Page 1

Technical Data Sheet

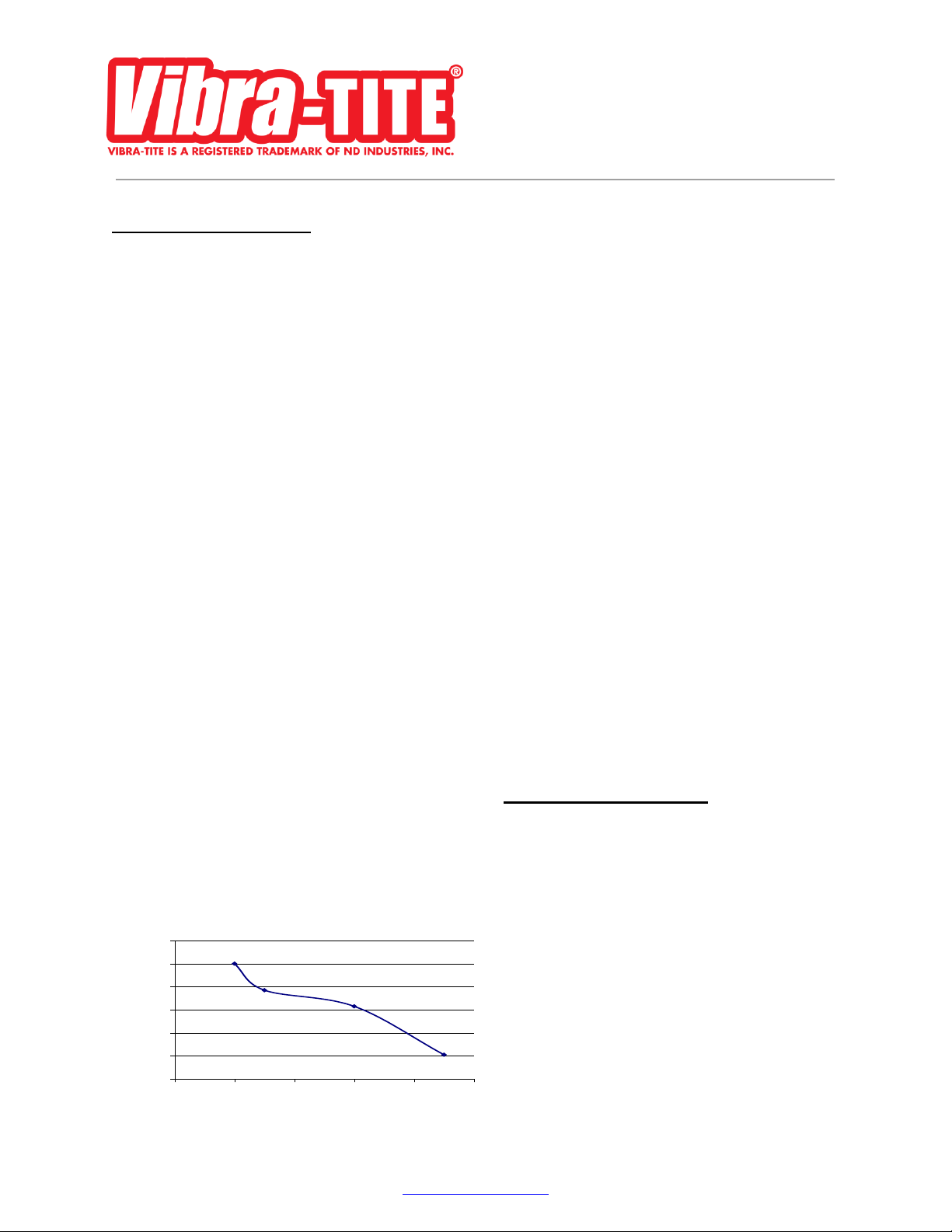

100

120

140

160

180

200

220

0 10 20 30 40 50

Cure Time (minutes)

Cure Temperature (C)

Vibra-Tite® 934

Epoxy

November 2012

Product Description

Vibra-Tite 934 is a single-part induction cured epoxy

adhesive with excellent adhesion to metal oily

surfaces as well as composite material. This epoxy

can be used to enhance joint stiffness and joint

durability. The high bond strength of this adhesive

allows it to replace mechanical fasteners, soldering,

brazing, or welding. This material requires heat in

the range of 120oC to 200oC. Vibra-Tite 934 is nonsagging allowing this product to be used in large gaps

and on vertical surfaces.

Features and Benefits

Induction Curable

Enhanced Joint Durability

Bonds Through Oily Substrates

Easy to Use 1K System

High Shear and Peel Strengths

Good High Temperature Performance

Good Chemical Resistance

Properties of Uncured Material

Chemical Type Epoxy

Appearance Silver Paste

Specific Gravity 1.38

Toxicity Low

Solids 100%

Viscosity @ 25ºC, cP 900,000

Thixotropic Index 3.01

Typical Curing Performance

Cure Speed

Heat is required to cure the epoxy. The cure time is

dependent on the temperature used. The following is

time required to cure the epoxy at different

temperatures.

Technical data contained within this document is intended for reference only

For assistance and recommendations on specifications for this product, contact ND Industries

info@ndindustries.com

11/13/2012 Page 1 of 1

Performance of Cured Material

Typical Values

Shear Strength PSI

Steel 5,000

Galvanized 4,500

Aluminum 3,900

Shear Strength Development

Induction Cure Strength

Typical Values

Shear Strength PSI

4 sec (1s ramp 3s hold) 840

@ 347oF (175oC)

6 sec (1s ramp 3s hold) 1,330

@ 392oF (200oC)

Environmental and Fluid Resistance

(Shear strength values)

Typical Values

Heat age 100%

Environmental Cycles 90%

Humidity 90%

Salt Spray 90%

SAE J2334 80%

General Information

Storage

Product should be stored in cool, dry conditions.

VIBRA-TITE 934 when un-mixed has a shelf life of

12 months when stored at 25°C. Storage in cool,

clean areas is recommended. Usable shelf life may

vary depending on method of applications and

storage conditions.

Note

The data are furnished for information only and are

believed to be reliable. We cannot assume

responsibility for the results obtained by others over

whose methods we have no control. It is

recommended that the product be tested in the

application for which it is to be used.

Loading...

Loading...