Viadrus K4 User Manual

VIADRUS K4

Manual for boiler operation and installation

GB_2017_24

GB_ 2015_31

Table of Contents

page

General Information

1

Produced Versions of the Boilers ............................................................................................................................................................. 3

2

Boiler Application and Benefits ................................................................................................................................................................. 3

3

Technical Data ......................................................................................................................................................................................... 4

4

Boiler Description ................................................................................................................................................................................... 15

4.1

4.2

4.3

4.4

4.5

4.6

Boiler Design ................................................................................................................................................................................... 15

Control Features .............................................................................................................................................................................. 15

4.2.1 Removing the front cover ........................................................................................................................................................... 15

Main Boiler Parts ............................................................................................................................................................................. 16

A diagram showing flue gas flow in the exchanger ........................................................................................................................... 18

Delivery and Accessory ................................................................................................................................................................... 18

Instructions before Putting into Operation ........................................................................................................................................ 18

User

5

Boiler Attendance by the User ................................................................................................................................................................ 19

5.1

5.2

5.3

5.4

5.5

5.6

5.7

6

7

8

9

Description of the Control ................................................................................................................................................................. 19

Modes of Operation ......................................................................................................................................................................... 19

Lockout condition codes................................................................................................................................................................... 21

Blocking codes ................................................................................................................................................................................. 22

Additional Functions ......................................................................................................................................................................... 23

5.5.1 LCD symbols test....................................................................................................................................................................... 23

5.5.2 Air purge function ...................................................................................................................................................................... 23

OpenTherm communication ............................................................................................................................................................. 23

5.6.1 History information ..................................................................................................................................................................... 23

Installer mode .................................................................................................................................................................................. 24

5.7.1 “tS” as Transparent Parameters mode (TSP) ............................................................................................................................. 24

5.7.2 “In” as Inquiry mode ................................................................................................................................................................... 24

5.7.3 “Hi” as History mode .................................................................................................................................................................. 25

5.7.4 “rES” as Reset of the History information ................................................................................................................................... 25

Maintenance .......................................................................................................................................................................................... 25

IMPORTANT NOTICES ......................................................................................................................................................................... 26

Instructions for Product Disposal After Its Service Life............................................................................................................................ 26

Warranty and Liability for Defects ........................................................................................................................................................... 27

Servicing

10 Placement and Installation ..................................................................................................................................................................... 28

10.1 Standards and regulations ............................................................................................................................................................... 28

10.2 Possible Placement ......................................................................................................................................................................... 29

10.3 Boiler Installation ............................................................................................................................................................................. 29

10.4 Connecting to the Heating System and Water Filling ........................................................................................................................ 31

10.5 Gas Connection ............................................................................................................................................................................... 31

10.6 Electric Power Supply Connection ................................................................................................................................................... 31

10.7 Condensate Discharge .................................................................................................................................................................... 31

10.8 Flue Gas Ducting ............................................................................................................................................................................. 31

10.9 Boiler Electrical Wiring ..................................................................................................................................................................... 32

10.9.1 Main components of boiler electrical equipment ......................................................................................................................... 32

10.9.2 Connection of the higher-level regulation and external boiler sensors ........................................................................................ 32

10.9.3 Connecting terminal ................................................................................................................................................................... 33

11 Flue Gas Ducting ................................................................................................................................................................................... 38

11.1 Flue gas ducting – examples of correct connection of flue duct and air supply ................................................................................. 39

11.2 Flue gas ducting – examples of incorrect connection of flue duct and air supply .............................................................................. 39

11.3 STARR D80 and FLEX 80 system connection ................................................................................................................................. 39

11.3.1 STARR, 2 x D 80 mm flue ducting diagram ................................................................................................................................ 40

11.3.2 FLEX, 2 x D 80 mm flue ducting diagram ................................................................................................................................... 41

11.4 LIK 60/100, 80/125 system connection ............................................................................................................................................ 42

11.4.1 Diagram for flue gas ducting of the LIK type, version 60/100 mm (max. length 5 m), or 80/125 .................................................. 43

11.5 Pressure Losses of Chimney Flue Elements in Case of VIADRUS K4 Boiler Usage ........................................................................ 44

12 Commissioning ...................................................................................................................................................................................... 44

12.1 Instructions before Putting into Operation ........................................................................................................................................ 45

12.2 Boiler Setting ................................................................................................................................................................................... 46

12.3 Conversion to a different type of fuel ................................................................................................................................................ 47

12.4 Boiler Electronics Setting ................................................................................................................................................................. 47

12.4.1 K4GXH24X - Honeywell electronics parameters set in the manufacturing factory (service parameters list neXsys S4962V3224)

12.4.2 K4GXH33X - Honeywell electronics parameters set in the manufacturing factory (service parameters list neXsys S4962V3224)

13 Servicing Inspection of the Boiler ........................................................................................................................................................... 50

.................................................................................................................................................................................................. 48

.................................................................................................................................................................................................. 49

2

General Information

X

1

Exchanger:

G:

X

Water heating:

1:

X

3

Electrical equipment:

H:

X

Output:

24:

X

Fuel: Z:

X

Cover color:

W:

Dear Customer

Thank you for your purchase of the VIADRUS K4 boiler and for your confidence in VIADRUS a.s.

To become familiar with a proper operation of your new product since the beginning, please read carefully the presented user´s manual,

especially Chapter No. 5 – Boiler Attendance by the user, Chapter No. 6 – Maintenance, and Chapter No. 7 – IMPORTANT NOTICES. We ask

you to follow the information presented below and especially to perform the prescribed annual inspections to be performed by an authorized

specialized company, which guarantees a long-term boiler operation free of failures to both your and our satisfaction.

1 Produced Versions of the Boilers

In your order specify the order specification code:

VIADRUS K4 X1X2X3X4X5X6

2

4

5

6

Conversion of the VIADRUS K4 boiler from natural gas to propane and vice-versa can be performed by a contracted service provider

only.

Chimney flue made by ALMEVA has been certified for this boiler. If you use chimney flue made by a different producer, it is necessary

to use a system with identical parameters as for the certified type of the chimney flue.

stainless Sermeta

without installed three-way valve with a pump

2: three-way valve, pump, HSW exchanger

3: with a three-way valve with a pump

Honeywell

24 kW

33: 33 kW

natural gas

P: propane

white

R: red

S: silver

B: black

2 Boiler Application and Benefits

The VIADRUS K4 condensing boiler has been designed for combustion of low pressure natural gas.

The size of the condensing boiler is suitable for heating of family houses and recreational facilities as well as for reconstruction of heat sources

in individual apartment units. The condensation heat output is 5 – 24 kW, 10 – 33 kW.

The boiler body efficiency at the 50/30 °C temperature gradient varies in a range of 101 – 105 % depending on the required output.

Boiler Benefits:

• Low gas consumption

• High combustion efficiency

• Smooth output modulation

• Easy attendance and maintenance

• The boiler enables connecting to a reservoir of hot service water heater and ensures its preferential heating

• Reliability of the regulation and safety components

• Low weight

• Equithermal boiler regulation

3

General Information

2H I2E

2H I2E

2H I2E

53, C83

-

1

-

1

-

1

3 Technical Data

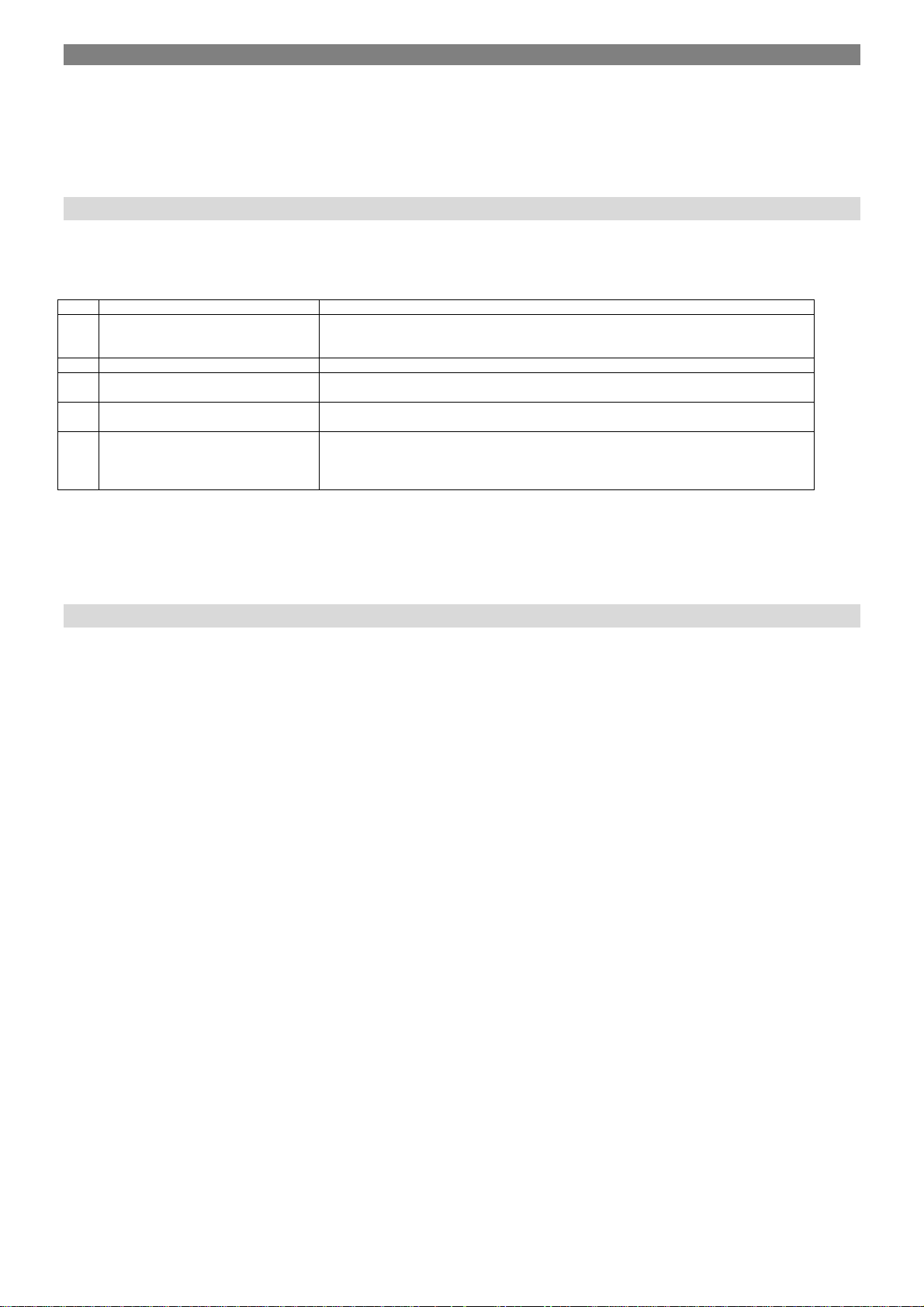

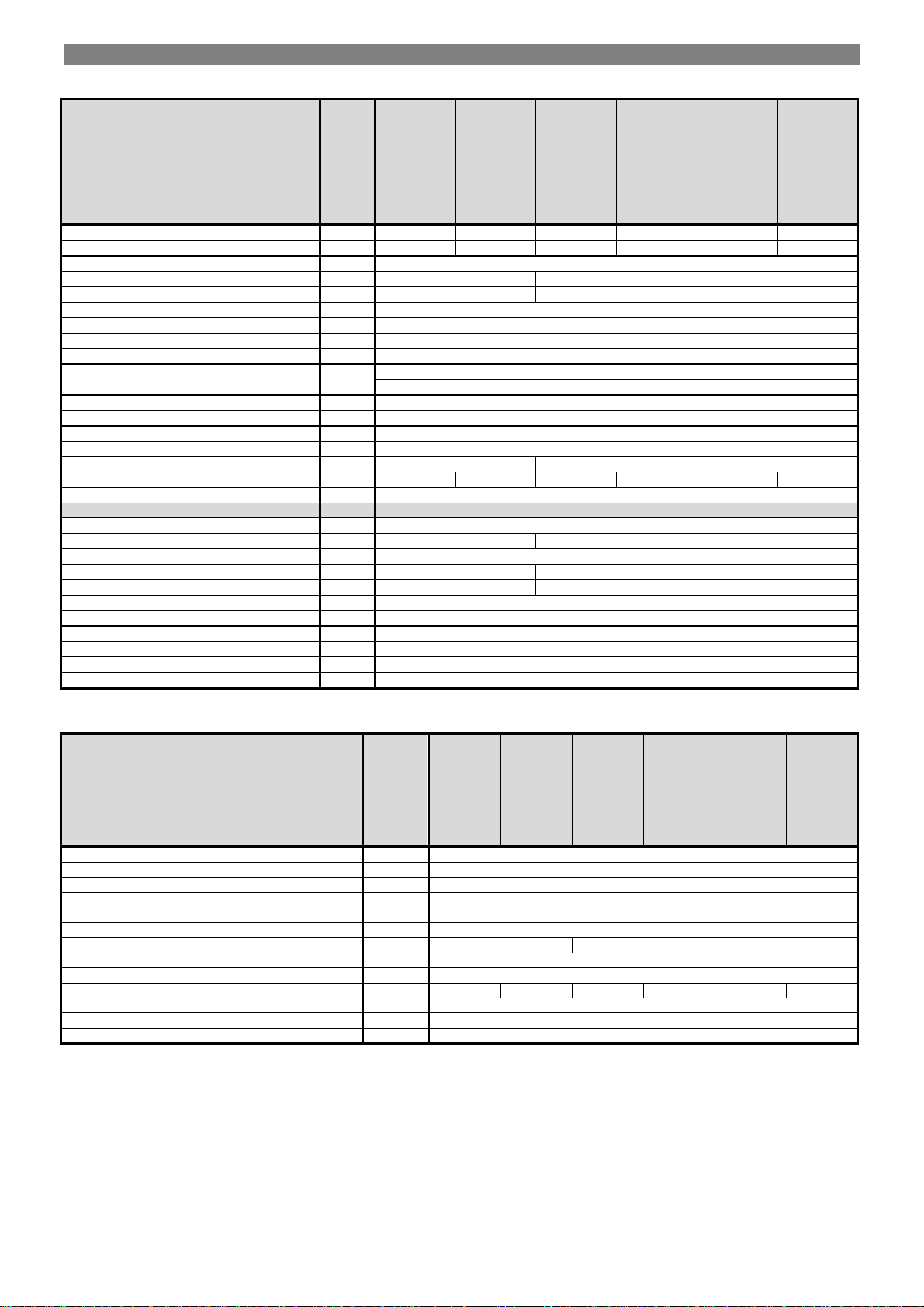

Tab. . 1 Sizes, operation temperature and electrical variables - VIADRUS K4GXH24XX

K4G1H24ZX

K4G1H24PX

K4G2H24ZX

K4G2H24PX

K4G3H24ZX

K4G3H24PX

Fuel type [-] ZP Propane ZP Propane ZP Propane

Category of appliance [-] I

Version C13,C33, C43, C

I3P I

I3P I

I3P

Weight [kg] 26 27.5 26.5

Water volume [l] 2 3 2

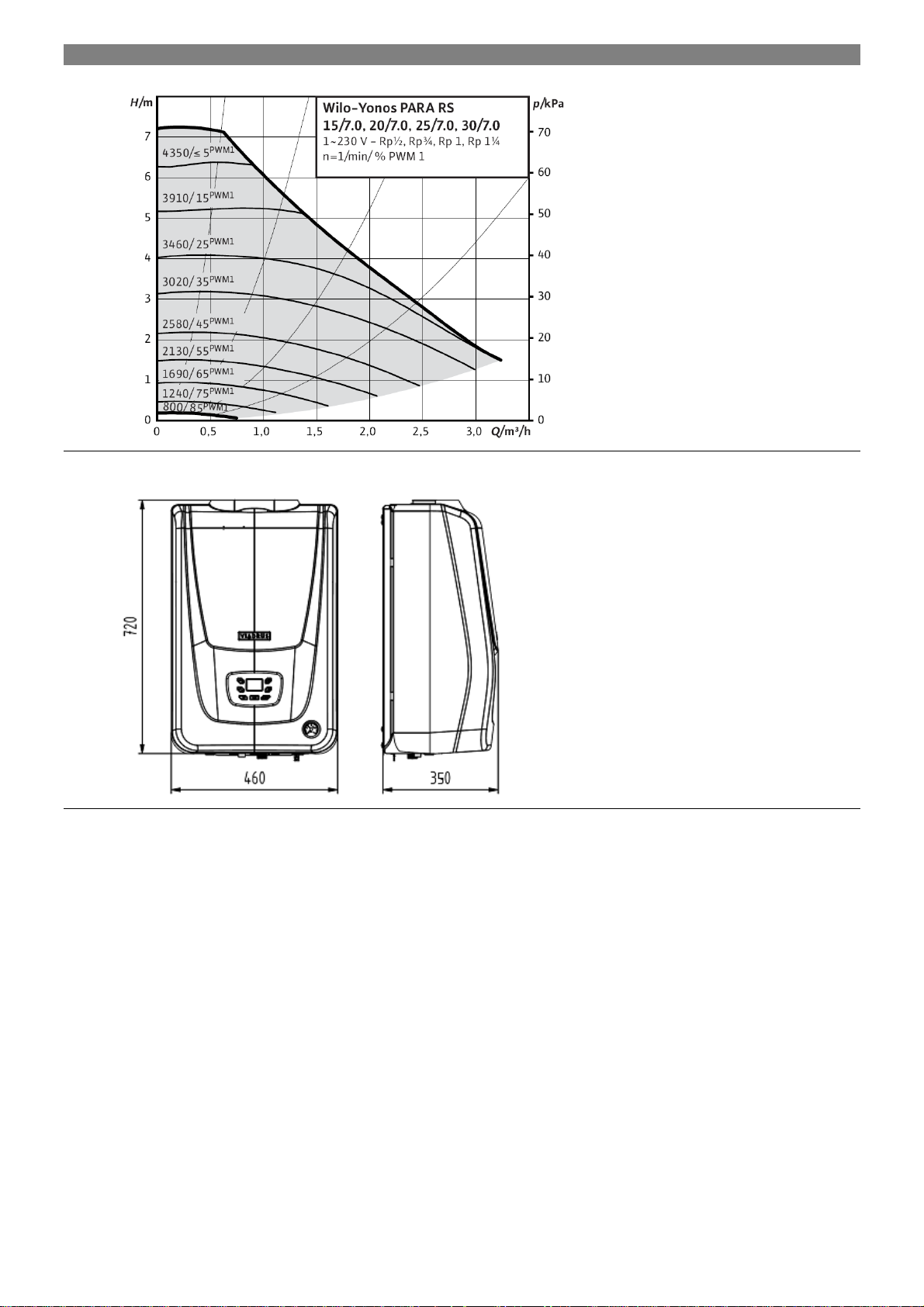

Boiler dimensions – width [mm] 460

– depth [mm] 350

– height [mm] 720

Ø of combustion air connection [mm] 80 / 100 (see fig. no 10)

Ø flue gas socket [mm] 80, 60

Working water overpressure [bar] 3

Testing water overpressure [bar] 5

Pressure loss [-] See diagram 1

Maximum permitted working temperature [°C] 85

Heating water setting range [°C] 25 - 85

Hot water setting range [°C] - 35 - 60 35 - 60

Connecting overpressure of fuel [mbar] 20 37 20 37 20 37

Noise level [dB] < 50

Boiler connection

- heating water output [Js] 3/4“

- heating water input to the heater [Js] - 1/2“ 1/2“

- return heating water input [Js] 3/4“

- return water input from the heater [Js] 1/2“ 3/4“

- system water filling inlet [Js] 1/2" - -

- condensate outlet [mm] Ø 25

- safety valve output [mm] Ø 21,2

- gas inlet [Js] 3/4“

Connecting voltage 1/N/PE 230VAC 50 Hz, TN-S

El. power input including pump [W] 110

El. covering IP 40

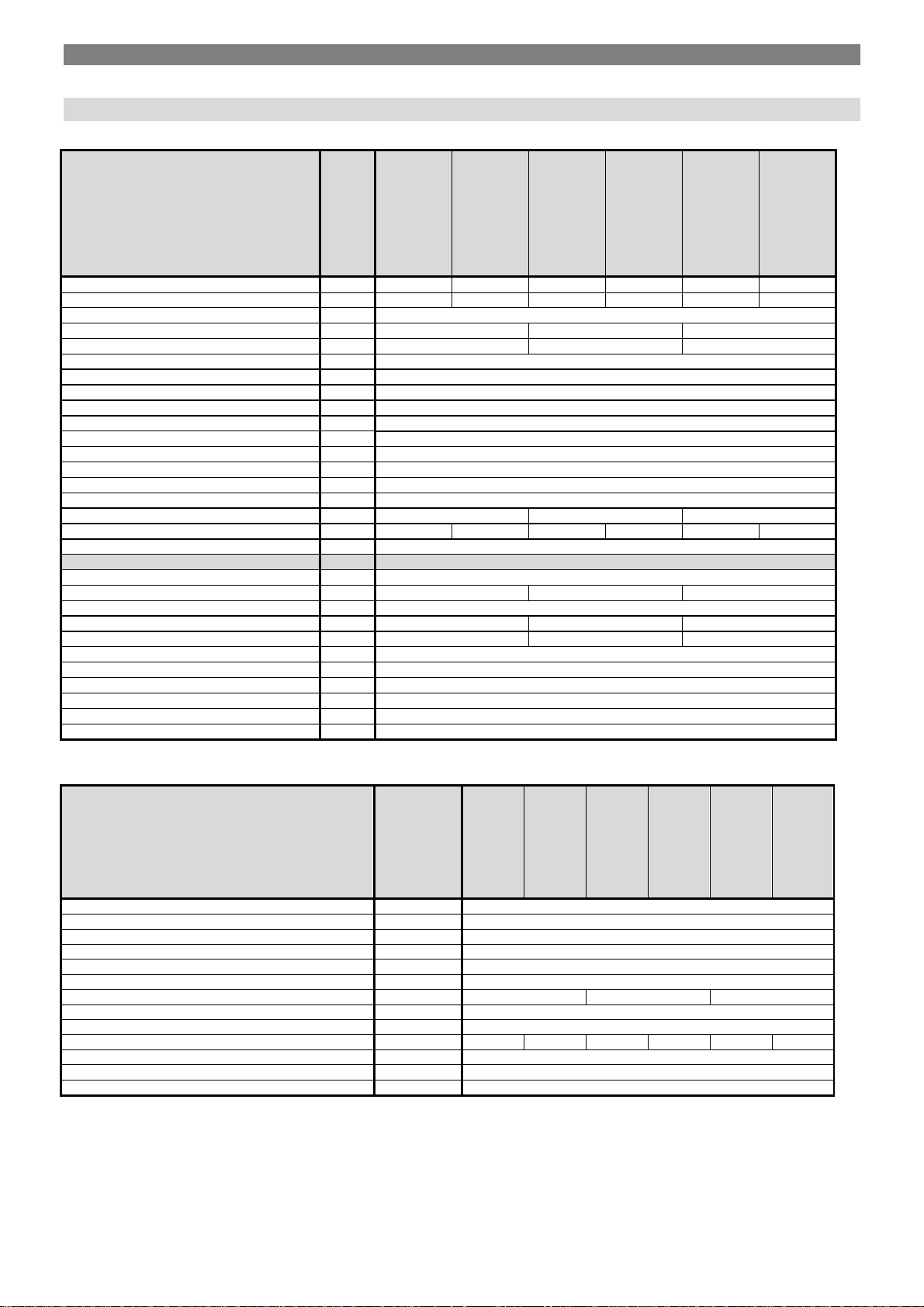

Tab. . 2 Thermal – technical parameters - VIADRUS K4GXH24XX

comparison conditions 15 °C and 101.325 kPa, dry gas

K4G1H24ZX

K4G1H24PX

K4G2H24ZX

Boiler output range [kW] 5 - 24

Nominal output 80/60 °C [kW] 22,2

Nominal output 50/30 °C [kW] P=24

Minimum output 50/30 °C [kW] P=5

Maximum nominal heat input [kW] Q=22.8

Minimum nominal heat input [kW] Q=4.6

DHW flow with ∆T [l.min

] - See diagram 2 Boiler efficiency at the nominal output 80/60°C [%] Up to 98

Boiler efficiency at the nominal output 50/30°C [%] Up to 105

Volume flow rate of fuel [m3.h

Mass flow rate of flue gas [kg.h

] 0.5-2.4 0.2-0.9 0.5-2.4 0.2-0.9 0.5-2.4 0.2-0.9

] 8 - 45

Nox class [-] 5

Flue gas temperature (max.) [°C] 85

K4G2H24PX

K4G3H24ZX

K4G3H24PX

4

General Information

2H I2E

2H I2E

2H I2E

53, C83

-

1

-

1

-

1

Tab. . 3 Sizes, operation temperature and electrical variables - VIADRUS K4GXH33XX

K4G1H33ZX

K4G1H33PX

K4G2H33ZX

K4G2H33PX

K4G3H33ZX

K4G3H33PX

Fuel type [-] ZP Propane ZP Propane ZP Propane

Category of appliance [-] I

Version C13,C33, C43, C

I3P I

I3P I

I3P

Weight [kg] 28 29,5 28,5

Water volume [l] 3 4 3

Boiler dimensions – width [mm] 460

– depth [mm] 350

– height [mm] 720

Ø of combustion air connection [mm] 80 / 100

Ø flue gas socket [mm] 80, 60 (see fig. no 10)

Working water overpressure [bar] 3

Testing water overpressure [bar] 5

Pressure loss [-] See diagram 1

Maximum permitted working temperature [°C] 85

Heating water setting range [°C] 25 - 85

Hot water setting range [°C] - 35 - 60 35 - 60

Connecting overpressure of fuel [mbar] 20 37 20 37 20 37

Noise level [dB] < 50

Boiler connection

- heating water output [Js] 3/4“

- heating water input to the heater [Js] - 1/2“ 1/2“

- return heating water input [Js] 3/4“

- return water input from the heater [Js] 1/2“ 3/4“

- system water filling inlet [Js] 1/2" - -

- condensate outlet [mm] Ø 25

- safety valve output [mm] Ø 21,2

- gas inlet [Js] 3/4“

Connecting voltage 1/N/PE 230VAC 50 Hz, TN-S

El. power input including pump [W] 110

El. covering IP 40

Tab. . 4 Thermal – technical parameters - VIADRUS K4GXH33XX

comparison conditions 15 °C and 101.325 kPa, dry gas

K4G1H33ZX

K4G1H33PX

K4G2H33ZX

Boiler output range [kW] 6,5 - 33

Nominal output 80/60 °C [kW] P=30,5

Nominal output 50/30 °C [kW] P=33

Minimum output 50/30 °C [kW] P=6,5

Maximum nominal heat input [kW] Q=31,4

Minimum nominal heat input [kW] Q=6,3

DHW flow with ∆T [l.min

] - See diagram 3 Boiler efficiency at the nominal output 80/60°C [%] Up to 98

Boiler efficiency at the nominal output 50/30°C [%] Up to 105

Volume flow rate of fuel [m3.h

Mass flow rate of flue gas [kg.h

] 0,68-3,3 0,28-1,28 0,68-3,3 0,28-1,28 0,68-3,3 0,28-,28

] 11 - 62

Nox class [-] 5

Flue gas temperature (max.) [°C] 85

K4G2H33PX

K4G3H33ZX

K4G3H33PX

5

General Information

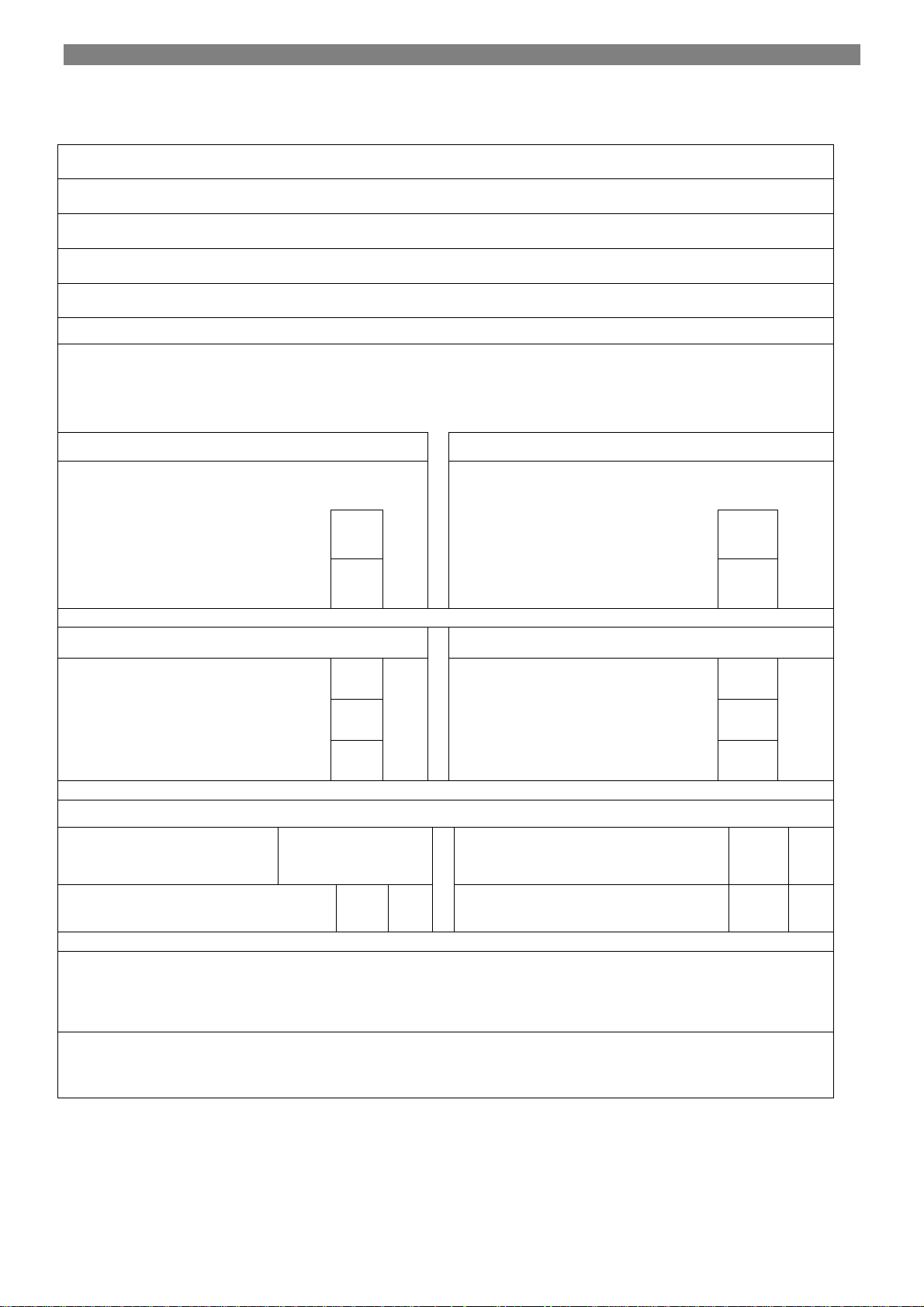

Diagram no. 1 A diagram of the boiler heating circuit hydraulic loss

Fig. . 1 The main boiler dimensions

6

General Information

16,50

14,50

12,50

10,50

(kW)

Výkon kotle (kW)

8,50

6,50

4,50

2,50 3,50 4,50 5,50 6,50 7,50 8,50 9,50

24,00

K4G2H24.. Ohřev TV -T 25°C

K4G2H24.. Hot water heating - T 25 °C

Hot water flow rate (l/min)

Průtok TV (l/min)

K4G2H24.. Ohřev TV -

K4G2H24.. Hot water heating - T 30 °C

T=30°C

19,00

14,00

(kW)

Výkon kotle (kW)

9,00

4,00

2,00 3,00 4,00 5,00 6,00 7,00 8,00 9,00 1 0,00 11,00

K4G2H24.. Ohřev TV -T 35°C

K4G2H24.. Hot water heating - T 35 °C

23,00

21,00

19,00

17,00

15,00

(kW)

13,00

Výkon kotle (kW)

11,00

Hot water flow rate (l/min)

Průtok TV (l/min)

9,00

7,00

2,50 3,50 4,50 5,50 6,50 7,50 8,50 9,50

Průtok TV (l/min)

Hot water flow rate (l/min)

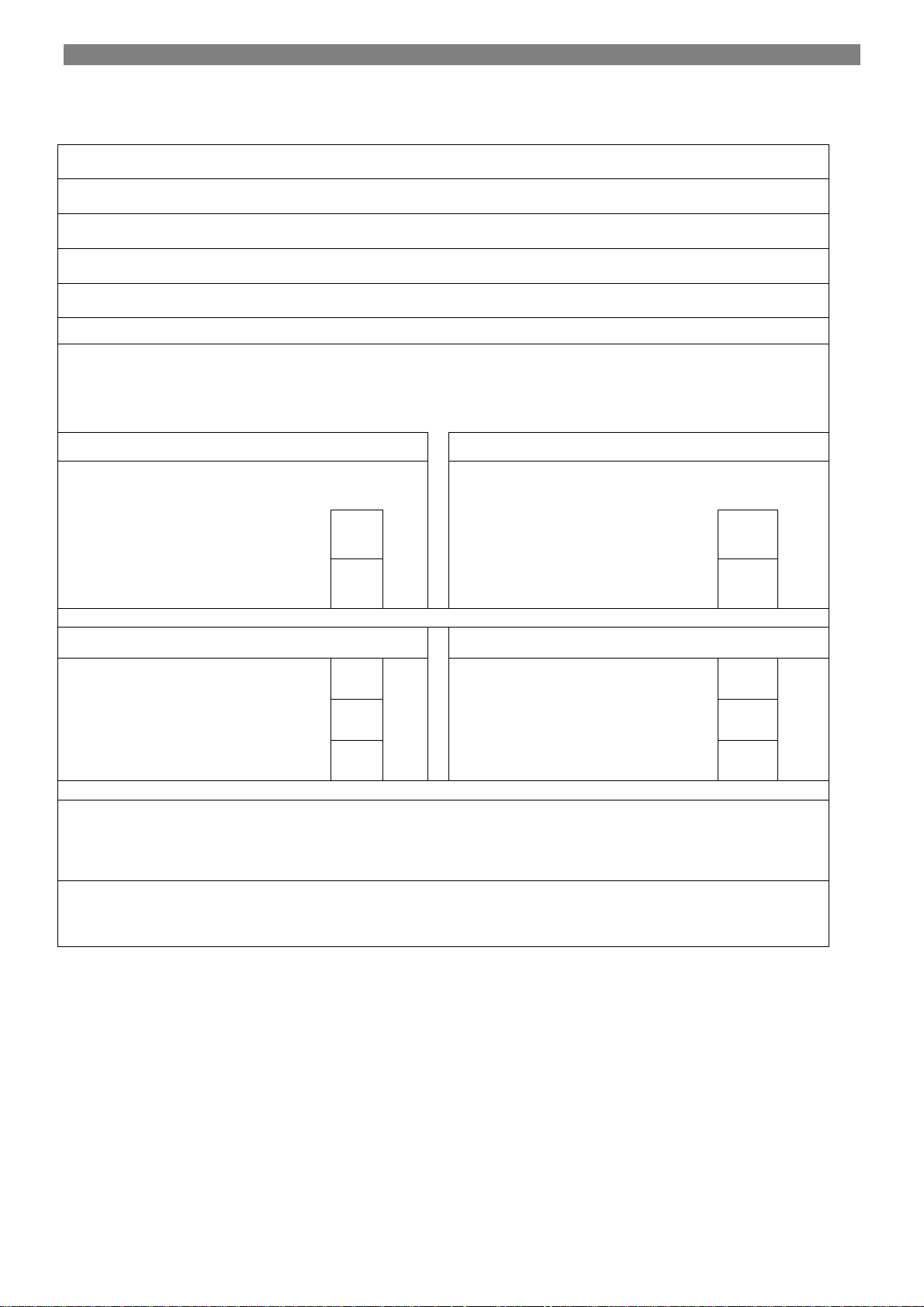

Graph No. 2 Dependence of boiler power on flow rate of heated hot water (version VIADRUS K4G2H24XX)

7

General Information

24,00

19,00

(kW)

14,00

Výkon kotle (kW)

9,00

4,00

3,00 5,00 7,00 9,00 11,00 13 ,00 15,00

34,00

K4G2H33.. Ohřev TV -T 35°C

K4G2H33.. Hot water heating - T 25 °C

Hot water flow rate (l/min)

Průtok TV (l/min

K4G2H33.. Ohřev TV -T 30°C

K4G2H33.. Hot water heating - T 30 °C

)

29,00

24,00

(kW)

19,00

Výkon kotle (kW)

14,00

9,00

4,00

2,00 4,00 6,00 8,00 10,00 1 2,00 14 ,00 16 ,00

Hot water flow rate (l/min)

Průtok TV (l/min)

K4G2H33.. Ohřev TV -T 35°C

34,00

29,00

24,00

19,00

(kW)

K4G2H33.. Hot water heating - T 35 °C

Výkon kotle (kW)

14,00

9,00

4,00

3,00 5,00 7,00 9,00 11,00 13,00

Průtok TV (l/min

Hot water flow rate (l/min)

)

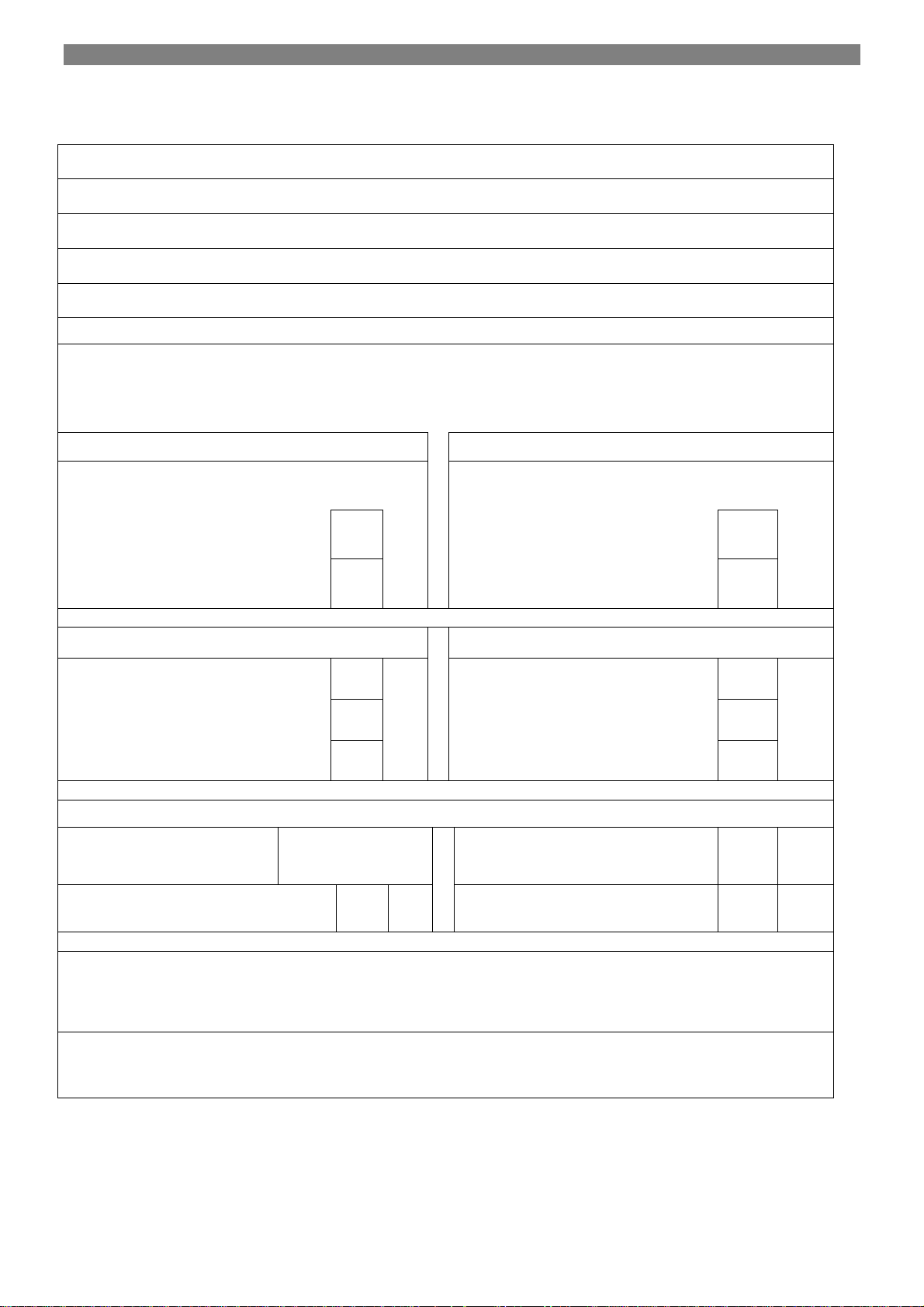

Graph No. 3 Dependence of boiler power on flow rate of heated hot water (version VIADRUS K4G2H33XX)

8

General Information

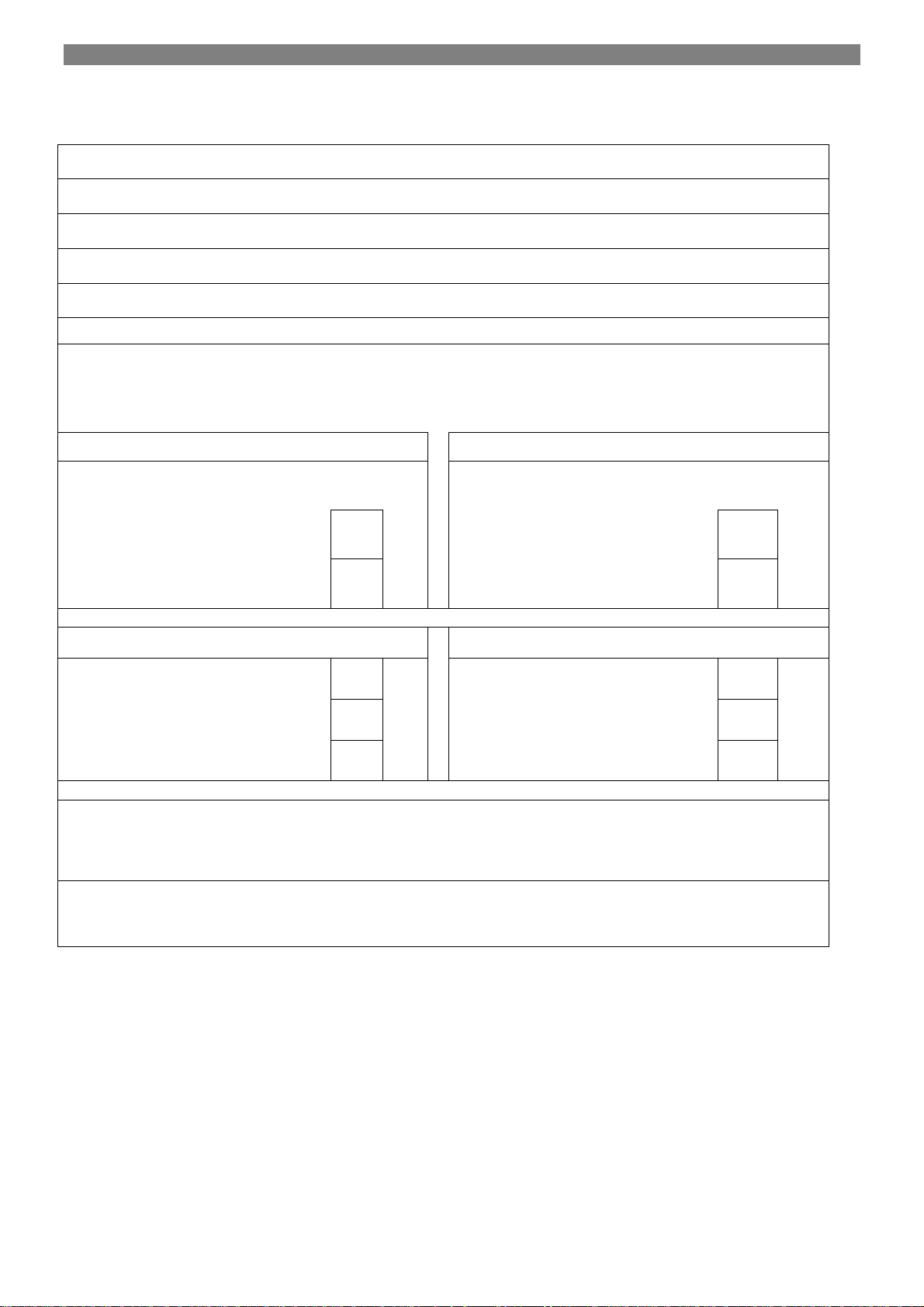

Seasonal space heating energy

Information requirements for boiler space heaters, boiler combination heaters

and cogeneration space heaters

Model(s): VIADRUS K4G1H24XX

Condensing boiler: yes

Low-temperature (**) boiler: no

B1 boiler: no

Cogeneration space heater: no If yes, equipped with a supplementary heater:

Combination heater: no

Rated heat output

Item

Symbol

Prated 24 kW

Value

For boiler space heaters and boiler combination heaters: Useful

heat output

At rated heat output and hightemperature regime (*)

At 30 % of rated heat output and

low-temperature regime (**)

P4 24 kW

P1 4 kW

Unit

efficiency

For boiler space heaters and boiler combination heaters: Useful

efficiency

At rated heat output and hightemperature regime (*)

At 30 % of rated heat output and lowtemperature regime (**)

Item

Symbol

ƞ

90 %

s

ƞ

97,53 %

4

ƞ

105,72 %

1

Value

Auxiliary electricity consumption Other items

At full load el

0,02 kW

max

Standby heat loss P

0,045 kW

stby

At part load el

0,011 kW

min

Ignition burner power consumption P

- kW

ign

In standby mode PSB 0,003 kW

Emissions of nitrogen oxides NOx 25

Contact details

VIADRUS a.s.

Bezručova 300

Bohumín

735 81

Czech Republic

Unit

mg/

kWh

(*) High-temperature regime means 60 °C return temperature at heater inlet and 80 °C feed temperature at heater outlet.

(**) Low temperature means for condensing boilers 30 °C, for low-temperature boilers 37 °C and for other heaters 50 °C return

temperature (at heater inlet).

9

General Information

Seasonal space heating energy

Information requirements for boiler space heaters, boiler combination heaters

and cogeneration space heaters

Model(s): VIADRUS K4G2H24XX

Condensing boiler: yes

Low-temperature (**) boiler: no

B1 boiler: no

Cogeneration space heater: no If yes, equipped with a supplementary heater:

Combination heater: yes

Rated heat output

Item

Symbol

Prated 24 kW

Value

For boiler space heaters and boiler combination heaters: Useful

heat output

At rated heat output and hightemperature regime (*)

At 30 % of rated heat output and

low-temperature regime (**)

P4 24 kW

P1 4 kW

Unit

efficiency

For boiler space heaters and boiler combination heaters: Useful

efficiency

At rated heat output and hightemperature regime (*)

At 30 % of rated heat output and lowtemperature regime (**)

Item

Symbol

ƞ

90 %

s

ƞ

97,53 %

4

ƞ

105,72 %

1

Value

Auxiliary electricity consumption Other items

At full load el

0,02 kW

max

Standby heat loss P

0,045 kW

stby

At part load el

0,011 kW

min

Ignition burner power consumption P

- kW

ign

In standby mode PSB 0,003 kW

Emissions of nitrogen oxides NOx 25

For combination heaters:

Unit

mg/

kWh

Declared load profile

Daily electricity consumption Q

Contact details

(*) High-temperature regime means 60 °C return temperature at heater inlet and 80 °C feed temperature at heater outlet.

(**) Low temperature means for condensing boilers 30 °C, for low-temperature boilers 37 °C and for other heaters 50 °C return

temperature (at heater inlet).

XL Water heating energy efficiency ƞwh 84 %

0,204 kWh

elec

VIADRUS a.s.

Bezručova 300

Bohumín

735 81

Czech Republic

Daily fuel consumption Q

23,215 kWh

fuel

10

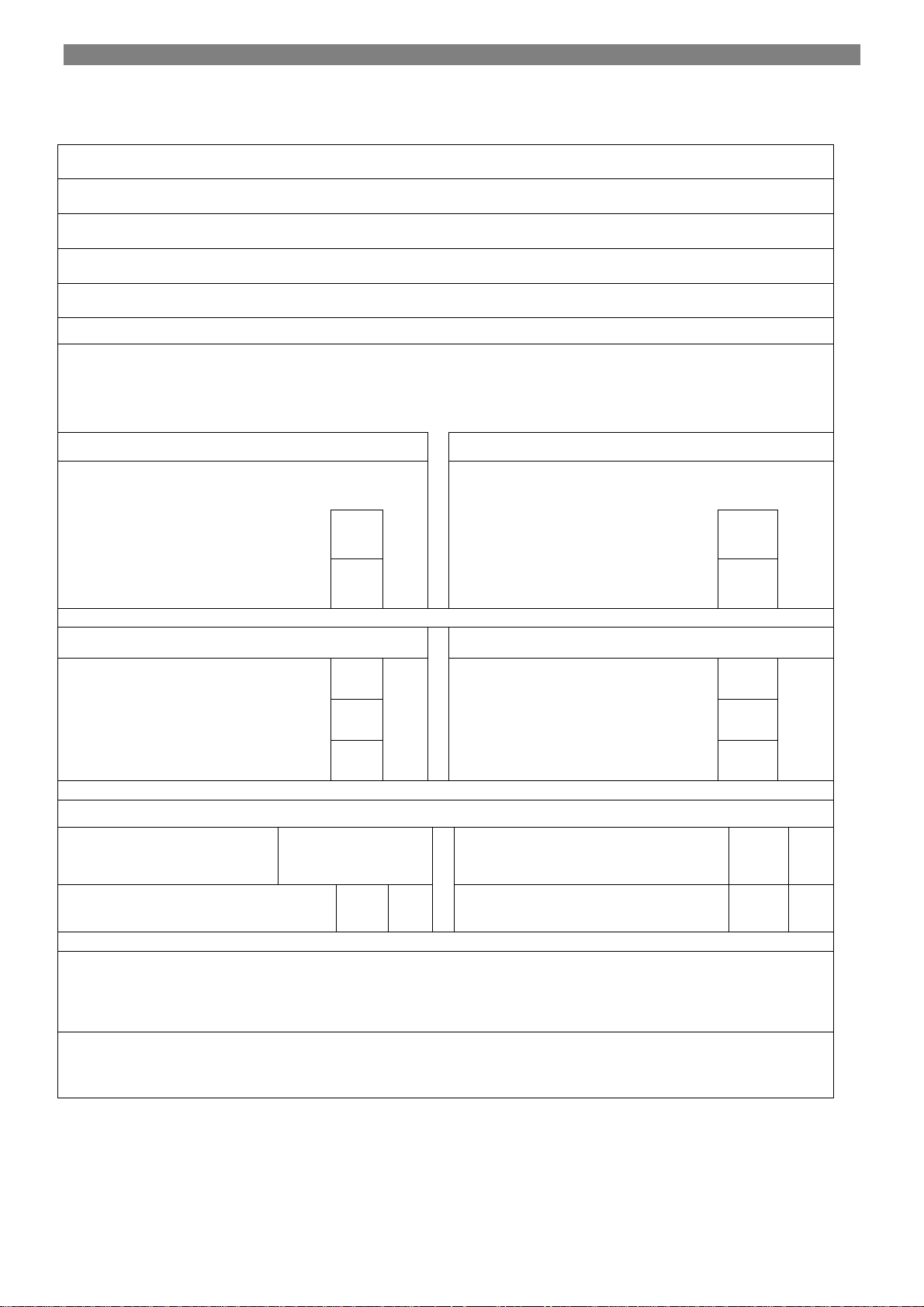

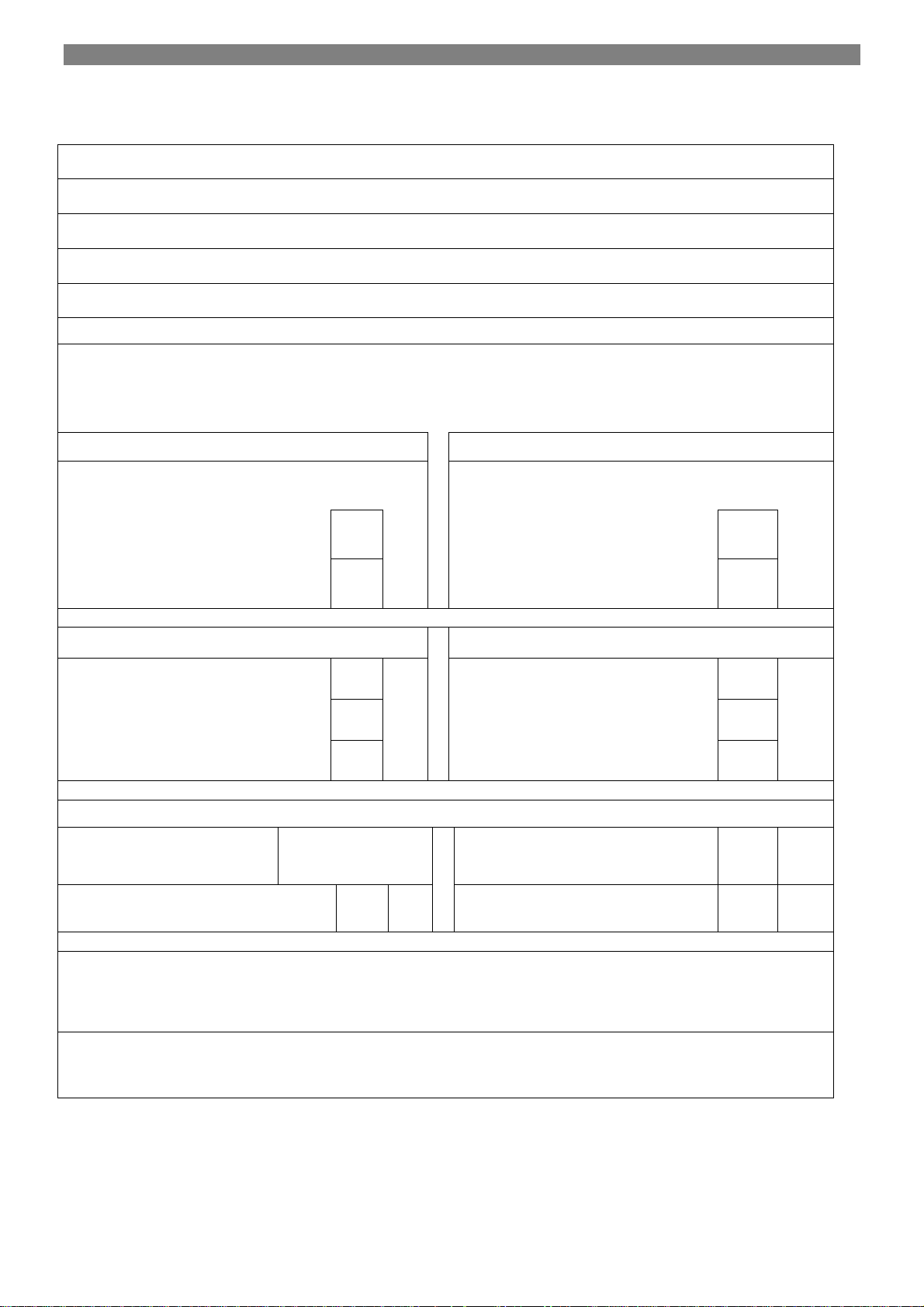

General Information

Seasonal space heating energy

Information requirements for boiler space heaters, boiler combination heaters

and cogeneration space heaters

Model(s): VIADRUS K4G3H24XX

Condensing boiler: yes

Low-temperature (**) boiler: no

B1 boiler: no

Cogeneration space heater: no If yes, equipped with a supplementary heater:

Combination heater: yes

Rated heat output

Item

Symbol

Prated 24 kW

Value

For boiler space heaters and boiler combination heaters: Useful

heat output

At rated heat output and hightemperature regime (*)

At 30 % of rated heat output and

low-temperature regime (**)

P4 24 kW

P1 4 kW

Unit

efficiency

For boiler space heaters and boiler combination heaters: Useful

efficiency

At rated heat output and hightemperature regime (*)

At 30 % of rated heat output and lowtemperature regime (**)

Item

Symbol

ƞ

90 %

s

ƞ

97,53 %

4

ƞ

105,72 %

1

Value

Auxiliary electricity consumption Other items

At full load el

0,02 kW

max

Standby heat loss P

0,045 kW

stby

At part load el

0,011 kW

min

Ignition burner power consumption P

- kW

ign

In standby mode PSB 0,003 kW

Emissions of nitrogen oxides NOx 25

For combination heaters:

Unit

mg/

kWh

Declared load profile

Daily electricity consumption Q

Contact details

(*) High-temperature regime means 60 °C return temperature at heater inlet and 80 °C feed temperature at heater outlet.

(**) Low temperature means for condensing boilers 30 °C, for low-temperature boilers 37 °C and for other heaters 50 °C return

temperature (at heater inlet).

XL Water heating energy efficiency ƞwh 81 %

0,222 kWh

elec

VIADRUS a.s.

Bezručova 300

Bohumín

735 81

Czech Republic

Daily fuel consumption Q

24,301 kWh

fuel

11

General Information

Seasonal space h

eating energy

Information requirements for boiler space heaters, boiler combination heaters

and cogeneration space heaters

Model(s): VIADRUS K4G1H33XX

Condensing boiler: yes

Low-temperature (**) boiler: no

B1 boiler: no

Cogeneration space heater: no If yes, equipped with a supplementary heater:

Combination heater: no

Rated heat output

Item

Symbol

Prated 33 kW

Value

For boiler space heaters and boiler combination heaters: Useful

heat output

At rated heat output and hightemperature regime (*)

At 30 % of rated heat output and

low-temperature regime (**)

P4 30,3 kW

P1 6 kW

Unit

efficiency

For boiler space heaters and boiler combination heaters: Useful

efficiency

At rated heat output and hightemperature regime (*)

At 30 % of rated heat output and lowtemperature regime (**)

Item

Symbol

ƞ

90 %

s

ƞ

98,4 %

4

ƞ

104,8 %

1

Value

Auxiliary electricity consumption Other items

At full load el

0,11 kW

max

Standby heat loss P

0,044 kW

stby

At part load el

0,04 kW

min

Ignition burner power consumption P

- kW

ign

In standby mode PSB 0,003 kW

Emissions of nitrogen oxides NOx 26

Contact details

VIADRUS a.s.

Bezručova 300

Bohumín

735 81

Czech Republic

Unit

mg/

kWh

(*) High-temperature regime means 60 °C return temperature at heater inlet and 80 °C feed temperature at heater outlet.

(**) Low temperature means for condensing boilers 30 °C, for low-temperature boilers 37 °C and for other heaters 50 °C return

temperature (at heater inlet).

12

General Information

Seasonal space heating energy

Information requirements for boiler space heaters, boiler combination heaters

and cogeneration space heaters

Model(s): VIADRUS K4G2H33XX

Condensing boiler: yes

Low-temperature (**) boiler: no

B1 boiler: no

Cogeneration space heater: no If yes, equipped with a supplementary heater:

Combination heater: yes

Rated heat output

Item

Symbol

Prated 33 kW

Value

For boiler space heaters and boiler combination heaters: Useful

heat output

At rated heat output and hightemperature regime (*)

At 30 % of rated heat output and

low-temperature regime (**)

P4 30,3 kW

P1 6 kW

Unit

efficiency

For boiler space heaters and boiler combination heaters: Useful

efficiency

At rated heat output and hightemperature regime (*)

At 30 % of rated heat output and lowtemperature regime (**)

Item

Symbol

ƞ

90 %

s

ƞ

98,4 %

4

ƞ

104,8 %

1

Value

Auxiliary electricity consumption Other items

At full load el

0,11 kW

max

Standby heat loss P

0,044 kW

stby

At part load el

0,04 kW

min

Ignition burner power consumption P

- kW

ign

In standby mode PSB 0,003 kW

Emissions of nitrogen oxides NOx 26

For combination heaters:

Unit

mg/

kWh

Declared load profile

Daily electricity consumption Q

Contact details

(*) High-temperature regime means 60 °C return temperature at heater inlet and 80 °C feed temperature at heater outlet.

(**) Low temperature means for condensing boilers 30 °C, for low-temperature boilers 37 °C and for other heaters 50 °C return

temperature (at heater inlet).

XL Water heating energy efficiency ƞwh 86 %

0,180 kWh

elec

VIADRUS a.s.

Bezručova 300

Bohumín

735 81

Czech Republic

Daily fuel consumption Q

22,66 kWh

fuel

13

General Information

Seasonal space heating energy

Information requirements for boiler space heaters, boiler combination heaters

and cogeneration space heaters

Model(s): VIADRUS K4G3H33XX

Condensing boiler: yes

Low-temperature (**) boiler: no

B1 boiler: no

Cogeneration space heater: no If yes, equipped with a supplementary heater:

Combination heater: yes

Rated heat output

Item

Symbol

Prated 33 kW

Value

For boiler space heaters and boiler combination heaters: Useful

heat output

At rated heat output and hightemperature regime (*)

At 30 % of rated heat output and

low-temperature regime (**)

P4 30,3 kW

P1 6 kW

Unit

efficiency

For boiler space heaters and boiler combination heaters: Useful

efficiency

At rated heat output and hightemperature regime (*)

At 30 % of rated heat output and lowtemperature regime (**)

Item

Symbol

ƞ

90 %

s

ƞ

98,4 %

4

ƞ

104,8 %

1

Value

Auxiliary electricity consumption Other items

At full load el

0,11 kW

max

Standby heat loss P

0,044 kW

stby

At part load el

0,04 kW

min

Ignition burner power consumption P

- kW

ign

In standby mode PSB 0,003 kW

Emissions of nitrogen oxides NOx 26

For combination heaters:

Unit

mg/

kWh

Declared load profile

Daily electricity consumption Q

Contact details

(*) High-temperature regime means 60 °C return temperature at heater inlet and 80 °C feed temperature at heater outlet.

(**) Low temperature means for condensing boilers 30 °C, for low-temperature boilers 37 °C and for other heaters 50 °C return

temperature (at heater inlet).

XL Water heating energy efficiency ƞwh 77 %

0,190 kWh

elec

VIADRUS a.s.

Bezručova 300

Bohumín

735 81

Czech Republic

Daily fuel consumption Q

25,742 kWh

fuel

14

General Information

•

4 Boiler Description

4.1 Boiler Design

The boiler elementary structure consists in a condensing exchanger made of stainless steel pipes. It is checked for tightness by test

overpressure 5 bar. The boiler is further equipped with a premix burner. The combustion mixture is mixed in a mixer in the preset air-gas ratio

within the entire output range. Air is supplied to the mixer by a modulation fan.

The boiler is made in three versions:

VIADRUS K4G1HXXXX version designed for heating only is equipped with a circulation pump

VIADRUS K4G2HXXXX version with a circulation pump and flow type hot water (hereafter referred to as “DHW”) heater

VIADRUS K4G3HXXXX version with a circulation pump and a three-way valve ready to be used in combination with a reservoir type hot

The Honeywell automatics is an electronic control and ignition automatics designed for gas-fired central heating boilers with a modulated fan

and burner with preliminary mixing.

The combustion air inlet and the flue gas outlet may be implemented by several means as follows:

-

to the chimney,

-

through the wall,

-

through the roof (either inclined or horizontal),

-

to a joint shaft.

The boiler is an appliance in version C, i.e., a closed appliance with electronic ignition and flame ionization.

water heater

4.2 Control Features

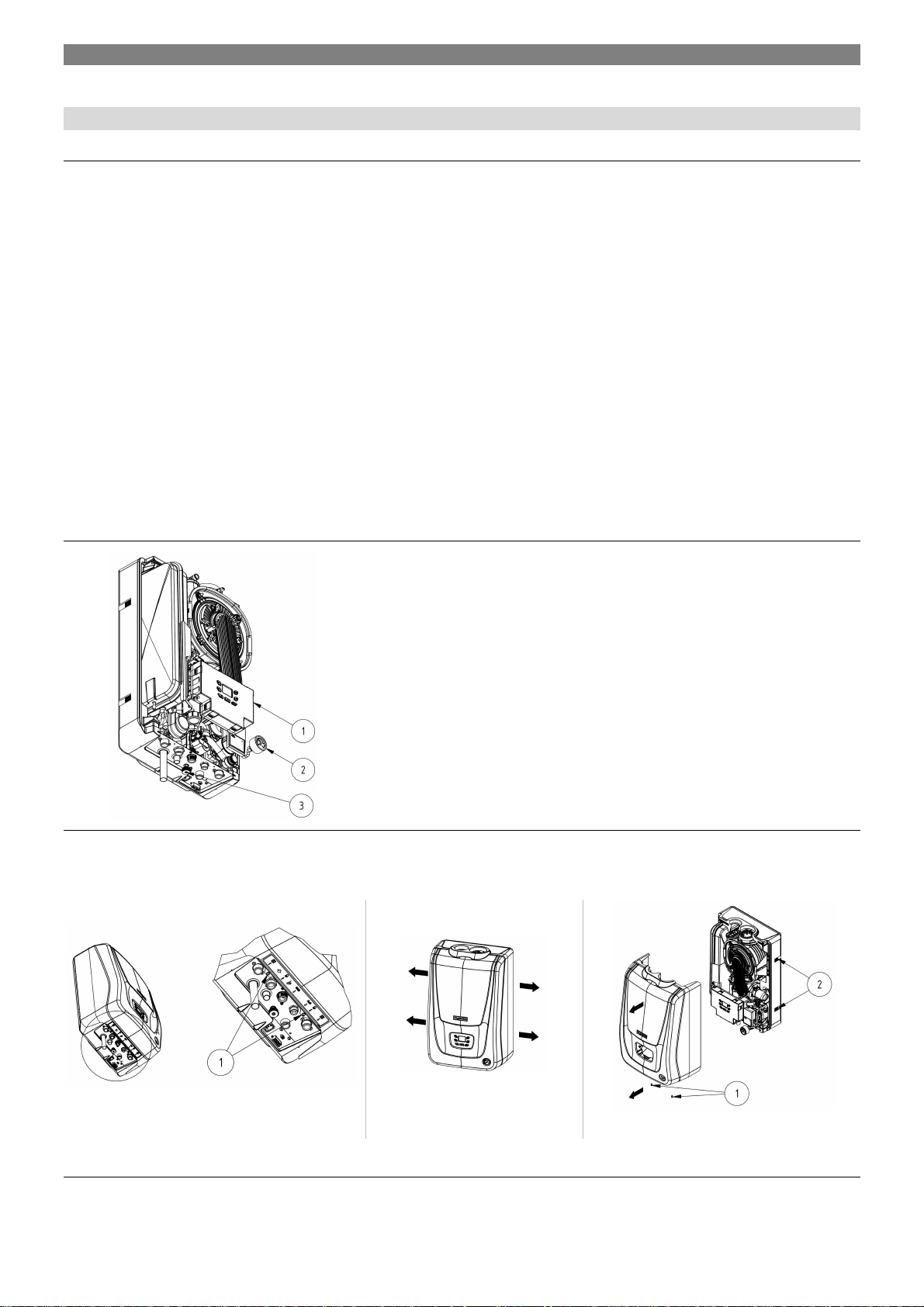

Fig. . 2 The VIADRUS K4 boiler control panel

4.2.1 Removing the front cover

1 electronic panel with the control panel

2 pressure gauge

3 valve for adding water to the heating system

• Remove the front cover

• Remove the bolts (1)

Fig. . 3 Removing the boiler front cover

Pulling the cover side detach

the Velcro strip (2)

15

General Information

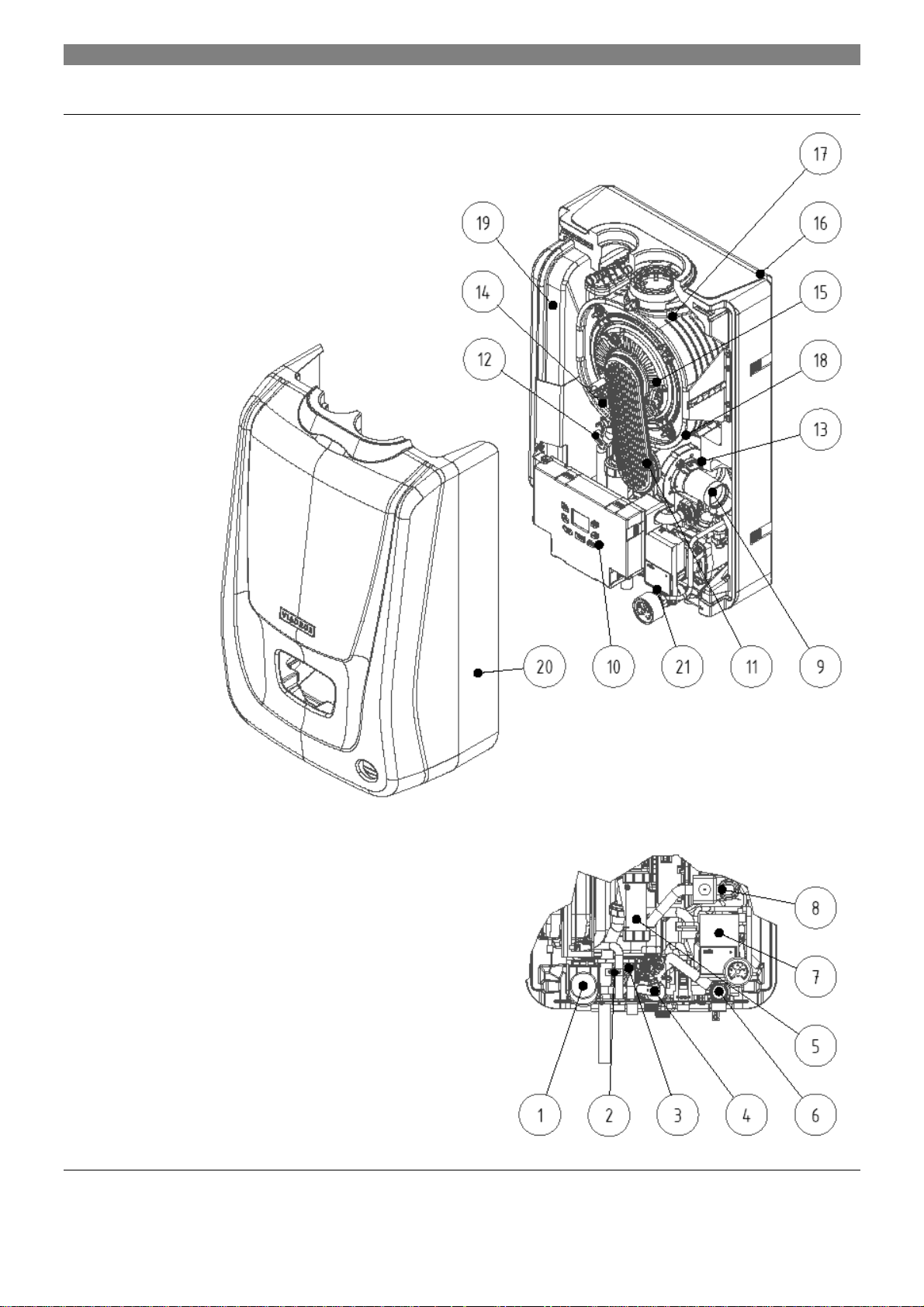

4.3 Main Boiler Parts

1 three-way valve (only for versions K4G2HXXXX and K4G3HXXXX)

2 HSW temperature sensor (only for version K4G2HXXXX)

3 HSW exchanger (only for version K4G2HXXXX)

4 gas valve

5 siphon

6 safety valve

7 circulation pump

8 gas supply pipe

9 bleeder valve

10 boiler electronics

11 burner plate

12 heating water temperature sensor

13 mixer

14 safety thermostat

15 combination electrode

16 boiler frame

17 exchanger

18 fan

19 expansion tank

20 pressure gauge

21 boiler front cover

Fig. . 4 The VIADRUS K4 boiler assembly (version shown - K4G2HXXXX)

16

General Information

1 condensing exchanger

2 input of return water to the exchanger

3 pump

4 input of return water to the pump

5 heating system (radiators)

Fig. . 5 VIADRUS K4G1HXXXX with only water heating for the system

(hydraulic diagram of the version and the sketch of the hydro-block)

1 condensing exchanger

2 input of return water to the exchanger

3 pump

4 input of return water to the pump

5 heating system (radiators)

6 output of hot water from the exchanger

Fig. . 6 VIADRUS K4G2HXXXX with a flow type heater

(hydraulic diagram of the version and the sketch of the hydro-block)

6 output of hot water from the exchanger

7 input of hot water to the radiators

8 filling valve

9 pressure relief valve

7 input of hot water to the radiators

8 three-way valve

9 flow type water heater

10 input of water to the flow type water heater

11 output of water from the flow type water heater

12 pressure relief valve

1 condensing exchanger

2 input of return water to the exchanger

3 pump

4 input of return water to the pump

5 heating system (radiators)

6 output of hot water from the exchanger

7 input of hot water to the radiators

8 three-way valve

Fig. . 7 VIADRUS K4G3HXXXX the boiler version

(hydraulic diagram of the version and the sketch of the hydro-block)

9 filling valve

10 output of hot water from the heater

11 refilling of water to the system

12 reservoir type water heater

13 relief valve of the heater

14 input of water to the heater

15 pressure relief valve

17

Loading...

Loading...