Page 1

Features

Benefits

Microcomputer-based

Exceptional accuracy and linearity

2% models 10 point calibration

3% models 3 point calibration

Increased accuracy and linearity across the

required control range

Timed RH level status LED

Rapid trouble-shooting and commissioning.

Humidity level is proportional to a 10 second

duty cycle. Ex, using a time clock, if pulse

duration is 6.5 seconds, sensed % RH by

transmitter is 65% RH

Elegant aesthetic design

Blends well in all environments

Various additional temperature

sensor options available

More functionality for DDC system installation

by combining local temperature and humidity

sensing in a single component

Model Output

Accuracy Temperature Sensor

Mounting

Extension

VH2

0 0-5 / 0-10 V

2 +/- 2%

0 None W Wall 1 4-20 mA

3 +/- 3%

1 3K Ohms thermistor

+/- 1%

D Duct 2 10K Ohms Type 2

+/- 1%

E Outdoor

3

10K Ohms Type 3

+/- 1%

4

100K Ohms thermistor

+/- 1% 5

1K Ohm NIFE

6

100 Ohms Platinum

7

1K Ohm Platinum

VH2

0 2 2 W 1000

Model:

Description:

Application:

Picture:

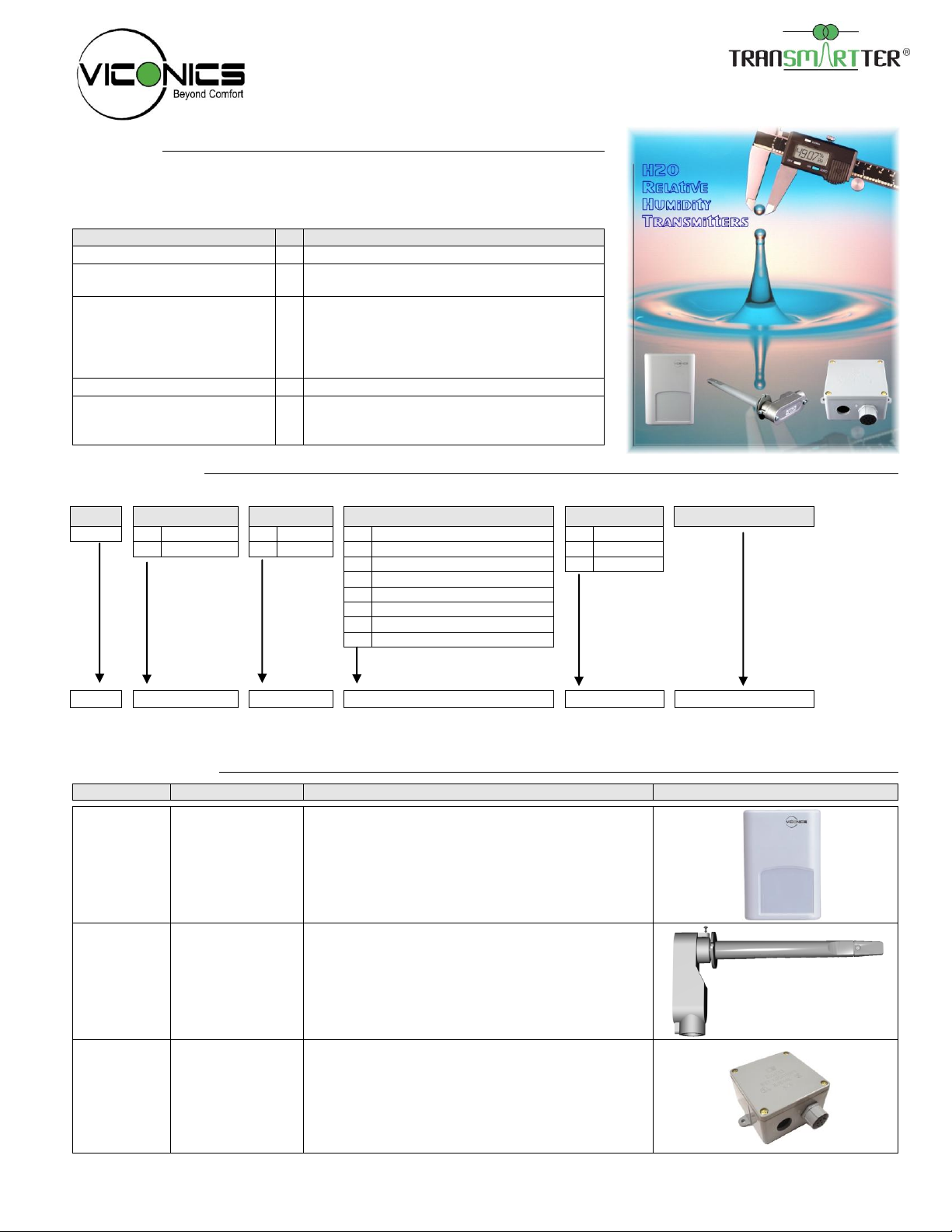

VH20 Wall

Room sensor

Remote room humidity sensing

Accessory temperature sensor available

VH20 Duct

Duct sensor with

junction box

Remote return air humidity sensing with the

sensor mounted on the return air duct.

Outside air humidity sensing with the sensor

installed in the fresh air plenum.

Supply air humidity sensor

Accessory temperature sensor available

VH20

Exterior

Outside air

sensor, NEMA 4

enclosure

Outside air humidity sensing with the sensor

installed directly exposed to the elements.

Sensor uses a water resistant NEMA 4 PVC

enclosure for outdoor applications

Accessory temperature sensor available

VH20 Electronic Humidity Transmitter Series

Description

The VH20 series, microcomputer-based humidity transmitters are designed for

accurate humidity sensing in non-corrosive commercial applications such as:

hospitals, schools, office buildings, retail stores, museums and computer rooms.

Available models

Example: Above model is VH2022W1000 for wall mount, 2% accuracy, 0-10 or 0-5 Vdc output with 10K Ohms Type 2

temperature sensor.

Models description

1

Page 2

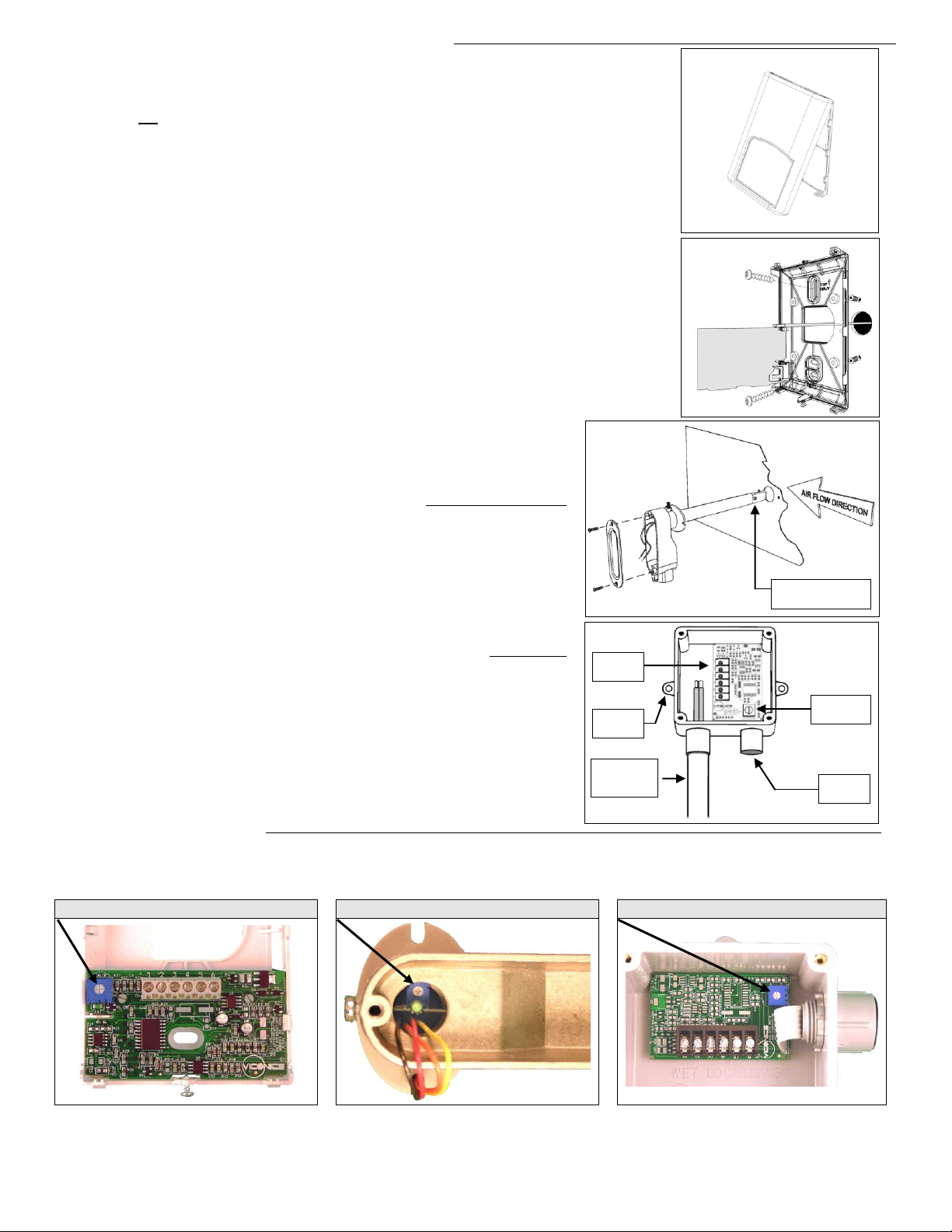

Fig. 2

Installation of room sensors (VH20 Wall) (Fig. 1 & 2)

VH20 Wall mounted

VH20 Duct mounted

VH20 Outdoor

Fig. 1

Fig.3

Probe tip, flat side

facing airflow

Fig.4

Calibration

+/- 5% RH

Sensing

probe

PCV conduit

Adapter by

others

Wiring

terminal

Mounting

hole

Remove security screw on the bottom of sensor cover.

Open up by pulling on the bottom side of sensor. (Fig.1)

Location:

1- Should not be installed on an outside wall.

2- Must be installed away from any heat source.

3- Should not be installed near an air discharge grill.

4- Should not be affected by direct sun radiation.

5- Nothing must restrain vertical air circulation to the sensor.

Installation:

1. Remove security screw on the bottom of thermostat cover.

2. Open up by pulling on the bottom side of thermostat.

3. Pull out cables 6” out of the wall.

4. Wall surface must be flat and clean.

5. Insert cable in the central hole of the base.

6. Flip printed circuit board to access mounting hole

7. Align the base and mark the location of the two mounting holes on the wall.

8. Install proper side of base up.

9. Install anchors in the wall.

10. Insert screws in mounting holes on each side of the base. DO NOT OVERTIGHTEN

11. Strip each wire 1/4 inch.

12. Insert each wire according to wiring diagram.

13. Gently push back into hole excess wring back into the wall.

14. Press back printed circuit board into place

15. Install the cover, top side first

16. Install security screw.

Installation of duct sensors (VH20 Duct) – (Fig.3)

1. Drill 1” [25mm] hole mid height on the side of the duct to insert the probe.

2. Direct the probe so that the flat side of probe tip is facing the airflow.

3. Mark the position of the two holes to be drilled for mounting the sensor on the

duct. Fasten the sensor to the duct with the two self-taping screws ( notincluded ). Do not overtighten!

4. Junction box must be directed downwards or sideways.

5. For best results, locate sensor as far as you can from heating/cooling source.

Installation of outside air sensor (VH20 Outdoor) – (Fig.4)

1. Install sensor using mounting holes on each side.

2. Install on a vertical surface, respect mounting orientation

3. Remove the four screws and remove the cover.

4. Strip each wire 1/4 inch.

5. Insert each wire according to wiring diagram.

6. Install the cover with supplied screws.

7. In snowy area allow sufficient height for snow accumulation.

Maintenance of transmitter

Calibration: The transmitter is factory calibrated. However, it can be field recalibrated by using the ( -5%, 0%, 5% ) potentiometer

inside the transmitter to adjust the zero. The transmitter is already factory calibrated to the center of the potentiometer. To

recalibrate the transmitter to the factory preset, turn the potentiometer to the 0% adjustment. (see pictures below)

Cleaning: The VH20 duct sensor probe needs inspection annually to be cleaned of any excess dirt on the sensing element tip.

The whole filter tip can be ordered and replaced if it cannot be cleaned properly. Part number: VH20DuctTip.

Page 3

0 to 10 Vdc / 0 to 5 Vdc output models

4 wires / terminals

0 to 10 Vdc / 0 to 5 Vdc output models

With optional temperature sensor

6 wires / terminals

4 to 20 mA output models

2 wires / terminals

4 to 20 mA output models

With optional temperature sensor

4 wires / terminals

-2

% R.H.

+2% R.H.

Reference

10 20 604030 50 70 80 90

Typical Calibration Curve 2% Model

% R.H.

Vdc Power (+) 12-30 Vdc

4 to 20 mA Output

VH20 Duct model

Red

Black

VH20 Wall and Outdoor models

2

1

Vdc Power (+) 12-30 Vdc

4 to 20 mA Output

2

1

VH20 Wall and Outdoor models

561

2

Temperature sensor

Temperature sensor

4 to 20 mA Output

Vdc Power (+) 12-30 Vdc

6

512

4 to 20 mA Output

Temperature sensor

Temperature sensor

Vdc Power (+) 12-30 Vdc

White

VH20 Duct model

Black

White

Red

VH20 Wall and Outdoor models

6

54321

Temperature sensor

Temperature sensor

6

5

0 to 10 Vdc Output

0 to 5 Vdc Output

Power (+) 12-30 Vdc / 24 Vac

Common (-)

243

1

VH20 Wall and Outdoor models

1

342

0 to 10 Vdc Output

0 to 5 Vdc Output

Power (+) 12-30 Vdc / 24 Vac

1

Common (-)

342

Power (+) 12-30 Vdc / 24 Vac

0 to 10 Vdc Output

0 to 5 Vdc Output

Orange

Black

Yellow

Red

VH20 Duct model

Common (-)

Temperature sensor

Temperature sensor

White

White

0 to 5 Vdc Output

Power (+) 12-30 Vdc / 24 Vac

0 to 10 Vdc Output

Orange

VH20 Duct model

Red

Yellow

Black

Common (-)

Typical calibration curve

The VH20 2% series, microcomputer-based humidity transmitters are calibrated with a 10 point curve with each point

equally spread from 10% to 90%

Wiring of VH20 transmitter

3

Page 4

Specifications:

Power supply

Vdc models output

Linear output 0 to 10 Vdc / 0 to 5 Vdc into 2K resistance min.

24 Vac / Vdc -15%, +10% Vac 50/60 Hz; 1 VA

Power supply

4-20 mA models output

Linear output 4 to 20 mA

12-30 Vdc

Calibration

10 point for 2% models; 3 point for 3% models

Humidity sensing element

10 points calibrated bulk polymer type sensor

Temperature effect

% RH is temperature compensated. Effect is less than 0.1% over the full range (0-100%)

Stability

Less than 1.0 % yearly (typical drift)

Field calibration

-5% / 0% factory / +5% trimmer

Optional temperature sensor

1 % accuracy typical

Maximum wire length

5,000 feet [1,525 m] for 24 GA wire and up

Warranty

18 months from date of purchase or 12 months from date of installation

Operating conditions:

32 F to 122 F ( 0 C to 50 C )

0% to 95% R.H. non-condensing

Time constant:

Less than 1 minute at 63%

Storage conditions:

-22 F to 122 F ( -30 C to 50 C )

0% to 95% R.H. non-condensing

Dimensions:

(refer to drawing Fig.5)

Appr. shipping weight:

0.4 LBS (0.2 kg )

Enclosure plastic type:

ABS - FRI [WT1337V] UV stabilized

Operating conditions:

-40 F to 122 F ( -40 C to 50 C )

0% to 95% R.H. non-condensing

Time constant:

Less than 10 seconds at 63%

Min. 100 FPM max. 1200 FPM

Storage conditions:

-40 F to 122 F ( -40 C to 50 C )

0% to 95% R.H. non-condensing

Dimensions:

(refer to drawing Fig.6)

Appr. shipping weight:

0.8 LBS [0.4 Kg]

Probe tip plastic type:

Fire retardant grade "HB" ABS

Operating and storage

conditions:

-40 F to 122 F ( -40 C to 50 C )

0% to 100% R.H.

Time constant:

Less than 1 minute at 63%

Dimensions:

(refer to drawing Fig.7)

Appr. shipping weight:

1.3 LBS [0.6 Kg]

Enclosure plastic type:

NEMA 4 PVC

Viconics Technologies Inc. 9245, Langelier Blvd, St-Leonard, Quebec, Canada H1P 3K9

028-0116

www.viconics.com

sales@viconics.com

1/2" [13 mm] FPT

Ø 0.75" [19 mm]

7.00" [178 mm]

1.30" [33 mm]

4.40" [112 mm]

1.75" [44 mm]

2.10" [53 mm]

Ø 5/32" [4 mm]

c/c 1.75" [44mm]

Fig.6

4.00"

[102 mm]

4.88" [124 mm]

3.45"

[88 mm]

3.67" [93 mm]

* Threaded

brass insert

Ø 8-32*

Ø 0.25"

[6 mm]

Ø 7/8"

[22 mm]

1.63"

[42 mm]

c/c 4.68" [119 mm]

5.25" [133 mm]

1.19" [30 mm] 1.19" [30 mm]

2.00"

[51 mm]

4.00" [102 mm]

3.45" [88 mm]

0.25" [6 mm]

2.125"

[54 mm]

Fig.7

Fig.5

3.38" [86 mm]

1.13" [29 mm]

4.94" [125 mm]

General for all sensors

Room sensors (VH20 Wall) (Fig.5)

Duct sensor (VH20 Duct) (Fig.6)

Outside air sensor (VH20 Exterior) (Fig.7)

Notes:

Humidity sensor is suitable for normal clean air.

Not to be used in corrosive or harmful environment.

Specifications and equipment are subject to change without prior

notice.

Important notice

undergone rigorous tests and verifications prior to shipment to ensure

proper and reliable operation in the field. Whenever a control failure

could lead to personal injury and/or loss of property, it becomes the

responsibility of the user / installer / electrical system designer to

incorporate safety devices ( such as relays, flow switch, high and low

limits, thermal protections, etc…) and/or alarm system to protect the

entire system against such catastrophic failures. Tampering of the

devices or mis application of the device will void warranty.

All VH20 series sensors are for use as operating controls

only and are not safety devices. These instruments have

05/04/12 LIT-VH20X-E06.doc

Loading...

Loading...