Page 1

ELECTRONIC THERMOSTATS

C1011

• One floating output

• Supply air temperature auto changeover input

DESCRIPTION

The C1011 series thermostats are microcomputer-based,

proportional and integral (PI) devices with one floating

(incremental) output. It can be used with most controlled

devices in the HVAC industry that are compatible with this

signal. Typical applications would be to control a floating

VAV or valve actuator. The thermostats also contain a berg

jumper for the actuator stroke time from full open to full

close.

Type of

output

Modulating

floating

SPECIFICATIONS

In cooling In heating

Modulating devices

Floating damper

actuator

Floating valve

actuator

Modulating devices

Floating damper

actuator

Floating valve

actuator

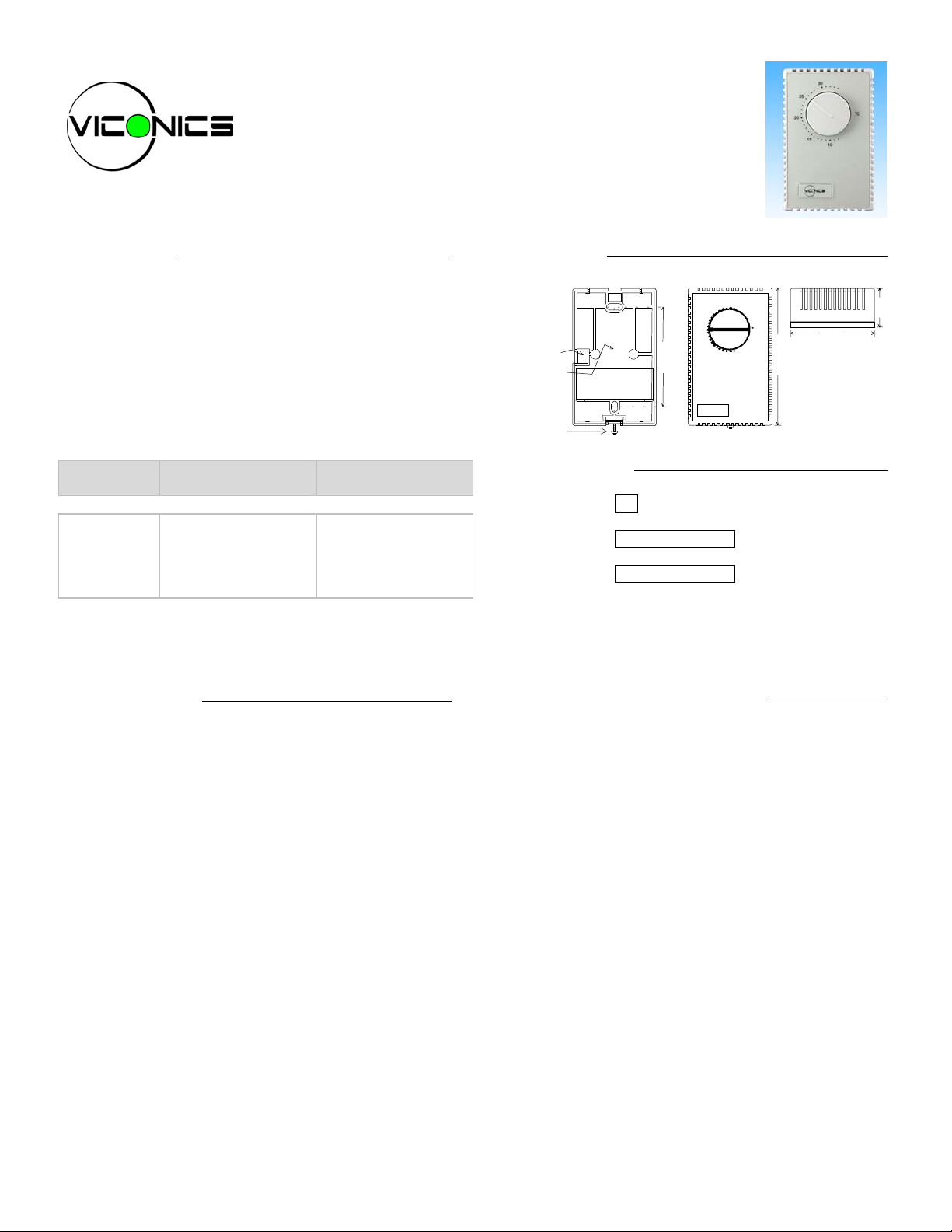

DIMENSIONS

WIRING

FROM TOP

OR FROM BACK

SECURITY SCREW

BASE

3.275"

( 83 mm )

90

80

70

F

60

50

4.5"

( 114 mm )

2.8"

( 71 mm )

HOW TO ORDER

C1011

Notes:

• Order changeover sensor separately.

• Vertical mounting is standard.

-

↓

00C = °C scale

↓

00F = °F scale

MODULATING FLOATING OUTPUT

1.275"

32 mm

Operating Conditions: 0 °C to 50 °C ( 32 °F to 122 °F )

0% to 95% R.H. non-condensing

Sens or: Local 47 K NT C thermistor

Resolution: ± 0.1 °C ( ± 0.2 °F )

Control accuracy: ± 0.2 ° C ( ± 0.4 °F ) ( calibrated )

Ranges: 10 °C to 32 °C ( 50 °F to 90 °F )

Proportional band f or r oom

temperature control: 1.8°C ( 3.2°F )

Floating output: Non isolated triac s: 30 Vac, ½ A max.

Power: 24 Vac -15%, +10% 50/60 Hz; 2 VA

This output is designed to give true PI modulation out of

floating actuator for VAV dampers and valves.

The thermostat is designed for operation with actuators that

have a running time of 1.5 to 2.5 minutes for the full open /

close stroke time.

The output is normally cooling but can be reversed to

heating mode with 2 different methods:

• Auto changeover to heating mode with a supply

sensor.

A remote supply sensor can be used for each thermostat.

Supply temperature > 78°F (26°C) = heating mode

Supply temperature < 75°F (24°C) = cooling mode

Hysterisys is 3°F (2°C)

• Auto changeover to heating mode with a dry contact.

A closed contact on the changeover input will change

operation of the floating output to heating mode.

Open contact = cooling mode

Closed contact = heating mode

1

Page 2

Characteristics of changeover sensor 47 KΩ

Temperature °F Temperature °C Sensor resistance

150.0 °F 65.6 °C 9.610 Kohm

140.0 °F 60.0 °C 11.700 Kohm

130.0 °F 54.4 °C 14.342 Kohm

120.0 °F 48.9 °C 17.682 Kohm

110.0 °F 43.3 °C 21.940 Kohm

100.0 °F 37.8 °C 27.412 Kohm

90.0 °F 32.2 °C 34.483 Kohm

80.0 °F 26.7 °C 43.704 Kohm

70.0 °F 21.1 °C 55.834 Kohm

60.0 °F 15.6 °C 71.866 Kohm

50.0 °F 10.0 °C 93.340 Kohm

40.0 °F 4.4 °C 122.298 Kohm

THERMOSTAT INSTALLATION

Important.

Electronic controllers require special care for wiring

and startup. To avoid problems, carefully follow the

procedures below.

Be sure to have all the literature on hand for all components

installed: controller, actuators, relay, etc...

Look at the wiring diagrams, and study them carefully. Be

sure that you understand how the system is supposed to

work.

Make the wiring according to the wiring diagrams. Respect

polarity for power terminals # 3 & # 4 between multiple

controllers if the same transformer is used.

Remove security screw on left side of thermostat cover.

•

Open up by pulling on the bottom side of thermostat.

•

A) Location:

1- Shouldn’t be installed on outside wall.

2- Must be installed away from any heat source.

3- Shouldn’t be affected by direct sun radiation.

4- Nothing must restrain vertical air circulation to the

thermostat.

B) Installation:

1- Pull out cables 6” out of the wall.

2- Wall surface must be flat and clean.

3- Separate the thermostat and the base by pulling

the cover by the bottom (same as the security

screw.)

4- Insert cable in the central hole of the base.

5- Align the base and mark the location of the two

mounting holes on the wall. Install proper side of

base up.

6- Install shields in the wall.

7- Insert screws in mounting holes on each side of the

base. DO NOT OVERTIGHTEN!

8- Strip each wire 1/4 inch.

9- Insert each wire according to wiring diagram.

10- Reinstall the cover ( top side first ) and gently push

back extra wire length in the hole in the wall.

11- Install security screw.

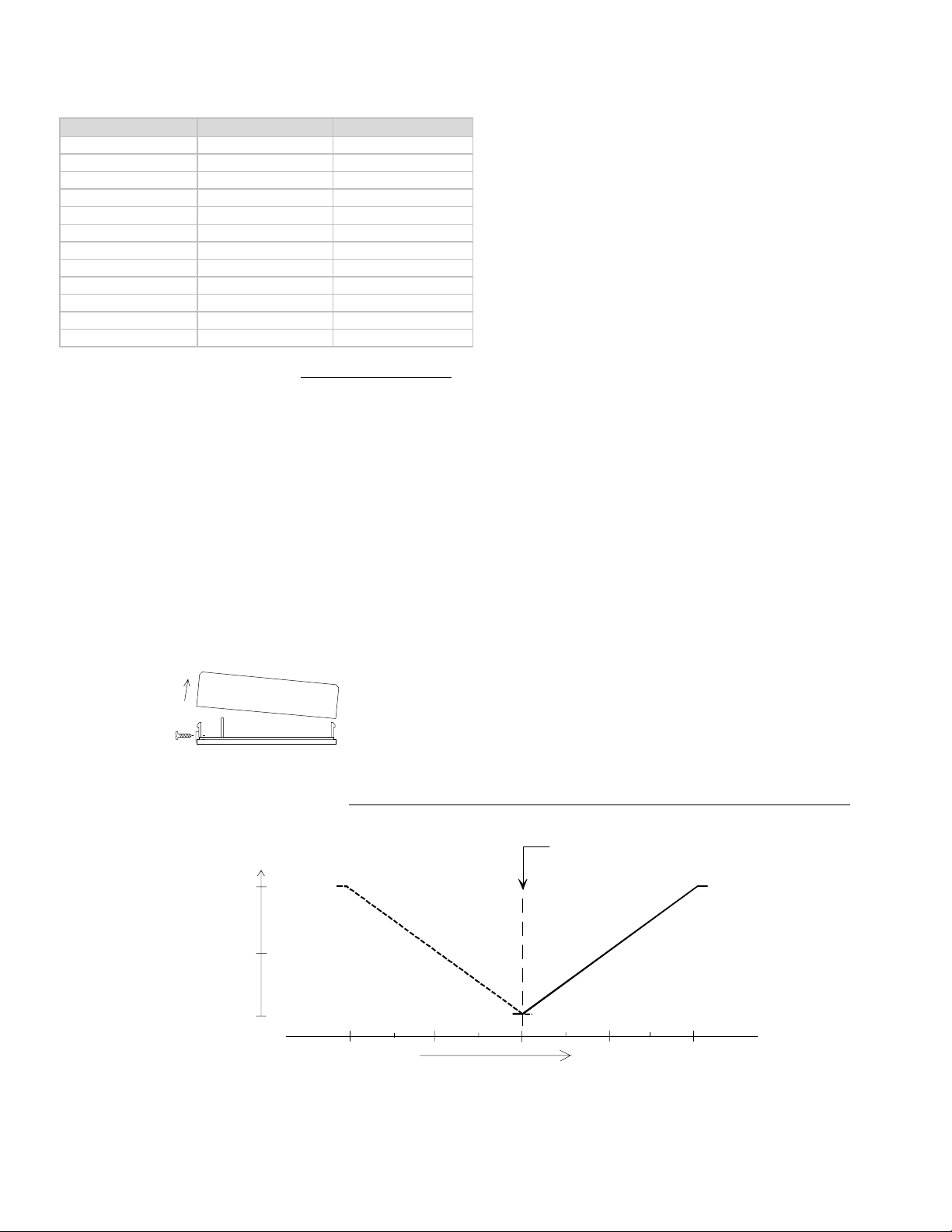

CONTROL CURVES AND SEQUENCE

SETPOINT DIAL

Opened

100%

50 %

Device

opened

Heating mode

changeover

input active

Device

opened

Cooling mode

Closed

0%

Device closed

Temperature increase

2

Page 3

TYPICAL APPLICATIONS

Pressure Dependent VAV

Modulating Floating

VAV Actuator

90

80

F

70

60

50

Room Temperature Control

Minimum & Maximum Position

Adjusted on the actuator

C/over

Common

24 Vac

Close

Open

2

3

4

5

6

Pressure Dependent VAV With:

Cool / Heat Auto Changeover Input

Changeover

Sensor

Room Temperature Control

Minimum & Maximum Position

Adjusted on the actuator

Modulating Floating

VAV Actuator

90

80

F

70

60

50

Supply air

temper ature senso r

C/over

2

Common

24 Vac

Close

Open

3

4

5

6

Valve Control With Room Thermostat ( Cooling Only )

Modulating Floating

Valve Cooling

90

80

F

70

60

50

Room Temperature

Control Thermostat

Modulating Floating

Valve Heating

90

80

F

70

60

50

Room Temperature

Control Thermostat

C/over

2

Common

24 Vac

Close

Open

3

4

5

6

Valve Control With Room Thermostat ( Heating Only )

C/over

2

Common

24 Vac

Close

Open

3

4

5

6

3

Page 4

Valve Control With Room Thermostat With:

Cool / Heat Auto Changeover Input

Modulating Floating Valve

Heating and/or Cooling

Optional Water

Supply Sensor

90

80

F

70

60

50

Room Temperature

Control Thermostat

C/over

Common

24 Vac

Close

Open

2

3

4

5

6

Supply water

temper ature sensor

24 VAC POWER AND FLOATING ACTUATOR TYPICAL WIRING

Power Supply 24 Vac -15% +10% 50/60 HZ 2 VA

•

If operation of the actuator is reversed, flip the reversing switch on

•

the actuator or reverse wires #5 & #6.

Note: terminals 2 and 3 can be wired together between each

•

thermostat if polarity is respected

Important: if using a common transformer, respect polarity ( Common

•

and 24 Vac between thermostats and actuator )

Common

24 Vac

Close

Open

3

4

5

6

Common

Close

Open

Modula ting floatin g actuat or

Open / Close type

Install 1 actuator

per thermostat

CHANGEOVER INPUT TYPICAL WIRING

1 SUPPLY CHANGEOVER SENSOR PER THERMOSTAT ( 1 SUPPLY SENSOR PER THERMOSTAT )

Auto changeover input using an S60, S70 duct supply sensor or S90

immersion supply sensor

• Supply temperature > 78°F (26°C) = Heating mode

• Supply temperature < 75°F (24°C) = Cooling mode

Cool / heat automatic

changeover input

Common

2

Changeove r sensor

3

• Hysterisys is 3°F (2°C) between heating and cooling

MULTIPLE TRANSFORMERS ( 1 DRY CONTACT FOR ALL THERMOSTATS )

Open contact = Cooling mode. Closed contact = Heating mode

24 Vac

Transformer

Primary

24 Vac

Common

Changeover

Input

4

24 Vac

3

2

Thermostat

Transformer

Primary

Do Not Ground Any

Transformer To Earth

Cool / Heat

Changeover Contact

24 Vac

Common

Changeover

Input

4

3

2

Thermostat

SINGLE TRANSFORMER ( 1 DRY CONTACT FOR ALL THERMOSTATS )

Open contact = Cooling mode. Closed contact = Heating mode

Primary Transformer

24 Vac

Common

4

3

24 Vac

Common

4

3

24 Vac

Cool / Heat

Changeover

Input

2

Thermostat

Viconics Electronics Inc. 9245, Langelier Blvd, St-Leonard, Quebec, Canada H1P 3K9 www.viconics.com

Changeover

Input

LIT-C1011-E01

2

Thermostat

Changeover Contact

sales@viconics.com

4

Loading...

Loading...