Viadrus HERCULES Green Eco Therm 32S, HERCULES Green Eco Therm, HERCULES Green Eco Therm 32J, HERCULES Green Eco Therm 25J, HERCULES Green Eco Therm 25S Series Manual

VIADRUS HERCULES Green Eco Therm

Manual for boiler operation and installation

GB_2015_11

Contents:

1. Produced variants of boiler .......................................................................................................................... 3

page

2. Technical data of the boiler ......................................................................................................................... 4

3. Boiler description ......................................................................................................................................... 6

3.1

Boiler drum construction ..................................................................................................................... 6

3.2

Control, regulation and safety elements ............................................................................................. 6

3.2

The construction of burner and transport routes of the fuel ................................................................ 9

4. Location and installation ............................................................................................................................ 11

4.1

Regulations and directives ................................................................................................................ 11

4.2

Positioning possibilities ..................................................................................................................... 12

5. Order, delivery and assembly .................................................................................................................... 14

5.1

Order ................................................................................................................................................. 14

5.2

Delivery and accessories .................................................................................................................. 14

5.3

Assembly procedure ......................................................................................................................... 16

5.3.1 Boiler drum installation .................................................................................................................. 16

5.3.2 Mounting of partitions of the combustion chamber and turbulators .............................................. 17

5.3.3 Mounting of burner ........................................................................................................................ 17

5.3.4 Mounting of the fuel reservoir ....................................................................................................... 19

5.3.5 Mounting of the shells ................................................................................................................... 20

5.3.6 Installation of electrical wiring ....................................................................................................... 21

5.3.6.1 Version VIADRUS HERCULES Green Eco Therm XJ ......................................................... 21

5.3.6.1 Version VIADRUS HERCULES Green Eco Therm XS ......................................................... 22

5.3.7 Assembly tools for brush............................................................................................................... 22

5.3.8 Filling of the heat system with water ............................................................................................. 22

5.3.9 Electrical scheme .......................................................................................................................... 23

5.3.10 Boiler hydraulic diagram ............................................................................................................... 27

6. Putting into operation - instructions for contractual service organization .................................................. 28

6.1

Inspections before start-up ............................................................................................................... 28

6.2

Boiler putting into operation .............................................................................................................. 28

7. Boiler operation by user ............................................................................................................................. 29

7.1

Version VIADRUS HERCULES Green Eco Therm XJ ..................................................................... 29

7.1.1 Setting of the heat output of burner .............................................................................................. 31

7.2

Version VIADRUS HERCULES Green Eco Therm XS..................................................................... 35

7.2.1 Setting of the heat output of burner .............................................................................................. 37

8. IMPORTANT WARNINGS ........................................................................................................................ 40

9. Maintenance .............................................................................................................................................. 41

10. Faults and their removal ........................................................................................................................ 43

11. Instructions for product liquidation after its operating life ....................................................................... 45

12. Warranty and defect liability ................................................................................................................... 45

2

Dear customer,

thank you for the purchase of VIADRUS HERCULES Green Eco Therm boiler; this purchase

demonstrates your confidence in VIADRUS a.s.

In order to get used to a proper treatment of your new product from the start please read these

instructions for its use (first of all the chapter no. 7 – Boiler attendance by user, chapter

no. 11 – Important warnings and chapter no. 12 – Maintenance by user). Please observe the

information given below in order to ensure a longstanding trouble-free operation of boiler so that

both you and we are satisfied.

1. Produced variants of boiler

•

Order specification code

VIADRUS HERCULES Green Eco Therm X X

Burner output:

25: 25 kW

32: 32 kW

The fuel tank is included in the standard boiler accessories

•

Optional accessories (see chapter no. 5.2)

The boiler design you received is only destined for wooden pellets combustion (specification see page 4)

and its trade name is VIADRUS HERCULES Green Eco Therm. It is the boiler with automatic fuel supply.

The burner is cleaned manually.

The boiler is manufactured as warm-water boiler with forced heating water circulation and working

overpressure up to 400 kPa (4 bar). The boiler is tested for tightness by applying 800 kPa (8 bar)

overpressure before despatch.

The use:

Type of burner:

J: Junior

S: Senior

The version of boiler VIADRUS HERCULES Green Eco Therm 25X is particularly destined for heating

of individual housing units, weekend houses, cottages etc.

The version of boiler VIADRUS HERCULES Green Eco Therm 32X is particularly destined for heating

of cottages, weekend houses, small business premises, smaller leisure amenities etc.

Advantages of boiler:

automatic boiler operation guarantees the heating comfort,

mechanical fuel feed from any reservoir

automatic ignition

simple, not time-consuming attendance and maintenance

high efficiency reaching 87,9 %,

boiler drum construction proven on a long-term basis

high service life of the cast iron boiler drum

five-year guarantee for the boiler drum

3

2. Technical data of the boiler

-

1

-

1

-1

-

1

Tab. no. 1 Dimensions, thermal parameters of boiler

VIADRUS HERCULES

Version of boiler

Green Eco Therm

25S 25J 32S 32J

Section number pcs 5 7

Class of boiler according to EN 303-5 - 4 3 3 4

Weight including the supplied fuel tank kg 332 401

Fuel tank weight on demand kg 65 65

Water space volume l 40,9 50,3

Diameter of smoke socket mm 156 156

Boiler dimensions (incl. burner): - height x width mm 1218 x 1309 1218 x 1309

- depth mm 1335 1527

Capacity of the supplied fuel tank dm3 130 130

kg 85 85

Fuel tank capacity on demand dm3 725 725

kg 470 470

Water operating overpressure kPa (bar) 400 (4) 400 (4)

Testing water overpressure kPa (bar) 800 (8) 800 (8)

Hydraulic loss (∆T 20 K) Pa 80 110

Recommended heat water operating temperature °C 60 - 80 60 - 80

Recommended return water operating temperature

Noise level

°C 60 60

dB

Doesn´t exceed level

65 dB (A)

Chimney draught mbar 0,15 - 0,25 0,20 - 0,30

Boiler connections - heat water G 1 1/2" G 1 1/2"

- return water G 1 1/2" G 1 1/2"

Connected voltage

Operating electric power/max.

W 100/1200 100/1200

1/N/PE 230 V AC 50 Hz

TN-S

Electric protection IP 20 IP 20

Tab. no. 2 Heat - technical parameters of the boiler

Version of boiler

Section number pcs 5 7

Nominal output kW 25 32

Minimum output kW 7,5 9,6

Efficiency % up to 86,8 up to 87,9

The approximate fuel consumption at rated output

The approximate fuel consumption at minimum

output

Burning time at nominal output - supplied tank / the

tank by request.

Burning time at minimum output - supplied tank /

the tank by request

kg.h

kg.h-1

h 14,17/78,33 10,625/58,75

h 60,7/335,71 35,42/195,83

Heating value MJ. kg

Flue gas temperature °C 120 - 210 120 - 210

Flue gases mass flow rate at nominal output kg.s

Flue gases mass flow rate at minimum output kg.s

Specified fuel:

VIADRUS HERCULES

Green Eco Therm 25X

5,8 8,2

1,74 2,45

17,189 17,189

0,018 0,021

0,009 0,014

The pellets must comply at least with one of the standards or regulations as follows:

Direction no. 14-2000 MŽP ČR

DIN 517 31

ÖNORM M 7135

Specified pellets granularity: between 6 and 8 mm

Maximum fuel water content. 12%.

Ash content max. 1,5 %

WARNING! A poor quality of fuel can markedly negatively affect the boiler output and emission

parameters.

VIADRUS HERCULES

Green Eco Therm

Doesn´t exceed level

65 dB (A)

1/N/PE 230 V AC 50 Hz

TN-S

VIADRUS HERCULES

Green Eco Therm 32X

4

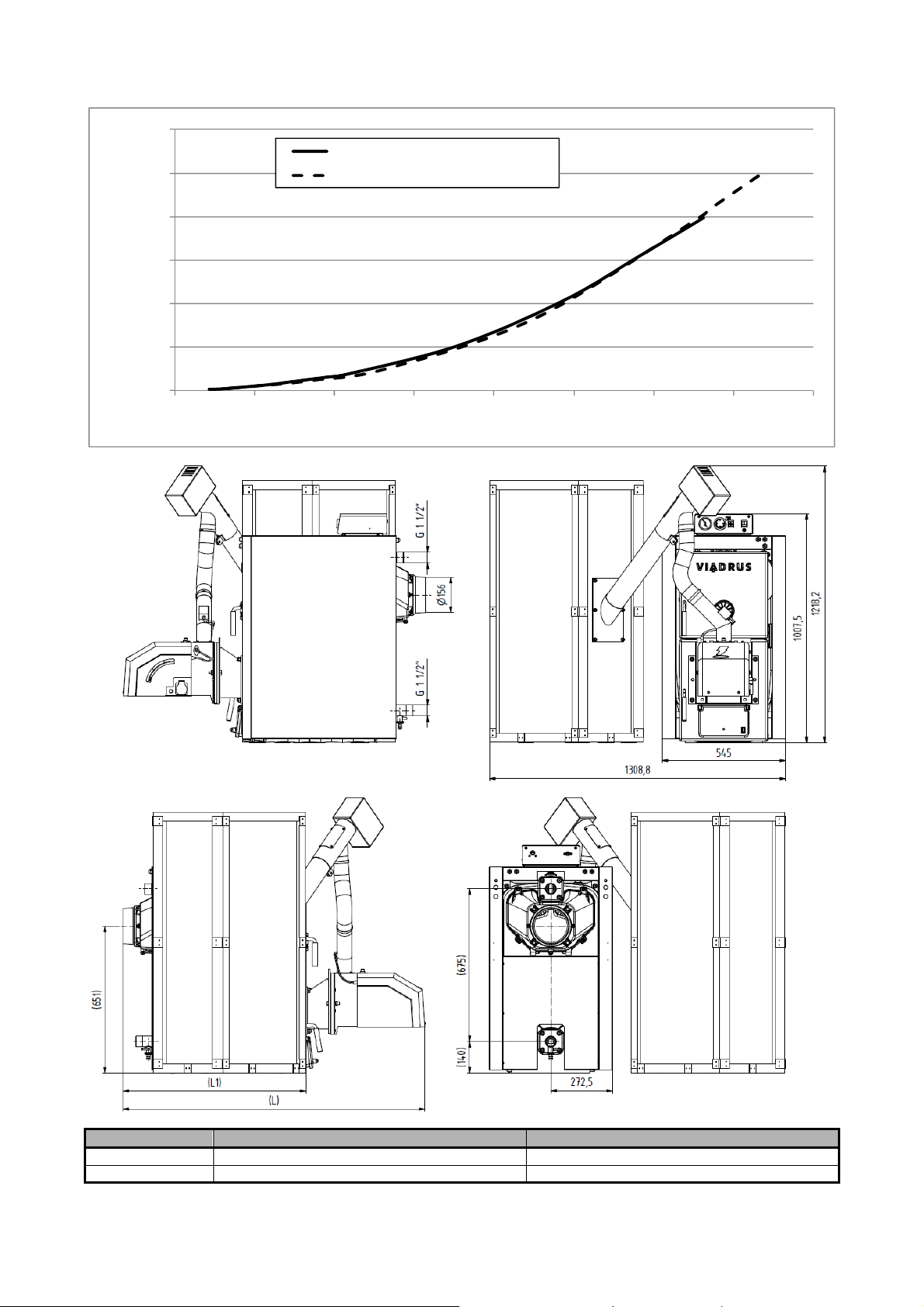

Hydraulic losses of boiler drum

3000

HERCULES Green Eco Therm 25X

[Pa]

z

p

2500

HERCULES Green Eco Therm 32X

2000

1500

1000

500

0

0 0,5 1 1,5 2 2,5 3 3,5 4

Q [dm3.s-1]

Version of boiler VIADRUS HERCULES Green Eco Therm 25X VIADRUS HERCULES Green Eco Therm 32X

L 1335 1527

L1 809 1001

Fig. no. 1 Boiler dimensions

5

3. Boiler description

3.1 Boiler drum construction

The cast iron section boiler drum is the main part of boiler and it is manufactured of grey cast iron according

to EN 1561

•

central sections – quality 150 (previously ČSN 42 2415)

•

front and rear sections – quality 200 (previously ČSN 42 2420)

The pressure parts of boiler conform to the strength requirements according to EN 303-5.

The boiler drum is assembled of sections by means of pressed on boiler insertions and secured by means of

anchor bolts. The sections create the combustion and ash-pan space, the water space and convection part.

The inlet and outlet of heating water are situated in the rear part of boiler.

The rear section of boiler in its upper part has a smoke extension piece and heating water flange, in the lower

part there is the return water flange with a sleeve piece for inlet and outlet cocks. The cleaning door and ash

door with mounted burner are affixed to the front boiler section.

The whole boiler drum is insulated by means of a health harmless mineral insulation which reduces the

losses caused by the heat transfer into ambient. The steel shell colour is treated by means of high-quality

komaxit spray.

3.2 Control, regulation and safety elements

Elements for control, regulation and safety placed in the control cabinet

Thermomanometer serves for measuring the temperature and pressure of water in the heating system and

is located in the upper part of the boiler shell. The check valve for pressure gauge connection is located in the

upper part of the rear boiler section.

Operating thermostat switches off / switches on the operation of the burner according to the set

temperature of heating water.

Signalling of safety thermostat signals the activation of the safety thermostat (overheating of the heating

system above 97 °C)

The safety thermostat is placed in the control box and serves for ensuring the heating system against

overheating. This thermostat is set by the manufacturer to a temperature of 95°C, i.e. to a higher temperature

than can be set as the desired temperature on the boiler. When you turn off the safety thermostat unblocking

must be done manually. The safety thermostat can be turned on only after the temperature has dropped

below the set value. We have to unscrew the black cap of the safety thermostat and by using a suitable

object we press the button.

In case of repeated switching of the thermostat the boiler must be shut down and the reason of repeated

overheating of the boiler must be found out.

The thermostat of the pump switches on and switches off the pump of heating water according to the set

temperature.

1. Termomanometer

2. Operating thermostat

3. The switch "start of burner"

4. Signalling of safety thermostat

5. Fuse 10A

6. Main switch

7. Safety thermostat

8. Thermostat of pump

Fig. no. 2 Control box

Elements for control, regulation and safety placed on the boiler body

The air rosette of cleaning door and the lower stifling element is not used at the boiler with an automatic

combustion of wooden pellets and must be permanently closed.

6

Elements for control, regulation and safety placed on the burner

219

THERMAX

219

THERMAX

•

Control Module of boiler (version VIADRUS HERCULES Green Eco Therm XJ) or automatic (version

VIADRUS HERCULES Green Eco Therm XS).

•

LCD display with control buttons, that is designed for change of the values of operating parameters

(version VIADRUS HERCULES Green Eco Therm XJ).

•

Potentiometer – for setting the boiler output (version VIADRUS HERCULES Green Eco Therm XS).

•

Photo sensor, which monitors the intensity of the combustion process.

•

Transport hose with reinforcing spiral, which melts in the case of penetration of fuel back through the

knee of burner, thus preventing further supply of pellets into the burner.

•

Sensor of penetration of fuel (TD) is placed on the knee of burner and is activated in case of the

surface temperature above 90 °C. Burner and fuel feeder are stopped in case of activation of this sensor

and the system is switched over into reporting of a failure. The failure mode is deactivated by switching

off and on of the main switch. It is necessary to determine the cause of the failure and take appropriate

measures, namely before restarting of the burner;

•

Reversible thermal label displays the operating temperature of the burner body. This temperature is an

indicator for operating mode of the burner and temperature of flue gases which pass the combustion

chamber back into the fuel tank. The initial state is shown in black colour for all thermally active parts. If

the temperature is increased, the segments gradually are getting a light colour, according to the

temperature range of individual heat-active segments. The reversible thermal label should be checked

as needed. Increased temperature in this section signals the necessity to clean the boiler, grate of

burner or routes of flue gasses and smoke flue. During cooling of the main burner body the colour of the

label returns to its original state (all segments are black).

•

Irreversible thermal label displays overheating of the knee of burner. This label in case exceeding of

temperature of the burner knee irreversibly changes its colour.

The initial status, the active segment is white, the temperature hasn’t

reached the degree of activation 104 °C;

The status at activation, the active segment is dark, the temperature

104

°C

°F

has exceeded the degree for activation 104 °C; activation of 104 °C;

°C

°F

104

CAUTION:

• Activation of irreversible thermal label is signalling overheating of the knee of burner. Status of this

label is irreversible and in case of damage it has to be replaced. Control and service of burner may be

performed only by an authorized technician.

• This thermal label is activated for example when hot combustion products pass back via the fuel feeder

due to an increased resistance of the smoke flue or a lower draft in the chimney. In such cases the

transport hose that connects the fuel feeder and burner body can be damaged and will be necessary its

replacement.

• In case of these emergency statuses the warranty for the burner is void.

7

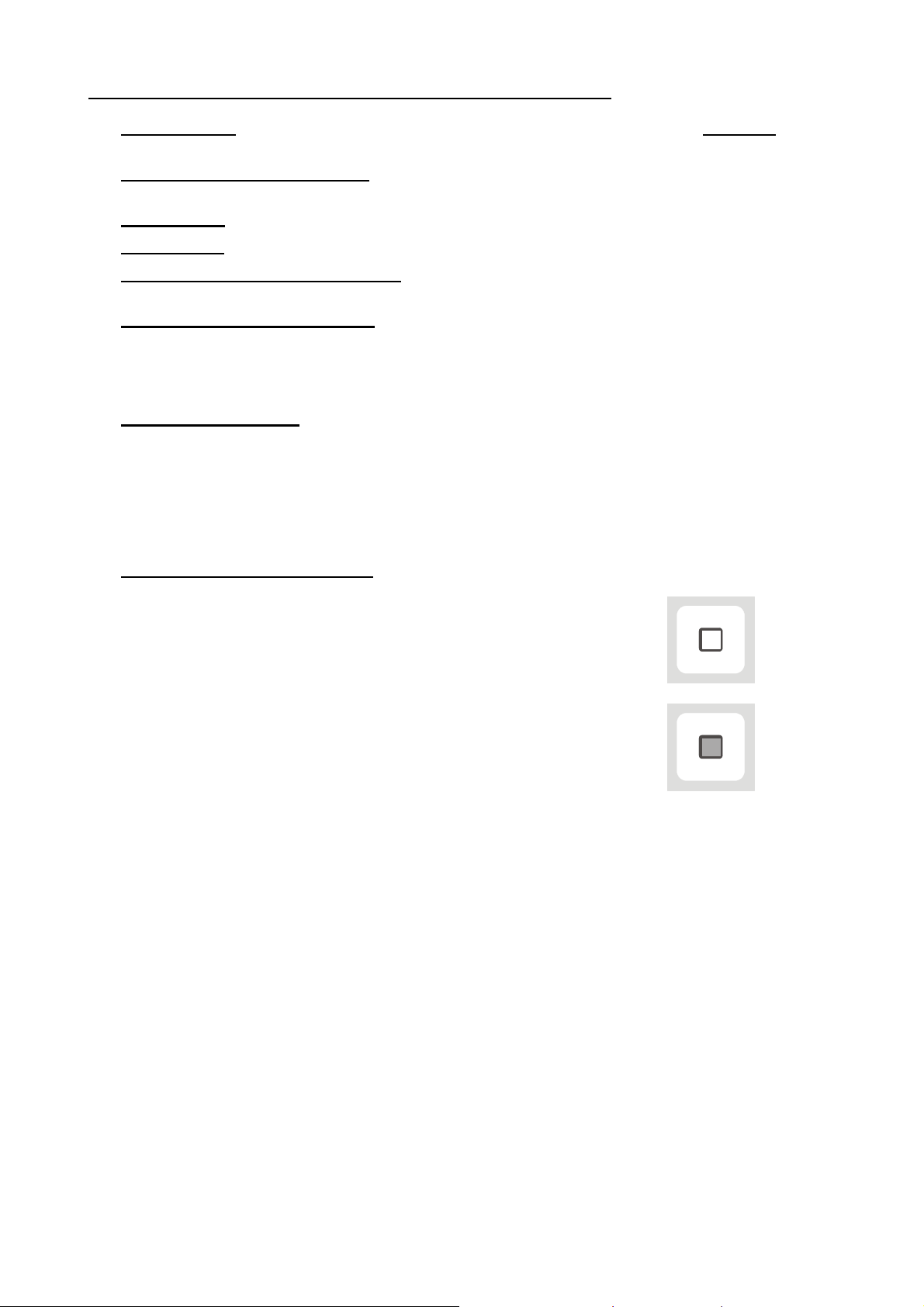

1. Boiler drum

2. Boiler shell with ashtray

3. Cleaning door

4. Burner

5. Transitionary flange

6. Insulation of burner

7. The ash door

8. Fuel tank

9. Fuel feeder

10. Transport hose with reinforcing spiral

11. Control box

12. Flange of heating water

Fig. no. 3 Boiler assembly

13. Flange of return water

14. Fill and drain cock

15. Sealing 90 x 60 x 3

16. Assembly of smoke adapter

17. Turbulators

18. Partition of flue way

19. Partition of the combustion chamber- the

front section

20. Partition of the combustion chamber

21. Hose clamp

22. Screw M10 x 50

23. Screw M10 x 30

8

3.2 The construction of burner and transport routes of the fuel

The version VIADRUS HERCULES Green Eco Therm XJ

• Control module with microprocessor;

• LCD display with control buttons, that is designed for change of the values of operating parameters;

Version VIADRUS HERCULES Green Eco Therm XS

• Control panel on which there is placed a potentiometer for setting the boiler output;

• Colour scale on which we can set the position of throttle flap of the fan (the output power of fan) to the

same colour as the setting of the thermal output potentiometer.

• Manual setting of throttle flap of the fan.

Version of boiler

Nominal heat output 25 25 32 32

power range 7,5 - 25 7,5 - 25 9,6 - 32 9,6 - 32

The burner consists of following components:

• Combustion chamber, which serves for burning pellets and made from high quality stainless steel;

• Removable grate of combustion chamber;

• Electric spiral, by means of which the fuel is ignited. It is located behind the inclined plate of grate in the

combustion chamber;

• Fan for intake of air, equipped with Hall effect sensor for sensing the rotational speed;

• Photo sensor, which monitors the intensity of the combustion process;

• Sensor for penetration of burning fuel (TD) which stops the operation of the burner in case of break

forth of flame into the fuel feeder;

• Socket for connecting the fuel feeder, which ensures power supply into the motor of the fuel feeder;

• Reversible thermal label from a liquid crystal with the indicator of current temperature of the

body of burner.

• Irreversible thermal label from a liquid crystal which signals the high temperature of the knee of

burner, preliminarily sets the conditions for the non-warranty service of the main module of burner and of

any kind of damage to the hose for fuel supply;

• Fuel feeder with an inlet cable and 1 ~ plug.

• Transport hose with reinforcing spiral, which is made partly of a transparent heat-resistant material

(in case of burning does not emit toxic substances and does not maintain the process of burning), that

interconnects the fuel feeder and the knee of burner;

25J 25S 32J 32S

VIADRUS HERCULES Green Eco Therm

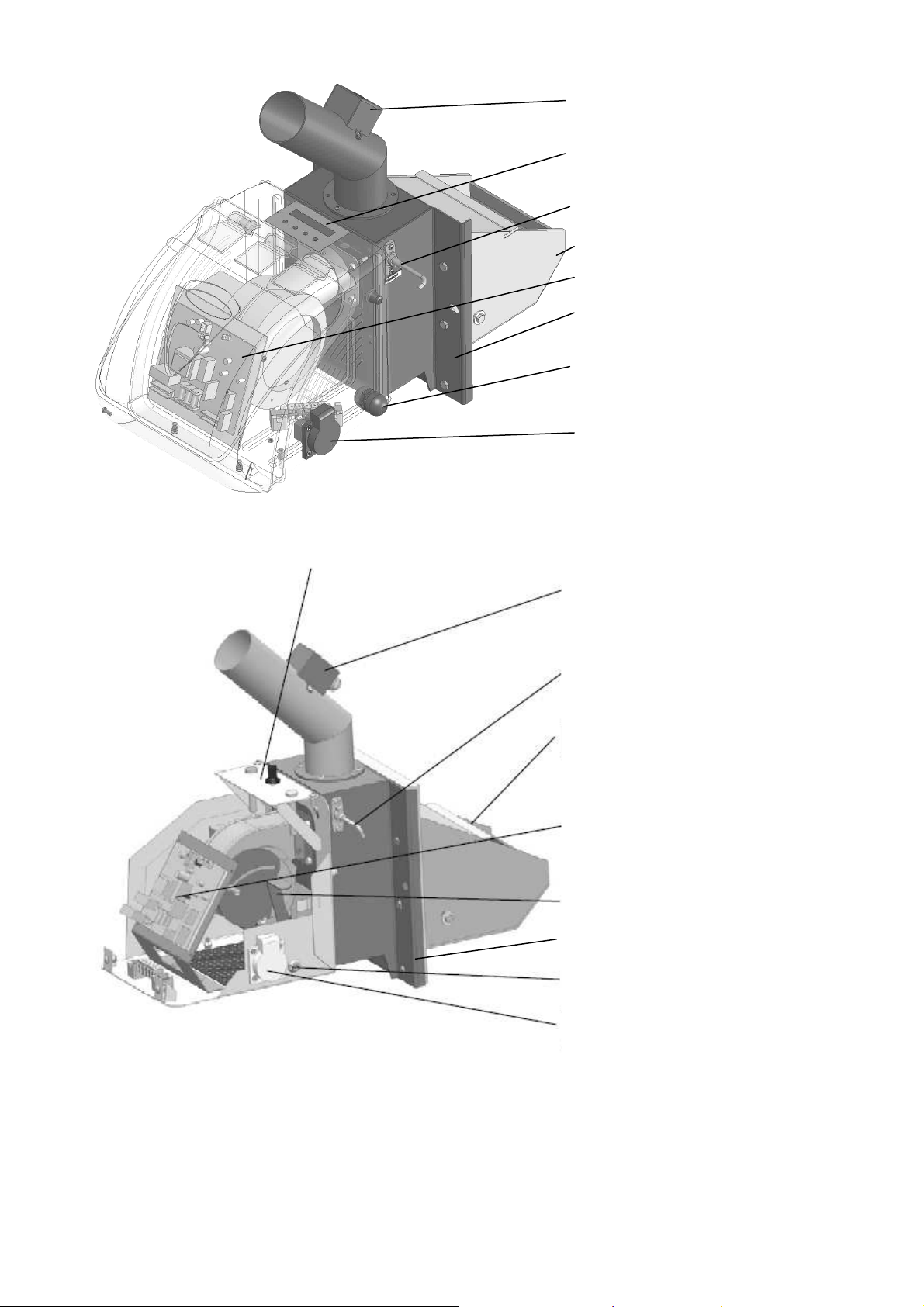

Fuel feeder

Fig. no. 4 Burner and fuel feeder

9

Transport hose

with reinforcing

spiral

Knee of

the burner

Burner

Sensor for penetration of burning fuel

(TD)

LCD display with control buttons

Photo sensor

Combustion chamber

Control module of boiler

Transitionary flange for mounting the

burner to the door of boiler

Inlet of electricity

Socket for connection of the fuel feeder

Fig. no. 5 Basic components of the burner of boiler VIADRUS HERCULES Green Eco Therm XJ

Control panel

Sensor for penetration of burning

fuel (TD)

Photo sensor

Combustion chamber

Control module of boiler

Throttling flap of the fan

Transitionary flange for mounting the

burner to the door of boiler

Inlet of electricity

Fig. no. 6 Basic components of the burner of boiler VIADRUS HERCULES Green Eco Therm XS

10

Irreversible thermal

label

Reversible thermal

label with indicator of

current temperature

of the body of burner

Fig. no. 7 Positioning of thermal labels on the burner

4. Location and installation

4.1 Regulations and directives

The solid fuel boiler can only by mounted by a company holding a valid authorization to install these

equipments.

A project according to the valid regulations must be prepared for the installation.

The heating system must be filled with water that matches the requirements of ČSN 07 7401 and

especially its hardness must not exceed the required parameters.

Recommended values

Hardness mmol/l 1

Ca2+ mmol/l 0,3

Concentration of total Fe + Mn mg/l (0,3)*

*) Recommended value

WARNING!!! The use of anti-freeze mixture is not recommended by the manufacturer.

a) to the heating system

ČSN 06 0310 Heating systems in buildings – Designing and installation

ČSN 06 0830 Heating systems in buildings – protecting device

ČSN 07 7401 Water and steam for thermal energy equipments with working pressure

up to 8 MPa.

EN 303-5 Boilers for central heating – Part 5: Solid fuel boilers for central heating with

manual or automatic feed and max. 500 kW nominal thermal output:

terminology, requirements, testing and marking.

b) to the chimney

ČSN 73 4201 Chimneys and flue gas ducting– designing, implementation and connection of

fuel consumers.

c) regarding the fire regulations

ČSN 06 1008 Fire safety of heat installations.

EN 13501-1 +A1 Fire classification of construction products and building elements – Part 1:

Classification using test data from reaction to fire tests

d) to the system of HWS heating

ČSN 06 0320 Heating systems in buildings – Hot water preparation – Designing and planning

ČSN 06 0830 Heating systems in buildings – Safety devices.

ČSN 75 5409 Water installations inside buildings.

e) regarding the electric network

CSN 33 0165 Electrical regulations. Identification of conductors by colours or numerals.

Procedure provisions

ČSN 33 1500 Electrical regulations; revision of electrical equipments

11

ČSN 33 2000-1 ed. 2 Low-voltage electrical installations – Part 1: Fundamental principles,

assessment of general characteristics, definitions.

ČSN 33 2000-4-41 ed. 2 Low voltage electrical installations - Part 4-

41: Protection for safety -

Protection against electric shock

ČSN 33 2000-5-51 ed. 3 Electrical installations of buildings – Part 5-51: Selection and erection of

electrical equipment – Common rules

ČSN 33 2130 ed. 2 Low-voltage electrical installations – Internal electric distribution lines

ČSN 33 2180 Electrical regulations: Connection of electric instruments and appliances

ČSN 34 0350 ed. 2 Safety requirements for flexibile cords and cables

EN 60079-10-1 Explosive atmospheres — Part 10-1: Classification of areas — Explosive gas

atmospheres

EN 60079-14 ed.3 Explosive atmospheres - Part 14: Electrical installations design, selection and

erection

EN 60252-1 ed. 2 Capacitors for AC motors – Part 1: In general – Design, testing, dimensioning

– Safety requirements – Instructions for installation and operation.

EN 60 335-1 ed.2 Electric appliances for household and similar purposes – Safety – Part 1:

General requirements

EN 60 335-2-102 Electric appliances for household and similar purposes – Safety – Part 2-102:

Special demands on appliances containing the electric connections and

burning the gas, oil and solid fuels

EN 60445 ed. 4 Basic and safety principles for man-machine interface, marking and

identification – Identification of equipment terminals, conductor terminations

and conductors

EN 61000-6-3 ed. 2 Electromagnetic compatibility (EMC) - Part 6-3: Generic standards – Emission

standard for residential, commercial and and light industrial environments

EN 61000-3-2 ed. 3 Electromagnetic compatibility (EMC) - Part 3-2: Limits - Limits for harmonic

current emissions (equipment input current ≤16 A per phase)

EN 61000-3-3 ed. 2 (ed. 3) Electromagnetic compatibility (EMC) - Part 3-3: Limits - Limitation of voltage

changes, voltage fluctuations and flicker in public low-voltage supply systems,

for equipment with rated current ≤16 A per phase and not subject to

conditional connection.

4.2 Positioning possibilities

Boiler positioning in the living space (including corridors) is prohibited!

The installation of the boiler must comply with all requirements of ČSN 06 1008.

ATTENTION!

In the event that it is installed the delivered wooden fuel reservoir, then it is necessary to install a

fireproof bulkhead between the reservoir and boiler.

Boiler placing with regard to fire regulations:

1. Placing on floor of flame resistant material (Fig. no. 8)

- boiler to be put on a flame resistant backing exceeding the boiler platform over 20 mm at sides and

only on the boiler drum depth.

- if the boiler is situated in a cellar we recommend to place it on a bedding of minimum 50 mm height.

2. A safe distance from the combustible materials:

- when installing and operating the boiler it is necessary to keep a safety distance of 200 mm from the

materials of combustibility grade A1, A2, B and C (D);

- for easily combustible materials of combustibility grade E (F), which quickly burn and burn

themselves even after removal of ignition source (such as paper, cardboard, asphalt and tar paper,

wood and wood-fiber boards, plastics, floor coverings) the safe distance has to be doubled, i.e. to

400 mm;

- safe distance should be doubled as bulb where the grade of reaction to fire has not been proved.

Tab. no. 3 Grade of reaction to fire

Grade of reaction to fire

A1 – incombustible

A2 – combustible with difficulty

B – hardly combustible

C (D) – medium combustible

E (F) – easily combustible

Examples of building materials and products included in the reaction to fire

(Extract from EN 13 501-1 + A1)

Granite, sandstone, concrete, bricpcs, ceramic tiles, mortars, fireproof plasters, …

acumin, izumin, heraklit, lignos, boards and basalt felt, fibreglass boards,...

Beech and oak wood, hobrex boards, plywood, werzalit, umakart, sirkolit,...

Pinewood, larch, whitewood, chipboard and cork boards, rubber flooring,...

Asphaltboard, fibreboards, cellulose materials, polyurethane, polystyrene,

polyethylene, PVC,…

12

Section number

L [mm]

5 7

680 872

Fig. no. 8 Bedding dimensions

The boiler placing with respect to the necessary handling space:

•

basic surroundings of AA5/AB5 according to ČSN 33 2000-1 ed. 2;

•

handling space of minimum 1000 mm in front of the boiler must be maintained;

•

a minimum distance of 400 mm between the back part of the boiler and the wall;

•

from the side of the boiler there must be maintained a space at least 500 mm for the door opening and

for the access to the rear part of the boiler;

•

a minimum distance of 100 mm from the side wall.

•

a minimum boiler-room height 2 100 mm

Fig. no. 9 Boiler placing in a boiler room

Fuel placing:

•

dry fuel (up to the 12% moisture) must be used in order to guarantee the correct combustion in the

boiler. The pellets should be stored in their original packing from the manufacturer

(e.g. PET sacpcs) at a dry place;

•

it is impossible to store fuel behind the boiler or unload it next to the boiler in a distance smaller than

400 mm;

•

the manufacturer recommends that min. 1000 distance is kept between the boiler and fuel or the fuel is

placed in a room different from that where the boiler is installed

13

Boiler positioning with regard to electricity network:

•

the boiler must be placed so that the plug in socket (230 V/50 Hz) is always accessible;

•

the boiler is connected to the mains by a fixed movable inlet with a normalized plug;

•

the electric shock prevention must be guaranteed according to valid EN (see chap. 4.1.)

A permanent air supply for combustion and ventilation must be guaranteed in the room where

the boiler is installed (the air consumption of VIADRUS HERCULES Green Eco Therm 5X boiler

amounts to approx. 80 m3.h-1, the air consumption of VIADRUS HERCULES Green Eco Therm 7X

boiler amounts to approx. 160 m3.h-1.

The connection of heating system piping must be carried out by a person authorised according to

the valid regulations.

.

CAUTION: When connecting the boiler to the heating system there must be installed a inlet and

outlet cocpcs in the lowest point and as near as possible to the boiler (at the return

water flange).

5. Order, delivery and assembly

5.1 Order

In the order the following is needed to be specified:

1. Output and type of burner (see chap. 1)

2. Requirements for accessories offered on request

5.2 Delivery and accessories

Boiler VIADRUS HERCULES Green Eco Therm is supplied so that on a pallet there is placed the complete

boiler drum and on the side there is attached the wrapped boiler shell. The accessories are stored inside the

boiler drum and are accessible after opening the cleaning door. On the other pallet there is stored wooden

fuel container, in which there is stored the burner, the fuel feeder and their accessories. The boiler is packed

into a shipping container and must not be flipped during shipping; it is only permitted to tilt to the sides in

order to remove the wrapping from the boiler drum.

Standard accessories to boiler:

•

Boiler with the appropriate number of boiler sections on the palette

•

Flange of heating water G 1 1/2" 1 pc

•

Return water flange G 1 1/2 "with socket Js 1/2" for the fill and drain cock 1 pc

•

Sealing φ 90 x 60 x 3 2 pcs

•

Washer 10,5 8 pcs

•

Nut M10 8 pcs

•

The fill and drain cock Js 1/2“ 1 pc

•

Three-position sump of thermostat G 1/2" 1 pc

•

spring of the capillary 1 pc

•

Blind plug Js 6/4“ 1 pc

•

Sealing 60 x 48 x 2 1 pc

•

The boiler shell including the ashtray and insulation in the adequate size

•

Fasteners for jacketing

-

console 1 assembly 2 pcs

-

console 2 assembly 2 pcs

-

washer 10,5 4 pcs

-

nut M10 4 pcs

-

connecting pin 4 pcs

-

screw M5 x 12 4 pcs

-

washer 5,3 4 pcs

-

screw into the plate ST 4,2 x 9,5 6 pcs

-

spring clamp 4 pcs

-

bushing PG 9 7 pcs

•

control box 1 pc

-

screw M5 x 12 4 pcs

-

serrated washer 5,3 4 pcs

•

cleaning equipment

-

hook 1 pc

-

brush with handle 1 pc

14

-

pike 1 pc

-

cleaning equipment holder 1 pcs

-

handling key 1 pc

•

turbulator 4 pcs

•

partition of combustion chamber – the front segment 1 pc

•

the partition of combustion chamber 4 pcs - 7 sect.

•

the partition of smoke channel 2 pcs

•

burner 1 pc

•

fasteners for mounting of burner and for mounting of a transitionary flange

-

screw M10 x 50 3 pcs

-

screw M10 x 30 3 pcs

-

spring washer 10 6 pcs

-

washer 10,5 6 pcs

-

nut M10 6 pcs

•

insulation of burner 1 pc

•

transitionary flange of the burner 1 pc

•

fuel feeder 1 pc

-

transport hose with reinforcing spiral 1 pc

-

hose clamp 2 pcs

•

fuel reservoir 1 pc

-

sloping bottom 2 pcs

-

flange of the fuel feeder 1 pc

•

fasteners for the fuel reservoir

-

screw M8 10 pcs

-

nut M8 10 pcs

-

washer 8,4 10 pcs

•

flexo cord 5 m 1 pc

•

boiler label 1 pc

•

business – technical documentation

Accessories delivered by request:

•

fuel reservoir 725 l

- the side of fuel reservoir 3 pcs

- the side of fuel reservoir with the hole for spiral worm 1 pc

- the foot of fuel reservoir 4 pcs

- the bottom of fuel reservoir 2 pcs

- the bottom of fuel reservoir A 2 pcs

- the cover of fuel reservoir 1 pc

- handle 1 pc

•

connection accessories for fuel reservoir assembly

- pendant chainlet 1 pcs

- screw M6 x 12 72 pcs

- washer 6,4 72 pcs

- nut M6 72 pcs

- screw M6 x 16 2 pcs

- washer 8,4 2 pcs

The boiler equipment delivered “by request“ is not included in the basic price of boiler

15

Loading...

Loading...