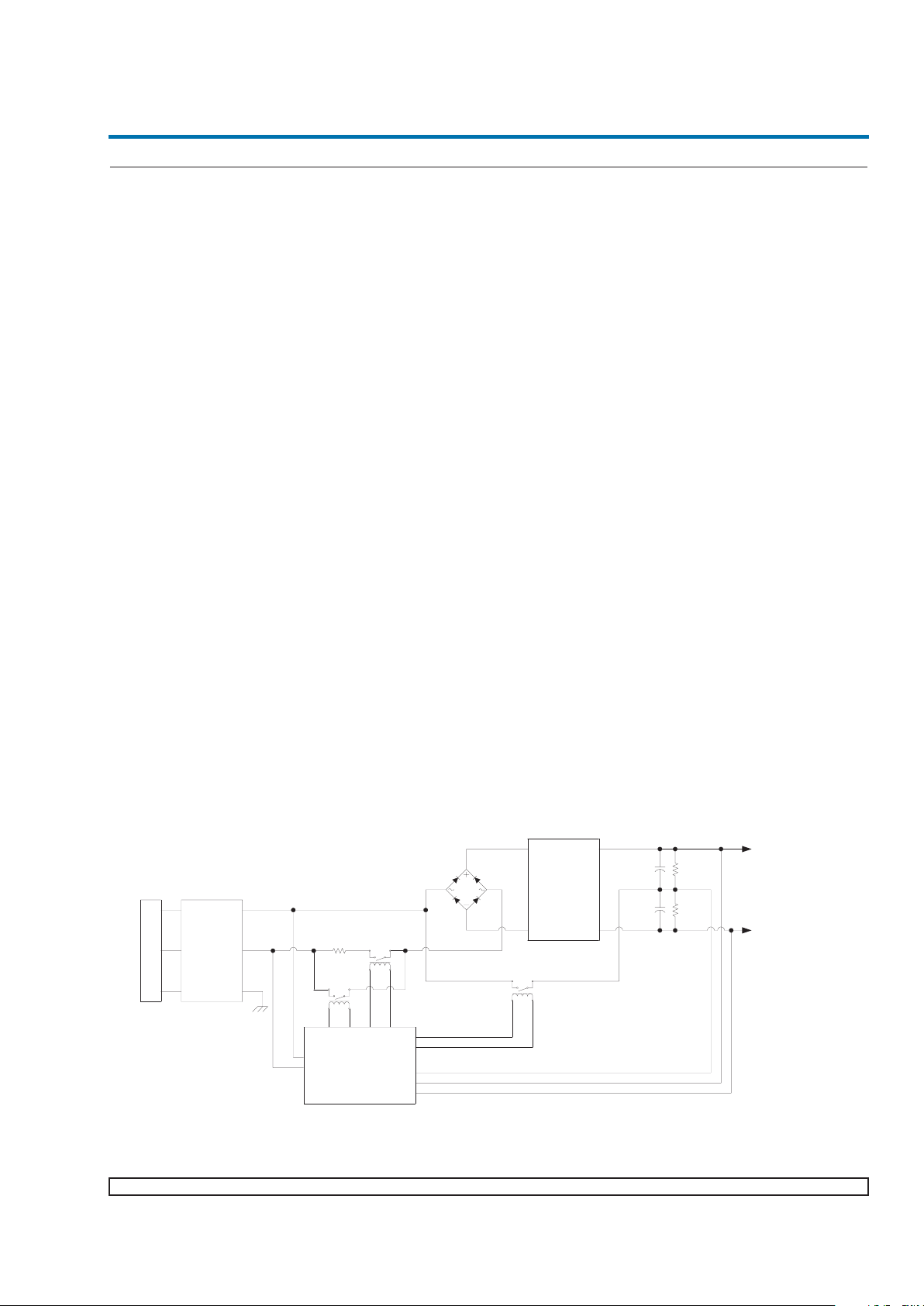

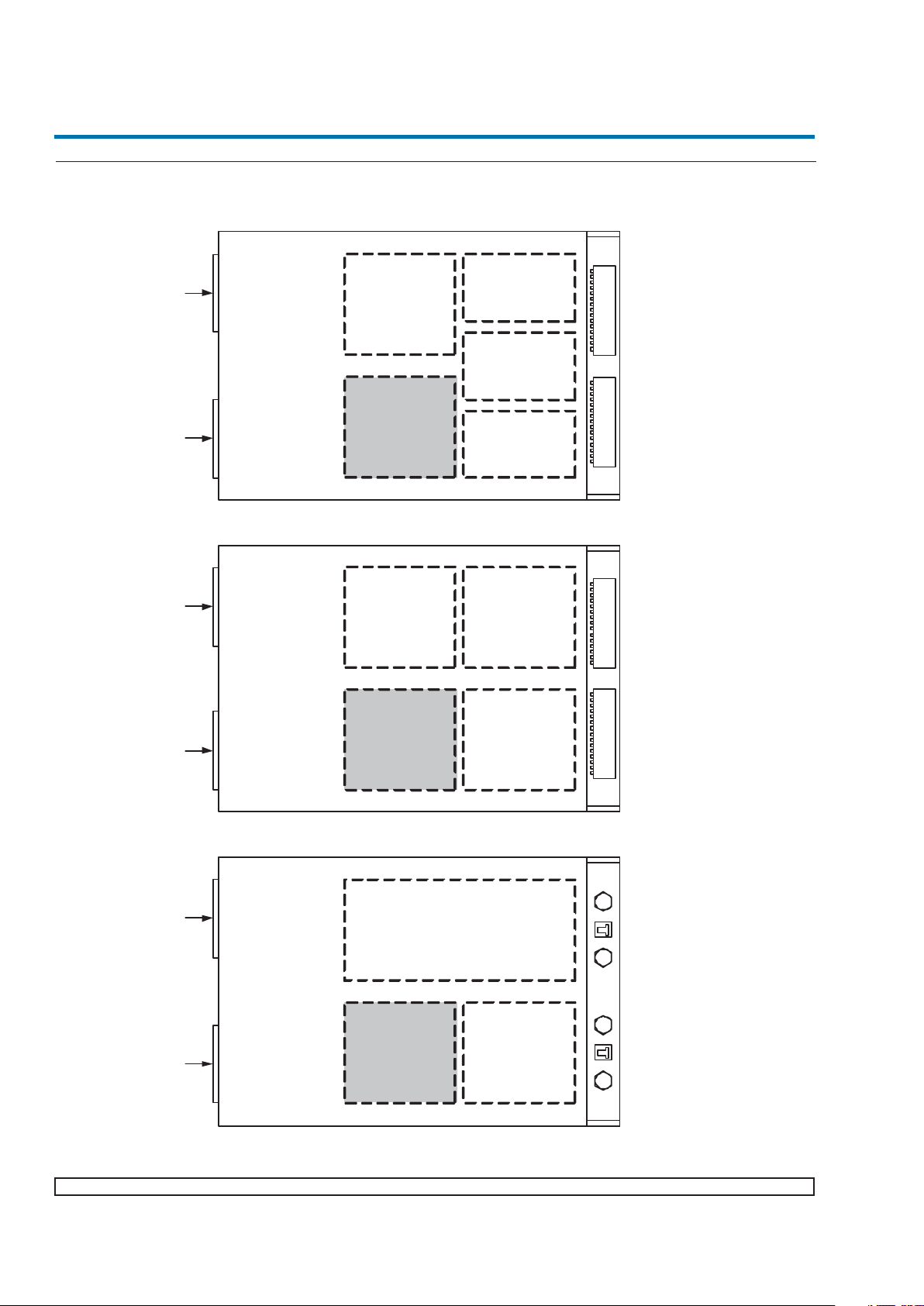

FlatPAC-EN Configuration Layout

Pg. 6 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 4/2003

FlatPAC-EN Design Guide

CBJ1

Interface Conn.

M2

VI-200,

Maxi

or

Batmod

M1

VI-J00

or

Mini

MBJ1

Input Conn.

MiniHAM

CBJ1

Interface Conn.

MBJ1

Input Conn.

M2

Micro

M1

Micro

M3

Micro

MiniHAM

M4

VI-J00

or

Mini

CBJ1

Interface Conn.

M1

VI-J00

or

Mini

MBJ1

Input Conn.

MiniHAM

M2

VI-J00

or

Mini

M3

VI-J00

or

Mini

Single or Dual Outputs

(Stud Connectors)

Triple Outputs

(Two 18 pin Molex Connectors)

Quadruple Outputs

(Two 18 pin Molex Connectors)

For a single output configuration,

either M1or M2 is used

FlatPAC-EN “Quick Install” Instructions (For mechanical drawings, see page 10)

Mounting the FlatPAC-EN

• Mount the FlatPAC-EN on the bottom (cannot be mounted from the

front).

• For standard mounting (forced air cooling), use A1, A2, A3, A4 mounting holes.

For standard mounting (conduction cooling), use A1, A2, A3, A4, B and B2

mounting holes.

• For a Vicor 2 Up FlatPAC retrofit replacement, use C1 and C2 as these

two are identical to the mounting holes on the FlatPAC.

• For increased ruggedness, use additional mounting holes to secure the

power supply.

• Use #8-32 or 4mm mounting screws. For mounting holes A1, A2, A3 and

A4, the maximum penetration should not exceed 0.125 in. (3mm). For mounting holes B1, B2, C1 and C2, do not exceed maximum penetration of 0.250 in.

(6 mm).

* The maximum allowable torque is 5 in. lbs.,

Input Connections

Input Power MBJ1

• Apply input AC power connector MBJ1 using a maximum torque of 5 in. lbs

• Place a fuse or circuit breaker in the input line for safety requirements

(10A).

• Use Molex mating receptacle 39-01-4051, terminals 39-00-0090 and crimp

tool Molex # 11-01-0199.

Output Connections

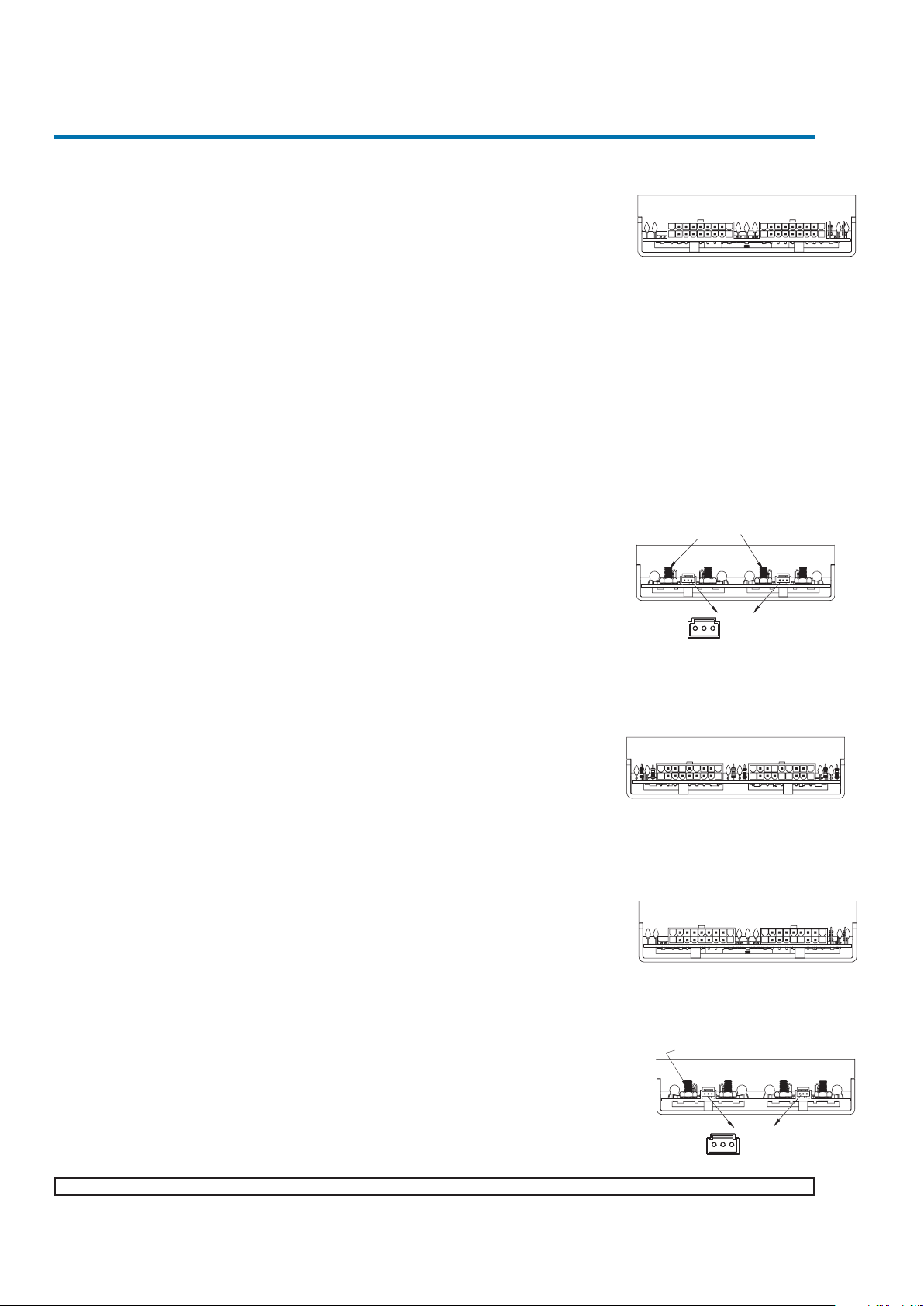

Power Connections

Installing power connectors on single and dual output (Uses 10-32 output

studs):

• Install #10 ring lugs on output studs

* The right stud is positive and the left stud is the return when viewed

from the output end.

• Remove the nut and place ring lug over output stud.

• Replace and tighten the nut to a torque of 10 inch pounds. Do Not Over-

Tighten Nuts.

Installing power connectors on triple output (Uses 18 Pin Housing):

• The output M1 slot accepts either a Mini or a Junior module. J2-7, J2-8, J216 are positive, while pins J2-9, J2-17 and J2-18 are the returns.

• J2-1, J2-2, J2-3, J2-4, J2-5, J2-10, J2-11, J2-12 and J2-14 are not connected.

• The output M2 slot accepts either a Mini or a Junior module. J3-7, J3-8,

and J3-16 are positive while pins J3-9, J3-17 and J3-18 are the returns.

• The output M3 slot accepts either a Mini or a Junior module. J3-1, J3-10,

J11 are positive while pins J3-2, J3-3, J3-12 are the returns.

• For this 18 pin housing, use Molex mating receptacle #39-01-2180 with #3900-0039 terminals.

• Attach 24-30 AWG stranded wire using Molex tool #11-01-0197.

Rev. 4/2003 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Pg. 7

FlatPAC-EN Design Guide

MBJ1

N/C

N/C

L1

L2/N

GND

OUTPUT M1

OUTPUT M2

10-32 STUDS

+

J2

-

M1

-

J1

+

SINGLE AND DUAL OUTPUT

Identical mounting

holes (CI & C2) to Vicor's

2 UP FlatPAC

C1

C2

B1

B2

A3

A4

A1

A2

OUTPUTS M2 & M3

OUTPUT M1

TRIPLE OUTPUT

J2

J3

1

18

9

10

1

9

10

18

PIN DESCRIPTION

1 N/C

2 N/C

3 N/C

4 N/C

5 N/C

6 TRIM M1

7 +V OUT M1

8 +V OUT M1

9 -V OUT M1

PIN DESCRIPTION

10 N/C

11 N/C

12 N/C

13 + SENSE M1

14 N/C

15 - SENSE M1

16 +V OUT M1

17 - V OUT M1

18 - V OUT M1

J2

PIN DESCRIPTION

1 +V OUT M3

2 -V OUT M3

3 -V OUT M3

4 + SENSE M3

5 - SENSE M3

6 TRIM M2

7 +V OUT M2

8 +V OUT M2

9 -V OUT M2

PIN DESCRIPTION

10 +V OUT M3

11 +V OUT M3

12 -V OUT M3

13 + SENSE M2

14 TRIM M3

15 - SENSE M2

16 +V OUT M2

17 - V OUT M2

18 - V OUT M2

J3

Installing power connectors on quadruple output (Uses 18 Pin Housing):

• The output M1 slot only accepts a Micro module. J2-7, J2-8, J2-13 and J2-16

are positive, while pins J2-9, J2-15, J2-17 and J2-18 are the returns.

• The output M2 slot only accepts a Micro module. J2-1, J2-4, J2-10, J2-11 are

positive, while pins J2-2, J2-3, J2-5 and J2-12 are the returns.

• The output M3 slot only accepts a Micro module. J3-7, J3-8, J3-13 and J316 are positive, while pins J3-9, J3-15, J3-17 and J3-18 are the returns.

• The output M4 slot only accepts either a Mini or a Junior module. J3-1, J3-10

and J3-11 are positive while pins J3-2, J3-3, and J3-12 are the returns.

• For this 18 pin housing, use Molex mating receptacle #39-01-2180 with #3900-0039 terminals.

• Attach 24-30 AWG stranded wire using Molex tool #11-01-0197

See page 10 for detailed diagrams of output connections.

Sense Connections

The FlatPAC-EN is shipped with Autosense installed (For more information on

Autosense, refer to page 14)

Sense Connections for single and dual isolated output:

• For Remote Sense, connect Remote Sense wires to Remote Sense/Trim Pin

Access Connector J1 or J2 for single output and J1/J2 for dual outputs.

* Connector pins J1-2 and J2-2 are the + Senses and J1-3 and J2-3 are

the -Senses.

• Use Molex mating receptacle #50-57-9403 with #16-02-0103 terminals.

• Attach terminals to 24-30 AWG stranded twisted pair wire using Molex tool #

11-01-0208.

• Attach opposite end of sense lines to their respective outputs to point where

regulation is desired. Verify that sense lines are not cross-connected.

Sense Connections on triple output:

• If Remote Sense is desired, connect Remote Sense wires to the sense lines of

Connector J2 for output 1 and J3 for outputs 2 and 3.

* For Output M1, J2-13 is the +Sense and J2-15 is the -Sense.

* For Output M2, J3-13 is the +Sense and J3-15 is the -Sense.

* For Output M3, J3-4 is the +Sense and J3-5 is the -Sense.

• Use Molex mating receptacle #39-01-2180 with #39-00-0039 terminals.

• Attach 24-30 AWG stranded twisted pair wire using Molex tool #11-01-0197.

Sense Connections on quadruple output:

• If Remote Sense is desired (available only on output M4), connect Remote

Sense wires to sense lines of Connector J3

* Remote Sense is NOT available for Micro modules and hence is not

available on outputs M1, M2 and M3.

* On output M4, J3-4 is the +Sense and J3-5 is the -Sense.

• Use Molex mating receptacle #39-01-2180 with #39-00-0039 terminals.

• Attach 24-30 AWG stranded twisted pair wire using Molex tool #11-01-0197

Trim Connections

Trim Connections on single and dual output :

• For output M1, J1-1 provides Trim Access

• For output M2, J2-2 provides Trim Access

• Use Molex mating receptacle #50-57-9403 with #16-02-0103 terminals.

• Attach 24-30 AWG stranded wire using Molex tool #11-01-0208.

Pg. 8 Vicor 800-735-6200 Westcor Division 408-522-5280 Applications Engineering 800-927-9474 Rev. 4/2003

FlatPAC-EN Design Guide

1

2

3

1 Trim Pin

2 + Remote Sense

3 - Remote Sense

Pin

OUTPUT M1

OUTPUT M2

10-32 STUDS

+

M2

J2

-

M2

M1

-

J1

+

TRIM: SINGLE AND DUAL OUTPUT

OUTPUT M1

OUTPUT M2

10-32 STUDS

+

M2

J2

-

M1

-

J1

+

SINGLE AND DUAL OUTPUT

1

2

3

1 Trim Pin

2 + Remote Sense

3 - Remote Sense

Pin

OUTPUTS M1 & M2

OUTPUTS M3 & M4

QUADRUPLE OUTPUT

J2

J3

PIN DESCRIPTION

1 +V OUT M2

2 -V OUT M2

3 -V OUT M2

4 +V OUT M2

5 - VOUT M2

6 TRIM M1

7 +V OUT M1

8 +V OUT M1

9 -V OUT M1

PIN DESCRIPTION

10 +V OUT M2

11 +V OUT M2

12 -V OUT M2

13 + VOUT M1

14 TRIM M2

15 - VOUT M1

16 +V OUT M1

17 - V OUT M1

18 - V OUT M1

PIN DESCRIPTION

1 +V OUT M4

2 -V OUT M4

3 -V OUT M4

4 + SENSE M4

5 - SENSE M4

6 TRIM M3

7 +V OUT M3

8 +V OUT M3

9 -V OUT M3

PIN DESCRIPTION

10 +V OUT M4

11 +V OUT M4

12 -V OUT M4

13 + VOUT M3

14 TRIM M4

15 - VOUT M3

16 +V OUT M3

17 - V OUT M3

18 - V OUT M3

1

9

10

18

1

9

10

18

OUTPUTS M2 & M3

OUTPUT M1

TRIPLE OUTPUT

J2

J3

J2-13 + SENSE M1

J2-15 - SENSE M1

J3-4 + SENSE M3

J3-5 - SENSE M3

J3-13 + SENSE M2

J3-15 - SENSE M2

1

18

9

10

1

9

10

18

+S

-S

+S

-S

+S

-S

OUTPUTS M1 & M2

OUTPUTS M3 & M4

QUADRUPLE OUTPUT

J2

J3

M4 accepts 1 Mini or 1

Junior

J3-4 + SENSE M4

J3-5 - SENSE M4

1

9

10

18

1

9

10

18

M1, M2, M3 accept Micro modules

No sense connections are available

for Micro modules

+S

-S

Loading...

Loading...