Page 1

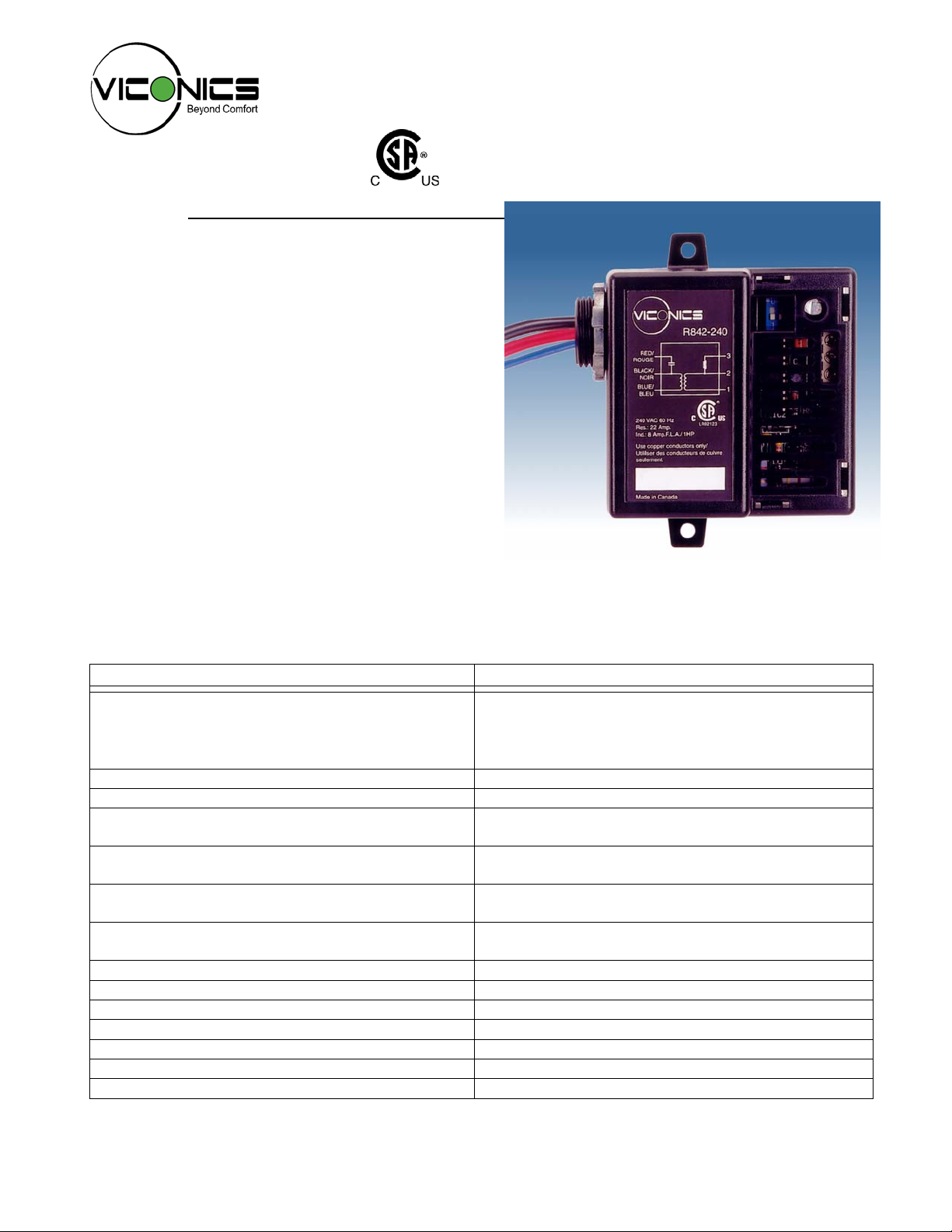

R842 Electronic Relay For Electric Baseboards

Description

Viconics’ innovative R842 electronic relay has been

designed for silent control of high voltage resistive

heater loads (120V to 600 Vac) from a low voltage

control circuit. Typical applications include control of

electric baseboard and cabinet heaters in commercial

buildings. Inductive motor loads can also be controlled

(120 and 240 Vac models only).

Using advanced microprocessor-based circuitry, the

R842 is capable of handling greater than 500,000 cycles

(typical). It has a built-in transformer and is compatible

with most industry standard electromechanical or

electronic thermostats with on/off outputs. A unique

feature of product is that it can operate with a value

priced Viconics’ T186 electronic PI (proportional and

integral) room thermostat with setpoint capability,

providing exceptional accuracy, comfort, and energy

savings.

Features Benefits

• Built-in transformer

• Universal replacement part

• Compatible with electronic T186 room sensor

Fig.1 - R842 relay for electric baseboards

⇒ Permits fully electronic PI control

• Unique compatibility with Viconics’ own designer

electronic thermostat

⇒ Improved accuracy (+/-0.3ºC) and comfort

⇒ Energy savings

⇒ Aesthetically pleasing thermostat

• Reliable microprocessor-based design ⇒ Long life

• Compatible with all standard 24 V thermostats ⇒ Adds flexibility

• Constant 10 second time delay

• Built-in transformer

• Broad voltage ranges available: 120, 208, 240,

⇒ Not affected by ambient temperatures typically

found in older, thermal type baseboard relays

⇒ Less inventory to stock

⇒ Easier installation

⇒ Covers most voltage applications

277, 347, 600 Vac.

• Status LED

⇒ Confirms operation

⇒ Simplifies troubleshooting

• Silent operation ⇒ Will not disturb occupants

• Direct replacement of competitive models ⇒ Easy to retrofit

• Large resistive amperage load rating ⇒ Will handle the largest baseboards with ease

• Inductive ratings ⇒ Used to control motor loads (fans, pumps, etc)

• Compact enclosure ⇒ Fits inside baseboard

• Standard ½” male conduit bushing ⇒ Can be installed on most electrical junction boxes

• 2 year warranty ⇒ Assured dependability

1

Page 2

Description (Cont’d)

(

)

The R842 has several advantages over traditional

electromechanical baseboard relays. The latter use

the principle of thermal expansion to make or break

the high voltage circuit. This operation typically takes

45 seconds and adds inaccuracy to the temperature

control loop. The R842, with enhanced electronic

circuitry, substantially reduces this long time delay

and is not affected by ambient temperature

conditions.

Due to its compact design, the R842 easily fits into

most electric baseboard enclosures and can replace

most competitive models. For junction box mounting,

a standard ½” male screwed fitting is available. In

addition, a high intensity LED is provided to indicate

operation and simplify troubleshooting. Silent

operation will ensure that each installation is trouble

free.

R842 Relay Models

Model No.

R842-120

R842-208

R842-240

R842-277

R842-347

R842-600

Voltage

Vac)

120 22

208 22

240 22

277 19

347 18

600 10

Amperage

(A

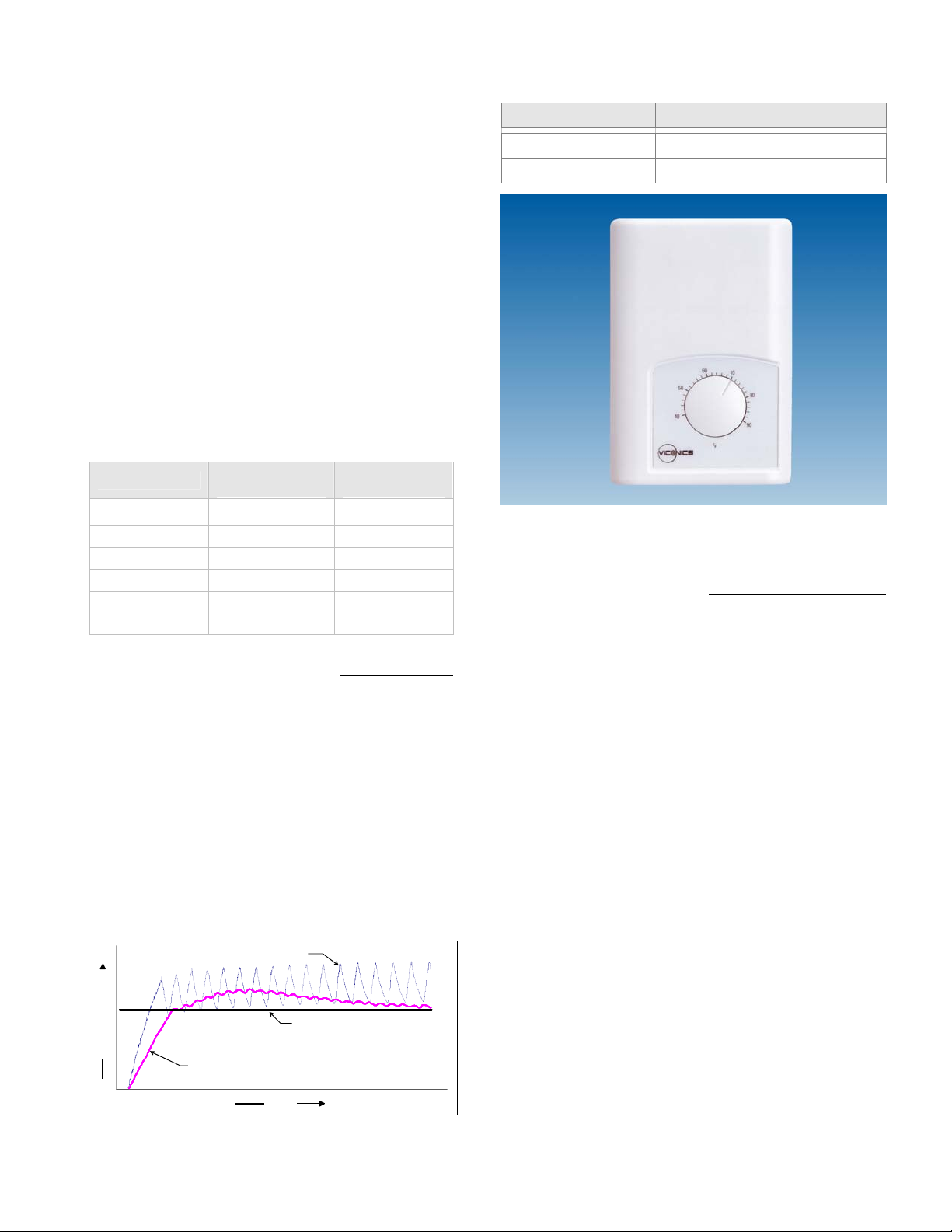

T186 Electronic PI Thermostat

The microprocessor-based design of the R842

permits the use of T186 electronic room sensor with

setpoint as an alternative to electromechanical

thermostats. The T186 transmits the actual

temperature and setpoint to the R842. The resulting

solid state PI control loop is much more accurate

than that offered by conventional thermostats and

eliminates wasted energy caused by on/off cycling

with these types of thermostats (see Fig. 2).

The T186 can also be used as lower cost alternative

to the use of solid state relays and pulse width

modulated thermostats, sometimes used to control

electric heat baseboards.

Electromechanical thermostat

Temperature

T186 PI control

Setpoint (comfort temperature)

Fig.2 - On/Off mechanical control vs PI electronic control

Time

T186 Sensor Models

Model No. Scale Range

T186C-01

T186F-01

5 °C to 30 °C

40 °F to 90 °F

Fig.3 - T186 electronic PI room sensor with setpoint

Typical Guide Specification

The relay shall be a microcomputer-based with PI, time

proportioning control capability. It should have an

average life of greater than 500,000 cycles and include

a built-in transformer. Relays shall be compatible with

all of the following control signals: Viconics T186

electronic room sensor with setpoint permitting PI

control with an accuracy of +/-0.3ºC and standard 24

Vac thermostats. Relay shall have a constant 10 second

time delay and shall not be affected by ambient

temperatures. The relays shall be equipped with a

status LED to confirm operation. Required quality: R842

electronic baseboard relay from Viconics.

2

Page 3

Installation

p

r

Important: All wiring must conform to local and

national electrical code regulations. Please read

these instructions carefully before the installation.

Failure to follow the instructions could damage the

product or cause a hazardous condition. Installation

must only be performed by a qualified service

technician. Disconnect power supply before installing

in order to prevent electrical shock. There are two

basic methods to install the R842 baseboard relay.

A. Installation Inside Electric Baseboard

Electric baseboard strip

Fig.4 - R842 relay installation Fig.5 - R842 relay, installation in an electrical junction box

1. Use the plastic mounting tabs to secure the unit

to the inside of the electrical enclosure.

2. Secure to the cabinet with screws.

3. Cut one or both plastic mounting tabs if space is

needed inside the enclosure.

4. If a high voltage separation barrier is needed,

please contact the baseboard manufacturer.

5. Do not exceed the maximum rated temperature

of the R842 unit. (65°C/149°F)

Secure inside cabinet

using mounting screws

B. Junction Box Installation

Use the supplied lock nut to secure the relay to the

electrical junction box. It is possible to mount the relay

completely inside the junction box or outside, as

desired. In the case of the former, make sure that the

front of the R842 relay is facing the cover of the junction

box. For mounting outside of the junction box, make

sure that the front of the relay is visible. In both cases,

this will permit the installer to view the red LED in order

to confirm operation.

From other high voltage

junction boxes

Standard 4 "x 4" junction box

installed in the ceiling

Electric baseboard strip

Dip Switch Settings

High voltage

wires

24 Vac Low voltage

control wires

To other high voltage

juction boxes

T186 sensor

Whenever using one R842 relay, please set the dip

switches as follows, depending on the input signal:

1. Two wire low voltage electromechanical thermostat:

set both switches to "ON"

2. Viconics' T186 set both switches to "OFF"

For all applications involving multiple R842 relays,

please refer to the diagrams on pages 4, 5, and 6

24 Vac Low voltage

control wires to

thermo st a t

ON

2

1

ON

1

If a high voltage separation barrier is needed,

lease contact baseboard manufacture

Fig.6 - R842 relay, installation inside baseboard cabinet Fig.7 - R842 relay, location of dip switches

Refer to wiring diagrams for dip switch setting

per application.

2

3

Page 4

A

A

A

A

Typical applications & wiring

Two wire low voltage thermostat using R842 baseboard

relay internal transformer

Baseboard(s) / load(s)

Relay(s)

Thermostat(s)

Transformer

One

One

One

Internal

RED

BLACK

BLUE

1

Internal circuit

ON

2

1

2 wire low voltage

thermostat

3

2

1

3

Load side

L1

L2 / N

Junction box

Set both switch on relay

to factory default ON position

2

Two wire low voltage thermostat using R842 baseboard

relay internal transformer for multiple relay

arrangement

Baseboard(s) / load(s)

Relay(s)

Thermostat(s)

Transformer

Load side

Load side

Load side

L1

L2 / N

RED

BLACK

BLUE

RED

BLACK

BLUE

1

RED

BLACK

BLUE

1

Maximum of 10 slave units

Internal circuit

ON

12

Internal circuit

ON

12

Internal circuit

ON

12

Multiple

Multiple

One

Internal

2 wire low

voltage thermostat

3

2

1

3

3

2

1

3

3

2

1

3

djust thermostat

anticipator to 0.1 A

or less.

Set both switch

on master relay

to factory default

position

ON

Master

Slave(s)

Set switch on

all slave relays to

S1 =

&

ON

S2 =

OFF.

djust thermostat

anticipator to 0.1 A

Two wire low voltage thermostat using a separate

24 Vac transformer

Baseboard(s) / load(s)

Relay(s)

Thermostat(s)

Transformer

One

One

One

External

2 wire low voltage

thermostat

Load side

Junction box

RED

BLACK

BLUE

1

L1

L2 / N

Internal circuit

ON

12

2

3

2

1

Set both switch on relay

to factory default ON position

Separate remote

3

24 Vac transformer

Two wire low voltage thermostat using a separate

24 Vac transformer for multiple relay arrangement

Baseboard(s) / load(s)

Relay(s)

Thermostat(s)

Transformer

2

4

L1

L2 / N

Internal circuit

RED

Load side

Load side

Load side

BLACK

BLUE

RED

BLACK

BLUE

RED

BLACK

BLUE

Internal circuit

Internal circuit

ON

2

1

ON

12

ON

12

Multiple

Multiple

One

External

2 wire low

voltage thermostat

3

2

1

3

2

1

3

2

1

djust thermostat

anticipator to 0.1 A

or less.

Separate remote

24 Vac transformer

L1

L2 / N

Set both switch on master

relay to factory default

position

ON

Set switch on

all slave relays to

S1 = ON &

S2 =

OFF.

djust thermostat

anticipator to 0.1 A

or less.

L1

L2 / N

Master

Slave(s)

1 High voltage blue wire is always connected. R842 units are powered devices.

2 Provide overload protection and disconnect as required.

3 Do not use 24 Vac terminal #1 as power supply to an electronic thermostat. Use a separate transformer.

4 L1, L2 & L3 can be mixed / matched.

5 Operates only if all relays control the same phase of a 3 phase system or on a single phase branch.

4

Page 5

A

Multiple two wire low voltage thermostats using the

same separate 24 Vac transformer to control

multiple R842 baseboard relays

Baseboard(s) / load(s)

Relay(s)

Thermostat(s)

Transformer

L1

L2 / N

Internal circuit

RED

Load side

Load side

Load side

BLACK

BLUE

RED

BLACK

BLUE

RED

BLACK

BLUE

Internal circuit

Internal circuit

ON

12

ON

12

ON

12

Multiple

Multiple

Multiple

External

2 wire low

voltage thermostats

3

2

1

3

2

1

3

2

1

L1

L2 / N

Separate remote

24 Vac

transformer

Set both switch

on all relays

to factory default

position

ON

Baseboard(s) / load(s)

Relay(s)

T186 thermostat

Load side

Junction box

Viconics T186 sensor to control

one R842 baseboard relay

One

One

One

sensor

T186

2 wire non polarized

Internal circuit

RED

BLACK

BLUE

L1

L2 / N

ON

1

3

2

2

1

Set both switch on relay

to

position

OFF

djust thermostat

anticipator to 0.1 A

or less.

Viconics T186 sensor for

master / slave arrangement of R842 baseboard relays

Baseboard(s) / load(s)

Electrical Specifications:

Relay(s)

T186 Thermostat

Load side

Load side

Load side

2

5

L1

L2 / N

RED

BLACK

BLUE

1

RED

BLACK

BLUE

1

RED

BLACK

BLUE

1

Maximum of 10 slave units

Internal circuit

Internal circuit

Internal circuit

1 High voltage blue wire is always connected. R842 units are powered devices.

2 Provide overload protection and disconnect as required.

3 Do not use 24 Vac terminal #1 as power supply to an electronic thermostat. Use a separate transformer.

4 L1, L2 & L3 can be mixed / matched.

5 Operates only if all relays control the same phase of a 3 phase system or on a single phase branch.

ON

12

ON

1

ON

12

2

Multiple

Multiple

One

2 wire non polarized

3

2

1

3

3

2

1

3

3

2

1

3

sensor

T186

Set both switch

on master relay

to

Set both switch

on slave relays

to factory default

ON

Install a jumper

across terminals

1 and 3 on all

slave relays

Note: Slave units life cycle is

100,000 cycles

position

OFF

Master

Slave(s)

position

Model Volt

Resistive

Rating (A)

Inductive

Rating (HP)

R842-120 120 22

R842-208 208 22

R842-240 240 22

½ HP

8 Amp

1 HP

8.8 Amp

1 HP

8 Amp

R842-277 277 19 N/A

R842-347 347 18 N/A

R842-600 600 10 N/A

5

Page 6

]

Specifications

Physical Specifications:

Ambient Operating

Temperature and Humidity Limits

• -20°C to 65°C (-4°F to 149°F )

• 0 % to 95 % R.H. non-condensing

Ambient Storage

Temperature and Humidity Limits

• -40°C to 80°C ( -40°F to 176°F )

• 0 % to 95 % R.H. non-condensing

• Greater than 500,000 (typical, resistive loads)

Life cycles

• 100,000 (typical, inductive loads for models

R842-120, R842-208 and R842-240 only)

Internal R842 transformer rating

Wire length

Net weight

Recommended wire size for screw terminal

Agency approval

• 24 Vac, -15%, +10% 50/60 Hz;

• 2.4 VA Class 2 transformer

• 8 inches [20 cm]

• 0.51 Lbs / 0.23 Kg

• 18-22 gauge

CSAus File no. LR92123 as per CSA Standard

• c

C22.2 no 24

Dimensions:

0.40" [10 mm]

3.70" [94 mm]

2.90" [74 mm]

0.40" [10 mm]

1.93" [49 mm]

0.90" [23 mm]

0.30" [8 mm]

Ø0.16" [4 mm]

1.77" [45 mm]

0.82" [21 mm]

1.65" [42 mm] 1.20" [30 mm]

0.39" [10 mm]

2.85" [72 mm]0.35" [9 mm]

1.60" [41 mm]

0.39" [10 mm]

0.12" [3 mm]

NOTE: VICONICS RESERVES THE RIGHT TO MAKE MODIFICATIONS WITHOUT PRIOR NOTICE.

All R842 series controls are for use as operating controls only and are not safety devices. These instruments have

undergone rigorous tests and verifications prior to shipm ent to ensure proper and reliable operation in the field.

Whenever a control failure could lead to personal in jury an d/or loss of property, it becomes the res ponsi bility of th e

user / installer / electrical panel designer to incorporate safety devices ( such as relays, flow switch, thermal

protections, etc… ) and/or alarm system to protect the entire system against such catastro phic failures. Tampering

of the devices or miss application of the device will void warranty.

Viconics Electronics Inc.

9245, Langelier Blvd, St-Leonard, Quebec, Canada H1P 3K9

LIT-R842X-E04

0.65" [17 mm

0.95" [24 mm]

sales@viconics.com

www.viconics.com

6

Loading...

Loading...