Viadrus aguro Installation, Operation And Maintanance Manual

AGURO

Manual for installation, operation

and maintenance

GB_2016_30

GB_2016_31

It was tested according to/complies with norms:

• EN 14 785:2007

• 15a B-VG

• Din +

• BIm SchV 2

CONTENT

page

1 Pellet stove usage and advantages ........................................................................................................................ 3

2 Pellet stove technical description ............................................................................................................................ 3

3 Transportation and storage ..................................................................................................................................... 5

3.1 Transportation .................................................................................................................................................. 5

3.2 Storage ............................................................................................................................................................ 5

4 Placement and installation ...................................................................................................................................... 5

4.1 Regulations and directives ............................................................................................................................... 5

4.2 General instructions for placement and installation ......................................................................................... 5

4.3 Rules for placement ......................................................................................................................................... 6

4.4 Connection of the pellet stove to the chimney ................................................................................................. 7

4.5 Connection of central air supply ...................................................................................................................... 7

5 Commissioning ........................................................................................................................................................ 8

5.1 Opening of the pellet stove door ...................................................................................................................... 8

5.2 Safety instructions ........................................................................................................................................... 8

5.3 Fuel .................................................................................................................................................................. 9

5.4 Main principles of operation ............................................................................................................................. 9

5.5 The first commissioning ................................................................................................................................. 10

6 Manipulation with the control electronics .............................................................................................................. 10

6.1 User menu ..................................................................................................................................................... 10

6.2 Remote control .............................................................................................................................................. 15

6.3 Stove first ignition and shutdown procedure.................................................................................................. 16

6.4 Power degree selection mode ....................................................................................................................... 16

6.5 Room thermostat value adjustment mode ..................................................................................................... 16

6.6 Pellet supply and exhaust fan rpm adjustment mode .................................................................................... 17

6.7 Alarms on the display and their removal ....................................................................................................... 17

7 Pellet stove maintenance and cleaning ................................................................................................................ 18

7.1 Clean-up of glass and the stove surfaces ..................................................................................................... 18

7.2 Clean-up of the heating chamber .................................................................................................................. 19

7.3 Clean-up of the pellet reservoir...................................................................................................................... 19

7.4 Clean-up of the flue channel .......................................................................................................................... 19

7.5 Clean-up of the smoke-flues and the smoke-flue pipes ................................................................................ 20

7.6 Clean-up of the cladding of the exhaust fan (it is not necessary, or only in extraordinary cases) ................ 20

8 Possible causes of operation problems and their removal ................................................................................... 21

9 Liquidation of transporting packing, liquidation of the product after the lapse of service life ................................ 22

10 Warranty conditions............................................................................................................................................... 22

3

Dear customer,

We thank you that you have bought a AGURO pellet stove, thus having shown your confidence in VIADRUS brand.

Your new stove was manufactured in a company that is a holder of ISO 9001:2000 certification.

Before installation and commissioning, please carefully acquaintance with the instruction manual for your new

pellet stove. It will help you to avoid possible problems incurred as a result of violation of guidance and instructions

specified in this manual, which can – under certain circumstances – lead to a damage of the stove. Save this

manual for searching other information in the future.

1 Pellet stove usage and advantages

The automatic AGURO pellet stove is also determined for permanent heating of dwelling and commercial premises.

Fuel is conveyed by means of an auger from the fuel reservoir into the burner bowl, whereas the fuel quantity is

automatically corrected in dependence on a required heating power. In case of the full fuel reservoir, depending on

the required temperature in the room, the stove can be operated during about 30 hours.

The stove is controlled with help of a control unit, which is integrated in the fuel reservoir cover. A user can choose

one of the working modes: “Heating” or "Auto" with the week programming.

The control unit regulates the kindling phase, the heating phase and cooling phase, and ensures by this safety

operation of the pellet stove. The display displays a working mode, in which the stove is occurred at the moment.

Eventual error messages are displayed on the display in a text form with specification of date and time.

2 Pellet stove technical description

It is a stove assembled from high quality steel plates. The stove furnace is equipped with a cast-iron burner bowl.

The pellet stove doors are equipped with a heat-resistant glass, and their structure allows opening in the horizontal

direction to the left. A part of the pellet stove is a removable ash-pan. The pellet stove surface is protected by heatresistant painting with the resistance up to 650°C (heating chamber) and 350°C (other steel-plate parts – a side

wall, a rear cover, a stove cover, etc.).

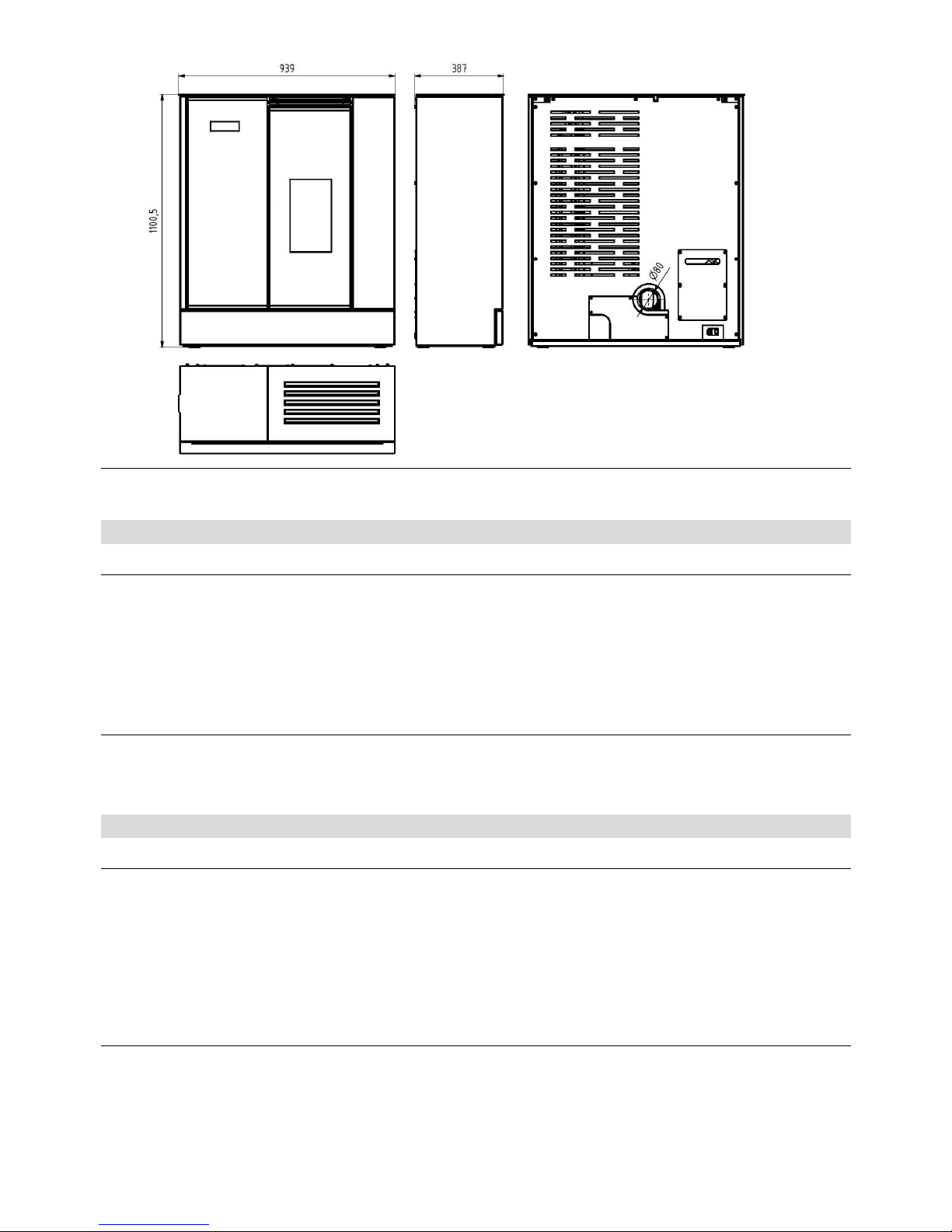

Tab. №. 1 Main thermo-technical parameters of the pellet stove

Total high mm 1101

Width mm 931

Depth mm 396,

Dead weight kg 209

Neck - chimney mm 80

Neck – air supply mm 50

Fuel reservoir volume kg 35 kg

Min. chimney operation draught Pa 10-15

Dwelling premise heat ability

(in dependence on a degree of facility insulation)

m3 50 - 220

Effectiveness % 87,3

Nominal heating power kW 6,4

Heating power range kW 2,6 – 6,5

Electric power supply V/Hz 230/50

Fuel consumption of electric energy W appr. 25

Electric fuse A 2,5

Fuel consumption at min ~ max heating power

kg/h

0,7 ~ 1,6

Average combustion products temperature behind the neck °C 143

Combustion products’ mass flow rate g/s 6,5

Content of CO at 13% O2 % 0,018

Connection to the electric power supply network:

The stove is supplied from the electric power supply network with help of a cable with the length of about 1,5 m

with an Euro terminal, which is a part of the package of the stove. The cable is to be connected to the electric

socket of 230 V/50 Hz. The average consumption of electric energy during operation is about 25 W, and the

average consumption of electric energy during the kindling process is 135 W. The supply cable has to be laid so

that it is not in contact with sharp edges or corners and is not in contact with hot surfaces of the stove.

4

Legend:

1. Protective grate

2. Reservoir

3. Auger

4. Auger motor

5. Control unit

6. Manostat

7. Flue exhauster

8. Cast-iron door frame

9. Display

10. Cast-iron door

11. Reservoir cover

12. Ash-pan

13. Door

14. Stone

15. Stone

16. Steel heat-exchanger

17. Insulation

18. Ceramic insulation

19. Rear cladding

20. Cast-iron burner bowl

21. Heating chamber

22. Cast-iron heat-exchanger

23. Cleaning cover

24. Tangential electric fan

25. Cleaning cover

26. Height-adjustable legs

27. Side cladding

Fig. №. 1 Main parts

5

Fig. №. 2 Main dimensions

3 Transportation and storage

3.1 Transportation

The pellet stove has to be only transported in the vertical position, in the original package and with properly fixation

against movement and falling. Transportation has to be performed in close space in order to avoid damage from

atmospheric conditions. During handling it is necessary to follow the vertical position; the stove mustn’t be declined

in any way to avoid its damaging. The stove has to be griped and convey by the bottom metal parts.

After taking-over the product, please properly check integrity and completeness of the package, including

its content.

3.2 Storage

The pellet stove has to be stored in a dry and tempered environment. It is necessary to store and handl it in the

vertical position. Please be extra careful during handling.

4 Placement and installation

4.1 Regulations and directives

EN 14 785:2007 Pellet stoves.

ČSN 73 4230 Hearths with open and closed fire grates.

ČSN EN 1443 Chimneys – General requirements.

ČSN 73 4201 Hearths and smoke-flues – Design, implementation and connection of fuel consumers.

ČSN EN 13501-1+A1 Fire protection classification of building products and building structures.

ČSN 06 1008 Fire safety of heating equipment.

.

4.2 General instructions for placement and installation

Each pellet stove has to be implicitly placed and installed so that there were observed the conditions specified by

local regulations or national and European norms as amended, including their additions, as well as in accordance

with instructions specified in this instruction manual.

The pellet stoves are determined for installation in dry premises that are characterized by a valid norm as

unaggressive environment without any explosive are combustible gases.

6

Before installation of pellet stoves it is necessary to carry out revision of the breast, into which the stove has to be

connected, including design and assessment of the flue channel, which has to provide safety exhaust of flue gases

from the connected stove. Only one consumer can be connected to the flue channel.

At installation it is necessary to provide sufficient access for cleaning of the consumer, the flue gas ducting and the

chimney.

In interior where a pellet stove is placed, it is not recommended to place equipment for air exhausting (for example,

a fume hood), which could invoke backward draught and leakage of flue gases into a room. If anyhow this

equipment is placed in the interior, it is necessary to provide regulation of its draught and suction of combustion air

from an extern room (a cellar, a technical room, etc.). Only overpressure air conditioning can be used.

4.3 Rules for placement

The consumer has to be put up on a firm basement with a corresponding capacity, preferably on a concrete or

other inflammable plate. If the existing set doesn’t comply with this necessary condition, it is necessary to make

sufficient measures to satisfy this requirement.

In case of installation to the floor from a combustible material, it is necessary to place the consumer on an

insulating pad from an inflammable material, which overlapped the ground plan of the consumer by 800 mm in the

direction of radiation, 400 mm from remaining sides.

It is not allowed to put subjects from combustible materials on the consumer and on the distance less than the

safety distance (see the following table). In case of unknown stage of combustibility it is necessary to go from the

distance for the stage E (F).

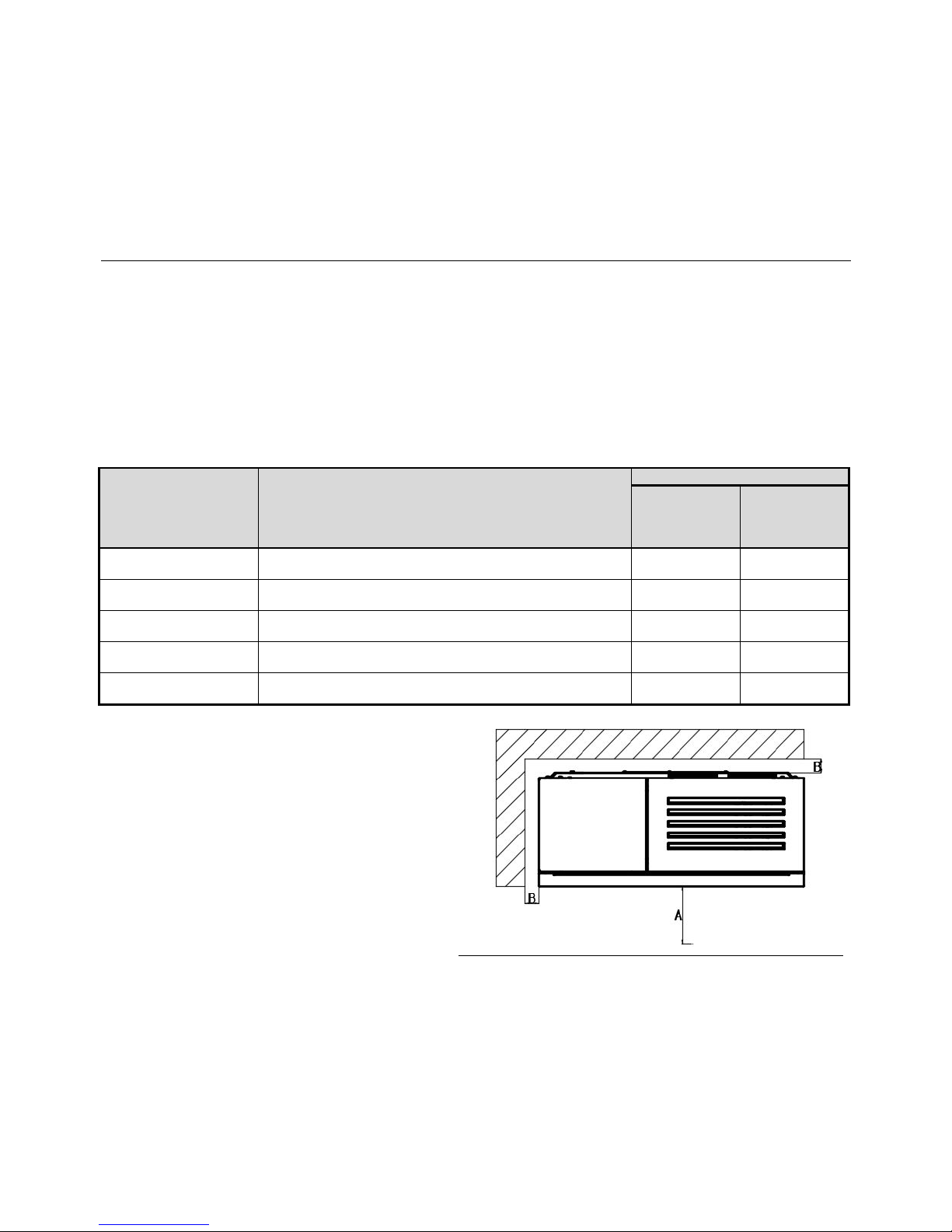

Tab. č. 1 Grade of reaction to fire

Grade of reaction to fire

Examples of building materials and products included in

the reaction of fire (extract from ČSN EN 13501-1+A1)

Minimum distance (mm)

Direction

perpendicular

to the radiating

wall

Other

directions

A1 – incombustible

Granite, sandstone, concrete, bricks, ceramic tiles, mortars,

fireproof plasters,...

- -

A2 – hardly combustible

acumin, izumin, heraklit, lignos, boards and basalt felt,

fibreglass boards,...

800 400

B – heavily combustible

Beech and oak wood, hobrex boards, plywood, werzalit,

umakart, sirkolit,...

800 400

C (D)

– moderately

combustible

Pinewood, larch, whitewood, chipboard and cork boards,

rubber flooring,...

800 400

E (F) – lightly combustible

Asphaltboard, fibreboards, cellulose materials, polyurethane,

polystyrene, polyethylene, PVC,...

1600 800

As the minimal distance from combustible or noncombustible materials, you can follow the following

values:

Combustible materials:

A > 800 mm

B > 100 mm

Non-combustible materials:

A > 400 mm

B > 50 mm

Fig. №. 3

7

4.4 Connection of the pellet stove to the chimney

Before commissioning the pellet stove, check and testing of the flue channel has to be

performed even before closing the flue channel by the sheathing of the heat-air chamber.

These activities may be only performed by a qualified person, for example, a chimney-sweeper

company. The result of checking has to be recorded into the revision report of the flue

channel.

With regard to low demand factor of installation of the pellet stove, a customer may install the

stove by himself/herself. However we recommend ordering this installation from a proper

trained specialized building company or a chimney-sweeper or a stove-fitter company.

Revision of the flue channels has to be car

ried out:

•

before commissioning the flue channel

•

after each building modification of the chimney

•

before a change or new installation of the consumer.

Revision has to be performed by a qualified person in the sphere of chimneys – by

engineering inspector of chimneys.

• Flue exhausting is ensured by means of a flue exhauster, which is a part of the pellet stove.

• The stove has to be connected to a separate chimney. It is not allowed to draw off flue gasses from other

equipment to this chimney.

• The chimney can be in classical design (a brickwork), or from stainless steel or from ceramics.

• Usual pipes or springy steel pipes for flue gas ducting can be used for connection to the chimney.

• All parts of the flue gas ducting up to the entrance to the chimney have to be gas-tight from the reason of

possible occurrence of overpressure in the output of flue gases.

• The pipe of the flue gas ducting mustn’t intervene to a free cross-section of the chimney.

• The stove complies with requirements for connection to chimneys designed for temperature of flue gases of

350 °C.

• The minimum required chimney draught is 10 Pa. Draught is influenced both by the length of the chimney, and

by the surface of the chimney, and by quality of its sealing. The minimum recommended length of the chimney

is 3,5 m from the place of falling-in the flue gas ducting to the chimney and a suitable minimum cross-section

is 150 x 150 cm.

• The outer diameter of the connecting mouthpiece for smoke gas is 80 x 1,5 mm.

• The flue gas ducting has to be made from tightened steel or stainless pipes. Two 90° elbow-pieces can be

used.

• In case of placement of the flue gas ducting on the outer side of the building, it has to be equipped with

thermal insulation.

• Flue gas ducts with sharp bends and a horizontal routing decrease chimney draught. The maximum horizontal

piece of the flue gas ducting is 2 m, under condition that the length of the flue gas ducting is at least 5 m.

• The flue gas ducting has to be accessible for checking and cleaning. It is necessary to provide possibility of

sweeping of the entire length of the chimney, and the chimney door has to be easily accessible.

• Check attentively whether the chimney is tight and that no leakage of flue gases occurs around the chimney

door and connection of the flue gas ducts.

• Flue gases are to be drawn through the flue gas ducting with the diameter of 150 mm connected to the neck of

the flue gas ducting of the stove, which is placed on the upper (rear) part of the stove.

4.5 Connection of central air supply

Connection of central air supply has to be realized in air-tight buildings, where the content

of oxygen in the room heated by the pellet stove can be decreased.

• Connect the hose to the suction neck for air on the rear wall (Ø 50 mm).

• The entrance of the air supply line has to be placed in outdoor space or in sufficiently vented room of the

building.

• At installation of the stove in a building with controlled ventilation of habitable premises, the entrance of air

supply mustn’t be placed in a room, which is connected to the associated ventilation system.

• In order to ensure sufficient air supply, the supply line mustn’t by longer than 3 m and mustn’t have too much

bends. The minimum diameter of the supply line is 50 mm.

• If the supply line enters into the outdoor space, it has to be bent by 90° in the down direction or has to be

ended in the dead air region.

8

5 Commissioning

Wrong operation and insufficient combustion of fuel brings to a damage of

the product.

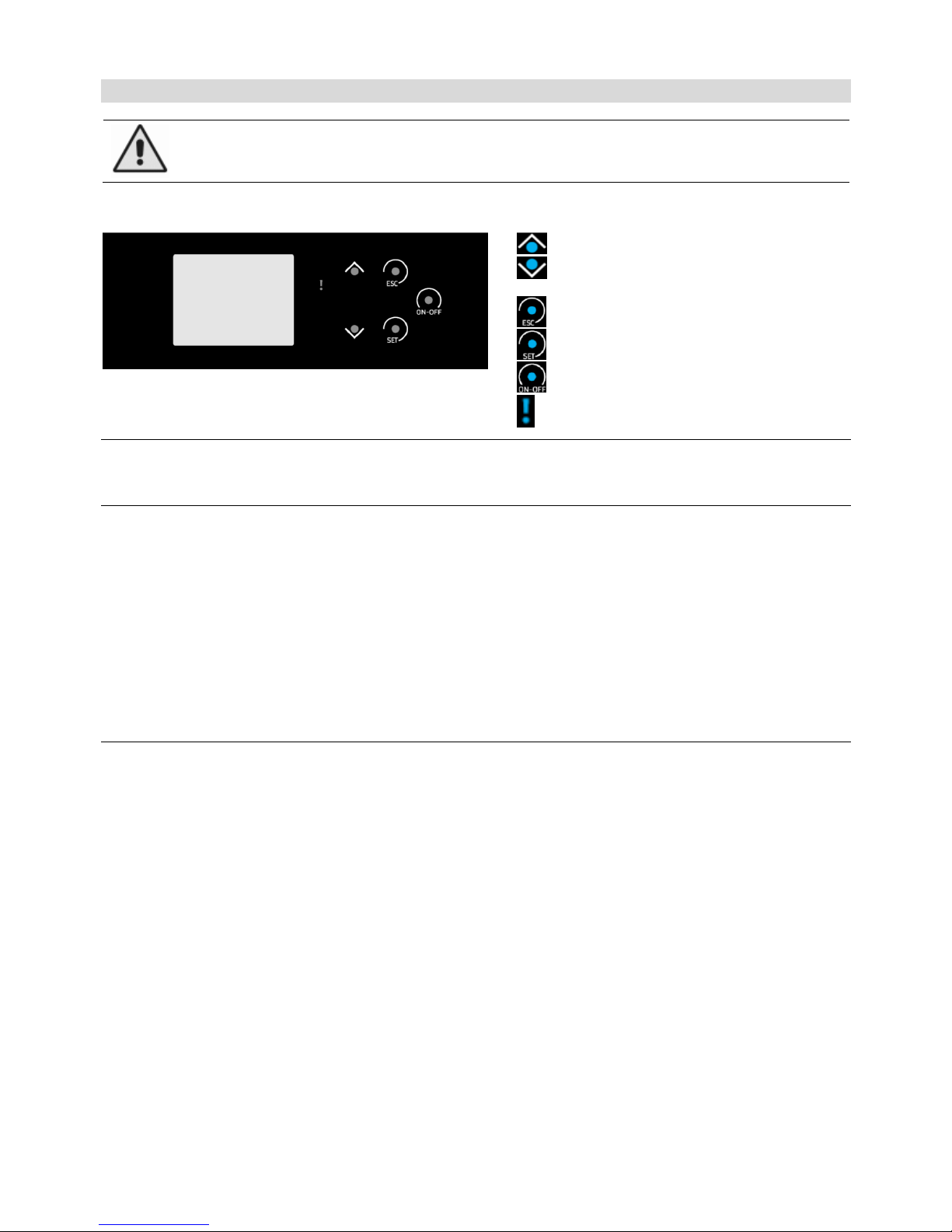

The control of the AGURO pellet stove is very easy. Control elements of the pellet stove are displayed in Fig. 4

Navigation in menu „UP“, increase the value

Navigation in menu „DOWN“, decrease the

value

Button in menu „EXIT“

Button in menu „CONFIRM“

Button in menu „ON/OFF“

Button „WARNING“

Fig. №. 4

5.1 Opening of the pellet stove door

The stove has two doors. The cast-iron door separates the heating chamber from other environment, and the

glassed one is decorative and completes the pellet stove design.

Be particular about sealing surfaces of the inner frame of the cast-iron door to ensure their easiest closing. The

cast-iron door can be opened with help of a handle; the decorative door can be opened by means of a clip and a

magnet (they are a part of delivery). Observe cleanness of the both doors.

The both doors always during stove operation have to be closed, otherwise the stove wouldn’t work

correctly and can be damaged!

If necessary, always open the cast-iron door slowly and carefully, in order to avoid sudden change of pressure in

the heating chamber and escape of smoke into the room.

5.2 Safety instructions

• At handling and unpacking, be careful and observe safety instructions!

• In case that there is a danger of occurrence of flammable gases for the temporary period in the room

with an installed stove (for example, during gluing of linoleum, at painting work, etc.), the pellet stove

has to be put out of operation even before occurrence of this danger!

• During burning of the surface painting of the stove at the first firing-up, it is necessary to ventilate all

the time and bring sufficient quantity of fresh air into the room!

• At operation it is necessary to provide sufficient supply of combustion air and safety withdrawal of

flue gases!

• The both doors have to be always closed!

• The pellet stove may only be operated by a capable adult person!

• Ensure that children, persons with mental disabilities and domestic animals cannot get to the space of

the furnace itself or very hot parts during operation of the stove (doors, glass, side covers, the furnace

cover, etc.) – danger of burning and possible life danger!

• For the entire period of operation, fire in the stove has to be regularly checked!

• In case of simultaneous operation of other heating device in the same room, it is necessary to ensure

sufficient ventilation!

• Don’t touch the outer surfaces of the stove – danger of burning and possible life danger, except of

control and regulating elements!

• Never extinguish fire in the pellet stove by water!

• Ash from the ash-pan has to be removed carefully and with using of protective equipment, and only

when the pellet stove is out of operation!

Loading...

Loading...