Viadrus Hercules P 1 Manual, Operation And Installation

Hercules U26

Návod k obsluze

Hefaistos P 1

MANUAL FOR BOILER OPERATION

AND INSTALLATION

Table of contents:

page

1.

Produced variants of boilers ................................................................................................................... 3

1.1 Order ................................................................................................................................................... 3

2.

Technical information .............................................................................................................................. 3

2.1 The use of boiler.................................................................................................................................. 3

2.2 Advantages of boiler ........................................................................................................................... 3

2.3 Technical data of boiler Hefaistos P1 ................................................................................................. 4

2.4 The main dimensions of the boiler ...................................................................................................... 5

2.4.1 The main dimensions of the boiler Hefaistos P1 T ...................................................................... 5

2.4.2 The main dimensions of the boiler Hefaistos P1 E ...................................................................... 6

2.5 The main parts of boiler ...................................................................................................................... 7

2.5.1 The main parts of boiler Hefaistos P1 T ...................................................................................... 7

2.5.2 The main parts of boiler Hefaistos P1 E ...................................................................................... 8

3.

Installation instructions ........................................................................................................................... 9

3.1 Boiler construction ............................................................................................................................... 9

3.2 Regulations and guidelines ............................................................................................................... 10

3.3 Placement options ............................................................................................................................. 11

3.4 Delivery and accessories .................................................................................................................. 13

3.4.1 Delivery and accessories - Hefaistos P1 T ................................................................................ 13

3.4.2 Delivery and accessories - Hefaistos P1 E ................................................................................ 13

3.5 Installation process............................................................................................................................ 14

3.5.1 Installing the boiler drum ............................................................................................................ 14

3.5.1.1 Installing the boiler drum – Hefaistos P1 T (see Fig. no. 8 and 9) ..................................... 14

3.5.1.2 Installing the boiler drum – Hefaistos P1 E (see Fig. no. 8 and 9) ..................................... 14

3.5.2 Mounting the control box ............................................................................................................ 18

3.5.2.1 Mounting the control box – Hefaistos P1 T (see Fig. no. 10) ............................................. 18

3.5.2.2 Mounting the control box – Hefaistos P1 E (see Fig. no. 10) ............................................. 18

3.5.3 Limit switch installation – Hefaistos P1 E .................................................................................. 20

3.5.4 Installation of cleaning tools ....................................................................................................... 20

4.

Commissioning ..................................................................................................................................... 21

4.1 Control activities before starting ........................................................................................................ 21

4.2 Putting the boiler into operation ........................................................................................................ 22

4.3 Regulatory and signaling elements ................................................................................................... 23

4.3.1 Regulatory and signaling elements – Hefaistos P1 T ................................................................ 23

4.3.2 Regulatory and signaling elements – Hefaistos P1 E ................................................................ 23

4.5 Equipment to remove excess heat .................................................................................................... 24

4.6 Equipment for heat removal - storage tanks ..................................................................................... 26

4.7 Diagram of connection-boiler Hefaistos P1 ....................................................................................... 26

4.8 Electrical connection ......................................................................................................................... 28

4.8.1 Electrical connection – Hefaistos P1 T ...................................................................................... 28

4.8.2 Electrical connection – Hefaistos P1 E ...................................................................................... 30

5.

Operating manual ................................................................................................................................. 32

5.1 Operation of boiler by user ................................................................................................................ 32

5.1.1 Operation of boiler by user – Hefaistos P1 T ............................................................................. 32

5.1.2 Operation of boiler by user – Hefaistos P1 E ............................................................................. 34

6.

Boiler cleaning - maintenance .............................................................................................................. 35

7.

Fault conditions ..................................................................................................................................... 37

8.

IMPORTANT NOTICES ........................................................................................................................ 38

9.

Instructions for disposal of the product after its life time....................................................................... 39

10. Warranty and liability for defects ........................................................................................................... 39

3

Dear Customer,

Thank you for purchasing the pyrolytic boiler Hefaistos P1 and thus showing your confidence in the

company VIADRUS a.s.

Before you start to use your new product please read this manual (especially the chapter No. 5.1 Operation of boiler by user, and Chapter 8 – Important notices) so that from the beginning you get

used to its proper handling. Please respect the following information, thereby ensuring a long

trouble-free operation of your boiler to both your and our satisfaction.

1. Produced variants of boilers

1.1 Order

Following data must be specified in the order:

O

rder specification code

HEFAISTOS P1 X X

2. Technical information

Boiler Hefaistos P1 is a pyrolytic sectional cast-iron low pressure boiler with a metal sheet feed hopper

designed for burning the lump wood.

The control of boiler Hefaistos P1 T (thermostatic option) is solved by means of thermostats (in operation,

flue gases and pump -see chapter 4.3.1.).

Note: The thermostatic variant is used 6 – 7-sectional models.

The control of boiler Hefaistos P1 E (electronic version) is solved by means of controller ST 81.

Note: The electronic version is only applied to 3 – 5-sectional models.

The ventilator is equipped with a probe for speed sensing.

Combustion of other fuels and materials such as plastics is not permissible.

2.1 The use of boiler

Three-section model of boiler Hefaistos P1 is suitable for heating the family houses. Larger sizes of the

boiler meet the requirements of shops, schools, recreational facilities, weekend houses etc.

The boiler is manufactured as the hot water boiler with forced heating water circulation and working

overpressure up to 400 kPa (4 bar). Before the dispatch the boiler is tested for leakage by applying the test

overpressure of 800 kPa (8 bar).

The boiler is designed for heating both in closed and open heating systems.

The boiler must be designed with one of these options of connection:

•

storage tanks

•

three-way valve

•

four-way valve

•

ladomat

2.2 Advantages of boiler

1. High service life of cast-iron heat exchanger and all other parts due to the quality of the materials.

2. Sophisticated manufacturing technology on automatic moulding lines with stable and proven quality of

manufacturing process (ISO 9001, ISO 14001).

3. Combustion efficiency 83 – 89%.

4. Simple operation and maintenance.

5. Gradation of performance according to number of sections.

6. The version Hefaistos P1 E allows hot water preparation with the possibility to select the strategy of

boiler control.

Boiler size:

3: 3 sect. model

4: 4 sect. model

5: 5 sect. model

6: 6 sect. model

7: 7 sect. model

Boiler control:

T: thermostatic

E: electronic

4

7. Ecological operation that meets the requirements for the granting the trademark ESV (Environmentally

friendly product)

2.3 Technical data of boiler

Tab. No. 1 Dimensions, technical parameters – fuel: wood

Number of sections

pcs 3 4 5 6 7

Rated thermal output kW 30 40 49,5 75 100

Fuel consumption at rated thermal output kg.h

-

1

8,0 10,66 13,32 19,99 26,65

Fuel efficiency MJ.kg

-

1

15,01 15,01 15,01 15,01 15,01

Feed hopper volume l 99 138 177 216 255

Burning time at rated output hour 3 3 3 3 3

Flue gases temperature at outlet °C 140 – 200

Flue gases mass flow at rated thermal output g.sec

-

1

16,33 21,77 27,22 40,83 54,43

Efficiency % 83 – 89

Boiler class according to EN 303 – 5 - 3 3 3 3 3

Water volume l 52,9 68,9 85 99,1 117,2

Weight

kg

584 702 820 959

1077

Combustion chamber depth mm 354 495 636 777 918

Diameter of smoke throat mm 160 200

Boiler dimensions: – height x width mm 1541 x 833

– depth mm 1167 1308 1449 1794 1935

Filling opening dimensions mm 505 x 256

Maximum working water overpressure kPa (bar) 400 (4)

Minimum working water overpressure kPa (bar) 50 (0,5)

Testing water overpressure kPa (bar) 800 (8)

Boiler hydraulic losses - see Fig. no. 1

Input water minimum temperature °C 60

Water temperature control range °C 60 – 85

Noise level

dB Does not exceed the level of 65 dB (A)

Required draught mbar 0,25 – 0,35

Boiler connections – heating water “ 6/4

– return water “ 6/4

Cooling water temperature for equipment to remove excess

heat

°C 5 – 20

Cooling water overpressure for equipment to remove excess

heat

kPa (bar) 200 – 600 (2 - 6)

Connecting voltage 1/N/PE 230V AC 50 Hz TN - S

Electric input W 180 800

Electric coverage IP 40

Depen den c e of pres s u re los s o n rate of flow

0

2000

4000

6000

8000

10000

12000

14000

0 0,2 0,4 0,6 0,8 1 1,2 1,4 1,6 1,8

Qz (10

-3m3.s-1

)

pz (Pa)

3 s ections

4 s ections

5 s ections

6 s ections

7 s ections

Fig. no. 1 Hydraulic losses of boiler drum

5

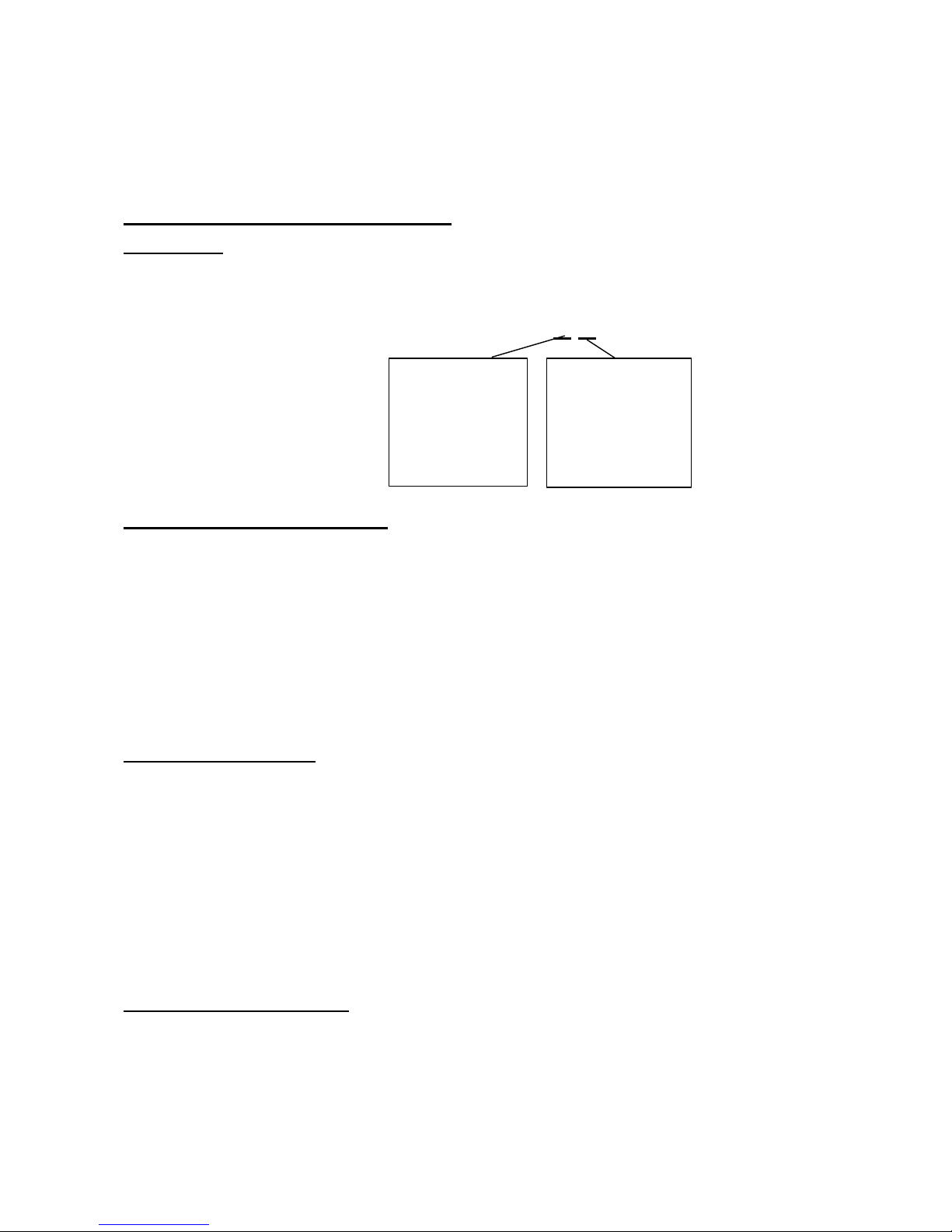

2.4 The main dimensions of the boiler

2.4.1 The main dimensions of the boiler Hefaistos P1 T

6 7

L

[mm] 998 1139

Fig.no. 2 The main dimensions of the boiler Hefaistos P1 T

6

2.4.2 The main dimensions of the boiler Hefaistos P1 E

3 4 5

L

[mm] 575 716 857

Fig. no. 3 The main dimensions of the boiler Hefaistos P1 E

7

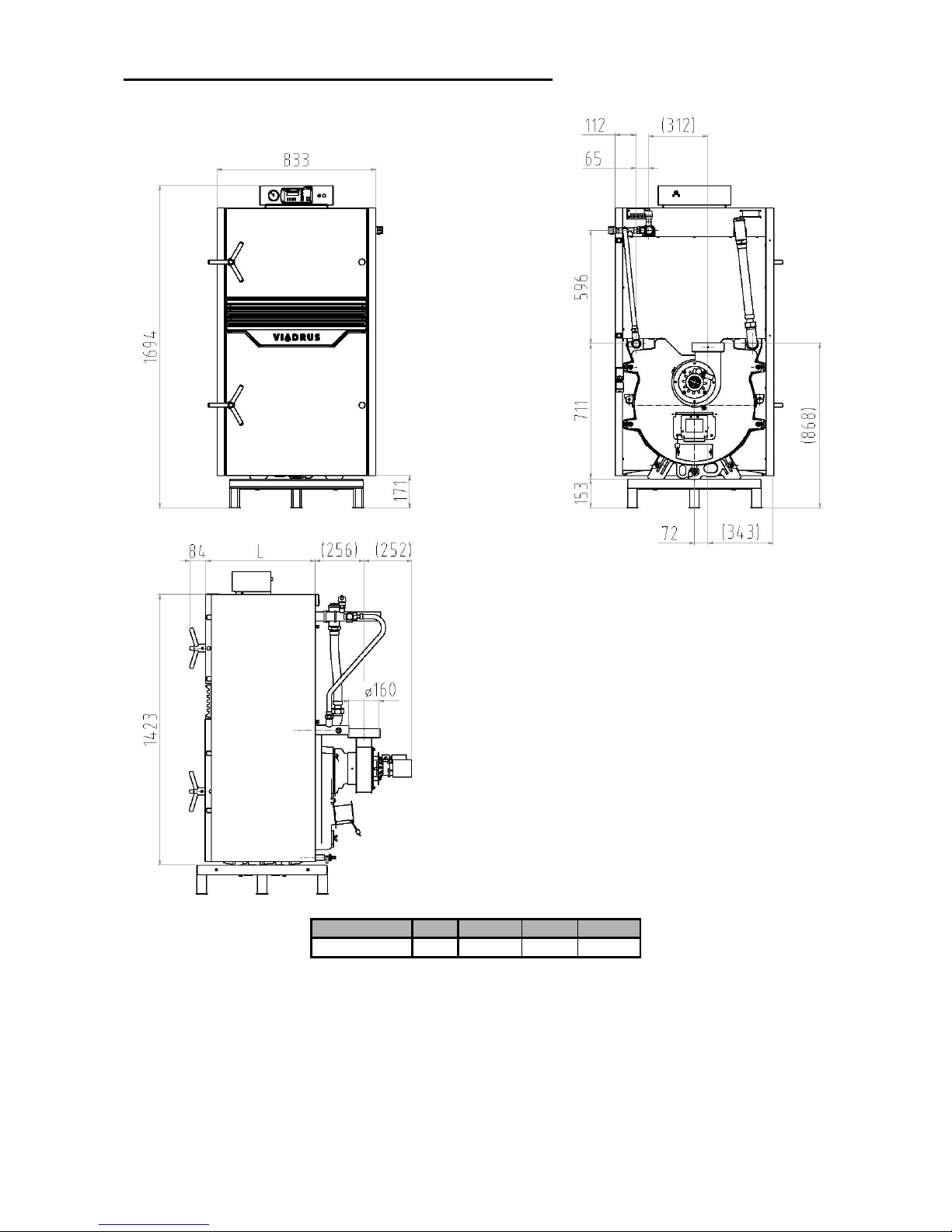

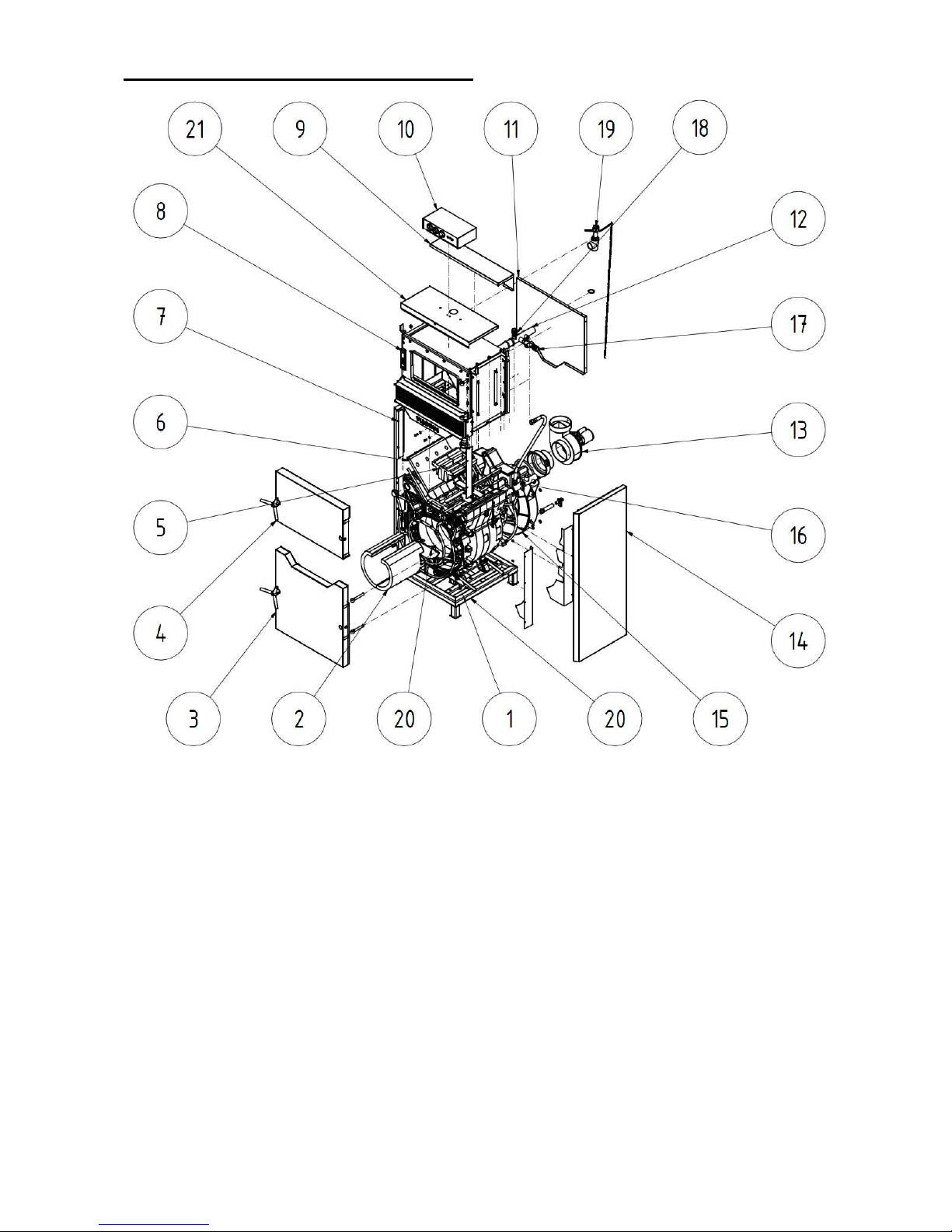

2.5 The main parts of boiler

2.5.1 The main parts of boiler Hefaistos P1 T

1 boiler drum

2 combustion chamber lining

3 ash pan door

4 stoking door

5 nozzle

6 feed hopper lining

7 boiler shell-left part

8 feed hopper

9 boiler shell-upper part

10 control box

11 boiler shell-rear part

12 outlet pipe

13 exhaust ventilator

14 boiler shell-right part

15 smoke adaptor

16 inlet pipe

17 two-way safety valve DBV 1 – 02

18 air release valve

19 draught controller

20 stand

21 boiler shell-front part

Fig.no. 4a) Main parts of boiler Hefaistos P1 T

8

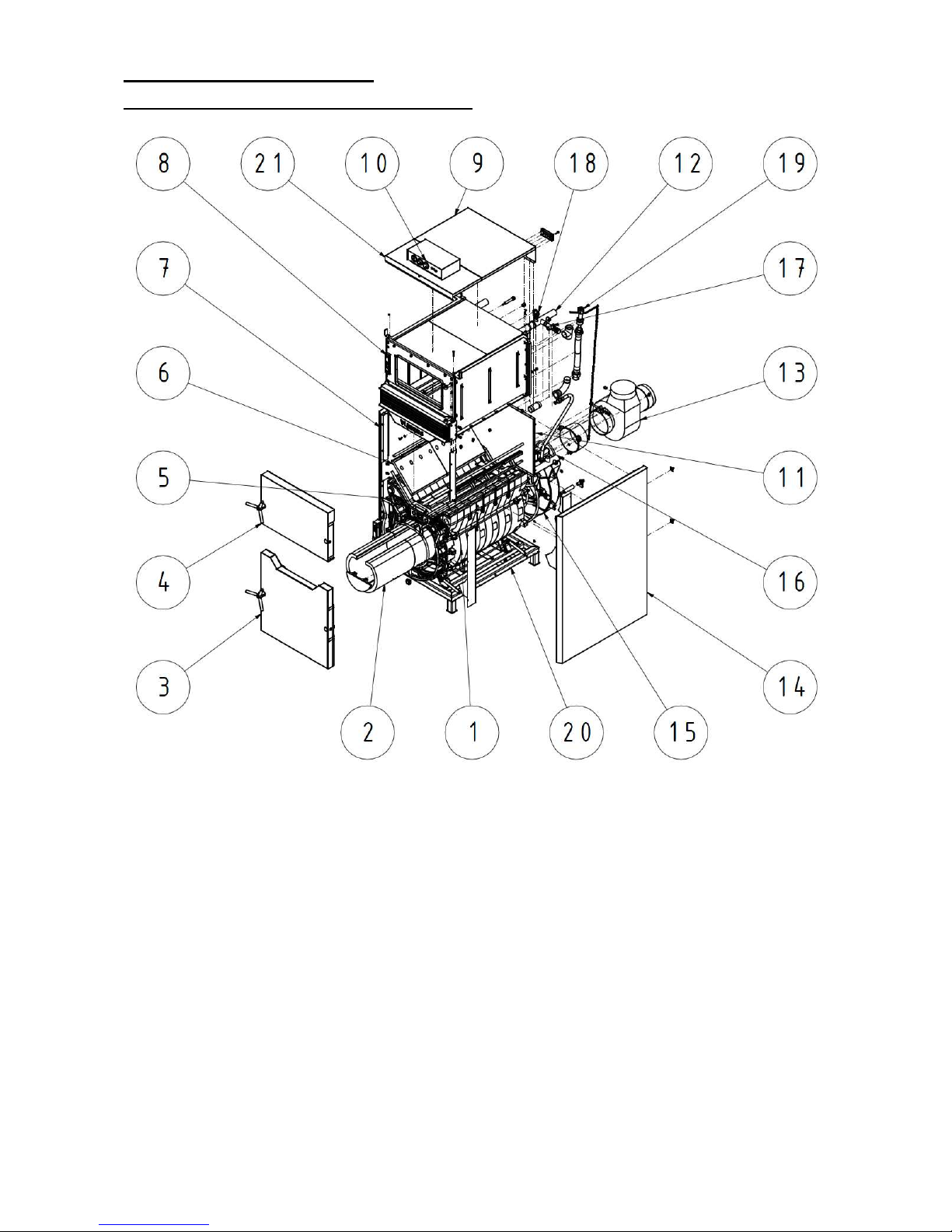

2.5.2 The main parts of boiler Hefaistos P1 E

1 boiler drum

2 combustion chamber lining

3 ash pan door

4 stoking door

5 nozzle

6 feed hopper lining

7 boiler shell-left part

8 feed hopper

9 boiler shell-upper part

10 control box

11 boiler shell-rear part

12 outlet pipe

13 exhaust ventilator

14 boiler shell-right part

15 smoke adaptor

16 inlet pipe

17 two-way safety valve DBV 1 – 02

18 air release valve

19 boiler shell-front part

20 stand

Fig. no. 4b) Main parts of boiler Hefaistos P1 E

9

3. Installation instructions

3.1 Boiler construction

The sectional boiler drum made of grey cast iron according to EN 1561, quality 150 is the main part of the

boiler.

Pressure parts of boiler correspond to strength requirements according to EN 303 - 5 – Heating boilers –

Part 5: Heating boilers for solid fuels with manual or automatic stoking and nominal heat output of up to

300 kW – Terminology, requirements, testing and marking.

The boiler drum is made of sections by means of pressed boiler inserts (nipples) Φ 56 mm and rubber orings and secured by anchor bolts. The sections create combustion space, ash pan and water spaces and

also the convection part. The feed shaft consists of feed hopper, which is made of sheet metal intended for

combustion processes. The upper part of the feed hopper is water-cooled. The heating water inlet and outlet

are situated at the rear part of the boiler.

At the rear section of the boiler there is mounted the smoke adaptor with air exchanger and exhaust

ventilator. The return water connection is situated in the upper part of boiler drum. The heating water

connection is situated in the upper part of the feed hopper. Water inlet and outlet can be connected by

means of threaded pipes. The stoking door is mounted to the feed hopper and the ash pan door to the front

boiler section. The ash pan and stoking door are made with the possibility of left-right opening (see Fig.

No. 5).The whole boiler drum is insulated by using the harmless mineral insulation, which reduces the losses

caused by the heat transfer to the ambient. The boiler shell is coated with high-quality comaxit spray.

Fig.no. 5 Left-right opening

10

3.2 Regulations and guidelines

A solid fuel boiler can only be installed by a firm holding a valid concession for boiler installation and

maintenance. A project according to the valid regulations must be prepared for the installation. Before the

boiler installation to an older heating system, the installation company must ensure that the whole heating

system is rinsed out (washed out). The heating system must be filled with water which meets the

ČSN 07 7401 requirements, especially its hardness must not exceed the required parameters.

Recommended values

Hardness mmol/l 1

Ca2+ mmol/l 0,3

Concentration of total Fe + Mn mg/l (0,3)*

*) recommended value

WARNING!!! The use of anti-freeze mixture is not recommended by the manufacturer.

In case the two-way safety equipment is signalling that boiler has been filled with the water which

does not meet the ČSN 077401 requirements it is necessary to treat the water in the system so that it

again meets this standard requirements.

a) To the heating system

ČSN 06 0310 Heating systems in buildings – Designing and installation

ČSN 06 0830 Heating systems in buildings – protecting device

ČSN 07 7401 Water and steam for thermal energy equipments with working pressure up to

8 MPa

EN 303-5 Heating boilers – Part 5: Heating boilers for solid fuels, manually and

automatically stoked, nominal heat output of up to 300 kW – Terminology,

requirements, testing and marking

b) To the chimney

ČSN 73 4201 Chimneys and flue gas ducting– designing, implementation and connection of

fuel consumers.

c) Regarding the fire regulations

ČSN 06 1008 Fire safety of heat installations

EN 13501-1 + A1 Fire classification of construction products and building structures – Part 1:

Classification using data from reaction to fire tests

d) To the electrical network

ČSN 33 0165 Electrical regulations. Marking the conductors with colours or digits.

Implementing regulations.

ČSN 33 1500 Electrical regulations. Electrical equipments revision

ČSN 33 2000-3 Electrical regulations. Electrical equipments Part 3: Setting the basic

characteristics.

ČSN 33 2000-4-41 Electric equipments: part 4: Safety chap. 41: Protection against electric shocks.

ČSN 33 2000-5-51 ed. 2 Electrical regulations. Electrical equipments construction.

ČSN 33 2130 Electrical regulations. Internal wiring.

ČSN 33 2180 Electrical regulations. Connection of electrical devices and appliances.

ČSN 34 0350 Electrical regulations. Regulations for mobile connections and cord extension

sets.

EN 60079-10 Electrical regulations. Regulations for electric equipments at the places with

danger of explosion of flammable gases and vapours

EN 60 335-1 ed.2 Electrical appliances for household and similar purposes – Safety – Part 1:

General requirements.

EN 60 335-2-102 Electrical appliances for household and similar purposes – Safety – Part 2-102:

Particular requirements for appliances burning gas, oil and solid-fuel and having

electrical connections.

EN 60445 ed. 3 Basic and safety principles for man – machine interface, marking and

identification

EN 60446 ed.2 Basic and safety principles when operating the machinery Identification of

conductors by colours or numerals

e) To the system of HWS heating

ČSN 06 0320 Heating systems in buildings – Hot water preparation – Designing and planning

ČSN 06 0830 Heating systems in buildings – Safety devices.

ČSN 73 6660 Internal water conduits

11

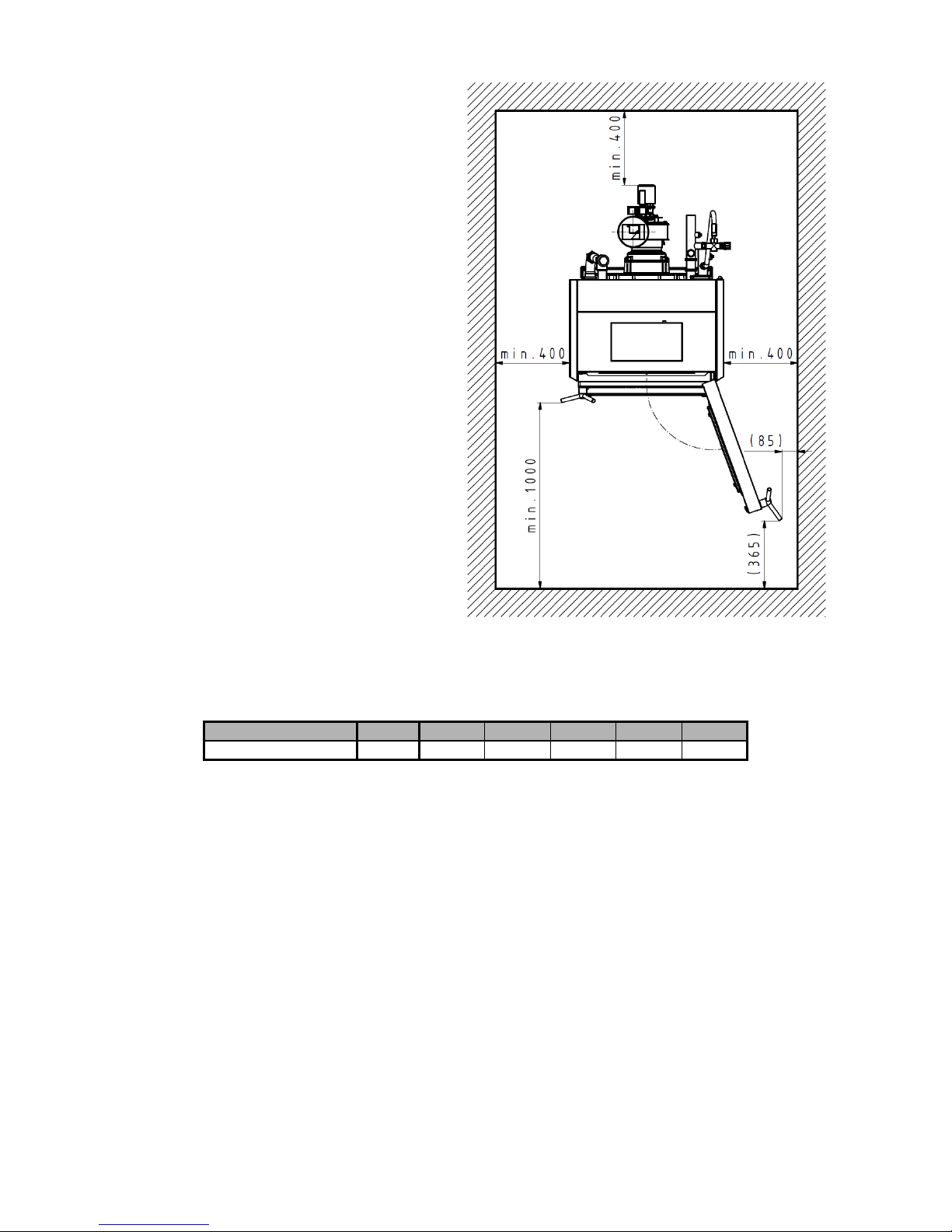

3.3 Placement options

Boiler is approved for installation in non-residential premises (for example cellar, corridor etc.) and

in AA5/AB5 basic environment according to ČSN 33 2000-3.

The boiler is equipped with a movable mains supply and a plug. According to EN 60 335 – 1 ed. 2 Art. 7.12.4

the boiler must be positioned in a way so that the plug is accessible.

The installation of the boiler must comply with all requirements of ČSN 06 1008

Boiler positioning with regard to fire regulations:

1. Positioning on the floor made of incombustible material

− The boiler must be installed on a fireproof bottom, which exceeds the boiler platform by 20 mm on the

sides (see fig. No. 6).

Number of sections

3 4 5 6 7

L [mm]

695 695 975 975

Fig. No. 6 Socle dimensions

2. A safe distance from the combustible materials:

− when installing and operating the boiler it is necessary to keep a safety distance of 200 mm from the

materials of combustibility grade A1, A2, B and C (D);

− for easily combustible materials of combustibility grade E (F), which quickly burn and burn themselves

even after removal of ignition source (such as paper, cardboard, asphalt and tar paper, wood and

wood-fiber boards, plastics, floor coverings) the safe distance has to be doubled, i.e. to 400 mm;

− safe distance should be doubled as bulb where the grade of reaction to fire has not been proved.

Tab. no. 2 Grade of reaction to fire

Grade of reaction to fire

Examples of building materials and products included in the reaction to fire

(Extract from EN 13 501-1 + A1)

A1

– incombustible

Granite, sandstone, concrete, bricks, ceramic tiles, mortars, fireproof plasters, …

A2

– combustible with difficulty

acumin, izumin, heraklit, lignos, boards and basalt felt, fibreglass boards,...

B

– hardly combustible

Beech and oak wood, hobrex boards, plywood, werzalit, umakart, sirkolit,...

C (D)

– medium combustible

Pinewood, larch, whitewood, chipboard and cork boards, rubber flooring,...

E (F) – easily combustible

Asphaltboard, fibreboards, cellulose materials, polyurethane, polystyrene,

polyethylene, PVC,…

12

Location of boiler with regard to

necessary handling space:

− at least 1000 mm handling space must

be left in front of the boiler;

− the minimum distance between the rear

part of the boiler and wall is 400 mm;

− on both sides keep the space at least

400 mm for access to the rear part of the

boiler.

Fuel location:

− it is forbidden to store the fuel behind or

next to the boiler in a distance lower

than 400 mm;

− it is forbidden to store the fuel between

two boilers in boiler-room;

− it is recommended by the manufacturer

that minimum distance of 1000 mm

− is maintained between the boiler and

fuel or the fuel should be stored in

another room.

Fig.no. 7 Location of boiler in boiler room

A continuous air supply for burning and eventual ventilation must be ensured for the room where the

boiler is installed.

Air consumption of boiler:

Number of sections

3 4 5 6 7

Air cinsumption [m3.h

-

1

] 100 140 170 285 390

The choice of the right size of boiler

The choice of the right size of boiler i.e. its heat output is very important condition for economic operation

and a correct function of the boiler. The boiler must be chosen so that its rated thermal output corresponds to

the heat losses of the building. The rated output is calculated according to valid standards for outside

temperatures –12 °C, -15 °C and –18 °C. The choice of boiler with too high rated output (oversizing) results

in increased tarring and retting of the boiler. That’s why it is not suitable to use boilers with the output higher

than the heat losses of the building

This does not apply in case the boiler is connected in the system with a storage tank.

Chimney draught

The chimney with its proper draught is a fundamental prerequisite for a good function of boiler. It influences

both boiler output and its efficiency. The boiler may be connected to chimney vent which has a sufficient

draught (see chapter 2.3) and the revision must be carried out by an authorized organization.

13

3.4 Delivery and accessories

Boiler is delivered according to the order and on the pallet there is placed the complete boiler drum plus

boiler shell in a wooden casing. The accessories are inside the boiler drum and are accessible when opening

the stoking door has been opened. The boiler is packed in shipping wrapping and it must not be tipped over

during transport.

.

3.4.1 Delivery and accessories - Hefaistos P1 T

Standard boiler delivery:

• the boiler on the pallet in the casing with the relevant number of sections including the boiler shell

• cleaning kit (cleaner, hook, brush with handle, poker, dowel 2 pcs, direct hook with thread 2 pcs)

• complete control box with electro accessories 1 pc

• filling and drain valve Js 1/2“ 1 pc

• complete draft controller 1 pc

• connecting hose G 3/4“ with sealing G 3/4“ 1 pc

• connecting hose G 1½“ with sealing G 1½“ 1 pc

• T –joint G 1 ½“ 1 pc

• long bend G 1 ½“ 1 pc

• boiler plug 2 pcs

• adaptor reduced N4 1 ½“ x ¾“ 1 pc

• air release valve 1 pc

• ventilator (6 – 7 sect.) 1 pc

• manipulation key 1 pc

• two way safety valve DBV 1 – 02 1 pc

• business/technical documentation

By request:

• Safety valve 1 pc

The boiler accessories ordered „by request“ are not included in the basic price of the boiler.

3.4.2 Delivery and accessories - Hefaistos P1 E

Standard boiler delivery:

• the boiler on the pallet in the casing with the relevant number of sections including the boiler shell

• cleaning kit (cleaner, hook, brush with handle, poker, dowel 2 pcs, direct hook with thread 2 pcs)

• complete control box with electro accessories 1 pc

• filling and drain valve Js 1/2“ 1 pc

• complete draft controller 1 pc

• connecting hose G 3/4“ with sealing G 3/4“ 1 pc

• connecting hose G 1½“ with sealing G 1½“ 1 pc

• T –joint G 1 ½“ 1 pc

• long bend G 1 ½“ 1 pc

• boiler plug 2 pcs

• radiator plug 1 1/2“ 1 pc

• sealing 1 1/2“ 1 pc

• air release valve 1 pc

• shell with ventilator (3 – 5 sect.) 1 pc

• manipulation key 1 pc

• two way safety valve DBV 1 – 02 1 pc

• business/technical documentation

By request:

• Safety valve 1 pc

The boiler accessories ordered „by request“ are not included in the basic price of the boiler.

14

3.5 Installation process

3.5.1 Installing the boiler drum

3.5.1.1 Installing the boiler drum – Hefaistos P1 T (see Fig. no. 8 and 9)

1. Set the boiler drum on the socle (underlay).

2. Dismount the rear part of the shell (1) by means of 4,8 x13 screws and serrated lock washers 5,3 - see

detail A and the upper part of the shell (2) according to the Figure no.8.

3. Install T- joint (13), the reduced adaptor (16) into T- joint, then mount the long bend (12) and the

interconnection pipe G 1 ½“ (14) via sealing 1 ½“ according to the Fig. no.9a.

4. Install the outlet pipe. Install the air-release valve (10) and two-way safety valve DBV 1 – 02 (8) to the

heating water outlet (6) (see Fig. no. 9a, 14, 15) – the valve can be installed only in the horizontal

position. The heating water outlet pipe (6) must be connected via a demountable joint to the heating

system.

5. The return water inlet (3) must be connected via a demountable joint to the heating system.

6. Install the filling and drain valve G 1/2“ (1).

7. Install the control box see chap. no. 3.5.2.

8. Screw the draft controller (15) into the opening in the reduced adaptor (16). The procedure of setting the

boiler draft controller is shown in chapter no.5.1.1-Operation.

9. Put the smoke pipe on the exhaust ventilator (2) and push it into the chimney hole. The smoke pipe

diameter is stated in tab. No.1.

3.5.1.2 Installing the boiler drum – Hefaistos P1 E (see Fig. no. 8 and 9)

1. Set the boiler drum on the socle (underlay).

2. Dismount the rear part of the shell (1) by means of 4,8 x13 screws and serrated lock washers 5,3 - see

detail A and the upper part of the shell (2) according to the Figure no.8.

3. Install T- joint (13), the radiator plug (15) into T- joint, then mount the long bend (12) and the

interconnection pipe G 1 ½“ (14) via sealing 1 ½“ according to the Fig. no.9b.

4. Install the outlet pipe. Install the air-release valve (10) and two-way safety valve DBV 1 – 02 (8) to the

heating water outlet (6) (see Fig. no. 9b, 14, 15) – the valve can be installed only in the horizontal

position. The heating water outlet pipe (6) must be connected via a demountable joint to the heating

system.

5. The return water inlet (3) must be connected via a demountable joint to the heating system.

6. Install the filling and drain valve G 1/2“ (1).

7. Install the control box see chap. no. 3.5.2.

8. Put the smoke pipe on the exhaust ventilator (2) and push it into the chimney hole. The smoke pipe

diameter is stated in tab. No.1

15

Fig.no. 8 Dismantling of the upper rear part of the boiler shell

1. boiler shell-rear part

2. boiler shell-front part

3. boiler shell-upper part

Loading...

Loading...