Page 1

Table of Contents Rev. 9/19/2018 SWA, MANUAL

Table of Contents

Limited Warranty…...……………………………………………………………………………………………………… 19

Vestil Manufacturing Co.

www.vestilmfg.com

SWA-50, SWA-70, & SWA-51-AR Semi-Automatic Stretch Wrap Machines

Instruction Manual

Receiving instructions:

After delivery, remove the packaging from the product. Inspect the product closely to determine

whether it sustained damage during transport. If damage is discovered, record a complete description

of it on the bill of lading. If the product is undamaged, discard the packaging.

NOTE:

The end-user is solely responsible for confirming that product design, use, and maintenance

comply with laws, regulations, codes, and mandatory standards applied where the product is used.

Replacement Parts and Technical Assistance:

For answers to questions not addressed in these instructions and to order replacement parts,

labels, and accessories, call our Technical Service and Parts Department at (260) 665-7586. The

department can also be contacted online at http://www.vestilmfg.com/parts_info.htm

Specifications…………….…………………………………..……………………………………………………………… 2

Signal Words….……………………………………………………………………………………………………… …….. 2

Hazards of Improper Use……………………………………………………………………..…………………….. …….. 3

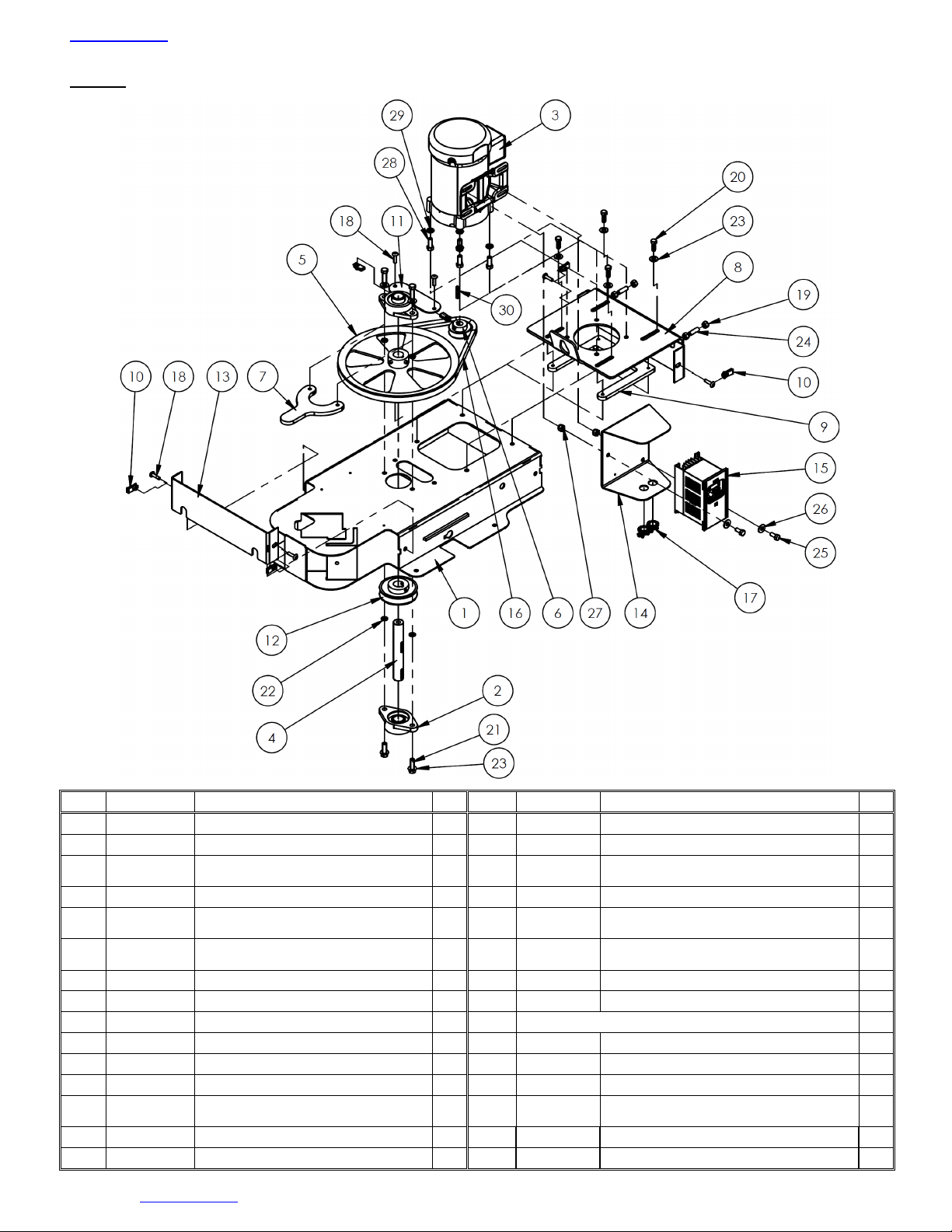

FIG. 1: SWA-50 exploded parts diagram & bill of materials……………………………………………………………. 4

FIG. 2A: Stretch wrap carriage subassembly exploded parts diagram & bill of materials…………………… …….. 5

FIG. 2B: Manual counterbalanced mast subassembly exploded parts diagram & bill of materials………… …….. 5

FIG. 2C: Thrust bearing subassembly exploded parts diagram & bill of materials…………………………… …….. 5

FIG. 3: Power unit subassembly with sheave exploded parts diagram & bill of materials…………………... …….. 6

FIG. 4: SWA-70 exploded parts diagram & bill of materials…………………………………………………….. …….. 7

FIG. 5: SWA-51-AR exploded parts diagram & bill of materials………………………………………………………. 8

FIG. 6: Electrical system diagram………………………………………………………………………………….. …….. 9

FIG. 7: Powered mast electrical diagram…………………………………………………………………………. …… 10

Delta Motor Speed Controller………………………………………………………………………………………. …… 11

Installation……………………………………………………………………………………………………………. 12 – 13

Stretch Wrap Holder Assembly……………..……………………………………………………………………… …… 13

Belt Tensioning Procedure …………..

Use Instructions……………………………………………………………………………………………………… 15 – 16

Inspections & Maintenance……………………………………………………………………………………………….. 16

Labeling Diagram…………..…...…………………………………………………………………………………………. 17

Troubleshooting……………………………………………………………………………………………………………. 18

…………………………………………………………........................... 14 – 15

.

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 1 of 19

Page 2

Table of Contents Rev. 9/19/2018 SWA, MANUAL

Turntable

diameter

Maximum

service height

SWA-50

50in. (127cm)

82in. (208.3cm)

2in. (5cm)

4,000lb. (1,818kg)

499lb. (~226.8kg)

SWA-70

70in. (178cm)

82in. (208.3cm)

21/4in. (5.7cm)

4,000lb. (1,818kg)

926lb. (~420.9kg)

SWA-51-LP

51in. (129.5cm)

83in. (211cm)

1in. (2.5cm)

4,000lb. (1,818kg)

470lb. (~214kg)

Model

SWA-5070LP-PMO

Powered mast option (50in. and 70in. diameter)

400lb. (~181.8kg)

SWA-50-R-4848

Approach ramp: 48in. x 48in. x 2in. (W x L x H)

150lb. (~68.2kg)

SWA-70-R-4848

Approach ramp: 48in. x 48in. x 2in. (W x L x H)

268lb. (~121.8kg)

SWA-50-SCALE

Digital scale (50in. diameter)

680lb. (~309.1kg)

SWA-70-SCALE

Digital scale option (70in. diameter)

884lb. (~401.8kg)

SWA-50-R-4860-SCL

Approach ramp for scale option

346lb. (~157.3kg)

SWA-70-R-4860-SCL

Approach ramp for scale option

335lb. (~152.3kg)

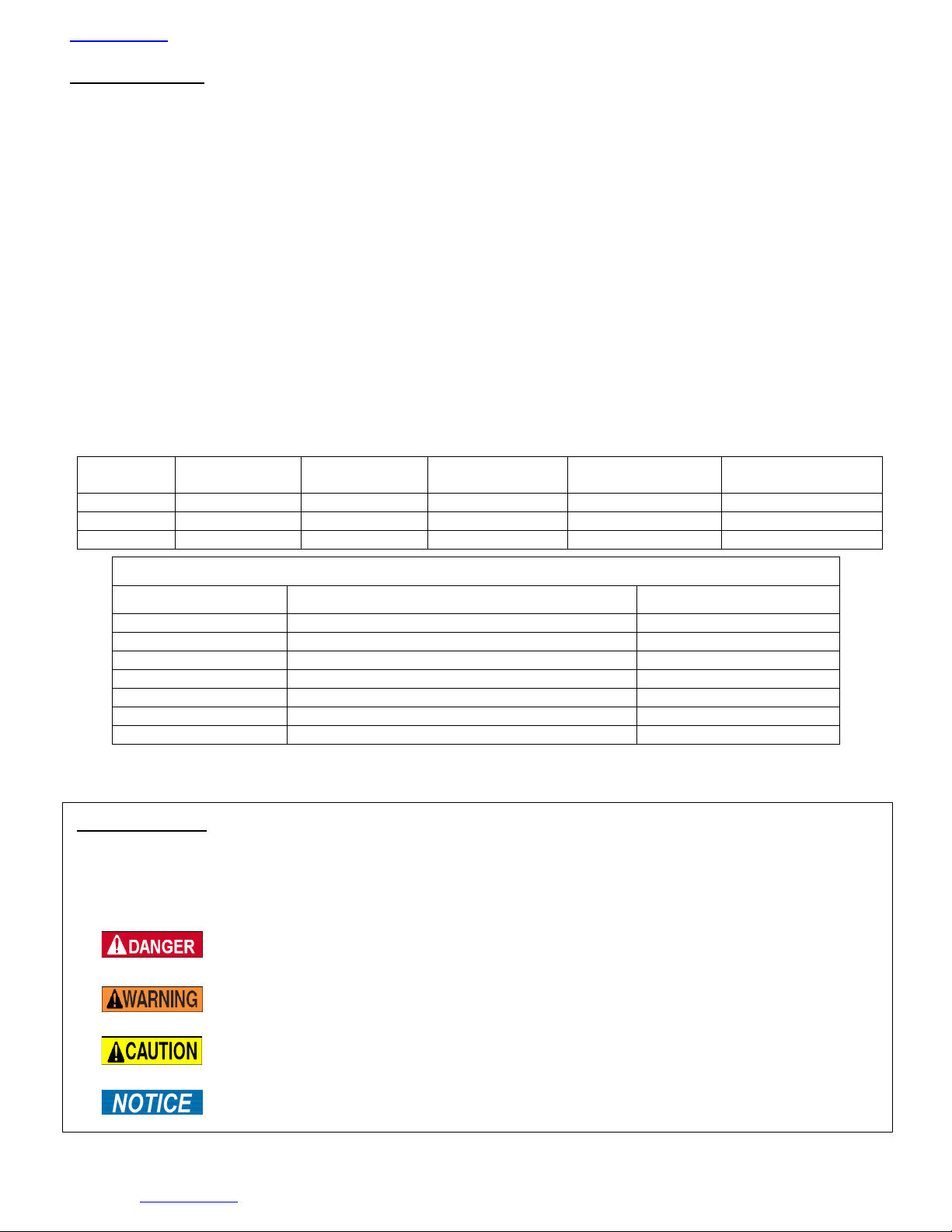

Specifications

Thank you for purchasing a semi-automatic stretch wrap machine made by Vestil Manufacturing Company

(“Vestil”). Our wrapping machines are designed for dependability and incorporate numerous safety-enhancing

features. Although use and maintenance procedures are relatively intuitive, all persons who might use or maintain

this product must familiarize themselves with the instructions provided in this manual.

Notable features of standard models include:

• Carousel rotation controlled by a (foot) pedal switch connected to an 8 foot cord. The standard 115V,

variable AC motor allows adjustable rotation speeds of 3-12 rpm and includes soft-starting and stopping

capability.

• Adjustable stretch-wrap tension controlled by a friction-brake assembly. Film placement is controlled

manually by moving the carriage assembly up and down on the vertical mast. An easy-to-release, hand

operated carriage-brake allows the carriage to move freely making film application fast and simple.

• Adaptability to use stretch wrap rolls 10"-20" long.

• Minimal assembly is necessary. Each wrapping machine is shipped with the mast disconnected.

Assembly simply requires raising the mast and bolting it in place.

• The stretch-wrap delivery mechanism can be upgraded to a 115V, single phase, AC-powered mast option

(PMO).

• Ability to be used in conjunction with an optional ramp, which allows the operator to load and unload the

machine with a pallet truck.

Dimensions and other product specifications of standard wrapping machine models appear in the following

tables:

Model

Turntable height Uniform capacity Net weight

Optional equipment

Description Weight in pounds (~kg)

Signal Words

This manual uses SIGNAL WORDS to draw the reader’s attention to safety-related information. Signal words

indicate the likelihood of personal injuries as well as the probable seriousness of those injuries, if the product is

misused in the ways described. Other signal words call attention to uses of the product likely cause property

damage. Signal words used in this manual appear below along with the meaning of each word:

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or SERIOUS

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or

Identifies practices likely to result in product/property damage, such as operation that

INJURY. Use of this signal word is limited to the most extreme situations.

SERIOUS INJURY.

MODERATE injury.

might damage the product.

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 2 of 19

Page 3

Table of Contents Rev. 9/19/2018 SWA, MANUAL

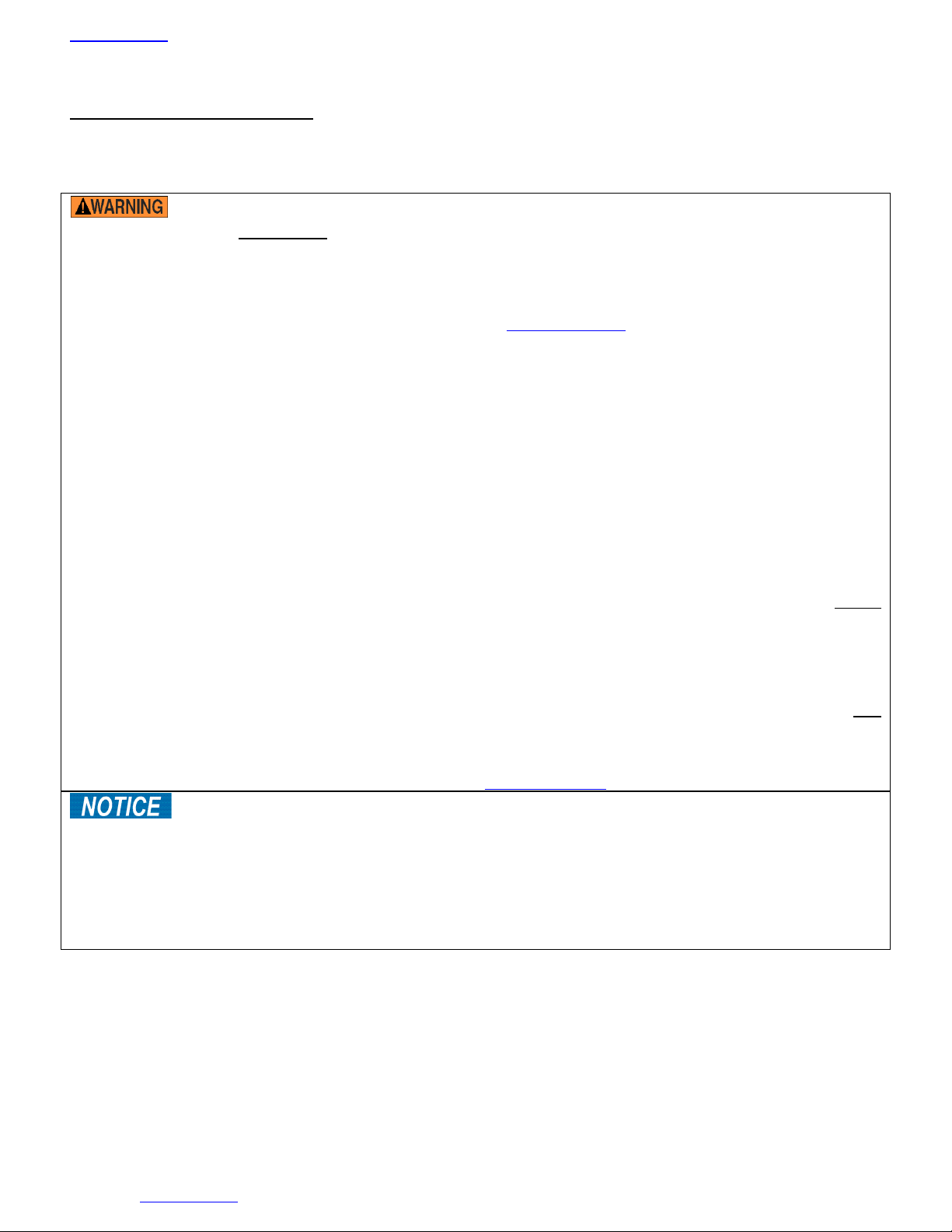

Hazards of Improper Use

Vestil diligently strives to identify foreseeable hazards associated with the use of its products. However, material

handling is inherently dangerous and no manual can address every conceivable risk. The end-user ultimately is

responsible for exercising sound judgment at all times.

Failure to read and understand the entire manual before assembling, installing, using and

servicing the product is a misuse of the product. If this product is used improperly or carelessly, the operator

and/or bystanders might sustain serious personal injuries. To reduce the likelihood of injury:

• DO NOT modify the product in any way UNLESS you first obtain written approval from Vestil. Unauthorized

modifications automatically void the Limited Warranty and might make the product unsafe to use.

• Read the manual to refresh your understanding of proper use and maintenance procedures.

• DO NOT exceed the maximum rated load. See Label 287 in Labeling diagram on p. 17.

• DO NOT stand or sit on the turntable or on the load at any time.

• Loads must not extend over the shelves of the cart.

• Install the machine ONLY on even, level surfaces where the machine will not be exposed to the outdoor

environment.

• Keep hand, clothing, etc. out of contact with all moving parts of the machine.

• BEFORE using the wrapping machine, instruct all bystanders to stand away from the machine and the item to be

wrapped.

• The person operating the turntable should stand where the mast is between him and the turntable.

• DO NOT activate the turntable UNLESS the load is centered on it and stable. Be prepared to stop the turntable,

because rotation can cause the load to shift and become unstable. Because an unstable load might topple during the

wrapping process, EVERY person involved should remain far enough away from the machine to avoid contact with

the load if it falls. Higher rotation speeds can cause an unstable load to be flung from the turntable.

• DO NOT continue to use the machine if you observe abnormal motion or noise. Immediately tag the unit “Out of

service” and report the problem to maintenance personnel.

• DO NOT attempt to resolve any problem(s) with the product unless you are both authorized to do so and certain

that it will be safe to use afterwards.

• Inspect the product before each use:

A. DO NOT use this product if the inspection reveals structural damage. Examples of structural damage

include, but are not limited to, the following: 1) Cracked, broken or significantly deformed frame, mast or

turntable; 2) cracked welds; 3) corrosion, severe wear, or other condition that affects the ability of the product to

support weight. Replace each part that fails to pass an inspection, and DO NOT use the product until it is fully

restored to normal condition.

B. DO NOT use the product if any unusual noise or movement is observed. If a malfunction occurs, remove

the unit from service and notify your supervisor & maintenance personnel about the issue.

• DO NOT use this device UNLESS all product labels (see Labeling Diagram) are readable and undamaged.

Proper use, maintenance, and storage are essential for this product to function properly.

o Always use this product in accordance with the instructions in this manual and consistent with any training relevant

to machines, devices, etc. used in conjunction with this product.

o Periodically lubricate the chain.

o Keep the product clean & dry.

o Vestil uses only quality parts to make the equipment we manufacture. Vestil bears no responsibility for problems

that result as a consequence of using unapproved replacement parts. To order replacement or spare parts for this

equipment, contact the factory.

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 3 of 19

Page 4

Table of Contents Rev. 9/19/2018 SWA, MANUAL

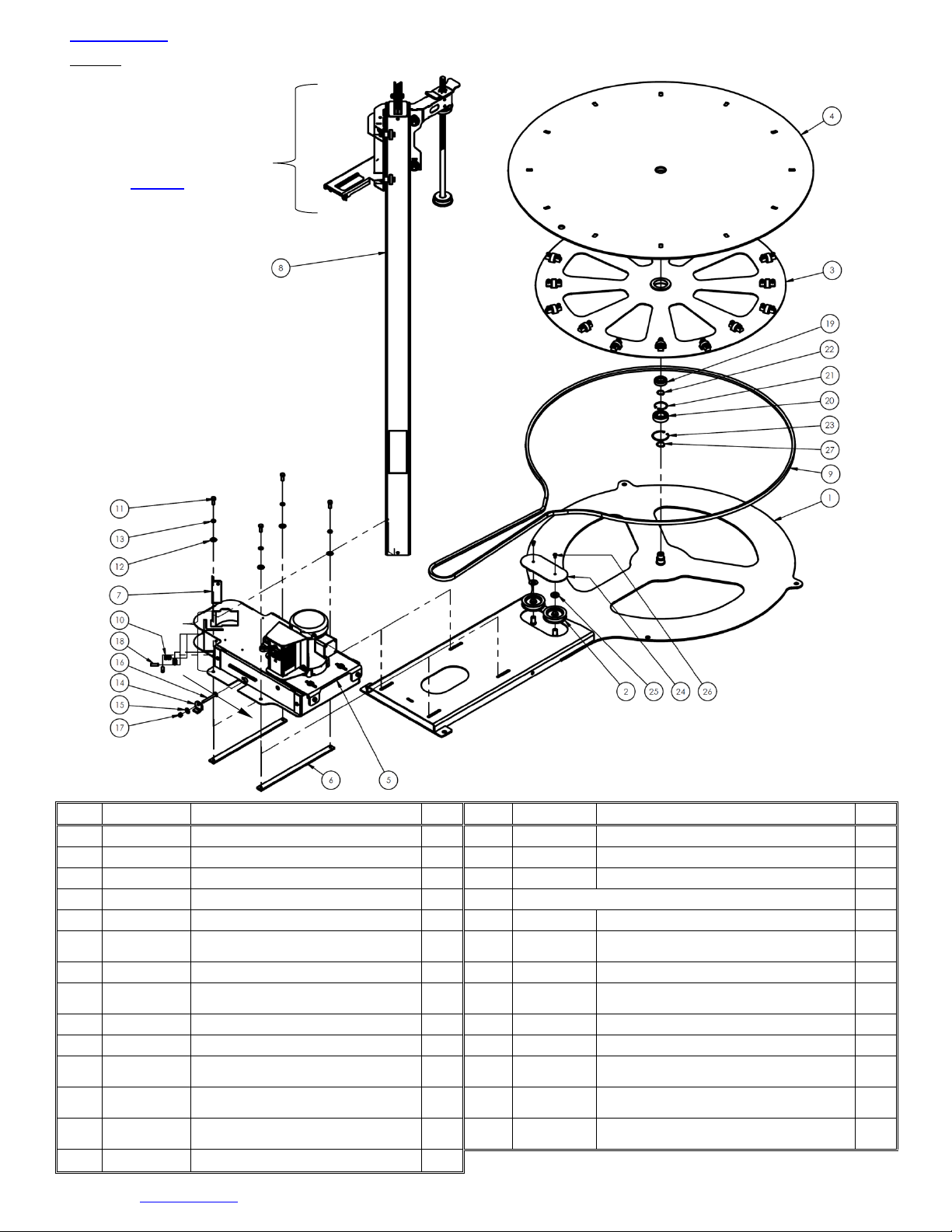

Stretch wrap carriage

Item

Part no.

Description

Qty

Item

Part no.

Description

Qty

5

2

20-027-012

Belt idler

2

16

21265 5/16in. – 18 UNC x 3in. zinc-plated bolt

1

5

4

20-513-098

Weldment, SWA-50 deck

1

18

SSFLASKT 0.375-16x1.25-HX-N

2

6206 bearing, 1.18 ID x 2.44 OD x 0.62

thick

7

20-014-117

Frame, bar, squeeze

1

21

20-117-001

Internal retaining ring, 2in.

1

Subassembly, counterbalanced mast,

manual (see FIG. 2B on p.5)

External retaining ring, 1in. diameter

shaft

10

36106

3

/8in. – 16 zinc-plated hex nut

4

24

20-024-025

Cover plate, idler access

1

3

/8in. – 16 x 1in. HHCS #2 zinc-plated

bolt

Hex bolt, grade A, zinc plated, 1/4in. – 16

x 1/2in.

External retaining ring, phosphate finish,

11/8in.

FIG. 1: SWA-50 Exploded Parts Diagram & Bill of Materials

subassembly (part no. 20538-005 shown in exploded

form in

FIG. 2A on p. 5).

1 20-514-078 Weldment, base frame 1 15 33006

3 20-610-001 Subassembly, thrust bearing 1 17 37021

5 20-160-001 Power unit subassembly with sheave 1 19 20-110-001 Single row ball bearing, shielded, R16Z 1

6 20-113-024 Spacer, plate 2 20 20-110-022

8 20-514-084

9 20-027-007 Belt, B190 (large belt) 1 23 20-117-005 Internal retaining ring, 27/16in. 1

11 11105

12 33008

13 33622

14 20-016-096 Bracket, tensioning, formed 1

3

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 4 of 19

/8in. USS zinc-plated flat washer 4 26 11001

3

/8in. zinc-plated lock washer 4 27 68021

1 22 20-117-003

4 25 33090

/16in. USS zinc-plated flat washer 1

/16in. – 18 #2 zinc-plated Nylon lock nut 1

5

/8in. SAE flat washer 2

1

1

2

1

Page 5

Table of Contents Rev. 9/19/2018 SWA, MANUAL

Item

Part no.

Description

Quantity

1

20-514-080

Weldment, carriage frame

1

Specialty hardware, clamp, wrap,

mounting

3

21-113-021

Spacer, bearing shaft

8

3

/8in. – 16 x 11/2in. HHCS #2

zinc—plated bolt

3

/8in. – 16 x 2in. HHCS #2 zinc—

plated bolt

7

20-040-001

Lever, brake release, formed

1

9

20-113-023

Spacer

1

3

3

14

64076

1

/8in. x 1in. zinc-plated cotter pin

1

3

/8in. – 16 x 1in. HHCS #2 zinc-

plated bolt

17

33622

3

/8in. zinc-plated lock washer

1

1

Item

Part no.

Description

Quantity

1

20-538-005

Subassembly, carriage

1

3

3

7

20-145-019

Specialty hardware, swage sleeve

2

9

28-014-179

Cast, counterweight (SWA-48)

1

Weldment, specialty hardware,

rod tension wing nut

12

20-014-005

Frame, tube retainer, (top)

1

14

20-014-006

Tube, retainer, (bottom)

1

Item

Part no.

Description

Qty

2

20-027-011

Load roller

16 3 26327

Shoulder screw 0.375in. x 0.5in.

32

5

/16in. - 18 zinc-plated #2 nylon lock

nut

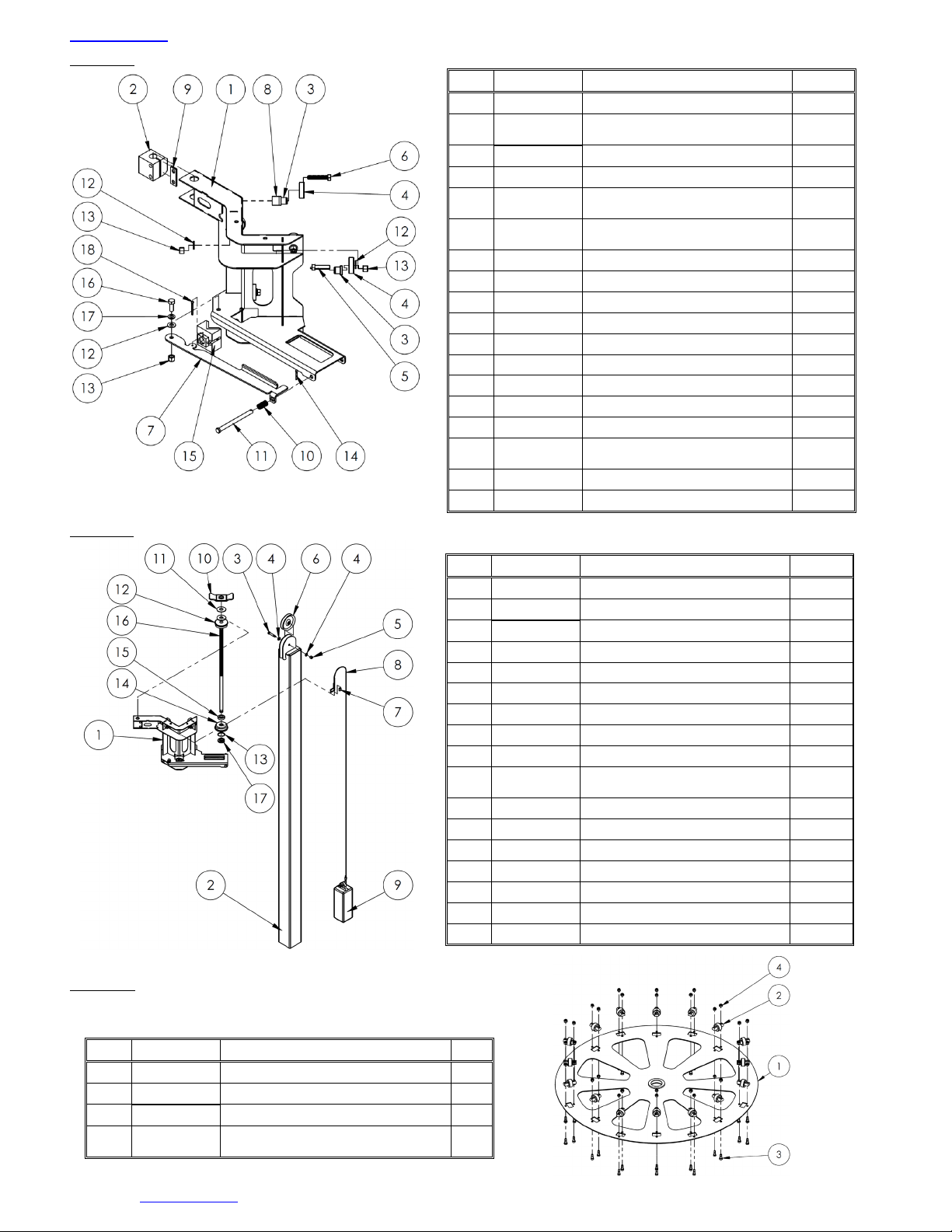

FIG. 2A: Stretch wrap carriage subassembly exploded parts diagram & bill of materials

2 20-145-010

4 20-110-006 Roller bearing 8

5 11109

6 11111

8 21-113-020 Spacer, bearing 4

10 20-146-008 Spring, compression spring 1

11 99-112-006 Pin, clevis 1

12 33008

13 37024

15 20-537-018 Brake pad assembly 1

16 11105

/8in. USS zinc-plated flat washer 10

/8in. Nylock insert nut 9

1

4

4

1

18 65078

/8in. x 11/2in. zinc-plated cotter pin 1

FIG. 2B: Manual counterbalanced mast subassembly exploded parts diagram & bill of materials

2 20-514-082 Subassembly, mast, manual 1

3 26333 Shoulder screw 0.375in. x 1.5in. 1

4 33008

5 37024

6 20-027-001 Pulley, counterweight 1

/8in. USS zinc-plated flat washer 2

/8in. Nylock insert nut 1

8 20-145-018 Specialty hardware, cable 1

10 20-620-001

11 20-113-003 7/8in. fiber washer 2

1

13 68061 15/8in. retainer ring 1

15 20-111-002 Bearing, 7R16 1

16 20-014-116 Frame, rod, wrap retainer 1

17 20-113-022 Spacer, lock 1

FIG. 2C: Thrust bearing subassembly exploded parts

diagram & bill of materials

1 20-610-003 Weldment, thrust bearing plate 1

4 37021

32

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 5 of 19

Page 6

Table of Contents Rev. 9/19/2018 SWA, MANUAL

Item

Part no.

Description

Qty

Item

Part no.

Description

Qty

Motor 1/2 HP, 3 PH, 1725 RPM,

230/460V, 60 Hz

Screw, machine, truss head

6

3

5

/16in. – 18 x 1in. HHCS zinc-plated #2

bolt

Sheave 5/8in. inner diameter x 2 in.

outer diameter

3

/8in. – 16 x 11/4in. HHCS zinc-plated #2

bolt

5

3

9

20-016-084

Bracket, motor, mounting plate

1

24

SSFLATSKT 0.375-16x1.25-HX-N

2

5

11

20-024-023

Plate cover, bearing

1

26

33006 5/16in. USS zinc-plated flat washer

2

5

3

/8in. – 16 x 1in. HHCS #2 zinc-plated

bolt

14

20-016-053

Bracket, mounting

1

29

33622

3

/8in. zinc-plated lock washer

4

1

FIG. 3: Power unit subassembly with sheave exploded parts diagram & bill of materials

1 20-514-099 Weldment, frame, subassembly 1 16 20-027-008 Belt, B40 1

2 20-110-014 Flange, 2 bolt, 1in. inner diameter 2 17 99-034-037 Accessories, electrical, Romex 0.375in. 2

3 20-135-004

4 20-112-015 Shaft pin, 1in. outer diameter 1 19 36106

5 20-027-010 Sheave, 12in., 1in. hub 1 20 11055

6 20-027-009

7 20-110-013 Bearing, mount, upper 1 22 33620

8 20-016-085 Bracket, motor, mounting plate 1 23 33008

10 0162854 U-spring, threaded nut 6 25 11052

12 20-042-019 Sheave, drive 1 27 37021

13 20-024-022 Guard, end, formed 2 28 11105

15 20-029-006 Accessories, electrical, delta controller 1 30 99-130-001 Pin, keystock

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 6 of 19

1 18 29185

1 21 11107

/8in. – 16 zinc-plated hex nut 4

4

4

/16in. zinc-plated lock washer 4

/8in. USS zinc-plated flat washer 8

/16in. – 18 UNC x 3/4in. HHCS screw 2

/16in. – 18 #2 zinc-plated Nylon lock nut 2

4

Page 7

Table of Contents Rev. 9/19/2018 SWA, MANUAL

Stretch wrap carriage

subassembly (part no.

20

counterbalanced mast

(shown in exploded

form in

on p. 5).

5

5

5

4

20-513-100

Weldment, SWA-70 deck

1

18

SSFLASKT 0.375-16x1.25-HX-N

2

Power unit subassembly with sheave

(see FIG. 3 on p. 6)

6206 bearing, 1.18 ID x 2.44 OD x 0.62

thick

Subassembly, counterbalanced mast,

manual (see FIG. 2B on p. 5)

3

3

/8in. – 16 x 1in. HHCS #2 zinc-plated

bolt

Hex bolt, grade A, zinc plated, 1/4in. – 16 x

/2in.

External retaining ring, phosphate finish,

11/8in.

FIG. 4: SWA-70 exploded parts diagram

-538-005) and

FIGS. 2A & 2B

Item Part no. Description Qty Item Part no. Description Qty

1 20-514-079 Weldment, base frame 1 15 33006

2 20-027-012 Belt idler 2 16 21265

3 20-610-002 Subassembly, thrust bearing 1 17 37021

5 20-160-001

6 20-113-024 Spacer, plate 2 20 20-110-022

7 20-014-117 Frame, bar, squeeze 1 21 20-117-001 Internal retaining ring, 2in. 1

8 20-514-084

9 20-027-014 Belt, B245 (large belt) 1 23 20-117-005 Internal retaining ring, 27/16in. 1

10 36106

11 11105

12 33008

13 33622

14 20-016-096 Bracket, tensioning, formed 1

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 7 of 19

/8in. – 16 zinc-plated hex nut 4 24 20-024-025 Cover plate, idler access 1

3

/8in. USS zinc-plated flat washer 4 26 11001

3

/8in. zinc-plated lock washer 4 27 68021

/16in. USS zinc-plated flat washer 1

/16in. – 18 UNC x 3in. zinc-plated bolt 1

/16in. – 18 #2 zinc-plated Nylon lock nut 1

1 19 20-110-001 Single row ball bearing, shielded, R16Z 1

1 22 20-117-003 External retaining ring, 1in. diameter shaft 1

4 25 33090

5

/8in. SAE flat washer 2

1

1

2

1

Page 8

Table of Contents Rev. 9/19/2018 SWA, MANUAL

Bolt, carriage, 5/16”-18UNCx3”, zinc

plated

Nylon insert lock nut, grade 2, zinc

finish, 5/16”-18

Sub-assembly, counterbalanced mast,

manual

Hex bolt, grade A, zinc plated, 3/8”16x1”

Split lock washer, carbon steel,

medium zinc finish, 3/8”

Flat washer, low carbon, USS, zinc

plated, 3/8”

10

20-113-024

Spacer, plate

2

22

68013

5

/8” external retaining ring

2

Bolt, 1/4”-20UNCx1”, HHCS #2 zinc

plated

Stretch wrap

FIG. 5: SWA-51-AR5 exploded parts diagram

holder

assembly

Item Part no. Description Qty Item Part no. Description Qty

1 20-514-135 Weldment, frame 1 13 20-042-033 Sprocket, idler assembly 2

2 20-514-136 Weldment, approach ramp 3 14 20-042-034 #35 chain 1

3 20-514-137 Weldment, approach ramp 1 15 21265

4 20-514-138 Weldment, approach ramp 1 16 33006 Flat washer, zinc plated, USS, 5/16” 1

5 20-160-002 Sub-assembly, power unit with sprocket 1 17 37021

6 20-514-084

7 20-014-117 Frame, bar, squeeze 1 19 33622

8 SSFLATSKT 0.375-16x1.25-HX-N 2 20 33008

9 36106 Hex nut, grade A, zinc plated, 3/8”-16 4 21 20-110-004 Bearing, ball 300

11 20-016-096 Bracket, tensioning, formed 1 23 20-117-003 External retaining ring, 1” diameter 1

12 20-513-052 Weldment, deck and sprocket 1 24 11005

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 8 of 19

1 18 11105

1

1

4

4

4

3

Page 9

Table of Contents Rev. 9/19/2018 SWA, MANUAL

FIG. 6: Electrical system diagram

Static electricity is produced

1

VFD004S11B

Delta control, freq. variable, AC

1

2

20-522-001

Switch, single foot, 108in. cord

1

Cord, 14/3, 9in. with 15A

molded plug

1

4

N/A

Cable, 18/3, pltc gray

1

5

N/A

Cable, 14/3, sjtd, yellow

1

Item Part no. Description Quantity

3 01-033-015

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 9 of 19

when items are stretch

wrapped. The static effect

can intensify in dry air. To

reduce the effects of static

electricity on the wrapping

machine, always ground the

control to the frame of the

machine.

If significant static electricity

is experienced, bond the

frame of the machine to a

driven ground rod (see

National Electrical Code for

details of driven grounding

electrodes).

Page 10

Table of Contents Rev. 9/19/2018 SWA, MANUAL

FIG. 7: Powered mast

electrical diagram

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 10 of 19

Page 11

Table of Contents Rev. 9/19/2018 SWA, MANUAL

To change the controller parameters, use the buttons on the keypad to select the

Speed controller parameter settings:

Parameter

Description of parameter

Setting

Description of setting

0-03

Start-up display selection

d2

Display the content of user-defined unit

Scales frequency so display shows approximate

turntable rpm

1-02

Maximum output voltage

d255

Sets maximum voltage to motor

Sets maximum rotation speed with speed knob

turned fully clockwise (~11 rpm)

Sets minimum rotation speed with speed knob

turned fully counterclockwise (~3 rpm)

Time to accelerate motor to maximum output

frequency in seconds

1-15

Auto accelerate/decelerate

d0*

Allows for linear acceleration of motor

1-16

S-curve in acceleration

d 7

Determines how smoothly drive accelerates

Allows turntable speed to be controlled by knob

on keypad

2-01

Source of operation command

d 1

Makes drive turn on external foot switch

2-02

Stop method

d 1

Allows turntable to coast to stop

Sets maximum motor current as percentage of

rated output

Detection enabled during acceleration &

continues until Continuous Output Time Limit

Sets maximum output torque as percentage of

rated output

Determines how long (in seconds) drive runs

after over-torque detected

Establishes maximum output current as

percentage of rated output

7-01

Motor no-load current

d 75

Sets motor slip compensation

7-02

Torque compensation

d 10

Sets maximum startup torque

Model

Parameter

Setting

Parameter

Setting

SWA-50

1-08

d10

1-07

d40

SWA-70

1-08

d8

1-07

d35

SWA-51-AR5

1-08

d20

1-07

d65

Delta Motor Speed Controller

desired settings (see “Speed controller parameter settings” table below):

a. PROG/DATA: press the “PROG DATA” button to initiate program mode;

then the following screen will appear:

This screen indicates which parameter number is selected (see table below),

which in this case is parameter 0. Press the up or down arrow button to

select the desired parameter number (0; 1; 2; 6; or 7). Press the

PROG/DATA button again to reveal the second set of numbers (on the right

side of the dash in the “parameter” column of the table below). Use the

arrow buttons to select the desired number. After completing the desired

combination of numbers, press the MODE button twice to return to the home

screen.

b. MODE: press the MODE button to display information about the status of the

drive. Successively pressing the MODE button displays different information.

For example, pressing the MODE button 3 times displays the current speed

(in rpm’s) of the turntable. (E.g. 12rpm displays as “u 12”.)

c. Arrow keys: press the up or down buttons to scroll through different

parameters. Press the up or down arrow key quickly to change parameter

0-05 User defined coefficient K d0.3

1-07 Upper bound of frequency d65

1-08 Lower bound of frequency d15

1-09 Acceleration time d10*

settings in single unit increments.

d. The following table indicates the controller settings for each model that are

required to achieve a minimum rotation speed of 3rpm and an upper rotation

speed of 12rpm:

2-00 Source of frequency command d 3

6-02 Over-current stall prevention limit d 150

6-03 Over-torque detection mode d3

6-04 Over-torque detection level d 200

6-05 Continuous output time limit d10

7-00 Motor rated current d 120

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 11 of 19

Page 12

Table of Contents Rev. 9/19/2018 SWA, MANUAL

Mast in receiver

Squeeze

Mast

3

/

in. Allen

Stretch wrap

carriage

Ramp (option)

Anchor tab

Mast

Counterweight

Anchor

tab

Anchor

Squeeze bar

Manual mast Powered mast

To install a ramp:

Installation

NOTE: Record the maximum turntable rotation speed when the machine is first installed.

1. Position it as desired in relation to the wrapping

machine. The ramp should not interfere with the

turntable as it rotates;

2. Fasten it to the ground with hardware as described

in step 5 below through each anchor tab.

16

wrench set

screws

bar

1. Move the machine to the desired installation location. Install the machine only on an even, level

surface.

2. Lift the mast into the upright position. Insert the mast through the mast sockets with the stretch wrap

carriage pointing towards the turntable.

3. Insert the squeeze bracket into the gap between the mast and the socket as shown below; then

tighten the set screws against it using a

plate flexion during use even with the squeeze angle firmly secured against the mast.]

4. [Manual models] Manual wrapping machines counterbalance the combined weight of the wrapping

material and the material carriage with a counterweight inside the mast. The machine is shipped with

the carriage raised to the top of the mast and the counterweight at the bottom of the mast. The

retaining screw (through the mast) prevents the counterweight from sliding inside the mast during the

shipping process, but must be removed now. The head of the screw is located approximately 12

inches from the base of the mast.

5. Fasten the machine to the floor with anchor bolts. There are 4 anchoring points: 2 in back and 2

under the turntable. Each of the 4 anchor tabs has a

engineer should evaluate the installation site and select

the location.

6. Shim and grout under the frame.

7. Connect the wrapping machine to an AC power source: Insert the turntable power cord into a 15A,

115 VAC receptacle.

• [Powered mast models] Powered mast models have 2 power cords: one for the turntable and

another for the wrapping carriage. The 2 cords can either both be plugged into a power outlet,

or be connected and plugged into an outlet. To connect the cords, plug the turntable power

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 12 of 19

tab

Rotate the turntable until the hole in the

tabletop aligns with an anchor tab.

3

/16in. Allen wrench. [NOTE: The mast will wobble due to

5

/8 in. hole for an anchor bolt. Your building

3

/8 in. anchor bolts of a length appropriate for

under turntable

Page 13

Table of Contents Rev. 9/19/2018 SWA, MANUAL

Item

no.

1

20-014-116

Frame, rod, wrap retainer

1

2

20-014-006

Tube retainer (bottom)

1

3

20-014-005

Tube retainer (top)

1

4

20-110-002

Bearing, ball, 3/4 in., shield

1

5

68061

15/8 in. retainer ring

1

6

20-113-022

Spacer, lock

1

7

20-113-003

7

/8 in. fiber washer

1

20in. plastic wrap (not

included)

The wrap holder accommodates 10-20 inch

rolls of stretch wrap.

Loading stretch wrap

1.

2.

3.

4.

5.

6.

Stretch Wrap Holder Assembly

Assembled stretch wrap holder

A

2

1 3 7

7

cord into the pigtail cord of the mast control enclosure; then plug the power cord for the mast

into a 115 VAC receptacle.

8. Test the powered functions:

a. Turntable rotation: press the foot pedal to initiate rotation. The turntable will rotate as long

as the pedal is pressed.

b. Delta speed controller: refer to the Delta operation manual.

c. Powered mast models: raise and lower the stretch wrap carriage with the UP and DOWN

buttons on the pendant (hand) controller. Confirm that the carriages moves smoothly and

that both the upper and lower travel limit switches function properly.

Unwind the wing nut (A) sufficiently to

remove the lock spacer (6) underneath the

bottom retainer (2).

Remove the lock spacer.

:

Remove the retainer (5) and bearing (4).

Remove the spent roll of stretch wrap and

install a new roll.

Reinstall the retainer (5) and secure it in

place with the lock spacer (6).

Tighten the wing nut (A) until the roll is

snugly grasped between the tube retainers

(2) and (3). Adjust the tightness of the wing

nut to achieve the desired degree of

material stretch—the material will stretch

more the more tightly the roll is grasped.

Part no. Description Quantity

*8 SRF-18

1

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 13 of 19

Page 14

Table of Contents Rev. 9/19/2018 SWA, MANUAL

(2)

Belt Tensioning Procedure

The wrapping machine uses 2 belts to rotate the turntable and the tension of each belt occasionally

requires adjustment. For instance, if the turntable vibrates or rattles, the tension of the lower belt needs to

be adjusted. Similarly, if the turntable drive motor (or the metal box that supports the motor) vibrates, the

tension of the upper belt should be increased.

1. Adjust the tension of the upper (small) belt.

• Loosen all four bolts (1) adequately to allow the motor mounting bracket to slide. [NOTE: Only

three bolts are shown in the diagram above.]

• Loosen the jamb nuts on the set screws (2).

• Remove the end guard by removing both end guard bolts.

• Assess the adequacy of belt tension by doing the following:

a. Locate the access opening (C); then insert a metal rod approximately 3/8” x 10” long, into

the access opening. The rod must have a smooth, flat end without sharp projections that

might damage the belt.

b. Locate the belt with the end of the rod. Lightly contact the belt at the point approximately

halfway between the two pulleys. The rod should be perpendicular to the belt. Do not

press the rod against the belt. Make a first mark on the rod that is flush with the top of the

access opening (C). Make a second mark

1

/8 in. above the first mark.

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 14 of 19

Page 15

Table of Contents Rev. 9/19/2018 SWA, MANUAL

c. Using a “pencil type” compression spring scale, measure the force required to push the

1

rod

/8 in., that is, the force required to move the rod inwardly so that the second mark is

flush with the top of the opening (C).

d. If necessary, adjust the tension of the belt. If the belt is new, the force measured by the

spring scale should equal 16 lbs. After a belt is broken in, the force required should be

between 8-12 lbs. To adjust belt tension, use a

3

/16 in. Allen wrench to turn the set screws

(2). To increase tension, turn the screws clockwise. To decrease tension, turn the screws

counterclockwise. Turn both set screws the same amount.

• When belt tension is proper, retighten the jamb nuts on both set screws firmly against the bracket

tabs; then reinstall the end guard and tighten all four of the motor mounting bracket bolts (1).

2. Adjust the tension of the lower (large) belt.

• Loosen all 4 power unit subassembly bolts (A). [NOTE: Only 2 bolts are shown in the diagram; the

other bolts are on the opposite side of the subassembly.]

a. Locate the access opening (D); then insert a metal rod approximately 3/8” x 10” long, into

the access opening. The rod must have a smooth, flat end without sharp projections that

might damage the belt.

b. Locate the belt with the end of the rod. Lightly contact the belt at the point approximately

halfway between the two pulleys. The rod should be perpendicular to the belt. Do not

press the rod against the belt. Make a first mark on the rod that is flush with the top of the

access opening (D). Make a second mark

c. Using a “pencil type” compression spring scale, measure the force required to push the

3

rod

/8 in., that is, the force required to move the rod inwardly so that the second mark is

3

/8 in. above the first mark.

flush with the top of the opening (D).

d. If necessary, adjust the tension of the belt. If the belt is new, the force measured by the

spring scale should equal 16 lbs. After a belt is broken in, the force required should be

between 8-12 lbs. To increase tension, use a

carriage bolt (B)

• When belt tension is proper, retighten the lock nut firmly against the carriage bolt tab; then tighten

all 4 power unit subassembly bolts (A).

clockwise. To decrease tension, turn the nut counterclockwise.

9

/16 in. wrench to turn the lock nut on

Use Instructions

Standard SWA-50 and -70 wrapping machines must be used indoors. They are designed for moderate

duty, intermittent cycling and will wrap loads weighing up to 4,000 pounds (1,818.2kg). The net weight of

the pallet or skid and the items stacked on the pallet must not exceed 4,000 pounds. The load rating

appears on Label 287, which is affixed to the machine as shown in the Labeling diagram on p. 17.

Place a load on the turntable

DO NOT drop loads onto the turntable, because shock loading will cause the load bearings

to fail prematurely. DO NOT exceed the load rating; the drive system might be damaged or fail

prematurely.

To protect the load bearings, be careful when loading the turntable and slowly apply loads to the

turntable. In particular, take care to not drop items on the table or to slam the tines of your fork lift on it.

Wrap the load

Standard model wrapping machines are equipped with a constant-pressure (dead man style) foot pedal

control. As long as the pedal is pressed, the table will rotate. When the pedal is released, the turntable

will coast to a stop.

Turntable rotation speed is adjustable. To increase or decrease the speed, turn the knob on the Delta

controller (see p. 11) clockwise or counterclockwise, respectively. The number displayed on the screen of

the control is the approximate number of revolutions per minute.

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 15 of 19

Page 16

Table of Contents Rev. 9/19/2018 SWA, MANUAL

The tension applied to the roll of stretch wrap determines how much the material stretches as it wraps

around a load. Tension is also adjustable. To increase tension, turn the rod tension wing nut (item no. 1,

on p. 13)

clockwise. To decrease tension, turn the wing nut counterclockwise.

To begin wrapping a load, set the tension to allow the wrap to easily pull off of the roll. Fix the end of the

wrap to the load, for example by tying it to the pallet; then press the pedal control to rotate the turntable.

Next, tighten the wing nut to achieve the desired material tension after wrapping the material around the

load once or twice to prevent it from coming loose. To wrap the load, move the wrap holder assembly up

and down as necessary to achieve the coverage desired for the load. Cover the entire load with 2-3

layers of wrapping material. To complete the wrapping process, cut (or tear) the material and press the

end against the side of the load.

Inspections & Maintenance

DO NOT use the wrapping machine until all problems discovered during an inspection have

been resolved.

Before each use, inspect the listed components:

1. Wiring: examine the wires for fraying and damage.

2. Mast, turntable, and frame: Handrails: check each structure for bends, warps and cracks.

3. Power transmission and control equipment (particularly the foot pedal): inspect each component and

associated guards and cords for damage.

4. Operate the wrapper: observe and listen to the machine as it operates for unusual noise or

movement, or binding.

5. Product labels: all labels should be readable and located as shown in the “Labeling diagram” on p.

17. If a label(s) is unreadable or missing, order a replacement.

NOTE: Label appearance and content is subject to change over time, and consequently,

replacement labels might differ from labels shown in the manual supplied with the unit.

At least 1 time per month, inspect:

1. Electrical wiring: closely inspect wiring for regions of significant wear, cuts, frays, and other damage.

2. Fasteners (hardware): check fasteners for looseness and damage. Tighten all loose fasteners;

replace any that are damaged: Bolts, nuts, washers;

3. Turntable drive belt: inspect the drive belt for significant wear and looseness. If the belt is significantly

worn, replace the belt. Operate the turntable and compare the current maximum rotation speed with

the speed recorded when the machine was first installed. If the top rotation speed is slower than the

initial figure, adjust the tightness of the belt. See Belt tensioning procedure

, pp. 14-15).

4. Motor speed control: if the speed control enclosure is broken, then the drive should be replaced.

5. Turntable: examine the turntable for significant wear and impact damage. Sharp projections might

develop along the edge of the turntable. Sand or grind off all projections, burrs, etc.

6. Load bearings: operate the turntable and listen for scraping sounds. If the turntable is noisy while it

rotates, replace the load bearings.

7. Turntable main bearing: the top of the turntable should be parallel to the supporting frame; it should

not wobble (press down and pull up on the edge of the turntable).

8. Carriage slides: inspect the slides for excessive wear.

9. Fiber washer (see item no. 2 on p. 13): check the fiber washer of the (shrink wrap) material holder.

Make sure that it is not significantly worn.

10. Anchoring points: check each of the anchor bolts and the concrete. The machine should be solidly

fixed to the floor. Tighten bolts, if necessary. Also inspect the concrete around each bolt. It should not

be cracked, chipped, etc.

11. Labels: confirm that all labels (shown in Labeling diagram

on p. 17) are present, undamaged and

readable.

12. Overall condition of wrapping machine: the structure should be clean, square and rigid, and free of

rust and corrosion. Remove dirt and debris. Do not use the machine if the base is excessively rusted

or corroded.

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 16 of 19

Page 17

Table of Contents Rev. 9/19/2018 SWA, MANUAL

A (Label 221)

D (Label 204)

E (Label 824)

C (Label 287)

C C

D & E

D & E

A & B

B (Label 325)

E

D

C

Powered mast models:

base of mast.

Labeling Diagram

The unit should be labeled as shown in the diagram. However, label

content and location are subject to change so your product might not

be labeled exactly as shown. Replace all labels that are damaged,

missing, or not easily readable (e.g. faded). To order replacement

labels, contact the technical service and parts department online at

http://www.vestilmfg.com/parts_info.htm. Alternatively, you may

request replacement parts and/or service by calling (260) 665-7586

and asking the operator to connect you to the Parts Department.

A and B also applied to junction box at

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 17 of 19

Page 18

Table of Contents Rev. 9/19/2018 SWA, MANUAL

Issue

Possible Cause

Corrective Action

1) Turntable does not

a) No power supply voltage

a) Check outlet for 115V power. If outlet lacks

inspect the belts.

2) Turntable cannot

achieve set speed

a) Belt is broken or slipping

a) If fan of drive motor spins but table does

3) Mast motor or control

a) Excessive voltage drop to motor

a) Check power supply for adequacy. Check

mast for looseness, etc.

4) Powered stretch wrap

a) Low control voltage or bad

f) Control relay 1 CR is loose

a) Confirm 24VAC at transformer secondary.

f) Verify that the relay is firmly in place.

5) Powered mast stretch

a) Control relay 2 CR is loose

a) Confirm that the relay is firmly in place

it from the path of the holder.

Troubleshooting:

rotate

rotate without

assistance, rotates

more slowly while

loaded, or does not

b) Speed control on lowest setting

c) No signal from pedal control

d) Motor controller fault or defective

motor controller

e) Belt is broken or slipping

power, determine cause of power loss

before restoring power to the wrapping

machine. [NOTE: If turntable power cord is

plugged into the pigtail cord of the powered

mast, confirm that powered mast cord is

plugged into a wall socket.]

b) Increase turntable speed using the knob

on the Delta motor speed controller (see p.

11).

c) Check continuity of foot pedal and the

cable connected to it.

d) Check the display on the Delta motor

speed controller for a fault code. If a fault

code is displayed, contact Vestil

Manufacturing (phone number on cover of

this manual).

e) If fan of drive motor spins but table does

not rotate, release the foot pedal; then

not rotate, release the foot pedal; then

inspect the belts.

enclosure hums,

chatters, or buzzes,

and the stretch wrap

holder moves slowly or

not at all.

holder does not

respond to commands

(UP and DOWN)

due to:

b) Damaged mast or stretch wrap

holder

c) Low control voltage or bad

connection in control circuit

connection in control circuit

b) Blown transformer fuse

c) No power supply voltage

d) Mast limit switch engaged or

malfunctioning

e) Control relay 1 CR contact is burnt

• Inadequate wiring;

• Wire run too long; or

• Incoming voltage too low.

incoming voltage while motor runs. If the

voltage is too low, correct by

• Installing circuit with larger wire;

• eliminating extension cord(s); or

• installing a buck/boost transformer.

b) Examine mast and holder for damage or

excessive wear.

c) Confirm 24VAC at transformer secondary.

Examine all wiring and connections in the

Examine all wiring and connections in the

mast for looseness, etc.

b) Test with meter; replace if bad (replace

with same fuse type and ampere rating)

c) Check outlet for 115V power. If outlet lacks

power, determine cause of power loss

before restoring power to the wrapping

machine. [NOTE: If turntable power cord is

plugged into the pigtail cord of the powered

mast, confirm that powered mast cord is

plugged into a wall socket.]

d) Inspect and test switch, Replace if bad.

e) Examine contact. Clean contact or replace

relay as necessary.

wrap holder rises on

command but does not

lower

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 18 of 19

b) CR 2 is defective

c) Bad connection in control circuit

d) Physical blockage in mast

b) Examine and test 2 CR. Replace if

necessary.

c) Test all parts of circuit with meter

d) Determine cause of blockage and remove

Page 19

Table of Contents Rev. 9/19/2018 SWA, MANUAL

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this product to be free of defects in material and workmanship

during the warranty period. Our warranty obligation is to provide a replacement for a defective, original part covered

by the warranty after we receive a proper request from the Warrantee (you) for warranty service.

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

Definition of “original part”?

An original part is a part used to make the product as shipped to the Warrantee.

What is a “proper request”?

A request for warranty service is proper if Vestil receives: 1) a photocopy of the Customer Invoice that displays the

shipping date; AND 2) a written request for warranty service including your name and phone number. Send requests

by one of the following methods:

US Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 info@vestil.com

2999 North Wayne Street, PO Box 507 Phone Enter “Warranty service request”

Angola, IN 46703 (260) 665-7586 in subject field.

In the written request, list the parts believed to be defective and include the address where replacements should be

delivered. After Vestil receives your request for warranty service, an authorized representative will contact you to

determine whether your claim is covered by the warranty. Before providing warranty service, Vestil will require you to

send the entire product, or just the defective part (or parts), to its facility in Angola, IN.

What is covered under the warranty?

The warranty covers defects in the following original, dynamic parts: motors, hydraulic pumps, motor controllers,

and cylinders. It also covers defects in original parts that wear under normal usage conditions (“wearing parts”), such

as bearings, hoses, wheels, seals, brushes, and batteries.

How long is the warranty period?

The warranty period for original dynamic components is 1 year. For wearing parts, the warranty period is 90 days.

Both warranty periods begin on the date Vestil ships the product to the Warrantee. If the product was purchased from

an authorized distributor, the periods begin when the distributor ships the product. Vestil may, at its sole discretion,

extend a warranty period for products shipped from authorized distributors by up to 30 days to account for shipping

time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will

contact you to discuss your claim.

What is not covered by the warranty?

The Warrantee (you) are responsible for paying labor costs and freight costs to return the product to Vestil for

warranty service.

Events that automatically void this Limited Warranty.

• Misuse;

• Negligent assembly, installation, operation or repair;

• Installation/use in corrosive environments;

• Inadequate or improper maintenance;

• Damage sustained during shipping;

• Collisions or other accidents that damage the product;

• Unauthorized modifications: Do not modify the product IN ANY WAY without first receiving written authorization

from Vestil.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to the extent

allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty. Vestil

makes no warranty or representation that this product complies with any state or local design, performance, or safety

code or standard. Noncompliance with any such code or standard is not a defect in material or workmanship.

Table of Contents Copyright 2018 Vestil Manufacturing Corp. Page 19 of 19

Loading...

Loading...