Viadrus A0C-X20P-00.16, A0C-X28P-00.16 User Manual

VIADRUS A0C

Manual for boiler operation and installation

GB_2016_28

GB_2017_30

2

Content

page

1 Usage and advantages of the boiler ............................................................................................................................................................ 3

2 Technical data of the boiler .......................................................................................................................................................................... 3

3 Description .................................................................................................................................................................................................. 6

3.1 Boiler structure .................................................................................................................................................................................... 6

3.2 Economizer ......................................................................................................................................................................................... 7

3.2.1 Mounting of the economizer ........................................................................................................................................................... 7

4 Placement and installation ........................................................................................................................................................................... 8

4.1 Regulations and directives .................................................................................................................................................................. 8

4.2 Possibility of placement ...................................................................................................................................................................... 9

5 Commissioning – instructions for contractual service organizations........................................................................................................... 10

5.1 Delivery and accessories content ...................................................................................................................................................... 10

5.2 Mounting procedure .......................................................................................................................................................................... 11

5.2.1 Boiler drum installation ................................................................................................................................................................. 11

5.2.2 Mounting of barriers of the combustion space and the baffles ...................................................................................................... 12

5.2.3 Burner mounting ........................................................................................................................................................................... 13

5.2.4 Mounting of the claddings ............................................................................................................................................................. 13

5.2.5 Mounting of the fuel reservoir ....................................................................................................................................................... 15

5.2.6 Mounting of the fuel feeder ........................................................................................................................................................... 15

5.2.7 Mounting of the fuel feeder to the boiler ........................................................................................................................................ 16

5.2.8 Reconstruction of the fuel reservoir to the left design ................................................................................................................... 17

5.3 Hydraulic scheme of the boiler .......................................................................................................................................................... 18

5.4 Electric connection scheme .............................................................................................................................................................. 20

5.5 Checking activities before actuation .................................................................................................................................................. 22

5.6 Boiler commissioning ........................................................................................................................................................................ 22

6 Handling of the boiler by a user ................................................................................................................................................................. 23

6.1 Description of control - S.Control ...................................................................................................................................................... 23

6.2 Boiler operation by a user – touch-type version S.Control Touch ...................................................................................................... 24

6.3 Control, regulating and safety elements ............................................................................................................................................ 25

6.3.1 Safety thermostat ......................................................................................................................................................................... 25

7 Maintenance .............................................................................................................................................................................................. 25

7.1 Clean-up of the boiler ........................................................................................................................................................................ 25

7.2 Clean-up of the burner ...................................................................................................................................................................... 25

7.2.1 Photo sensor ................................................................................................................................................................................ 25

7.2.2 Clean-up of the fuel feeder pipe .................................................................................................................................................... 26

7.2.3 Clean-up of the burner .................................................................................................................................................................. 26

7.2.4 Economizer cleaning-up ............................................................................................................................................................... 26

8 IMPORTANT WARNINGS ......................................................................................................................................................................... 27

9 Failure states ............................................................................................................................................................................................. 27

10 Instructions for liquidation of the product after the lapse of its service life .................................................................................................. 28

11 Warranty and responsibility for defects ...................................................................................................................................................... 29

12 Product fiche ............................................................................................................................................................................................. 30

This manual is the original manual for operation and installation.

3

Dear customer,

We thank you that you have bought a VIADRUS A0C automatic solid fuel boiler, thus having shown your confidence in VIADRUS brand. In

order to accustom to correct manipulation with your new product. Before installation and commissioning, please carefully acquaintance with the

instruction manual (mainly, chapter 6 – Operation with the stove by an user, chapter No. 7 – Maintenance, and chapter No. 8 – Important

warnings). Please observe the below mentioned information, and at the same time observe instructions of the producer, eventually a mounting

company, which installed your boiler, in order to ensure a long-term trouble-free operation to your and our satisfaction.

1 Usage and advantages of the boiler

Boiler trade name:

VIADRUS A0C

Boiler trade marking:

A0C- X1 X2 X3-X4.X

5

X1 Design: S: standard

A: advanced (with an economizer)

X2 Power: 20: 20 kW

28: 28 kW

X3 Fuel: P: pellets

X4

Revision in this year (boiler actualization)

X5

Year of introduction to the market

A hot-water automatic solid fuel boiler VIADRUS A0C is mainly determined for heating of single-family houses, cottages, small production

premises, etc.

Advantages of the boiler:

• Automatic operation of the boiler controlled by a room device guaranteed comfort;

• Possibility of heating of HW;

• Mechanic supply of fuel from an inbuilt reservoir;

• Simple, quick manipulation and maintenance;

• Low operational costs;

• Low emission;

• Low effectivity;

• Cooperation with an accumulating tank;

• Possibility of control of up to 3 heating circuits.

2 Technical data of the boiler

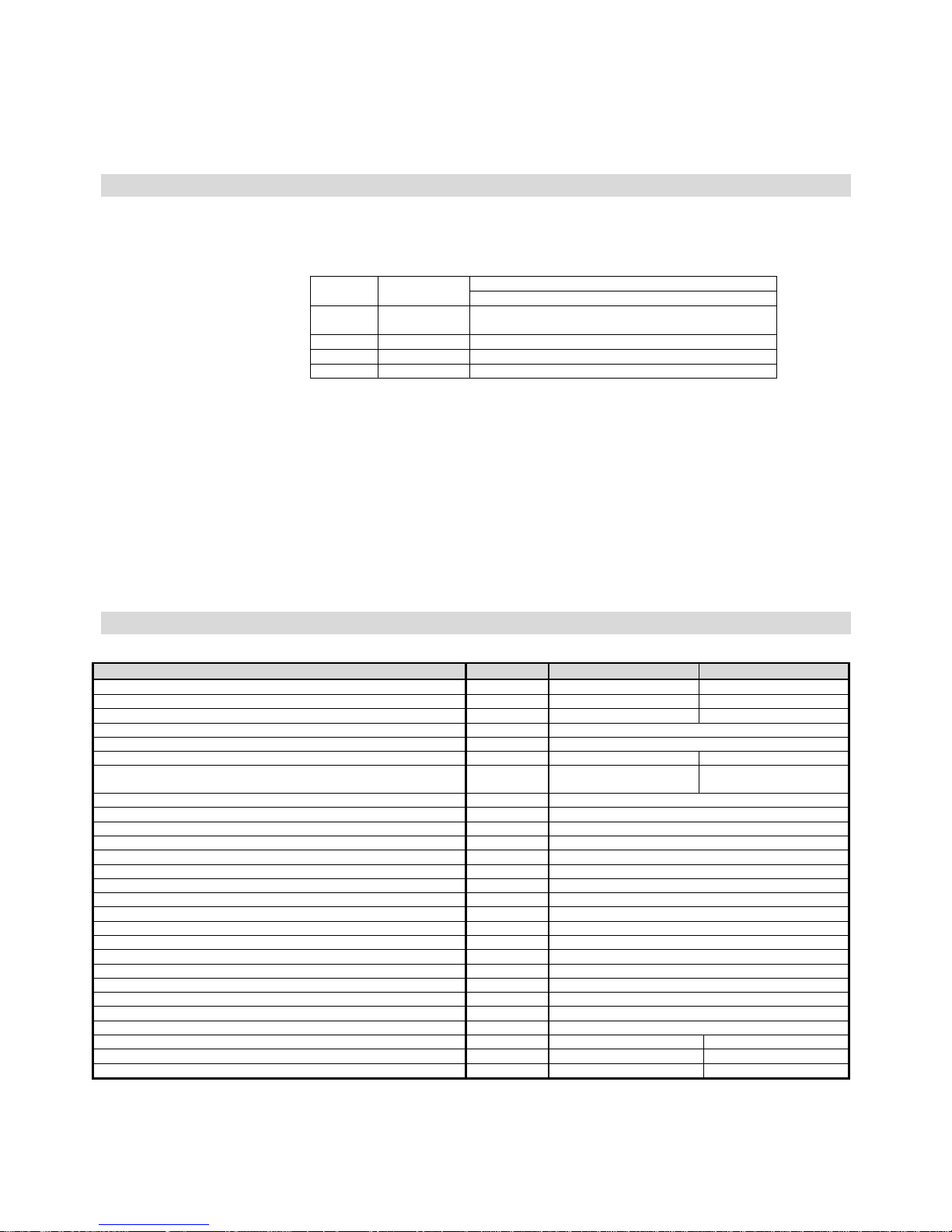

Tab. №. 1 Dimensions, technical parameters of the boiler

Boiler type A0C-X20P-00.16 A0C-X28P-00.16

Sections number pcs 5 7

Boiler weight (incl. the reservoir) kg 356 423

Water content l 40,9 81,3

Chimney throat diameter mm 156

Fuel reservoir capacity dm3 300

Boiler dimensions (incl. the reservoir): width x depth x high mm 1258 x 1207 x 1345 1258 x 1399 x 1345

Boiler dimensions (incl. the reservoir and the economizer):

width x depth x high

1258 x 1639 x 1345 1258 x 1833 x 1345

Receiving hopper capacity l 260

Diameter of the filling hole for manual filling mm 500

Diameter of the filling hole for automatic filling mm 50

Operation water overpressure kPa (bar) 400 (4)

Testing water overpressure kPa (bar) 800 (8)

Recommended operation heating water temperature °C 65 - 85

Minimum return water temperature °C 55

Cold water temperature °C 10

Overpressure for the safety heat-exchanger (DBV 1 – 02) bar 6

Boiler hydraulic loss (at ∆T 20 K) mbar 0,677

Hydraulic resistance coefficient 8,155

Noise level dB Not exceeding the level of 65 dB (A)

Chimney draught mbar 0,10 – 0,20

Boiler connections – heating water Js G 1 ½ “ (6/4“)

– return water Js G 1 ½ “ (6/4“)

Supply voltage 1/N/PE 230V AC 50 Hz TN - S

Electric cover IP 40

Electric energy consumption at the nominal power W 43 49

Electric energy consumption at the minimum power W 19 19

Electric energy consumption at the standby state W 2 2

4

Tab. №. 2 Heating technical parameters of the boiler

Boiler type A0C-X20P-00.16 A0C-X28P-00.16

Sections number pcs 5 7

Nominal power kW 20 28

Fuel consumption at the nominal power kg.h

-

1

4,9 6,7

Flue gases temperature at the nominal power - A0C-SXP/ A0C-AXP °C 211/113 154/109

Combustion time at the nominal power for the filled-up reservoir h 36 24

Minimum power kW 6,4 7,7

Fuel consumption at the minimum power kg/h 1,5 1,8

Flue gases temperature at the minimum power - A0C-SXP/ A0C-AXP

°C 114,5/74 96/70

Combustion time at the minimum power for the filled-up reservoir h 90 85

Minimum chimney draught mbar 0,14 0,14

Fuel heating power MJ.kg

-

1

16,78 16,78

Effectiveness - A0C-SXP/ A0C-AXP % 83,3/90 86,9/91,5

Mass flow rate of flue gases on the output side - A0C-SXP/ A0C-AXP

kg.s

-

1

0,014/0,014 0,018/0,017

Boiler class according to EN 303-5 - A0C-SXP/ A0C-AXP

4/5 4/5

Energy efficiency class A+ A+

Energy efficiency index - A0C-SXP/ A0C-AXP 107/114 113/117

Season energy efficiency - A0C-SXP/ A0C-AXP % 72/77 76/80

! Important warning:

The above specified heat technical parameters can be varied in dependence on a type, quality and humidity of the assessed fuel.

Values specified in table No. 1 and table No. 2 were measured during tests performed with usage of a prescribed fuel.

Pellets have to comply at least with one of the following directives and norms:

Directive No. 14-2000 of the Environmental Ministry of Czech Republic

DIN 517 31

ÖNORM M 7135

Prescribed pellet granulity 6 to 8 mm

Heating power 15 – 19 MJ.kg-1

Water content in fuel max. 12 %.

Ash content max. 1,5 %

WARNING! Bad fuel quality can dramatically negatively influence the output and emission parameters of the boiler.

Fig. №. 1 Boiler hydraulic loss

Power (kW)

Pressure loss pz (Pa)

5

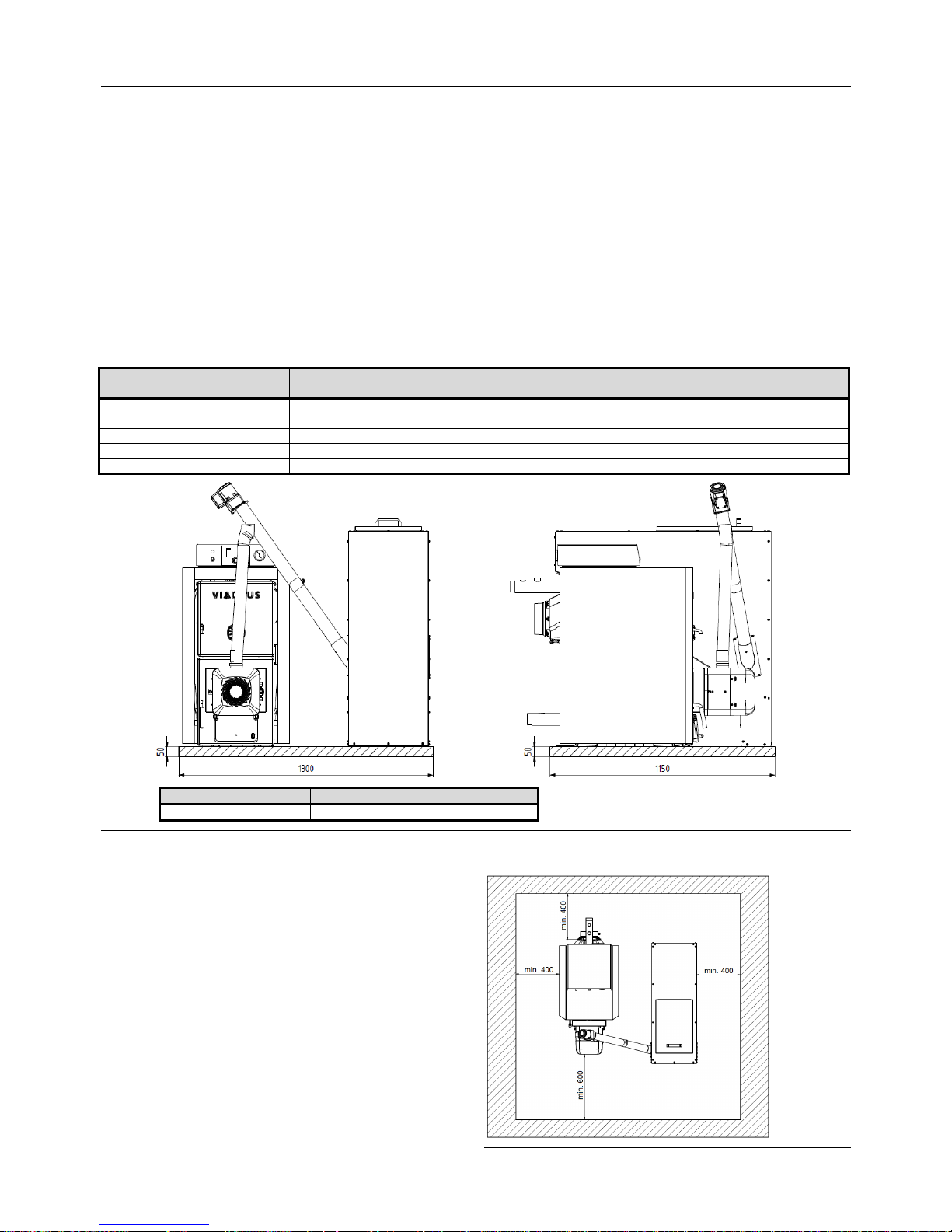

Fig. №. 2 Boiler main dimensions

VIADRUS A0C-S20P-00.16

*VIADRUS A0C-A20P-00.16

VIADRUS A0C-S28P-00.16

*VIADRUS A0C-A28P-00.16

6

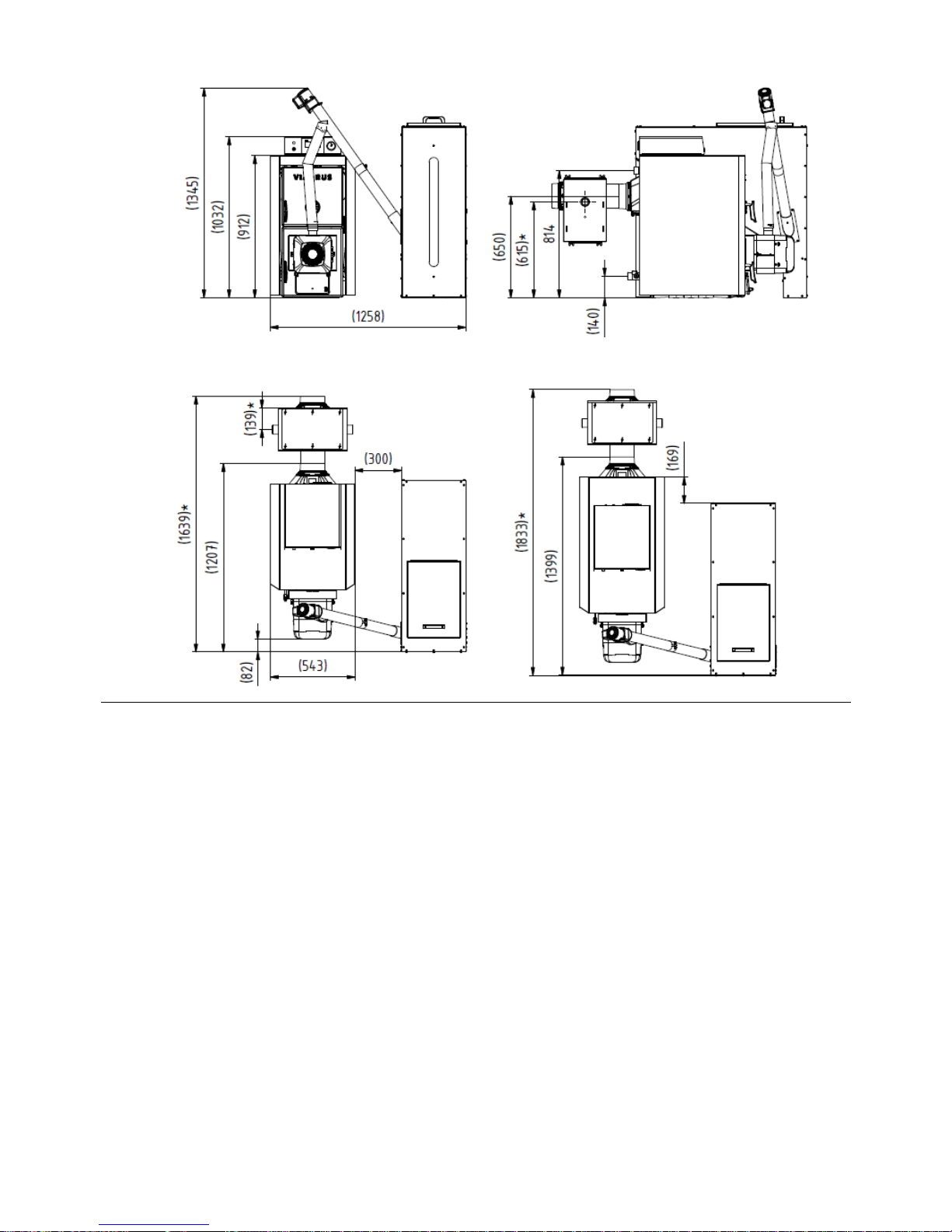

3 Description

3.1 Boiler structure

The main part of the boiler is the sectional boiler drum made from grey cast iron according to EN 1561 grade 150.

Pressurized parts of the boiler complies with requirements for stiffness according to EN 303-5.

The boiler drum is assembled from sections by means of pressed boiler insertions and is fixed by anchor bolts. The sections create the heating

and ash space, the water space and the convection part. The heating water input and output are situated in the rear part of the boiler.

The rear section of the boiler has in its upper part a chimney pot and a heating water flange, in its bottom part has a return water flange with a

mouthpiece for a filling and draining cock. The cleaning and ash doors with an inbuilt burner are fixed to the front section.

The whole boiler drum is isolated by healthy mineral insulation, which decreases losses caused by heat transmission to the surroundings. The

steel cladding is painted by quality comaxite paint coat.

A pellet burner of PellasX is mounted in the ash door. In the version VIADRUS A0C-S20P it is a burner PellasX Hybrid mini, and in the version

VIADRUS A0C-S28P it is a burner PellasX Hybrid 35. These burners are equipped with a fan.

On the right (on the left) from the boiler it is placed a steel-sheet pellet reservoir with a capacity of 300 l. The reservoir is connected with the

burner by means of a feeder and a connecting hose.

An electric cabinet, in which the control unit and a display are situated, is mounted on the upper part of the cladding.

The unit is supplied in two versions. The S.Control with button control or the S.Control Touch with touch display.

1. Front section

2. Central section

3. Rear section

4. Stocking door (with a rosette of primary air)

5. Ash door

6. Chimney pot

7. Burner sealing

8. Burner PellasX

9. Connecting hose

10. Feeder

11. Reservoir

12. Cladding (complete)

13. Control cabinet

14. Regulator control elements (S.Control / Touch)

15. Heating water pipe

16. Ash-pan

17. Burner flange

18. Flange insulation

19. Return water pipe

20. Baffle

21. Upper insulation of the stocking door

22. Bottom insulation of the stocking door

23. Upper insulation of the ash door

24. Bottom insulation of the ash door

25. Securing valve

26. Burner pipe

27. Bushing

Fig. №. 3 Boiler main parts

7

Fig. №. 4 VIADRUS A0C-X20P - burner PellasX Hybrid

mini

Fig. №. 5 VIADRUS A0C-X28P - burner PellasX Hybrid 35

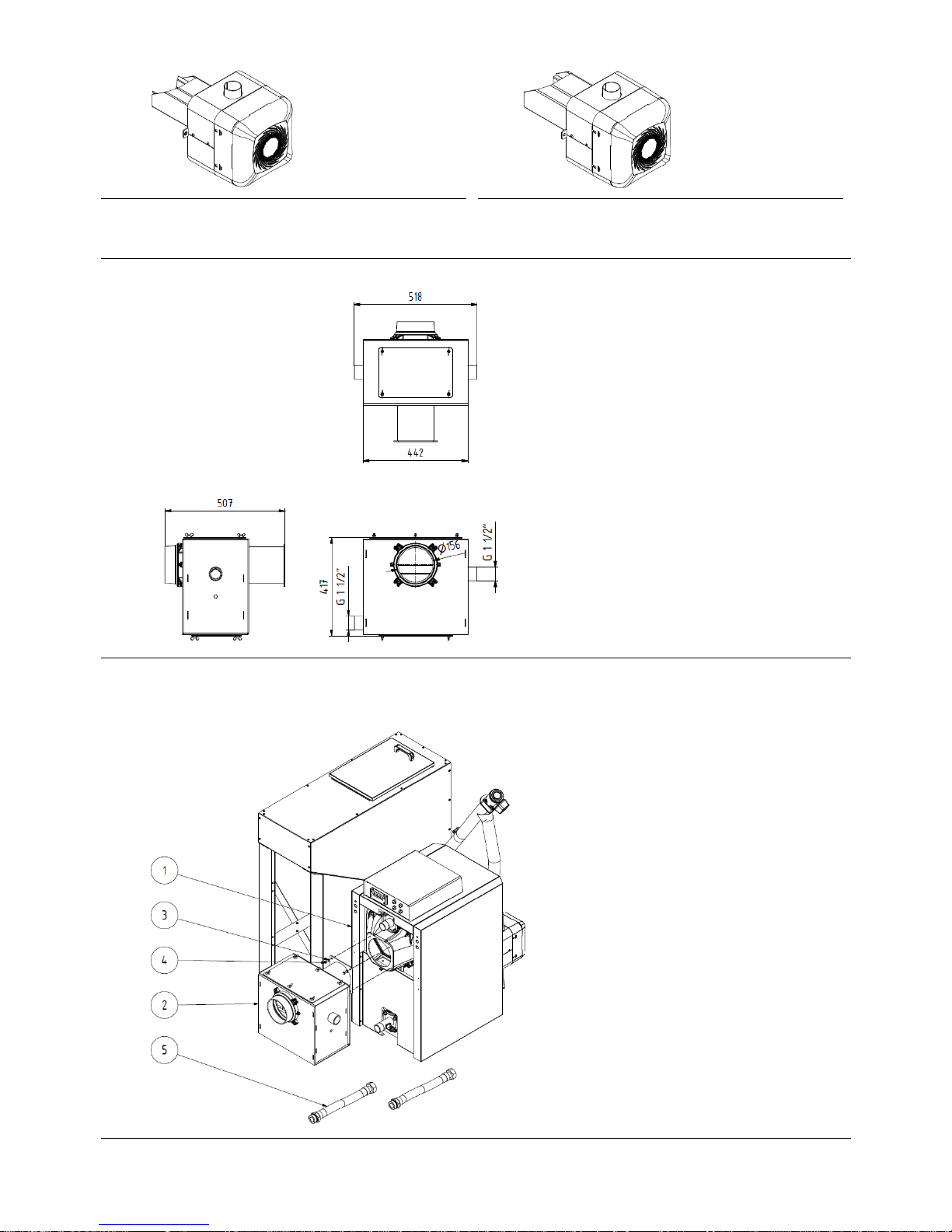

3.2 Economizer

Auxiliary equipment serving for getting the 5th emission class of the boiler.

Fig. №. 6 Economizer

3.2.1 Mounting of the economizer

Fig. №. 7 Mounting of the economizer

1. Boiler VIADRUS A0C

2. Economizer

3. Washer 8,4 (4 pcs)

4. Screw M8 x 20 (4 pcs)

5. Connecting hose

1. Put the economizer (2) on the chimney pot of the boiler

2. Screw up it with help of 4 pcs of the screws M8 (4) and the

washers 8,4 (4)

3. Connect the hose (5) and connect it to the output of the

economizer and to the return water pipe.

8

4 Placement and installation

4.1 Regulations and directives

The boiler complies with requirements of the following norms:

EN ISO 12100:2011 Safety of machine equipment – General principle for design – Assessment of risk and risk decreasing

EN 953+A1:2009 Safety of machine equipment – Protective covers – General requirements for design and production of firm and

movable protective covers

ČSN ISO 1819:1993 Equipment for continuous conveyance of loads. Safety rules. General provisions

ČSN ISO 11202:2010 Acoustics – Noise emitted by machines and equipment – Determination of levels of emission pressure on the

personnel working place and in other specified places with using of approximate corrections for environment

EN ISO 3746:2011 Acoustics - Determination of levels of acoustic power and levels of acoustic energy of noise sources by means of

acoustic pressure – Operation method with a measuring envelope above the reflective plane

EN 303-5:2013 Boilers for central heating - Part 5: Solid fuel boilers for central heating, with manual and automatic supply, with

nominal heat power up to 500 kW - Terminology, requirements, tests and marking

ČSN 061008:1997 Fire safety of heating equipment

EN 62233:2008 Measuring methods for electromagnetic fields for household and similar devices from the point of view of

exposition of persons

EN 60335 change A1 Safety of electric consumers for household and similar purposes. Part 1: General requirements

EN 15036-1:2007 Boilers for central heating – Testing rules for measurement of noise spread by air emitted by a heat source – Part

1: Emission of noise spread by air from heat sources

The boiler has to be only installed by a company which has authorization for performance of its installation and maintenance.

A project according to valid regulations has to be worked out for installation of the boiler.

The heating system has to be filled up by water, which complies with requirements of ČSN 07 7401, and mainly its hardness mustn’t

exceed the required parameters.

Tab. №. 3

Recommended values

Hardness mmol/l 1

Ca2+ mmol/l 0,3

Concentration of total Fe + Mn mg/l (0,3)*

*) recommended value

ATTENTION!!! The producer doesn’t recommend using of antifreezers.

a) for the heating system

ČSN 06 0310 Heat systems in buildings – Design and mounting

ČSN 06 0830 Heat systems in buildings – Securing devices

ČSN 07 7401 Water and steam for heat energetic equipment with steam operation pressure up to 8 MPa.

EN 303-5 Boilers for central heating – Part 5: Solid fuel boilers for central heating, with manual and automatic supply, with

nominal heat power up to 500 kW - Terminology, requirements, tests and marking.

b) for the chimney

ČSN 73 4201 Design of chimneys and flue gas ducts.

c) regarding to fire-fighting regulations

ČSN 06 1008 Fire safety of heat equipment.

EN 13501-1+A1 Fire classification of building products and building structures – Part 1: Classification according to results of tests

for reaction to fire.

d) for the hot water heating system

ČSN 06 0320 Heat systems in buildings – Preparation of hot water – Development and design.

ČSN 06 0830 Heat systems in buildings – Securing devices.

ČSN 75 5409 Inside water distributions

e) for electric network

ČSN 33 0165 Electric-technical regulations. Marking of conductors by colors or digits. Execution of provisions

ČSN 33 1500 Electric-technical regulations. Revisions of electric devices.

ČSN 33 2000-1 ed. 2 Low voltage electric installation – Part 1: Basic aspects, determination of basic characteristics, definitions

ČSN 33 2000-4-41 ed. 2 Low voltage electric installation – Part 4-41: Protective measures to ensure safety – Protection against electric

shock

ČSN 33 2000-5-51 ed. 3 Low voltage electric installation – Part 5-51: Selection and construction of electric devices – General regulations

ČSN 33 2130 ed. 2 Low voltage electric installation – Inside electric distributions

ČSN 33 2180 Electric-technical regulations. Connection of electric devices and consumers.

ČSN 34 0350 ed. 2 Safety requirements for movable power supplies and cords

EN 60079-10-1 Explosive atmospheres – Part 10-1: Determination of dangerous premises – Explosive gaseous atmospheres

EN 60079-14 ed.3 Explosive atmospheres – Part 14: Development, selection and performance of electric installations

EN 60252-1 ed. 2 Capacitors for AC motors – Part 1: In general – Fulfilment, testing, dimensioning – Safety requirements –

Instructions for mounting and operation.

EN 60335-1 ed.2 Electric consumers for household and similar purpose – Safety – Part 1: General requirements.

EN 60335-2-102 Electric consumers for household and similar purpose – Safety – Part 2-102: Special requirements for consumers

combusting gaseous, oil and solid fuels, containing electric connections.

EN 60445 ed. 4 Basic and safety principles for the human-machine interface, marking and identification – Identification of clamps

of subjects, ends of conductors and conductors

EN 61000-6-3 ed. 2 Electromagnetic compatibility (EMC) – Part 6-3: Generic norms – Emission – Residential, trade and light-industry

environment.

EN 61000-3-2 ed. 3 Electromagnetic compatibility (EMC) - Part 3-2: Limits – Limits for emission of harmonic currents (equipment with

input phase current <= 16 A).

EN 61000-3-3 ed. 2 (ed. 3) Electromagnetic compatibility (EMC) – Part 3-3: Limits – Limitation of changes of voltage, fluctuation of voltage

and flickers in low voltage distribution networks with the nominal phase current <= 16 A, which is not a subject of

conditional connection.

9

4.2 Possibility of placement

During boiler mounting and operation it is necessary to observe all requirements of ČSN 06 1008.

It is prohibited to place the boiler in a residential premise (including corridors)!

Placement of the boiler in the view of fire regulations:

1. Placement on the floor from inflammable material

− Install the boiler on an inflammable, heat-insulated basement exceeding the ground-plan of the boiler with the reservoir on sides by 20

mm.

− If the boiler is placed in a cellar, we recommend to install it on a supporting brickwork with the high at least 50 mm. The boiler has to

stay horizontally, possible unlevelnesses of the supporting brickwork are to be eliminated by means of a regulating screw of the motor

seat.

2. Safety distance from flammable materials

− During installation and at operation of the boiler it is necessary to observe a safety distance 200 mm from flammable materials with the

combustibility grade A1, A2, B and C (D);

− For lightly combustible materials with the combustibility grade E (F), which quickly burn and burn themselves even after removal of the

ignition source (for example, paper, paste-board, cardboard, asphalt- and tarboard, wood and fiberboards, plastics, floor cloths) the

safety distance is doubled, it means to 400 mm;

− The safety distance is to be also doubled in case when the grade of reaction to fire is not proven.

Tab. №. 4 Grade of reaction to fire

Grade of reaction to fire

Examples of building materials and products included in the reaction of fire

(extract from EN 13501-1+A1)

A1 – incombustible

Granite, sandstone, concrete, bricks, ceramic tiles, mortars, fireproof plasters,...

A2 – hardly combustible

acumin, izumin, heraklit, lignos, boards and basalt felt, fibreglass boards,...

B – heavily combustible

Beech and oak wood, hobrex boards, plywood, werzalit, umakart, sirkolit,...

C (D) – moderately combustible

Pinewood, larch, whitewood, chipboard and cork boards, rubber flooring,...

E (F) – lightly combustible

Asphaltboard, fibreboards, cellulose materials, polyurethane, polystyrene, polyethylene, PVC,...

A0C-X20P-00.16 A0C-X28P-00.16

L [mm]

1150 1350

Fig. №. 8 Sizes of a supporting brickwork

Placement of the boiler with regard to a needed manipulation

space:

• basic environment AA5/AB5 according to ČSN 33 2000-1 ed. 2,

• in front of the boiler it is necessary to have a manipulation space

at least 600 mm,

• the minimum distance between the rear part of the boiler and a

wall 400 mm,

• on the side of the fuel reservoir – a gap at least

400 mm for a case of extraction of a feeding auger,

• the minimum distance from the side wall of the boiler 400 mm,

• above the boiler – at least 450 mm to enable cleaning-up of the

convection surface of the heat-exchanger.

Placement of the boiler with regard to an electric network:

• the boiler has to be placed so that the plug in the socket (230

V/50 Hz) was always accessible.

Fig. №. 9 Placement of the boiler in the boiler-room

10

Placement of fuel:

• For correct combustion in the boiler it is necessary to use dry fuel. The producer recommends to stock fuel in cellar premises or at

least under a penthouse,

• The producer recommends to observe distance between the boiler and fuel at least 1 000 mm, or place fuel to the room than the boiler.

It is necessary to provide constant supply of air for combustion and possible ventilation into the room where the boiler is installed (air

consumption of the boiler VIADRUS A0C-S20P is about 75 m3. h

-1

and the boiler VIADRUS A0C-S28P is about 105 m3. h-1). Connection of a

pipeline of the heating system, as well as an eventual pipeline of the heating insertion of the heater, has to be performed by an authorized

person.

WARNING: On connection of the boiler to the heating system it is necessary to place a discharging cock in the lowest place

and as close as it possible to the boiler.

5 Commissioning – instructions for contractual service organizations

Only contractual service organization authorized for performance of this activity has the right to perform commissioning of the

boiler.

5.1 Delivery and accessories content

The boiler VIADRUS A0C is supplied so that the complete boiler drum is situated on one pallet. The boiler cladding is packed separately.

Accessories laid inside the boiler drum are accessible after opening the cleaning door. The second pallet includes a burner, a fuel feeder and

their accessories. The boiler is packed in a transporting package and mustn’t be tripped during transportation; it is only allowed to incline to

sides to demount the package from the boiler drum.

Standard accessories:

• 1 pc boiler drum on a pallet with the corresponding number of sections

− 1 pc combustion space barrier – middle part

− 3 pcs combustion space barrier (A0C-X20P)

− 4 pcs combustion space barrier (A0C-X28P)

• 1 pc boiler drum cladding

− cladding insulation

− ash-pan with appropriate size

− holder for cleaning tools – type 2

• 2 pcs heating and return water pipe G 1 1/2"

• 1 pc cleaning tools - handle

• 1 pc pack

• 1 pc production label

• 1 pc control cabinet with electronics SControl/SControl Touch

• 1 pc burner PellasX according to a size

• 1 pc burner pipe

• 1 pc burner flange

• 3 pcs burner insulation

• 1 pc burner sealing

• 1 pc feeder PellasX

− 1 pc upper feeder pipe

− 1 pc bottom feeder pipe

− 1 pc feeder sealing

− 1 pc feeder motor

− 1 pc gear-box

− 1 pc sealing

• 1 pc manual for boiler operation and mounting

• 1 pc warranty certificate

• 1 pc list of contractual service organizations

The pack:

• 1 pc boiler plug G 1 1/2“ - blind

• 1 pc plug sealing Ø 60x48x2

• 2 pcs flange sealing 90 x 60 x 3

• 2 pcs door hinge

• 1 pc filling and discharging cock G 1/2“

• 1 pc manipulating wrench

• 1 pc brush

• 1 pc tip for piercer

• 1 pc handle 503a – 514

• 1 pc socket wrench with a handle - hexagonal 902-13

• 1 pc capillary spring

• 1 pc corrugated spring

• 1 pc thermowell

• connecting material:

− 5 pcs nut M8

− 3 pcs washer 8 (large-area)

− 12 pcs nut M10

− 4 pc washer 5,3

− 4 pc washer 6,4

11

− 2 pcs washer 8,4

− 12 pcs washer 10,5

− 4 pc connecting thorn

− 8 pc screw M5 x12

− 6 pc screw ST 4,2 x 9

− 4 pc spring clip

Obligatory accessories (it is not a part of supply):

• 1 pc securing valve according to max. operation overpressure of the boiler (see table No. 1)

On request:

• 1 pc outdoor sensor CT4 – P

• 1 pc room regulator ecoTOUCH

• 1 pc internet module NET CONTROL

• 1 pc securing valve

• 1 pc sensor CT4 – 4 m

• 1 pc reservoir

− 1 pc front metal sheet of the reservoir

− 1 pc rear metal sheet of the reservoir

− 1 pc right side metal sheet of the reservoir

− 1 pc left side metal sheet of the reservoir

− 1 pc upper metal sheet of the reservoir

− 1 pc reservoir leg

− 1 pc reservoir leg 2

− 1 pc reservoir cover

− 1 pc transversal part of the reservoir

− 1 pc feeder flange

− 1 pc hole cover

− 2 pcs reservoir brace

− 1 pc blind flange

− 1 pc transversal part 2 of the reservoir

• connecting material for the reservoir

− 2 pcs washer 5,3

− 2 pcs nut M5

− 2 pcs washer

− 9 pc screw ST 4,2 x 9,5 (ISO 7050)

− 4 pc screw ST 4,8 x 13

− 74 pc screw M5 x 12

− 2 pcs screw M6 x 12

− 1 pc piano hinge

− 1 pc handle

The boiler equipment ordered „on request“ is not included to the basic boiler price.

5.2 Mounting procedure

5.2.1 Boiler drum installation

1. Place the boiler drum onto the supporting brickwork.

2. Mount to the upper part of the rear boiler section the sealing φ 90 x 60 x 3 (1) and screw up the heating water flange (2), and connect the

other end to the heating system.

3. Mount to the bottom flange part of the rear boiler section the sealing φ 90 x 60 x 3 (5) and screw up the return water flange with a

mouthpiece (6) for a filling and discharging cock, and connect the other end to the heating system.

4. After connection the boiler to the heating system, screw up an elbow (9) with the filling and discharging cock into the mouthpiece of the

return water flange.

5. Screw up the thermostat well G 1/2“into the hole in the upper part of the rear section (see fig. 10).

Fig. №. 10 Thermowells mounting

6. Blind the hole with the thread Js 6/4" in the front section by a plug Js 6/4". Place sealing φ 60 x 48 x 2 under the plug.

7. Mount the chimney pipe to the chimney pot and insert it to the chimney hole.

1 Backward valve of the manometer

2 Thermostat well

Loading...

Loading...