Page 1

PIR Ready VT7600W Series

With & Without Local Schedule

Water Source Heat Pump

Terminal Equipment Controllers

Installation Guide

For Commercial HV AC Applications

May 3rd, 2012 / 028-035 5-R4

CONTENTS

Installation 2

Location 2

Installation 2

Theory of operation 3

Features overview 3

Model Chart 5

Network ready 5

Terminal, Identification and Function 6

Wiring 6

Screw terminal arrangement 7

Main outputs wiring 7

Typical applications 7

Remote sensor accessories 8

Configuring and Status Display Instructions 11

Status display 12

User Interface 13

User configuring instructions menu 13

Local keypad interface 14

Occupied setpoints adjustments 15

Installer Configuration Parameter Menu 22

Troubleshooting guide 32

All models 32

Specifications 34

Drawing & Dimensions 35

1 | PIR Ready VT76xxW Series-Installation Guide

Page 2

INSTALLATION

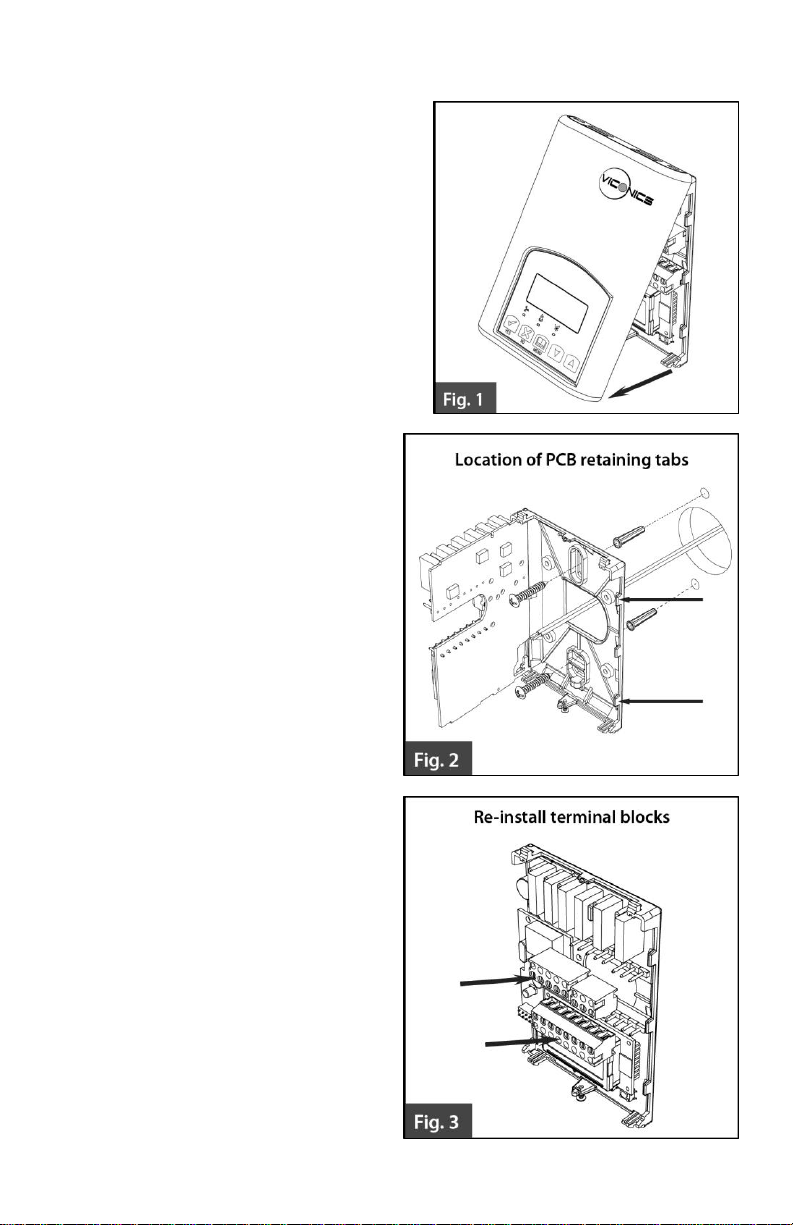

Remove the security screw on the bottom of

Terminal Equipment Controller cover.

Open unit by pulling on the bottom

side of Terminal Equipment

Controller (fig. 1).

Remove wiring terminals from sticker.

Please read the FCC ID and IC label

installed in the cover upon removal of

cover for the wireless products.

Location

1. Should not be installed on an outside

wall.

2. Must be installed away from any

direct heat source.

3. Should not be installed near an

air discharge grill.

4. Should not be affected by direct

sun radiation.

5. Nothing should restrict vertical

air circulation to the Terminal

Equipment Controller.

Installation

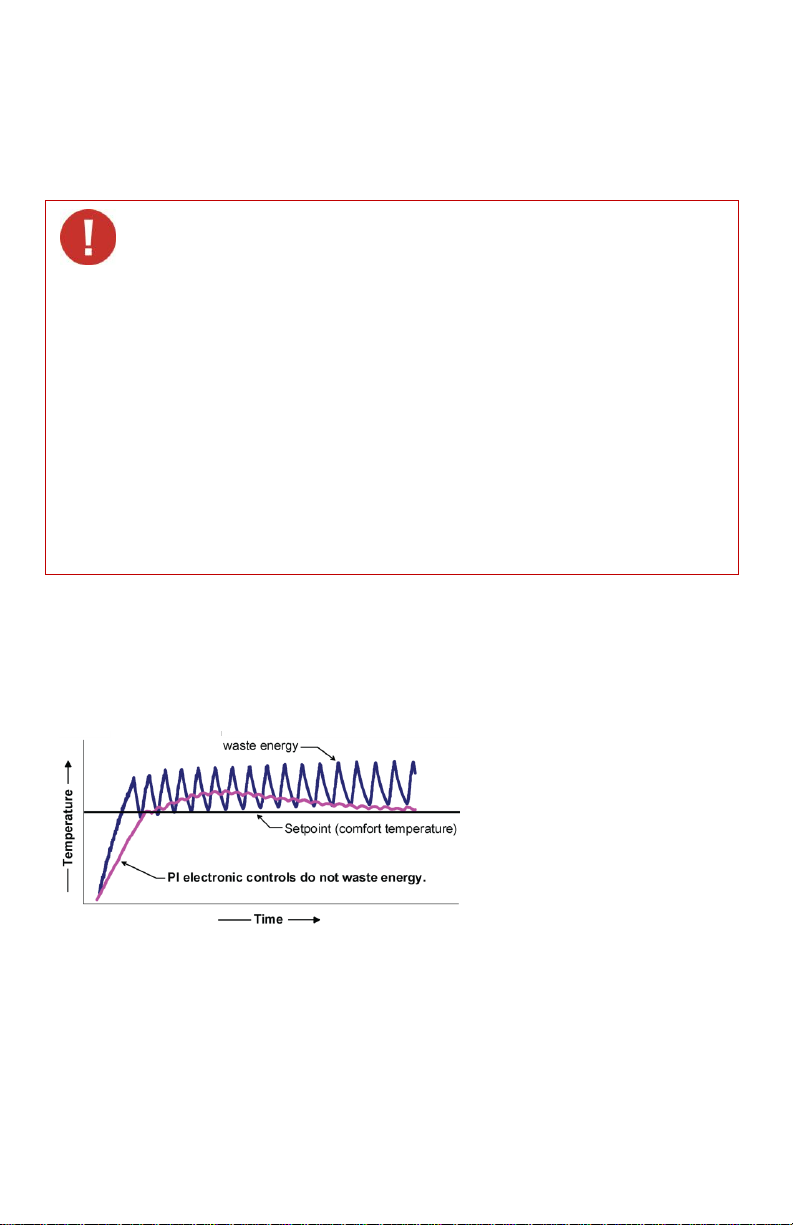

1. Swing open the Terminal

Equipment Controller PCB to

the left by pressing the PCB

locking tabs (fig. 2).

2. Pull out cables 6” out from the

wall.

3. Wall surface must be flat and

clean.

4. Insert cable in the central hole

of the base.

5. Align the base and mark the

location of the two mounting

holes on the wall. Install base in

the proper orientation. Arrow on

base should be facing up.

6. Install anchors in the wall.

7. Insert screws in mounting holes

on each side of the base (fig. 2).

8. Gently swing back the circuit

board on the base and push on

it until the tabs lock it.

9. Strip each wire 1/4 inch from

end.

2 | PIR Ready VT76xxW Series-Installation Guide

Page 3

10. Insert each wire according to wiring diagram.

When replacing an existing Terminal Equipment Controller, label the

wires before removal of the Terminal Equipment Controller.

Electronic controls are static sensitive devices. Discharge yourself

properly before manipulating and installing the Terminal Equipment

Controller.

A short circuit or wrong wiring may permanently damage the Terminal

Equipment Controller or the equipment.

All VT7000 series Terminal Equipment Controllers are designed for use

as operating controls only and are not safety devices. These instruments

have undergone rigorous tests and verification prior to shipping to ensure

proper and reliable operation in the field. Whenever a control failure

could lead to personal injury and/or loss of property, it becomes the

responsibility of the user / installer / electrical system designer to

incorporate safety devices (such as relays, flow switch, thermal

protections, etc…) and/or an alarm system to protect the entire system

against such catastrophic failures. Tampering with the devices or

unintended application of the devices will result in a void of warranty.

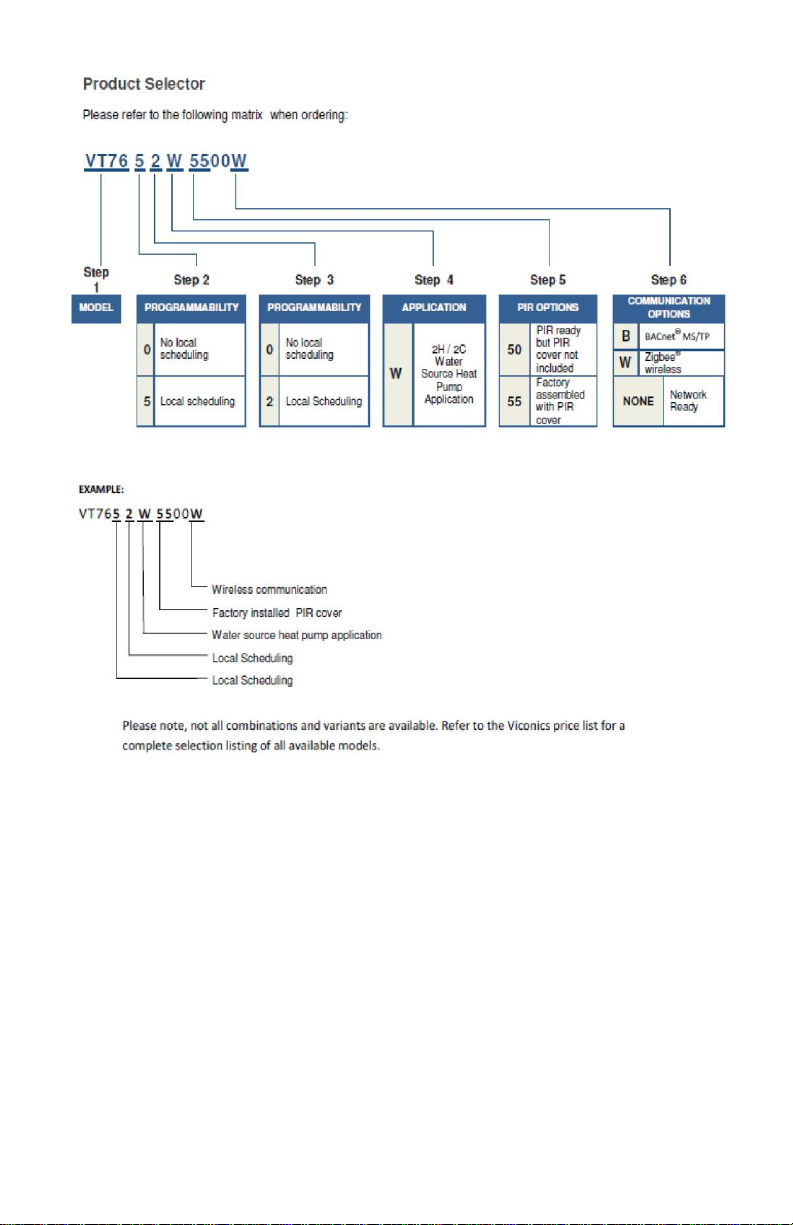

11. Gently push excess wiring back into hole (fig. 3).

12. Re-Install wiring terminals in their correct locations (fig. 3).

13. Re-install the cover (top side first) and gently push extra wire length back into

the hole in the wall.

14. Install security screw.

THEORY OF OPERATION

The VT7600 uses a Viconics proprietary adaptive logic algorithm to control the space

temperature. This algorithm controls the heating / air conditioning system to minimize

overshoot while still providing comfort. It provides exceptional accuracy due to its unique

PI time proportioning control algorithm, which virtually eliminates temperature offset

associated with traditional, differential-based on/off Terminal Equipment Controllers.

Fig.2 - On/Off mechanical control vs PI electronic control.

Features overview

7 day schedule models, 2 or 4 events

Built-in dehumidification control function with local ambient humidity sensing

Selectable single or dual compressor stages

Remote indoor averaging sensing capability

Temperature averaging with 2, 3, 4, 9 or 16 sensors

System mode lock out

3 | PIR Ready VT76xxW Series-Installation Guide

Page 4

Remote discharge air temperature sensor input for monitoring purpose

Remote water temperature sensor input for monitoring purpose

Lockable keypads for tamper proofing. No need for a separate guards

Anti short cycle and minimum on/off run time protection. Reduces wear and

maximizes life span of mechanical equipment.

2 configurable digital inputs for added flexibility. Each input can be configured as the

following:

None: No function will be associated with the input

Service: a backlit flashing Service alarm will be displayed on the Terminal

Equipment Controller LCD screen when the input is energized. It can be tied in

to the AC unit control card, which provides an alarm in case of malfunction.

Filter: a backlit flashing Filter alarm will be displayed on the Terminal

Equipment Controller LCD screen when the input is energized. It can be tied to a

differential pressure switch that monitor filters

Rem NSB: remote NSB timer clock input. Will disable the internal scheduling of

the Terminal Equipment Controller. The scheduling will now be set as per the

digital input. The menu part related to scheduling is disabled and no longer

accessible. It provides low cost setback operation via occupancy sensor or from

a dry contact

RemOVR: temporary occupancy contact. Disables all override menu function of

the Terminal Equipment Controller. . The override function is now controlled by a

manual remote momentarily closed contact. When configured in this mode, the

input operates in a toggle mode.

With this function enabled it is now possible to toggle between unoccupied &

occupied setpoints for the amount of time set by parameter (TOccTime)

temporary occupancy time.

Fan lock: used in conjunction with a local air flow sensor connected to the input.

Locks out the Terminal Equipment Controller heating and cooling action and

displays a local alarm if no air flow is detected 10 seconds after the fan (G

terminal) is energized.

Configurable smart fan operation saves energy during night mode

Non volatile EEPROM memory prevents loss of parameters during power shortage

Built in default profile set-up for easier start up and commissioning

Configurable SPST output relay for lighting, exhaust fan or fresh air control

6 hour typical reserve time for clock in case of power loss on scheduling models

4 | PIR Ready VT76xxW Series-Installation Guide

Page 5

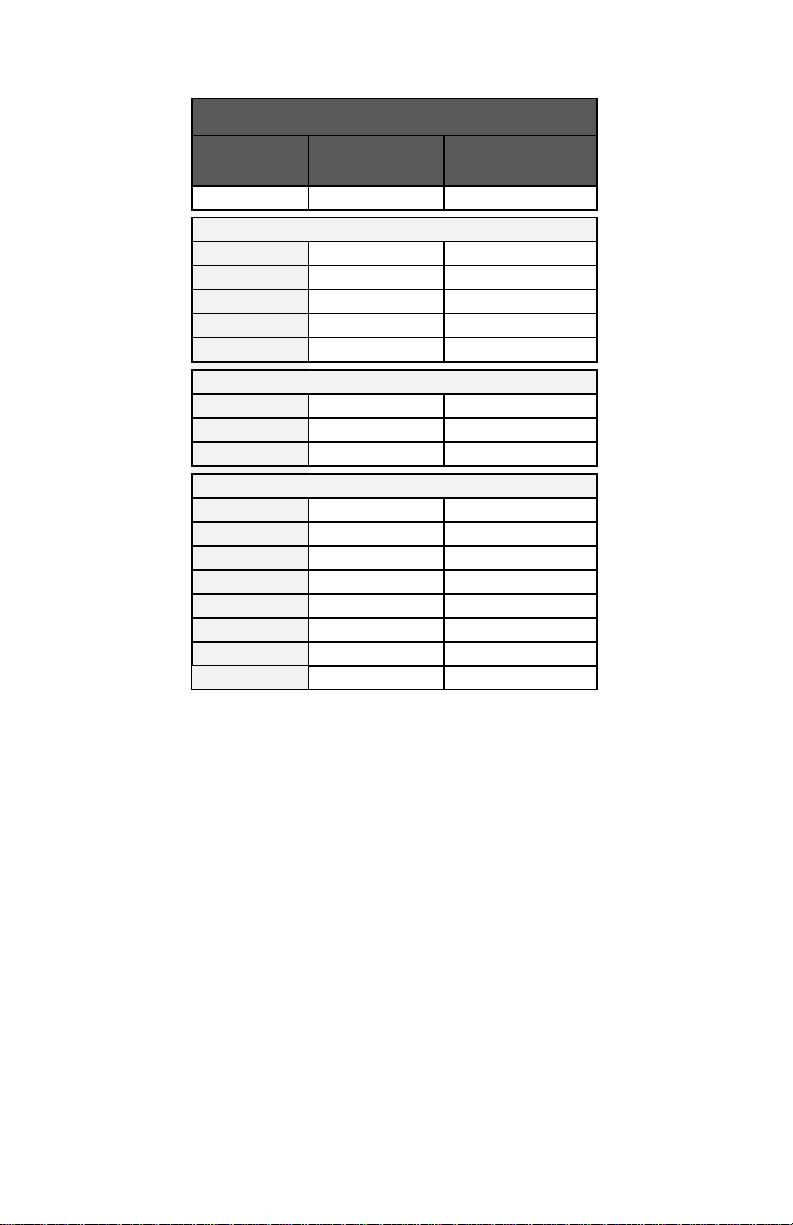

MODEL CHART

Network ready

All Viconics VT7600 series Terminal Equipment Controllers are designed for

stand-alone (Network Ready) operation.

They can be fully integrated into your choice of automation systems using the

available communication adapter options.

If required, stand-alone (Network Ready) Terminal Equipment Controllers can be

field retrofitted with the following communication adapters:

o VCM7600N5000B, Terminal Equipment Controller BACnet™ MS-TP®

communication adapter

o VCM7600N5000W Terminal Equipment Controller wireless Zigbee™

communication adapter

5 | PIR Ready VT76xxW Series-Installation Guide

Page 6

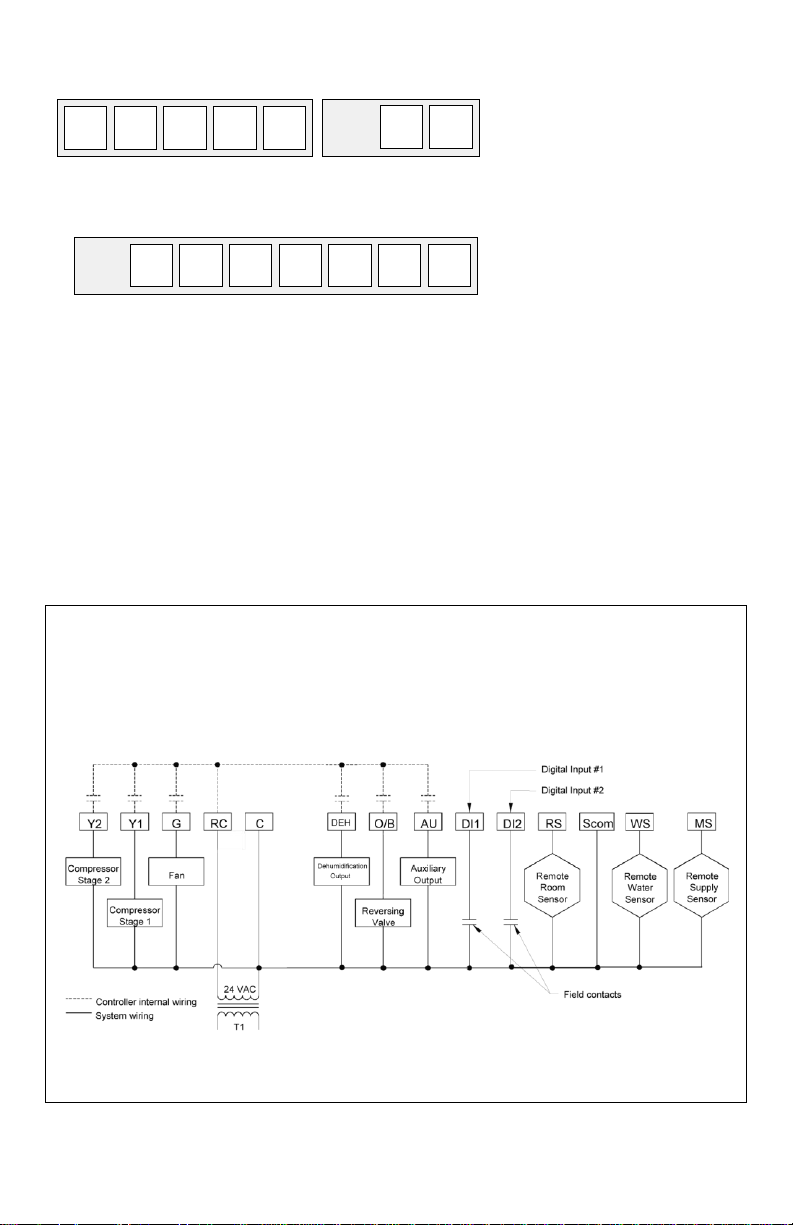

TERMINAL, IDENTIFICATION AND FUNCTION

Water Source Heat Pump

Part Number

VT7652W

VT7600W

Schedule

Yes

No

Top left terminal block

Y2 X X

Y1 X X G X X RC X X C X X Top right terminal block

DEH X X

O/B X X

Bottom terminal block

Aux X X

DI1 X X

DI2 X X

RS X X

Scom X X

WS X X

MS X X

Wiring

6 | PIR Ready VT76xxW Series-Installation Guide

Page 7

Screw terminal arrangement

VT7600W5X00(X)

Water Source Heat pump / Without Schedule

AU

D1

D2

RS

Scom

WS

MS

Y2

Y1 G RC

C

DEH

O/B

5 pole left top connector

2 pole left top connector

7 pole bottom connector

Main outputs wiring

Wiring notes:

Note 1: Electromechanical contacts are to be used with the digital inputs. Electronic triacs

cannot be used as mean of switching for the input. The switched leg to the input for

the input to activate is terminal C (common)

Note 2: The transformer of the unit provides power to the Terminal Equipment Controller

and the additional loads that will be wired to the Terminal Equipment Controller.

TYPICAL APPLICATIONS

7 | PIR Ready VT76xxW Series-Installation Guide

Page 8

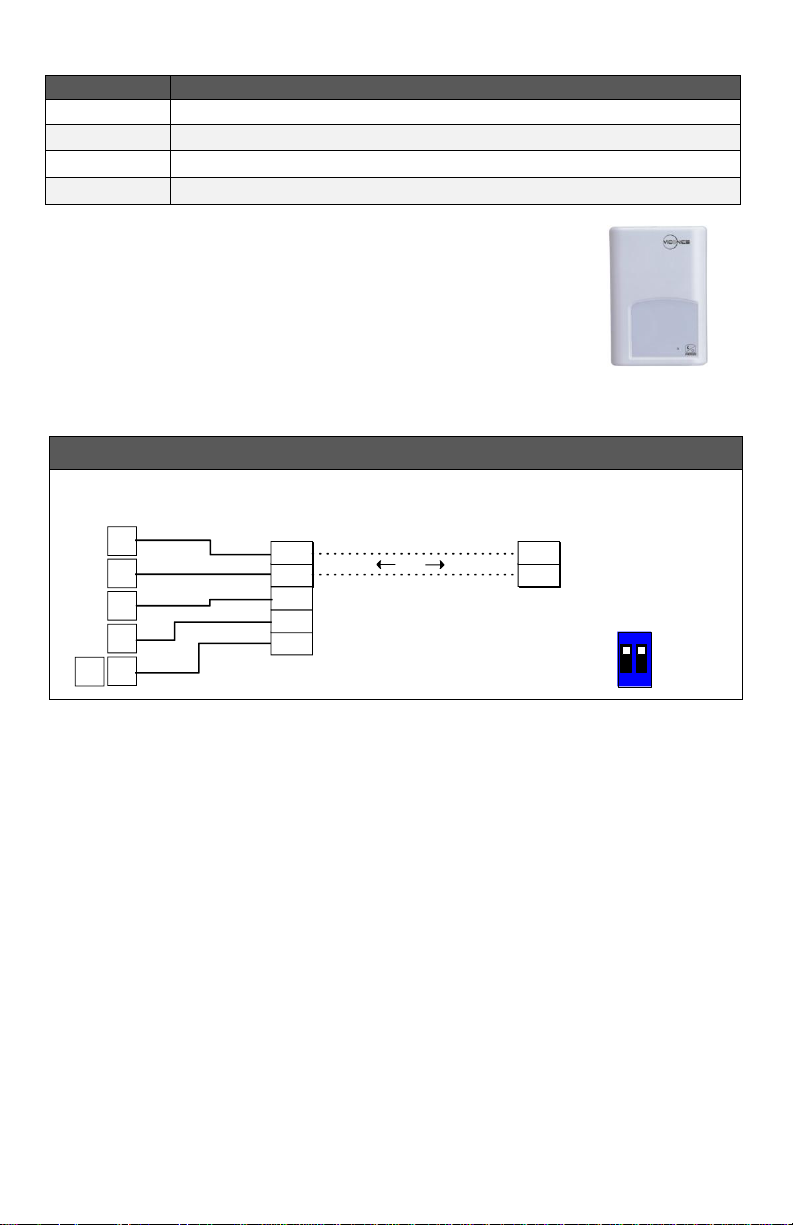

Remote sensor accessories

MODEL NO.

DESCRIPTION

S3010W1000

Wall mounted temperature sensor

S3020W1000

Wall mounted temperature sensor+override button and occupancy status

S2060A1000

Averaging temperature sensor

S2000D1000

Duct mounted temperature sensor

WIRING EXAMPLE OF SINGLE REMOTE ROOM SENSOR:

AU

D1

RS

Scom

C

D2

ScomRSScom

RS

C

DI

Aux

ScomRSScom

RS

OR

VT7600 Series

1x S3020W1000

Remote wiring 1 sensor

S2-1 = ON / S2-2 = ON

S3010W1000

Remote wiring 1 sensor

S2-1 = ON / S2-2 = ON

Dip switch

setting for:

1 sensor

S2-1 = ON

S2-2 = ON

1

2

ON

Dip switch

setting for:

1 sensor

S2-1 = ON

S2-2 = ON

Remote mount temperature sensors use 10K NTC thermistor.

This sensor can be used for:

Various averaging combinations

Optional occupancy led

Optional override key

Wall mounted sensor

8 | PIR Ready VT76xxW Series-Installation Guide

Page 9

WIRING EXAMPLES OF 2 REMOTE ROOM SENSORS FOR AVERAGING APPLICATIONS:

WIRING EXAMPLES OF 3 REMOTE ROOM SENSORS FOR AVERAGING APPLICATIONS:

ºC

ºF

Kohm

ºC

ºF

Kohm

ºC

ºF

Kohm

ºC

ºF

Kohm

ºC

ºF

Kohm

-40

-40

324.3197

-20

-4

94.5149 0

32

32.1910

20

68

12.4601

40

104

5.3467

-39

-38

303.6427

-19

-2

89.2521 1

34

30.6120

21

70

11.9177

41

106

5.1373

-38

-36

284.4189

-18 0 84.3147 2

36

29.1197

22

72

11.4018

42

108

4.9373

-37

-35

266.5373

-17 1 79.6808 3

37

27.7088

23

73

10.9112

43

109

4.7460

-36

-33

249.8958

-16 3 75.3299 4

39

26.3744

24

75

10.4443

44

111

4.5631

-35

-31

234.4009

-15 5 71.2430 5

41

25.1119

25

77

10.0000

45

113

4.3881

-34

-29

219.9666

-14 7 67.4028 6

43

23.9172

26

79

9.5754

46

115

4.2208

-33

-27

206.5140

-13 9 63.7928 7

45

22.7861

27

81

9.1711

47

117

4.0607

-32

-26

193.9703

-12

10

60.3980 8

46

21.7151

28

82

8.7860

48

118

3.9074

-31

-24

182.2686

-11

12

57.2044 9

48

20.7004

29

84

8.4190

49

120

3.7607

-30

-22

171.3474

-10

14

54.1988

10

50

19.7390

30

86

8.0694

50

122

3.6202

-29

-20

161.1499

-9

16

51.3692

11

52

18.8277

31

88

7.7360

51

124

3.4857

Notes for averaging applications:

S3010W1000 and S3020W1000

can be mixed matched.

S3010W1000 and S3020W1000

are to be wired in parallel.

Respect the dip switch setting in

each remote sensor.

AU

D1

RS

Scom

C

D2

ScomRSScom

RS

C

DI

Aux

ScomRSScom

RS

C

DI

Aux

AU

D1

RS

Scom

C

D2

ScomRSScom

RS

ScomRSScom

RS

C

DI

Aux

VT7600 Series

2x S3020W1000

Remote wiring 2 sensors

S2-1 = OFF / S2-2 = ON

AU

D1

RS

Scom

C

D2

ScomRSScom

RS

ScomRSScom

RS

2x S3010W1000

Remote wiring 2 sensors

S2-1 = OFF / S2-2 =

VT7600 Series

VT7600 Series

1x S3010W1000 and 1x S3020W1000

Remote wiring 2 sensors

S2-1 = OFF / S2-2 = ON

Dip switch

setting for:

2 sensors

S2-1 = OFF

S2-2 = ON

Temperature vs. resistance chart for 10 Kohm NTC thermistor

9 | PIR Ready VT76xxW Series-Installation Guide

Page 10

-28

-18

151.6239

-8

18

48.7042

12

54

17.9636

32

90

7.4182

52

126

3.3568

-27

-17

142.7211

-7

19

46.1933

13

55

17.1440

33

91

7.1150

53

127

3.2333

-26

-15

134.3971

-6

21

43.8268

14

57

16.3665

34

93

6.8259

54

129

3.1150

-25

-13

126.6109

-5

23

41.5956

15

59

15.6286

35

95

6.5499

55

131

3.0016

-24

-11

119.3244

-4

25

39.4921

16

61

14.9280

36

97

6.2866

56

133

2.8928

-23

-9

112.5028

-3

27

37.5056

17

63

14.2629

37

99

6.0351

57

135

2.7886

-22

-8

106.1135

-2

28

35.6316

18

64

13.6310

38

100

5.7950

58

136

2.6886

-21

-6

100.1268

-1

30

33.8622

19

66

13.0307

39

102

5.5657

59

138

2.5926

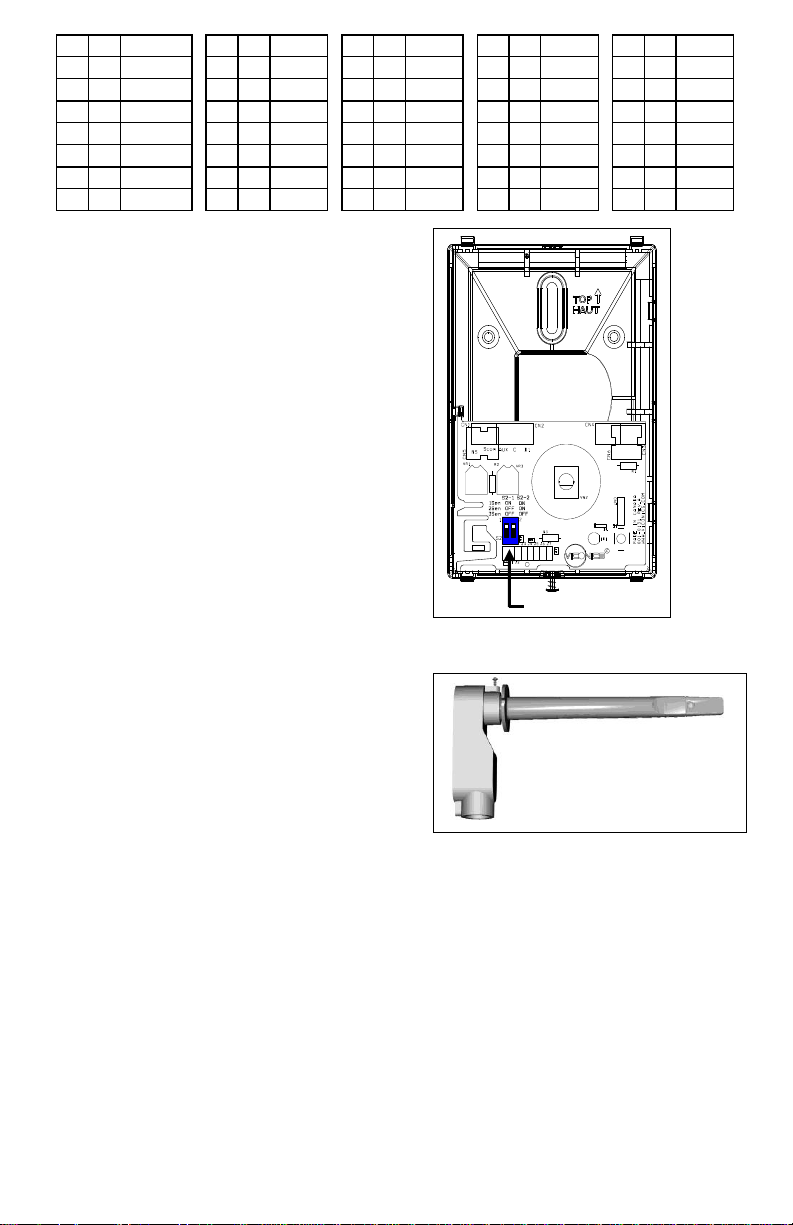

1 2

ON

Location of dip

S3010W1000 remote wall mounted

temperature sensor, dip switch location

S2000D1000, remote duct mounted temperature

sensor c/w junction box.

This sensor can be used for:

Remote return air temperature sensing with the

sensor mounted on the return air duct.

Outside air temperature sensing with the

sensor installed in the fresh air plenum.

Supply air temperature sensor

S2060A1000, remote averaging duct mounted temperature sensor c/w junction box.

This sensor can be used for:

Remote averaging return air temperature sensing with the sensor mounted on the return

air duct.

Outside air temperature averaging sensing with the sensor installed in the fresh air

plenum.

Mixed air temperature averaging sensor for economizer models with the sensor in the

mixing plenum.

10 | PIR Ready VT76xxW Series-Installation Guide

Page 11

WIRING S2000D1000, S2060A1000 AND S2020E1000

Remote wiring 1 sensor Remote wiring 4 sensors

10 K

10 K

10 K

10 K

10 K

Scom

MS

Scom

OS

Scom

RS

or

or

ScomMSScom

OS

Scom

RS

or

or

(

Schedule

set? Y/N

Sys mode

set? Y/N

Clock

set? Y/N

Temperat

set? Y/N

Schedule

hold Y/N

Exit

menu Y/N

Unocc HT

set? Y/N

°F/°C

set? Y/N

Heating

set? Y/N

Unocc CL

set? Y/N

Cooling

set? Y/N

°C

°F

Exit?

Y/N

Temperature

Temperature

Temperature

Temperature

MENU

12/24hrs

set? Y/N

12 / 24

Time

set? Y/N

Time

Day

set? Y/N

Day

Fan mode

set? Y/N

On

Smart

Auto

Sunday

set? Y/N

Saturday

set? Y/N

Friday

set? Y/N

Thursday

set? Y/N

Wednesda

set? Y/N

Tuesday

set? Y/N

Monday

set? Y/N

Exit?

Y/N

Occupied

day? Y/N

Occupied

12:00 pm

Time

Unoccup

12:00 pm

Time

Occupied

day? Y/N

Occupied

12:00 pm

Time

Unoccup

12:00 pm

Time

Occupied

day? Y/N

Occupied

12:00 pm

Time

Unoccup

12:00 pm

Time

Occupied

day? Y/N

Occupied

12:00 pm

Time

Unoccup

12:00 pm

Time

Occupied

day? Y/N

Occupied

12:00 pm

Time

Unoccup

12:00 pm

Time

Occupied

day? Y/N

Occupied

12:00 pm

Time

Unoccup

12:00 pm

Time

Occupied

day? Y/N

Occupied

12:00 pm

Time

Unoccup

12:00 pm

Time

Resume

Occ Hold

Uno Hold

Exit?

Y/N

off

heat

cool

auto

Override

schd Y/N

Cancel

ovrd Y/N

If status is:

Unoccupied

If status is:

Temporary Occupied Time,

Appears on stand-alone

models only

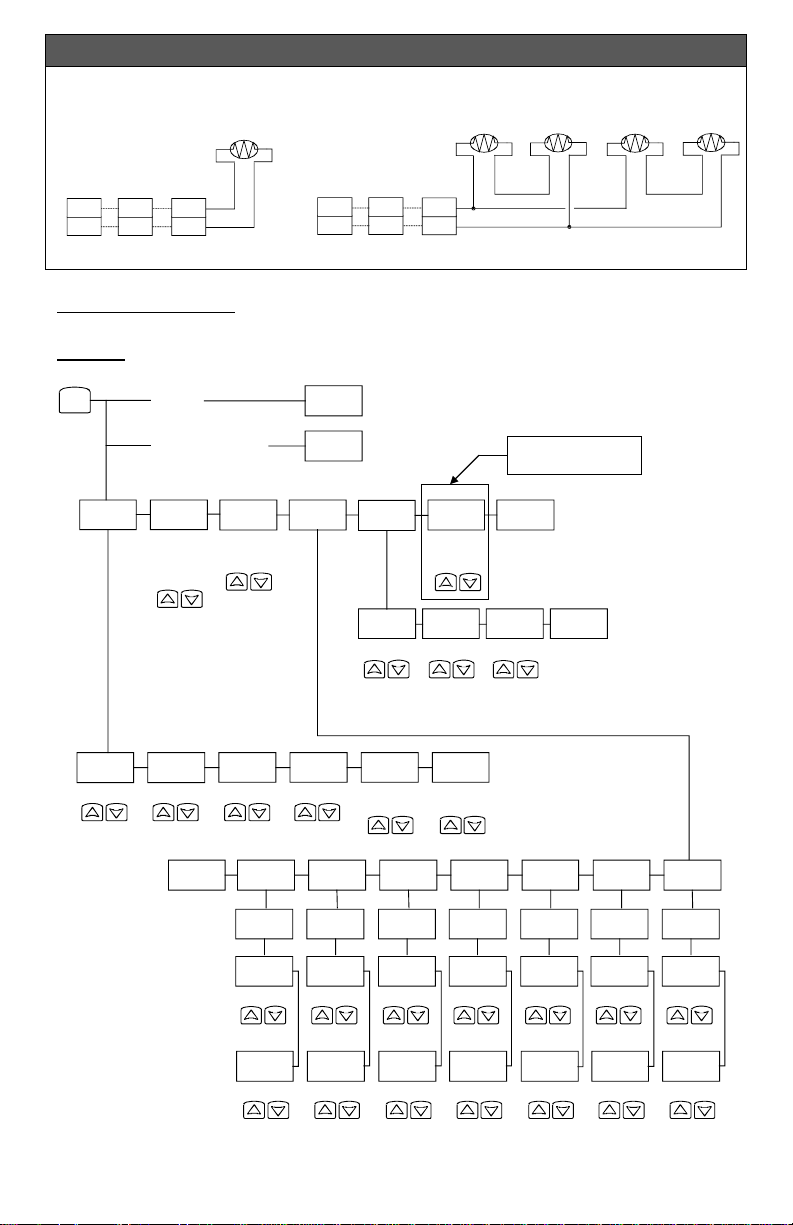

User menu flow chart:

NOTE: Prompts may not all be present depending on model selected

CONFIGURING AND STATUS DISPLAY INSTRUCTIONS

11 | PIR Ready VT76xxW Series-Installation Guide

Page 12

Status display

ROOM

TEMPERATURE

CLOCK

STATUS

SYSTEM

MODE

SCHEDULE

STATUS

OUTDOOR

TEMPERATURE

ALARMS

x.x °C

or °F

XX % RH

Monday

12:00

AM

Sys mode

auto

Occupied

Outdoor

x.x °C or°F

Service

Sys mode

off

Occupied

hold

Frost

ON

Sys mode

heat

Unoccup

SetClock

Sys mode

cool

Unoccup

hold

Filter

Fan lock

The Terminal Equipment Controller features a two-line, eight-character display. There is a

low level backlight level that is always active and can only be seen at night.

When left unattended, the Terminal Equipment Controller has an auto scrolling display

that shows the actual status of the system.

Each item is scrolled one by one with the back lighting in low level mode. Pressing any

key will cause the back light to come on to high level.

Manual scroll of each menu item is achieved by pressing the Yes (scroll) key repetitively.

The last item viewed will be shown on the display for 30 seconds before returning to

automatic scrolling. Temperature is automatically updated when scrolling is held.

Sequence of auto-scroll status display:

Alarms

If alarms are detected, they will automatically be displayed at the end of the status

display scroll.

During an alarm message display, the back lit screen will light up at the same time as

the message and shut off during the rest of the status display.

Two alarms maximum can appear at any given time.

The priority for the alarms is as follows:

12 | PIR Ready VT76xxW Series-Installation Guide

Page 13

Frost ON

Indicates that the heating is energized by the low limit frost protection room

temperature setpoint 5.6 °C ( 42 °F )

SetClock

Indicates that the clock needs to be reset. There has been a power failure

which has lasted longer than 6 hours

Service

Indicates that there is a service alarm as per one of the configurable digital

input ( DI1 or DI2 )

Filter

Indicates that the filters are dirty as per one of the configurable digital input (

DI1 or DI2 )

Fan lock

Indicates that the heating and cooling action are locked out due to a defective

fan operation

When any of the fan is ON, the FAN LED will illuminate

When heating is ON, the HEAT LED will illuminate

When cooling is ON, the COOL LED will illuminate

LED

OPERATION

HEATPUMP

MODELS

Fan LED on

When G Fan terminal

operates

Heating LED

on

When Y1 terminal

operates in heating

mode

Cooling LED

on

When Y1 terminal

operates in cooling

mode

Three status LEDs on the Terminal Equipment Controller cover are used to indicate the

status of the fan, a call for heat, or a call for cooling.

USER INTERFACE

User configuring instructions menu

The VT7600 series of Terminal Equipment

Controller feature an intuitive, menu-driven, back-lit

LCD display that walks users through the

configuring steps, making the configuring process

extremely simple. This menu is typically accessed

by the user to set the parameters such as

temperature and time events, system mode, fan

mode, etc.

It is possible to bring up the user menu at any time by depressing the MENU key. The

status display automatically resumes after exiting the user-configuring menu.

13 | PIR Ready VT76xxW Series-Installation Guide

Page 14

If the user pauses at any given time during configuring, Auto Help text is displayed to help

Ex.:

Press yes key to change cooling temperature setpoint

Use the up or down arrow to adjust cooling setpoint

The YES key is used to confirm a selection, to move onto the next menu item

and to manually scroll through the displayed information.

The NO key is used when you do not desire a parameter change, and to

advance to the next menu item. Can also be used to toggle between heating

and cooling setpoints.

The MENU key is used to access the Main User Menu or exit the menu.

The down arrow key is used to decrease temperature setpoint and to adjust

the desired values when configuring the Terminal Equipment Controller.

The up arrow key is used to increase temperature setpoint and to adjust the

desired values when configuring the Terminal Equipment Controller.

and guide the user through the usage and configuring of the Terminal Equipment

Controller.

Local keypad interface

Each of the sections in the menu is accessed and configured using 5 keys on the

Terminal Equipment Controller cover.

The priority for the alarms is as follows:

When left unattended for 45 seconds, the display will resume automatic status display

scrolling.

To turn on the back light, press any key on the front panel. The back lit display will turn off

when the Terminal Equipment Controller is left unattended for 45 seconds

14 | PIR Ready VT76xxW Series-Installation Guide

Page 15

Sequence of user menu:

OVERRIDE

RESUME

TEMPERATURE

SETPOINTS

SYSTEM

MODE

SETTING

FAN

MODE

SETTING

SCHEDULES

SETTING

CLOCK

SETTING

SCHEDULE

HOLD

Override

schd Y/N

Temperat

Set Y/N

Sys

mode

set

Y/N

Fan

mode

set Y/N

Schedule

set Y/N

Clock

set Y/N

Schedule

hold Y/N

Appears

only in

unoccupied

mode

Appears

only on

stand-alone

(Network

Ready)

models

Cancel

ovrd Y/N

Appears

only in

override

mode

DEFAULT TEMPERATURE SETPOINTS:

DEFAULT MODES:

Occupied cooling setpoint = 24 °C (75 °F)

System mode = Auto

Occupied heating setpoint = 22 °C (72 °F)

Fan mode = Smart (for models with a

communication module

or scheduling network

ready models)

Fan mode = Auto (for non-scheduling

network ready models)

Unoccupied cooling setpoint = 28 °C (82°F)

Unoccupied heating setpoint = 18 °C (65°F)

DEFAULT SCHEDULES:

Fahrenheit scale

Monday through Sunday

Setpoint type = permanent

Occupied time is: 12 00 AM

Unoccupied time is: 11:59 PM

Occupied setpoints adjustments

There is a default profile set in the Terminal Equipment Controller from the factory.

This enables the Terminal Equipment Controller to operate as a non-scheduling unit in

day mode operation at start up.

There will be a 1 minute unoccupied period every night at 11:59 PM with this default

configuration.

15 | PIR Ready VT76xxW Series-Installation Guide

Page 16

A) Override an unoccupied period

Override

schd Y/N

Cancel

ovrd Y/N

Temperat

set Y/N

COOLING

SETPOINT

OCCUPIED

MODE

HEATING

SETPOINT

OCCUPIED

MODE

COOLING

SETPOINT

UNOCCUPIED

MODE

HEATING

SETPOINT

UNOCCUPIED

MODE

°F OR °C

DISPLAY

SETTING

Cooling

set? Y/N

No next

Yes down

Heating

set? Y/N

No next

Yes down

Unocc CL

set? Y/N

No next

Yes down

Unocc HT

set? Y/N

No next

Yes down

°F or °C

set? Y/N

No next

Yes down

Use ▲▼ keys to set value, Yes key to confirm

Cooling

70.0 °F

Use ▲▼

To set

value

Heating

68.00 °F

Use ▲▼

To set

value

Unocc CL

80.0 °F

Use ▲▼

To set

value

Unocc HT

60.0 °F

Use ▲▼

To set

value

Units

°F

Use ▲▼

To set

value

This menu will appear only when the Terminal Equipment Controller is in unoccupied

mode. The unoccupied mode is enabled either by the internal timer scheduling or by a

remote NSB contact via DI1 or DI2.

If DI1 or DI2 is configured to operate as a remote temporary override contact, this menu

will be disabled.

Answering yes to this prompt will cause the Terminal Equipment Controller to go into

occupied mode for an amount of time equal to the parameter “TOccTime” (1 to 12 hours).

B) Resume regular scheduling

This menu does not appear in regular operation. It will appear only when the Terminal

Equipment Controller is in Unoccupied override mode.

Answering “Yes” to this question will cause the Terminal Equipment Controller to resume

the regular setpoints & scheduling.

C) Temperature setpoints

Permanent setpoint changes

This menu permits the adjustment of all permanent temperature setpoints (occupied and

unoccupied) as well as the desired temperature units (°F or °C). Permanent setpoints are

written to RAM and EEPROM.

Temporary setpoint changes

Temporary setpoints can be modified through the Up arrow key (▲) and the Down arrow

keys (▼).

User will be prompted with the present mode (Heating or Cooling) of the Terminal

Equipment Controller and its setpoint.

The Up (▲) arrow key will increment the setpoint by 0.5 degree (F or C).

The Down (▼) arrow key will decrement the setpoint by 0.5 degree (F or C).

Press the Yes key to accept the new setpoint.

16 | PIR Ready VT76xxW Series-Installation Guide

Page 17

Local changes to the heating or cooling setpoints made by the user directly using the up

Sys mode

set Y/N

Sys mode

auto

Automatic mode

Automatic changeover mode between heating and cooling operation

Sys mode

cooling

Cooling mode

Cooling operation mode only

Sys mode

heating

Heating mode

Heating operation mode only

Sys mode

off

Off mode Normal cooling or heating operation disabled

If enabled in installer parameters, only the automatic heating frost protection

at 50 °F ( 10 °C ) is enabled

Fan mode

set Y/N

Fan mode

On

On fan mode

Fan is on continuously, even when system mode is OFF.

Fan mode

Auto

Automatic fan mode

Fan cycles on a call for heating or cooling for both occupied & unoccupied

periods.

Fan mode

Smart

Smart fan mode

During occupied periods, fan is on continuously. In unoccupied mode, fan

cycles on a call for heating or cooling.

This selection is available on all models with a communication module, on

all stand-alone (Network Ready) scheduling models or if DI1 or DI2 is set

to RemNSB on stand-alone non-scheduling models.

or down arrow are temporary.

They will remain effective for the duration specified by ToccTime.

Setpoints will revert back to their default value after internal timer ToccTime expires.

If a permanent change to the setpoints is required, use the Temperat set ? menu

D) System mode setting

This menu is accessed to set system mode operation

Use ▲▼ to set value, Yes key to confirm

E) Fan mode setting

This section of the menu is permits the setting of the fan mode operation.

Use ▲▼ to set value, Yes key to confirm

17 | PIR Ready VT76xxW Series-Installation Guide

Page 18

F) Schedule set (2 events)

Schedule

set Y/N

MONDAY TIMER

SCHEDULE SET

TUESDAY

TIMER

SCHEDULE SET

WEDNESDAY

TIMER

SCHEDULE SET

OTHER DAYS ARE

IDENTICAL

Monday

set? Y/N

No next

Yes down

Tuesday

set? Y/N

No next

Yes down

Wednesda

set? Y/N

No next

Yes down

Selects the day to be scheduled or

modified

Yes key to access day scheduling, No key to jump to next day

Occupied

Day? Y/N

No next

Yes down

Occupied

Day? Y/N

No next

Yes down

Occupied

Day? Y/N

No next

Yes down

Yes = Daily schedules will be

accessed

No = Unoccupied mode all day

Yes key to access day scheduling, No key to jump to next day

Copy Y/N

Previous

Yes next

No down

Copy Y/N

Previous

Yes next

No down

Yes = Will copy previous day

schedule

No = Daily schedules will be

accessed

Yes key to copy previous day, No key to set new time value for each day

Occupied

00:00 AM

Use ▲▼

To set

value

Occupied

00:00 AM

Use ▲▼

To set

value

Occupied

00:00 AM

Use ▲▼

To set

value

Sets Event # 1 Occupied time

Will activate occupied setpoints

Use ▲▼ to set value, Yes key to confirm

Unoccup

00:00 AM

Use ▲▼

To set

value

Unoccup

00:00 AM

Use ▲▼

To set

value

Unoccup

00:00 AM

Use ▲▼

To set

value

Sets Event # 2 Unoccupied time

Will activate unoccupied setpoints

Use ▲▼ to set value, Yes key to confirm

Event

Period #1 - Event #1

Period #1 - Event #2

Occupied

Unoccupied

Setpoint

Cool

Heat

Cool

Heat Daily

72 °F

70 °F

80 °F

62 °F

Occupancy

Monday

7.00 AM

6.00 PM

Day time only

Tuesday

7.00 AM

6.00 PM

Day time only

Wednesday

7.00 AM

6.00 PM

Day time only

Thursday

7.00 AM

6.00 PM

Day time only

Friday

7.00 AM

6.00 PM

Day time only

Saturday

12.00 PM *

12.00 PM *

Unoccupied

Sunday

12.00 PM *

12.00 PM *

Unoccupied

Scheduling can have 2 or 4 events per day. This is set in the configuration menu as per

parameter (2/4event)

This section of the menu permits the user to set the whether 2 or 4 events is needed.

Each day can be tailored to specific schedules if needed.

2 events can be scheduled per day.

Occupied & unoccupied periods can be set for each day.

Typical examples of a 2 event office schedule:

Ex. #1 Office building closed all weekend

* Scheduling consecutive events to the same time will cause the Terminal Equipment

Controller to choose the last event as the time at which it will set its schedule. In the

above example, the Terminal Equipment Controller will control to the unoccupied set

point until 7:00 AM Monday.

18 | PIR Ready VT76xxW Series-Installation Guide

Page 19

Ex. #2 Commercial building which is occupied all weekend

Event

Period #1 - Event

#1

Period #1 - Event

#2

Occupied

Unoccupied

Setpoint

Cool

Heat

Cool

Heat Daily

72 °F

70 °F

80 °F

62 °F

Occupancy

Monday

8.00 AM

5.00 PM

Day time only

Tuesday

8.00 AM

5.00 PM

Day time only

Wednesday

8.00 AM

5.00 PM

Day time only

Thursday

8.00 AM

5.00 PM

Day time only

Friday

8.00 AM

5.00 PM

Day time only

Saturday

12.00 AM **

11.59 PM **

Occupied

Sunday

12.00 AM **

11.59 PM **

Occupied

Schedule

set Y/N

Monday timer

Schedule set

Tuesday timer

Schedule set

Wednesday timer

Schedule set

Other days are identical

Monday

set? Y/N

No next

Yes down

Tuesday

set? Y/N

No next

Yes down

Wednesda

set? Y/N

No next

Yes down

Selects the day to be scheduled or

modified

Yes key to access day scheduling, No key to jump to next day

Occupied

Day? Y/N

No next

Yes down

Occupied

Day? Y/N

No next

Yes down

Occupied

Day? Y/N

No next

Yes down

Yes = Daily schedules will be

accessed

No = Unoccupied mode all day

Yes key to access day scheduling, No key to jump to next day

Copy Y/N

Previous

Yes next

No down

Copy Y/N

Previous

Yes next

No down

Yes = Will copy previous day

schedule

No = Daily schedules will be

accessed

Yes key to copy previous day, No key to set new time value for each day

Occupied

00:00 AM

Use ▲▼

To set

value

Occupied

00:00 AM

Use ▲▼

To set

value

Occupied

00:00 AM

Use ▲▼

To set

value

Sets Event # 1 Occupied time

Will activate occupied setpoints

Use ▲▼ to set value, Yes key to confirm

Unoccup

00:00 AM

Use ▲▼

To set

value

Unoccup

00:00 AM

Use ▲▼

To set

value

Unoccup

00:00 AM

Use ▲▼

To set

value

Sets Event # 2 Unoccupied time

Will activate unoccupied

setpoints

Use ▲▼ to set value, Yes key to confirm

Occupie2

00:00 AM

Use ▲▼

To set

value

Occupie2

00:00 AM

Use ▲▼

To set

value

Occupie2

00:00 AM

Use ▲▼

To set

value

Sets Event # 3 Occupied time

Will activate occupied setpoints

Use ▲▼ to set value, Yes key to confirm

Unoccup2

00:00 AM

Use ▲▼

To set

value

Unoccup2

00:00 AM

Use ▲▼

To set

value

Unoccup2

00:00 AM

Use ▲▼

To set

value

Sets Event # 4 Unoccupied time

Will activate unoccupied

setpoints

Use ▲▼ to set value, Yes key to confirm

Note: 12:00 PM = Noon

** To schedule a day as occupied for 24 hours, set that day occupied time to 12:00 AM

and Unoccupied time to 11:59 PM There will be a 1 minute unoccupied period every

night at 11:59 PM with this schedule configuration.

G) Schedule set (4 events)

This section of the menu permits the user to set the whether 2 or 4 events is needed. Each

day can be tailored to specific schedules if needed.

4 events can be scheduled per day.

Occupied & Unoccupied periods can be set for each day.

Scheduling the 3rd. & 4th. Events to the same time will cancel the last period.

19 | PIR Ready VT76xxW Series-Installation Guide

Page 20

Ex. #1 Four event retail establishment schedule

Event

Period 1 -

Event 1

Period 1 -

Event 2

Period 2 -

Event 3

Period 2 -

Event 4

Setpoint

Occupied

Unoccupied

Occupied

Unoccupied

Cool

Heat

Cool

Heat

Cool

Heat

Cool

Heat

Daily

72°F

70°F

80°F

62°F

72°F

70 °F

80°F

62 °F

Occupancy

Monday

7.00 AM

5.00 PM

12.00 PM *

12.00 PM *

Day time only

Tuesday

7.00 AM

5.00 PM

12.00 PM *

12.00 PM *

Day time only

Wednesday

7.00 AM

5.00 PM

12.00 PM *

12.00 PM *

Day time only

Thursday

7.00 AM

5.00 PM

7.00 PM

10.30 PM

Day/evening

time only

Friday

7.00 AM

5.00 PM

7.00 PM

10.30 PM

Day/evening

time only

Saturday

12.00 PM *

12.00 PM *

12.00 PM *

12.00 PM *

Unoccupied

Sunday

12.00 PM *

12.00 PM *

12.00 PM *

12.00 PM *

Unoccupied

Event

Period 1 -

Event 1

Period 1 -

Event 2

Period 2 -

Event 3

Period 2 -

Event 4

Setpoint

Occupied

Unoccupied

Occupied

Unoccupied

Cool

Heat

Cool

Heat

Cool

Heat

Cool

Heat

Daily

72°F

70°F

80°F

62°F

72°F

70°F

80°F

62°F

Occupancy

Monday

6:00 AM

8:00 AM

4:00 PM

10:00 PM

Day/evening

time only

Tuesday

6:00 AM

8:00 AM

4:00 PM

10:00 PM

Day/evening

time only

Wednesday

6:00 AM

8:00 AM

4:00 PM

10:00 PM

Day/evening

time only

Thursday

6:00 AM

8:00 AM

4:00 PM

10:00 PM

Day/evening

time only

Friday

6:00 AM

8:00 AM

4:00 PM

11:30 PM

Day/evening

time only

Saturday

8:00 AM *

8:00 AM *

8:00 AM *

11:59 PM *

Day time

only

Sunday

12:00 AM *

12:00 AM *

12:00 AM *

11:59 PM *

Occupied all

day

* Scheduling events to the same time will cancel the last period and leave the Terminal

Equipment Controller in unoccupied mode

Ex. #2 Residential

* Scheduling consecutive events to the same time will cause the Terminal Equipment

Controller to choose the last event as the time at which it will set its schedule. In the above

example for Saturday, the Terminal Equipment Controller will control to the occupied set

point from 8:00 AM until 11:59 PM. Since it is desired to be in occupied mode throughout

the night, then it is necessary to schedule the first event on Sunday at 12:00 AM. The

Terminal Equipment Controller will force a one minute unoccupied period for a one minute

period (between 11:59 PM and 12:00 AM on Saturday).

20 | PIR Ready VT76xxW Series-Installation Guide

Page 21

H) Clock/Day Settings

Clock

set Y/N

Time setting

Day setting

Time format setting

Time

set? Y/N

No next

Yes down

Day

set? Y/N

No next

Yes down

12/24hrs

set? Y/N

No = exit

Yes down

Time

0:00

Use ▲▼

To set value

Day

Monday

Use ▲▼

To set value

12/24hrs

12 hrs

Use ▲▼

To set value

Schedule

hold Y/N

Schedule

resume

Resume regular scheduling cancels the permanent hold and re-enables

the regular scheduling as set per internal schedule or as per remote NSB

via one of the DI’s configured as remote NSB.

This action can also by accomplished by using the Resume menu.

Any temporary setpoint that are active will be left active for the duration of

the period as set per the TOccTime parameter.

Schedule

occ hold

Hold permanent occupied forces the Terminal Equipment Controller into

a permanent occupied mode using the occupied setpoints. All timed

scheduling functions are by-passed.

The PERMANENT OCCUPIED status will appear in the automatic status

scroll. To resume to regular scheduling, user must scroll to the Schedule

Hold menu and select the Schedule resume option.

This section of the menu permits the user to set the time and day.

J) Schedule hold

This menu will only appear on stand-alone (Network Ready) Terminal

Equipment Controller, i.e. without a BACnet™ / Echelon™ module.

This section of the menu permits the user to set a permanent schedule

hold, which bypasses the internal Terminal Equipment Controller

scheduling.

The permanent schedule hold function is typically used for non-

scheduled events that extend for various periods of time.

Enabling a permanent occupied or permanent unoccupied schedule hold

will cancel any active override.

The use of temporary setpoints during permanent hold is permitted. The

duration of the temporary setpoint is as set per the TOccTime parameter.

Ex. 3 hours

Use ▲▼ to set value, yes key to confirm

21 | PIR Ready VT76xxW Series-Installation Guide

Page 22

Schedule

uno hold

Hold permanent unoccupied forces the Terminal Equipment Controller

into a permanent unoccupied mode using the unoccupied setpoints. All

timed scheduling functions are by-passed.

The PERMANENT UNOCCUPIED status will appear in the automatic

status scroll. To resume to regular scheduling, user must scroll to the

Schedule Hold menu and select the Schedule resume option.

INSTALLER CONFIGURATION PARAMETER MENU

Configuration can be done through the network or locally at the Terminal Equipment

Controller.

To enter configuration, press and hold the middle button “Menu” for 8 seconds

If a password lockout is active, “Password” is prompted. Enter password value using the

“up” and “down” arrows and press “Yes” to gain access to all configuration properties of

the Terminal Equipment Controller. A wrong password entered will prevent local access to

the configuration menu.

Once in the configuration menu, press the “No” button repetitively to scroll between all the

available parameters.

When the desired parameter is displayed, press “Yes” to adjust it to the desired value

using “up” and “down” arrows. Once set, press “Yes” to scroll to the next parameter.

22 | PIR Ready VT76xxW Series-Installation Guide

Page 23

CONFIGURATION

PARAMETERS

DEFAULT VALUE

SIGNIFICANCE AND ADJUSTMENTS

PswrdSet

Configuration parameters

menu access password

Default value = 0

No password prompted

This parameter sets a password access to prevent

unauthorized access to the configuration menu

parameters. A default value of “0” will not prompt a

password or lock the access to the configuration

menu.

Range is: 0 to 1000

Com Addr

Terminal Equipment

Terminal Equipment Controller

networking address

Default value = 254

Range is: 0 to 254

Conditional parameter to BACnet™ MS-TP models

(VT76xxW5x00B)

Conditional parameter to Wireless models

(VT76xxW5x00W)

This parameter will only appear when a BACnet™ or

wireless network adapter is present. If the Terminal

Equipment Controller is installed as a stand-alone

(Network Ready) unit or with an Echelon™ adapter, this

parameter will not be used or displayed

-For BACnet™ MS-TP models, the valid range to is from

1 to 127. Default value of 254 disables BACnet™

communication for the Terminal Equipment Controller.

For wireless models valid range is 0 to 254 with a

maximum of 30 Terminal Equipment Controllers per

VWG

PAN ID

Personal Area Network

Identification

Default value = 0

Range is: 0 to 1000

Conditional parameter to Wireless models

(VT76xxW5x00W)

This parameter will only appear when a wireless

network adapter is present. If the Terminal

Equipment Controller is installed as a stand-alone

(Network Ready) unit or with a BACnet™ or

Echelon™ adapter, this parameter will not be used or

displayed

This parameter (Personal Area Network

Identification) is used to link specific Terminal

Equipment Controllers to a single specific Viconics

wireless gateway ( VWG ) For every Terminal

Equipment Controller reporting to a gateway

( maximum of 30 Terminal Equipment Controllers per

gateway ), be sure you set the SAME PAN ID value

both at the gateway and the Terminal Equipment

Controller(s).

The default value of 0 is NOT a valid PAN ID.

23 | PIR Ready VT76xxW Series-Installation Guide

Page 24

Channel

Channel selection

Default value = 10

Range is: 10 to 26

Conditional parameter to Wireless models

(VT76xxW5x00W)

This parameter will only appear when a wireless

network adapter is present. If the Terminal Equipment

Controller is installed as a stand-alone (Network

Ready) unit or with a BACnet™ or Echelon™ adapter,

this parameter will not be used or displayed

This parameter (Channel) is used to link specific

Terminal Equipment Controllers to specific Viconics

wireless gateway(s) (VWG) For every Terminal

Equipment Controller reporting to a gateway

(maximum of 30 Terminal Equipment Controllers per

gateway), be sure you set the SAME channel value

both at the gateway and the Terminal Equipment

Controller(s).

Viconics recommends using only the usage of

channels 15 and 25 only.

The default value of 10 is NOT a valid channel. The

valid range of available channel is from 11 to 26

Get From

Terminal Equipment Controller

Get From another device

configuration utility

Default value = 0

Range is: 0 to 254

Conditional parameter to Wireless models

VT76xxW5x00W

Entering a MAC address enables an automatic routine

that automatically fetches all the required configuration

properties of the current device from another already

configured device an copies the same required

configured property values.

If a value other than the default value of 255 is entered,

user will then be prompted to exit the Configuration

Menu thus leaving all other parameter configuration to

be copied from the referenced Terminal Equipment

Controller MAC address.

Ex.: If you are currently configuring MAC12 and the

settings matches exactly the settings of ZN MAC5,

then enter 5 as the current parameter value.

If the process is successful and all required

configuration properties have been copied, the

value will revert back to 255

If the process is NOT successful and all required

configuration properties have NOT been copied

( either the reference device is NOT the same

model number or is offline or does not exists ) the

value will revert back to 254 to indicate the failure

of the process

Leaving the Get From parameter to 255 means that

every configuration parameters will be set

manually.

24 | PIR Ready VT76xxW Series-Installation Guide

Page 25

DI 1

Digital input no.1

configuration

Open contact input =

function not energized

Closed contact input =

function energized

Default Value = None

(None) : No function will be associated with the input

(Rem NSB): remote NSB timer clock input. Will disable the

internal scheduling of the Terminal Equipment Controller. The

scheduling will now be set as per the digital input. The time is

still displayed as information, but the menu part related to

scheduling is disabled and no longer accessible.

Open contact = occupied setpoints

Closed contacts = unoccupied setpoints

(RemOVR): Temporary override remote contact. Disables all

override menu function of the Terminal Equipment Controller.

The override function is now controlled by a manual remote

momentarily closed contact. When configured in this mode, the

input operates in a toggle mode. With this function enabled it is

now possible to toggle between unoccupied & occupied

setpoints for the amount of time set by parameter (TOccTime)

temporary occupancy time. When Override is enabled, an

Override status message will be displayed

(Filter): a back-lit flashing Filter alarm will be displayed on the

Terminal Equipment Controller LCD screen when the input is

energized

(Service): a back-lit flashing Service alarm will be displayed on

the Terminal Equipment Controller LCD screen when the input is

energized

(Fan lock): a back-lit flashing Fan lock alarm will be displayed

on the Terminal Equipment Controller LCD screen when the

input is not energized. Used in conjunction with a local airflow

sensor connected to the input. Locks out the Terminal

Equipment Controller heating and cooling action if no airflow is

detected 10 seconds after the fan ( G terminal ) is energized.

Open contact = no airflow

Closed contacts = airflow present

DI 2

Digital input no. 2

configuration

Default value = None

Same as above. It is possible to configure both inputs to have

the same function.

MenuScro

Menu scroll

Default value = On =

Scroll active

Removes the scrolling display and only present the room

temperature/humidity to the user. With this option enabled, no

status is given of mode, schedule and outdoor temperature.

On = Scroll active

Off = Scroll not active

25 | PIR Ready VT76xxW Series-Installation Guide

Page 26

lockout Keypad lockout levels

Default value = 0 No lock

0 = No lock

1 = Low level

2 = High level

USER KEY FUNCTIONS

LEVEL

Resume/

Override scheduling

Permanent Occupied and

Unoccupied Setpoints

Temporary setpoints using

arrows

System mode setting

Fan mode setting

Schedules setting

Clock setting

Permanent hold

0

1

2

pwr del

Power-up delay

Default value = 10 seconds

On initial power up of the Terminal Equipment Controller

(each time 24 Vac power supply is removed & re-applied)

there is a delay before any operation is authorized (fan,

cooling or heating). This can be used to sequence start up

multiple units / Terminal Equipment Controller in one

location.

10 to 120 seconds

Frost pr

Frost protection enabled

Default value = Off

Off: no room frost protection

On: room frost protection enabled in all system mode at:

42 °F ( 5.6 °C )

Frost protection is enabled even in system Off mode

Off or On

heat max

Maximum heating setpoint

limit

Default value = 90 °F ( 32 °C )

Maximum occupied & unoccupied heating setpoint

adjustment. Heating setpoint range is:

40 to 90 °F ( 4.5 to 32.0 °C )

cool min

Minimum cooling setpoint limit

Default value = 54 °F ( 12 °C )

Minimum occupied & unoccupied cooling setpoint

adjustment. Cooling setpoint range is:

54 to 100 °F ( 12.0 to 37.5 °C )

26 | PIR Ready VT76xxW Series-Installation Guide

Page 27

Pband

Proportional Band

setting

Default value 2 = 2.0

°F ( 0.6 °C )

Adjust the proportional band used by the Terminal Equipment

Controller PI control loop.

Note that the default value of 2.0 °F ( 1.1 °C ) gives

satisfactory operation in most normal installation cases.

The use of a superior proportional band different than

the factory one is normally warranted in applications where the

Terminal Equipment Controller location is problematic and leads

to unwanted cycling of the unit. A typical example is a wall

mounted unit where the Terminal Equipment Controller is installed

between the return and supply air feeds and is directly influenced

by the supply air stream of the unit.

Value

F scale

Pband

C scale

Pband

2

2 F

1.1 C

3

3 F

1.7 C

4

4 F

2.2 C 5 5 F

2.8 C

6

6 F

3.3 C

7

7 F

3.9 C 8 8 F

4.4 C

Anticycle

Minimum on/off

operation time for

stages

Default value = 2

minutes

Minimum On/Off operation time of cooling & heating stages.

IMPORTANT, anti-short cycling can be set to 0 minutes for

equipment that posses their own anti cycling timer. Do not use this

value unless the equipment is equipped with such internal timer.

Failure to do so can damage the equipment.

0, 1, 2, 3, 4 & 5 minutes

Anti-short cycling can be set to 0 minutes for equipment that

posses their own anti cycling timer. Do not use that value unless

the equipment is equipped with such internal timer. Failure to do

so can damage the equipment.

% RH disp

Local RH Display

Default value = Off

Enables the display of humidity below the room temperature on the

display

On = Display %RH

Off = No display of %RH

cool cph

Heatpump stages

cycles per hour

Default value = 4

C.P.H.

Will set the maximum number of heatpump stage cycles per hour

under normal control operation. It represents the maximum number of

cycles that the equipment will turned on and off in one hour.

Note that a higher C.P.H will represent a higher accuracy of control at

the expense of wearing mechanical components faster.

3 or 4 C.P.H.

27 | PIR Ready VT76xxW Series-Installation Guide

Page 28

deadband

Minimum deadband

Default value = 2.0 °F

( 1.1 °C )

Minimum deadband value between the heating and cooling

setpoints. If modified, it will be applied only when any of the

setpoints are modified.

2, 3 or 4 °F ( 1.0 to 2.0 °C )

fan cont

Fan control

Default value = On

Fan control in heating mode.

When selecting On; the Terminal Equipment Controller in all cases

will always control the fan (terminal G).

Valid for On or Auto fan mode

When selecting Off; the fan (terminal G), when heating stages

(terminals W1 & W2) are solicited, will not be energized. The fan in

this case will be controlled by the equipment fan limit control.

Valid only for Auto fan mode. On fan mode will leave the fan

always on.

ON OR OFF

For multi stage models, fan control applies to W1 & W2

For heat pump models, fan control applies to W1 only

(Emergency heat)

fan del

Fan delay

Default value = Off

Fan delay extends fan operation by 60 seconds after the call for

heating or cooling ends.

Valid only for Auto fan mode. “On” fan mode will leave the fan

always on.

Off or On

ToccTime

Temporary

occupancy time

Default value = 3

hours

Temporary occupancy time with occupied mode setpoints when

override function is enabled

When the Terminal Equipment Controller is in unoccupied mode,

function is enabled with either the menu or DI1 or DI2 configured

as remote override input.

0,1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 & 12 hours

Cal RS

Room air temperature

sensor calibration

Default value = 0.0 °F

or °C

Offset that can be added/subtracted to actual displayed room

temperature

± 5.0 °F ( ± 2.5 °C )

Cal RH

Humidity sensor

calibration

Default value = 0

%RH

Offset that can be added/subtracted to the actual displayed

humidity by ± 15.0 %RH.

Range is : ± 15.0 %RH

28 | PIR Ready VT76xxW Series-Installation Guide

Page 29

HP stage

Number of heatpump

stages

Default value = 2 stages

Will revert the operation of 2 stage Terminal Equipment

Controller to single stage operation only when the second

compressor step is not needed.

1 or 2 stages

H lock

Outside air temperature

heating lockout

Default value = 120 °F (

49 °C )

Disables heating stage operation based on outdoor air

temperature.

Function will only be enabled if OS ( outside air temperature

network value ) is received.

From -15 °F up to 120 °F ( -26 °C up to 49 °C )

C lock

Outside air temperature

mechanical cooling

lockout.

Default value = -40 °F ( -

40 °C )

Disables cooling stage operation based on outdoor air

temperature.

Function will only be enabled if OS ( outside air temperature

network value ) is received.

From -40 °F up to 95 °F ( -40 °C up to 35 °C )

Unocc TM

Unoccupied Timer value

Default 0.5 hours

Time delay between the moment where the Terminal

Equipment Controller toggles from occupied to unoccupied after

the last movement has been detected by the PIR.

Range is: 0.5 to 24.0 hours in 0.5 hour increments

2/4event

Number of events

configuration

Default value = 2 event

2 events, will set up scheduling for the following

Event 1 is for Occupied setpoints

Event 2 is for Unoccupied setpoints

4 events, will set up scheduling for the following

Event 1 is for Occupied setpoints

Event 2 is for Unoccupied setpoints

Event 3 is for Occupied setpoints

Event 4 is for Unoccupied setpoints

29 | PIR Ready VT76xxW Series-Installation Guide

Page 30

aux cont

Auxiliary contact

configuration

Default value = N.O.

normally open

This contact can be used to energize peripheral devices such

as: lighting equipment, exhaust fans, economizers, etc.

This contact will operate in parallel with the internal

occupied/unoccupied schedule of the Terminal Equipment

Controller or the remote NSB contact if DI1 or DI2 is used.

When the system is in OFF mode, the contact will remain in its

unoccupied status independently of the occupied / unoccupied

schedule.

Configured

Contact

occupied status

Contact

unoccupied status

N.O.

Closed

Opened

N.C.

opened

Closed

Prog rec

Progressive recovery

enabled

Default value = Off

Progressive recovery is

automatically disabled if

DI 1 and / or DI 2 are

configured remote NSB

Off, = no progressive recovery

The occupied schedule time is the time at which the system will

restart.

On, = progressive recovery active.

The occupied schedule time is the time at which the desired

occupied temperature will be attained. The Terminal Equipment

Controller will automatically optimize the equipment start time.

In any case, the latest a system will restart is 10 minutes prior

to the occupied period time.

Re valve

Reversing valve operation

O/B

Default value = O

Heat pump reversing valve operation

O will energize the valve in cooling operation.

B will energize the valve in heating operation

O OR B

30 | PIR Ready VT76xxW Series-Installation Guide

Page 31

Dhu set

Dehumidification setpoint

Default is 50 % RH

Used only if dehumidification sequence is enabled:

Range is: 30-95% RH

DHumiLCK

Dehumidification lockout

Default value:

Restrict

Enables, restricts or disables the dehumidification sequence.

Dhu Disa: Dehumidification disabled

Restrict: will restrict the dehumidification process based on

the following:

- System mode = Needs to be Cool or Auto ( currently

operating in cooling only )

- Low ambient room temperature protection enabled

Dhu Enab: will not restrict the dehumidification process:

- System mode = Needs to be Cool, Heat or Auto

There is no ambient room temperature protection enabled

Dhu OALK

Dehumidification outside air

temperature lockout

Default value = 32°F (0°C)

Outside air temperature under which the dehumidification

sequence is disabled.

Only valid if an outdoor air sensor is connected at the

Terminal Equipment Controller or a network value is

transmitted to the Terminal Equipment Controller.

From –40°F up to 122°F (-40°C to 50°C)

DehuHyst

Dehumidification

Hysteresys

Default = 5 % RH

Humidity control hysteresis. Used only if dehumidification

sequence is enabled:

Range is: 2 to 20% RH

MS dis

Display mixed air

temperature

Economizer model only,

only if sensor is installed

Used as diagnostic / service help to troubleshoot and

diagnose economizer operation.

31 | PIR Ready VT76xxW Series-Installation Guide

Page 32

TROUBLESHOOTING GUIDE

Symptom

Possible Cause

Corrective Action

No display on the

Terminal

Equipment

Controller

Absent or incorrect

supply voltage

1. Check power supply voltage between C

& RC to be from 19-30 VAC

2. Check for tripped fuse or circuit breaker

Overloaded power

transformer

Verify that the transformer used is

powerful enough (enough VA’s) to supply

all controlled devices including the

Terminal Equipment Controller

Keyboard menu

does not access

all functions

Keyboard locked

Change configuration parameter

LOCKOUT to value “0” to access all levels

of the menu

Temperature

setpoints revert to

original value

after a certain

time period

Temporary setpoint

option selected

1. The Terminal Equipment Controller

needs to be in Permanent setpoint

mode for the new setpoint to be kept

and memory and used all the time

2. Go to the Set temperature menu.

3. The last prompt is setpoint type. Set it

to Permanent setpoint

Terminal

Equipment

Controller will not

call for heating

Wrong mode selected

Select heating mode

Terminal Equipment

Controller in

Unoccupied mode

Select Occupied Hold in Schedule hold or

Override to force the Terminal Equipment

Controller Occupied heating setpoint

Anticycle delay active

Wait, the anticycling period will end and

the equipment will start

Heating setpoint is

satisfied

Raise the Heating setpoint

Heating lockout

attained

1. Mode is locked out based on outside air

temperature

2. Change configuration parameter H Lock

to value 120 °F ( 49 °C ) to by-pass

lockout

Wiring error

1. Start the Fan by forcing the Fan ON

mode

2. Put a jumper across terminals RH &

W1. The heating should come ON. If it

does not, verify wiring and check if a

jumper is required between RC & RH

Terminal

Equipment

Controller will not

call for cooling

Wrong mode selected

Select cooling mode

Terminal Equipment

Controller in

Unoccupied mode

Select Occupied Hold in Schedule hold or

Override to force the Terminal Equipment

Controller Occupied cooling setpoint

Anticycle delay active

Wait, the anticycling period will end and

the equipment will start

Cooling setpoint is

satisfied

Lower the cooling setpoint

Cooling lockout

attained

1. Mode is locked out based on outside air

temperature

2. Change configuration parameter C Lock

to value -40 °F ( -40 °C ) to by-pass

lockout

All models

32 | PIR Ready VT76xxW Series-Installation Guide

Page 33

Wiring error

1. Start the Fan by forcing the Fan ON

mode

2. Put a jumper across terminals RC & Y1.

The cooling should come ON. If it does

not, verify wiring

The Terminal

Equipment

Controller will not

turn on the fan

Wrong mode selected

1. Start the Fan by forcing the Fan ON

mode

2. Put a jumper across terminals RC & G.

The fan should come ON. If it does not,

verify wiring

Wiring error

Digital display

shows missing

digits or erratic

segments

Defective display

Replace Terminal Equipment Controller

33 | PIR Ready VT76xxW Series-Installation Guide

Page 34

SPECIFICATIONS

Terminal Equipment Controller power

requirements:

Operating conditions:

Storage conditions:

Temperature sensor:

Temperate sensor resolution:

Temperature control accuracy:

Contact output rating

Occ, Stand-By and Unocc cooling setpoint range:

Occ, Stand-By and Unocc heating setpoint range:

Room and outdoor air temperature display range:

Proportional band for room temperature control:

Digital inputs:

Wire gauge:

Approximate shipping weight:

Agency Approvals all models:

Agency Approvals all models:

Agency Approvals Wireless models:

19-30 VAC 50 or 60 Hz; 2 VA Class 2

0 °C to 50 °C ( 32 °F to 122 °F )

0% to 95% R.H. non-condensing

-30 °C to 50 °C ( -22 °F to 122 °F )

0% to 95% R.H. non-condensing

Local 10 K NTC thermistor

± 0.1 °C ( ± 0.2 °F )

± 0.5 ° C ( ± 0.9 °F ) @ 21 °C ( 70 °F )

typical calibrated

Relay output: 30 VAC, 1 Amp.

Maximum, 3 Amp. In-rush.

12.0 to 37.5 °C ( 54 to 100 °F )

4.5 °C to 32 °C ( 40 °F to 90 °F )

-40 °C to 50 °C ( -40 °F to 122 °F )

Cooling & Heating: Default: 1.1°C

( 2°F )

Dry contact across terminal DI1,

DI2

18 gauge maximum, 22 gauge

0.75 lb ( 0.34 kg )

UL: UL 873 (US) and CSA C22.2 No.

24 (Canada), File E27734 with CCN

XAPX (US) and XAPX7 (Canada)

Industry Canada: ICES-003 (Canada)

FCC: Compliant to CFR 47, Part 15,

Subpart B, Class A (US)

CE : EMC Directive 89/336/EEC

(Europe Union)

C-Tick: AS/NZS CISPR 22 Compliant

(Australia / New Zealand) Supplier

Code Number N10696

FCC: Compliant to: Part 15, Subpart C

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS SUBJECT

TO THE FOLLOWING TWO CONDITIONS: (1) THIS DEVICE MAY NOT CAUSE HARMFUL

INTERFERENCE, AND (2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE RECEIVED,

INCLUDING INTERFERENCE THAT MAY CAUSE UNDESIRED OPERATION.

Please check with your local government for instruction on disposal of this product.

34 | PIR Ready VT76xxW Series-Installation Guide

Page 35

DRAWING & DIMENSIONS

Viconics Technologies Inc.

Tel.: Fax: Toll free:

www.viconics.com

35 | PIR Ready VT76xxW Series-Installation Guide

Loading...

Loading...