Page 1

1

Zoning Product Series

VZ7260 & VZ7656 Series

For Commercial Zoning Systems

BACnet Integration Manual

ITG-VZ7xxx-BAC-E04.doc

(028-6011_R4 Issue Date: May 31st, 2012)

Page 2

2

Fig.2 -VZ7656BController

VZ7260 Product Overview

The Viconics VZ7260 PI controller family is specifically designed for local

pressure dependent VAV zone control within Viconics Zoning System

product family.

The product features a backlit LCD display with dedicated function menu

buttons for simple user operation. Accurate temperature control is achieved

due to the product’s PI proportional control algorithm, which virtually

eliminates temperature offset associated with traditional, differential-based

controllers.

The controllers are used in conjunction with the Viconics VZ76561000B

Roof Top Controller for total system operation of each zones and the RTU.

A local BACnet RS485 MS-TP communication bus between all devices insures proper communication and data

exchange of all required information between the Zone controllers and RTU controller. They can be seamlessly

integrated into any 3rd party BACnet supervision system.

The Zone controllers are also compatible with the new Viconics PIR cover accessories. Controllers equipped with a

PIR cover provide advanced active occupancy logic, which will automatically switch occupancy levels from

occupied to stand-by as required by local activity being present or not. This advanced occupancy functionality

provides advantageous energy savings during occupied hours without sacrificing occupant comfort. All Zone

controllers can be ordered with or without a factory installed PIR cover (see ordering notes below).

VZ7656 Product Overview

The Viconics VZ7656 controller is specifically designed for RTU control of the Viconics

Zoning System product family.

The RTU controller is designed for single stage or multi-stage control of heating and

cooling equipment such as rooftop and self-contained units used in zoning systems.

The product features a backlit LCD display with dedicated function menu buttons for

simple user operation. Accurate temperature control is achieved due to the product’s PI

proportional control algorithm, which virtually eliminates temperature offset associated

with traditional, differential-based controllers.

The controller also contains extra digital inputs, which can be set by the user to monitor

filter status or used as a general purpose service indicator. All models contain a SPST

auxiliary switch, which can be used to control lighting or disable the RTU economizer

function during unoccupied periods. It also features a discharge air sensor input.

Proportional static pressure logic (input and output) has been integrated onto the

controller to provide a complete single packaged unit for most small to medium size jobs.

The controllers are used in conjunction with the Viconics VZ7260 Zone controllers for total system operation of

each zones and the RTU.

A local BACnet RS485 MS-TP communication bus between all devices insures proper communication and data

exchange of all required information between the Zone controllers and the RTU controllers. They can be

seamlessly integrated into any 3rd party BACnet supervision system.

Page 3

3

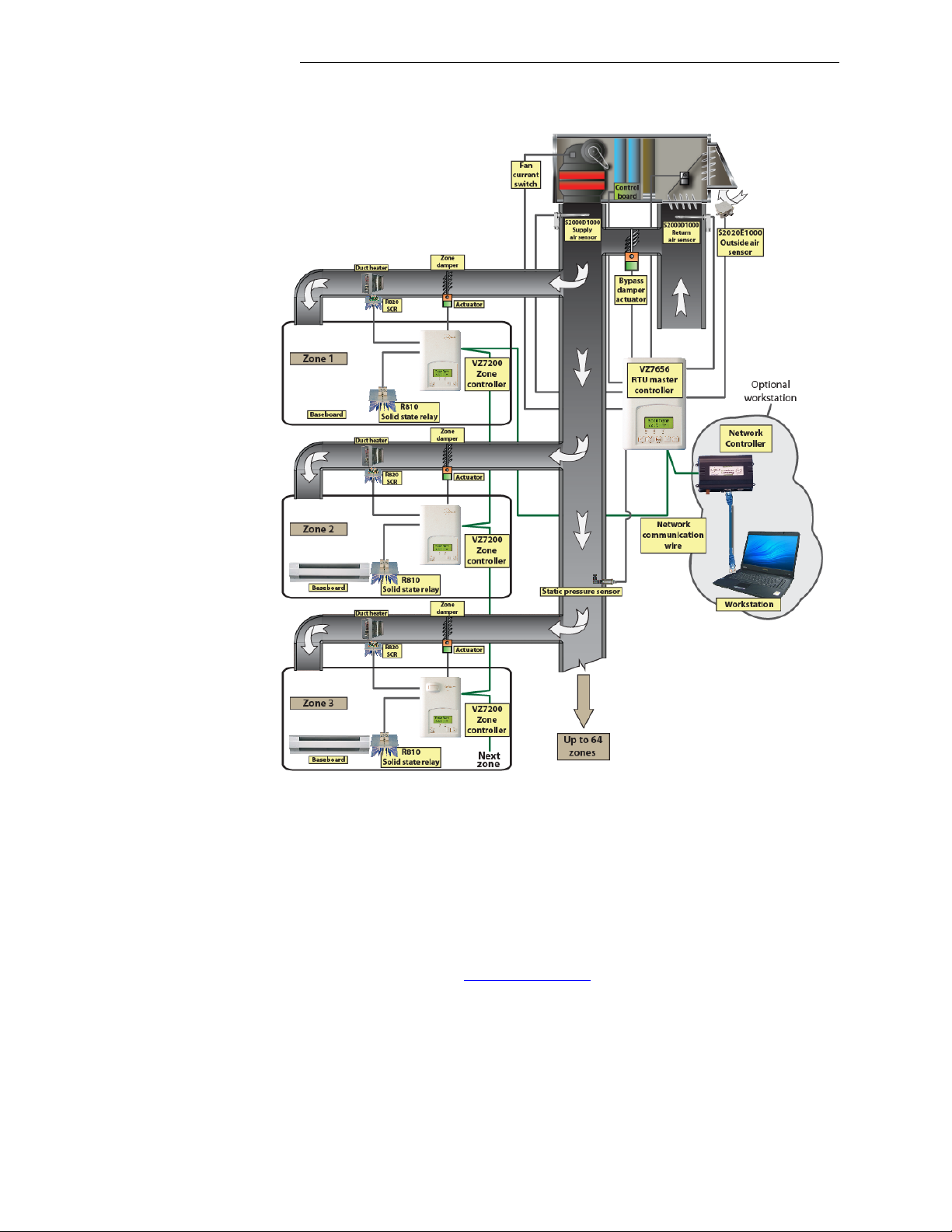

BACnet System Overview

Viconics VZ7260 zone controllers are used in conjunction with the VZ7656 roof top controllers. Combined, they

are designed for operate typical single or multistage RTUs and their associated local zones.

Typical BACnet zoning system installation

Please refer to the following Viconics documents for detailed information and design guidelines for the BACnet

zoning system version:

As an example, a typical job layout system may feature three RTU controllers with thirty one total zones. This

would bring to total number of nodes (individual Com addresses) to thirty four. RTU one would have ten zones

under its command, RTU two would have ten zones under its command and RTU three would have eleven

zones under its command.

The additional following documents are available at: www.viconics.com

For detailed information on the Viconics Zoning System, please refer to the Zoning System Product

Guide. Installation and commissioning information is available in document: Zoning-System-Guide-Exx

For detailed information on the Viconics VZ72 Zone controller, please refer and read the VZ72 Product

Guide. Installation and commissioning information is available on document: LIT-VZ7260-Exx

For detailed information on the Viconics VZ7656 RTU controller, please refer and read the VZ76 Product

Guide. Installation and commissioning information is available on document: LIT-VZ7656-Exx

PIR cover installation information is available in document: PIR Cover Installation-Exx

Page 4

4

Subject

VZ7260 series Protocol Implementation Conformance Statements (PICS)

Standard Object Types Supported

List of Proprietary Properties

List of Property Value Range

List of Property Enumeration Set for BI's and BV's

List of Property Enumeration Set for MV's

Integration

VZ7656 series Protocol Implementation Conformance Statements (PICS)

Standard Object Types Supported

List of Proprietary Properties

List of Property Value Range

List of Property Enumeration Set for BI's and BV's

List of Property Enumeration Set for MV's

Integration

Wiring Guide

Overview

Network Configuration

Maximum Number of Devices

Maximum Cable Length

EI-485 Repeaters

End Of Line Resistors

Network Adapter

Default Device Name and Device ID

Tips and Things You Need To Know

Troubleshooting Section

Document Control

Contents

Page 5

5

BACnet Interoperability Building Block

Data Sharing COV-B (DS-COV-B)

Data Sharing-ReadProperty-B (DS-RP-B)

Data Sharing-ReadPropertyMultiple-B (DS-RPM-B)

Data Sharing-WriteProperty-B (DS-WP-B)

Device Management-Dynamic Device Binding-B (DM-DDB-B)

Device Management-Dynamic Object Binding-B (DM-DOB-B)

Device Management-DeviceCommunicationControl-B (DM-DCC-B)

BACnet Interoperability Building Block

Data Sharing COV-A (DS-COV-A)

Data Sharing-ReadProperty-A (DS-RP-A)

Data Sharing-WriteProperty-A (DS-WP-A)

VZ7260 Series Protocol Implementation Conformance Statement (PICS)

Vendor Name: Viconics

Vendor ID: 140

Product Name: VZ7260 Zoning System Zone Controller

Product Model Number: VZ7260F5x00B

Product Description:

The Viconics VZ7260 PI controller family is specifically designed for local pressure dependent VAV zone control

within Viconics Zoning System product family.

The controllers are used in conjunction with the Viconics VZ76561000B Roof Top Controller for total system

operation of each zones and the RTU.

VZ7260 Supported BACnet Services

The BACnet communicating controller meets all requirements for designation as an Application Specific Controller

(B-ASC). The BACnet controller series supports the following BACnet Interoperability Building Blocks (BIBBs).

The following BACnet Interoperability Building Blocks supported are used ONLY with the VZ76561000B Roof Top

Controller for system operation. The following BiBBS are NOT listed under the “protocol service supported” device

attribute. As such, the VZ7260 application cannot use these services to communicate with “other” third party

devices (see Annex K in BACnet 2004):

Note: The controller does not support segmented requests or responses.

Page 6

6

Object Name

VZ7260F5x00B

VZ7260C5x00B

Object Property

Object Type

Instance #

GUI Damper Position

X

R AI

1

Cfg Zone MAC

X

X

R

AV 1 Cfg RTC MAC

X

X

R/W

AV

2

Cfg AO2 OA Lock Spt

X

R/W

AV

3

Cfg BO5 OA Lock Spt

X

X

R/W

AV

4

Cfg Damper Min Pos

X

X

R/W

AV

5

Cfg Damper Max Pos

X

X

R/W

AV

6

Cfg Damper Max Heat Pos

X

X

R/W

AV 7 Cfg Heating Stpt Limit

X

X

R/W

AV

8

Cfg Cooling Spt Limit

X

X

R/W

AV

9

Cfg Deadband

X

X

R/W

AV

10

GUI Occupied Heat Spt

X

X

R/W

AV

11

GUI Occupied Cool Spt

X

X

R/W

AV

12

GUI Unoccupied Heat Spt

X

X

R/W

AV

13

GUI Unoccupied Cool Spt

X

X

R/W

AV

14

GUI Stand-By Heat Spt

X

X

R/W

AV

15

GUI Stand-By Cool Spt

X

X

R/W

AV

16

GUI AO2 Status

X

R AV

17

GUI UI3 Status

X

X

R

AV

18

GUI PI Heat Weighted Demand

X

X

R

AV

19

GUI PI Cool Weighted Demand

X

X

R

AV

20

GUI Room Temperature

X

X

R

AV

21

GUI Outdoor Temperature

X

X

R/W

AV

22

Cfg Device Instance

X

X

R

AV

23

GUI PI Heat Demand

X

X

R

AV

24

GUI PI Cool Demand

X

X

R

AV

25

Cfg Password

X

X

R/W

AV

26

Cfg Stand-by Time

X

X

R/W

AV

27

Cfg Unoccupied Time

X

X

R/W

AV

28

GUI Heating Performance

X

X

R

AV

29

GUI Cooling Performance

X

X

R

AV

30

Cfg BO3-BO4 OA Lock Spt

X

R/W

AV

31

GUI Room CO2 Level

X

X

R/W

AV

32

GUI Transferred CO2 Value

X

X

R/W

AV

33

GUI AI4 Value

X

X

R

AV

34

GUI BI1 Status

X

X

R

BI

1

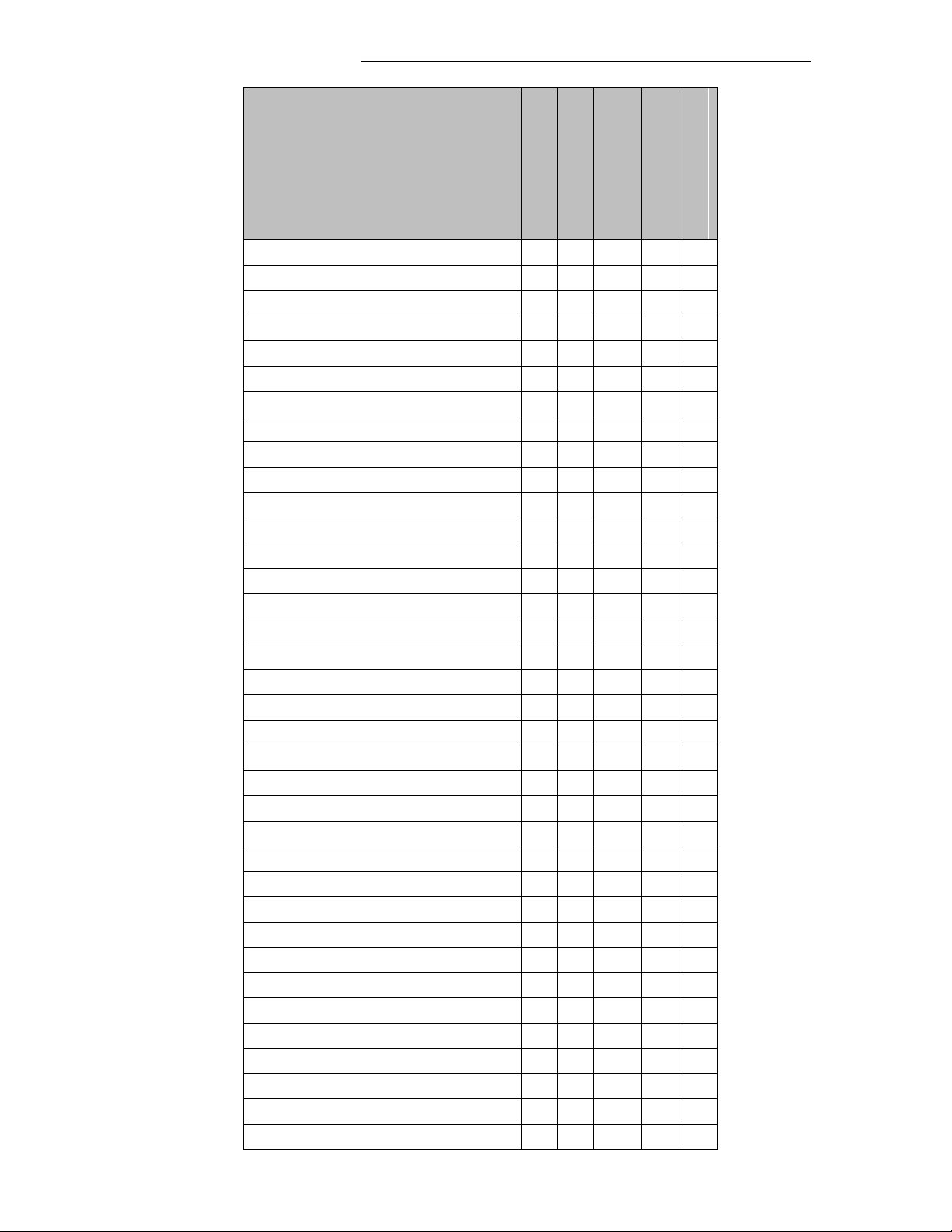

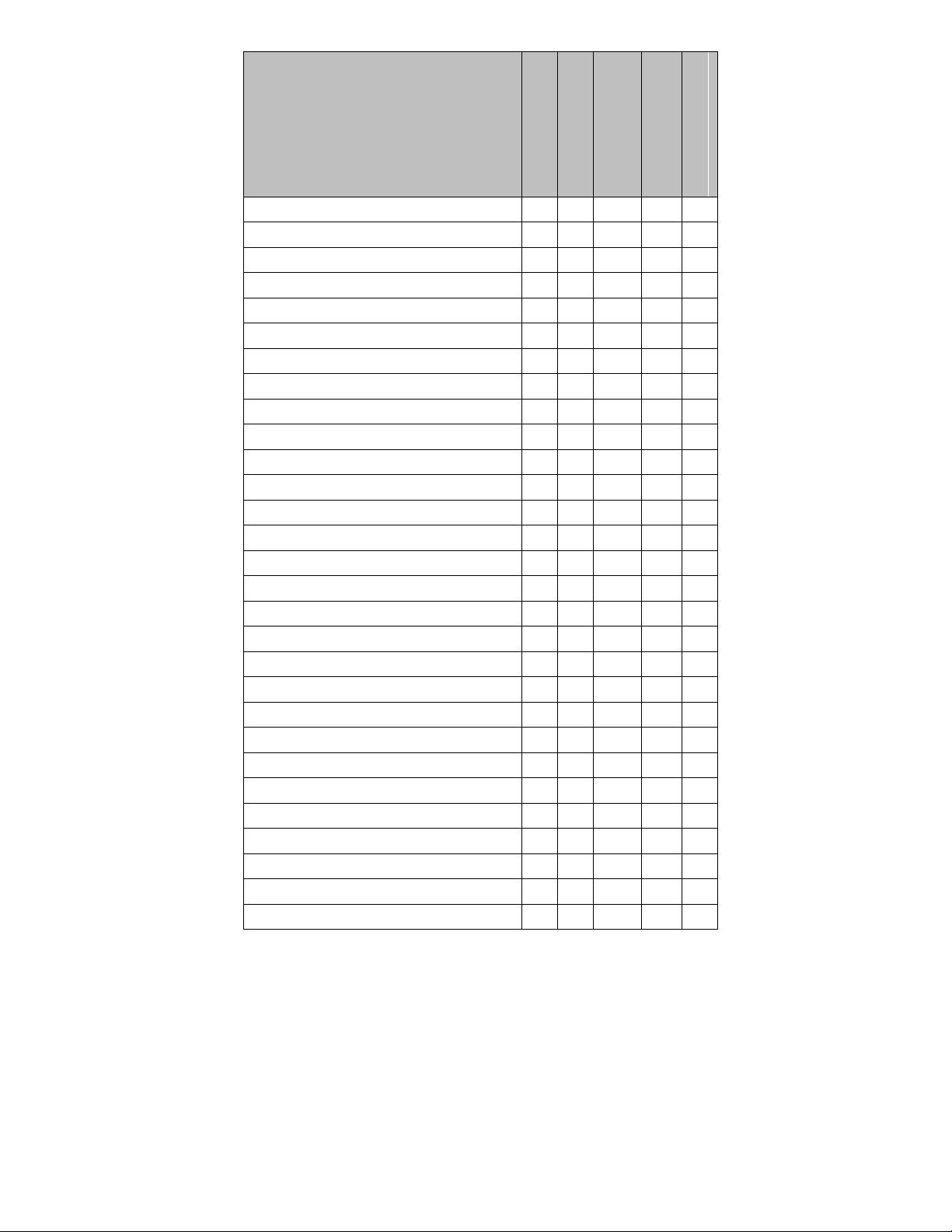

Device Object List for VZ7260 Models

Page 7

7

Object Name

VZ7260F5x00B

VZ7260C5x00B

Object Property

Object Type

Instance #

GUI BI1 Status

X

X

R

BI

1

Cfg Temperature Scale

X

X

R/W

BV

1

Cfg Menu Scroll

X

X

R/W

BV

2

Cfg AO2 DA/RA

X

R/W

BV 4 Cfg BO5 Time Base

X

X

R/W

BV

5

Cfg BO5 Conf

X

X

R/W

BV

6

GUI BO5 Status

X

X

R

BV

7

Sta AO2 Lock Status

X

R BV

8

Sta BO5 Lock Status

X

X

R

BV

9

GUI Room Temp Override

X

X

R/W

BV

10

Sta RTC Smart Recovery

X

X

R

BV

11

Cfg Setpoint Type

X

X

R/W

BV

12

Cfg Disable Min Pos

X

X

R/W

BV

13

Sta BO3-BO4 Lock Status

X R

BV

14

Cfg Zone Baud

X

X

R

MV

1

Cfg Reheat Config

X

X

R/W

MV 2 Cfg BI1 Configuration

X

X

R/W

MV

3

Cfg PI Heat Weight

X

X

R/W

MV

4

Cfg PI Cool Weight

X

X

R/W

MV

5

Cfg Temporary Occupancy Time

X

X

R

MV

6

Cfg Network Handle

X

X

R/W

MV

7

GUI Zone Keypad Lockout

X

X

R/W

MV 8 GUI Occupancy

X

X

R/W

MV

9

Sta RTC Zone Sequencing

X

X

R

MV

10

GUI Effective Occupancy

X

X

R

MV

11

Cfg BO1-BO2 Floating Time

X

R/W

MV

12

Cfg BO3-BO4 Floating Time

X

R/W

MV

13

Cfg AI4 Configuration

X

X

R/W

MV

14

Cfg Proportional Band

X

X

R/W

MV

15

Page 8

8

Object Name

VZ7656R1000B

VZ7656H1000B

VZ7656F1000B

VZ7656E1000B

Object Property

Object Type

Instance #

GUI Discharge Air Temp

X X X

X

R

AI 1 GUI Analog Heat Output

X R AI 5 GUI By-Pass Damper / VFD

X X X

X

R

AI 4 GUI Return Air Temp

X X X

X

R

AI 2 GUI Static Pressure

X X X

X

R

AI 3 Cfg RTC MAC

X X X

X

R

AV 1 Cfg Device Instance

X X X

X

R

AV

21

GUI Highest PI Cool Demand

X X X

X

R

AV

18

GUI Highest PI Heat Demand

X X X

X

R

AV

17

GUI CO2 Level

X

R

AV

40

GUI Current Zone PI Cool

Demand

X X X

X

R

AV

12

GUI Current Zone PI Heat

Demand

X X X

X

R

AV

11

GUI Economizer Output

X

R

AV

42

GUI Fresh Air Level

X

R

AV

39

GUI Highest CO2 Zone

X R

AV

41

GUI Highest PI Cool Zone

X X X

X

R

AV

16

GUI Highest PI Heat Zone

X X X

X

R

AV

15

GUI Supply PI Heat Demand

X R AV

28

GUI Transferred PI Cool

Demand

X X X

X

R

AV

14

GUI Transferred PI Heat

Demand

X X X

X

R

AV

13

Cfg Changeover Setpoint

X

R/W

AV

30

Cfg Cooling Lockout Temp

X X X

X

R/W

AV 3 Cfg Deadband

X X X

X

R/W

AV

22

Cfg Discharge High Limit Spt

X X X

X

R/W

AV

5

Cfg Discharge Low Limit Spt

X X X

X

R/W

AV

6

Cfg Economizer Max Position

X

R/W

AV

33

Cfg Economizer Min Position

X

R/W

AV

32

Cfg Fresh Air Max Range

X

R/W

AV

34

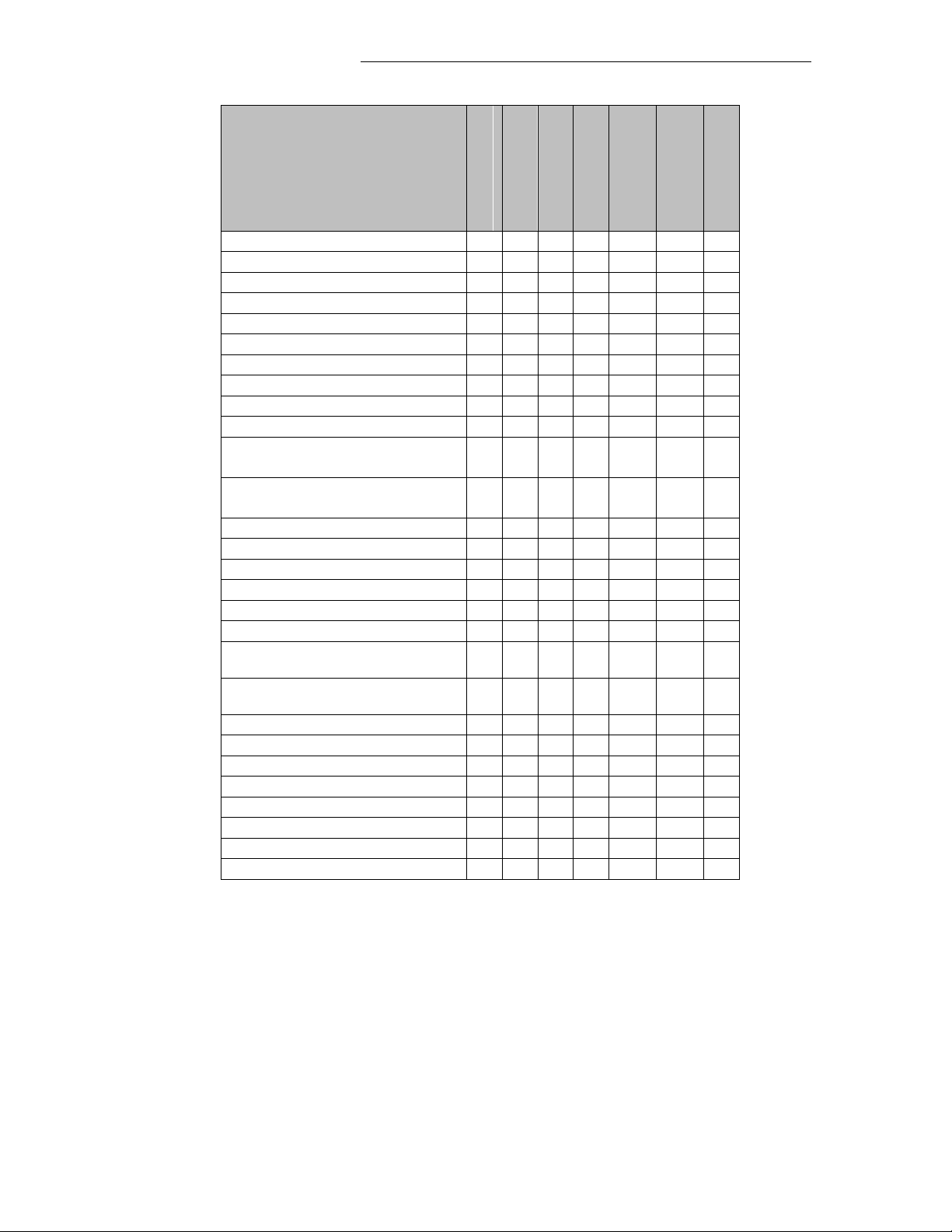

Device Object List for VZ7656 Models

Page 9

9

Object Name

VZ7656R1000B

VZ7656H1000B

VZ7656F1000B

VZ7656E1000B

Object Property

Object Type

Instance #

Cfg Heating Lockout Temp

X X X

X

R/W

AV 2 Cfg High Balance Point

X R/W

AV

24

Cfg Low Balance Point

X R/W

AV

25

Cfg Maximum CO2 Level

X

R/W

AV

38

Cfg Maximum Fresh Air

X

R/W

AV

36

Cfg Minimum CO2 Level

X

R/W

AV

37

Cfg Minimum Fresh Air

X

R/W

AV

35

Cfg Minimum Supply Heat

Setpoint

X

R/W

AV

26

Cfg Mixed Air Setpoint

X

R/W

AV

31

Cfg Password

X X X

X

R/W

AV

23

Cfg Power-up Delay

X X X

X

R/W

AV

20

Cfg Return Air Occ CL Spt

X X X

X

R/W

AV 7 Cfg Return Air Occ HT Spt

X X X

X

R/W

AV

9

Cfg Return Air Unocc CL

Spt

X X X

X

R/W

AV

8

Cfg Return Air Unocc HT

Spt

X X X

X

R/W

AV

10

Cfg Static Pressure Spt

X X X

X

R/W

AV

4

Cfg Supply Heat Lockout

Temperature

X

R/W

AV

27

GUI Outdoor Temperature

X X X

X

R/W

AV

19

GUI AUX Status

X X X

R BI 7 GUI BI Status

X X X

R BI 6 GUI G Fan

X X X

X

R

BI 1 GUI W1 Heat

X

X X

R

BI 4 GUI W2 Heat

X

X R

BI 5 GUI Y1 Compressor

X R

BI

16

GUI Y1 Cool

X X

X

R

BI 2 GUI Y2 Compressor

X R

BI

15

GUI Y2 Cool

X X

X

R

BI 3 Sta Clock Alarm

X X X

X

R

BI

12

Sta Cooling Lockout Status

X X X

X

R

BI 9 Sta Discharge Temp Alarm

X X X

X

R

BI

13

Sta Filter Alarm

X X X

X

R

BI

11

Sta Fresh Air Alarm

X R

BI

17

Page 10

10

Object Name

VZ7656R1000B

VZ7656H1000B

VZ7656F1000B

VZ7656E1000B

Object Property

Object Type

Instance #

Sta Heating Lockout Status

X X X

X

R

BI 8 Sta High CO2 Alarm

X R

BI

18

Sta Reversing Valve Status

X R

BI

14

Sta Service Alarm

X X X

X

R

BI

10

GUI Smart Recovery

X X X

X

R

BV 7 Sta Comm Lost Status

X X X

X

R

BV 3 Sta Supply Heat Lockout Status

X R BV

12

Cfg Aux Contact

X X X

R/W

BV 4 Cfg Compressor Interlock

X R/W

BV

11

Cfg Emergency Heat Mode

X R/W

BV 9 Cfg Fan Purge Delay

X X X

X

R/W

BV 5 Cfg Progressive Recovery

X X X

X

R/W

BV 2 Cfg Reversing Valve

X R/W

BV

10

Cfg Static Pressure Ctrl Type

X X X

X

R/W

BV 8 Cfg Units

X X X

X

R/W

BV 1 GUI Outdoor Temp Override

X X X

X

R/W

BV 6 Cfg RTC Baud

X X X

X

R

MV

1

GUI Zone Sequence

X X X

X

R

MV

4

Cfg BI1 Configuration

X X X

R/W

MV

11

Cfg CO2 Control Type

X R/W

MV

18

Cfg Control Type

X X X

X

R/W

MV

2

Cfg Cooling CPH

X X X

X

R/W

MV

9

Cfg Cooling Stages

X X

X

R/W

MV

7

Cfg Event Display

X X X

X

R/W

MV

13

Cfg Heat Pump Stages

X R/W

MV

16

Cfg Heating CPH

X

X X

R/W

MV

8

Cfg Heating Stages

X

X R/W

MV

6

Cfg Local Keypad Lockout

X X X

X

R/W

MV

3

Cfg Minimum On/Off Time

X X X

X

R/W

MV

10

Cfg Static Pressure Transducer

Range

X X X

X

R/W

MV

5

Cfg Temporary Occupied Time

X X X

X

R/W

MV

12

GUI System Mode

X X

X

R/W

MV

15

GUI System Mode HP

X R/W

MV

17

GUI Occupancy

X X X

X

R/W

MV

14

GUI Schedule

X X X

X

R

SCH

1

Page 11

11

Object Name

Type and

Instance

Object Property

Controller Parameter

VZ7260F5x00B

Device

Object_Identifier

Property 75 (R,W)

Unique ID number of a device on a network

Object_Name

Property 77 (R,W)

Unique name of a Device on a network

Model Name

Property 70 (R)

Controller Model number

Firmware Revision

Property 44 (R)

Current BACnet firmware revision used by the

controller

Protocol Version

Property 98 (R)

Current BACnet firmware protocol version

Default is Version 1

Protocol Revision

Property 139 (R)

Current BACnet firmware protocol revision

Default is Version 2

Max ADPU Length

Property 62 (R)

Maximum ADPU Length accepted

Default is 244

ADPU Timeout

Property 10 (R)

ADPU timeout value

Default is60 000 ms

Max_Master (R,W)

Maximum master devices allowed to be part of the

network. 0 to 127, default is 127

VZ7260 Device Object Table

Page 12

12

Object Type

Supported

Dynamically

Creatable

Dynamically

Removable

Optional

Properties

Supported

Writable Properties

Analog Input

Reliability

Out_of_Service

Analog Value

Reliability

Present_Valuea

Out_of_Service

Binary Input

Reliability

Active_Text

Inactive_Text

Out_of_Service

Binary Value

Reliability

Active_Text

Inactive_Text

Present_Valueb

Out_of_Service

Device

Max_Master

Max_Info_frames

Object_Identifier

Object_name

Max_Master

Multi-state Value

Reliability

States_Text

Present_Valuec

Out_of_Service

VZ7260 Standard Object Types Supported

a: Present_Value property is writable for every AV objects except :

Cfg Zone MAC (AV 1)

Cfg RTC MAC (AV 2)

GUI AO2 Status (AV 17)

GUI UI3 Status (AV 18)

GUI PI Heat Weighted Demand (AV 19)

GUI PI Cool Weighted Demand (AV 20)

GUI Room Temperature (AV 21) ( Present Value can be only be written if BV 10 GUI Room Temp

Override is set to true )

GUI Outdoor Temperature (AV 22)

Cfg Device Instance (AV 23) – This object is not writable even when OUT OF SERVICE is TRUE.

Changing the device ID will affect communication to the device even is OUT OF SERVICE is TRUE, so

it’s not recommended.

b: Present_Value property is writable for every BV objects except :

GUI BO5 Status (BV 7)

Sta AO2 Lock Status (BV 8)

Sta BO5 Lock Status (BV 9)

Sta RTC Prog Recovery (BV 11)

c: Present_Value property is writable for every MV objects except :

Cfg Zone Baud (MV 1)

GUI Occupancy (MV 9) ( Present Value can be only be written permanently if MV 7 Cfg Network

Handle is set to index 2 or 3. Index 1 resets present value as per application )

GUI Effective Occupancy (MV 11)

Page 13

13

Object name

Object Type

and instance

Under range

value

Over range

value

Default

value

GUI Damper Position

AI 1

0%

100%

N/A

Cfg Zone MAC

AV 1 1 255

255

Cfg RTC MAC

AV 2 1 127

4

Cfg AO2 OA Lock Setpoint

AV 3

-40°F (-40°C)

122°F (50°C)

55°F (13°C)

Cfg BO5 OA Lock Setpoint

AV 4

-40°F (-40°C)

122°F (50°C)

32°F (0°C)

Cfg Damper Min Pos

AV 5

0%

100%

10%

Cfg Damper Max Pos

AV 6

0%

100%

100%

Cfg Damper Max Heat Pos

AV 7

0%

100%

30%

Cfg Heating Spt Limit

AV 8

40°F (4.5°C)

90°F (32°C)

90°F (32°C)

Cfg Cooling Spt Limit

AV 9

54°F (12°C)

100°F (37.5)

54°F (12°C)

Cfg Deadband

AV 10

2°F (1°C)

5°F (2.5°C)

2°F (1°C)

GUI Occupied Heat Spt

AV 11

40°F (4.5°C)

90°F (32°C)

72°F (22°C)

GUI Occupied Cool Spt

AV 12

54°F (12°C)

100°F (37.5°C)

74°F (24°C)

GUI Unoccupied Heat Spt

AV 13

40°F (4.5°C)

90°F (32°C)

72°F (22°C)

GUI Unoccupied Cool Spt

AV 14

54°F (12°C)

100°F (37.5°C)

74°F (24°C)

GUI Stand-by Heat Spt

AV 15

40°F (4.5°C)

90°F (32°C)

62°F

(16.5°C)

GUI Stand-by Cool Spt

AV 16

54°F (12°C)

100°F (37.5°C)

80°F

(26.5°C)

GUI AO2 Status

AV 17

0%

100%

N/A

GUI UI3 Status

AV 18

-40°F (-40°C)

122°F (50°C)

N/A

GUI PI Heat Weighted

Demand

AV 19

0%

100%

N/A

GUI PI Cool Weighted

Demand

AV 20

0%

100%

N/A

GUI Room Temperature

AV 21

-40°F (-40°C)

122°F (50°C)

N/A

GUI Outdoor Temperature

AV 22

-40°F (-40°C)

122°F (50°C)

N/A

Cfg Device Instance

AV 23

72000

72255

N/A

GUI PI Heat Demand

AV 24

0%

100%

N/A

GUI PI Cool Demand

AV 25

0%

100%

N/A

Cfg Password

AV 26

0

1000

N/A

Cfg Stand-by Time

AV 27

0.5 hours

24 hours

0.5 hours

Cfg Unoccupied Time

AV 28

0 hours

24 hours

0 hours

GUI Heating Performance

AV 29

32°F (0°C)

100°F (37.5°C)

N/A

GUI Cooling Performance

AV 30

32°F (0°C)

100°F (37.5°C)

N/A

Cfg BO3-BO4 OA Lock Spt

AV 31

-40°F (-40°C)

122°F (50°C)

N/A

GUI Room CO2 Level

AV 32

0 PPM

2000 PPM

N/A

GUI Transferred CO2 Value

AV 33

0 PPM

2000 PPM

N/A

GUI AI4 Value

AV 34

0 VDC

10 VDC

N/A

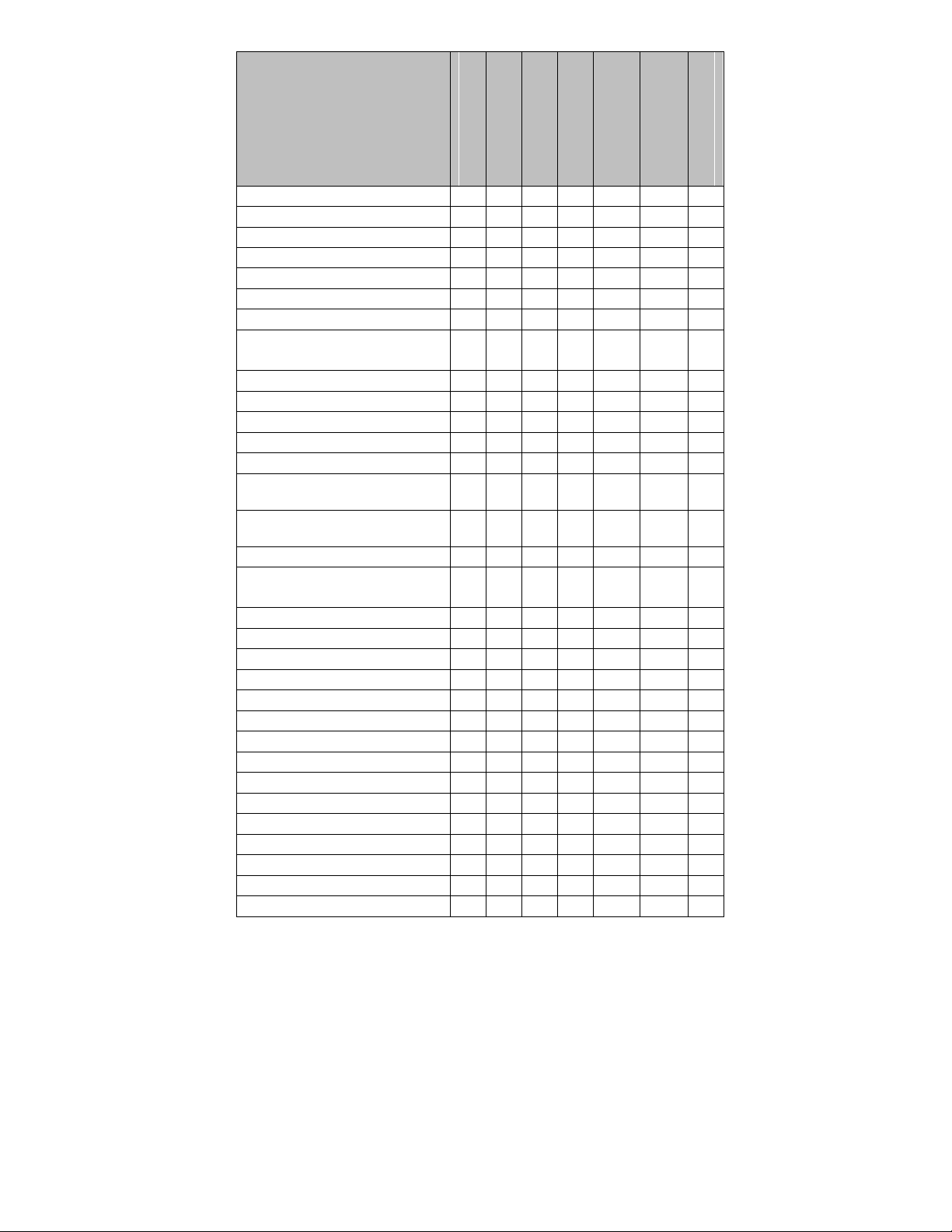

VZ7260 List of Property Value Range Restrictions for AI and AV objects

Page 14

14

Object Name

Object Type and

instance

Inactive_Text

Active_Text

Default

value

GUI BI 1 Status

BI 1

Not Activated

Activated

Not Activated

GUI BI 2 Status

BI 2

Not Activated

Activated

Not Activated

Cfg Temperature Scale

BV 1

°C

°F

°F

Cfg Menu Scroll

BV 2

No Scroll

Scroll Active

Scroll Active

Cfg Motion Detector

Function

BV 3

Not Activated

Activated

Not Activated

Cfg AO2 RA/DA

BV 4

Direct Acting

Reverse

Acting

Direct Acting

Cfg BO5 Time Base

BV 5

15 Minutes

10 Seconds

15 Minutes

Cfg BO5 Configuration

BV 6

N.O.

N.C.

N.O.

GUI BO5 Status

BV 7

Off

On

Off

Sta AO2 Lock Status

BV 8

Not Activated

Activated

Not Activated

Sta BO5 Lock Status

BV 9

Not Activated

Activated

Not Activated

GUI Room Temp Override

BV 10

Normal

Override

Normal

Sta RTC Prog Recovery

BV 11

Off

On

Off

Cfg Setpoint Type

BV 12

Permanent

Temporary

Permanent

Cfg Disable Min Pos

BV 13

Enabled

Disabled

Disabled

Sta BO3-BO4 Lock Status

BV 14

Inactive

Active

Inactive

VZ7260 List of Property Enumeration Sets for BI and BV objects

Page 15

15

Object Name

Object

Type and

instance

BACnet Index

Text

Default value

Cfg Zone Baud

MV 1

1

9600 ( Bps )

Auto

2

19200 ( Bps )

3

38400 ( Bps )

4

76800 ( Bps )

5

Auto

Cfg Reheat

Configuration

MV 2

1

None

None

2

Analog Duct Heater

Only

3

On/Off Duct Heater

Only

4

On/Off Perimeter

Heater Only

5

Analog Duct Heater

with On/Off Perimeter

Heater

Cfg BI1

Configuration

MV 3

1

None

None

2

Motion NO

3

Motion NC

Cfg PI Heat Weight

MV 4

1

0 %

100 %

2

25 %

3

50 %

4

75 %

5

100 %

Cfg PI Cool Weight

MV 5

1

0 %

100 %

2

25 %

3

50 %

4

75 %

5

100 %

Cfg Temporary

Occupancy Time

MV 6

1

0 hour

2 hours

2

1 hour

3

2 hours

4

3 hours

5

4 hours

6

5 hours

7

6 hours

8

7 hours

9

8 hours

10

9 hours

11

10 hours

12

11 hours

13

12 hours

VZ7260 List of Property Enumeration Sets for MV Objects

Page 16

16

Object Name

Object

Type and

instance

BACnet Index

Text

Default value

Network Handle

MV 7

1

Default Zone Handle

Default Zone

Handle

2

Default Minus

Occupancy

3

Full Release

Network Handle

Occupancy

PI Heat

Weighted

PI Cool

Weighted

Prog Rec

Enabled

RTC

Sequence

1 = Default Zone

Handling

From the

VZ76

To the VZ76

To the VZ76

From the

VZ76

From the

VZ76

2 = Zone Handling

minus occupancy

To the VZ76

To the VZ76

From the

VZ76

From the

VZ76

3 = Full Release

The VZ7260 controller will operate without any dependencies from the VZ7656

RTU controller. It can be fully integrated with any supervision device for control

and operation

Object Name

Object

Type and

instance

BACnet Index

Text

Default value

Cfg Zone Keypad

Lockout

MV 8

1

Level 0

Level 0

2

Level 1

3

Level 2

4

Level 3

GUI Occupancy

Command

MV 9

1

Local Occupancy

Local Occupancy

2

Occupied

3

Unoccupied

Cfg RTC Zone

Sequencing

MV 10

1

Cool

Cool

2

Heat

GUI Effective

Occupancy

MV 11

1

Occupied

Depends on local

occupancy

2

Unoccupied

3

Temporary Occupied

4

Stand-by

Cfg BO1-BO2

Floating Time

MV 12

1

0.5 minutes

1. 5 minutes

2

1 minute

3

1.5 minutes

4

2 minutes

5

2.5 minutes

6

3 minutes

7

3.5 minutes

8

4 minutes

9

4.5 minutes

10

5 minutes

11

5.5 minutes

12

6 minutes

13

6.5 minutes

14

7 minutes

15

7.5 minutes

16

8 minutes

17

8.5 minutes

18

9 minutes

This property is used to release the functions of the VZ7260 Zone controller from its attached master RTC VZ7656. It is used

when remote scheduling of the zones are required externally to the master VZ7656 RTU controller or when integration is

required without a VZ7656 RTU controller.

Page 17

17

Object Name

Object

Type and

instance

BACnet Index

Text

Default value

Cfg BO3-BO4

Floating Time

MV 13

1

0.5 minutes

1.5 minutes

2

1 minute

3

1.5 minutes

4

2 minutes

5

2.5 minutes

6

3 minutes

7

3.5 minutes

8

4 minutes

9

4.5 minutes

10

5 minutes

11

5.5 minutes

12

6 minutes

13

6.5 minutes

14

7 minutes

15

7.5 minutes

16

8 minutes

17

8.5 minutes

18

9 minutes

Cfg A14

Configuration

MV 14

1

None

None

2

CO2

Cfg Proportional

Band

MV 15

1

3°F(1.7°C)

3°F(1.7°C)

2

4°F(2.2°C)

3

5°F(2.8°C)

4

6°F(3.3°C)

5

7°F(3.9°C)

6

8°F(4.4°C)

7

9°F(5.0°C)

8

10°F(5.6°C)

Page 18

18

VZ7260 Integration

Please note that no special programming or network bindings are required for the Zoning system to operate. As

such the VZ7260 Zone controllers and their associated VZ7656 RTU controller can operate in stand-alone mode

with all required data transfer binding already handled by the controllers themselves. If BACnet supervision is

added, it is only for GUI, trends, logs or remote views of the devices. The zoning system operation is already taken

care of by the controllers themselves.

The example showed below is valid on MV 7 (Network Handle) index being: 1 – Default Zone Handle. As such

outdoor temperature, Zone mode and Zone Occupancy are NOT dependent on the BAS font end and are objects

dependent on the attached VZ76561000B RTU controller

All object names staring with a “GUI” prompt are normally used for graphic GUI views.

All object names staring with a “Sta” prompt are Status normally used for graphic GUI views.

All object name staring with a “Cfg” prompt are associated to configuration properties of the controller and

typically do not need to be associated to any GUI views

If your BAS allows you to remove objects from your database, Viconics recommends removing all configuration

objects once your setup is complete. This will prevent unnecessary polling of non-used objects and will help speed

up your network.

The following figure shows the typical objects from the controller which can be monitored and commanded from a

BAS front-end.

The following objects could be typically used in a GUI:

Room Temperature (AV 21);

Occupied, Stand-by and Unoccupied Heat Setpoints (AV 11, AV 13 and AV 15);

Occupied, Stand-by and Unoccupied Cool Setpoints (AV 12, AV 14 and AV 16);

Outdoor Temperature (AV 22); Value from VZ7656

UI3 Status / Supply Temperature (AV 18) (If available);

Occupancy Command (MV 9); Value from VZ7656

RTC Zone Sequencing (MV 10);

Damper Position (AI 1);

AO2 Status (AV 17);

PI Heat Demand & Weighted PI Heat Demand (AV 19 & AV 24)

PI Cool Demand & Weighted PI Cool Demand (AV 20 & AV 25)

Page 19

19

BACnet Interoperability Building Block

Data Sharing COV-B (DS-COV-B)

Data Sharing-ReadProperty-B (DS-RP-B)

Data Sharing-ReadPropertyMultiple-B (DS-RPM-B)

Data Sharing-WriteProperty-B (DS-WP-B)

Device Management-Dynamic Device Binding-B (DM-DDB-B)

Device Management-Dynamic Object Binding-B (DM-DOB-B)

Device Management-DeviceCommunicationControl-B (DM-DCC-B)

Device Management-TimeSynchronisation-B (DM-TS-B)

Scheduling-Readonly-B (SCHED-R-B)

VZ7656 Series Protocol Implementation Conformance Statement (PICS)

Vendor Name: Viconics

Vendor ID: 140

Product Name: VZ7656 Zoning System RTU Controller

Product Model Number: VZ76561000B

Product Description:

The Viconics VZ76561000B controller is specifically designed for RTU control of the Viconics Zoning System

product family.

The RTU controller is designed for single stage or multi-stage control of heating and cooling equipment such as

rooftop and self-contained units used in zoning systems.

The controllers are used in conjunction with the Viconics VZ7260F5x00B Zone controllers for total system

operation of each zones and the RTU.

VZ7656 Supported BACnet Services

The BACnet communicating controller meets all requirements for designation as an Application Specific Controller

(B-ASC). The BACnet controller series supports the following BACnet Interoperability Building Blocks (BIBBs).

Note: The controller does not support segmented requests or responses.

Page 20

20

Object Name

Type and

Instance

Object Property

Controller Parameter

VZ7656

Device

Object_Identifier

Property 75 (R,W)

Unique ID number of a device on a network

Object_Name

Property 77 (R,W)

Unique name of a Device on a network

Model Name

Property 70 (R)

Controller Model number

Firmware Revision

Property 44 (R)

Current BACnet firmware revision used by the

controller

Protocol Version

Property 98 (R)

Current BACnet firmware protocol version

Default is Version 1

Protocol Revision

Property 139 (R)

Current BACnet firmware protocol revision

Default is Version 2

Max ADPU Length

Property 62 (R)

Maximum ADPU Length accepted

Default is 244

ADPU Timeout

Property 10 (R)

ADPU timeout value

Default is60 000 ms

Max_Master (R,W)

Maximum master devices allowed to be part of the

network. 0 to 127, default is 127

VZ7656 Device Object Table

Page 21

21

Object Type

Supported

Dynamically

Creatable

Dynamically

Removable

Optional

Properties

Supported

Writable Properties

Analog Input

Reliability

Out_of_Service

Analog Value

Reliability

Present_Valuea

Out_of_Service

Binary Input

Reliability

Active_Text

Inactive_Text

Out_of_Service

Binary Value

Reliability

Active_Text

Inactive_Text

Present_Valueb

Out_of_Service

Device

Max_Master

Max_Info_frames

Object_Identifier

Object_name

Max_Master

Multi-state Value

Reliability

States_Text

Present_Valuec

Out_of_Service

Schedule

Weekly_schedule

Read Only

VZ7656 Standard Object Types Supported

a: Present_Value property is writable for every AV objects except :

Cfg RTC MAC (AV 1)

GUI Current Zone PI Heat Demand (AV 11)

GUI Current Zone PI Cool Demand (AV 12)

GUI Transferred PI Heat Demand (AV 13)

GUI Transferred PI Cool Demand (AV 14)

GUI Highest PI Heat Zone (AV 15)

GUI Highest PI Cool Zone (AV 16)

GUI Highest PI Heat Demand (AV 17)

GUI Highest PI Cool Demand (AV 18)

Cfg Device Instance (AV 21)

b: Present_Value and Out_of_Service properties are writable for every BV objects except :

Sta Comm Lost Status (BV 3)

Sta Smart Recovery (BV 7)

c: Present_Value and Out_of_Service properties are writable for every MV objects except :

Cfg RTC Baud (MV 1)

GUI Zone Sequence (MV 4)

Page 22

22

Object name

Object Type

and instance

Under range

value

Over range

value

Default value

GUI Discharge Air Temp

AI 1

-40°F (-40°C)

150°F (65°C)

N/A

GUI Return Air Temp

AI 2

-40°F (-40°C)

122°F (50°C)

N/A

GUI Static Pressure Input

AI 3

0” WC

(0 Pa)

5” WC

(1250 Pa)

N/A

GUI By-Pass Damper

AI 4

0%

100%

N/A

Cfg RTC MAC

AV 1

1

255

4

Cfg Heating Lockout

Temperature

AV 2

-15°F (-26°C)

120°F (49°C)

120°F (49°C)

Cfg Cooling Lockout

Temperature

AV 3

-40°F (-40°C)

95°F (35°C)

-40°F (-40°C)

Cfg Static Pressure Spt

AV 4

0” WC

(0 Pa)

2” WC

(500 Pa)

0.8” WC

(200 Pa)

Cfg Discharge High Limit Spt

AV 5

70°F (21°C)

150°F (65°C)

120°F (49°C)

Cfg Discharge Low Limit Spt

AV 6

35°F (2°C)

65°F (19°C)

45°F (7°C)

Cfg Return Air Occ Cool Spt

AV 7

54°F (12°C)

100°F (37.5°C)

74°F (24°C)

Cfg Return Air Unocc Cool Spt

AV 8

54°F (12°C)

100°F (37.5°C)

74°F (24°C)

Cfg Return Air Occ Heat Spt

AV 9

40°F (4.5°C)

90°F (32°C)

72°F (22°C)

Cfg Return Air Unocc Heat Spt

AV 10

40°F (4.5°C)

90°F (32°C)

72°F (22°C)

GUI Current Zone

PI Heat Demand

AV 11

0%

100%

N/A

GUI Current Zone

PI Cool Demand

AV 12

0%

100%

N/A

GUI Transferred PI Heat Demand

AV 13

0%

100%

N/A

GUI Transferred PI Cool Demand

AV 14

0%

100%

N/A

GUI Highest PI Heat Zone

(Com Address)

AV 15

0

255

N/A

GUI Highest PI Cool Zone

(Com Address)

AV 16

0

255

N/A

GUI Highest PI Heat Demand

AV 17

0%

100%

N/A

GUI Highest PI Cool Demand

AV 18

0%

100%

N/A

GUI Outdoor Temperature

AV 19

-40°F (-40°C)

122°F (50°C)

N/A

Cfg Power Delay

AV 20

10 Seconds

120 Seconds

30 Seconds

Cfg Device Instance

AV 21

76000

76255

N/A

Cfg Deadband

AV 22

2°F (1°C)

4°F (2°C)

2°F (1°C)

Cfg Password

AV 23

0

1000

N/A

Cfg High Balance Point

AV 24

34°F(1°C)

90°F(32°C)

90°F(32°C)

Cfg Low Balance Point

AV 25

-40°F(1°C)

-40°F(32°C)

-40°F(-40°C)

Cfg Minimum Supply Heat

Setpoint

AV 26

50°F(1°C)

72°F(32°C)

64°F(18°C)

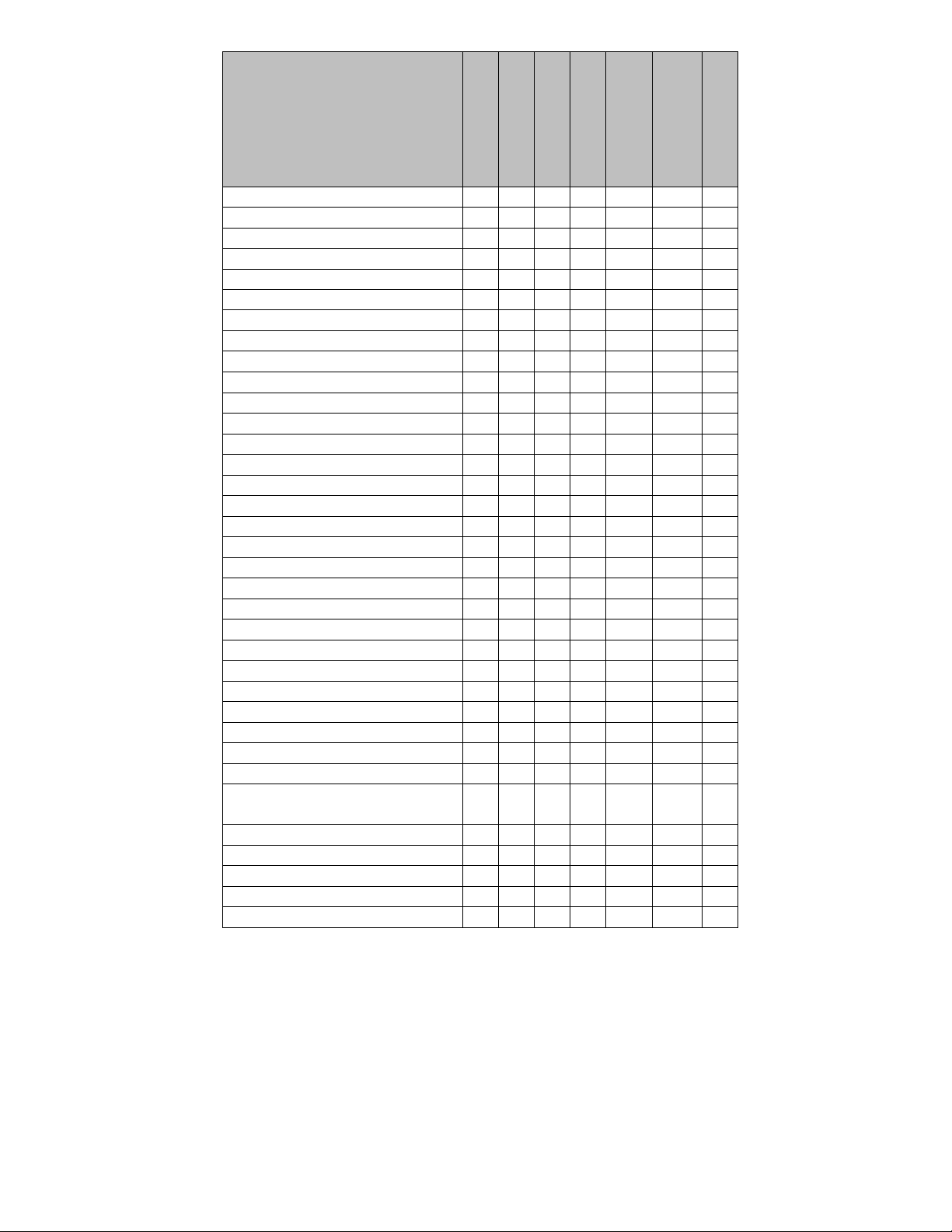

VZ7656 List of Property Value Range Restrictions for AI and AV objects

Page 23

23

Cfg Supply Heat Lockout

AV 27

-15°F(-26°C)

120°F(49°C)

32°F(0°C)

GUI Supply PI Heat Demand

AV 28

0%

100%

N/A

Cfg Changeover Setpoint

AV 30

14°F(-26°C)

70°F(-26°C)

55°F(13°C)

Cfg Mixed Air Setpoint

AV 31

50°F(10°C)

90°F(32°C)

55°F(13°C)

Cfg Economizer Min Position

AV 32

0%

100%

0%

Cfg Economizer Max Position

AV 33

0%

100%

100%

Cfg Fresh Air Max Range

AV 34

0 CFM (0 l/s)

20000 CFM

(9440 l/s)

0 CFM (0 l/s)

Cfg Minimum Fresh Air

AV 35

0 CFM (0 l/s)

20000 CFM

(9440 l/s)

0 CFM (0 l/s)

Cfg Maximum Fresh Air

AV 36

0 CFM (0 l/s)

20000 CFM

(9440 l/s)

0 CFM (0 l/s)

Cfg Minimum CO2 Level

AV 37

0 PPM

2000 PPM

800 PPM

Cfg Maximum CO2 Level

AV 38

0 PPM

2000 PPM

1200 PPM

GUI Fresh Air Level

AV 39

0 CFM (0 l/s)

20000 CFM

(9440 l/s)

N/A

GUI CO2 Level

AV 40

0 PPM

2000 PPM

N/A

GUI Highest CO2 Zone

AV 41

1

127

N/A

GUI Economizer Output

AV 42

0%

100%

N/A

Note:

The GUI Current Zone PI Heat & Cool Demand objects represent the actual calculated average demand values from either the

highest, the demands of the actual highest 3 zones or the demands of the actual highest 5 zones as per selected by MV2

Control Type object.

Page 24

24

Object Name

Object Type and

instance

Inactive_Text

Active_Text

Default

value

GUI G Fan

BI 1

Off

On

N/A

GUI Y1 Cool

BI 2

Off

On

N/A

GUI Y2 Cool

BI 3

Off

On

N/A

GUI W1 Heat

BI 4

Off

On

N/A

GUI W2 Heat

BI 5

Off

On

N/A

GUI BI 1 Status

BI 6

Not Activated

Activated

Not Activated

GUI Aux Status

BI 7

Off

On

N/A

Sta Heating Stages Lockout

Status

BI 8

Not Activated

Activated

Not Activated

Sta Cooling Stages Lockout

Status

BI 9

Not Activated

Activated

Not Activated

Sta Service Alarm

BI 10

Off

On

Off

Sta Filter Alarm

BI 11

Off

On

Off

Sta Clock Alarm

BI 12

Off

On

Off

Sta Discharge Temp Alarm

BI 13

Off

On

Off

Sta Reversing Valve Status

BI 14

Off

On

Off

GUI Y2 Compressor

BI 15

Off

On

Off

GUI Y1 Compressor

BI 16

Off

On

Off

Sta Fresh Air Alarm

BI 17

Off

On

Off

Sta High CO2 Alarm

BI 18

Off

On

Off

Cfg Units

BV 1

°C / SI Units

°F / Imperial

Units

°F / Imperial

Units

Cfg Progressive Recovery

BV 2

Off

Active

Off

Sta Com Lost Status

BV 3

Down

Up

N/A

Cfg Aux Contact

BV 4

N.O.

N.C.

N.O.

VZ7656 List of Property Enumeration Sets for BI and BV objects

Page 25

25

Cfg Fan Purge Delay

BV 5

Off

On

Off

GUI Outdoor Temp

Override

BV 6

Normal

Override

Normal

Cfg Smart Recovery

BV 7

Off

Active

Off

Cfg Static Pressure Ctrl

Type

BV 8

By-Pass

Damper

VFD

VFD

Cfg Emergency Heat Mode

BV 9

Off

On

On

Cfg Reversing Valve

BV 10

Normally Cool

Normally

Heat

Normally

Heat

Cfg Compressor Interlock

BV 11

Off

On

On

Sta Supply Heat Lockout

Status

BV 12

Inactive

Active

Active

Page 26

26

Object Name

Object

Type and

instance

BACnet Index

Text

Default value

Cfg RTC Baud

MV 1

1

9600 ( Bps )

Auto

2

19200 ( Bps )

3

38400 ( Bps )

4

76800 ( Bps )

5

Auto

Cfg Control Type

MV 2

1

Highest

AV_H3 /Average

of Highest 3

Zones

2

AV_H3 /Average of

Highest 3 Zones

3

AV_H5 /Average of

Highest 5 Zones

Cfg Local Keypad

Lockout

MV 3

1

Level 0 / No Lockout

Level 0 / No

Lockout

2

Level 1

3

Level 2

GUI Zone

Sequence

MV 4

1

Off / Never used

Cool

2

Cool

3

Heat

Cfg Static Pressure

Transducer Range

MV 5

1

0 to 1.5“ of WC

0 to 1.5“ of WC

2

0 to 2.0“ of WC

3

0 to 3.0“ of WC

4

0 to 4.0“ of WC

5

0 to 5.0“ of WC

Cfg Heating Stages

MV 6

1

1 Stage

2 Stages

2

2 Stages

Cfg Cooling Stages

MV 7

1

1 Stage

2 Stages

2

2 Stages

Cfg Heating CPH

MV 8

1

3 CPH

4 CPH

2

4 CPH

3

5 CPH

4

6 CPH

5

7 CPH

6

8 CPH

Cfg Cooling CPH

MV 9

1

3 CPH

4 CPH

2

4 CPH

Cfg Min. On/Off

Time

(Anticycle)

MV 10

1

0 minute

2 minutes

2

1 minute

3

2 minutes

4

3 minutes

5

4 minutes

6

5 minutes

VZ7656 List of Property Enumeration Sets for MV Objects

Page 27

27

Object Name

Object

Type and

instance

BACnet Index

Text

Default value

Cfg BI1

Configuration

MV 11

1

None

None

2

RemNSB

3

RemOVR

4

Filter

5

Service

Cfg Temporary

Occupancy Time

MV 12

1

0 hour

2 hours

2

1 hour

3

2 hours

4

3 hours

5

4 hours

6

5 hours

7

6 hours

8

7 hours

9

8 hours

10

9 hours

11

10 hours

12

11 hours

13

12 hours

Cfg Event Display

MV 13

1

2 Events

2 Event

2

4 Events

GUI Occupancy

MV 14

1

Local Occupancy

Local Occupancy

2

Occupied

3

Unoccupied

GUI System Mode

MV 15

1

Off

Auto

2

Auto

Cfg Heat Pump

Stages

MV 16

1

1 Stage

2 Stages

2

2 Stages

GUI System Mode

HP

MV 17

1

Off

Auto

2

Auto

3

Cool

4

Heat

5

Emergency Heat

Cfg CO2 Control

Type

MV 18

1

Highest

AV_H3

2

AV_H3

3

AV_H5

Page 28

28

(BI 38)

(BI 25)

(BI 26)

(BI 27)

(BI 28)

(BI 29)

(MV 12)

(MV 14)

(BI 24)

(BI 31)

( B I 3 2 )

(BI 36)

(BI 39)

(AI 16)

(AV 42)

(AV 43)

(AV 44)

(AV 45)

Return Air Temperture (AI 2)

VZ7656 Integration

Please note that no special programming or network bindings are required for the Zoning system to operate. As

such the VZ7260 Zone controllers & their associated VZ7656 RTU controller can operate in stand-alone mode with

all required data transfer binding already handled by the controllers themselves. If BACnet supervision is added, it

is only for GUI, trends, logs or remote views of the devices. The zoning system operation is already taken care of

by the controllers.

All object names staring with a “GUI” prompt are normally used for graphic GUI views.

All object names staring with a “Sta” prompt are Status normally used for graphic GUI views.

All object name staring with a “Cfg” prompt are associated to configuration properties of the controller and

typically do not need to be associated to any GUI views

If your BAS allows you to remove objects from your database, Viconics recommends removing all configuration

objects once your setup is complete. This will prevent unnecessary polling of non used objects and will help speed

up your network.

The following figure shows the typical objects from the controller can be monitored and commanded from a BAS

front-end.

The following objects could be typically used in a GUI:

Return Air Temperature (AI 2); Outdoor Temperature (AV 19); Discharge Air Temperature (AI 1)

Return Air Occupied and Unoccupied Heat Setpoints (AV 9 and AV 10);

Return Air Occupied and Unoccupied Cool Setpoints (AV 7 and AV 8);

Static Pressure & Static Pressure Setpoint (A1 3 and AV 4)

Occupancy (MV 14); System Mode (MV 15); Zone Sequence (MV 4);

G Fan (BI 1); Y1 Cool (BI 2); Y2 Cool (BI 3); W1 Heat (BI 4); W2 Heat (BI 5);

Aux Status (BI 7); BI 1 Status (BI 6);

Filter Alarm (BI 11) (if available); Service Alarm (BI 10) (if available);

Discharge Air Temperature Alarm (BI 13)

Current Zone PI Heat Demand (AV 11);

Current Zone PI Cool Demand (AV 12);

Page 29

29

Parameter

Details

Media

Twisted pair 22AWG-24 AWG, shielded recommended

Characteristic Impedance

100-130 ohms

Distributed capacitance

Less than 100 pF per meter (30 pF per foot)

Maximum length per segment

1200 meters (4000 feet) Note: AWG 18 cable

Polarity

Polarity sensitive

Multi-drop

Daisy-chain (no T connections)

Terminations

1. Viconics’ devices are installed at both ends of the

MSTP network:

120 Ohms resistor should be installed at each end.

2. A Viconics device is installed at one end of the MSTP

network and a 3rd party device is installed at the other

end:

Install an End-Of-Line resistor value that matches the 3 rd

party device instruction regarding the End-Of-Line resistors

3. 3rd party devices are installed at both ends of the MSTP

network:

Follow the 3rd party device instructions regarding the EndOf-Line resistors.

Network Bias Resistors

510 ohms per wire (max. of two sets per segment)

Maximum number of nodes per

segment

64 (Viconics devices only)

Maximum number of nodes per

network

128

Baud rate

9600, 19200, 38400, 76800 (Auto detect)

Wiring Guide Overview

Viconics uses EIA-485 as the physical layer between their devices and supervisory controllers.

For clarity we will use the term “Device” to represent any product with an active EIA-485 network connection,

including Viconics and non-Viconics controllers.

Summary Specifications:

Table 1: Summary of Specifications for a Viconics’ EIA-485 Network

Page 30

30

Cable Type

Viconics recommends the use of balanced 22-24 AWG twisted pair with characteristic impedance of 100-130

ohms, capacitance of 30 pF per ft or lower. A braided shield is recommended.

Impedance

A value based on the inherent conductance, resistance, capacitance and inductance that represent the impedance

of an infinitely long cable. The nominal impedance of the cable should be between 100Ωand 120Ω. However

using120Ω will result in a lighter load on the network.

Capacitance (pF per ft)

The amount of equivalent capacitive load of the cable, typically listed in a per foot basis. One of the factors limiting

total cable length is the capacitive load. Systems with long lengths benefit from using low capacitance cable (i.e.

17pF per ft or lower).

Network Configuration

EIA-485 networks use a daisy chain configuration. A daisy chain means that there is only one main cable and

every network device is connected directly along its path.

(Figure 3) illustrates two improper network configurations and the proper daisy chain configuration.

Other methods of wiring an EIA-485 network may give unreliable and unpredictable results. There are no

troubleshooting methods for these types of networks. Therefore, a great deal of site experimentation may have to

be done, making this a difficult task with no guarantee of success. Viconics will only support daisy chain

configurations.

Figure 3: Three different network configurations: star, bus, and daisy chain. Only the daisy

chain configuration is correct for an EIA-485 network.

Page 31

31

Maximum Number of Devices

A maximum of 64 nodes is allowed on a single daisy chain segment. A node is defined as any device (Panel,

Zone, Repeater, etc) connected to the RS485 network. Terminators do not count as a node.

To determine the number of nodes on a network, add the following:

One node for each device, including main panels

One node for each repeater on the chain

For the example in (Figure 4), we have one node for the main Panel, plus 4 for the controllers, for a total of 5

nodes.

Figure 4: Five nodes network example.

If you have more than 64 devices, then repeaters are required to extend the network.

Maximum Cable Length

The maximum length of a chain is related to its transmission speed. The longer the chain the slower the speed

of transmission will be. Using proper cable, the maximum length of an EIA-485 daisy chain is 4000-ft (1200

m). This will only work reliably for data rates up to 100,000 bps. Viconics’ maximum data rate is 76,800 bps.

If you require a maximum network length of more than 4000 feet, then repeaters are required to extend the

network.

EIA-485 Repeaters

If you have more than 64 devices, or require a maximum network length of more than 4000 feet, then

repeaters are required to extend the network. The best configuration is to daisy chain the repeaters to the

main panel. From each of these repeaters, a separate daisy chain will branch off. (Figure 5) demonstrates a

valid use of repeaters in an EIA-485 network.

Page 32

32

Figure 5: Correct usage – repeaters are daisy chained to the supervisory controller

and separate daisy chains branch from each repeater.

Do not install repeaters in series, as this may result in network reliability problems. (Figure 6) demonstrates an

incorrect use of a repeater in an EIA-485 network.

Figure 6: Incorrect usage – the second repeater in series may result in an

unreliable system

Page 33

33

End of Line (EOL) Resistors

MS/TP network must be properly terminated. For daisy chain configurations, you must install an EOL resistor at

each end of the daisy chain. Depending on your MSTP network configuration, the resistance value of the EOL

resistor may change:

Viconics’ devices are installed at both ends of the MSTP network:

120 Ohms resistor should be installed at each end.

A Viconics device is installed at one end of the MSTP network and a 3rd party device is installed at the

other end:

Install an End-Of-Line resistor value that matches the 3rd party devices instructions regarding its EOL

resistor value.

3rd party devices are installed at both ends of the MSTP network:

Follow the 3rd party devices instructions regarding its EOL resistor value.

Network Adapter

The polarity of the connection to the cable is important. From one module to the other it is important that the same

coloured wire be connected to “plus” or “+” and the other coloured wire be connected to the “minus” or ”-“. (Figures

7) shows the proper MS/TP connections and the location of the Status LED. This Status LED may help to

troubleshoot network problems.

Figure 7: Correct MS/TP connections and location of a Status LED on a BACnet module

IMPORTANT NOTE: The Ref terminal should NEVER be used to wire shields. The 2 shields from each feed of the

network connection to a controller should be wired together in the back of the controller and properly protected to

prevent any accidental connection to the ground.

The joined shield connection should then be grounded at a single point on the whole segment. More than one

ground connection to a shielded wire may induce ground loop noises and affect communication.

Page 34

34

Condition of the Status LED

Possible Cause

Solution

2 short blink (no wires

connected to the module)

Controller is searching for an MSTP BACnet network. Either at

selected Baud rate or is currently

Auto-Bauding

Connect Controller to

Network

2 short blink (wires

connected to the module)

Module is not at the same baud

rate as the network or set at a

different Baud rate than Main

network

If Auto-Bauding, power off

and on the controller.

If wrong Baud rate is

selected, match network

Baud rate for each device.

2 short blinks and a longer

blink (wires connected to

the module)

The module has detected the

presence of a network and is in the

Token Pass of the ring

N/A

Table 2 shows the different possibilities with the Status LED behaviour of the BACnet module.

Table 2: Status LED condition and possible solutions

Default Device Name and default Device ID

Default Device Name is set to: Model number – MAC:

Where MAC is the current MAC address of the device.

Where Model number is Viconics part number.

The device name will be upgraded as soon as there is a change to the device MAC address.

Default Device ID is set to: 76000 + MAC

Where MAC is the current MAC address of the device.

The device ID will also be upgraded as soon as there is a change to the device’s MAC.

For an RTU controller example, when a VZ76561000B controller with a MAC address of 63 is connected to a

network, its default Device Name will be VZ76561000B-63 and its default Device ID will be 76063.

For a zone controller example, when a VZ7260F5x00B controller with a MAC address of 12 is connected to a

network, its default Device Name will be VZ7260F5x00B-12 and its default Device ID will be 72012.

Device Name and Device ID properties are writable in Viconics’ device object. Both properties can be renamed

from any BACnet network management tool as long as the tool itself can write to these properties.

Page 35

35

Error / Trouble

Condition

Possible Cause

Solution

Controller does not

come online

Two or more controllers have the same

MAC address.

Modify each duplicate address to a

unique number.

The MS/TP network has too many

devices.

Do not exceed the maximum number of

devices and maximum length allowed

by the EIA-485 specifications.

Too many devices were installed

without any repeaters.

Repeaters need to be installed as

specified in this document.

The MS/TP cable runs are broken

Locate the break and correct wiring

MS/TP connections at the module

were reversed

Respect polarity of the wires on a

MS/TP network.

The controller does not have power

Apply power to the controller

Things You Need To Know

After the initial configuration of your device and if your BAS allows you to remove objects, we suggest

that you remove all the configuration objects to prevent unnecessary polling of non used objects and to

help speed up the network.

In its default mode of operation (Auto-Bauding), the device will automatically match its baud rate to the

baud rate of the network. Automatic baud rate detection will occur when the MS/TP communication

port is initialized (on power up). If the network speed is changed, the device will keep listening at the

previously detected speed for 2.5 minutes before resuming auto-bauding. Re-powering the devices will

force right away auto-bauding.

If the device should go off-line, the following binded controller parameters will be released:

Room Temperature

Outdoor Temperature

Occupancy

The BACnet Data Link layer has two key parameters: the device object name and the device object ID.

The device object name must be unique from any other BACnet device object name on the BACnet

network (i.e. not just the MS/TP sub-network). The device object ID must be unique from any other

BACnet device object ID on the entire BACnet network (i.e. not just the MS/TP sub-network).

For the VZ76561000B. Time synchronization can be made through a network even if the controller

does not support the full date. The local date & time reported are not dynamic & will represent the last

time stamp received during the last synchronization.

Device Name and Device ID properties are writable in Viconics’ device object. Both properties can be

renamed from any BACnet network management tool as long as the tool gives write access to these

properties.

Troubleshooting Section

Loading...

Loading...