Page 1

VZ7260X5X00W

Zigbee™ Wireless Zone Terminal Equipment

Controller

Installation Guide

For Commercial Zoning Systems

July 27th, 2012 / 028-0329-R3

CONTENTS

Installation 2

Location 2

Installation 2

Theory of Operation 3

Features and benefits overview 3

Wireless System Overview 5

Terminal, Identifi cation and Function 6

Wiring 6

Typical Applications 7

Main outputs wiring 7

Remote sensor accessories 11

CO2 sensor wiri ng 12

Configuring and Status Displa y Inst ructions 13

Status display 13

User interface 14

User configuration menu 14

Local keypad interf ace 15

Installer Configuration Parameter M enu 15

AI4 Input for CO2 Sensor 29

Referenced Operational Control Curves 30

Specifications Error! Bookmar k not defined.

Drawing & Dimensions 38

1 | VZ7260W Series- Installation Guide

Page 2

INSTALLATION

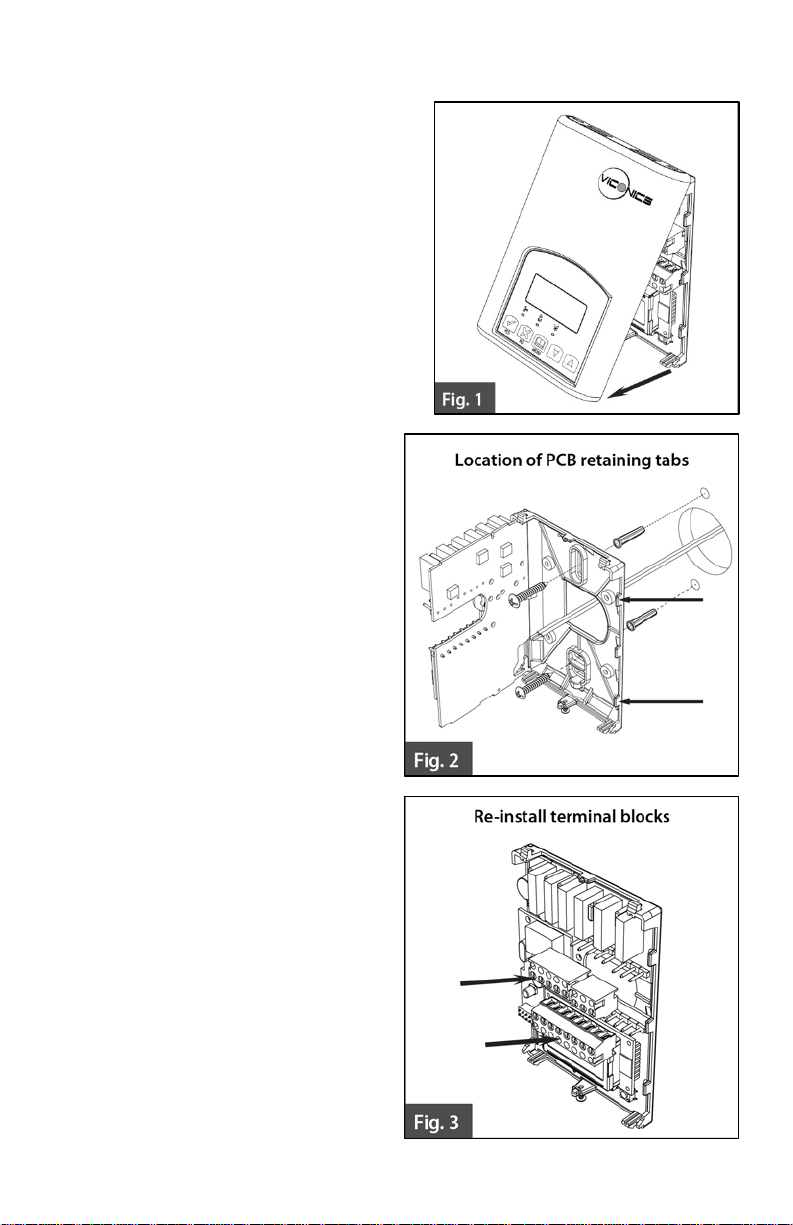

Remove the security screw on the bottom of

Terminal Equipment C ontroller cover.

Open unit by pulling on the bottom

side of Terminal Equipment

Controller (fig. 1).

Remove wiring terminal s from sticker .

Please read the FCC ID and IC label

installed in the cover upon removal of

cover for the wireless products.

Location

1. Should not be instal led on an outside

wall.

2. Must be installed away from any

direct heat source.

3. Should not be instal led near an

air discharge grill.

4. Should not be affected by direct

sun radiation.

5. Nothing should restrict vertical

air circulat ion to the Terminal

Equipment Controller.

Installation

1. Swing open the Terminal

Equipment Controller PCB to

the left by pressing the PCB

locking tabs (f ig. 2).

2. Pull out cables 6” out from the

wall.

3. Wall surface must be flat and

clean.

4. Insert cable in t he central hole

of the base.

5. Align the base and mark the

location of the tw o m ounting

holes on the wall. I nstall base in

the proper orientat ion. Arrow on

base should be facing up.

6. Install anchor s in the wall.

7. Insert screws in mounting holes

on each side of the bas e (f ig. 2) .

8. Gently swing back the circuit

board on the base and pus h on

it until the tabs lock it.

9. Strip each wire 1/4 inch from

end.

2 | VZ7260W Series- Installation Guide

Page 3

10. Insert each wire according to wiring diagr am .

11. Gently push excess w iring back into hole (fig. 3).

12. Re-Install wiri ng terminals in their c orrect locations (fig. 3).

13. Re-install the cover (top side first) and gent ly push extra wire length back into

the hole in the wall.

14. Install security screw.

When replacing an existing Terminal Equipment Controller, label the

wires before rem oval of the Terminal Equipment Controller.

Electronic controls are static sensitive devices. Dischar ge yourself

properly before manipulating and installing the Terminal Equi pment

Controller.

A short circuit or improper wiring may permanently damage the Terminal

Equipment Controller or the equipment.

All VT7000 series Terminal Equipment Controllers are desi gned for use

as operating controls only and are not saf ety devices. These inst ruments

have undergone rigorous tests and verifi cation prior to shipping to ensure

proper and reliabl e operation in the field. Whenever a control f ailure

could lead to personal injury and or loss of property, it becomes the

responsibili ty of the user or installer or electrical system designer to

incorporate safety devices (such as relays, flow s witch, thermal

protections, etc…) and or an alarm s ystem to protect the entir e system

against such catastrophic failures. Tampering with the devices or

unintended application of the devices w ill result in a void of warrant y.

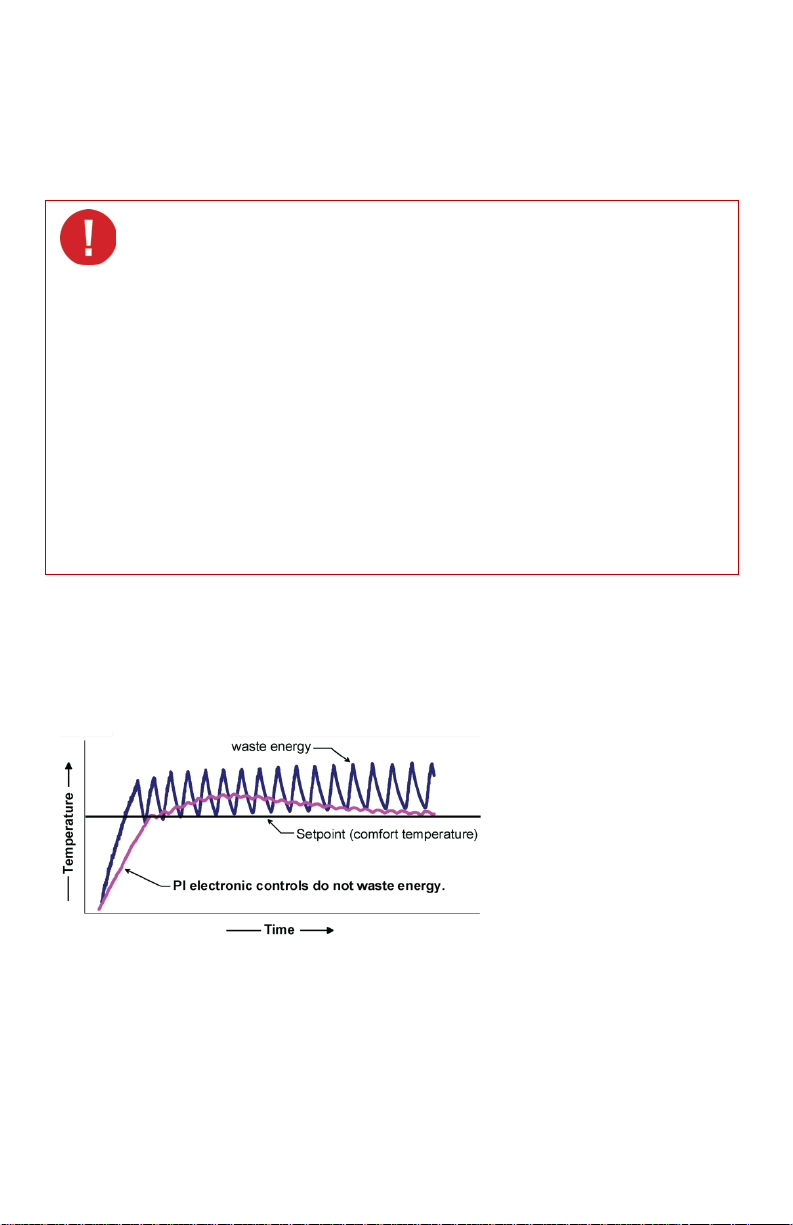

THEORY OF OPERATION

The VZ7260 series uses a Viconics proprietary adaptive logic algorithm to control the

space temperatur e. This algorithm c ontrols the heati ng and or air condit ioning system to

minimize oversho ot while still providing comf ort. It provides excepti onal accuracy due to

its unique PI time propor tioning control algorithm , which virtually eliminates t emperature

offset associated with traditional, differential-based On-Off thermostats.

Fig.2 - On-Off mechanical control vs. PI electronic control.

Features and benefits overview

• Available with analog or f loating outputs (model dependent).

• Adjustable Proportional Band.

• Password protected configuration menu.

• Removable terminal blocks.

• Hinged PC board design.

• EEPROM memory.

3 | VZ7260W Series- Installation Guide

Page 4

• PIR and Stand-by setpoints s upported.

• Local keypad lockable.

• PI time proportioning algorithm.

• Auxiliary output.

• Auto central system RTU changeover.

• Unique local configuration setup utility.

• C02 sensor input for monitor ing and control.

• Configurable zone sequences of operation.

• Pre-engineered design, sof tware and documentation.

• Self-discovering and self-binding database.

• Increased energy savings.

• Improves indoor air quality.

• Compatible with most actuator types (model dependent).

• No loss of program.

• Access to mounting holes.

• Facilitates wiring.

Easy configuration and self-binding operation

• Easy configurati on w ithout using any special software or additional tools.

• Can be used as stand-alone or with supervisi on controller for monitoring purposed.

• Truly scalable i n terms of supported number of zones and RTU units.

4 | VZ7260W Series- Installation Guide

Page 5

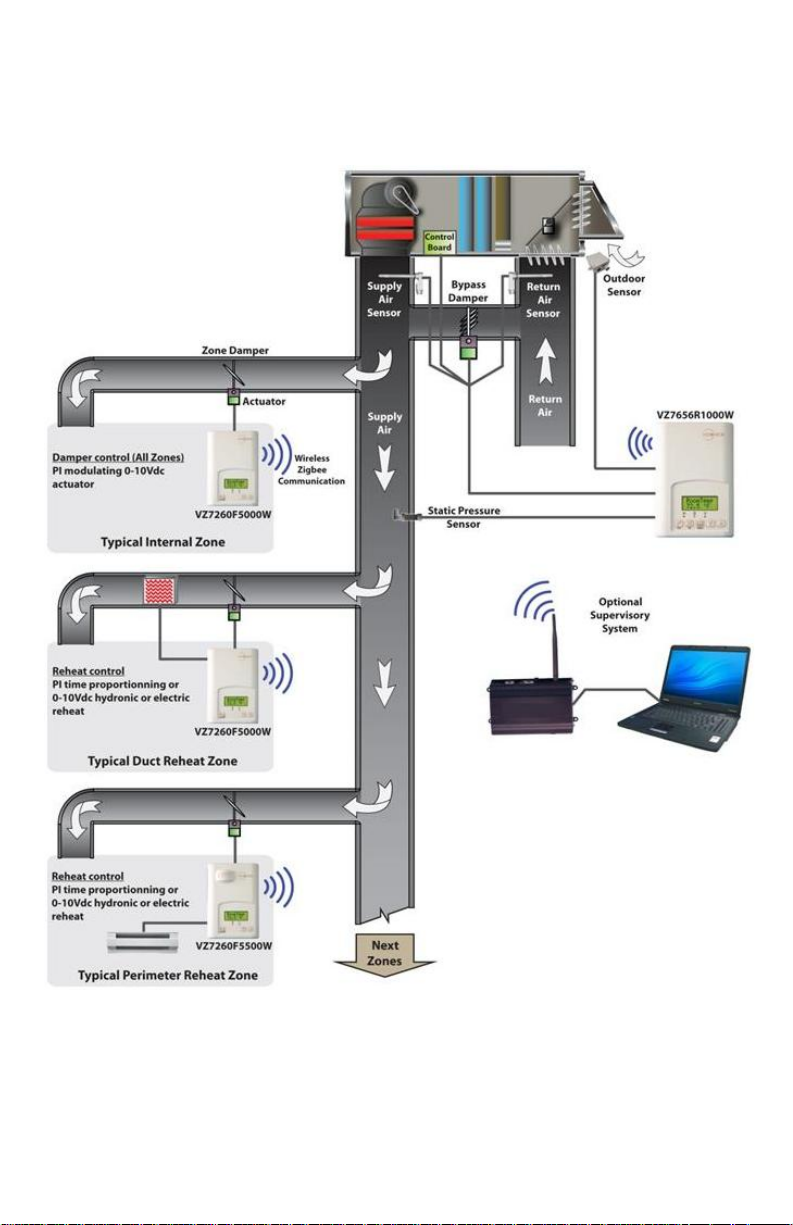

WIRELESS SYSTEM OVERVIEW

Viconics VZ7260X5x00W Zone controllers are used in conjunction with the

VZ7656X1000W Roof Top Controller controllers. Combined, the y are designed for typical

single or multis tage RTU, HP’s and their associated local zones.

Typical Wireless Zoning System Installation

5 | VZ7260W Series- Installation Guide

Page 6

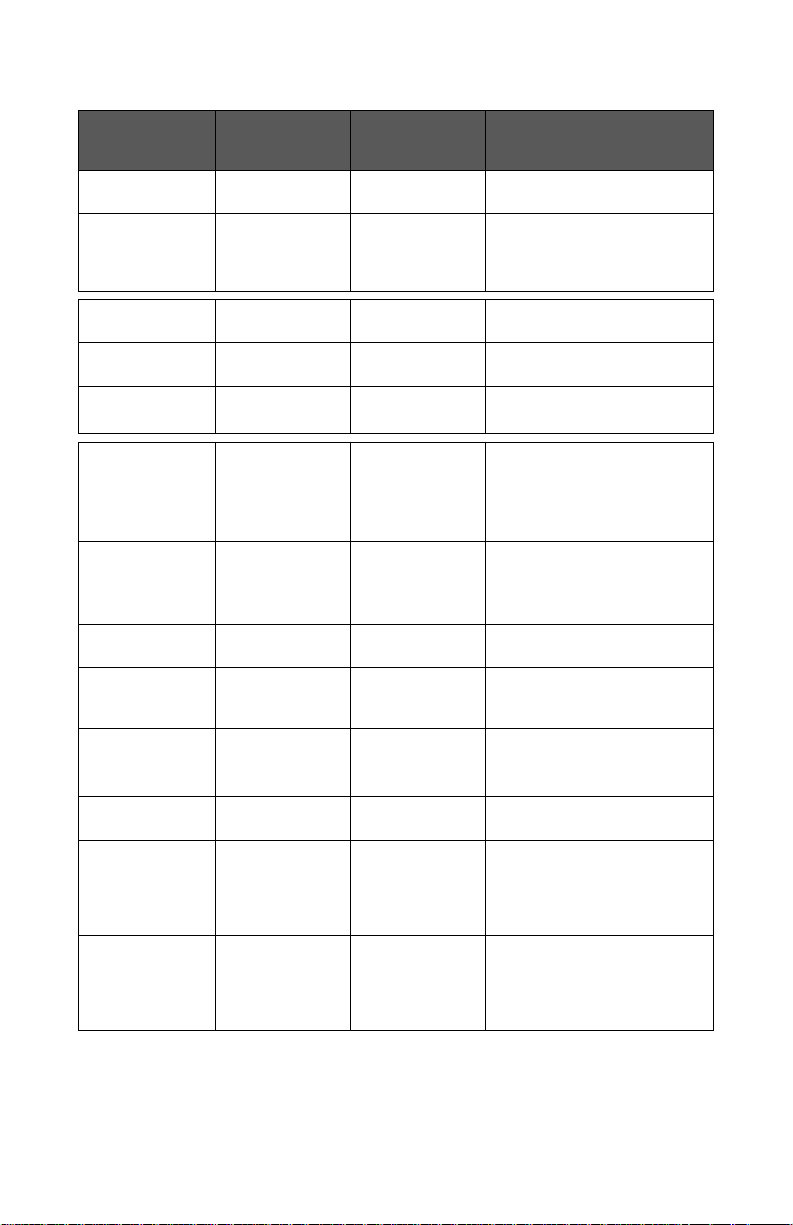

TERMINAL, IDENTIFICATION AND FUNCTION

Terminal

VZ7260F

Terminal

VZ7260C

Wiring

Terminal Use

4 - 24 V ~ Hot

5 - 0 V ~ Com

6- On-Off Rht

7- On-Off Rht

8- Primary Rh t

9 – Primary

Rht

10 – VAV

Damper

11 – VAV

Damper

12 – BI1

13 – AI4

14 - Scom

15 - RS

16 – UI3 / SS

Identification

24V ~Hot 24V ~Hot

0V~Com 0V~Com

BO5 BO5

BO5 BO5

Not used

AO2 BO4

AO1 BO1

Not used BO2

BI1 BI1

AI4

Scom Scom

RS RS

UI3 UI3

Identification

BO3

AI4

Description

Power supply of controller, hot

side (De livered from t he RTU).

Power supply of controller,

common si de. Also used as

reference for the analog

outputs when used.

Local isolated triac reheat

output when used.

Local isolated triac reheat

output when used.

24 VAC triac reheat output

(open).

For VZ7260F: Local analog 0 -

10 VDC reheat output when

used.

For VZ7260C: 24VAC triac

reheat output (close).

For VZ7260F: Local VAV

analog 0 - 10 VDC.

For VZ7260C: 24VAC triac

VAV output (open).

For VZ7260C: 24VAC triac

VAV output (closed).

Configurable extra digital

input. See parameter section

for more in fo rmation.

0-10VDC analog input for

remote CO2 or other sensor

(airflow, etc...)

Reference input for BI 1, BI 2,

UI3 and RS.

Remote room sensor input

when used. Input auto-detects

a remote sensor and will

automatically by-pass the

internal sensor when used.

Non-configurable extra analog

input for monitoring local

discharge or supply

temperatures over the

network.

6 | VZ7260W Series- Installation Guide

Page 7

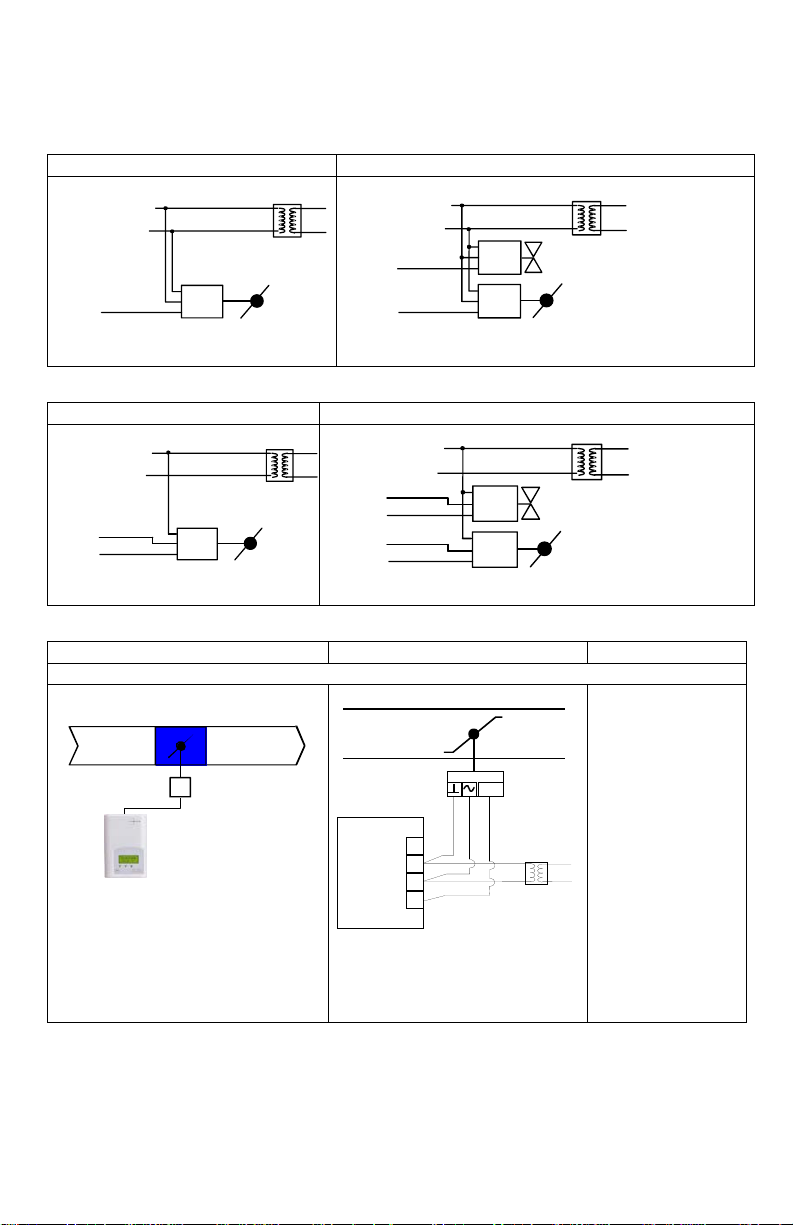

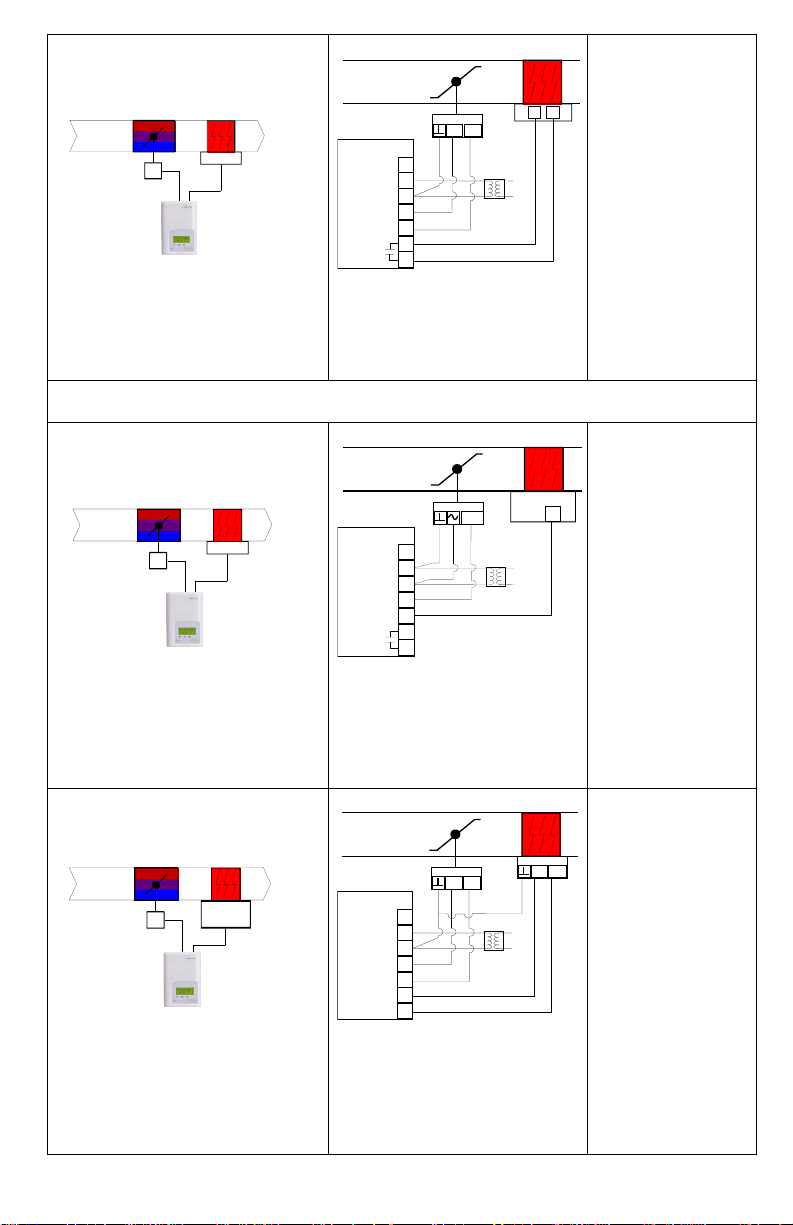

TYPICAL APPLICATIONS

VAV Damper Wiring

VAV Damper and Analog Reheat Wiring

VAV Damper Wiring

VAV Damper and Floating Reheat Wiring

Schematic

Wiring

Settings

Pressure dependent VAV cooling only system

Mandatory

VAV Damper

Motor

Com

24 VAC

0-10 VDC

24 V~ Hot

24 V~ Com

AO 1

24 V~ Hot

24 V~ Com

AO 2

AO 1

Com 24 VAC

0-10 VDC

Reheat Valve or SCR

VAV Damper Motor

Com

24 VAC

0-10 VDC

VAV Damper

Motor

Com

Open

Close

24 V~ Hot

24 V~ Com

BO 2

BO 1

24 V~ Hot

24 V~ Com

BO 4

BO 2

Com

Open

Close

Reheat Valve

VAV Damper Motor

Com

Open

Close

BO 3

BO 1

Analog VAV Actuator

Room Temperature Control

Minimum

& Maximum

Position

Adjusted at Controller

0 to 10

VDC

UI3

0 V~ Com

24 V~ Hot

AO1

Main outputs wiring

7 | VZ7260W Series- Installation Guide

RehtCon= 0 None

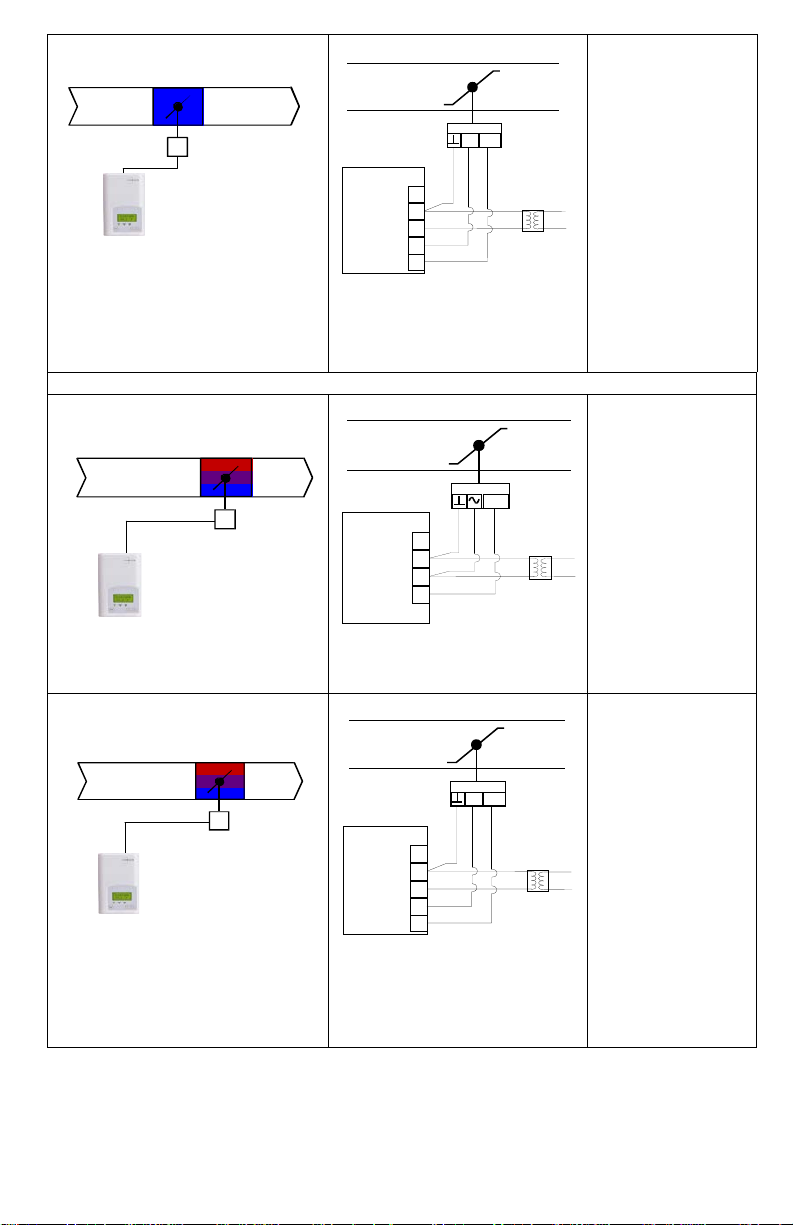

Page 8

Mandatory

RehtConf = 0 None

Pressure dependent VAV cooling or heating system with central changeover

Mandatory

Mandatory

Tri-State Floating

Actuator

Room Temperature Control

Minimum

& Maximum

Position

Adjusted at Controller

Floating VAV Actuator

Room Temperature Control

Minimum

& Maximum

Position

Adjusted at Controller

Close

UI3

0 V~ Com

24 V~ Hot

BO1

BO2

Open

0 to 10 Vdc

Analog Actuator

Room Temperature Control

Minimum

& Maximum

Position

Adjusted at Controller

0 to 10 VDC

UI3

0 V~ Com

24 V~ Hot

AO1

Close

UI3

0 V~ Com

24 V~ Hot

BO1

BO2

Open

RehtConf = 0 None

RehtConf = 0 None

8 | VZ7260W Series- Installation Guide

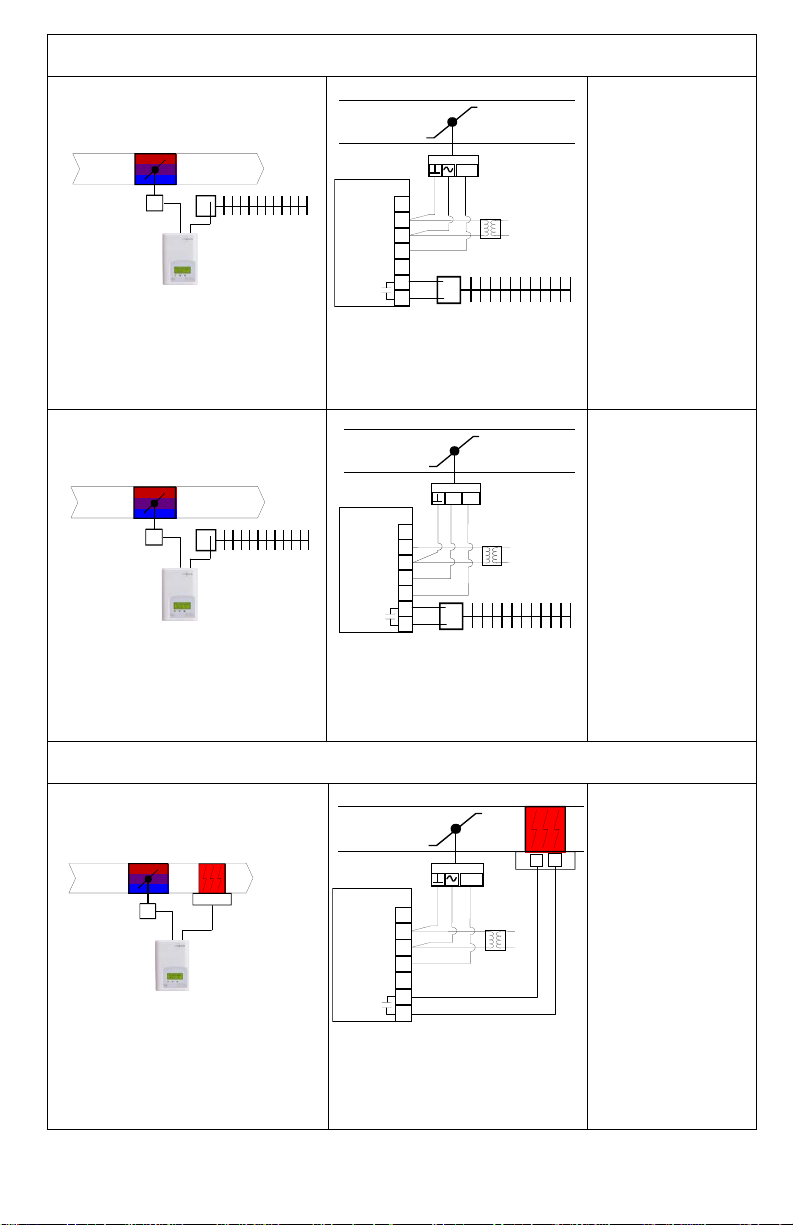

Page 9

Pressure dependent VAV cooling or heating system with local On-Off perimeter

reheat and central changeover

Mandatory

RehtConf = 3 =

Mandatory

Pressure dependent VAV cooling or heating system with local On-Off duct

reheat and central changeover

Mandatory

Tri-State Floating VAV Actuator

Heating and/or Cooling

& On/Off Baseboard

Room Temperature Control

Minimum

& Maximum

Position

Adjusted at Controller

UI3

0 V~ Com

24 V~ Hot

BO1

BO5-Aux

BO5-Aux

BO2

R

Close

Open

Analog

VAV Actuator

Heating and/or Cooling

& On/Off Baseboard

Room Temperature Control

Minimum

& Maximum

Position

Adjusted at Controller

0 to 10

VDC

UI3

0 V~ Com

24 V~ Hot

AO1

BO5-Aux

BO5-Aux

AO2

R

Analog

VAV Actuator

Heating and/or Cooling

& On/Off Duct Heater

Room Temperature Control

Min, Max and HeatFlow

Positions Adjusted at Controller

1

C

0 to 10

VDC

UI3

0 V~ Com

24 V~ Hot

AO1

BO5-Aux

BO5-Aux

AO2

On-Off Perimeter

Reheat Only

Set BO5 Time to

0= 15 minutes if

using regular 24

VAC relays

Set BO5 Time to

1= 10 seconds if

using 24 VAC

Solid State Relays

(SSRs) for

proportional cont rol

RehtConf = 3 =

On-Off Perimeter

Reheat Only

Set BO5 Time to

0= 15 minutes if

using regular 24

VAC relays

Set BO5 Time to

1= 10 seconds if

using 24 VAC

Solid State Relays

(SSRs) for

proportional cont rol

RehtConf = 2 =

On-Off Duct

Reheat Only

Set BO5 Time to

0= 15 minutes if

using regular 24

VAC relays

Set BO5 Time to

1= 10 seconds if

using 24 VAC

Solid State Relays

(SSRs) for

proportional cont rol

9 | VZ7260W Series- Installation Guide

Page 10

Mandatory

RehtConf = 2 =

Pressure dependent VAV cooling or heating system with local Analog duct

reheat and central changeover

Mandatory

Mandatory

Tri-State Floating VAV

Heating and/or Cooling

& Hot Water Reheat Valve

Room Temperature Control

Min, Max and HeatFlow

Positions Adjusted at Controller

Hot Water

Valve

Tri-State Floating VAV

Heating and/or Cooling

& On/Off Duct Heater

Room Temperature Control

Min, Max and HeatFlow

Positions Adjusted at Controller

UI3

0 V~ Com

24 V~ Hot

BO1

BO5-Aux

BO5-Aux

BO2

Close

Open

1

C

Analog

VAV Actuator

Heating and/or Cooling

& Analog Duct Heater

Room Temperature Control

Min, Max and HeatFlow

Positions Adjusted at Controller

SCR

SCR O-10VDC

Input

0 to 10

VDC

UI3

0 V~ Com

24 V~ Hot

AO1

BO5-Aux

BO5-Aux

AO2

UI3 0 V~ Com

24 V~ Hot

BO1

BO2

Close

Open

Close

Open

BO3

BO4

On-Off Duct

Reheat Only

Set BO5 Time to

0= 15 minutes if

using regular 24

VAC relays

Set BO5 Time to

1= 10 seconds if

using 24 VAC

Solid State Relays

(SSRs) for

proportional cont rol

RehtConf = 1 =

Analog Duct

Reheat Only

Set AO2RA/DA to

DA if SCR input

signal is Direct

Acting 0 to 10 VDC

Set AO2RA/DA to

RA if SCR input

signal is Reverse

Acting 10 to 0 VDC

RehtConf = 1 =

Analog Duct

Reheat Only

10 | VZ7260W Series- Installation Guide

Page 11

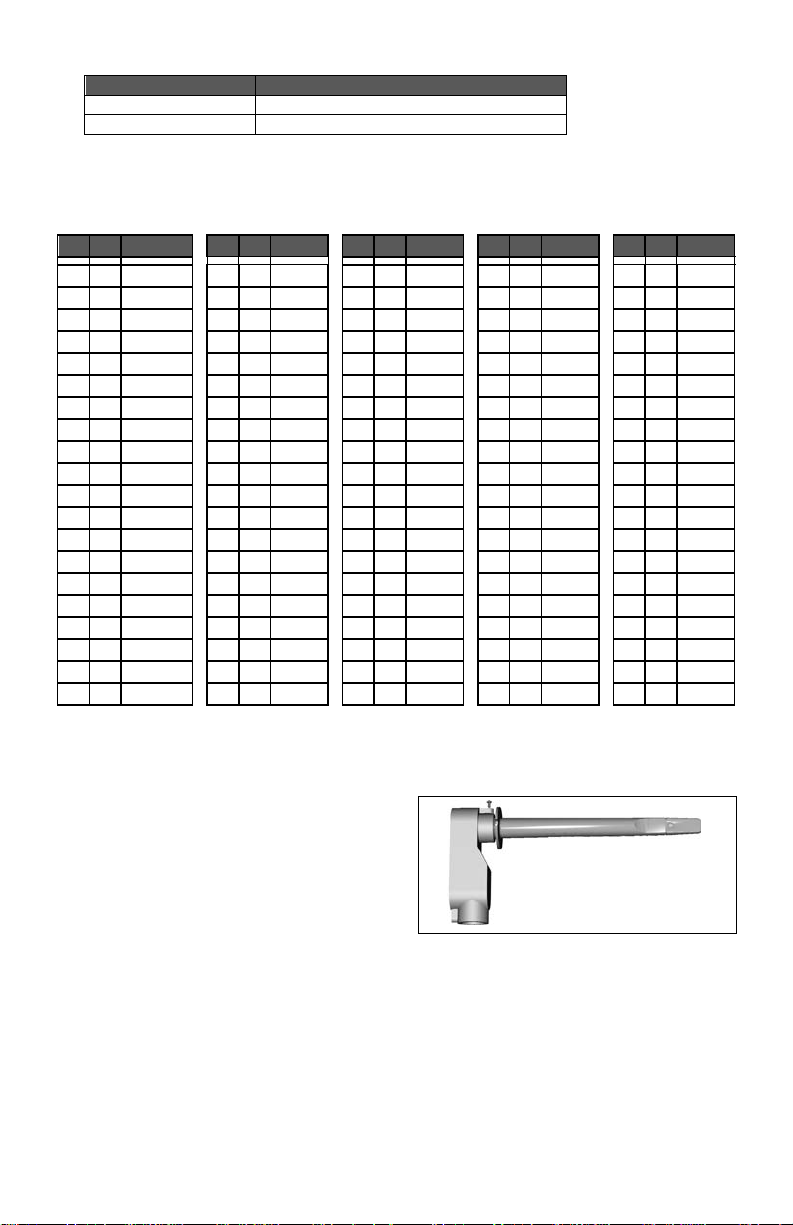

Remote sensor accessories

Model no.

Description

S3010W1000

Wall mounted temperature sensor

S2000D1000

Duct mounted temperature sensor

Fig.10 – Remote Duct Mounted Temperature Sensor

Remote mount temperature sensors use 10K NTC thermistor.

Temperature vs. Resistance Chart for 10 Kohm NTC Thermistor

(R

ºC ºF Kohm ºC ºF Kohm ºC ºF Kohm ºC ºF Kohm ºC ºF Kohm

-40 -40 324.3197 -20 -4 94.5149 0 32 32.1910 20 68 12.4601 40 104 5.3467

-39 -38 303.6427 -19 -2 89.2521 1 34 30.6120 21 70 11.9177 41 106 5.1373

-38 -36 284.4189 -18 0 84.3147 2 36 29.1197 22 72 11.4018 42 108 4.9373

-37 -35 266.5373 -17 1 79.6808 3 37 27.7088 23 73 10.9112 43 109 4.7460

-36 -33 249.8958 -16 3 75.3299 4 39 26.3744 24 75 10.4443 44 111 4.5631

-35 -31 234.4009 -15 5 71.2430 5 41 25.1119 25 77 10.0000 45 113 4.3881

-34 -29 219.9666 -14 7 67.4028 6 43 23.9172 26 79 9.5754 46 115 4.2208

-33 -27 206.5140 -13 9 63.7928 7 45 22.7861 27 81 9.1711 47 117 4.0607

-32 -26 193.9703 -12 10 60.3980 8 46 21.7151 28 82 8.7860 48 118 3.9074

-31 -24 182.2686 -11 12 57.2044 9 48 20.7004 29 84 8.4190 49 120 3.7607

-30 -22 171.3474 -10 14 54.1988 10 50 19.7390 30 86 8.0694 50 122 3.6202

-29 -20 161.1499 -9 16 51.3692 11 52 18.8277 31 88 7.7360 51 124 3.4857

-28 -18 151.6239 -8 18 48.7042 12 54 17.9636 32 90 7.4182 52 126 3.3568

-27 -17 142.7211 -7 19 46.1933 13 55 17.1440 33 91 7.1150 53 127 3.2333

-26 -15 134.3971 -6 21 43.8268 14 57 16.3665 34 93 6.8259 54 129 3.1150

-25 -13 126.6109 -5 23 41.5956 15 59 15.6286 35 95 6.5499 55 131 3.0016

-24 -11 119.3244 -4 25 39.4921 16 61 14.9280 36 97 6.2866 56 133 2.8928

-23 -9 112.5028 -3 27 37.5056 17 63 14.2629 37 99 6.0351 57 135 2.7886

-22 -8 106.1135 -2 28 35.6316 18 64 13.6310 38 100 5.7950 58 136 2.6886

-21 -6 100.1268 -1 30 33.8622 19 66 13.0307 39 102 5.5657 59 138 2.5926

= 10KΩ±3% - B

25°C

= 3975K±1.5%)

25/85°C

S2000D1000; remote duct mounted temperature sensor c/w junction box.

This sensor can be us ed for:

• Remote return air temperature

sensing with the sensor

mounted on the return air duct.

• Outside air temperature sensing

with the sensor installed in the

fresh air plenum.

• Supply air temperature sensing.

11 | VZ7260W Series- Installation Guide

Page 12

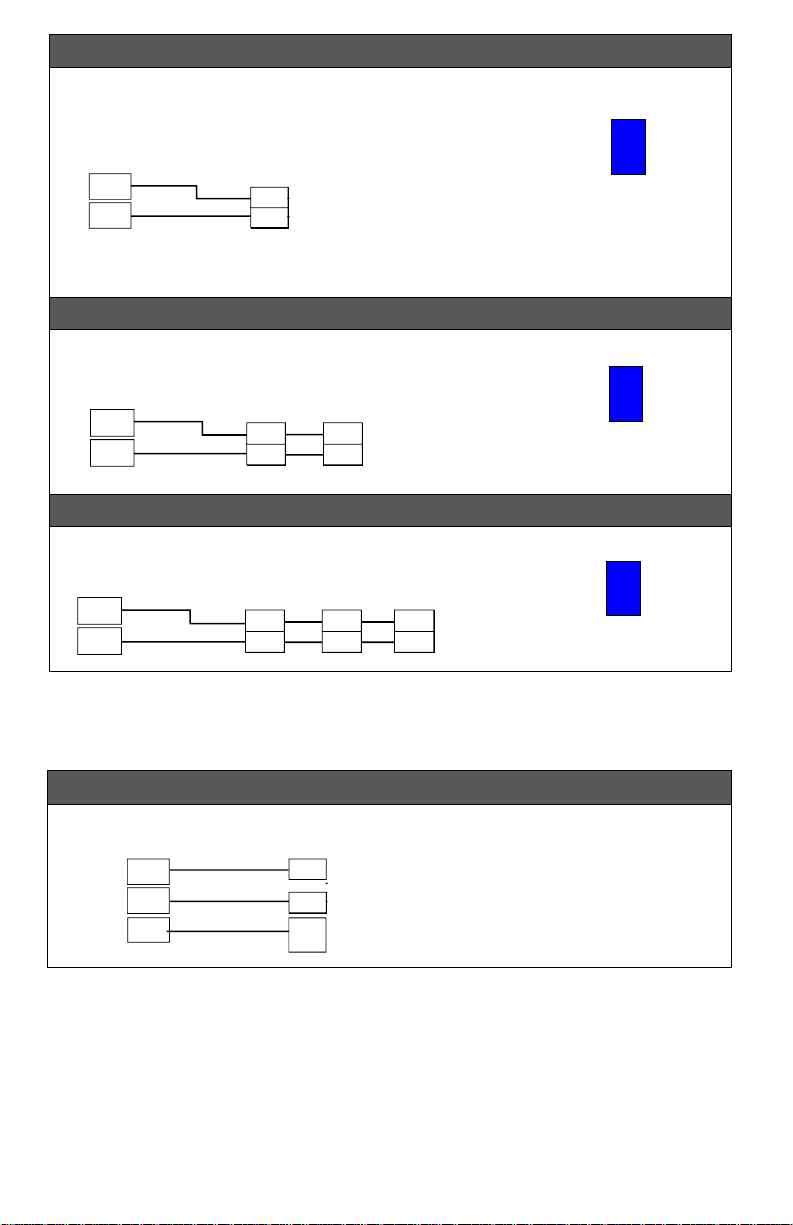

Wiring example of single remote room sensor:

1

2

ON

Dip switch

setting for:

1 sensor

S2-1 = ON

S2

1

2

ON

Dip switch

setting for:

2 sensors

S2-1 = OFF

S2

1

2

ON

Dip switch

setting for:

3 sensors

S2-1 = OFF

S3010W1000

Remote wiring 1 sensor

S2=On,

S3=On

VZ7260 Series

Controller

RS

Scom

Scom

RS

Scom

RS

2 x S3010W1000

Remote wiring 2 sensors

S2=On,

S3=Off

Scom

RS

Scom

RS

VZ7260 Series

Controller

RS

Scom

Scom

RS

Scom

RS

3x S3010W1000

Remote wiring 3 sensors

S2=Off,

S3=Off

Scom

RS

Scom

RS

Scom

RS

Scom

RS

VZ7260

Series

Controller

RS

Scom

Scom

RS

Scom

RS

Co2 Sensor

VZ7260 Series

Controller

24VAC

Com

Com

RS 24VAC

AI4

0-10

VDC

Wiring examples of 2 remote room sensors for averaging applicat ions:

Wiring examples of 3 remote room sensors for averaging applicat ions:

-2 = ON

-2 = ON

CO2 sensor wiring

Wiring example of C O 2 sensor:

12 | VZ7260W Series- Installation Guide

Page 13

CONFIGURING AND STATUS DISPLAY INSTRUCTIONS

Stand-By

Unoccup

Status disp lay

The Terminal Eq uipme nt Cont rol ler features a t wo-l ine, ei ght-character di splay. There i s a

low backlight level that is always act ive and can only be seen at night.

When left unattended, the Terminal Equipment Controller has an auto scrolling display

that shows the current status of the system.

Each item is sc rolled sequentially with the bac k light in low level mode. Press ing any key

will cause the back light to come on to high level.

Manual scrolling of each menu item is achieved by pressing the Yes (scroll) key

repetitively. The last item viewed will be shown on the display for 30 seconds before

returning to automat ic scrolling. Temperature is automatically updated when scr olling is

held.

Sequence of auto-scroll status display:

ROOM

TEMPERATURE

RoomTemp

x.x °C or°F

OCCUPANCY

STATUS

Occupied

OUTDOOR

TEMPERATURE

Outdoor

x.x °C or°F

Override

Outdoor air temperature

Outdoor air temperature display is only enabled when outdoor air temperature sensor is

connected.

• A maximum range status display of 50 °C ( 122 °F ) indicates a shorted sensor.

Associated functions, such as mode lock outs and economizer func tion are

automatically di sabled.

• A minimum range status -40 °C ( -40 °F ) is not displayed and indicates a opened

sensor or a sensor not connected. Associ ated functions, such as m ode lockouts and

economizer func tion are automatically disabled.

Occupancy Status

• Oc cupied, Stand-By, Unoccupied and Override status are displayed on the scrolling

display.

• Two s tatus LED’s on the controller cover are used t o indicate a call for heat or a call

for cooling

When heating & reheat is ON, the HEAT LED will illuminate

When cooling is O N, the COOL LED will illumi nate

13 | VZ7260W Series- Installation Guide

Page 14

USER INTERFACE

An Override can be made during an Unoccupied per iod. If the Override

“ToccTime.”

Adjust the setpoints down;

Local Zone Mode as Dictated by Attached Master RTU Controller

RTU in cooling mode with Local Reheat enabled

current displayed one and the other.

Cool XX.X °F or °C and Heat XX.X °F or °C

simultaneously

User configuration menu

• Unoccupied mode Override

An Override can be made during an unoccupied

period. If the Over ride option is enabled in the

lockout configuration pressing the Over ride button

will resume occupied setpoints for a time specified

by the parameter; “ToccTime.”

• Keypad interface

Override

Down

option is enabled i n the lockout configurat ion pressing the overri de key will

resume occupied setpoints for a time specified by the parameter;

In cooling mode only the cooling setpoint displayed.

In heating mode onl y the heating setpoint displayed.

In auto mode; (See below).

Adjust the setpoints up;

Up

In cooling mode onl y the cooling setpoint displayed.

In heating mode onl y the heating setpoint displayed.

In auto mode; (See below).

1. Any setpoint change can be perm a n ent or temporary based on configura ti o n param e te r (Setpoint Type).

2. Any setpoint written through the network will be permanent and cancel any active temporary setpoints.

3. Lockouts to access certain functions are made with configuration parameter (lockout).

4. If in Unoccupied period, pressing the Down button will display the following message on the display: “Press

Override First”.

Occupied setpoint adjustments

• Setpoint presented to user is the setpoint from t he

last action tak en by the controller or the one

RTU in

cooling

mode

RTU In

heating

mode

currently in use.

• Both heating and cooling setpoints are changed

simultaneously while respecting the minimum

configured deadband.

• If the other setpoint is t he one desired, then the

OVERRIDE button is used to toggle between the

Cool XX.X

°F or °C

Heat XX.X

°F or °C

Both heating & cooling setpoints are changed

Unoccupied and Stand-By setpoints adjustments

Setting the Unoccupied and Stand-By setpoints is done through the net w ork or through

configuration s etup only.

When in Unoccupied period, pressing the up or down button will display the following

message on the display: “Press Override Fi rst”.

14 | VZ7260W Series- Installation Guide

Page 15

Local keypad interface

An Override can be made during an unoccupied period. If the Override

ToccTime

In cooling mode only the cooling setpoint is displayed,

In auto mode, (See below )

In cooling mode only t he cooling setpoint i s displayed,

In auto mode, (See below)

option is enabled i n the lockout configurat ion pressing the overri de key

will resume occupied setpoints for a time specified by parameter

In heating mode only the heating setpoint is displayed

In heating mode only the heating setpoint is displayed

When left unattended for 45 seconds, the display will resume automatic status

display scroll ing.

To turn on the back light, press any key on the fr ont panel. The back lit display will

turn off automati cally after 45 seconds.

INSTALLER CONFIGURATION PARAMETER MENU

Configuration can be done through the network or locally at the Termi nal Equipment

Controller.

To enter configuration, press and hold the mi ddle button (°C/°F or O verride) for

8 seconds.

• If a password lockout is active, “Password” is prompted. Enter pass w ord value

using the “up” and “down” arrows and press the middle button again to gain

access to all configuration properties of the Terminal Equipment Controller.

Entering a wrong password will prevent local access to the configur ation menu.

Press the same middle button repetit ively to scroll between all the available

parameters.

Use the up and down key to change the parameter to the desired value.

To acknowledge and save the new value, press the middle button again.

The next parameter w ill now be displayed.

15 | VZ7260W Series- Installation Guide

Page 16

Configuration Parameters

Range is: 0 to 1000

Zone MAC

RTC MAC address must be unique for the entir e

127.

PAN ID

This parameter (P ersonal Area Network I dentification) is

Default Value

Significance and Adjustments

PswrdSet

Configuration parameters

menu access password

Default value = 0

No password prompted

Zone Controller Controller

network address

Default Value: 255

Personal Area Networ k

Identification

Default value = 0

Range is: 0 to 500

This parameter s ets a password access to prevent

unauthorized access to the configurati on m enu

parameters. A default value of “0” will not prompt a

password or lock the access to the configurat ion

menu.

network.

1 to 255 (Increment s: 1 or 10)

For BACnet™ models valid range to use is from 1 to

used to link specific controllers to a single specific

Viconics wireless gateway ( VWG / Jace-Driver ) or a

specific VZ76 RTU controller. For every controller

reporting to a VW G / Jace-Driver or VZ76 controller, be

sure you set the SAME PAN ID value.

The default value of 0 is NOT a valid PAN ID. The valid

range of available PAN ID is from 1 to 500

16 | VZ7260W Series- Installation Guide

Page 17

When PAN ID is used with a range of 251 to 500, for (SA) Stand-Alone System s

In this applic ation, the VZ76 controller(s) are the coordinators to their own system. I.E.

they are the network masters for each VZ72 controller reporting to them.

• Wireless controller factory default Channel & PAN ID = Controller( s) offline

• VZ76 RTU controller is the network coordinator.

• Range of PAN ID on all controllers to use 251 to 500. This r ange is reserved for

stand-alone syst em operation.

Examples:

Notes:

Each system with a VZ76 RTU master will use a uni que P AN ID and / or Channel settings.

17 | VZ7260W Series- Installation Guide

Page 18

When PAN ID is used with a range of 1 to 250, for (NS) Networked System s

In this applic ation, any controller( s) are simply router to t he system. The VWG / Jace-

Driver is the coordinators to the system. I.E. the VWG / Jace-Driver is the network

masters for ANY controller(s) reporting to them.

• Wireless controller factory default Channel & PAN ID = Controller( s) offline

• VWG Jace -Driver is the network coordinator

• Any controllers ( VZ72’s, VZ76xx RTU’s or any VT7xxx wireless controllers ) act

as routers.

• Range of PAN ID on all controllers to use 1 to 250. Reserved for networked

system operation.

Examples:

Notes:

• Each controller(s) to use same PAN ID and Channel as VWG Jace-Driver

coordinator.

• VWG / Jace-Driver supports network integr ation for required GUI / System /

Status objects.

18 | VZ7260W Series- Installation Guide

Page 19

Channel

Conditional parameter to Wireless models

ZoneBaud

Conditional parameter to BACnet MS-TP models

Channel selection

Default value = 10

(VZ7260CX5x00W) o nly

This parameter wi ll only appear when a wireless network

adapter is present. If the thermostat is installed with a

BACnet adapter, this parameter will not be used or

displayed

This parameter (C hannel) is used to link specific

thermostats to specific Viconics wir eless gateway(s)

( VWG / Jace-Driver) or main VZ76 RTU t hermostat. For

any system, be sur e you set the SAME channel value

both at the network coordinator and all the VZ 72

thermostat(s).

Viconics recommends using only the f ollowing

channels: 15, 25 & 26

The default value of 10 is NOT a valid channel. The valid

range of available c hannel is from 11 to 26

Range is: 10 to 26

Zone Thermostat

Communication Baud Rate

Default Value: 4 = Auto

(VZ7260CX5x00B) o nly

This parameter wi ll set the network’s baud r ate.

0 = 9600 KBps

1 = 19200 KBps

2 = 38400 KBps

3 = 76800 KBps

4 = Auto Bauding ( Baud Rat e will match detected Baud

Rate

19 | VZ7260W Series- Installation Guide

Page 20

Get From

Controller Get From another

Entering a new MAC address enabled an automat ic

RTC MAC

Master VZ76 RTU sys tem controller to which current

Removes the scrolling display and only presents the

Off = Scroll not act ive

°F for Fahrenheit scale

device configurat ion utility

Default value = 255

Range is: 1 to 255

routine that automat ically fetches al l the required

configuration pr operty of the current devi ce from another

one already configured to the same required property

values. If another value than the default value of 255 is

entered, user will then be prompted to exit the

Configuration Menu.

Ex.: If you are currently configuring MAC12 and the

settings exactly match the settings of ZN MAC5, then

enter 5 as the current parameter value.

If the process is successful and all required configuration

properties have been copied, the value will revert back to

255.

If the process is NOT successful and all required

configuration pr operties have NOT been copied ( either

the reference device is NOT the same model number or

is offline or does not exists ) the value will revert back to

254 to indicate the failure of the process.

Leaving the Get From parameter to 255 means that

every configurati on parameters has to be set manually.

RTC Controller network

address

Default: 4

MenuScro

Menu scroll

Default: On = Scr oll active

C or F

Sets the display scale of the

controller

Default: °F

VZ72 Zone controller is attached

1 to 127 (Increment s: 1 or 10)

room temperature t o the user.

With this option enabled, no status is given for

occupancy and outdo or temperature.

On = Scroll active

°C for Celsius sc ale

20 | VZ7260W Series- Installation Guide

Page 21

Lockout Keypad lockout

0

1

2

3

BI1

(None): No functi on w ill be associated wit h the input. Point

AI4

(None): No function will be associated wi th the input. Point

levels

Default value = 0 No lock

0 = No lock

1 = Low level

2 = Medium level

3 = High level

USER KEY FUNCTIONS

LEVEL

Binary input no.1 configuration

Default: None

Occupied temperatu re

setpoints

Local override only

can still be monit ored through the BACnet™ network.

(Motion NO): Used in Occupied Mode only to toggle from

the Occupied setpoints to the Stand-By setpoints when no

motion is detected for 60 minutes at the zone.

When motion is detected at the zone, the Occupied setpoint

resumes.

Contact opened = No motion detected.

Contact closed = M otion detected.

(Motion NC): Used in Occupied Mode only to toggle fr om

the Occupied setpoints to the Stand-By setpoints when no

motion is detected for 60 minutes at the zone.

When motion is detected at the zone, the Occupied setpoint

resumes.

Contact opened = Moti on detected.

Contact closed = N o m otion detected.

Global override

access

Analog input no.4 configuration

Default: None

can still be monit ored through the BACnet net w ork.

CO2: Used when a 0-10VDC CO2 sensor is connected to

AI4 input. The value of the input signal is displayed in AI4

Dis parameter.

21 | VZ7260W Series- Installation Guide

Page 22

RehtConf

Number of Reheat Stages and

0 = None

1 = Modulating Duct Reheat Only

2 = On-Off Duct Reheat Only

Off reheat output for a local

RTU in heating mode with reheat uses Control Curve 6

3 = On-Off Perimeter Reheat Only

Off reheat output for a local

RTU in heating mode uses Control Curve 6

4 = Modulating Duct Reheat & On-Off Perimeter Reheat

The first reheat stage will use the modulating reheat output for a

RTU in heating mode uses Control Curve 10

their applications

Default: 1 = Modulating Duct

Reheat Only

Zone will operate in VAV heating or cooling only based on the

Master RTU mode without any reheat.

RTU in cooling mode uses Control Curve 1

Zone will operate in VAV heating or cooling based on the

Master RTU mode and uses the Modulating reheat output for a

local Modulating duct reheat device like a proportional hot water

valve or an SCR. The local reheat can be enabled or disabled

based on the outdoor air temperature and AO2 OALK.

RTU in cooling mode uses Control Curve 3

Zone will operate in VAV heating or cooling based on the

Master RTU mode and uses the OnOn-Off duct reheat device like a 2 position hot water valve or a

single electric duct heater. The local reheat can be enabled or

disabled based on the outdoor air temperature and BO5 OALK.

RTU in cooling mode with On-Off Reheat (BO5 Time=0=15

minutes) uses Control Curve 5b

RTU in cooling mode with On-Off Pulsed Reheat (BO5

Time=1=10 seconds) uses Control Curve 5a

Zone will operate in VAV heating or cooling based on the

Master RTU mode and uses the OnOn-Off perimeter reheat device like a 2 position hot water valve

or a electric baseboard unit. The local reheat can be enabled or

disabled based on the outdoor air temperature and BO5 OALK.

RTU in cooling mode uses Control Curve 7

Zone will operate in VAV heating or cooling based on the

Master RTU mode and uses 2 stages of local reheat.

local modulating duct reheat device like a proportional hot water

valve or an SCR. The local reheat stage can be enabled or

disabled based on the outdoor air temperature and AO2 OALK.

The second reheat stage will use the On-Off reheat output for a

local On-Off perimeter reheat device like a 2 position hot water

valve or a electric baseboard unit. The local reheat stage can

be enabled or disabled based on the outdoor air temperature

and BO5 OALK

RTU in cooling mode uses Control Curve 9

22 | VZ7260W Series- Installation Guide

Page 23

5 = Duct heater & On-Off/Pulsed perimeter r eheat (All

electric)

OALK

Zone will operate in VAV heating or cooling based on the

Master RTU mode and use 2 stages of local reheat .

The first reheat s tage will use the modulating BO5 reheat

output (10s or 15m c ycles) for a local modulat ing electric

duct reheat device with a 24 Vac fired SSR. The local reheat

stage can be enabled or disabled based on the outdoor air

temperature and BO5 OALK

The second reheat s tage will use the reheat out put BO3

(15m cycles) and/or BO4 (10s cycles) for a local OnOff/Pulsed perimeter reheat device like a 2 position electri c

baseboard unit. The local reheat stage can be enabled or

disabled based on the outdoor air temperature and FO2

23 | VZ7260W Series- Installation Guide

Page 24

AO2RA/DA

AO2 OAL K

Outdoor air temperature value from the RTU controller under

VZ7260F5x00B models only

FO2 OALK

Outdoor air temperature value from the RTU controller under

BO5 OAL K

Outdoor air temperature value from the RTU controller under

(Increments : 5° or 50°)

RA/DA

Reverse acting or D irect acting

actuator signal for Reheat 1

Analog output signals

Default: DA signal

Changes the action of the reheat 1 analog output .

Valid only if analo g reheat sequences are enabled

DA = Direct acting

0 to 100 % = 0 to 10 VDC

RA = Reverse acting

0 to 100 % - 10 to 0 VDC

VZ7260F5x00B models only

Zone’s analog reheat (AO2)

outside air temperature lockout

Default: 55°F (13 °C )

FL TM Dp

Floating damper actuator

timing – Output BO1-BO2

Default: 1.5 min utes

FL TM Rh

Floating damper actuator

timing – Output BO3-BO4

Default: 1.5 min utes

Zone’s BO3-BO4 reheat

floating output outside air

temperature lockout

Default: 55°F (13 °C )

which the analog reheat stage will be allow ed to be used.

Function will onl y be enabled if a valid outside air

temperature value is received at the zone.

-40 to 122 °F (-40.0 to 50.0 °C )

(Increments : 5° or 50°)

Maximum stroke time of floating damper actuator

Output BO1-BO2.

0.5 to 9.0 in 0.5 minutes increment

VZ7260C5x00B models only

Maximum stroke time of floating damper actuator

Output BO3-BO4.

0.5 to 9.0 in 0.5 minutes increment

VZ7260C5x00B models only

which the BO3-BO4 rehe at output stage will be allowed to

be used

Function will onl y be enabled if a valid outside air

temperature value is received at the zone.

-40 to 122 °F (-40.0 to 50.0 °C ) (Increments: 5° or 50°)

VZ7260C5x00B models only

Zone’s On-Off reheat (BO5)

outside air temperature lockout

Default: 32°F (0°C)

which the On-Off reheat stage will be allowed to be used.

Function will onl y be enabled if a valid outside air

temperature value is received at the zone.

-40 to 122 °F (- 40.0 to 50. 0 °C )

24 | VZ7260W Series- Installation Guide

Page 25

BO5 Time

Default: 0 = 15 minute

BO5 cont

Contact Closed

Time delay between t he m oment when the PIR cover

Time delay between t he m oment where the controller

Range is: 0.0 to 24.0 hours in 0.5hr incr em ents.

Default: 80 °F (27°)

Sets the time base for the ONOff reheat output i f used

Valid only if reheat sequences are enabled wi th BO5

0= 15 minutes

1= 10 seconds for Sol id state relays

BO5 contact func tion

Default value = 0 = NO

St-By TM

Stand-by Timer value

Default 0.5 hours

Unocc TM

Unoccupied Timer val ue

Default 0.0 hours

Unocc HT

Unoccupied heating setpoint

Default: 62 °F (17°C)

Enables the use of normally opened or normally closed 2

position reheat valves.

0 = NO, Energized = Contact Closed / De-energized =

Contact Opened

1 = NC, Energized = Contact Opened / De-energized =

detected the last movement in the area and the time when

the controller’s stand-by mode and setpoi nts become active.

Range is: 0.5 to 24.0 hours in 0.5hr incr em ents.

toggles to stand-by m ode and the time which t he controller

unoccupied mode and setpoints become active.

The factory value or 0.0 hours: Setting this parameter to its

default value of 0.0 hours disables the unoccupied timer.

This prevents the controller to drif t from stand-by mode to

unoccupied mode when PIR functions are used.

Unoccupied heating setpoint adjustment.

Heating setpoint r ange is:

40 to 90 °F (4.5 to 32.0 °C)

(Increments :0.5° or 5°)

Unocc CL

Unoccupied cooling setpoint

limit

Unoccupied cooling setpoint adjustment.

Cooling setpoint r ange is:

54 to 100 °F (12.0 to 37. 5 °C ) (Increments: . 5° or 5°)

25 | VZ7260W Series- Installation Guide

Page 26

St-By HT

St-By CL

saved to permanent memory.

Cal RS

Deadband

(1.0 to 2.5 °C, 0.5 °C increments)

Stand-by heating s etpoint

Default: 65 °F (18°C)

Stand-by cooling s etpoint limit

Default: 75 °F (24°C)

Stand-by heating s etpoint adjustment. This setpoint will be

used if there is a motion detector connect ed and configured

on BI1 or a PIR sensor cover used.

Heating setpoint r ange is:

40 to 90 °F (4.5 to 32.0 °C)

Stand-by cooling s etpoint adjustment. This setpoint will be

used if there is a motion detector connect ed and configured

on BI1 or a PIR sensor cover used.

Cooling setpoint r ange is:

54 to 100 °F (12.0 to 37. 5 °C )

Set Type

Temporary user setpoints

enable

Default: permnent

TOccTime

Temporary occupancy time

Default value = 2 hours

Room air temperatur e sensor

calibration

Default: 0.0 °F or °C

Minimum deadband

Default: 2.0 °F (1.0 °C)

Enables temporar y setpoints feature t o any local change of

occupied setpoints.

temporar: (t em porary) Any new setpoints entered by the

user will revert back to their default value after internal timer

ToccTime expires.

To change setpoints permanently, revert to No this variable

or write new setpoint values through the net w ork. Any

setpoints writ ten through the network w ill be permanent ones

and saved to permanent m emory.

permnent: (permanent) Any changes of occ upied setpoints

entered by the user through the keypad are perm anent and

Temporary occupancy time with occupied m ode setpoints

when override function is enabled.

When the controller is in unoccupi ed m ode, function is

enabled with the local override keypad button.

Range is: 0,1, 2, 3, 4 & up to 12 hours

(Increments : 1 hr or 10 hr)

Offset that can be added or subtracted to actual displayed

and used room temperature

± 5.0 °F, 1.0 °F increments

(± 2.5 °C, 0.5 °C increments)

Minimum deadband value between the heating and cooling

setpoints. If m odified, it will be first applied only when a

setpoint is modified.

2, 3, 4 or 5 °F, 1.0 °F increments

26 | VZ7260W Series- Installation Guide

Page 27

Pband

Value

F scale

C scale

3

3 F

1.7 C 4 4 F

2.2 C 5 5 F

2.8 C 6 6 F

3.3 C 7 7 F

3.9 C 8 8 F

4.4 C 9 9 F

5.0 C

10

10 F

5.6 C

Heat max

Default: 90 °F (32 °C)

Cool min

DisMinPo

Proportionnal band setting

Default is : 3

Adjust the proportional band used by the controller PI

control loop.

Warning. Note that t he default value of 3.0 °F (1. 2 °C )

gives satisfactory operation in most normal installation

cases. The use of a s uperior proportional ba nd different

than the factory one i s normally warranted in applications

where the controller location is probl em atic and leads to

unwanted cycling of the unit. A typical example is a wall

mounted unit where the controller is installed between the

return and supply air feeds and is directly influenced by

the supply air st ream of the unit.

Maximum local heati ng

setpoint limi t

Minimum local cooling

setpoint limi t

Default: 54 °F (12 °C)

Enable / Disable damper

minimum position

Default : On

27 | VZ7260W Series- Installation Guide

Maximum local occupied heating user setpoints

adjustments.

Heating setpoint r ange is:

40 to 90 °F (4.5 to 32.0 °C) (Increments: 0.5° or 5°)

Minimum local occupied cooling user s etpoints

adjustments.

Cooling setpoint r ange is:

54 to 100 °F (12.0 to 37. 5 °C ) (Increments: 0.5° or 5°)

Enables or disabled the damper minimum position

(parameter Min PO) if the controller cooling or heating

demand is not the s am e as the zone sequence. Example:

if controller c all s for heating and the zone sequence is

Cool (sent by the VZ7 6xx master controller).

On = Enable Minimum Position

Off = Disable Minimum P osition

Page 28

Min Pos

Zone damper minimum

Max Pos

Sets the maximum position of the damper for both heating

MaxHTPos

Opens the damper up to t his maximum position when the

0 to 100% (Increments: 1% or 10%)

PIHT Wei

Weight of the zone in the calculation of the PI Heating

PICL Wei

Calculation of t he R TU controller.

Not a configurati on parameter. Only dis plays the

hours. These

position

Default : 10%

Sets the minimum position of the damper.

0 to 100% (Increments: 1% or 10%)

Zone damper maximum

position

Default : 100%

Zone damper Maximum

heating positi on

Default : 30%

PI heating weight zone output

used for RTU controller

demand calculations

Default value: 100%

and cooling mode of the RT U .

0 to 100% (Increments: 1% or 10%)

primary air is col d and used only when the RTU is in

cooling mode and there is a local call for reheat using the

reheat output(s).

This will maximizes the efficiency and del ivery of a duct

mounted reheat device by augmenting the airflow on a

single duct VAV.

Demand calculat ion of the RTU controller.

If a zone has a special application (servers room,

mechanical room, etc) and have impact on ot her rooms’

comfort, this parameter can be set to 0%.

Please refer to the Zoning System Application Guide for

more information that impacts systems operation.

Set all heating weig ht to 0% if the RTU is cooling only.

Valid range: 0%, 25%, 50%, 75% and 100%

PI cooling weight zone output

used for RTU controller

demand calculations

Default value: 100%

If a zone has a special application (servers room,

mechanical room, etc) and have impact on ot her rooms’

comfort, this par ameter can be set to 0%.

Please refer to the Zoning System Application Guide for

more information that impacts systems operation.

HT Perfo

Controller’s heating

performance

Valid range: 0%, 25%, 50%, 75% and 100%

controller’ s performance in heating mod e.

This value is only val id if there’s no change in system

mode, setpoints or occupancy for at least 1.5

changes cause the value to reset to an invali d value

Default value: None

28 | VZ7260W Series- Installation Guide

(above 20°F)

Page 29

CL Perfo

Not a configurati on parameter. Only dis plays the

Room CO2

object)

AI4 Value

object)

YES (Only in

Occupied mode)

Controller’s cooling

performance

Default value: None

controller’ s performance in cooling mod e.

This value is only val id if there’s no change c hange in

system mode, setpoints or occupancy for at least 1.5

hours. These chang es cause the value to reset to an

invalid value (abo ve 20°F)

UI3 Dis

UI3 display value

CO2

Room CO2 value

Used as diagnostic / service help to troubleshoot and

diagnose sensor operation

Supply or Disc harge temperature

Used as diagnostic / service help to troubleshoot and

diagnose sensor operation. This value is displayed only if

AI4 parameter is set to CO2.

0 to 2000 ppm

AI4 INPUT FOR CO2 SENSOR

The VZ7260X5x00B s eries features a 0-10VDC CO2 s ensor input which value can be used

by the VZ7656E1000B controller for Indoor Air Quality (AIQ) control.

Here’s the table showing the CO2 value treatm ent based on the AI4 paramet er setting:

AI4

parameter

setting

CO2 display

at the

controller

Value Written to

VZ7656E1000B

Value available

in ppm (BACnet

available in

VDC (BACnet

None NO NO NO YES

CO2 YES

29 | VZ7260W Series- Installation Guide

YES YES

Page 30

REFERENCED OPERATIONAL CONTROL CURVES

Temperature increase

Device opened

10 Vdc or Max Pos

AO1

RTC in Heating mode

RehtConf = 0 (No reheat at the zone

CC2

Device closed

Cooling

Setpoint

DEAD BAND

Heating

Setpoint

AO2 = 0 Vdc & BO5 = Off

Min Pos

if DisMinPo = Enabled

or

0 Vdc

if DisMinPo = Disabled

Temperature increase

Deviceopened

10 Vdc or Max Pos

Deviceclosed

Min Pos

if DisMinPo = Enabled

AO1

Cooling

Setpoint

RTC in Cooling mode

RehtConf = 0 (No reheat at the zone)

CC1

DEAD BAND

Heating

Setpoint

AO2 = 0 Vdc & BO5 = Off

or

0 Vdc

if DisMinPo = Disabled

Temperature increase

Deviceopened

100% or Max Pos

Deviceclosed

Min Pos

if DisMinPo = Enabled

BO1-BO2

Cooling

Setpoint

RTC in Cooling mode

RehtConf = 0 (No reheat at the zone)

CC1

DEAD BAND

Heating

Setpoint

BO3-BO4 = 0% & BO5 = Off

or

0%

if DisMinPo = Disabled

Temperature increase

Device opened

100% or Max Pos

BO1-BO2

RTC in Heating mode

RehtConf = 0 (No reheat at the zone)

CC2

Device closed

Cooling

Setpoint

DEAD BAND

Heating

Setpoint

BO3-BO4 = 0% & BO5 = Off

Min Pos

if DisMinPo = Enabled

or

0%

if DisMinPo = Disabled

RehtConf = 0 = None

VZ7260F Series: Analog Outputs

VZ7260C Series: Floating Out puts

30 | VZ7260W Series- Installation Guide

Page 31

RehtConf = 1 = Analog Duct Reheat Only

Temperature increase

Cooling

Setpoint

RTC in cooling mode

RehtConf = 1 (Analog Duct Reht Only)

BO5 = Off

(1) If AO2 stage is locked, AO1 = Min Pos

(2) If AO2 stage is locked, AO1 = 0Vdc

DEAD BAND

Heating

Setpoint

Device closed

0%

Device opened

100%

CC3

Device closed

Min Pos

AO1

Device opened

MaxHeat Pos (1)

AO2

Deviceopened

10 Vdc or Max Pos

0Vdc

if DisMinPo = Disabled (2)

Temperature increase

AO1

Device

opened 100%

Device

closed 0%

AO2

CC4

Cooling

Setpoint

DEAD BAND

Heating

Setpoint

RTC in Heating mode

RehtConf = 1 (Analog Duct Reht Only)

BO5 = Off

Device opened

10 Vdc or Max Pos

Device closed

Min Pos

if DisMinPo = Enabled

or

0 Vdc

if DisMinPo = Disabled

Temperature increase

Cooling

Setpoint

RTC in cooling mode

RehtConf = 1 (Analog Duct Reht Only)

BO5 = Off

(1) If BO3-BO4 stage is locked, BO1-BO2 = Min Pos

(2) If BO3-BO4 stage is locked, BO1-BO2 = 0%

DEAD BAND

Heating

Setpoint

Device closed

0%

Device opened

100%

CC3

Device closed

Min Pos

BO1-BO2

Device opened

MaxHeat Pos (1)

BO3-BO4

Deviceopened

100% or Max Pos

0%

if DisMinPo = Disabled (2)

Temperature increase

BO1-BO2

Device

opened 100%

Device

closed 0%

BO3-BO4

CC4

Cooling

Setpoint

DEAD BAND

Heating

Setpoint

RTC in Heating mode

RehtConf = 1 (Floating Duct Reht Only)

BO5 = Off

Device

opened

100% or Max Pos

Device closed

Min Pos

if DisMinPo = Enabled

or

0%

if DisMinPo = Disabled

VZ7260F Series: Analog Outputs

VZ7260C Series: Floating Out puts

31 | VZ7260W Series- Installation Guide

Page 32

RehtConf = 2 = On-Off Duct Reheat O nly

RTC in Cooling mode

RehtConf = 2 ( On/Off Duct Reht Only)

AO2 = 0%

On/Off Rht Time Base = 10 sec

(1) If BO5 stage is locked, AO1 = Min Pos

When BO5 = 0%, AO1 = Min Pos

When BO5 = 100%, AO1 = Max Pos

Otherwise, AO1 output is proportional to BO5 output

Temperature increase

Cooling

Setpoint

DEAD BAND

Heating

Setpoint

Device closed

0%

Device opened

100%

CC5a

Device closed

Min Pos

AO1

Device opened

MaxHeat Pos (1)

BO5

Device opened

10 Vdc or Max Pos

0Vdc

if DisMinPo = Disabled (2)

(2) If BO5 stage is locked, AO1 = 0Vdc

When BO5 = 0%, AO1 = 0 Vdc

When BO5 = 100%, AO1 = Max Pos

Otherwise, AO1 output is proportional to BO5 output

RTC in Cooling mode

RehtConf = 2 ( On/Off Duct Reht Only)

AO2 = 0%

On/Off Rht Time Base = 15 min

(1) If BO5 stage is locked, AO1 = Min Pos

When BO5 = Off, AO1 = Min Pos

When BO5 = On, AO1 = Max Pos

Temperature increase

Cooling

Setpoint

DEAD BAND

Heating

Setpoint

Device Off

Device On

CC5b

Device closed

Min Pos

AO1

Device opened

MaxHeat Pos (1)

BO5

Device opened

10 Vdc or Max Pos

BO5 Output Off

BO5 Output On

Device closed

Min Pos

if DisMinPo = Enabled

or

0 Vdc

if DisMinPo = Disabled (2)

(2) If BO5 stage is locked, AO1 = 0Vdc

When BO5 = Off, AO1 = 0Vdc

When BO5 = On, AO1 = Max Pos

Temperature increase

AO1

Device

On

Device

Off

BO5

CC6

Cooling

Setpoint

DEAD BAND

Heating

Setpoint

RTC in Heating mode

RehtConf = 2 (On/Off Duct Reht Only)

AO2 = Off

Device opened

10 Vdc or Max Pos

Device closed

Min Pos

if DisMinPo = Enabled

or

0 Vdc

if DisMinPo = Disabled

VZ7260F Series: Analog Outputs

10

32 | VZ7260W Series- Installation Guide

Page 33

VZ7260C Series: Floating Out puts

RTC in Cooling mode

RehtConf = 2 ( On/Off Duct Reht Only)

BO3-BO4 = 0%

On/Off Rht Time Base = 10 sec

(1) If BO5 stage is locked, BO1-BO2 = Min Pos

When BO5 = 0%, BO1-BO2 = Min Pos

When BO5 = 100%, BO1-BO2 = Max Pos

Otherwise, BO1-BO2 output is proportional to BO5 output

Temperature increase

Cooling

Setpoint

DEAD BAND

Heating

Setpoint

Device closed

0%

Device opened

100%

CC5a

Device closed

Min Pos

BO1-BO2

Device opened

MaxHeat Pos (1)

BO5

Device opened

100% or Max Pos

0%

if DisMinPo = Disabled (2)

(2) If BO5 stage is locked, BO1-BO2 = 0%

When BO5 = 0%, BO1-BO2 = 0%

When BO5 = 100%, BO1-BO2 = Max Pos

Otherwise, BO1-BO2 output is proportional to BO5 output

RTC in Cooling mode

RehtConf = 2 ( On/Off Duct Reht Only)

BO3-BO4 = 0%

On/Off Rht Time Base = 15 min

(1) If BO5 stage is locked, BO1-BO2 = Min Pos

When BO5 = Off, BO1-BO2 = Min Pos

When BO5 = On, BO1-BO2 = Max Pos

Temperature increase

Cooling

Setpoint

DEAD BAND

Heating

Setpoint

Device Off

Device On

CC5b

Device closed

Min Pos

BO1-BO2

Device opened

MaxHeat Pos (1)

BO5

Device opened

100% or Max Pos

BO5 Output Off

BO5 Output On

Device closed

Min Pos

if DisMinPo = Enabled

or

0%

if DisMinPo = Disabled (2)

(2) If BO5 stage is locked, BO1-BO2 = 0%

When BO5 = Off, BO1-BO2 = 0%

When BO5 = On, BO1-BO2 = Max Pos

Temperature increase

BO1-BO2

Device

On

Device

Off

BO5

CC6

Cooling

Setpoint

DEAD BAND

Heating

Setpoint

RTC in Heating mode

RehtConf = 2 (On/Off Duct Reht Only)

BO3-BO4 = Off

Device opened

100% or Max Pos

Device closed

Min Pos

if DisMinPo = Enabled

or

0%

if DisMinPo = Disabled

33 | VZ7260W Series- Installation Guide

Page 34

RehtConf = 3 = On-Off Perimeter Reheat Only

Temperature increase

AO1

Device

On

Device

Off

BO5

CC6

Cooling

Setpoint

DEAD BAND

Heating

Setpoint

RTC in Heating mode

RehtConf = 2 (On/Off Duct Reht Only)

AO2 = Off

Device

opened

10 Vdc or Max Pos

Device closed

Min Pos

if DisMinPo = Enabled

or

0 Vdc

if DisMinPo = Disabled

Temperature increase

Device closed

Min Pos

AO1

Cooling

Setpoint

RTC in cooling mode

RehtConf = 3 ( On/Off Peri Rht Only)

AO2 = 0%

CC7

DEAD BAND

Heating

Setpoint

Device Off

Device On

BO5

AO1

Device opened

10 Vdc or Max Pos

AO1 = 0Vdc

if DisMinPo = Disabled

Temperature increase

BO1-BO2

Device

On

Device

Off

BO5

CC6

Cooling

Setpoint

DEAD BAND

Heating

Setpoint

RTC in Heating mode

RehtConf = 2 (On/Off Duct Reht Only)

BO3-BO4 = Off

Device opened

100% or Max Pos

Device closed

Min Pos

if DisMinPo = Enabled

or

0%

if DisMinPo = Disabled

Temperature increase

Device closed

Min Pos

BO1-BO2

Cooling

Setpoint

RTC in cooling mode

RehtConf = 3 ( On/Off Peri Rht Only)

BO3-BO4 = 0%

CC7

DEAD BAND

Heating

Setpoint

Device Off

Device On

BO5

BO1

-

BO2

Device opened

100% or Max Pos

BO1-BO2 = 0%

if DisMinPo = Disabled

VZ7260F Series: Analog Outputs

VZ7260C Series: Fl oating Outputs

34 | VZ7260W Series- Installation Guide

Page 35

RehtConf = 4 = Analog Duct Reheat & On-Off Perimeter Reheat

Temperature increase

Deviceclosed

Min Pos

Cooling

Setpoint

RTC in cooling mode

RehtConf = 4 (Terminal reheat on AO2 &

Perimeter Heating on BO5)

(1) If AO2 stage is locked, AO1 = Min Pos

(2) If AO2 stage is locked, AO1 = 0Vdc

CC9

DEAD BAND

Heating

Setpoint

Device opened

Max Heat Pos (1)

AO2

Device closed

0%

Device

On

Device

Off

BO5

Device opened

100%

AO1

Device opened

10 Vdc or Max Pos

0Vdc

if DisMinPo = Disabled (2)

Temperature increase

AO1

Device

Opened 100%

Device

Closed 0%

AO2

CC10

Cooling

Setpoint

DEAD BAND

Heating

Setpoint

RTC in Heating mode

RehtConf = 4 (Terminal reheat on AO2 &

Perimeter Heating on BO5)

Device

opened

10 Vdc or Max Pos

Device

On

BO5

Device

Off

Device closed

Min Pos

if DisMinPo = Enabled

or

0 Vdc

if DisMinPo = Disabled

Temperature increase

Deviceclosed

Min Pos

Cooling

Setpoint

RTC in cooling mode

RehtConf = 4 (Terminal reheat on BO3-BO4 &

Perimeter Heating on BO5)

(1) If BO3-BO4 stage is locked, BO1-BO2 = Min Pos

(2) If BO3-BO4 stage is locked, BO1-BO2 = 0%

CC9

DEAD BAND

Heating

Setpoint

Device opened

Max Heat Pos (1)

BO3-BO4

Device closed

0%

Device

On

Device

Off

BO5

Device opened

100%

BO1-BO2

Device opened

100% or Max Pos

0%

if DisMinPo = Disabled (2)

Temperature increase

BO1-BO2

Device

Opened 100%

Device

Closed 0%

BO3-BO4

CC10

Cooling

Setpoint

DEAD BAND

Heating

Setpoint

RTC in Heating mode

RehtConf = 4 (Terminal reheat on BO3-BO4 & Perimeter Heating on BO5)

Device opened

100% or Max Pos

Device

On

BO5

Device

Off

Device closed

Min Pos

if DisMinPo = Enabled

or

0%

if DisMinPo = Disabled

VZ7260F Series: Analog Outputs

VZ7260C Series: Floating Out puts

35 | VZ7260W Series- Installation Guide

Page 36

RehtConf = 5 = Pulsed Duct heater & On-Off/Pulsed perimeter reheat (All electric)

Temperature increase

Deviceclosed

Min Pos

Cooling

Setpoint

RTC in cooling mode

1) If BO5 OALK is active & DisMinPo Disabled, BO1-BO2 =Min Pos

2) If BO5 OALK is active & DisMinPo Disabled, BO1-BO2 =0%

CC11a

DEAD BAND

Heating

Setpoint

Device opened

Max Heat Pos (1)

BO5

Device

0%

Device

On

Device

Off

BO3

Device

100%

BO1-BO2

Device opened

100% or Max Pos

0%

if DisMinPo = Disabled

(2)

BO4

RehtConf = 5 Duct reheat on BO5 (BO5 Time = 10s) &

Perimeter Heating on BO3 (15m) and/or

BO4 (10s)

Temperature increase

Deviceclosed

Min Pos

Cooling

Setpoint

RTC in cooling mode

CC11b

DEAD BAND

Heating

Setpoint

Device

On

Device

Off

BO3

BO1-BO2

Device opened

100% or Max Pos

BO4

RehtConf = 5 Duct reheat on BO5 (BO5 Time = 15m) &

Perimeter Heating on BO3 (15m) and/or

BO4 (10s)

1) If BO5 OALK is active & DisMinPo Disabled, BO1-BO2 =Min Pos

2) If BO5 OALK is active & DisMinPo Disabled, BO1-BO2 =0%

Device opened

MaxHeat Pos (1)

BO5 Output Off

BO5 Output On

Device closed

Min Pos

if DisMinPo = Enabled or

0% if DisMinPo = Disabled (2)

Temperature increase

BO1-BO2

CC12

Cooling

Setpoint

DEAD BAND

Heating

Setpoint

RTC in Heating mode

Device opened

100% or Max Pos

Device

On

Device

Off

Device closed

Min Pos

if DisMinPo = Enabled

or

0%

if DisMinPo = Disabled

BO5

BO3

Device

0%

Device

100%

BO4

RehtConf = 5 Duct reheat on BO5 &

Perimeter Heating on BO3 (15m) and/or

BO4 (10s)

VZ7260C Series: Floating Out puts

36 | VZ7260W Series- Installation Guide

Page 37

SPECIFICATIONS

Terminal Equipment Controller power

Class (US)

requirements:

Operating conditions:

Storage conditions:

Sensor:

Resolution:

Temperature control accuracy:

Contact output rating:

Occ, Stand-By and Unocc cooling setpoint range:

Occ, Stand-By and Unocc heating setpoint range:

Room and outdoor air temperature display range:

Proportional band for room temperature control:

Binary inputs:

AI4 Analog input:

Wire gauge:

Approximate shipping weight:

Agency Approvals all models:

Agency Approvals all models:

Agency Approvals Wireless models:

19-30 VAC 50 or 60 Hz; 2 VA Class 2

0 °C to 50 °C ( 32 °F to 122 °F )

0% to 95% R.H. non-condensing

-30 °C to 50 °C ( -22 °F to 122 °F )

0% to 95% R.H. non-condensing

Local 10 K NTC thermistor

± 0.1 °C ( ± 0.2 °F )

± 0.5 ° C ( ± 0.9 °F ) @ 21 °C ( 70 °F )

typical calibrated

Relay outputs: 30 VAC, 1 Amp.

Maximum, 3 Amp . In -rush.

0 to 10 VDC into 2 KΩ resistance min.

12.0 to 37.5 °C ( 54 to 100 °F )

4.5 °C to 32 °C ( 40 °F to 90 °F )

-40 °C to 50 °C ( -40 °F to 122 °F )

Cooling & Heating: 1.8°C (3. 2°F)

Dry contact across terminal BI1 & UI3

to Scom

0 to 10 VDC into 10KΩ resistance min.

18 gauge maximum, 22 gauge

0.75 lb ( 0.34 kg )

UL: UL 873 (US) and CSA C22.2 No.

24 (Canada), File E27734 with CCN

XAPX (US) and XAPX7 (Canada)

Industry Canada: ICES-003 (Canada)

FCC: Compliant to CFR 47, Part 15,

Subpart B, Class A (US)

CE : EMC Directive 2004/108/EC

(Europe Union)

C-Tick: AS/NZS CISPR 22 Compliant

(Australia / New Zealand) Supplier

Code Number N10696

FCC: Compliant to: Part 15, Subpart B,

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS SUBJECT

TO THE FOLLOWING TWO CONDITIONS: (1) THIS DEVICE MAY NOT CAUSE HARMFUL

INTERFERENCE AND (2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE RECEIVED,

INCLUDING INTERFERENCE THAT MAY CAUSE UNDESI RED OPERA TIO N

Please check wi th your local government for instruction on disposal of this product

37 | VZ7260W Series- Installation Guide

Page 38

DRAWING & DIMENSIONS

9245 Langelier Blvd. I St-Leonard I Quebec I Canada I H1P 3K9

Tel.: (514) 321.5660 I Fax: (514) 321.4150 Toll free: 1 800.563.5660

38 | VZ7260W Series- Installation Guide

Viconics Tech n ologies Inc.

sales@viconics.com I www.viconics.com

Loading...

Loading...