Page 1

FlatPAC Family

50 to 600 Watt

AC-DC Switchers

Application Notes

Functional and Mechanical Layout

Installation and Operation Guidelines

Product Description

The FlatPAC family of user-definable offline power supplies provides a complete

power solution that incorporates one, two, or three standard Vicor DC-DC converters

and a front-end subassembly in a modular package. FlatPAC is available with one,

two, or three outputs and total output ratings of up to 600 W. The two-up and

three-up models (maximum output 400 W and 600 W) feature an autoranging input,

which automatically senses the input line voltage and sets the power supply’s input

range accordingly. FlatPAC’s unique modular design accommodates over 10,000

different configurations.

FlatPAC switchers that contain BatMod current source modules instead of VI-200

converters are indicated by the suffix -BM following the FlatPAC part number.

BatMod converters provide a programmable output current, rather than a controlled

output voltage. Consequently, the output supervisory terminal functions differ on

FlatPACs with BatMod modules.

F-Series

(Strappable Input)

A-Series

(Autoranging Input)

12

Page 2

Application Notes

2

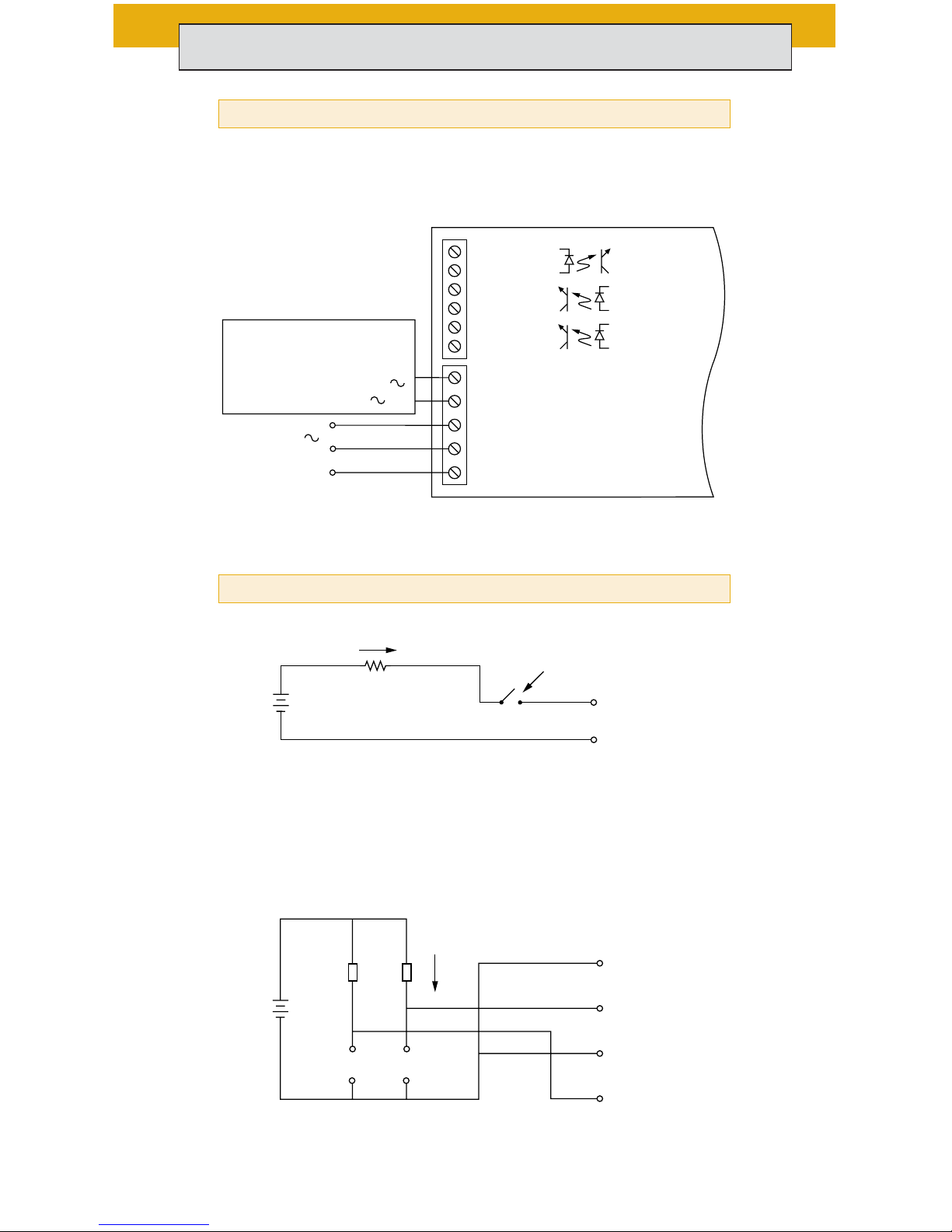

MOD-DIS Input. Apply a current of 1–30 mA to disable output.

Forward voltage drop of internal opto diode is 1.65 V max. @

30 mA max.

AC-OK and BUS-OK Status Outputs. Output transistors saturated

if OK. Vce sat. = < 0.4 V @ 1.5 mA. Maximum voltage is 70 Vdc.

30 mA max.

Disable

MOD DIS +

MOD DIS –

V

+

AC OK –

AC OK +

BUS OK –

Status

1.5mA max.

V

+

r

r

AC Mains Connections

Supervisory Connections (2-up and 3-up models)

AC Mains

Earth Ground

MOD DIS –

MOD DIS +

AC OK –

AC OK +

BUS OK –

BUS OK +

Internal

Supervisory

Circuits

(Optocouplers)

Autoranging models:

Do not connect

Manual strap models:

Connect for 115 Vac

Open for 230 Vac

ST2

ST1

L2/N

L1

GND

Page 3

3

+Sense and –Sense must be connected locally or remotely (shown).

+ V

OUT

To Load

– V

OUT

R1

10K

R2

+ OUT

+ SENSE

TRIM

– SENSE

– OUT

RESISTOR VALUES FOR TRIMMING STANDARD OUTPUT VOLTAGES

Nominal Output Voltage 5 V 12 V 15 V 24 V 28 V 48 V Trim Range

R1(kΩ) .953 15.8 22.1 41.2 48.7 90.9

R2(kΩ)909090909090

+10%, -10%

V

LINE

> 90 (180) Vac

AC Line

Interrupted

AC

Line

AC OK

DC OK

T0

T1 T2

T3

T4

Conditions: Full Load 90 (180) Vac, AC Line

Timing Diagram—Status Signals (2-up and 3-up models)

Output Trimming (All models with VI-200s)

Battery

Charger

External

Control

Functions

+ OUT

V

TRIM

I

TRIM

I

MON

– OUT

Programmable

Current Source

12–48V

Battery

+

–

➧

➧

Load

+

–

OR

Typical Applications (FlatPACs with BatMods only)

Time Interval Min Typ Max Units Notes

T1-T0 0 0.1 1.0 ms

T3-T2 0 – – ms

T4-T2 5 – – ms Ride-through time

T4-T3 5 – – ms AC fail warning time

Page 4

Functional and Mechanical Layout

4

LF-Series

Single output

50-200 W

MA/MF-Series

Single output

200-400 W

NA/NF-Series

Single output

450-600 W

PA/PF-Series

Dual output

100-400 W

QA/QF-Series

Dual output

250-600 W

RA/RF-Series

Triple output

150-600 W

NA-, QA-, and RA-Series

MA-, PA-Series

LF-Series

Inputs

All Models

10

11

8

9

7

6

1

2

5

4

3

7.38

(187,5)

1.99

(50,6)

4.42

(106,7)

.20

(5,1)

.18

(4,6)

6.00

(152,4

2.288

(58,12)

2.420

(61,47)

7.00

(177,8)

.20

(5,1)

5 PLACES

.25

(6,4)

5 PLACES

.19

(4,8)

12

ø.150 ± .005

(ø3,81 ± 0,13)

THRU 6 PLACES

.18

(4,6)

6.00

(152,4)

.192

(4,88)

2.156

(54,77)

2.54

(64,5)

.20

(5,1)

.87

(22,1)

.20

(5,1)

TYP

1

3

5

4

2

12

ø.150 ± .005

(ø3,81 ± 0,13)

THRU 4 PLACES

.199

(5,06)

.90

(22,9)

3.05

(77,5)

4.96

(126,0)

.25

(6,4)

.20

(5,1)

.20

(5,1)

.18

(4,6)

2.281

(57,94)

9

7

11

8

6

1

2

5

4

3

10

5 PLACES

5 PLACES

4.562

(115,87)

6.0

(152

ø.150 ± .005

(ø3,81 ± 0,13)

THRU 5 PLAC

1.37

(34,8)

Page 5

5

Drawing: P.N. 10873

NA-Series QA-Series RA-Series

MA-Series PA-Series

LF-Series

Outputs

Inputs

1 Earthground

2L1

3 L2/N

4

1

ST1

51ST2

6 BUS OK+

7 BUS OK–

8 AC OK+

9 AC OK–

10 MOD DIS+

11 MOD DIS–

1

Not used on

autoranging models

Outputs

A +Out

B +Sense*

C Trim*

D –Sense*

E –Out

*

On FlatPACs

with BatMods:

BV

TRIM

CI

TRIM

DI

MON

#8-32 STUD

#10-32 STUD

#10-32 STUD

#8-32 STUD

6 PLACES

2.76

(70,1)

3.07

(78,0)

E

D

C

B

A

E

D

C

B

A

E

D

C

B

A

E

D

C

B

A

E

D

C

B

A

E

D

C

B

A

.41 (10,41)

6.95 (176,53)

6.37 (161,80)

5.98 (151,89)

5.59 (141,99)

5.25 (133,35)

4.53 (115,06)

3.95 (100,33)

3.56 (90,42)

3.17 (80,52)

2.83 (71,88)

2.11 (53,59)

1.53 (38,86)

1.14 (28,96)

.75 (19,05)

0

.25 TYP

OUTPUT 1

OUTPUT 2

OUTPUT 3

OUTPUT 1

OUTPUT 2

OUTPUT 1

2.76

(70,1)

#8-32 STUD

2 PLACES

E

D

C

B

A

.41 (10,41)

2.11 (53,59)

1.53 (38,86)

1.14 (28,96)

.75 (19,05)

0

.25 TYP

OUTPUT 1

2.76

(70,1)

3.07

(78,0)

12

#10-32 STUD

2 PLACES

E

D

C

B

A

#8-32 STUD

4 PLACES

E

D

C

B

A

E

D

C

B

A

.41 (10,41)

4.53 (115,06)

3.95 (100,33)

3.56 (90,42)

3.17 (80,52)

2.83 (71,88)

2.11 (53,59)

1.53 (38,86)

1.14 (28,96)

.75 (19,05)

0

.25 TYP

OUTPUT 1

OUTPUT 2

OUTPUT 1

ES

0.41

(10,4)

1.12

(28,5)

9.25

(235,0)

8.61

(218,7)

Page 6

Fusing. The FlatPAC’s internal fuses are not user-replaceable. Please return the

unit to vendor if servicing is necessary.

Grounding. For safe operation, the FlatPAC unit must be grounded. Connect a

ground lead to the terminal marked (GND). Use the same wire gauge as that

specified for your FlatPAC unit’s input voltage connections, below.

Input Voltage Connections. Connect the line voltage to L1 (hot) and L2N

(neutral). For one-up FlatPAC models (max. output 200 W), use #16 input wire; for

two-up and three-up models (max. output 400 W and 600 W), use #14 input wire.

Recommended connector screw torque is 5 to 7 in-lbs (0.5 to 0.8 N-m). Use your

FlatPAC model only with the corresponding input voltages and frequencies shown

in the table below. Either connect or do not connect ST1 to ST2 as indicated.

Output Wire Gauge. Use the output wire gauge that corresponds to the output

current of your FlatPAC unit, below:

105 A–160 A : #4 26 A–40 A : #10 7 A–10 A : #16

66 A–104 A : #6 16 A–25 A : #12 4 A–6 A : #18

41 A–65 A : #8 11 A–15 A : #14 0 A–3 A : #20

Output Voltage Trimming. Do not trim the outputs higher than 110% of their

nominal output voltage. When an output is trimmed up, do not exceed its

maximum rated output power.

Operating Temperature. Do not allow the FlatPAC to exceed its maximum

operating temperature, which is reached when the heat sink is 85°C. (Full power

can be delivered up to this temperature.) Heat sink temperature is a function of the

output power and voltage of the supply, ambient temperature, and airflow across

the heat sink. Refer to the Vicor Applications Manual to determine the maximum

ambient temperature for your application. Always use worst-case conditions when

calculating operating temperature. Note: To ensure proper heat transfer from the

internal module(s) to the heat sink, the mounting holes through the heat sink (2, 3,

and 4 holes on one-, two-, and three-up models, respectively) must contain

torqued screws at all times during operation, whether or not the unit is mounted.

Installation and Operation Guidelines

6

90–132 Vac 180–264 Vac

C-Grade

Model 47–63 Hz

Strappable VI– ■■ F–C■■ Connect Open

Autoranging VI–■■ A–C ■■ Open Open

90–132 Vac 180–264 Vac

I-Grade

Model 47–440 Hz

Strappable VI– ■■ F–I ■■ Connect Open

Autoranging VI–■■ A–I ■■ Open Open

Page 7

If the unit is operated unmounted, insert a #6 or metric screw through each hole

from below and secure with a nut on top, torqued to 6 in-lbs (0.7 N-m).

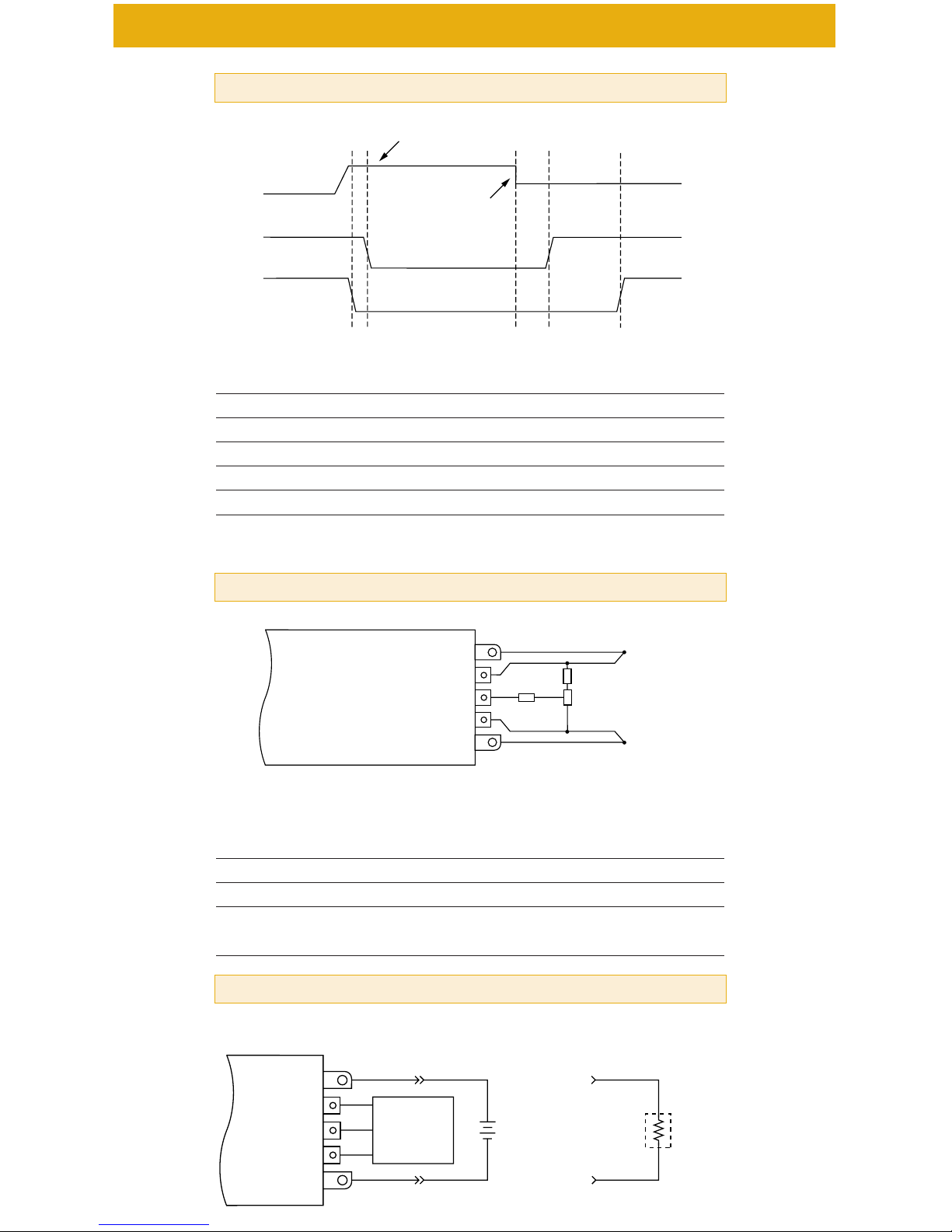

Output Terminal Connections. A hardware kit with parts for output terminal

connections is provided with each FlatPAC unit. The following drawing shows the

assembly of those parts for the proper connection of metal power terminals.

Assembly for PCB power terminals is the same except that they do not require an

external tooth lockwasher. Consult the table below for the recommended torque

level for each stud size.

For More Information

The Vicor Applications Manual and product data sheet contain complete

information about FlatPAC AC-DC Switchers. To receive literature or to consult

an applications engineer about installation or operation of this product, contact

your nearest Vicor office. (See page 8.)

(Bitte lesen Sie die Sicherheits-Vorschriften auf Seite 8.)

“AMP” and “Faston” are registered trademarks of AMP, Incorporated, Harrisburg, PA.

7

Metal Terminal

Drawing: P.N. 10894 #1

Terminal and Terminal Recommended

Product Model Style Stud Size Torque

–Output, +Output

LF-, PA/PF-, & PCB 8-32 UNC 10 in-lbs (1.1 N-m)

RA/RF-Series

MA/MF- & Metal 10-32 UNC 15 in-lbs (1.7 N-m)

NA/NF-Series

QA/QF-Series PCB 8-32 UNC 10 in-lbs (1.1 N-m)

Metal 10-32 UNC 15 in-lbs (1.7 N-m)

Supervisory Sized to accept AMP Faston®insulated

All models receptacle #2-520184-2

EXTERNAL TOOTH

LOCKWASHER

#10 TERMINAL

RETAINING NUT

#10 NUT PLATE

USER OUTPUT

TERMINALS

#10 BRASS STUD

HELICAL

LOCKWASHER

(FITS WITHIN

OPENING PROVIDED)

TERMINAL COVER

NEGATIVE

Page 8

Sicherheits-Vorschriften

8

Sicherungen. Die internen Sicherungen im FlatPAC können nicht vom Anwender

ausgetauscht werden. Für Servicearbeiten schicken Sie das Teil bitte an den

Händler zurück.

Erdung. Um den IEC 950 Klasse I Erdungsforderungen zu entsprechen, muß ein

Erdungskabel an den Anschluß (GND) angeschlossen werden. Für FlatPAC

Modelle mit einem Modul (max. Leistung 200W) benutzen Sie bitte AWG 16- und

für Modelle mit 2 und 3 Modulen (max. Leistung 400 W und 600 W) AWG 14-Kabel.

Eingangsverbindungen. Abhängig von Ihrem FlatPAC Modell und der

Eingangsspannung müssen ST1 und ST2 offen sein oder miteinander verbunden

werden—wie nachstehend aufgeführt.

Modell 90-132 Vac 180-264 Vac

Strappable (VI–■■ F–■■ ■■ ) Verbinden Offen

Autoranging (VI–■■ A–■■ ■■ ) Offen Offen

Betriebstemperatur. Die maximale Betriebstemperatur des FlatPAC-Gerätes darf

nicht überschritten werden. Dies ist gegeben, wenn der Kühlkörper eine

Temperatur von 85 Grad Celsius erreicht hat.

Weitere Informationen. Das Vicor Applications Manual und Produkt-Datenblätter

enthalten ausführliche Informationen über FlatPAC AC-DC Wandler. Fordern Sie

bitte Unterlagen bei Vicor oder Ihrer nächsten Vicor Vertretung an.

Vicor Corporation

Andover, MA, U.S.A

Tel: 978-470-2900

Fax: 978-475-6715

Vicor France

Tel: +33 1 34 52 18 30

Fax: +33 1 34 52 28 30

Vicor Germany

Tel: +49 89 962 439 0

Fax: +49 89 962 439 39

Chicago, IL

Tel: 630-769-8780

Fax: 630-769-8782

Vicor Italy

Tel: +39 02 22 47 23 26

Fax: +39 02 22 47 31 66

Vicor U.K.

Tel: +44 1276 678222

Fax: +44 1276 681269

Sunnyvale, CA

Tel: 408-522-5280

Fax: 408-774-5555

Vicor Hong Kong

Tel: +852-2956-1782

Fax: +852-2956-0782

Vicor Japan

Tel: +81-3-5487-3880

Fax: +81-3-5487-3885

Printed in U.S.A. Pt. No. 23786 Rev 4.0 2/04/100M

Visit Vicor’s Website at:

vicorpower.com

Loading...

Loading...