S

17:30

10.06.2017

TM

TM

тм

OPERATION MANUAL

VIBRO-LASER

AVOID

EXPOSURE

AVOID

EXPOSURE

M

тм

OPERATION MANUAL

VIBRO-LASER

CONTENT

PREFACE

LIMITED WARRANTY

LITHIUM ION BATTERY LIMITED WARRANTY

SAFETY INSTRUCTIONS

LASER LIGHT SOURCE HANDLING RULES

CHARGING THE SENSOR

MAINTENANCE

INTENDED PURPOSE

SPECIFICATIONS

SYSTEM DESCRIPTION

PREPARATION FOR WORK

PRELIMINARY WORKS

SETTINGS

4

5

6

6

6

7

7

8

8

9

10

11

12

SENSOR UNIT READINGS

SOFT FOOT

HORIZONTAL ALIGNMENT

CARRY OUT MEASUREMENTS (9-3-12 METHOD)

2

14

15

18

20

CUT ANGLE METHOD

25

THERMAL EXPANSION CORRECTION

VERTICAL ALIGNMENT

SAVING DATA AND REPORT CREATION

INFORMATION

ABOUT SYSTEM AND SOFTWARE

28

30

36

39

3

PREFACE

Thank you for your purchase of a VIBRO-LASER alignment system!

We are sure that you have made the right choice and hope that the system

will not only meet your expectations but exceed them as well.

Before system operation it is important that you read and understand this

manual, most signicantly the chapters on safety and maintenance.

This manual is intended to provide information on the various operations and

control procedures for the software and hardware of the system.

ALWAYS ALIGNED™

Klim, Fedya, Misha, Olga, Vladimir, Mike & Megh

4

LIMITED WARRANTY

This product is manufactured with the greatest care following the

VIBRO-LASER quality control system. Should the product fail within one (1)

year from the date of purchase under normal usage conditions, VIBRO-LASER

will repair or replace the product free of charge in accordance with our

warranty policy as solely interpreted by VIBRO-LASER.

1. Using new or refurbished replacement parts.

2. Exchange the product with a product that is new or which has been

manufactured from new or serviceable used parts and is at least functionally

equivalent to the original product.

Proof of purchase date is required, and sent together with a copy of the

original purchase document. Warranty is valid under normal usage conditions

as described in the user’s manual included with the product. The warranty

covers failure on VIBRO-LASER products that could be related to material

and/or fabrication errors. The warranty is valid only in the country of purchase

by the original purchaser. The warranty is not valid in the following cases:

• If the product is broken due to mishandling or incorrect operation

• If the product has been exposed to extreme temperature, calamity, chock or

high voltage.

• If the product has been modied, repaired or disassembled by unauthorized

personnel.

• Compensation for possible damage due to failure on VIBRO-LASER product

is not included in the warranty. Freight cost to VIBRO-LASER is not included in

the warranty.

Note!

Before delivery of the product for warranty repair, it is the responsibility of

the buyer to backup all data. Data recovery is not included in the warranty

service and VIBRO-LASER is not responsible for data that may be lost or

damaged during transit or repair!

5

LITHIUM ION BATTERY LIMITED WARRANTY

Lithium ion batteries inevitably lose power during their lifetimes, depending

on usage temperatures and the number of charging cycles. Therefore, the

internal rechargeable batteries used in VIBRO-LASER products are not

included in our general 1-year warranty. There is 6 months warranty for the

battery capacity not to fall below 70 % (a normal change means that the

battery must have more than 70 % capacity after more than 300 charging

cycles). A 1 year warranty applies if the battery becomes unusable because of

a manufacturing fault or factors that VIBRO-LASER could be expected to have

control of, or if the battery displays abnormal loss of capacity in relation to

use.

SAFETY INSTRUCTIONS

Follow all the safety and control rules, regulation, procedures, and general

common sense VIBRO-LASER is not responsible whatsoever for any injuries,

loss of production or capacity, or any failure of any kind as a result of the

user/owner not following instructions as set forth in this manual, on product

labels, in their work area, or general industry practices and common sense.

Do take notice of any warning labels on the device and in the operation

manuals.

Lack of the consideration to such warning labels may cause personal injuries

and damage to the equipment.

LASER LIGHT SOURCE HANDLING RULES

VIBRO-LASER system uses laser diodes with 1.0 MW output capacity, which

complies with the Class 2 standards of SS-EN-60825-1-1994. This class is

considered to be safe for operation providing the following precautionary

measures are taken:

strictly follow safety rules during operation;

the device might be used only for its

intended purpose;

do not use the device if it or its parts

are damaged in any way;

do not open laser source blocks;

6

do not look in the laser source when it is working;

do not direct laser beam into other people’s eyes;

All repair or calibration of the laser source may only be completed by

VIBRO-LASER or those authorized by VIBRO-LASER in writing.

CHARGING THE SENSOR

Attention!

It is forbidden to charge the sensor units in an explosion-hazard area!

It is only allowed to use the original power USB cables. Use of any other USB

cables may cause personal injuries and damage to the equipment.

During the charging of S and M sensor units the charge LED indicator will

illuminate.

After the indicator is o, please disconnect the adapter from the sensor units.

Follow your facility/company lock out tag out equipment shutdown rules

Do not use vibro-laser until the equipment to be aligned is veried

100% de-energized

MAINTENANCE

The system should be cleaned with a lint free cotton cloth or cotton buds

dampened with mild soap solution. Detector and laser windows,

however, should be wiped with alcohol swabs or cleaning pad.

Do not use paper tissues as they may

damage the surface of the detector;

Do not use acetone;

To insure proper operation and life

keep your VIBRO-LASER product clean.

It is best practice to clean the system

after use.

7

INTENDED PURPOSE

VIBRO-LASER shaft alignment systems are a portable high-precision device

designed for alignment control of rotating machines (pumps, electric motors,

reduction units, compressors, etc).

SPECIFICATIONS

SENSOR UNITS M and S

Material

Dimensions

Laser emission

Laser power

Distance between blocks

Detector receiver length

Detector type

Detector resolution

Measuring accuracy

Digital inclinator

Protection class

Batteries

Time of operation

Bluetooth 4.0

Anodized aluminium

90mm x 60mm x 32mm

Diode laser with wavelength 635nm, class II

< 1 mW

up to 10 m

30 mm

Digital — CCD detector

0,001 mm

0,3% ± 7um

0.1

IP65

lithium-ion

up to 20 hours

Yes

Operating temperature

from -0 º С to +60 º С

8

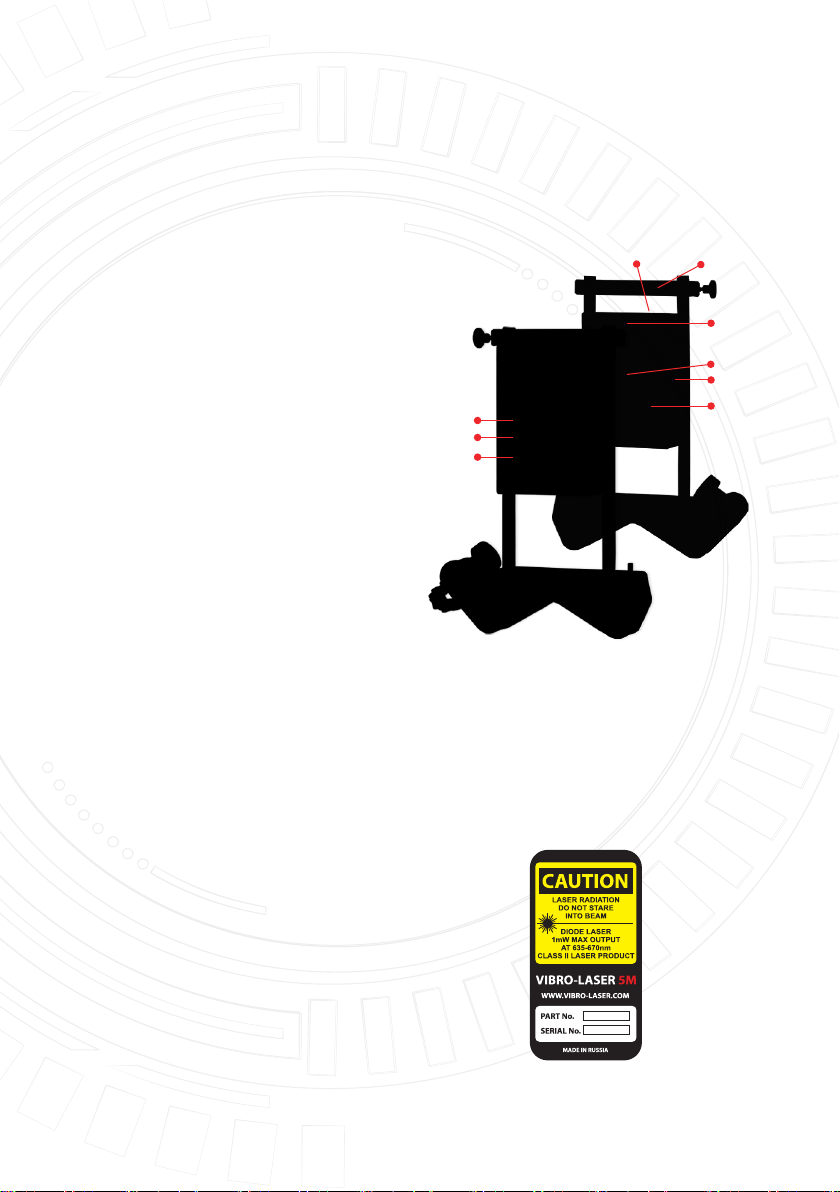

SYSTEM DESCRIPTION

SENSOR UNITS M and S

ON/OFF button (hold for 2-3

1

seconds to turn o)

Mini USB port (for charging)

2

3

Clamping bar with screw

4

Charge indicator (illuminates

green during charging then turns

o)

Connection indicator (illuminates

5

blue when connects, blinks during

transfer)

6

ON indicator (illuminates red when

ready for work, illuminates green

when ready for measurements)

7

Laser beam window

8

Detector receiver

9

4

5

6

3

7

8

2

1

Adjustment screw (for vertical laser positioning).

9

LABELING

Model, and Serial Number are printed on the

name plate on the back of sensor units.

9

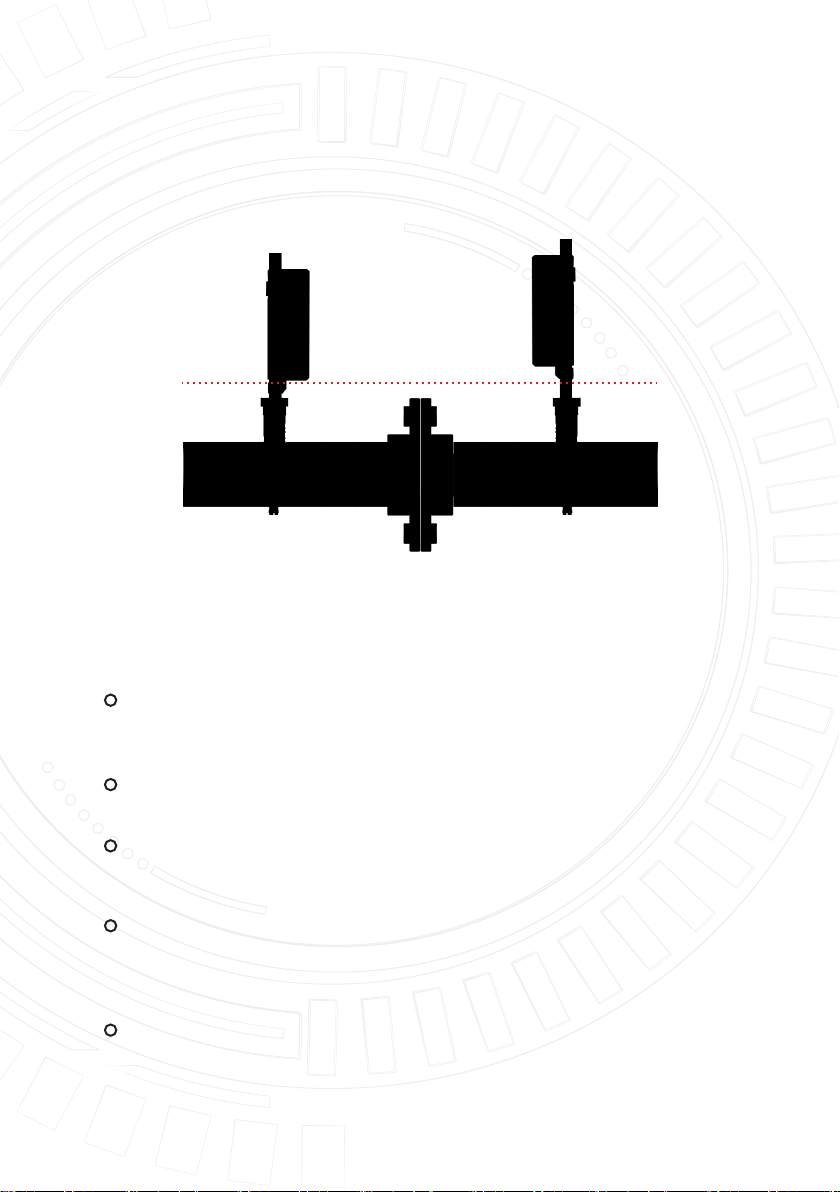

PREPARATION FOR WORK

Fix the sensor unit with the M label to the movable part of the machine, and

then x the S-labeled sensor unit to the stationary. Mounting each sensor for

each side as shown below.

The sensor units should be xed with a shift (see the gure).

Note!

Fix the sensors at a reasonable distance from eachother not beyond 10m

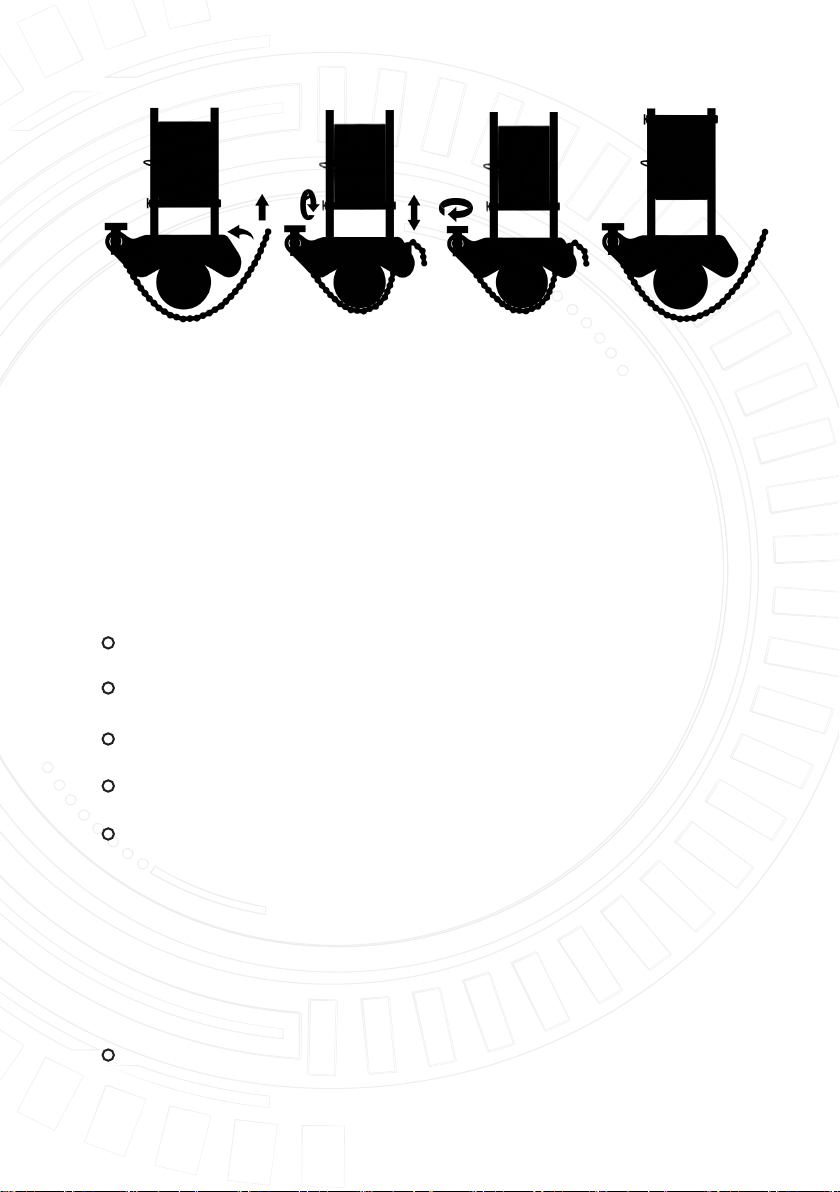

Place the v-bracket vertically on the shaft of the machine being

aligned. Take the loose end of the chain and pull it to remove the

whipping, then x it to the hook. (Fig. A)

Pull the chain tightly via the screw. Try to avoid excessive tightness.

(Fig. B)

If the shaft diameter is too big, use extension chains or replace with

common chains from any hardware store or industrial supplier to

make the chain longer. (Fig. C)

Correct the height of the units by slowly moving them along the bars

until the laser beam points to the center of the receiver of each unit.

Fix the units with the locking screw on the сlamping bar. (You can ne

tune the beams with the dial)

Clamping bars might be xed under units (recommended) as above

them. (Figг. D)

1010

(Fig. A) (Fig. B) (Fig. C) (Fig. D)

Attention!

M unit laser direction can be adjusted with the adjusting screw at the top

of the unit. Normally, it is not required, but it may be needed if the distance

between units is large.

PRELIMINARY WORKS

Before start of the alignment check for following:

What are the alignment tolerances required?

Are there any thermal compensation requirements?

Are there any size restrictions for measurement system installation?

Are the shafts able to be rotated?

What size shims will be needed?

Before the installation of the measurement system to the machine, check its

base, bolts and preinstalled shims. Check for restrictions (is there enough

space for moving the machine).

After the visual check proceed with the following:

Remove old and rusty shims (if removable);

11

Check socket joint and loosen fasteners;

Check for soft foot;

Check how loose is the machine;

Check for run out of the shaft and the socket joint;

Check for pipe strain;

Check for end clearance between the shafts (axial alignment).

SETTINGS

Mount the sensor units on the shafts.

Turn the S and M units on (the red LED indicator goes on).

Turn the VIBRO-LASER software.

Touch the Icon “Global settings”

12

Touch the Icon “Sensor units search”

When connected, the indicators

will illuminate in blue.

Attention! After initial use the sensor units will be automatically

connected by default.

Choose Measurement Resolution.

Choose units of measurement (millimeters or

inches). Choose between metric and imperial

measurement convention, and the necessary

resolution (default setting is 0.01 mm or 0.4

mils).

Set the averaging lter from 1 to 20

Attention!

If laser beam passes through air with variable temperature or in the case of

signicant background noise, the beam directionality may be aected.

1

13

Variation of the results might be caused by instability of measurement

process. Try reducing the intensity of air movement between laser and the

detector (e.G. By replacing the heat sources or closing doors). If the results

are still instable, increase the lter value. Default setting is 1. Most

common values are from 1 to 3.

SENSOR UNIT READINGS

Start the program by touching the Icon

«Sensor Unit Readings» in the main menu

During the program loading the display shows data received directly from

the sensor units (position of the laser beam on the sensor and inclinometer

angle).

If no value is available, the display shows

To reset the readings touch the Icon

0

14

SOFT FOOT

Note!

Before any alignment the soft foot (loose t of the base) should be

addressed. Otherwise the results of a precision alignment will be

inneective. The removal of the soft foot is impossible without any

measuring devices. In your VIBRO-LASER embedded alignment program

you are able to provide to identify and correct soft foot.

Touch the Icon “Soft foot”

Before Soft Foot process you need to enter following dimensions: distance

between bars; distance between M unit and rst set of feet; distance

between the rst and the second sets of feet.

Set the units to the 12 o’clock (the green LED indicator of M and S units will

glow green).

Check bolt tensioning of each foot.

Touch the Icon “Next”

15

Choose the bolt by touching the Icon

First loosen the chosen bolt completely, then tighten it rmly. It is

recommended to use a torque wrench for tightening.

Save the measurement result by touching the “OK” Icon

Repeat these actions for other bolts.

Note!

You can carry out new measurement at any time by touching the

corresponding Icon.

To reset measurements touch the Icon

Values show shim plate thickness to eliminate the soft foot.

16

Make the required corrections then check each foot once more.

Note!

Allowed values from 0mm to 0.06 mm

17

HORIZONTAL ALIGNMENT

Touch the icon “Horizontal alignment”

in main men

Complete the alignment procedure step by step, following the arrow

indicator.

Note!

You can backup to the horizontal alignment menu anytime to conrm

your step.

18

Insert the tolerance values according to the rotation rate of the machine.

Touch the icon

Insert the dimensions

Touch the icon to insert the dimensions.

19

The eld activates a calculator interface. To submit the inserted dimensions,

touch ОК.

Use the supplied tape measure for measuring:

• Distance between the BARS CENTRES OF M and S UNITS

• Distance between the center of coupling joint and the BAR CENTER of M unit

• Distance between M unit and the rst set of feet (support).

• Distance between the rst and the second set of feet (support).

Touch the Icon

CARRY OUT MEASUREMENTS (9-3-12 METHOD)

This type of measurement requires rotating the shaft with the M and S units

in such a way that ag indicator on the information circle is in the green zone

(3-6-9-12o’clock).

Note!

For results please take measurements in at least three of four possible

control positions.

Set the M and S sensor units to the 9 o’clock green zone in such a way that

they have roughly the same angles (control the angles of M and S sensor

units via the virtual level).

20

Touch the Icon

The rst measurement is registered in the table.

To reset the data, touch the Icon

Turn the shafts to the 3 o’clock.

Tap the measurement icon

The second measurement is registered in the table.

Turn the shafts to the 12 o’clock

21

Touch the measurement icon

The third measurement is registered in the table.

Results of measurements

Touch the Icon

22

This screen shows the misalignment values according to the coupling joint

and the feet position (horizontal as well as vertical). Symbols on the left of the

value indicate angular and parallel misalignment and bias directions, as well

as indicates whether the values are within the allowable limits.

Within the tolerance limits (green)

Within the doubled tolerance limits (yellow)

Beyond the doubled tolerance limits (red)

Symbols next to the soupling joint REPEAT THE LIMIT READINGS.

Within the tolerance limits

Within the doubled tolerance limits

Beyond the doubled tolerance limits.

Note!.

The symbols above show whether the misalignment and bias values are

within the selected tolerances.

Touch the Icon

Live Alignment Mode

To adjust the shafts position vertically, rotate the shafts to 12 or 6 o’clock.

To set the M and S sensor units, use the displayed virtual levels. Adjust the

machine’s vertical position until the values are within the allowable limits.

Arrows next to the feet show the direction to move the machine in real time.

23

Note!

Use VIBRO-LASER SHIMS to align the machine vertically.

To adjust the shafts position horizontally, rotate the shafts to 3 or 9 o’clock.

Use the displayed virtual levels for precise alignment. Adjust the machine’s

horizontal position until the values are within the allowable limits according

to the arrows next to the feet.

Note!

First adjust the position of the machine vertically, then horizontally.

24

Note!

Tighten the foot bolts crosswise with same force using a calibrated torque

wrench to avoid changes of results!

The alignment is complete

To carry out

the verication measurements touch

Carry out the verication measurement using the Clock method.

After the verication measurement the Horizontal Alignment menu is opened.

Note!

To carry out more precise alignment after the verication measurement use the Live Alignment to continue align.

Save results, touch the Icon

CUT ANGLE METHOD

If 180 degree rotation of the shaft is impossible for some reason, please use

the CUT ANGLE METHOD.

The minimal rotation required is 40 degrees. The more rotation, the better

and more precise the alignment.

25

Touch the Icon

Start measuring from any point.

Rotate shafts in the next position according to the animation.

Touch the measurement Icon

The rst measurement is registered in the table.

Rotate shafts in the next position according to the animation.

26

Touch the Icon

The second measurement is registered in the table.

Rotate shafts in the next position according to the animation.

Touch the Icon

The third measurement is registered in the table.

Attention!

When taking measurements, rotate the shafts so the sectors do not

overlap each other

Note!

For the best accurate maintain the sensors with maximum distance.

Note!

When using this method the shafts should be connected to provide

maximum precision of the measurements and the alignment.

27

THERMAL EXPANSION CORRECTION

During the operation the equipment is exposed to various factors and forces.

The most common inuence on alignment is change of the machine

temperature which leads to the enlargement of a shaft and subsequent

misalignment. This process is called thermal expansion or growth.

To compensate the thermal expansion you need to make a correction for the

expansion of the cold machine during its heating through out operation.

Touch the icon in the alignment screen

Insert the correction via calculator

28

When the results are received, the sign is shown,

indicating that the thermal correction is made.

29

VERTICAL ALIGNMENT

Vertical shafts alignment is carried out by moving the machine

ange/coupling until the axes are coaxial enough to stay in the assigned limits.

The system is able to work with an allowance table.

Touch the Icon

Complete the alignment procedure step by step, following the arrow indicator.

Note!

You can open the vertical alignment menu at anytime to verify your step

30

Insert the tolerance values according to the RPM of the machine.

Touch the icon to insert the dimensions.

VThe eld activates a calculator interface. To submit the inserted dimensions,

touch ОК.

Use a measuring tape for measuring:

Distance between the BARS CENTERS OF M and S UNITS

Distance between the center of coupling joint and the BAR CENTER of

M unit

Distance between the centers of outer bolts.

Number of bolts (it is helpful to use a paint market or grease pencil to

mark the machine with the applicable bolt number for future

The vertical alignment program calculates the machine position by

measurements in three shaft positions when they are rotated 180°.

31

Touch the measurement icon

The rst measurement is registered in the table.

Rotate shafts in the next position according to the animation.

32

Touch the measurement icon

The second measurement is registered in the table.

Rotate shafts in the next position according to the animation.

Touch the measurement icon

The third measurement is registered in the table.

Touch the button

to get the measurement result

The measurement results screen shows the misalignment values according to

the coupling joint in both directions. Symbols on the left of the value stand

for parallel and angular directions and also indicates whether the values are

within the allowable limits.

33

The table on the right contains bolts numbers with designation of shims

required for eliminating misalignment.

within the allowable limits (green)

within the doubled allowable limits (yellow)

beyond the doubled allowable limits (red)

Symbols next to the socket joint repeat the limit readings.

within the allowable limits

within the doubled allowable limits

beyond the doubled allowable limits

Touch the button

to get the measurement result

34

To carry out the verication measurements

touch

Carry out the verication measurement.

After the verication measurement the Vertical Alignment menu is opened.

Save results by touching

35

SAVING DATA AND REPORT CREATION

Note!

The program has autosaving function: every time the program is started,

the previous result is shown.

To reset them, touch

One of our system advantages is possibility to save, restore and edit the

results of the alignment on any stage!

Touch the icon

to save alignment results

Insert the name of the report with the

virtual keyboard and touch

To cancel, touch

To upload the results touch

36

Note!

Upload a previously saved report and continue alignment from where you

stopped.

To create a report touch

You can edit the report header with your machine and company information

using the touch screen and virtual keyboard.

37

Options of report menu

Print the repor

Save the report as PDF

Save the report as PDF

38

INFORMATION ABOUT SYSTEM AND SOFTWARE

To see the system data, tap the button

i

Vibro-laser instruments corporation thanks you for your business.

Should you require support please go to www.Vibro-laser.Com

39

тм

тм

Loading...

Loading...