Page 1

USER GUIDE | UG:017

Analog Control 3623 and 4623 ChiP DCMs

Evaluation Board

Arthur Russell

VI Chip® Applications Engineering

October 2014

Contents Page

Introduction 1

Contents 3

Features 3

Board Description 4

General Components 4

Test Points Description 6

Schematic, Assembly Drawing

and Bill of Materials 7

Recommended Test

Equipment 14

Basic Connections 14

Board Operation Details 14

Trim Control 15

Fault Monitoring 15

Chassis Ground 16

Paralleling 16

Introduction

The Analog Control 3623 and 4623 ChiP DCM evaluation boards described in this document are

designed to be used with the DCM family of isolated, DC-DC converters. The 3623 DCM board is used

for the analog control, low input voltage 3623 ChiP products, while the 4623 DCM board is used for

the analog control, high input voltage (offline) 4623 ChiP products.

The DCM evaluation board can be configured for various enabling and fault monitoring schemes,

as well as to exercise various modes of trimming, depending on the application requirements. The

evaluation board can be used to evaluate DCMs in either a stand-alone configuration, or as an

array of modules.

Enable options:

1. On-board mechanical switch (default)

2. External control

Trim options:

1. Fixed trim operation (default): the TR pin is permitted to float at initial startup.

The DCM disables output trimming and the output trim is programmed to the nominal rated V

2. Variable trim operation, on-board variable resistor: The trim pin voltage is ratiometric,

with a rheostat working against a pull-up resistor inside the DCM to VCC.

3. Variable trim operation, off-board control: The trim pin voltage is controlled via external

programming control, which is referenced to the –IN of each specific DCM in the system.

OUT

.

Fault monitor options:

1. On-board LED: the FT pin drives a visible LED for visual feedback on fault status.

2. On-board optocoupler: the FT pin drives an on-board optocoupler to bring

fault status across the primary-secondary isolation boundary.

UG:017 vicorpower.com Applications Engineering: 800 927.9474 Page 1

Page 2

IMPORTANT NOTICE:

Hazardous voltages are present on the DCM Evaluation Board under power.

PERSONAL CONTACT WITH LINE VOLTAGE MAY RESULT IN SEVERE INJURY, DISABILITY, OR

DEATH. IMPROPER OR UNSAFE HANDLING OF THIS BOARD MAY RESULT IN SERIOUS INJURY

OR DEATH.

Read the precautions below entirely BEFORE using the DCM Evaluation Board. Do not operate the

evaluation board unless you have the appropriate safety precautions in place on your bench to

guarantee safety.

The list below is not comprehensive and is not a substitute for common sense and

good practice.

During operation, the power devices and surrounding structures can be operated

safely at high temperatures.

Remove power and use caution when connecting and disconnecting test probes

and interface lines to avoid inadvertent short circuits and contact with hot surfaces.

Never use a jumper in place of the fuse.

When testing electronic products always use approved safety glasses. Follow good

laboratory practice and procedures.

Avoid creating ground loops when making measurements of the isolated input

or output voltage.

Care should be taken to protect the user from accidental contact when

under power.

Care should be taken to avoid reversing polarities if connecting to the opposite

(solder) side of the board.

The product evaluation boards described in this document are designed for

general laboratory evaluation, and are not suitable for installation in

end user equipment.

Refer to the specific DCM module data sheet for electrical, thermal, and mechanical

product details

UG:017 vicorpower.com Applications Engineering: 800 927.9474 Page 2

Page 3

These boards provide a convenient way to evaluate/demonstrate the performance of Vicor’s DCM

products. Kelvin connections are provided for accurate voltage measurements on power nodes. Sockets

are provided to permit quick installation and changing of bulk filtering capacitors. The evaluation board

also provides lugs for input/output connections, test points and sockets for easy connection to standard

test-equipment, and a high performance air cooled heatsink assembly.

Contents

The evaluation board arrives with the following contents:

1 x DCM evaluation board

1 x top and belly heatsink assembly (pre-installed)

1 x hardware kit

Features

The DCM evaluation board has the following features:

1. Input and output lugs for source and load connections

2. Input fuse (appropriately rated)

3. Basic input filtering, including sockets to add through-hole input aluminum-electrolytic capacitors

for additional source decoupling

Note: The filtering used in the eval board is for demonstration purposes only and might not be the optimal

solution for all applications. For optimal filter design for parallel array application, consult the datasheet of the

DCM in use and the online filter design tool at:

http://app2.vicorpower.com/filterDesign/intiFilter.do

4. Basic output filtering, including sockets to add through-hole output

aluminum-electrolytic capacitors

5. Toggle switch for enabling and disabling the DCM via the ENABLE pin

6. Trim control selection

a. Using potentiometer

b. Using external voltage source

c. Open, to disable trimming and latch the model nominal trim condition

7. Provisions to replace input and output differential mode inductors with wire loops,

for oscilloscope/shunt based current measurements

8. Oscilloscope probe jack for accurate, high frequency output voltage measurements

9. Dual paralleling connectors for ENABLE, TRIM, FAULT and SGND signal connections, for daisy

chaining control to other DCM evaluation boards in an array

10. Kelvin voltage test points for all power pins

11. Top and bottom heatsink assembly for the DCM

UG:017 vicorpower.com Applications Engineering: 800 927.9474 Page 3

Page 4

Board Description

The following section provides a detailed description of the evaluation board components, test points

and sockets.

General Components

1. DCM (PS01)

2. Input lugs: Sized for #10 hardware. Use these for making connection to the input source.

This board does not contain reverse polarity protection. Check for proper polarity before

applying the power.

3. Input fuse (F01 & F02): Appropriately rated for the DCM model on the board.

4. Input filter: Ceramic input capacitors (C15-C22), filtering inductor (L01) and damping resistor

(R08) provide input filtering. Sockets (H01-H02, H03-H04) can be used for easy installation of

aluminum-electrolytic input capacitors. The 3623 board also adds H09-H10 for additional

input bypassing.

5. Enable / Disable switch (SW01): When actuator is in top position towards “ON” text on the board,

the ENABLE pin will be open and the DCM will be enabled. When actuator is in bottom position

towards “OFF” text on the board, the ENABLE pin will be connected to SGND and the DCM will be

disabled. When switch SW01 is ON, an external voltage source can control the ENABLE state.

6. Header-jumper for trim control (J09): Provides the option to enable the trim function to set the

DCM programmed trim value via either the on board trim rheostat or an external voltage source:

a. Using potentiometer (R26)

b. Using external voltage source.

7. Output lugs: Sized for #10 hardware. Use these lugs to connect the output directly to the load.

8. Output oscilloscope probe Jack (J01): Used for making accurate scope measurements of the output

voltage (e.g. ripple). The jack is directly compatible with many common passive voltage probes

models. Remove the grounding lead and insulating barrel of the probe and insert the probe tip and

barrel directly into the jack, ensuring that the probe tip seats in the center socket of the jack. To

avoid the risk of an inadvertent short circuit, do not attempt to install while power is applied.

9. Output filter: Output capacitor (C201), filtering inductor (L02) and damping resistors (R16-R17), and

ceramic output capacitors (C02-C05) provide output filtering. Sockets H05-H06, and H03-H04 can

be used for easy installation of aluminum-electrolytic output capacitors.

10. High side current sense wire loops: By depopulating the associated inductor and damping resistors,

all input or output currents can be passed through a wire loop or use with an oscilloscope current

probe. The wire loop is installed at the large pair of plated through-holes near the applicable

inductor location.

11. Dual paralleling wire-to-board connectors (J02 and J03): Used for bussing control signals and their

reference (ENABLE, SHARE, FAULT, and SGND) across board assemblies during parallel operation.

The connector style provides simple “strip and insert” use with 18 – 24 AWG solid wires. Once

inserted, a spring loaded barb retains each wire with no need for soldering. To release the wire,

insert a thin bladed tool (AVX 06-9276-7001-01-000 or similar) into the slot above each

wire entry point.

UG:017 vicorpower.com Applications Engineering: 800 927.9474 Page 4

Page 5

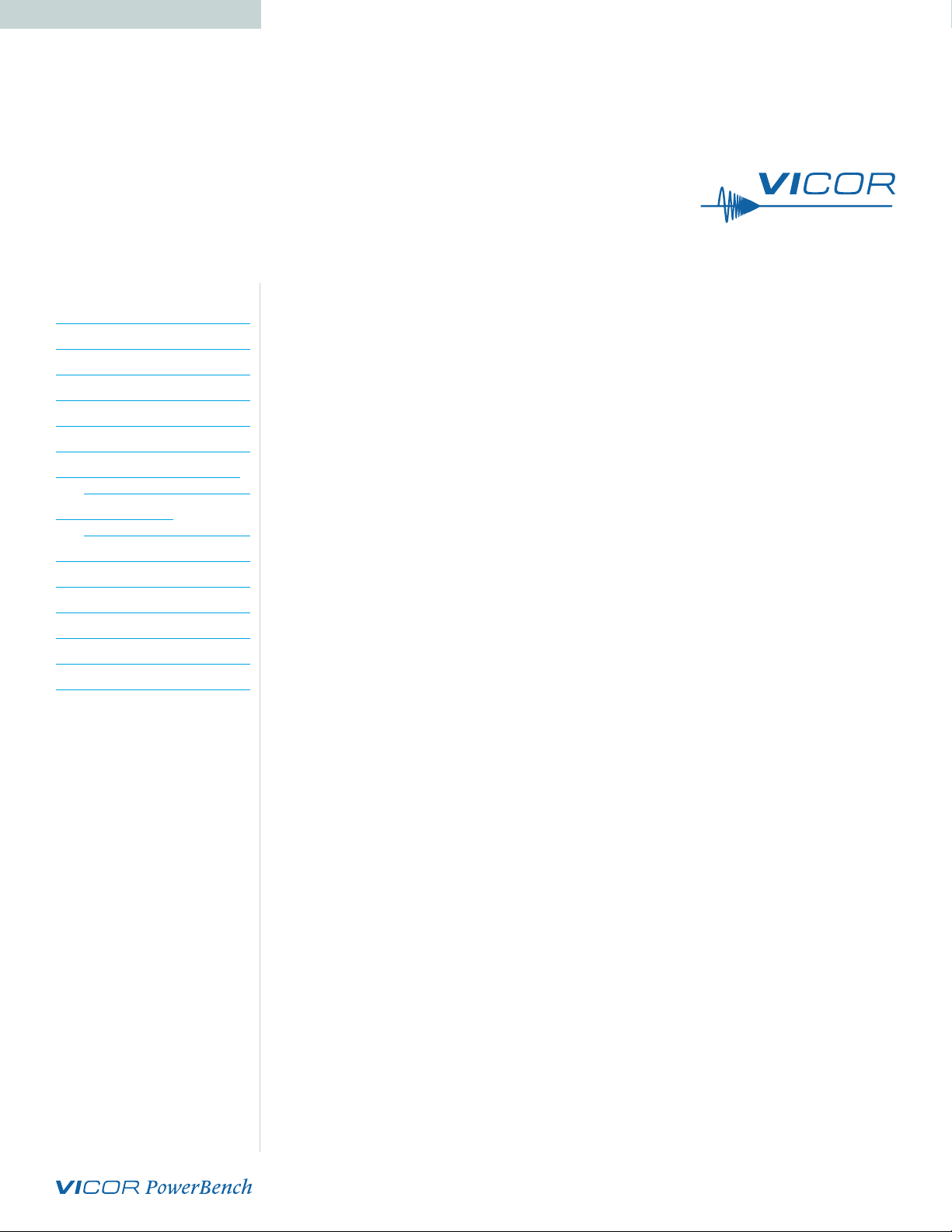

Figure 1

3623 DCM evaluation

board photo, top side

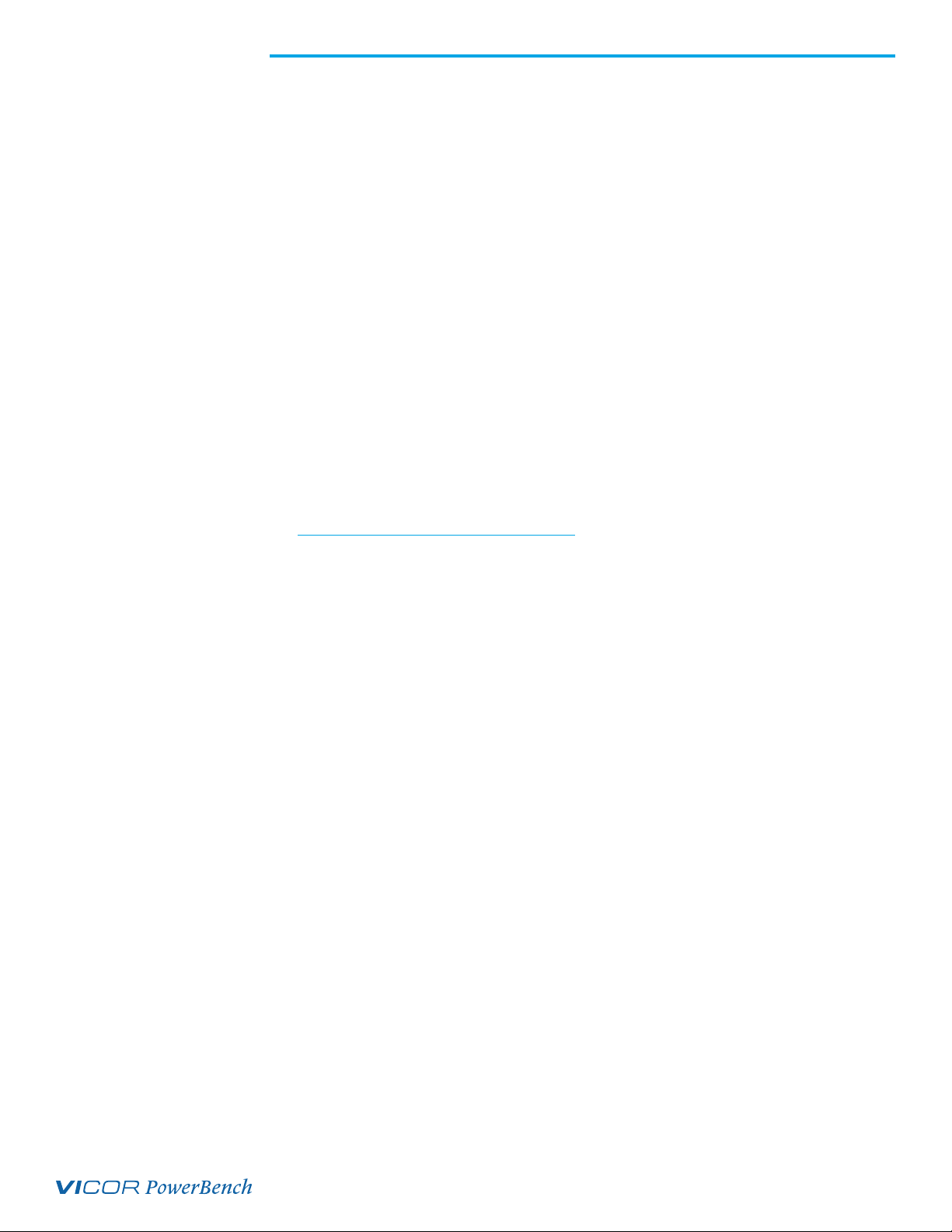

Figure 2

4623 DCM evaluation

board photo, top side

UG:017 vicorpower.com Applications Engineering: 800 927.9474 Page 5

Page 6

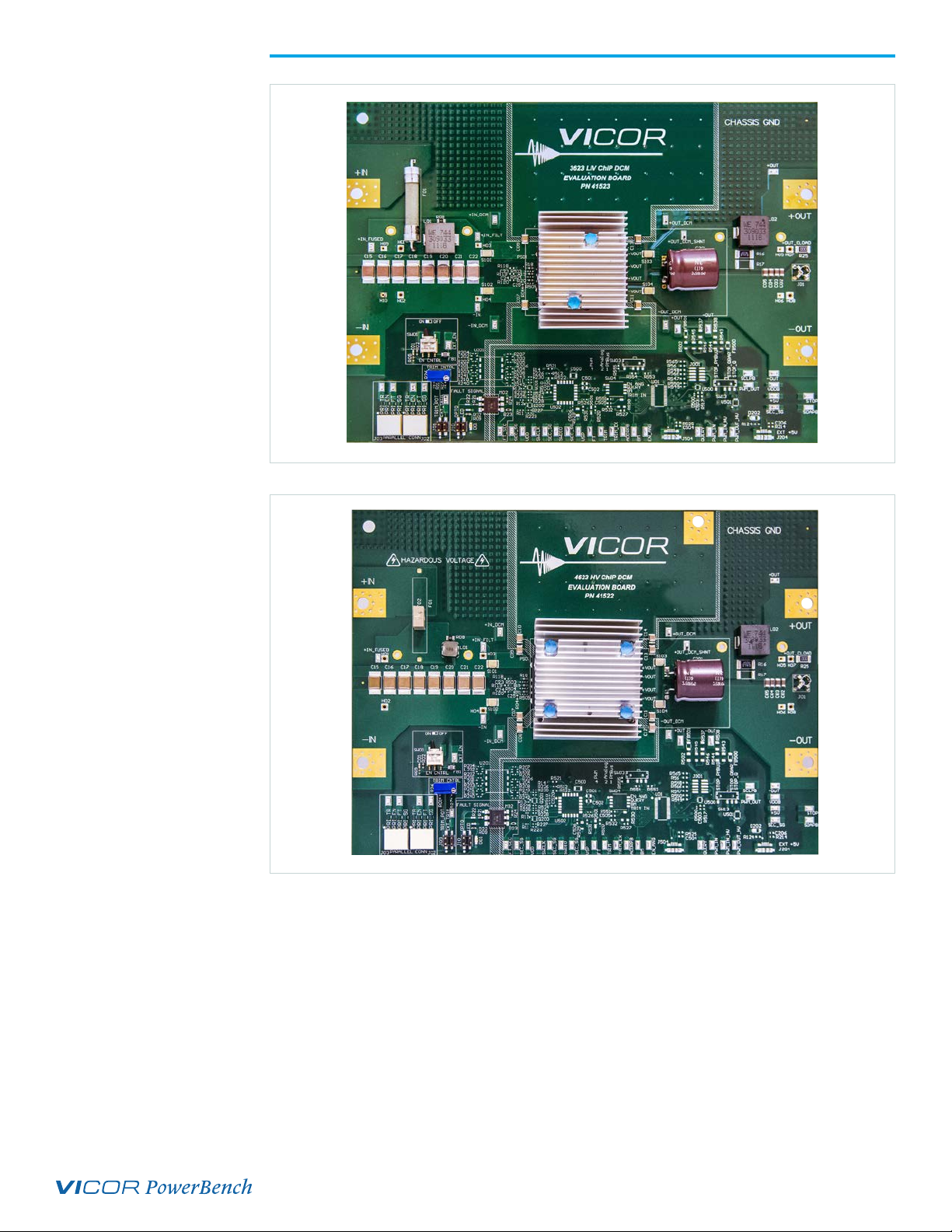

Table 1

Primary referred

test point descriptions

Table 2

Secondary referred

test point descriptions

Test Points Description

Test nodes are labeled and include a SMT test point for attaching miniature probes, clips or hooks.

Name Description

+IN_FUSED,

+IN_FILT,

–IN

+IN_DCM,

–IN_DCM

PRI_SG

EXT_EN Testpoint to drive the ENABLE signal (relative to PRI_SG) using an external source.

PRI_EN Testpoint to measure the ENABLE signal (relative to PRI_SG).

EXT_TR Testpoint to drive the TRIM signal (relative to PRI_SG) using an external source.

PRI_TR Testpoint to measure the TRIM signal (relative to PRI_SG).

PRI_FT Testpoint to measure the FAULT signal (relative to PRI_SG).

Name Description

+OUT_DCM,

–OUT_DCM

+OUT_DCM_SHNT,

+OUT,

–OUT

SEC_SG

FT_SEC

+5 V

Provide measurement testpoints for the input voltage to the board in various locations, rela-

tive to the –IN board lug. +IN_FUSED is taken after input fusing, +IN_FILT is taken after the

input filtering network.

Provide Kelvin connection to input pins of the DCM. Use these test points for measuring the

input voltage at the module, excluding errors due to finite connection resistance leading up

to the module.

Testpoint for Signal Ground on the primary/input side of the isolation boundary. This is the

reference for all primary side control circuitry and all control pins of the DCM.

Output voltage test points provide Kelvin connection to output pin group of the DCM. Use

these test points for measuring the output voltage at the module, excluding voltage errors

due to finite connection resistance and the module output current.

Provides measurement testpoints for the output voltage in various locations, relative to the

–OUT board lug. +OUT_DCM_SHNT is taken before the output filtering, and +OUT is taken

at the +OUT board lug.

Testpoints for the +5V bias supply return, and for measuring the FT_SEC fault monitor out-

put.

Testpoint to measure the FAULT signal relative to SEC_SG once it has passed through the

opto-coupler, if used. Bias power must be supplied to +5V for voltage output to appear here.

Testpoint to provide a bias voltage (relative to secondary ground) for the fault opto-coupler,

if used.

UG:017 vicorpower.com Applications Engineering: 800 927.9474 Page 6

Page 7

One plated through-hole on each side of L02 for

optional current loop

One plated through-hole on each side of L02 for

optional current loop

Figure 3

3623 DCM evaluation board

schematic

Schematic, Assembly Drawing and Bill of Materials

J106

+OUT

TP4

H07

R25

H05

R17

2512

R16

2512

+OUT_DCM_SHNT

TP1

TP6

+OUT_DCM

3623

J107

TP8

-OUT

-OUT

+OUT

2010

C02

1206

1206

C04

L02

+OUT_DCM_SHNT

S103

+OUT_DCM

TP106

+OUT

H08

H06

1206

C03

1206

C05

C201

S104

29581

29581

1612

1612

-OUT_DCM

TP9

TP107

-OUT

Note: Scope Jack

J01

-OUT_DCM

CHASSIS-GND

CHASSIS_GND

J108

1210

C13

+OUT_DCM

GND

HS02

1210

C09

+IN_DCM

-OUT_DCM

1210

C11

GND

HS01

C07

1210

-IN_DCM

FT_SEC

ISOLATION BOUNDRY

PS01

PRIMARY SECONDARY

PRI_SG

-IN

FT

EN

TR

0402

TP104

TP103

TP102

AD

DA

R18

0603

R118

0603

PRI_SER_OUT

PRI_TR

0603

R19

0603

R119

PRI_SER_IN

PRI_EN

C25

0402

R505

CL

R20

0402

C24

0402

R504

0402

C23

R503

0402

0603

0603

R120

PRI_PWM

PRI_FT

+IN_FILT

TP3

1206

R08

H09

+IN_FUSED

TP2

+IN

TP101

PRI_SG

+IN_DCM

TP5

+IN_DCM

S101

29581

1612

H03

+IN_FILT

L01

H01

F01

+IN

J104

TP100

0603

R04

-IN_DCM

TP7

-IN_DCM

S102

29581

1612

C22

2220

C21

2220

C20

2220

C19

2220

C18

2220

C17

2220

C16

2220

2220

C15

H04

H02

H10

-IN

TP27

-IN

J105

+5V

J10

TP29

0603

R23

0603

R24

43

6

M02

1

2 5

PRI_FT

3

1

4

2

0603

R09

PRI_TR

3

1

J09

4

2

Trim_Pot

External_Trim

EXT_TRIM

TP28

SEC_SG

0603

R21

PRI_SG

0603

R22

FAULT INDICATOR

0603

R32

D01

LED-0805

PRI_SG

3

1

3

1

J03

J02

4

2

4

2

PRI_TR

PRI_EN

PRI_FT

PRI_SG

PARALLELING CONNECTORS

TP34

TP32

TP31

TP30

PRI_SG

PRI_FT

PRI_EN

PRI_TR

PRI_EN

0603

R05

0603

C01

PRI_SGPRI_SG

2

SW01

3

1

OFF

RES TRIM POT 500K OHM 1/2W 10% TH

R26

2

0603

R01

2

3

1

3

1

0603

R27

ON/External_Ctrl

PRI_SG

TRIM CONTROL

FB1

1206

EXT_EN

TP33

ENABLE CONTROL

0603

R02

UG:017 vicorpower.com Applications Engineering: 800 927.9474 Page 7

Page 8

One plated through-hole on each side of L02 for

optional current loop

Figure 4

4623 DCM evaluation board

schematic

Schematic, Assembly Drawing and Bill of Materials (Cont.)

J106

+OUT

J107

+OUT

TP4

2010

R25

H07

H05

R17

2512

R16

2512

+OUT_DCM_SHNT

TP1

S103

TP6

+OUT_DCM

TP106

4623

-OUT

TP8

-OUT

-OUT

+OUT

H08

1206

C02

1206

C03

1206

C04

1206

C05

L02

C201

+OUT_DCM_SHNT

S104

29581

29581

+OUT_DCM

-OUT_DCM

TP107

-OUT

+OUT

note:ScopeJack

J01

H06

CHASSIS-GND

CHASSIS_GND

J108

1210

C13

1210

C14

+OUT_DCM

GND

HS02

1210

C09

1210

C10

TP9

-OUT_DCM

+IN_DCM

C12

GND

HS01

1210

C07

C08

-OUT_DCM

1210

C11

1210

1210

-IN_DCM

FT_SEC

ISOLATION BOUNDRY

PS01

CL

DA

AD

0402

TP104

TP103

TP102

AD

DA

R18

0603

0603

R118

0603

PRI_SER_OUT

PRI_TR

0603

R19

0603

R119

PRI_SER_IN

PRI_EN

C25

0402

R505

CL

R20

0402

C24

0402

R504

0402

C23

R503

0402

0603

0603

0603

R120

0603

H03

PRI_PWM

PRI_FT

+IN_FILT

TP3

1206

R08

H01

TP2

+IN_FUSED

+IN

TP101

PRI_SG

+IN_DCM

TP5

+IN_DCM

S101

29581

C22

C21

C20

C19

C18

+IN_FILT

C17

L01

1

C16

C15

F01

F02

+IN

J104

+IN

PRIMARY SECONDARY

-IN

PRI_SG

TP100

0603

R04

-IN_DCM

TP7

-IN_DCM

S102

29581

2220

2220

2220

2220

2220

2220

2220

2220

H04

H02

-IN

TP27

-IN

J105

-IN

+5V

J10

TP29

0603

R23

0603

R24

43

6

M02

1

2 5

PRI_FT

3

1

4

2

0603

R09

PRI_TR

3

1

J09

4

2

Trim_Pot

External_Trim

EXT_TRIM

TP28

SEC_SG

0603

R21

PRI_SG

0603

R22

FAULT INDICATOR

0603

R32

D01

PRI_SG

RES TRIM POT 500K OHM 1/2W 10% TH

R26

2

0603

R01

2

3

1

3

1

0603

R27

3

1

3

1

J03

J02

4

2

4

2

PRI_TR

PRI_EN

PRI_FT

PRI_SG

PARALLELING CONNECTORS

TP34

TP32

TP31

TP30

PRI_SG

PRI_FT

PRI_EN

PRI_TR

PRI_EN

0603

R05

0603

C01

PRI_SGPRI_SG

2

SW01

3

1

OFF

ON/External_Ctrl

PRI_SG

TRIM CONTROL

FB1

1206

EXT_EN

TP33

ENABLE CONTROL

0603

R02

UG:017 vicorpower.com Applications Engineering: 800 927.9474 Page 8

Page 9

Figure 5

3623 DCM evaluation board,

assembly drawing, top side

Schematic, Assembly Drawing and Bill of Materials (Cont.)

J108

F01

R08

H01

C17

C16

H02

TP30

TP32

J03J02

L01

C19

C18

C01

R02

FB1

SW01

R05

R26

TP31

TP34

R01

J09J10

TP2

H09

C15

H10

J105

TP5

TP3TP27

C09

H03

S101

PS01

R18

R118

C23

R503

R19

R119

C22

C21

C20

TP33

R204

L202

R202

R201

L201

R203

R241

L210

R240

R27

TP28

R22

R32

R09

C24

R504

R20

R120

C25

R505

S102

H04

R21

R04

C07

TP7

R207

L203

R205

R206

U201

L204

R208

R243

L211

R242

R13

R12

R24

M02

R23

R11

D01

TP24

TP01

TP29

HS01

R521

R512

C500

R14

R522

R226

R230

C501

C520

Q201

C502

R229

U502

R510

R225

R524

R224

R228

Q200

R227

R223

TP12

TP11

TP10

SW04

R526

R551

C505

R532

C506

R520

R531

D501

R529

TP22

TP06

TP18

TP17

TP14

TP6

TP1

C13

S103

S104

HS02

C11

TP9

TP19

FB501

R502

R565

SW03

TP09

R554 R553

TP15

R56

R548

R566

R547

R550

R549

U01

R525

C504

TP16

J504

R555

R530

R527

R16

R17

C201

TP20

R538

R537

R546

R545

R544

R543

FB500

J001

SW13

U500

C503

R517

D500

U501

TP05

TP04

TP02

TP13

TOP VIEW

TP4

J106J104

L02

H05

H07

R25

J01

C05

C04

C03

C02

H06

H08

J107

TP07

TP8

TP03

TP25

TP26

TP23

TP21

D202

TP08

C206

R124

R214

J204

Figure 6

4623 DCM evaluation board

assembly drawing, top side

J108

F01F02

R08

H01

TP2

C16

C15

H02

L01

C19

C18

C17

TP5TP7

C10C09C08 C07

TP3TP27

H03

S101

PS01

R18

R118

C23

R503

R19

R119

C22

C21

C20

H04

R504

C24

R20

R120

C25

R505

S102

R04

HS01

TP33

C01

TP30

TP32

J03J02

R02

R204

FB1

SW01

R05

R26

TP31

TP34

R01

R27

TP28

R22

R32

R09

J09J10

R207

L202

L203

R202

R205

R201

R206

L201

U201

R203

R241

L210

R240

R21

M02

D01

R521

L204

R512

R208

R243

L211

R242

R12

R24

R23

TP01

TP29

C500

R14

R522

R226

R230

C501

C520

Q201

R13

R11

TP24

C502

R229

R510

R225

R524

R224

R228

Q200

R227

R223

TP12

TP11

TP10

SW04

U502

R526

R551

C505

R532

C506

R520

R531

D501

R529

TP22

TP18

TP17

TP14

TP06

J105

TP6TP9

C14C13C12C11

TP1

S103

C201

S104

HS02

TP20

TP19

R538

R537

FB501

R546

R545

R544

R502

R565

SW03

R555

R554 R553

R530

R527

TP15

TP09

J001

R56

R548

R566

R547

R550

SW13

R549

U500

U01

C503

R517

D500

R525

C504

TP16

TP13

J504

TP02

TP4

J106J104

L02

H05

H07

R16

R17

R543

FB500

TP07

TP03

U501

TP05

TP04

J204

R25

J01

C05

C04

C03

C02

H06

H08

J107

TP8

TP25

TP26

TP23

TP21

D202

TP08

C206

R214

R124

TOP VIEW

UG:017 vicorpower.com Applications Engineering: 800 927.9474 Page 9

Page 10

Schematic, Assembly Drawing and Bill of Materials (Cont.)

Table 3

DCM evaluation board BOM,

components common

to all boards

Reference

Designator

Common Components

C01 CAP X7R 0.10µF 10% 16V 0603 AVX 0603YC104KAT2A

C02 – C05 CAP X7S 4.7µF 10% 100V 1206 AVX 12061Z475KAT2A

C07 – C14 Board specific - See table 4 BOMs

C15 – C22 Board specific - See table 4 BOMs

C201 Design specific - See table 5 BOMs

D01 LED RED 0805 ROHM SML-211UTT86

FB1 FERRITE BEAD 33 OHM 6A 1206 MURATA BLM31PG330SN1L

F01, F02 Design specific - See table 5 BOMs

HS01 – HS02 Board specific - See table 4 BOMs

J02 – J03 CONN 4 POS WIRE TO BOARD AVX 009276004021106

J01 PCB TP ADAPTER, 3.5mm PROBE TESTPATH 131-5031-00

L01 Board specific - See table 4 BOMs

L02 IND 0.33µH 20% 50A WURTH 744309033

M02 IC 6 PIN OPTO VISHAY CNY17-3X017T

R02, R04, R05,

R18, R19, R20

PS01 Design specific - See table 5 BOMs VICOR

R08 RES 1 OHM ¼ W 5% 1206 KOA RK73B2BTTE1R0J

R16 RES 250 mOHM 1W 2512 VISHAY WSL2512R2500FEA

R09, R21 RES 1 KOHM 1/10W 5% 0603 KOA RK73B1JTTD102J

R22, R32 RES 49.9 KOHM 1/10W 1% 0603 KOA RK73H1JTTD4992F

R23 RES 4.99 KOHM 1/1W 0.1% 0603 THIN FILM TECH CR0603E4991B-T5

R24, R01 RES 0 OHM JUMPER 0603 KOA RK73Z1JTTD

R25 RES 0 OHM JUMPER 2010 VISHAY CRCW20100000Z0EF

R26 RES TRIM POT 500 kOHM 1/2W 10% COPAL CT-94EW504

S102 - S104 RES 0 OHM JUMPER 1612 COPPER EXCELTOOL & DIE 29581

SW01 SW TOGGLE SPDT 1 POS

JMPSOK for

J09 – J10

Description Manufacturer

RES 0 OHM JUMPER 0603 KOA RK73Z1JTTD

C&K COMPO-

NENTS

JUMPER SOCKET XJ8A OMRON XJ8A-0211

Manufacturer

Part Number

GT11MSABE

UG:017 vicorpower.com Applications Engineering: 800 927.9474 Page 10

Page 11

Schematic, Assembly Drawing and Bill of Materials: (Cont.)

Table 4 a

BOM additions, components

common to all 3623 DCM

evaluation boards

Table 4 b

BOM additions, components

common to all 4623 DCM

evaluation boards

Reference

Designator

3623 board components

C07, C09, C11,

C13

C08, C10, C12,

C14

C15 – C22 CAP X7R 4.7µF 20% 100V 2220 TDK C5750X7R2A475M230KA

L01 IND 0.33µH 20% 50A WURTH 744309033

HS01 - HS02 3623 DUAL HTSNK VICOR 40526

S101 RES 0 OHM JUMPER 1612 COPPER EXCELTOOL & DIE 29581

CIN @

H01 - H02

Reference

Designator

4623 board components

C07 – C14 CAP X7R 4700pF 10% 2kV 1210 KEMET C1210C472KGRAC7800

C15 – C22 CAP X7T 0.47µF 10% 630V 2220 TDK C5750X7T2J474K250KC

Description Manufacturer

CAP X7R 4700pF 10% 2kV 1210 KEMET C1210C472KGRAC7800

N/A (not present in design) N/A N/A

CAP ALEL 680µF 20% 63V RADIAL

18 X 20

Description Manufacturer

UNITED

CHEMI CON

Manufacturer

Part Number

ELXZ630ELL681MM20S

Manufacturer

Part Number

L01 IND 1.0µH 20% 13A BOURNS SRP7030-1R0FM

HS01 - HS02 4623 DUAL HTSNK VICOR 40519

S101 BEAD 680 OHM 4A 1812 TAIYO YUDEN FBMH4532HM681-T

CIN @

H01 - H02

AP ALEL 10µ 20% 450V RAD

UNITED

CHEMI CON

EKXG451ELL100MK20S

UG:017 vicorpower.com Applications Engineering: 800 927.9474 Page 11

Page 12

Schematic, Assembly Drawing and Bill of Materials: (Cont.)

Table 5

Example: BOM additions,

components which are

DCM model specific.

Reference

Designator

Evaluation board number: DCM3623E50M06A8M00

PS01 DCM - 3623 VICOR DCM3623T50M06A8M00

F01 FUSE 30A 125V AXIAL LITTELFUSE 324 030P

C201

Evaluation board number: DCM3623E50M13C2M00

PS01 DCM - 3623 VICOR DCM3623T50M13C2M00

F01 FUSE 30A 125V AXIAL LITTELFUSE 324 030P

C201

Evaluation board number: DCM3623E50M17C2M00

PS01 DCM - 3623 VICOR DCM3623T50M17C2M00

F02 FUSE 30A 125V AXIAL LITTELFUSE 324 030P

C201

Evaluation board numbers: DCM3623E50M26C2M00, DCM3623E50M31C2M00

PS01 DCM - 3623 VICOR

F01 FUSE 30A 125V AXIAL LITTELFUSE 324 030P

C201

Evaluation board number: DCM3623E50M53C2M00

PS01 DCM - 3623 VICOR DCM3623T50M53C2M00

F01 FUSE 30A 125V AXIAL LITTELFUSE 324 030P

C201

Evaluation board numbers: DCM4623EC8G16F0T00, DCM4623ED2J13D0X00, DCM4623ED2H26F0X00

PS01 DCM - 4623 VICOR

F01 FUSE 5A 450V FAST 6.3 X 32 RADIAL

C201

Description Manufacturer

CAP ALEL 10000µF 20% 10V RADIAL

18 x 26.5

CAP ALEL 4700µF 20% 25V RADIAL

16 x 25

CAP ALEL 2200µF 20% 25V RADIAL

16 x 25

CAP ALEL 1000µF 20% 50V RADIAL

18 x 20

CAP ALEL 220µF 20% 80V RADIAL

18 x 16.5

CAP ALEL 1000µF 20% 50V RADIAL

18 x 20

NICHICON URS1A103MHD1TN

NICHICON UVY1E472MHD

NICHICON UPW1E222MHD

UNITED

CHEMICON

NICHICON UPJ1K221MHD6TN

COOPER

BUSSMANN

UNITED

CHEMICON

Manufacturer

Part Number

One of

DCM3623T50M26C2M00

DCM3623T50M31C2M00

EKY-500ELL102MM20S

One of

DCM4623TC8G16F0T00

DCM4623TD2J13D0T00

DCM4623TD2J13D0M00

DCM4623TD2H26F0T00

DCM4623TD2H26F0M00

BK/PCD-5-R

EKY-500ELL102MM20S

UG:017 vicorpower.com Applications Engineering: 800 927.9474 Page 12

Page 13

Schematic, Assembly Drawing and Bill of Materials: (Cont.)

Table 5 (Cont.)

Example: BOM additions,

components which are

DCM model specific.

Reference

Designator

Evaluation board numbers: DCM4623ED2H31E0X00, DCM4623ED2H53E0X00

PS01 DCM - 4623 VICOR

F01 FUSE 5A 450V FAST 6.3 X 32 RADIAL

C201

Description Manufacturer

COOPER

BUSSMANN

CAP ALEL 220µF 20% 80V RADIAL

18 x 16.5

NICHICON UPJ1K221MHD6TN

Manufacturer

Part Number

One of

DCM4623TD2H31E0T00

DCM4623TD2H31E0M00

DCM4623TD2H53E0T00

DCM4623T02H53E0M00

BK/PCD-5-R

General BOM rules for various DCM Evaluation Boards

PS01: This is the Vicor DCM, whose part number is coded in the evaluation board part number.

For example, eval board DCM4623ED2K53E0M00 uses DCM4623TD2K53E0M00.

F01: This is the input fuse. See the datas heet for the specific DCM for appropriate fuse needed to

meet listed safety agency approvals.

C201: This is the external output capacitor for the DCM. It is an Aluminum electrolytic with value

that satisfies the DCM datasheet C

OUT-TRANS

minimum.

UG:017 vicorpower.com Applications Engineering: 800 927.9474 Page 13

Page 14

Recommended Test Equipment

The following is a list of recommended test equipment.

1. Safety glasses

2. DC power supply: Refer to the specific DCM model datasheet to ensure the supply has

sufficient power and current capability, especially at low line, to satisfy current inrush when the

DCM is started

3. Electronic load: Refer to the specific DCM model datasheet to ensure the load has sufficient power

handling and current capability for testing

4. Cooling fan

5. Digital multi-meters (DMMs)

6. Oscilloscope and probes

7. Function generator

8. Auxiliary bench voltage supply (optional, for bias of secondary side fault monitor opto-coupler)

9. Interconnect wires, cables and fastening hardware

10. Calibrated input and output shunts, appropriately rated

11. Thin bladed tool for extracting wires from paralleling connectors

(AVX 06-9276-7001-01-000 or similar)

Basic Connections

Confirm bench equipment is powered off.

Connect the input DC power supply positive lead to the +IN input lug of the evaluation board,

connect the input power supply negative lead to the –IN input lug of the evaluation board.

Connect the CHASSIS_GROUND lug of the evaluation board to a safety “green wire” earth ground.

Connect the +OUT lug of the evaluation board to the electronic load positive input, connect the

–OUT lug of the evaluation board to the electronic load negative input.

Direct airflow from the cooling fan through the DCM heatsink fins.

Have the latest DCM datasheet on hand for reference.

Board Operation Details

SW01 provides control over enable.

In the “OFF” position, the switch will connect SG the EN net, which disables the DCM.

In the “ON” position, SG is disconnected from the EN net.

External connection to EN is permitted using the PRI_EN testpoint. SW01 should be set to “ON” to

permit external control.

The J02 & J03 paralleling connectors can be used to connect EN nets across different boards.

Note: to enable the DCMs in a parallel array, all boards need SW01 set to “ON” to avoid pulling the

EN node low.

UG:017 vicorpower.com Applications Engineering: 800 927.9474 Page 14

Page 15

Trim Control

Jumper block J09 configures trimming.

With no jumpers installed, neither the trim potentiometer nor the test point for external trim con-

trol is connected to the TR net. Note that the paralleling connectors always connect to the TR net.

With a jumper loaded across J09.1 and J09.2, the trim potentiometer R26 is

connected as a rheostat between the TR node and SG.

With a jumper loaded across J09.3 and J09.4, the external trim test point is

connected to the TR node.

The DCM contains an internal pull-up resistor to VCC (3.3V nominal). When VIN is applied to the DCM

it samples the TR node voltage. If it has pulled up to VCC, the DCM disables trimming as long as it

has input power, and the programmed trim condition will be nominal rated VOUT of the DCM model.

If the TR node is not permitted to pull-up to VCC when VIN is applied, trimming is enabled for as long

as the DCM has input power.

Note: Any load on the TR node may cause the DCM to select trim mode when VIN is applied,

including: the external trim testpoint (if selected with the jumper block), the trim potentiometer

(if selected with the jumper block), and other DCM evaluation boards attached to the

paralleling connectors.

The trim potentiometer adds a variable resistance between the TR node and SG, from between

0Ω nominal, to the value of the potentiometer (500kΩ). This resistance range will generate TR pin

voltages which cover the entire functional range of the TR pin. Care should be taken to ensure the

programmed trim condition is within the rated trim range of the DCM in order for the DCM to meet

specifications.

In a parallel setup using the J02 & J03 paralleling connectors, all boards besides the top one should

have the trim jumper select block at J09 open.

In a parallel setup with multiple DCM evaluation boards, each DCM contributes another internal

pull-up resistor to a 3.3V nominal rail. With any resistive based trimming of the TR node, the resultant

trim condition will be modified by the number of DCMs which are attached and have VIN applied.

Conversely with a voltage source applied to the TR node, adding additional DCMs to the system has

minimal impact on the resultant trim condition.

Fault Monitoring

Jumper block J10 configures how the FT node is monitored.

With no jumpers installed, neither the visible LED nor the opto-coupler is connected to the FT net.

Note that the paralleling connectors always connect to the FT net.

With a jumper loaded across J10.3 and J10.4, the visible LED at D01 and its bias resistor network

R09 & R32 are connected to the FT node.

With a jumper loaded across J10.1 and J10.2, the opto-coupler at M02 and its bias resistor net-

work R21 & R22 is connected to the FT node.

The DCM FT output is intended to be directly paralleled with the FT output of other DCMs in an array.

The FT node in an array forms a “wired-OR”, where any DCM can drive the FT node high.

UG:017 vicorpower.com Applications Engineering: 800 927.9474 Page 15

Page 16

Both the visible LED and the opco-coupler draw current from the FT node in a fault condition. The FT

pin on the DCM has limited drive-high capabilities, and so care must be taken to avoid excess loading

of the pin. To avoid overload, do not configure J10 to use both the LED and opto-coupler indicators

simultaneously. When connecting external circuitry or test equipment to the FT test point, ensure that

the maximum load on the FT node is within the DCM datasheet ratings.

In a parallel setup using the J02 & J03 paralleling connectors, all boards besides the top one should

have the fault jumper select block at J10 open.

When using the opto-coupler, the status of the FT node can be easily transferred to the secondary side

of the DCM(s) isolation boundary. To resolve the fault state on the secondary side, the collector side

of the opto requires a bias voltage. A 5V bench supply should be connected between the “+5V” and

“SEC_SG” testpoints. With no fault present, “FT_SEC” will be at 0V, and when a fault occurs and the

opto-coupler is active, “FT_SEC” will pull up to 5V, relative to SEC_SG.

Chassis Ground

The heatsink assembly of the DCM is connected to the CHASSIS_GND node of the board, as well as the

y-caps from each power connection of the DCM. A connection from the CHASSIS_GND lug to earth

ground is required.

Paralleling

The paralleling and sharing performance of multiple DCMs can be easily demonstrated by stacking

multiple evaluation boards and interconnecting the inputs and outputs with standoffs to create a

parallel array. The DCM uses a negative load-line to implement wireless droop-sharing in an array. Each

DCM in an array operates in the same way as it does as a stand-alone unit. With equal trim conditions,

the load is effectively shared across multiple DCMs. Mismatches in this case are modest, and are further

canceled by an effective negative voltage vs. temperature coefficient. See the DCM datasheet for more

detail on load line and tempco. DCMs in an array require no derating of maximum output power or

current.

DCMs in an array with mismatched trim conditions will not share the load equally at light- to

moderate-load conditions. As the load increases, one or more DCMs (starting with those with the

highest programmed output trim voltage) will go into current limit and their contribution to the overall

output current will plateau. For DCMs, current limit is not a fault condition, rather it is a valid constantcurrent mode of operation and a DCM in current limit will provide constant current to the load. As long

as the load does not exceed the maximum load rating of the array of DCMs, the output voltage will

continue to be regulated by any remaining DCMs still in constant voltage mode. Even with mismatched

trim conditions, the array can be safely loaded up to the full rated array capacity.

The following connections and settings should be used for an array of DCM evaluation boards:

All DCMs in a parallel array must be the same model.

The boards should be physically stacked using metal standoffs at the +IN & –IN lugs, the +OUT &

–OUT lugs, and the CHASSIS_GND lug. This also connects these nodes electrically so that a single

source, single load, and earth ground connection can be made to the system.

The +IN lugs are not required to be connected together for an array of DCMs. The wireless

sharing does not require the same differential input voltage be present on all DCMs in the array.

In some applications dissimilar input voltages may be needed, which is fully supported.

UG:017 vicorpower.com Applications Engineering: 800 927.9474 Page 16

Page 17

Figure 7

DCM evaluation boards stacked

to form a high power parallel

array, using common -IN and

the paralleling connectors.

The –IN lugs must be connected together if the paralleling connector is used, or if the EN, TR,

or FT pins are interconnected in any fashion. However if all control signals of all DCMs are fully

isolated from one another, then both the +IN and –IN lugs can remain independent across the

evaluation boards, and the DCMs can be operated with fully independent input supplies.

Standoffs must be sufficient in length to avoid contact between boards, and to permit airflow to

all DCMs in the system.

If coordinated enable control, trimming or fault monitoring is desired, then the paralleling connectors

J09 & J10 can be used to easily interconnect the PRI_FT, PRI_EN, PRI_TR_ and PRI_FT

nodes across boards.

The paralleling connectors at J02 & J03 can be used for coordinated enable and trim control and fault

monitoring. The enable, trim and fault monitor features of the top most board should be used for

convenience, while the remaining boards should have their jumper blocks depopulated and enable

switches set to enable.

The paralleling wire-to-board connectors (at J02 and J03) are provided to daisy chain control signals and

PRI_SG, with a simple strip and insert option. They will accept 18 – 24 AWG solid wires.

Information furnished by Vicor is believed to be accurate and reliable. However, no responsibility is

assumed by Vicor for its use. Vicor components are not designed to be used in applications, such

as life support systems, wherein a failure or malfunction could result in injury or death. All sales are

subject to Vicor’s Terms and Conditions of Sale, which are available upon request.

Specifications are subject to change without notice.

Rev 1.6 04/17 vicorpower.com Applications Engineering: 800 927.9474 Page 17

Page 18

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Vicor:

DCM3623EA5N06A2T70 DCM3623EA5N13B4T00 DCM3623EA5N26B4T70 DCM3623EA5N17B4T00

DCM3623EA5N0480T00 DCM3623EA5N53B4T70 DCM3623EA5N31B4T00 DCM3623EA5N0480T70

DCM3623EA5N53B4T00 DCM3623EA5N17B4T70 DCM3623EA5N06A2T00 DCM3623EA5N26B4T00

DCM3623EA5N13B4T70 DCM3623EA5N31B4T70 MDCD270P120M500A40 MDCD270P480M500A40

MDCD270P240M500A40 MDCD270P280M500A40 MDCD270P050M250A40 MDCD270P150M500A40

DCM3623E75X1780T00 DCM3623E75X1780T70 DCM3623E50M06A8M00 DCM3623E50T26A6M00

DCM3623E75H53C2T00 DCM3623E36G26C2T00 DCM3623E50T0480M00 DCM3623E50T0680M00

DCM4623ED2K04A5M00 DCM4623ED2N06A9T00 DCM4623ED2H15E0T00 DCM4623ED2K31E0M00

DCM3623E36G17C2T00 DCM3623E50M04A2M00 DCM4623ED2N13C8T00 DCM4623ED2K26E0M00

DCM3623E36G06A8T00 DCM3623E50M31C2M00 DCM3623E50M53C2M00 DCM3623E75H26C2T00

DCM3623E75H40C2T00 DCM4623ED2K53E0M00 DCM3623E50M13C2M00 DCM3623E50M17C2M00

DCM3623E50T31A6M00 DCM3623E50T53A6M00 DCM3623E75H06A6T00 DCM4623ED2H31E0T00

DCM4623ED2H53E0T00 DCM4623ED2N26C8T00 DCM3623E50M26C2M00 DCM3623E75H13C2T00

DCM4623EC8G16F0T00 DCM4623ED2J13D0T00 DCM4623ED2K17E0M00 DCM3623E36G31C2T00

DCM3623E36G40C2T00 DCM3623E36G53C2T00 DCM4623ED2N53C8T00 DCM3623E50T13A6M00

DCM4623ED2K06B5M00 DCM4623ED2N31C8T00 DCM3623E75H31C2T00 DCM4623ED2K13E0M00

DCM3623E36G13C2T00

Loading...

Loading...