Page 1

VT8300 Series Installation Guide

24 Vac Low Voltage

Commercial and Hotel/Lodging HVAC Fan Coil Applications

CONTENTS

Installation 2

Configurable BI/UI Universal Inputs Overview 3

Setup Screen Display 3

Terminal Identification & Function 4

Terminal identification 4

Wiring 5

Typical Applications 6

2 pipe systems cooling and/or heating 6

4 pipe systems cooling and heating 7

2 pipe systems cooling or heating with reheat 8

Remote Sensor Accessories 9

Wiring example of single remote room sensor 9

Wiring examples of 2 remote room sensors 10

Wiring examples of 2 remote room sensors 10

Home Screen Display 11

How to Enter Setup Screen 12

Page 2

2

INSTALLATION

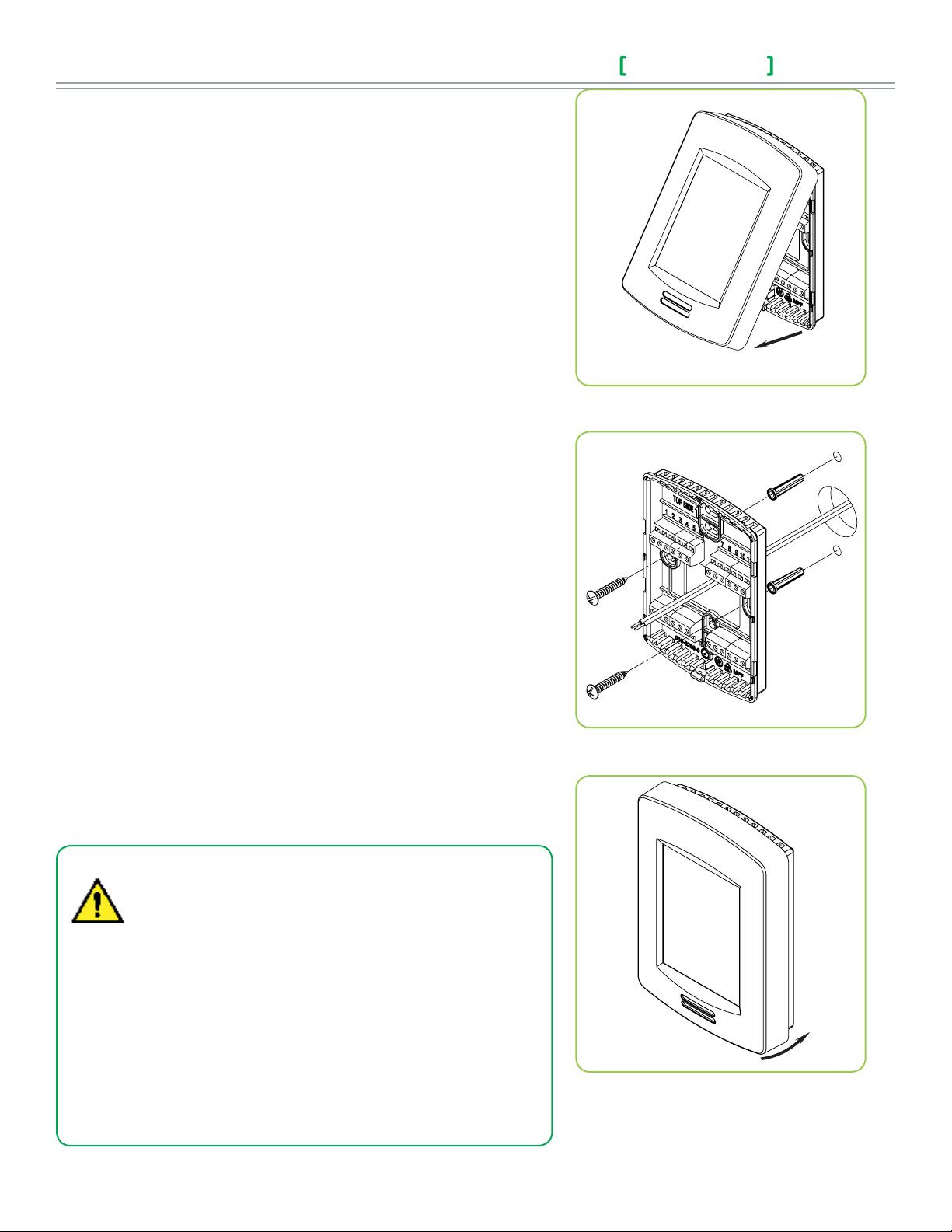

Preparation

• Remove the security screw (if any) on the bottom of the Terminal Equipment

Controller cover.

• Open unit by pulling on bottom side of the Terminal Equipment Controller

(Fig. 1).

• Read FCC ID and IC label installed in cover before installing any wireless

product.

• Ensure correct side of base faces up.

Location

1. Do not install on outside wall.

2. Do not install in areas with direct heat source.

3. Do no install near any air discharge grill.

4. Do not install in areas exposed to direct sunlight.

5. Ensure Controller has sufficient air circulation.

6. Ensure wall surface is flat and clean.

Installation

1. Pull cables 15 cm ( 6” ) out from wall.

2. Align base and mark location of two mounting holes on wall.

3. Install anchors in wall.

4. Insert cable in central hole of base.

5. Insert screws in mounting holes on each side of base.

6. Strip each wire 1/4” ( 0.6 cm) from end.

7. Insert each wire and screw according to wiring chart.

8. Gently push excess wiring back into hole.

9. Gently align cover to top of base and snap in place from bottom.

10. Install security screw.

Installation Guide

Figure-1 Ope n the cover

Figure-2 Install the bas e

VT8300 Series

• If replacing an existing Line Voltage FCU Controller, label wires

before removal of Controller.

• Electronic controls are static sensitive devices. Discharge

yourself correctly before manipulating and installing Controller.

• A short circuit or wrong wiring may permanently damage

Controller or equipment.

• All VT8300 ® series controls are designed for use as operating

controls only and are not safety devices. Tampering with the

devices or unintended application of the devices will result in a

void of warranty.

• This device must be installed to provide a separation distance

of at least 8in (40cm) from all persons and must not be

collocated or operating in conjunction with any other antenna

Figure-3 Reinstall cover

or transmitter.

Viconics Technologies Inc. | 9245 La ngeli er Blvd. | St.-Leonard | Quebec | Canada | H1P 3K9 | Tel : (514) 321-5660 | Fa x: ( 514) 32 1-415 0

028-0429-02 www.viconics.com | sales @viconics.com February 2015

©2015 Viconics Technologies Inc. All rights reserved.

Page 3

Installation Guide

VT8300 Series

3

CONFIGURABLE BI/UI UNIVERSAL INPUTS OVERVIEW

Universal input #16 can be configured for the following binary

functions:

1. (None): No function will be associated with the input

2. (Rem NSB): remote NSB timer clock input. The scheduling will now be

set as per the binary input. It provides low cost setback operation via a dry

contact.

Contact opened = Occupied

Contact closed = Unoccupied

3. (Motion NO) and (Motion NC): Advanced PIR occupancy functions using

a normally open (NO) or normally closed (NC) remote PIR motion sensor.

Occupancy mode is now set as per applied PIR function and configuration.

Application information and examples are available on document: APP-PIRSE8xxx. This document will provide the installers and system designers with

detailed examples on applications, parameter configuration information,

sequence of operation, troubleshooting and diagnostic help required for the

proper usage of the onboard PIR sensor.

4. (Window) EMS: Forces the system to disable any current heating or cooling

action by the Terminal Equipment Controller. The mode stays the same and

the current setpoints are the same occupied setpoints. Only the outputs

are disabled. There is a Door/Window alarm displayed on the Terminal

Equipment Controller to indicate to the local tenant that the door/window

needs to be closed for cooling or heating to resume. Use NC contact.

Contact opened = System disabled with local Window alarm

Contact closed = System enabled

Universal input #17 can be configured for the following binary

functions:

1. (None): No function will be associated with the input

2. (Door Dry) Door contact & Motion detector: This configuration is only

functional if binary input #1 is set to Motion NO or Motion NC or an onboard

PIR sensor is used. With this sequence enabled, the occupancy is now

dictated through those 2 inputs. Any motion detected will set the zone

to occupied status. The zone will remain permanently in occupied mode

until the door contact switch opens momentarily. The Terminal Equipment

Controller will then go in stand-by mode. If more movements are detected,

the occupied mode will resume. While the door is opened, any movements

detected by the remote PIR sensor or the onboard PIR sensor will be

ignored. Use a Normally Closed contact switching device.

4. (Filter): a Filter alarm short text message will be

displayed on the Terminal Equipment Controller

screen when the input is energized. It can be

tied to a differential pressure switch that monitor

filters

Contact opened = No alarm

Contact closed = Alarm displayed

5. (Service): a Service alarm short text message

will be displayed on the Terminal Equipment

Controller screen when the input is energized. It

can be tied in to the AC unit control card, which

provides an alarm in case of malfunction.

Contact opened = No alarm

Contact closed = Alarm displayed

Universal input #19 can be configured for

the following functions:

1. (None): No function will be associated with the

input

2. (COC/NH) Change over dry contact.

Normally Heat: Used for hot / cold air / water

change over switching in 2 pipe systems.

Contact closed = Cold air/water present

Contact opened = Hot air/water present

Only used and valid if Room Controller is set

up for a 2 pipe system.

3. (COC/NC) Change over dry contact.

Normally Cool: Used for hot / cold air / water

change over switching in 2 pipe systems.

Contact closed = Hot air/water present

Contact opened = Cold air/water

present

Only used and valid if Room Controller is set

up for a 2 pipe system.

4. (COS) Change over analog sensor: Used for

hot / cold air / water change over switching in 2

pipe systems.

Contact opened = Door opened

Contact closed = Door closed

3. (RemOVR): temporary occupancy remote override contact. This function

disables the central button override function on the Terminal Equipment

Controller. The override function is now controlled by a manual remote

momentarily closed contact. When configured in this mode, the input

operates in a toggle mode. It is now possible to toggle between unoccupied

& occupied setpoints for the amount of time set by parameter (TOccTime)

temporary occupancy time.

Viconics Technologies Inc. | 9245 La ngeli er Blvd. | St.-Leonard | Quebec | Canada | H1P 3K9 | Tel : (514) 321-5660 | Fa x: ( 514) 32 1-415 0

028-0429-02 www.viconics.com | sales @viconics.com February 2015

Only used and valid if Room Controller is set

up for a 2 pipe system.

If temperature is > 77 °F = Hot air / water

present

If temperature is < 75 °F = Cold air / water

present

©2015 Viconics Technologies Inc. All rights reserved.

Page 4

4

TERMINAL IDENTIFICATION & FUNCTION

Terminal identification

Installation Guide

VT8300 Series

VT83xxU

Description / Application

2 & 4 Pipe 2 & 4 Pipe 2 & 4 Pipe

Control Type = On/Off Control Type = Floating Control Type = Analog

Internal Temperature X X X

Internal Humidity

1- BO1

2- BO2

3- BO3

4- BO4

5- RC / 24 V~ Hot

6- C / 24 V~ Com

7- RH

8- BO8

9- UO9

10- UO10

11- UO 11

12- UO12

Model Dependent Model Dependent Model Dependent

Not used Not used Not used

Fan-L Fan-L Fan-L

Fan-M Fan-M Fan-M

Fan-H Fan-H Fan-H

24 V~ Hot 24 V~ Hot 24 V~ Hot

24 V~ Com 24 V~ Com 24 V~ Com

Aux Heat Aux Heat Aux Heat

Aux Heat Aux Heat Aux Heat

Normally Close Cool Valve Close Cool Valve Not used

Normally Close Heat Valve Close Heat Valve Not used

Normally Open Cool Valve Open Cool Valve Analog Heat valve

Normally Open Heat Valve Open Heat Valve Analog Cool Valve

Used in applications

13- RS485 +

14- RS485 -

15- RS485 Ref

16- UI16

17- UI17

18- Common

19- UI19

20- UI20

21- Common

22- UI22

23- UI23

24- UI24

BACnet MS-TP + BACnet MS-TP + BACnet MS-TP +

BACnet MS-TP - BACnet MS-TP - BACnet MS-TP -

BACnet MS-TP Ref BACnet MS-TP Ref BACnet MS-TP Ref

UI16 Function UI16 Function UI16 Function

UI17 Function UI17 Function UI17 Function

Common Common Common

UI19 Function UI19 Function UI19 Function

Remote Room Sensor Remote Room Sensor Remote Room Sensor

Common Common Common

Remote Supply Sensor Remote Supply Sensor Remote Supply Sensor

Not used Not used Not used

Not used Not used Not used

Viconics Technologies Inc. | 9245 La ngeli er Blvd. | St.-Leonard | Quebec | Canada | H1P 3K9 | Tel : (514) 321-5660 | Fa x: ( 514) 32 1-415 0

028-0429-02 www.viconics.com | sales @viconics.com February 2015

©2015 Viconics Technologies Inc. All rights reserved.

Page 5

Installation Guide

2 Pipe Applications

Com

24Vac

Com

4 Pipe Applications

2 Pipe Applications 4 Pipe Applications

Com

24Vac

Com

24Vac

Com

Open

Close

Com

Open

Com

24Vac

Com

24Vac

Com

Open

Close

Com

24 Vac

0-10 Vdc

Com

Com

24Vac

Com

24Vac

Com

Open

Close

Com

Open

Close

Com

24Vac

Com

24Vac

Com

Open

Close

Com

Open

Close

VT8300 Series

Wiring

Power & Fan (All Models)

3 Speed 2 Speed Single Speed

LOW LOW

LOW LOW

MED

MED

5

HIGH HIGH

HIGHHIGH HIGH

HIGH

BO8 Auxilliary output wiring

Dry contact to end device 24 V~ maximum 24 Vac power to relay

RC (24 Vac)

C (Common)

RC (24 Vac)

C (Common)

R

RH

BO8 - Aux Heat

Main outputs wiring

2 Pipe Applications 4 Pipe Applications

Control type = On-Off

RH

BO8 - Aux Heat

24 Vac

Transformer

R

UO9

UO11

OR

Heating / Cooling valve

Com

24Vac

Floating control

UO11

UO9

Heating / Cooling valve

Com

Open

Close

Analog control

UO10 NC

UO12 NO

UO11 NO

UO11 NC

UO12

UO10

UO11

UO9

Com

OR

OR

24Vac

Com

24Vac

Com

Open

Close

Com

Open

Close

Heating valve

Cooling valve

Heating valve

Cooling valve

Heating / Cooling valve

Com

24Vac

UO12

Viconics Technologies Inc. | 9245 La ngeli er Blvd. | St.-Leonard | Quebec | Canada | H1P 3K9 | Tel : (514) 321-5660 | Fa x: ( 514) 32 1-415 0

028-0429-02 www.viconics.com | sales @viconics.com February 2015

0-10Vdc

UO11

UO12

Com

24 Vac

0-10 Vdc

Com

24 Vac

0-10 Vdc

Heating valve

Cooling valve

©2015 Viconics Technologies Inc. All rights reserved.

Page 6

6

24 Vac fan relays

TYPICAL APPLICATIONS

Schematic Wiring Settings

Normally Closed

3 Speed Fan

Sensor

Room Temperature

Control Thermostat

On/Off

Cooling / Heating

Valve

2 pipe system cooling and/or heating

Control type = On / Off

24 Vac fan relays

2

3

4

5

6

7

8

9

10

11

12

18

19

BO2 - Fan L

BO3 - Fan M

BO4 - Fan H

RC (24 Vac)

C (Common)

RH

BO8 - Aux Heat

UO9 NC

UO10

UO11

UO12

SCom

UI 19 - UI13

LOW

MED

HIGH

Optional supply water

temperature sensor

24 Vac Transformer

Normally Closed

2 pipe system cooling and/or heating

Control type = Floating

Installation Guide

VT8300 Series

Mandatory

• Pipe no = 2 pipes

• CntrltTyp = On/Off

• Fan Menu = 0 (L-M-H)

• FL time = N/A

If cooling only set::

• SeqOpera = 0 Cooling only

If heating only set:

• SeqOpera = 1 Heating only

If heat / cool auto-changeover with

a local water temperature sensor set:

• SeqOpera = 0 Cooling only

• UI3 = COS

3 Speed Fan

Room Temperature

Control Thermostat

Modulating Floating

Cooling / Heating

Sensor

Valve

2

3

4

5

6

7

8

9

10

11

12

18

19

BO2 - Fan L

BO3 - Fan M

BO4 - Fan H

RC (24 Vac)

C (Common)

RH

BO8 - Aux Heat

UO9

UO10

UO11

UO12

SCom

UI 19 - UI13

LOW

MED

HIGH

Optional supply water

temperature sensor

24 Vac Transformer

Normally Closed

Mandatory

• Pipe no = 2 pipes

• CntrltTyp = Floating

• Fan Menu = 0 (L-M-H)

• FL time = as per actuator

If cooling only set:

• SeqOpera = 0 Cooling only

If heating only set:

• SeqOpera = 1 Heating only

If heat / cool auto-changeover with

a local water temperature sensor set:

• SeqOpera = 0 Cooling only

• UI3 = COS

Viconics Technologies Inc. | 9245 La ngeli er Blvd. | St.-Leonard | Quebec | Canada | H1P 3K9 | Tel : (514) 321-5660 | Fa x: ( 514) 32 1-415 0

028-0429-02 www.viconics.com | sales @viconics.com February 2015

©2015 Viconics Technologies Inc. All rights reserved.

Page 7

Installation Guide

24 Vac fan relays

Schematic Wiring Settings

3 Speed Fan

Sensor

Room Temperature

Control Thermostat

VT8300 Series

Modulating Analog

Cooling / Heating

Valve

2 pipe system cooling and/or heating

Control type = Analog

24 Vac fan relays

2

3

4

5

6

7

8

9

10

11

12

18

19

BO2 - Fan L

BO3 - Fan M

BO4 - Fan H

RC (24 Vac)

C (Common)

RH

BO8 - Aux Heat

UO9

UO10

UO11

UO12

SCom

UI 19 - UI13

LOW

MED

HIGH

Optional supply water

temperature sensor

24 Vac Transformer

0 to 10

Vdc

Normally Closed

7

Mandatory

• Pipe no = 2 pipes

• CntrltTyp = Analog

• Fan Menu = 0 (L-M-H)

• RA/DA = as per actuator

If cooling only set:

• SeqOpera = 0 Cooling only

If heating only set:

• SeqOpera = 1 Heating only

If heat / cool auto-changeover with

a local water temperature sensor set:

• SeqOpera = 0 Cooling only

• UI3 = COS

4 pipe system cooling and heating

Control type = On / Off

3 Speed Fan

Room Temperature

Control Thermostat

Normally Closed

On/Off

Cooling

Valve

Heating

Valve

2

3

4

5

6

7

8

9

10

11

12

BO2 - Fan L

BO3 - Fan M

BO4 - Fan H

RC (24 Vac)

C (Common)

RH

BO8 - Aux Heat

UO9 NC

UO10

UO11 NC

UO12

LOW

MED

HIGH

Normally Closed

Heating

24 Vac Transformer

Cooling

Mandatory

• Pipe no = 4 pipes

• CntrltTyp = On/Off

• Fan Menu = 0 (L-M-H)

• SeqOpera = 4 Cool/Heat

4 pipe system cooling and heating

Control type = Floating

24 Vac fan relays

LOW

MED

HIGH

Heating

24 Vac Transformer

Cooling

Mandatory

• Pipe no = 4 pipes

• CntrltTyp = Floating

• Fan Menu = 0 (L-M-H)

• FL time = as per actuator

• SeqOpera = 4 Cool/Heat

3 Speed Fan

Room Temperature

Modulating Floating

Cooling

Valve

Heating

Valve

2

3

4

5

6

7

8

9

10

11

12

BO2 - Fan L

BO3 - Fan M

BO4 - Fan H

RC (24 Vac)

C (Common)

RH

BO8 - Aux Heat

UO9

UO10

UO11

UO12

Control Thermostat

Viconics Technologies Inc. | 9245 La ngeli er Blvd. | St.-Leonard | Quebec | Canada | H1P 3K9 | Tel : (514) 321-5660 | Fa x: ( 514) 32 1-415 0

028-0429-02 www.viconics.com | sales @viconics.com February 2015

©2015 Viconics Technologies Inc. All rights reserved.

Page 8

8

3 Speed Fan

Installation Guide

Schematic Wiring Settings

4 pipe system cooling and heating

Control type = Analog

Modulating Analog

Cooling

Valve

Room Temperature

Control Thermostat

Heating

Valve

2

3

4

5

6

7

8

9

10

11

12

BO2 - Fan L

BO3 - Fan M

BO4 - Fan H

RC (24 Vac)

C (Common)

RH

BO8 - Aux Heat

UO9

UO10

UO11

UO12

2 pipe system cooling or heating with reheat

Control type = Floating

24 Vac fan relays

LOW

MED

HIGH

0 to 10

Vdc

Heating

24 Vac Transformer

0 to 10

Vdc

Cooling

Mandatory

• Pipe no = 4 pipes

• CntrltTyp = Analog

• Fan Menu = 0 (L-M-H)

• RA/DA = as per actuator

• SeqOpera = 4 Cool/Heat

VT8300 Series

3 Speed Fan

Modulating Floationg

Cooling / Heating

Valve

Sensor

Room Temperature

Control Thermostat

Electric

Reheat

2

3

4

5

6

7

8

9

10

11

12

18

19

BO2 - Fan L

BO3 - Fan M

BO4 - Fan H

RC (24 Vac)

C (Common)

RH

BO8 - Aux Heat

UO9

UO10

UO11

UO12

SCom

UI 19 - UI13

24 Vac fan relays

LOW

MED

HIGH

Electric

Reheat

Optional supply water

temperature sensor

24 Vac Transformer

Normally Closed

Mandatory

• Pipe no = 2 pipes

• CntrltTyp = Floating

• Fan Menu = 0 (L-M-H)

• FL time = as per actuator

• SeqOpera = 2 Cool/Reheat

• UI3 = COS

Viconics Technologies Inc. | 9245 La ngeli er Blvd. | St.-Leonard | Quebec | Canada | H1P 3K9 | Tel : (514) 321-5660 | Fa x: ( 514) 32 1-415 0

028-0429-02 www.viconics.com | sales @viconics.com February 2015

©2015 Viconics Technologies Inc. All rights reserved.

Page 9

Installation Guide

VT8300 Series

REMOTE SENSOR ACCESSORIES

Model no. Description

S3010W1000 Wall mounted temperature sensor

S3020W1000 Wall mounted temperature sensor with override button and occupancy status

LED

The VT8300 room controller is compatible with remote mount temperature sensors using 10K type 2 NTC thermistors.

Note:

If one or multiple sensor(s) is/are connected into the RS terminal, the internal temperature sensor is automatically disabled. Disconnecting

the sensor(s) in the RS terminal will re-activate the internal sensor.

Features:

• Each sensor can be configured for various averaging combinations

• Optional occupancy led

• Optional override key

Wiring example of single remote room sensor:

9

VT8300

Series Controller

Common

UI 20

BO8

24 Vac Com

UI17

S3020W1000

Remote wiring 1 sensor

S2-1= On, S2-2=On

SCom

OR

RS

Aux

C

DI

S3010W1000

Remote wiring 1 sensor

S2-1= On, S2-2=On

SCom

RS

Dip switch

setting for:

1 sensor

ON

1 2

S2-1 = ON

S2-2 = ON

Viconics Technologies Inc. | 9245 La ngeli er Blvd. | St.-Leonard | Quebec | Canada | H1P 3K9 | Tel : (514) 321-5660 | Fa x: ( 514) 32 1-415 0

028-0429-02 www.viconics.com | sales @viconics.com February 2015

©2015 Viconics Technologies Inc. All rights reserved.

Page 10

10

VT8300

2 x S3010W1000

1 2

1 2

Installation Guide

Wiring examples of 2 remote room sensors for averaging applications:

VT8300 Series

VT8300

Series Controller

Common

UI 20

BO8

24 Vac Com

UI17

Series Controller

Common

UI 20

1 x S3010W1000 & 1 x S3020W1000

Remote wiring 2 sensor

S2-1= On, S2-2=Off

SCom

RS

Aux

C

DI

Remote wiring 2 sensor

S2-1= On, S2-2=Off

SCom

RS

SCom

RS

SCom

RS

Notes for averaging applications:

• S3010W1000andS3020W1000canbe

mixedmatched.

• S3010W1000andS3020W1000aretobe

wiredinparallel.

• Respectthedipswitchsettingineach

remotesensor.

VT8300

Series Controller

Common

UI 20

BO8

24 Vac Com

UI17

Dip switch

setting for:

2 sensors

2 x S3020W1000

Remote wiring 2 sensor

S2-1= On, S2-2=Off

SCom

RS

Aux

C

DI

ON

S2-1 = ON

S2-2 = OFF

SCom

RS

Wiring examples of 3 remote room sensors for averaging applications:

VT8300

Series Controller

Common

UI 20

BO8

24 Vac Com

UI17

Temperature vs. resistance chart for 10 Kohm NTC thermistor (R25°C = 10KΩ±3%, B25/85°C = 3975K±1.5%)

ºC ºF Kohm ºC ºF Kohm ºC ºF Kohm ºC ºF Kohm ºC ºF Kohm

-40 -40 324.3197 -20 -4 94.5149 0 32 32.1910 20 68 12.4601 40 104 5.3467

-35 -31 234.4009 -15 5 71.2430 5 41 25.1119 25 77 10.0000 45 113 4.3881

-30 -22 171.3474 -10 14 54.1988 10 50 19.7390 30 86 8.0694 50 122 3.6202

-25 -13 126.6109 -5 23 41.5956 15 59 15.6286 35 95 6.5499 55 131 3.0016

2 x S3010W1000 & 1x S3020W1000

Remote wiring 3 sensor

S2-1= Off, S2-2=Off

SCom

RS

Aux

C

DI

SCom

RS

SCom

RS

VT8300

Series Controller

Common

UI 20

3 x S3010W1000

Remote wiring 3 sensor

S2-1= Off, S2-2=Off

SCom

RS

Dip switch

setting for:

3 sensors

SCom

RS

ON

S2-1 = OFF

S2-2 = OFF

SCom

RS

028-0429-02 www.viconics.com | sales @viconics.com February 2015

Viconics Technologies Inc. | 9245 La ngeli er Blvd. | St.-Leonard | Quebec | Canada | H1P 3K9 | Tel : (514) 321-5660 | Fa x: ( 514) 32 1-415 0

©2015 Viconics Technologies Inc. All rights reserved.

Page 11

Installation Guide

VT8300 Series

HOME SCREEN DISPLAY

11

Hospitality User Interface Shown

Date

Occupancy Status

Indoor Temperature

Indoor Humidity

Outdoor Temperature

System Mode

Short Network

Message

Time

System Status

Fan Status

Up Arrow

Increase Temperature Setpoint

Actual Setpoint

Down Arrow

Decrease Temperature

Setpoint

Help

Fan Mode

Language Selection

Temperature Units

Note: User HMI is configurable and allows display functions such as Date, Time,

Humidity, Outdoor Temperature, Setpoint, and others to be enabled or disabled by

setting various parameters.

Viconics Technologies Inc. | 9245 La ngeli er Blvd. | St.-Leonard | Quebec | Canada | H1P 3K9 | Tel : (514) 321-5660 | Fa x: ( 514) 32 1-415 0

028-0429-02 www.viconics.com | sales @viconics.com February 2015

©2015 Viconics Technologies Inc. All rights reserved.

Page 12

12

Setup

Network

Configuration

Setpoints - Display

Service view

Test outputs

HOW TO ENTER SET-UP SCREEN

Installation Guide

VT8300 Series

SET-UP SCREEN DISPLAY

Touch and hold this point

for 3 seconds to enter set-up mode

Note: If a configuration/installer

password is activated to prevent

unauthorised access to the

configuration menu parameters, a

password entry prompt shows to

prevent access to device configuration

components.

For more information on using and

configuring the functions of the HMI,

refer to the following document:

VT8300 Series

Terminal Equipment Controller

User Interface Guide

Return to

home screen

Enter BACnet

Enter parameter configuration menu

Enter setpoint & display settings

Enter status and service view

Enter output testing mode

Enter language selection

Discover Mode The Controller

becomes discoverable on the wireless

ZigBee® network for 1 minute (this

button is hidden if ZigBee® settings are

not configured)

®

& ZigBee® network settings

General Note:

Adjustable parameter

Non-adjustable parameter

Viconics Technologies Inc. | 9245 La ngeli er Blvd. | St.-Leonard | Quebec | Canada | H1P 3K9 | Tel : (514) 321-5660 | Fa x: ( 514) 32 1-415 0

028-0429-02 www.viconics.com | sales @viconics.com February 2015

©2015 Viconics Technologies Inc. All rights reserved.

Page 13

Installation Guide

VT8300 Series

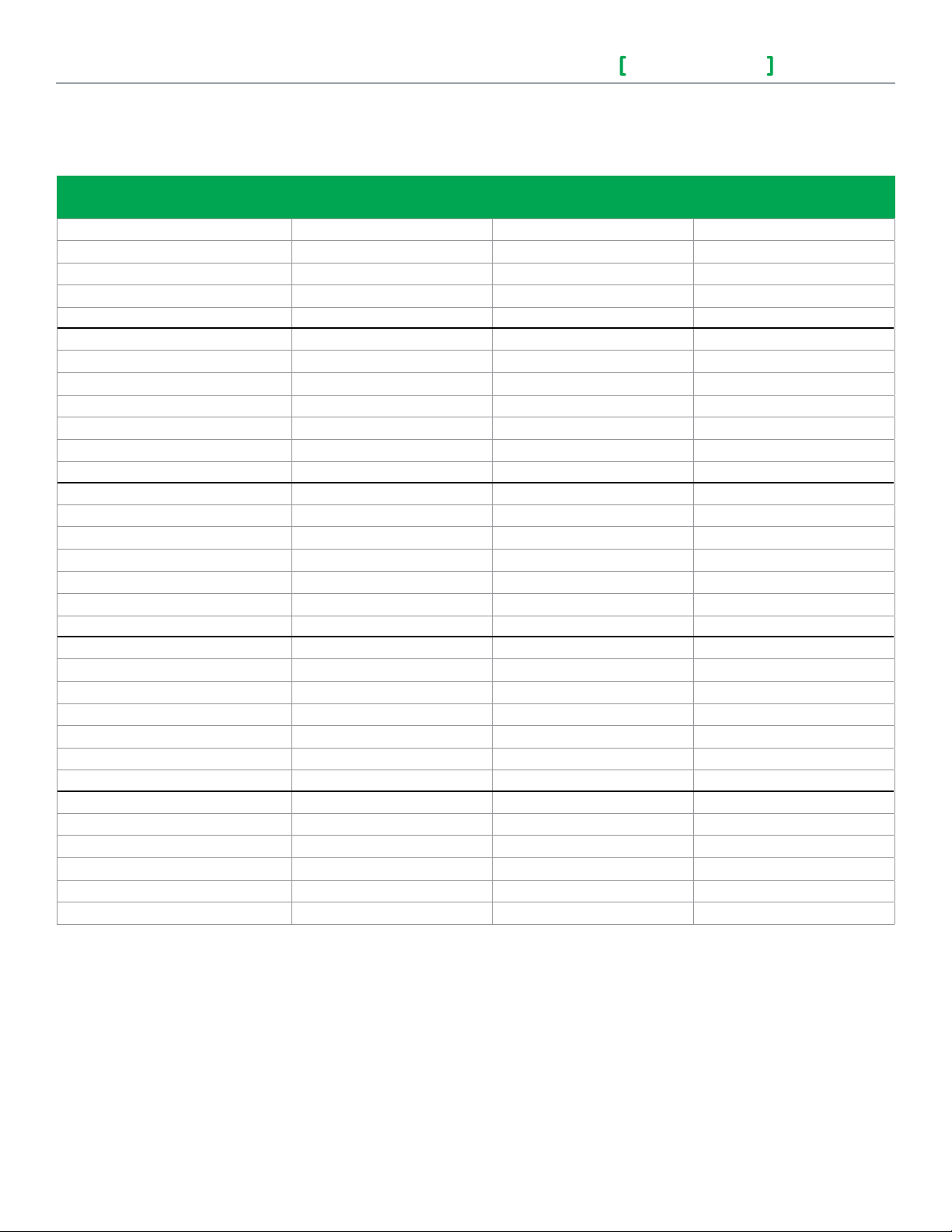

APPENDIX A: TERMINAL CORRESPONDANCE

The terminals of a VT8300 are identified differently and have a wider range of possible functions compared to those of any of the

VT7000 series Room Controllers. Nonetheless, there is a direct correspondance of functions between the terminals of the VT7000

series and the VT8300 series. Consult the table below to verify the appropriate terminal when replacing a VT7000 Room

Controller with a VT8300 Room Controller.

VT7000 VT8300

Terminal name Terminal ID Terminal name Terminal ID

Binary Input 1 BI1 Universal Input 16 UI16

Binary Input 2 BI2 Universal Input 17 UI17

Universal Input 3 UI3 Universal Input 19 UI19

Sensor Common Scom Terminal 18 Common COM

Remote Sensor RS Universal Input 20 UI20 - RS

Sensor Common Scom Terminal 21 Common COM

Mix/Supply Sensor MS Universal Input 22 UI22 - SS

13

APPENDIX B: POWER OUTAGE CLOCK RESET

In the event of a power outage, VT8300 Room Controllers retain the correct time as long as the duration of the power outage is

not prolonged. Depending on the duration of the power outage, the Room Controllers internal clock may need to be updated

or reset completely. The following table gives an indication of the expected clock performance after a power outage of a given

duration.

Outage duration Room Controller behaviour

0 - 24 hours Clock functions are normal

24 - 36 hours Clock accuracy not guaranteed, time may need to be adjusted

36 - 72 hours Clock no longer increments and will need to be adjusted when power is

restored.

72+ hours Clock functions are fully reset, and will need to be reinitialized as per a

new installation.

Viconics Technologies Inc. | 9245 La ngeli er Blvd. | St.-Leonard | Quebec | Canada | H1P 3K9 | Tel : (514) 321-5660 | Fa x: ( 514) 32 1-415 0

028-0429-02 www.viconics.com | sales @viconics.com February 2015

©2015 Viconics Technologies Inc. All rights reserved.

Loading...

Loading...