Page 1

I N D E X

1 Introduction................................................................................................................................... 1

2 Machine Dimension...................................................................................................................... 2

3 Safety Instruction.......................................................................................................................... 3

3-

1Warning labels............................................................................................................................ 3

3-

2 Safety devices of turning table & interlocking function of safety guard .................................. 4

3-

3 Safety guards............................................................................................................................. 5

3-

4 Moving elements....................................................................................................................... 6

3-

5 Safety related components......................................................................................................... 7

4 Installation of the machine............................................................................................................ 8

4-

1 Setting the machine and choosing base..................................................................................... 8

4-

2 Packing and Unpacking............................................................................................................. 8

4-

3 Handling and Transportation.................................................................................................... 10

4-

4 Installation of machine............................................................................................................. 11

4-

5 Assemble the Pre-stretch Unit.................................................................................................. 12

5 Control Panel................................................................................................................................ 13

5-

1 Description of key pad’s function on the control panel............................................................14

5-

2 Wrapping function control........................................................................................................ 16

5-

3 Status indication....................................................................................................................... 18

5-

4 Breakdown indication............................................................................................................... 20

5-

5 Motion indication.......................................................................................................... ...........21

6 Film Loading................................................................................................................................ 23

7 Film Tension Adjust.....................................................................................................................24

8 Operation Procedure .................................................................................................................. 25

9 Maintenance................................................................................................................................. 26

9-

1 Installing and removing turntable ............................................................................................ 26

9-

2 Adjusting tightness of turntable chain...................................................................................... 27

10 Electrical .................................................................................................................................... 28

10-1 Parts list of electrical components...................................................................................... 28

10-2 EMC component list........................................................................................................... 33

10-3 Electrical wiring diagram ................................................................................................... 34

11 T roubleshooting..........................................................................................................................46

11

-1-1 Power indication hasn’t lighted on...................................................................................... 46

11

-1-2 There isn’t DC12 Volt. On power supply PD-25A ............................................................. 47

Page 2

11

-1-3 There isn’t DC24 Volt. On power supply PS-65-24............................................................ 48

11

-2-1 Turntable motor not operating (Inverter) ............................................................................ 49

11

-2-2 Turntable motor Speed not adjustable................................................................................. 49

11

-3-1 Film-seat motor brake (BK2) not working.......................................................................... 50

11

-3-2 Film-seat elevator motor not rising..................................................................................... 51

11

-3-3 Film-seat elevator motor not rising..................................................................................... 52

11

-4 Film-seat doesn’t stop when reached package limit ............................................................. 53

11

-5 Film-seat doesn’t pause.......................................................................................................... 53

11

-6-1 Film-seat doesn’t stop after reaching maximum packaging limit....................................... 54

11

-6-2 Film-seat doesn’t stop after returning to starting position.................................................. 54

11

-6-3 Film-seat motor speed not adjustable ................................................................................ 55

11

-7-1 Turntable hasn’t slowed down before completing wrapping cycle..................................... 55

11

-7-2 Turntable doesn’t stop after completing wrapping cycle.................................................... 56

11

-8 LS1, LS2, PS1, PS2 & PH not operating normally on PC board KS-050202-key ................ 56

11

-9 Control panel buttons not working......................................................................................... 57

11

-10 Pre-stretch motor M3 hasn’t worked.................................................................................... 58

12 Machine parts diagram............................................................................................................... 60

13

-1-1 Fig-11000 Pillar parts diagram............................................................................................61

12

-1-2 Fig-11000 Pillar parts table ............................................................................................... 62

12

-2-1 Fig-12000 Film-seat elevator parts diagram....................................................................... 65

12

-2-2 Fig-12000 Film-seat elevator parts table ............................................................................ 66

12

-3-1 Fig-14000 Bottom plate diagram........................................................................................ 67

12

-3-2 Fig-14000 Bottom plate parts table..................................................................................... 68

12

-4-1 Fig-18000 Control box diagram.......................................................................................... 70

12

-4-2 Fig-18000 Control box table............................................................................................... 71

12

-5-1 Fig-18100 Control box diagram.......................................................................................... 74

12

-5-2 Fig-18100 Control box table............................................................................................... 75

12

-6-1 Fig-19000 Pre-Stretch Unit diagram................................................................................... 76

12

-6-2 Fig-19000 Pre-Stretch Unit table........................................................................................ 77

12

-7-1 Fig-19100 Pre-Stretch Unit diagram................................................................................... 82

12

-7-2 Fig-19100 Pre-Stretch Unit table........................................................................................ 83

13 Parts list...................................................................................................................................... 84

Page 3

1 Introduction

Thank you for purchasing a state-of-the-art SHII-MEEI stretch film pallet wrapping machine.

All of us at SHII-MEEI would like to express our gratitude, and our desire to continue serving you

in the best possible way.

Please read all the instructions in this User’s Guide before attempting to operate the machine.

This will enable you to operate the machine safely and at peak efficiency. We have made every

effort to ensure that all information in this Guide is up to date. However, our commitment to

continuously improve all our products may result in you receiving a machine that does not conform

exactly to these instructions. Since we are quick to take advantage of new technology as it becomes

available, we must reserve the right to change our products and User’s Guide without prior notice.

All our distributors are fully knowledgeable about all aspects of our products. If you have any

need for advice or service, please do no hesitate to call upon them.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 1 -

Page 4

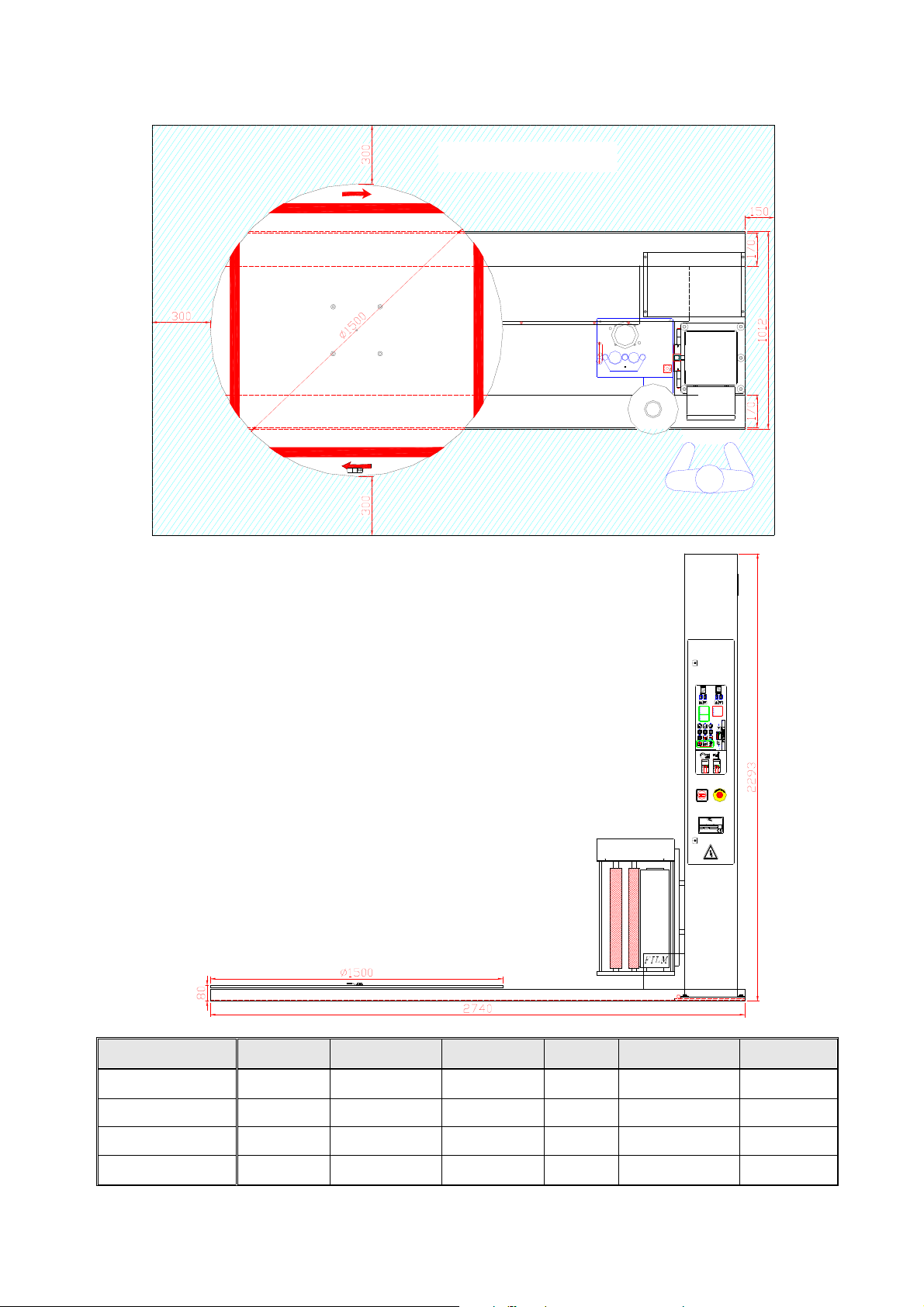

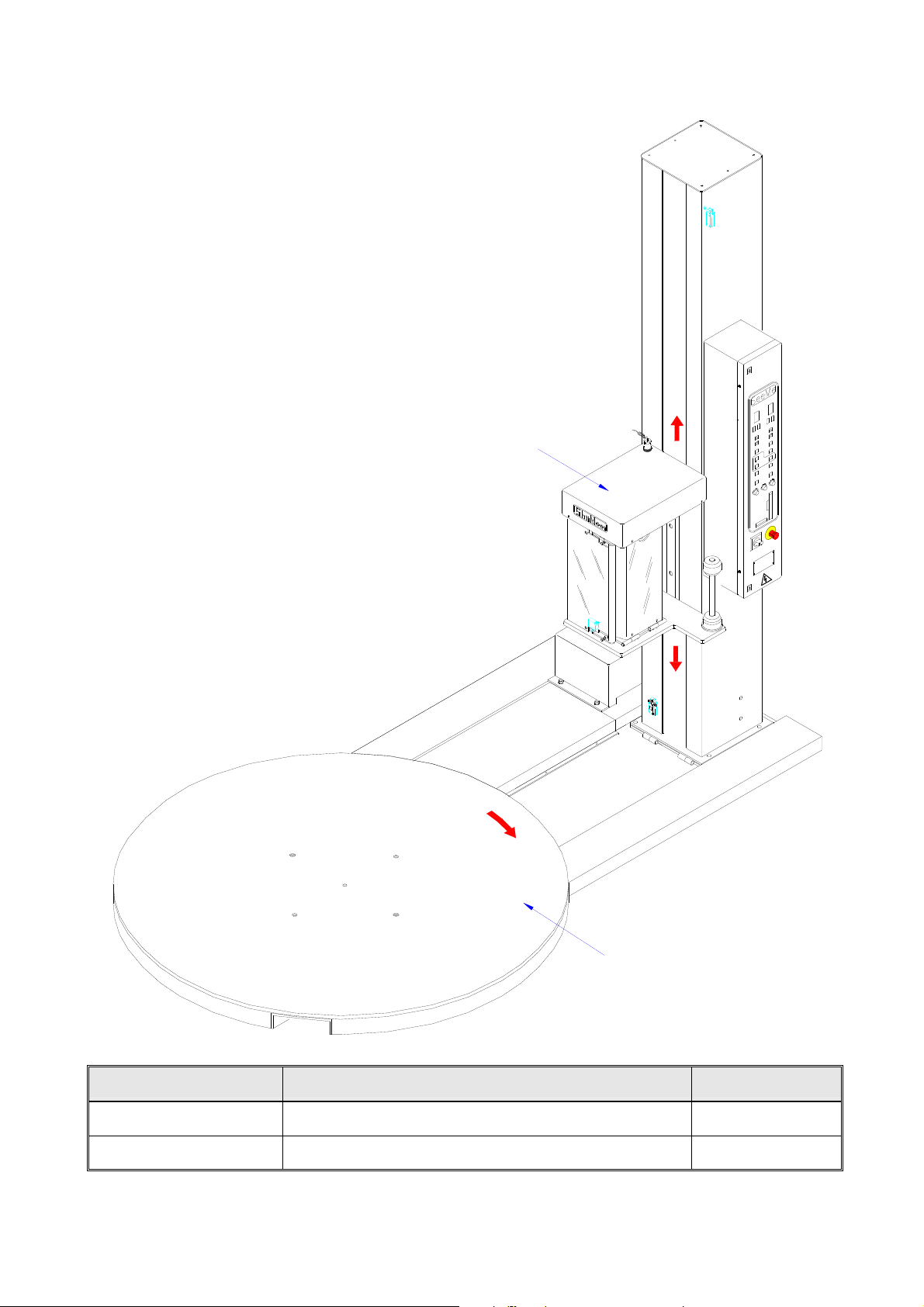

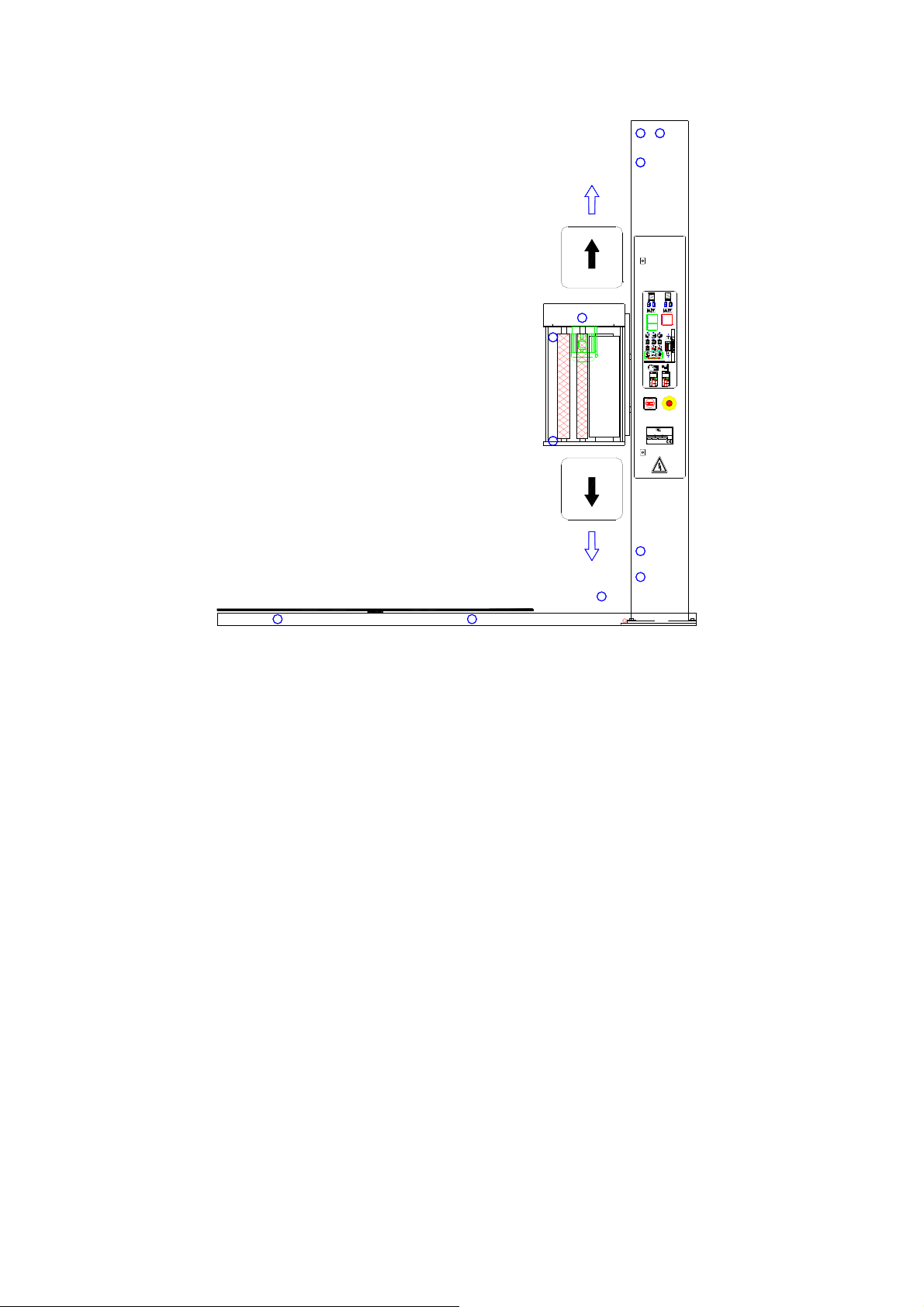

2 Machine Dimension

Clearance area

FILM

CONTROL

BOX

Missionary

Power

Stand By (AUTO)

Film Seat Zero Return

Turntable Zero Return

Film Cut

Turntable Slow Down

For SM-2517 Only

Follower-Plate Up

LS3-Up

Follower-Plate Down

LS4-Down

12

5

4

87

PS2

MODE

ENTER

FREQ. SET

LC-M2E

l ON

F

F

O

0

STRETCH WRAPPING MACHINE

ITEM NO.

SM-

AIR

bar

SHII MEEI INDUSTRIAL CO., LTD.

26, Sec. 1, Ta Fu Road, Tan Tzu Hsiang,

Taichung Hsien, Taiwan, R.O.C.

TEL:886 4 533−6601

Breakdown Indicator

No Film (SM-1517R)

M1 Motor Trip-Out

M2 Motor Trip-Out

Emergency Stop

BK2 Fail

BK2 Fuse Fail

M2

BK2

LS1

M3

3

PH

6

LS2-2

9

LS2-1

LS2

M1

PS1

DIGITAL KEYPAD

DIGITAL KEYPAD

RUN

RUN

MODE

STOP

STOP

ENTER

RESET

RESET

VFD-M

VFD-M

FREQ. SET

LC-M2E

R

SERIES NO. POWER

A

Hz

V

WEIGHT

DATE

Phase

Kgs.

FAX:886 4 533−6776

Model L W H H1 Turntable Weight

SM-1517R 2,740mm 1,500mm 2,293mm 80m/m Ø 1,500mm 530kg

SM-1517R -18 3,100mm 1,800mm 2,293mm 80m/m Ø 1,800mm 580kg

SM-1517R-20 3,300mm 2,000mm 2,293mm 80m/m Ø 2,000mm 630kg

SM-1517R-23 3,500mm 2,300mm 2,293mm 80m/m Ø 2,300mm 680kg

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 2 -

Page 5

3 Safety Cautions

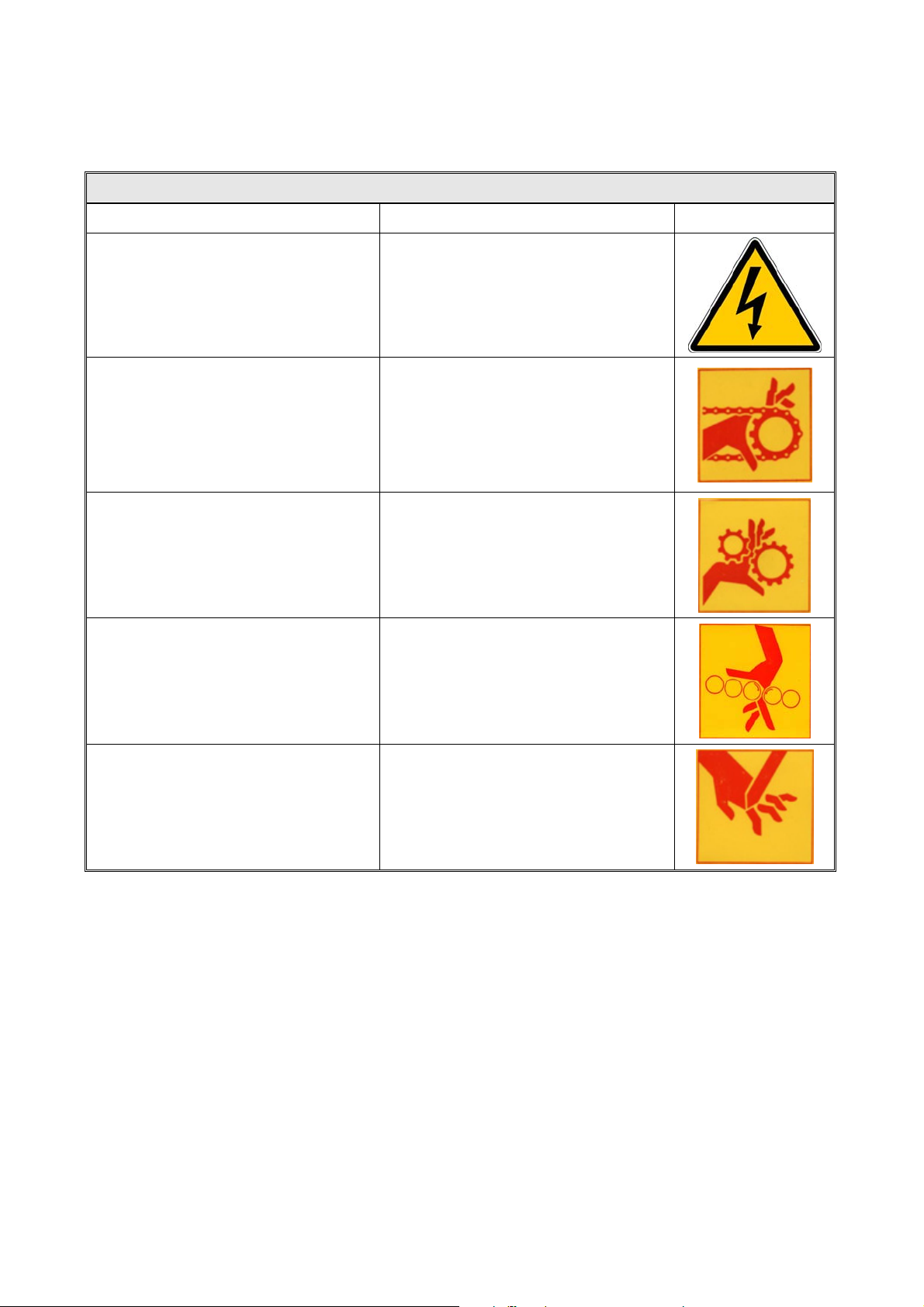

3-1 Warning labels

Dangerous Location Precaution Marking Label

Dangerous Area and Working Environment

The dangerous location is inside the

control panel.

The dangerous location is inside the

right and left rising & descending

columns.

The dangerous location is in motor

reduction gear head.

Dangerous location is on the driving

rollers of the pre-stretch unit. So, we

have stuck the label on the fixed guard

Hazardous voltage. Turn power off

before open the panel.

Keep hand, cloths and body clear of

the rotating chain. If hand tangled into

the chain and sprocket can cause

severe injury.

Keep hand, cloths and body clear of

the rotating gears. If hand tangled into

the gears can cause severe injury.

Drawing-in hazard caused by driving

rollers.

of the rollers.

The dangerous location is on the tape

cutter

Keep hand away from the cutter. If

hand placed under the cutter and the

cutter move downward can cause

severe injury.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 3 -

Page 6

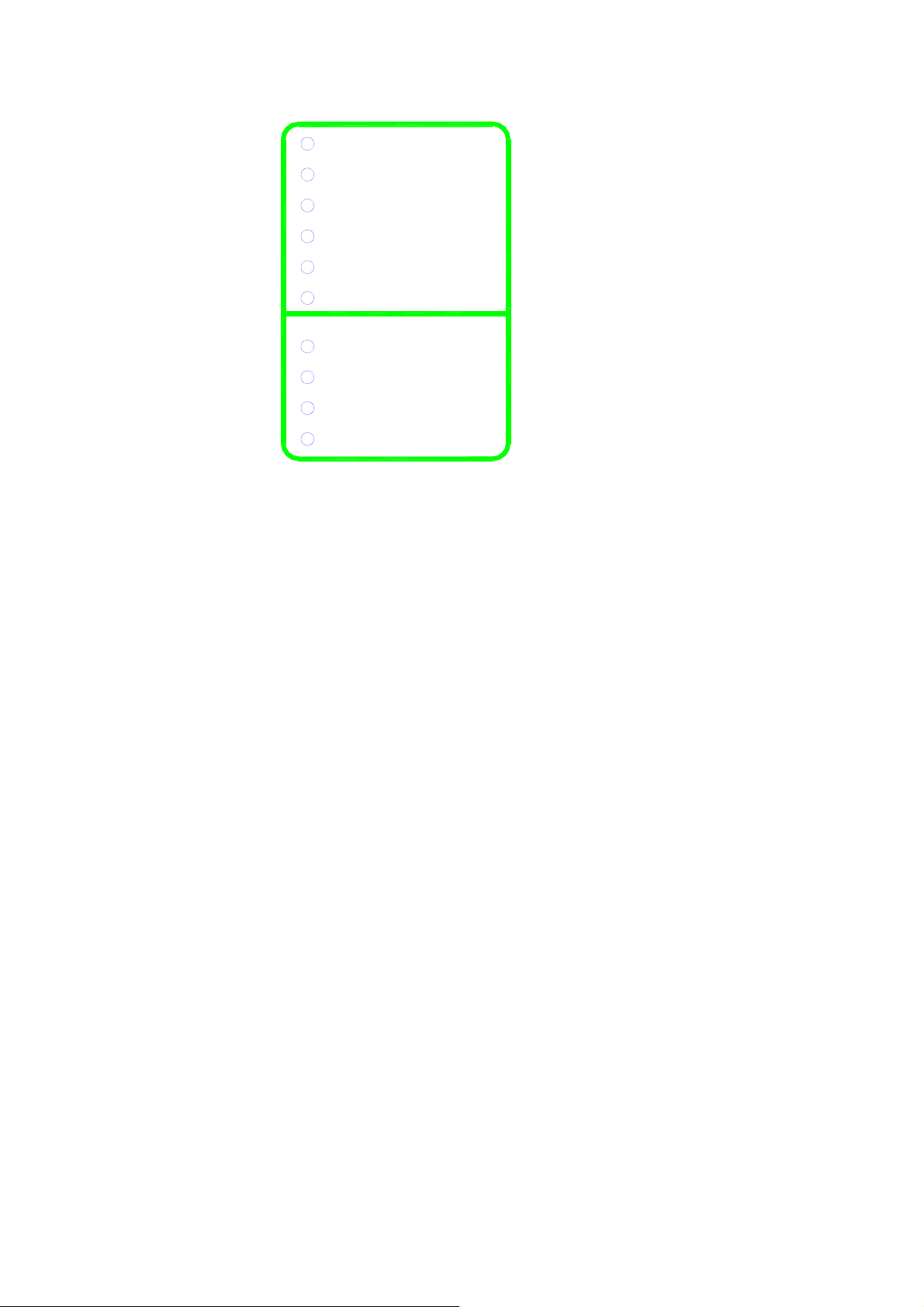

3-2 Safety devices of turning table & interlocking function of safety guard

Buttons of emergency stop are SB1 which would disconnect to main power and SB2 which would

disconnect to controller.

SB1

SB2

Power disconnect

Controller PCB input

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 4 -

Page 7

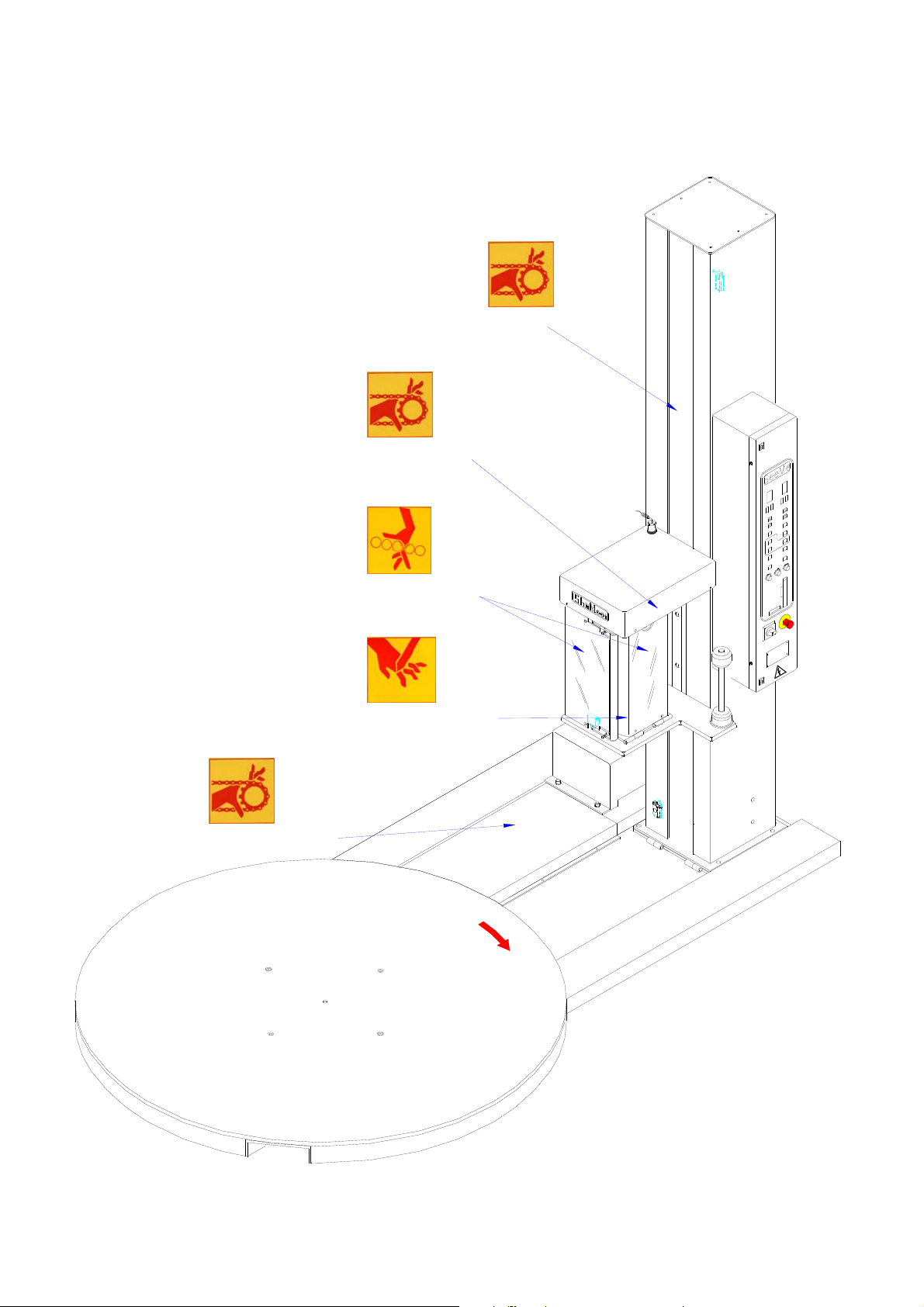

3-3 Safety guards

Fixed guard for chain

Fixed guard for chain

Fixed guard for roller

Fixed guard for knife

Fixed guard for chain

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 5 -

Page 8

3-4 Moving elements

Pre-Stretch Unit

Turntable

Moving parts name Movement Power source

Pre-Stretch Unit Up or down Motor

Turntable Up to open, down to close Motor

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 6 -

Page 9

3-5 Safety related components

Upper limit switch

Lower limit switch

Emergency stop button

Main power switch

Lower limit switch

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 7 -

Page 10

4 Installation of the machine

4-1 Setting the machine and choosing base

1. The site for the machine should provide the conditions essential for precision installation,

2. If the machine is placed on an upper floor, it shall ensure that the floor has adequate

strength for this machine.

3. A clear area must be provided along the rear face of the machine in accordance with the

diagram forward in page 2 and it is essential for efficient maintenance and assembly.

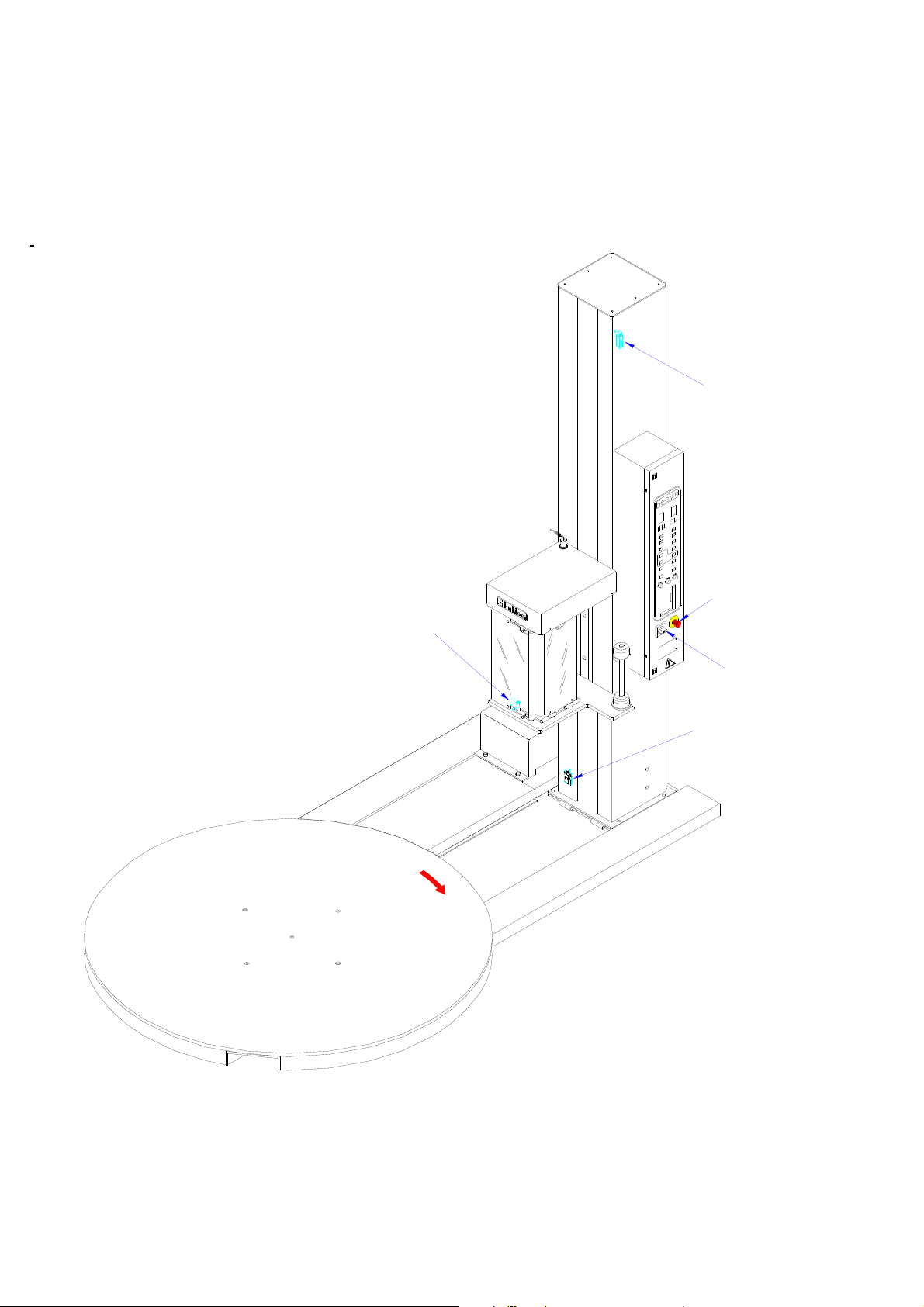

4-2 Packing and Unpacking

1. In general, the machine was packed with carton and pallet. The processes are as follows:

2. Please refer to machine weight in page 2 to arrange handling equipment.

3. Before unpacking always keep the mark Ï (or “up” arrow sign) upward and keep the

packing away from impact for preventing any damage on the machine.

4. Remove top portion first. Then, remove the side portions.

5. Do not damage any components inside the carton.

6. About the packing procedures, please refer to the following illustration diagrams.

7. The unpacking procedure is the reversal of packing.

1. Firstly, fix the side portion. Reserve the gap between the column and the side portion for

minimum 1 cm.

2. Fix the opposite side portion.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 8 -

Page 11

3. Fix the supporting frames.

4. Put and fix the side carton.

5. Fold the carton to cover the top and fix by nails with plastic washers.

6. Tighten the pack with steel strips.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 9 -

Page 12

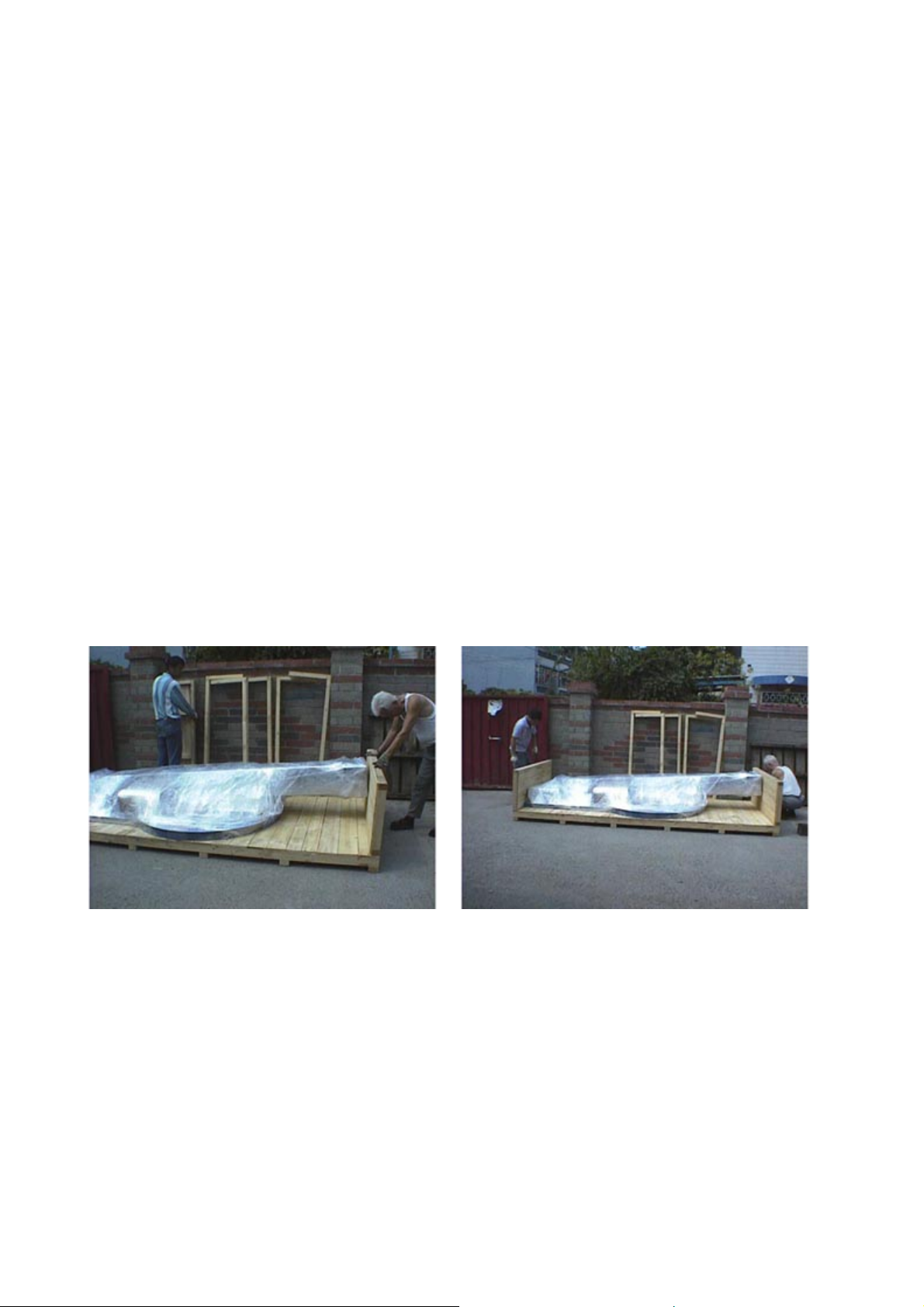

4-3 Handling and Transportation

Caution!

The machine shall be moved by persons who are qualified. Persons exclude the

operators are not allowed to stay in the work place during transporting the machine.

1. Please refer to machine specifications to arrange handling equipment. Be sure to use capable

fork-lifter to lift of machine.

2. The handling and transportation shall be carried out by qualified persons.

3. Forklift that used in handling the machine shall be operated by a qualified driver.

4. Before handling, make sure all movable parts are secured in their positions and all movable

accessories should be removed from machine.

5. During handling, people are strictly prohibited from entering into the path of machine

movement.

6. While transportation, keep attention to the balance of machine.

7. As the fork position, please refer to the diagrams shown below.

Fig.1 Fig.2

For machine pack transportation:

1. If the machine pack is transported from the narrow side, the fork length used on the forklift

should be more than 2.2 m. (as shown in the illustration diagram Fig.1)

2. If the machine pack is transported from the wide side, the fork length used on the forklift should

be more than 1 m. (as shown in the illustration diagram Fig.2)

Fig.3 Fig.4

For machine handling, please do it according to that shown in the illustration diagram Fig.3 and

Fig.4

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 10 -

Page 13

4-4 Installation of machine

1. First fix an eye end screw on the top of Pillar. 2. Hook the chain on the eye end.

3. Attached the chain or steel cable on a fork lift.

Get five M5X25 screws ready from the tool box.

5. Slowly move back the fork lift until the Pillar

is up around 80 degree to the ground.

4. Rise the fork up around 2m high,

6.Push the Pillar until it is right up.

7. Use 5 M12×25 Socket head screws with

washers to tight up the Pillar on the base. Be

sure those 5 screws have been fastened securely.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 11 -

Page 14

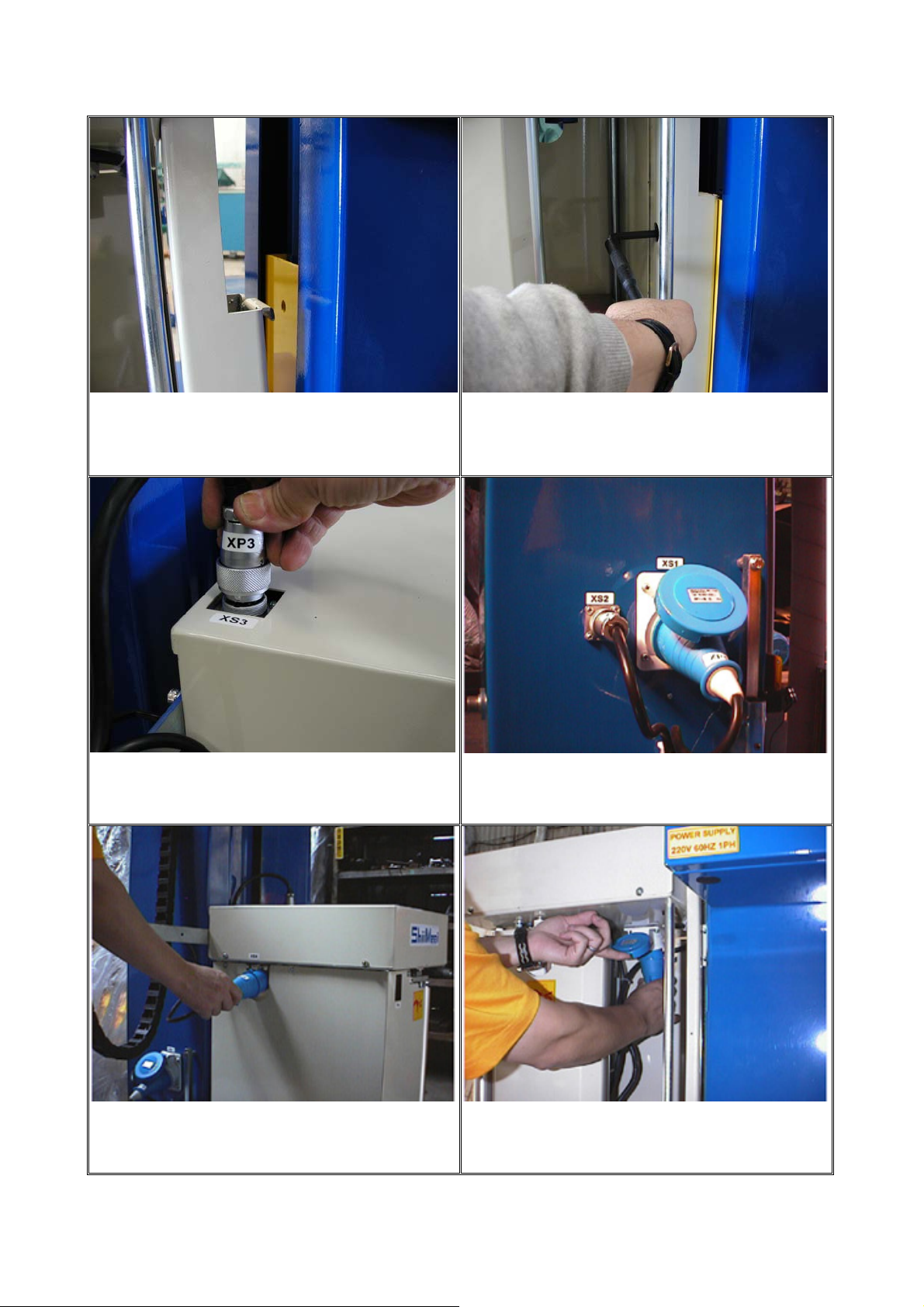

4-5 Assemble the Pre-stretch Unit

Place the M12 x 55 bolts into place and hook the

pre-stretch unit onto the film seat.

Connect XP3 onto XS3 and tighten.

Make sure bolts are tightened onto the film seat

to secure the pre-stretch unit and ensure safe

operation.

Connect XP1 onto XS1.

Extend connection point XP4 through the

Connect XP4 onto XS4.

pre-stretch unit.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 12 -

Page 15

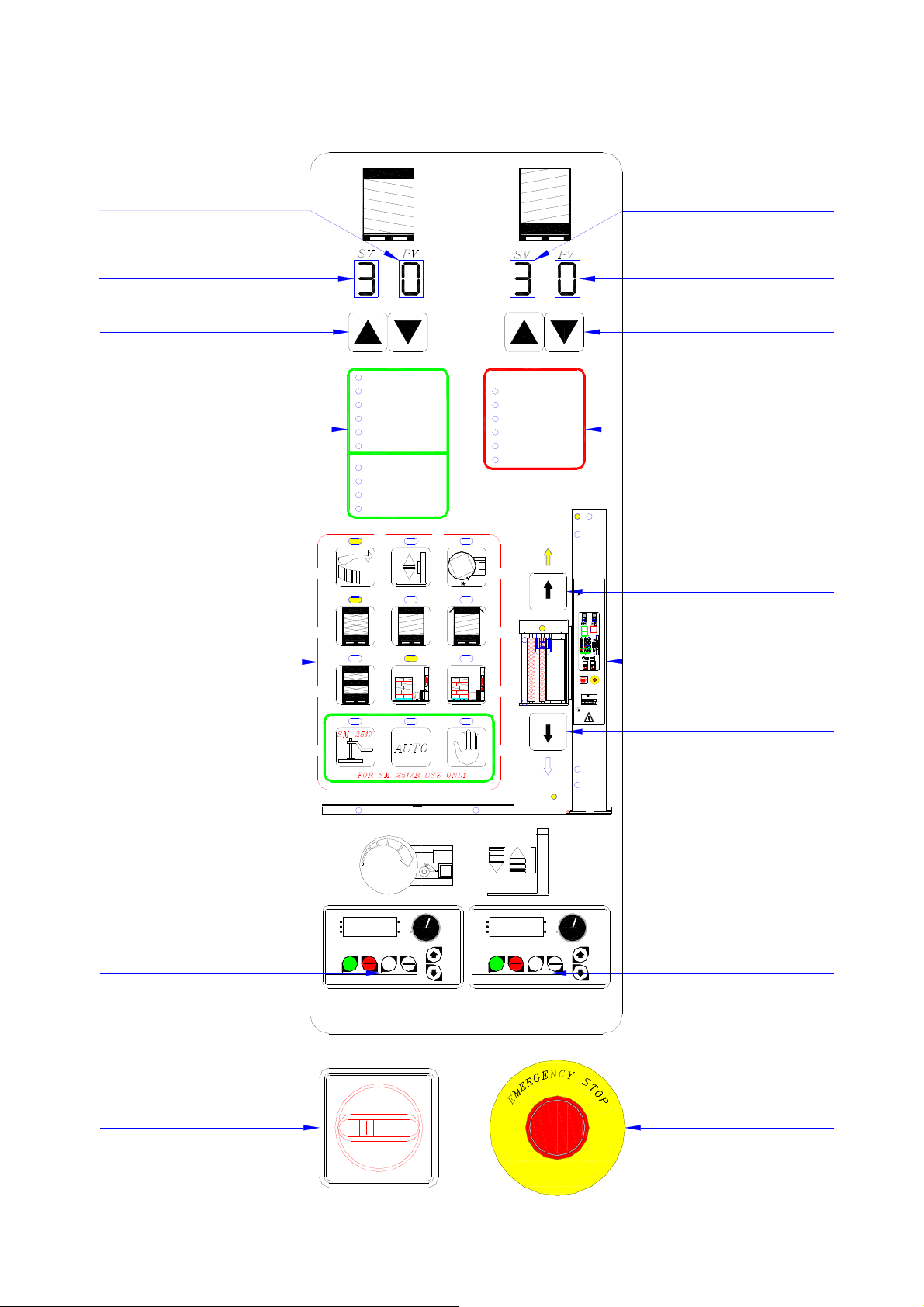

5 Control Panel

No. of Upper Layers Counted

No. of Upper layers Set

Cycle Setting of Upper layer

No. of Lower Layers Counted

No. of lower Layers Set

Cycle setting of Lower layer

Status Indication

Wrapping Function Control

Power

Stand By (AUTO)

Film Seat Zero Return

Turntable Zero Return

Film Cut

Turntable Slow Down

For SM-2517 Only

Follower-Plate Up

LS3-Up

Follower-Plate Down

LS4-Down

1 32

465

7

PS2

89

PS1

Breakdown Indicator

No Film (SM-1517R)

M1 Motor Trip-Out

M2 Motor Trip-Out

Emergency Stop

BK2 Fail

BK2 Fuse Fail

M3

PH

LS2-2

M1

LS2-1

Breakdown Indicator

BK2

M2

LS1

Pre-stretch Unit Carrier Ascent Key

Power

Breakdown Indicator

Stand By (AUTO)

No Film (SM-1517R)

Film Seat Zero Return

M1 Motor Trip-Out

Turntable Zero Return

M2 Motor Trip-Out

Film Cut

Emergency Stop

Turntable Slow Down

BK2 Fail

For SM-2517 Only

BK2 Fuse Fail

Follower-Plate Up

LS3-Up

Follower-Plate Down

LS4-Down

M2

BK2

LS1

M3

1

23

PH

564

LS2-2

7 98

LS2-1

LS2

M1

Motion Indication

PS2

PS1

l ON

F

F

O

0

STRETCH WRAPPING MACHINE

SERIES NO.

ITEM NO.

POWER

A

SM-

Hz

V

WEIGHT

DATE

AIR

Phase

Kgs.

bar

SHII MEEI INDUSTRIAL CO., LTD.

FAX:886 4 533−6776

TEL:886 4 533−6601

Pre-stretch Unit Carrier Descent Key

LS2

Turntable Speed Adjustment

RUN STOP

FWD

REV

PROG

PROG

RUN

MODE

RUN

DATA

DATA

VFD-e

PROG

DATA

RUN STOP

FWD

REV

PROG

PROG

RUN

MODE

RUN

DATA

DATA

VFD-e

PROG

DATA

Film-seat Speed Adjustment

l ON

F

Power Switch

F:\Manual\SM-1517R-110V-100514 14.05.2010.

F

O

0

- 13 -

Emergency Stop Button

Page 16

5-1 Description of Key pad’s function on the control panel

No. of Upper Layers Counted:

Displays the number of completed upper layer wrapping cycles. Screen should be blank prior to

start of wrapping cycle. When wrapping cycle begins, for each completed upper layer wrapping

cycle the number increases by 1. When number of upper layers counted reaches the number of

upper layers set, the film-seat will start descending.

No. of Upper Layers Set:

Displays the number of wrapping cycles set for the upper layer.

Cycle Setting of Upper Layer:

Sets the number of upper layer wrapping cycles. Press “▲” once increases wrapping cycle by 1 and

press “▼” decreases wrapping cycle by 1. Wrapping cycle can be set to 9 as maximum, however

usually is set between 2-5 depending on different needs. Please note that wrapping cycle can not be

set to 0, as to lengthen the life span of the elevation motor.

No. of Lower Layers Counted:

Displays the number of completed lower layer wrapping cycles. Screen should be blank prior to

start of wrapping cycle. When wrapping cycle begins, for each completed lower layer wrapping

cycle the number increases by 1. When number of lower layers counted reaches the number of

lower layers set, the film-seat will start ascending.

No. of Lower Layers Set:

Displays the number of wrapping cycles set for the lower layer.

Cycle Setting of Lower Layer:

Sets the number of lower layer wrapping cycles. Press “▲” once increases wrapping cycle by 1 and

press “▼” decreases wrapping cycle by 1. Wrapping cycle can be set to 9 as maximum, however

usually is set between 2-5 depending on different needs.

Status Indication:

For detail, refer section 5-3.

Breakdown Indication:

For detail, refer section 5-4.

Wrapping Function Control:

For detail, refer section 5-2.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 14 -

Page 17

Motion Indication:

For detail, refer section 5-5.

Turntable Speed Adjuster:

Turntable speed can be adjusted between 0-13rpm. This function should be used in conjunction

with the Film-seat Speed Adjuster, refer to Film-seat Speed Adjuster section for more detail.

Film-seat Speed Adjuster:

Film-seat speed can be adjusted between 0~3m/min, either quicken or slower film-seat elevation

speed for desired level of film overlap. When wrapping a test package, adjust turntable speed to

maximum 13rpm and film-seat to maximum 3m/min, then when wrapping completes study the level

of film overlap for further adjustment. If a higher level of film overlap is desired, slower the

film-seat speed; if a lower level of film overlap is desired, slower the turntable speed.

Power Switch:

Main power switch with a safety device. When switch is turned "ON", the switch will jam the

control panel door and prevent it from being opened to provide safety. Please note that if the control

panel door is to be opened this switch must be turned "OFF", or else if the door is forced open when

switch is at "ON" position, the switch will break. If the power switch is broken in such a manner, it

can not be replaced free of charge even if still under warranty.

Emergency Stop Button:

In case of emergency, press this button to stop the operation of the machine and the power will

automatically be turned off. Pull this button to deactivate the emergency stop.

Pre-stretch Unit Ascent Key:

This key is used to manually control the pre-stretch unit to ascent while the machine has stopped.

Press this key; the pre-stretch unit will go up. Release it, the pre-stretch unit will stop immediately.

Pre-stretch Unit Descent Key:

This key is used to manually control the pre-stretch unit to descent while the machine has stopped.

Press this key; the pre-stretch unit will go down. Release it; the pre-stretch unit will stop

immediately.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 15 -

Page 18

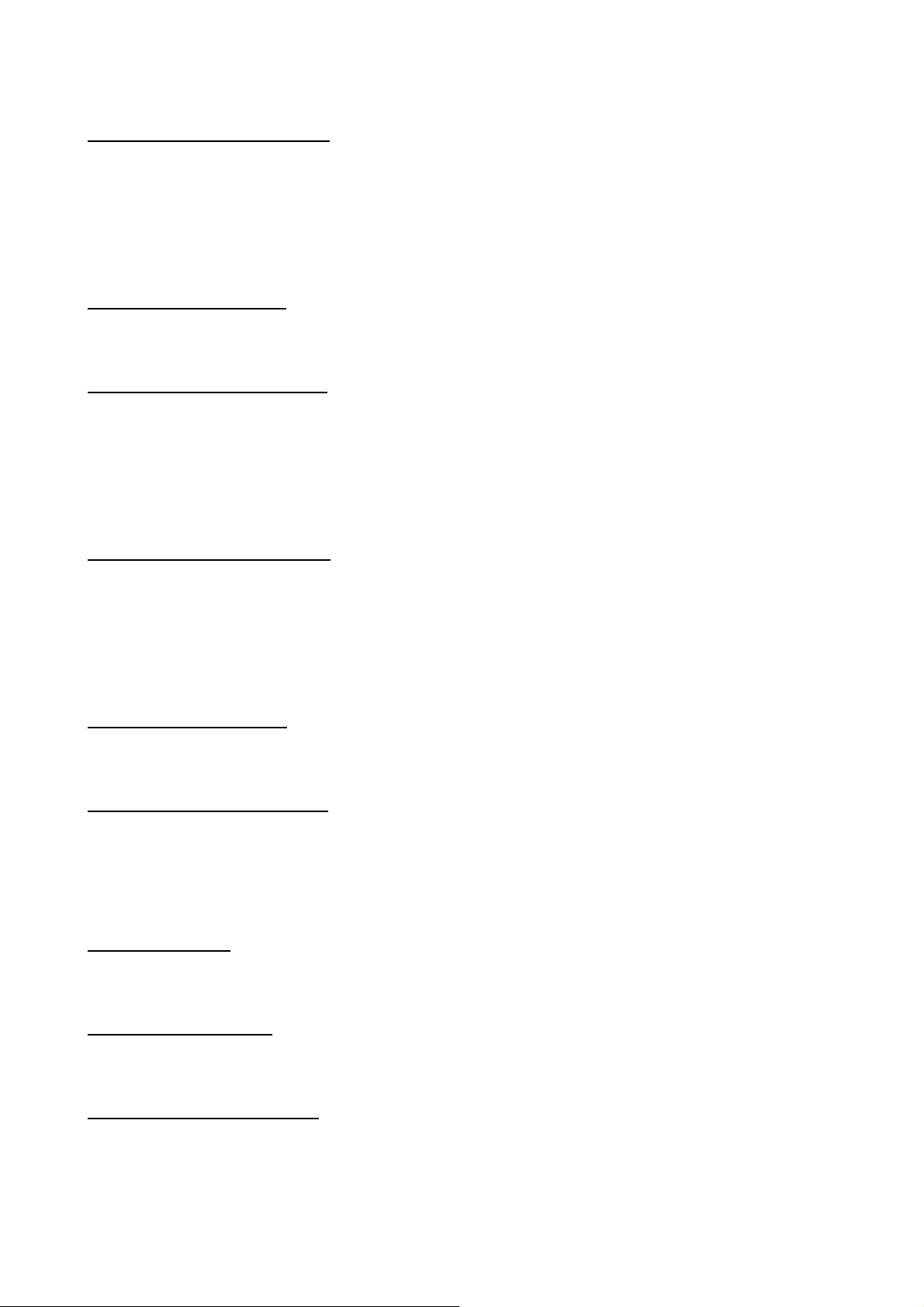

5-2 Wrapping Function Control

b

『Turntable Start』:

Starts the turntable rotation, motor will stop automatically when wrapping is

completed.

『Film-Seat Pause Button』:

When wrapping a particular section of the package that needs extra overlapping

of film to give strength, press and hold this button for the film-seat to pause at

the desired section of overlapping. When the operator is satisfied with the

amount of overlapping, release this button and the film-seat will continue its

ascending/descending.

『Turntable and Film-seat Zero-return Button』:

This button has two functions:

1: It can be used to determine the height of package in case of malfunctioning

of the electronic eye. When electronic eye malfunctions, the film-seat can not

sense the height of the package and will continue to ascend, in which case by

pressing this button the film-seat will cease ascending and start counting number

of upper layer wrapping cycles. Also press this button if the film wrapping

reaches a particular height of the package and further more wrapping above is

not desired.

2: If the emergency button is activated during wrapping, the turntable and the

film-seat will not be stopped at the starting position. Therefore in order for both

the turntable and the film-seat to return to their starting position, press this

utton once for turntable to return to starting position and press again for

film-seat to return to starting position.

『Standard Wrapping』:

Film starts wrapping from the bottom of the package to the top, and once from

top back to bottom。

『Single Layer Wrapping』:

Film wraps once from bottom to top and stops when turntable comes to a halt.

Film set then automatically descends down to starting point.

『Water Proof Wrapping』:

Film wraps from bottom to top and then comes to a halt at

approximately 10cm~15cm below the top of the package, then a sheet of water

proofing film or plastic should be manually placed on top of the package. Press

the Turntable Start button once more to restart the wrapping process, at which

the film will start wrapping from top back to bottom.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 16 -

Page 19

『Midpoint Strengthen Wrapping』:

Film wraps from bottom to top and completes the upper layer wrapping cycle.

When returning from top back to bottom, film set will pause at the midpoint of

the package to complete 2 wrapping cycles and then back to bottom to

complete wrapping.

『Auto cut option』:

l ON

0 OFF

To choose the auto cut option.

『Non-auto cut option』:

l ON

0 OFF

R

STRETCH WRAPPING MACHINE

ITEM NO.

POWER

SERIES NO.

SM-

V

A

Hz

DATE

AIR

WEIGHT

Phase

Kgs.

bar

SHII MEEI INDUSTRIAL CO., LTD.

26, Sec. 1, Ta Fu Road, Tan Tzu Hsiang,

Taichung Hsien, Taiwan, R.O.C.

TEL:886 4 533−6601

FAX:886 4 533−6776

To choose the non-auto cut option.

For SM-2517 & SM-2517R Use only

『Follower-Plate Fall Down Button』:

To lower the follower-plate, used in conjunction with the 『Auto 』&

『Manual』buttons. When set at 『Auto』, press this button to lower

follower-plate onto package until tight, after which the follower-plate stops

lowering and turntable rotation starts. If set at 『Manual』, press this button to

lower follower-plate to stop lowering follower-plate. There is need to press

the Turntable 『Start』button to start turntable rotation when using 『Manual』

function..

『Auto』Wrapping Modes Setting Key:

When this function is set the button will light up. Press the “Follower-plate

Down” button when this function is activated, the follower-plate will

automatically lower onto package until tight and turntable rotation will start.

When wrapping cycle is completed, the follower-plate will lift up again. No

need to press any other button.

『Manual』Wrapping Modes Setting:

When this function is set, press the “Follower-plate Down” button to lower the

follower-plate and limit switch LS4 is touched to stop lowering. The turntable

will not start automatically, therefore press “Turntable Start” button to start

turntable rotation.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 17 -

Page 20

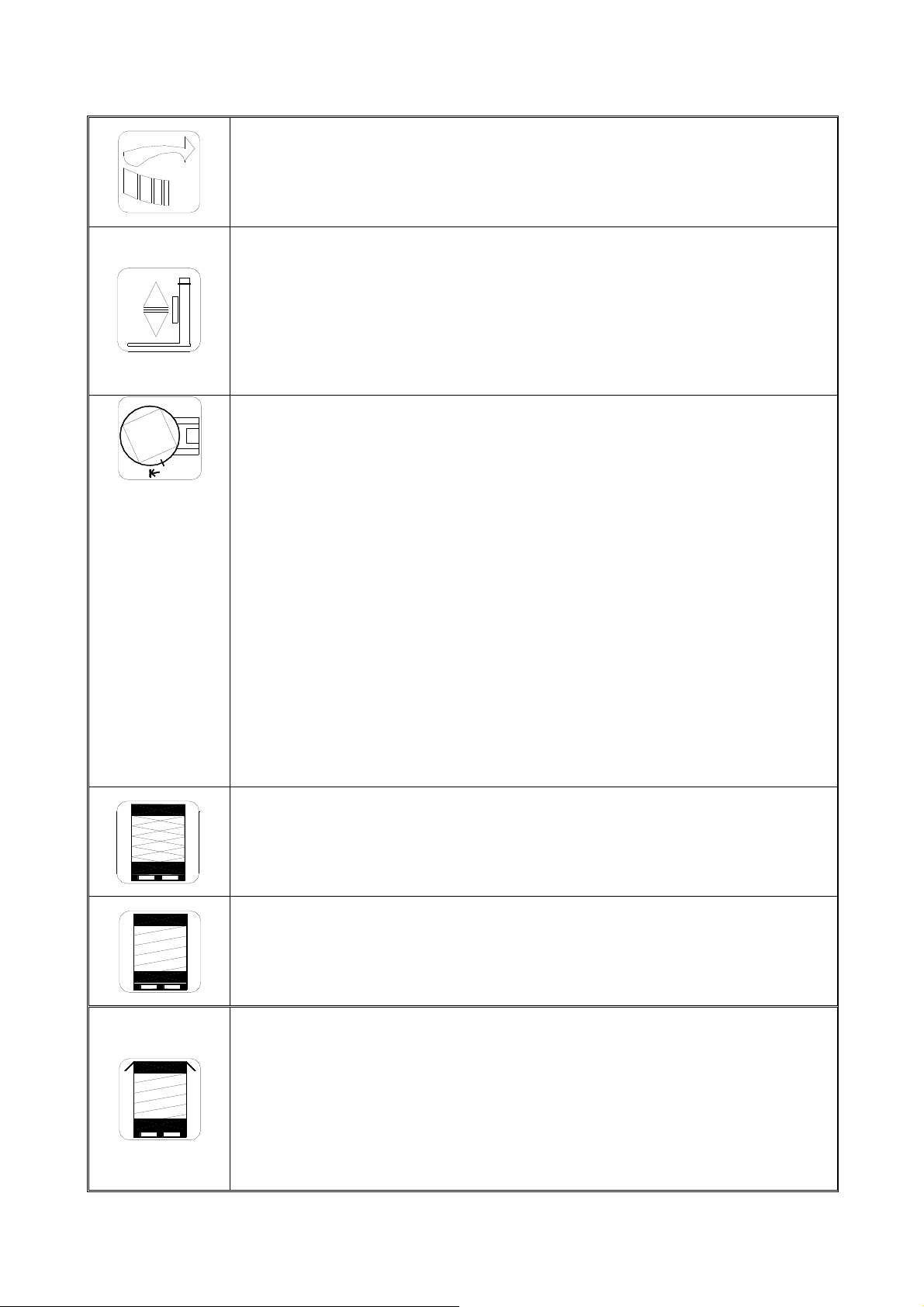

5-3 Status Indication

Power

Stand By (AUTO)

Film Seat Zero Return

Turntable Zero Return

Film Cut

Turntable Slow Down

For SM-2517 Only

Follower-Plate Up

LS3-Up

Follower-Plate Down

LS4-Down

○Power Pilot

When LED light is on, the power is at the “ON” status; when LED light is off, the power is at the

“OFF” status.

○Stand By (AUTO)

The machine is in standby status.

○Film Seat Zero Return:

The film carrier is descending back to the Zero point.

○Turntable Zero Return:

The turntable is rotating back to the Zero point.

○Film Cut

The machine is breaking the film,

○Turntable Slow Down

The turntable is slowing down,

○Follower-Plate Up

The Follower-Plate is ascending,

○LS3-Up

LS3 is the (Zero point) limit switch: If this light on indicates the “Follower-Plate” has ascended

back to the Zero Point. If the “Follower-Plate” has not back to the Zero Point the machine will not

be operated.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 18 -

Page 21

○Follower-Plate Down

The Follower-Plate is descending,

○LS4-Down

If this light on, indicates the “Follower-Plate” has clamped the package tight and the

“Follower-Plate” will be stopped. If this light has not on, the machine will not be operated.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 19 -

Page 22

5-4 Breakdown Indication

Breakdown Indicator

No Film (SM-1517R)

M1 Motor Trip-Out

M2 Motor Trip-Out

Emergency Stop

BK2 Fail

BK2 Fuse Fail

○No Film:

Indicates no film; only SM-1517Rhas this function.

○M1 Motor Trip-Out:

The M1 motor is overloaded and its breaker jumped.

○M2 Motor Trip-Out:

The M2 motor is overloaded and its breaker jumped.

○Emergency Stop:

Emergency Stop Indicator, When the LED light is on, the emergency stop button is currently being

activated.

○BK2 Fail:

The BK2 electrical Break has failed.

○Bk2 Fuse Fail:

The fuse of the BK2 electrical Break has failed.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 20 -

Page 23

5-5 Motion Indication

M2

BK2

LS1

M3

PH

Power

Breakdown Indicator

No Film (SM-1517R)

Stand By (AUTO)

M1 Motor Trip-Out

Film Seat Zero Return

M2 Motor Trip-Out

Turntable Zero Return

Emergency Stop

Film Cut

BK2 Fail

Turntable Slow Down

For SM-2517 Only

BK2 Fuse Fail

Follower-Plate Up

LS3-Up

Follower-Plate Down

LS4-Down

M2

BK2

LS1

M3

3

2

PH

6

514

LS2-2

987

LS2-1

LS2

M1

PS2

PS1

l ON

F

F

O

0

R

STRETCH WRAPPING MACHINE

SERIES NO.

ITEM NO.

POWER

A

SM-

Hz

V

WEIGHT

DATE

AIR

Phase

Kgs.

bar

SHII MEEI INDUSTRIAL CO., LTD.

26, Sec. 1, Ta Fu Road, Tan Tzu Hsiang,

Taichung Hsien, Taiwan, R.O.C.

TEL:886 4 533−6601

LS2-2

FAX:886 4 533−6776

LS2-1

LS2

M1

PS2

PS1

M2 Motor Ascending and Descending Indicator

If this LED light is on indicates the M2 motor is in operation, the pre-Stretch Unit is ascending or

descending.

LS1 Upper Limit Safety Switch Indicator

If this LED light is on, indicates the package has over the packing height limit of this machine or

the PH (height detecting optical sensor) has failed; please check if the package height has over the

limit or PH sensor has failed.

M3 Pre-Stretch Unit Motor Indicator

When the turntable is starting to rotate and the film pulls the free roller, this light will be on and the

film will start to be sent out from the Pre-Stretch Unit; if this LED light is not on, the film will not

be sent out from the Pre-Stretch Unit.

PH Height Detecting Optical Sensor Indicator

When PH has detected the package, this LED light will not be on. Once the film carrier ascend and

the PH sensor can not detect the package, this light will be on and the film carrier stop.

LS2-2 Pre-Stretch Unit Safety Switch Indicator

This switch is parallel link with the LS2 (lower Limit Safety Switch). When this LED light is on

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 21 -

Page 24

indicates the Pre-Stretch Unit has descended to the lower limit or the Pre-Stretch Unit has pressed

any object and the turntable will be stopped.

LS2-1 Lower Limit Switch Indicator

When this LED light is on indicates the Pre-Stretch Unit has descended to the bottom position and

the Pre-Stretch Unit will stop to descend.

LS2 Lower Limit Safety Switch Indicator

This switch is parallel link with the LS2-2 (Pre-Stretch Unit Safety Switch). When this LED light is

on indicates the Pre-Stretch Unit has descended and over the bottom of the machine or the LS2-1

has failed. Please check the LS2-1 switch.

M1 Turntable Motor Indicator

This LED light on indicates M1 (Turntable Motor) is operating and the turntable is rotating.

PS1 Allocation and Counter Indicator

When the turntable completes a rotation, this LED light will flash once. Therefore this indicator

expresses two functions: a counter and an indication of a complete rotation.

Counting Function:

When the turntable completes a rotation this indicator will flash once and the counter number will

be increased by one until the rotation number has reach the pre-set wrapping number. After that,

although the turntable completes one rotation and this indicator will still flash once, however the

counter number will not be increased.

Allocation Function:

When PS2 (Slow Stopping Indicator) flashes once, the turntable will start to slow down, once the

PS1 indicator flashes the turntable will be stopped immediately. This indicator’s light will be on to

indicate the turntable has stopped at the zero point.

PS2 Slow Stopping Indicator

When the LED light of LS2-1 is on, once the turntable passed the PS2 switch, the light of the “PS2

Slow Stopping Indicator” will flash once and the turntable will start to be slowing down until the

turntable has fully stopped.

Pre-Stretch Unit Ascending Indicator

This LED light on indicates the Pre-Stretch Unit is ascending.

Pre-Stretch Unit Descending Indicator

This LED light on indicates the Pre-Stretch Unit is descending.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 22 -

Page 25

6 Film Loading (For safety please switch off main power when loading film.)

1. Pull out approx. 60cm of film in counter-

Clock direction.

3. Pull down film seat cover lock.

2. Place film into film seat.

4. Open film seat cover.

5. Pull out film between film seat cover And

film seat rollers.

6. Have at least 20-30cm of film out through

between film seat cover and rollers.

7. Close film seat cover and switch on power

to start operation.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 23 -

Page 26

7 Film Tension Adjust

The pre-stretch unit has a set pre-stretch percentage of 240% (can not be changed) which is

called the First Stage Pre-stretch, therefore there is no pre-stretch setting device on the control panel.

The pre-stretch percentage can be slightly adjusted to a maximum of 320%, which is called the

Second Stage Pre-stretch, and its adjusting method is shown below:

There are 2 sets of nuts and bolts located on the top and bottom of the free roller and is used to

adjust pre-stretch ratio.

Pull away the free roller and 2 springs can be seen attached to the 2 sets of nuts and bolts.

Slightly tighten the nuts onto the bolts to pull on the springs in order to increase pre-stretch ratio.

Warning: Do not pull on free roller while pre-stretch unit in operation, as not to cause film

jamming into rollers.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 24 -

Page 27

8 Operation Procedure

1.

Turn power switch to "ON" position.

2.

Set number of upper and lower layer cycles.

3.

Set film tension.

4.

Set film-seat speed.

Pull out a small length of film and tie to pallet or to hook

5.

on turntable.

6.

Press start button.

7.

To continue wrapping, just repeat steps 5 and 6.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 25 -

Page 28

9 Maintenance

9-1 Installing and removing turntable

Firstly remove the 4 fixing screws from the

turntable, then screw on the 2 lifting devices

onto turntable perpendicularly.

Use one of the forklift’s forks to penetrate

the lifting devices.

Lift the turntable up and away from the

machine to begin maintenance and service.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 26 -

Page 29

9-2 Adjusting tightness of turntable chain

In case of turntable chain becoming loose.

1. Use a 6mm L shape spanner, in counter-clockwise direction, loosen the two M8 bolts.

2. Use a 14mm open spanner, in clockwise direction, turn the M14 nut to tighten the chain.

3. Similar to step 1, use a 6mm L shape spanner to tighten the two M8 bolts in clockwise

direction.

4. Put little amount of grease oil on the chain and the six turntable supporting wheels.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 27 -

Page 30

10 Electrical

10-1 Part list of electrical components

Item

designation

SP1 Switching power

SP2 Switching power

SP3 Switching power

KS-050201-MB Controller Kai Shun KS-050201-MB DC-5V

KS-050202-KEY Key board pcb Kai Shun KS-050202-KEY DC-5V EN61000-4-5

KS-050203-TB Terminal block pcb Kai Shun KS-050203-TB DC-5V,12V,24V EN61000-4-5

Description &

function

supply, supply dc

power to controller

supply, supply dc

power to sps1

supply, supply dc

power to brake

Manufacture Type Technical data Complies with the

following standards

Mean Well PD-25A Ue=240VAC

OUT1:DC5V 2.1A

OUT2:DC12V1.2A

Mean Well NES-15-24 Ue=240VAC

OUT:DC 24V 1A

Mean Well PS-65-24 Ue=240VAC

OUT:DC 24V 2.7A

6MHZ

EN61000-4-5,EN60950 CE,TUV

EN60950,EN61000-4-5 CE

EN60950,EN61000-4-5 CE

EN61000-4-5

ENV50204

ENV50204

Marking of

conformity granted

CE

CE

CE

ENV50204

MPSW1 Power switch ABB OT25E3 Ue=750VAC

Ith=32A

AC-23A=20A

LF Line filter Hi & Lo 20SS4-1BC2-B Ue=250VAC

Ith=20A

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 28 -

EN60204

IEC 947/1,3

IEC60947

E134751 CE

CE

Page 31

Item

designation

MS Protected inverters

Description &

function

Manufacture Type Technical data Complies with the

Iskra MS25-20 Ue=750VAC

and motors

IVR1 Inverter, controls

DELTA VFD007E11A Ue=115VAC

motor1’s speed

IVR2 Inverter, controls

DELTA VFD004E11A Ue=115VAC

motor2’s speed

IVR3 Inverter, controls

DELTA VFD004E11A Ue=115VAC

motor3’s speed

FAN Heat sink

PROFANTEC

P1082HST Ue=115VAC 0.14A EN 61000-3-2

E-STOP Emergency stop T.E. ZA5BT4/

10

F1

Fuse, Protected the

DEMEX FM04L-B/1A Ue=250V

Icu=100KA

Ie=20A

0.75KW

0.40KW

0.40KW

Ue=400VAC

Ith=10A

Marking of

following standards

EN60947-2

conformity granted

CE,UL,CSA

EN60947-4-1

EN60204-1

EN50178,

CE,UL

EN61800-3

EN50178,

CE,UL

EN61800-3

EN50178,

CE,UL

EN61800-3

CE,UL

IEC 801-4

EN60947-1,EN60947-5-1 CE,UL,CSA

CE 947.3 CE.UL

cutter of solenoid

Ith=10A

FUSE=1A

F2 Fuse, Protected the

cutter of solenoid

DEMEX FM04L-B/1A Ue=250V

Ith=10A

CE 947.3 CE,UL

FUSE=1A

F3 Fuse, Input ac

power to switching

power sp1,sp2

F:\Manual\SM-1517R-110V-100514 14.05.2010.

DEMEX FM04L-B/3A Ue=250V

Ith=10A

FUSE=3A

- 29 -

CE 947.3 CE,UL

Page 32

Item

designation

F4 Fuse, Input ac

LS1 Upper limit switch COCA AZ-8108 Ue=240VAC Ith=5A EN60947-5-1

Description &

function

power to switching

power sp1,sp2

Manufacture Type Technical data Complies with the

following standards

DEMEX FM04L-B/3A Ue=250V

CE 947.3 CE,UL

Ith=10A

FUSE=3A

conformity granted

CE

EN81

EN115

LS2 Lower limit switch COCA AZ-8104 Ue=240VAC Ith=5A 73/23/EEC CE

LS2-1 Lower limit switch COCA AZ-8104 Ue=240VAC Ith=5A 73/23/EEC CE

LS2-2 Lower limit switch OMRON Z-15GQ22-B Ue=250VAC

EN 60947-1 CE,VDE,UL

Ith=15A

PS1 Proximity

sensor

PS2 Proximity

sensor

TEND TP-SM-5N1 Ue=30VDC

Iout=150mA 4m/m

TEND TP-SM-5N1 Ue=30VDC

Iout=150mA

EN 50082-2,

EN61000-3-2

EN 50082-2,

EN61000-3-2

CE

CE

Marking of

4m/m

PH Photo Sensor FOTEK FR-2MX Ue=30VDC

Iout=150mA

EN50082-1

IEC802-1

IEC801-3

EN55011

SPS1 Proximity

sensor

PULSO 9914-0900 Ue=30VDC

Iout=10mA

EN 50010 CE

IP67

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 30 -

CE

Page 33

Item

designation

M 1 Motor

M 2 Motor

M 3 Motor

Description &

function

Manufacture Type Technical data Complies with the

following standards

ADLEE Co.,

Ltd.

T.G.P.Co 3~AC 230VAC

Liming Co.,

Ltd.

3~AC 230VAC

0.75kW

0.2kW

3~AC 230VAC

0.2kW

Ue=220VAC

EN60034-1 CE

IP55

Ue=220VAC

EN60034-1 CE

IP54

xxx

Marking of

conformity granted

BK2 Brake for motor2 T.G.P.Co. SBV-063 DC24V EN60034-1 CE

XS1 Connector

STARHL

CP00401627 Ue=380VAC

CEI23-12/VII CE

Ith=16A

4 POLES IP67

XP1 Connector

STARHL

CP11401627 Ue=380VAC

CEI23-12/VII CE

Ith=16A

4 POLES IP67

XS2 Connector APEX CO. PLS-207-RF -------

XP2 Connector APEX CO. PLS-207-PM -------

XS3 Connector APEX CO. PLS-207-RM -------

XP3 Connector APEX CO. PLS-207-PF -------

XS4 Connector

STARHL

CP01301624

Ue=220VAC

Ith=16A

CEI23-12/VII CE

3 POLES IP54

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 31 -

Page 34

Item

designation

XP4 Connector

Description &

function

Manufacture Type Technical data Complies with the

following standards

STARHL

CP20301624 Ue=220VAC

CEI23-12/VII CE

Marking of

conformity granted

Ith=16A

3 POLES IP54

TB9,TB11 Terminal block ENTRELEC D4/6 UE=660VAC

EN60847-1 CE

Ith=27A

TNR1 TNR MARCON 15G471K Ue=300VAC 80J. ------

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 32 -

Page 35

10-2 EMC Component List

Item Name Specification Refer to ckt. diagram Approved document

1 MOTOR1 3~ 0.75KW AC220V SM-1517R: P.1

2 MOTOR2 3~ 0.2KW AC220V SM-1517R: P.1

3 MOTOR3 3~ 0.2KW AC

220V

4 LINE FILTER 20SS4-1BC2-B

20A AC250V

5 INVERTER1 VFD007E-11A

0.75KW AC 115V

6 INVERTER2 VFD004E-11A

0.4KW AC 115V

7 INVERTER3 VFD004E-11A

0.4KW AC 115V

9 SWITCHING POWER

SUPPLY

10 SWITCHING POWER

SUPPLY

11 MAIN POWER

SWITCH

PD-25A DC5V SM-1517R: P.1 EMC-P.5

PS-65-24 DC24V

2.7A

OT25E3 Ith=32A

AC 250V

SM-1517R: P.5

SM-1517R: P.1 EMC-P.1

SM-1517R: P.1 EMC-P.2

SM-1517R: P.1 EMC-P.2

SM-1517R: P.5 EMC-P.2

SM-1517R: P.1 EMC-P.5

SM-1517R: P.1 EMC-P.6

12 PC BOARD KS-050201-MB SM-1517R: P.2, P.3 EMC-P.7

13 PC BPARD KS-050202-KEY SM-1517R: P.2 ,P.3,P4 EMC-P.7

14 PC BPARD KS-050203-TB SM-1517R: P.5 EMC-P.7

15 SWITCHING POWER

SUPPLY

16 FAN 3-115S

17 PROXIMITY

SENSOR

NES-15-24 DC 24V

0.7A

115VAC 0.07A

TP-SM5N1 DC30V SM-1517R: P.7 EMC-P.11

SM-1517R: P.5, P.7 EMC-P.8

SM-1517R: P.1 EMC-P.10

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 33 -

Page 36

10-3 Electrical Wiring Diagram

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 34 -

Page 37

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 35 -

Page 38

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 36 -

Page 39

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 37 -

Page 40

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 38 -

Page 41

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 39 -

Page 42

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 40 -

Page 43

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 41 -

Page 44

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 42 -

Page 45

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 43 -

Page 46

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 44 -

Page 47

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 45 -

Page 48

11 Troubleshooting

When problem with machine occurs, please check if power input is of correct voltage and

check that power supply PD-25A is outputting DC5V and DC12V and check that power supply

PS-65-24 is outputting DC24V ..

11-1-1 Power indication hasn’t lighted on

Refer to PC board KS-050201-MB, check

if there’s DC5V at P1 and P2 on CN1.

Refer to PC board PD-25A, check if there’s

DC5V at P1 and P2 on CN2.

Check if FUSE F1 on PC board PD-25A is

blown.

Refer to PC board PD-25A, check if there’s

AC220V at P1 and P2 on CN1.

Check if there’s AC110V at terminal L12

and L22.

NO

NO

NO

NO

YES Replace PC board KS-050202-KEY

and connection cord CN2

YES

Replace connection cord CN1.

YES

Replace FUSE.

YES

Replace PC board PD-25A.

YES

Replace FUSE F3 and F4(3A).

Check if there’s AC110V at terminal L12

and L22.

Check if input power voltage is normal.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

NO

NO

YES

YES

- 46 -

Replace Line Filter.

Replace Main Power Switch.

Page 49

11-1-2 There isn’t DC12 Volt. on power supply PD-25A

Refer to PC board KS-050201-MB, check

if there’s DC12V at P3 and P4 on CN1.

NO

Refer to PC board PD-25A, check if there’s

DC12V at P3 and P4 on CN2.

NO

Check if FUSE F1 on PC board PD-25A is

blown.

NO

Refer to PC board PD-25A, check if there’s

AC220V at P1 and P2 on CN1.

NO

Check if there’s AC110V at terminal L12

and L22.

YES

Replace connection cord CN11

YES

Replace connection cord CN1.

YES

Replace FUSE.

YES

Replace PC board PD-25A.

YES

Replace FUSE F3 and F4(3A).

NO

Check if there’s AC110V at terminal L11

and L21.

NO

Check if input power voltage is normal.

YES

Replace Line Filter.

YES

Replace Main Power Switch.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 47 -

Page 50

11-1-3 There isn’t DC24 Volt. on power supply PS-65-24

Refer to PC board PS-65A, check if there’s

DC24V at P1 and P4 on CN2.

Check if FUSE F1 on PC board PS-65A is

blown.

Refer to PC board PS-65A, check if there’s

AC220V at P1 and P2 on CN1.

Check if there’s AC110V at terminal L12

and L22.

Check if there’s AC110V at terminal L11

and L21.

NO

NO

NO

NO

YES

Replace connection cord CN9.

YES

Replace FUSE.

YES

Replace PC board PS-65A.

YES

Replace FUSE F3 and F4(3A).

YES

Replace Line Filter.

Check if input power voltage is normal.

NO

YES

Replace Main Power Switch.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 48 -

Page 51

11-2-1 Turntable motor not operating (Inverter)

Condition:

a.) LED M1 is lighting up on PC board KS-050202-KEY.

b.) Emergency Stop is normal and does not be activated.

c.) Variable resister VR1 has been normal and has been turned to maximum position.

d.) There’s AC110V at terminal R and T on Inverter IVR1.

e). Touch Start key and start LED light up.

Check if there’s AC220V at outputs U,V

and U,W and V,W on Inverter IVR1.

Refer to Inverter IVR1, short terminal MI1

and DCM with a wire. Check if the motor M1

is working.

Replace Inverter IVR1.

NO

NO

YES

YES

11-2-2. Turntable motor speed not adjustable

Replace motor M1.

Replace PC board

KS-050201-MB.

Check if Variable resister VR1 is working.

Check if Inverter IVR1 is working.

NO

YES

YES

Check if Inverter IVR1 is working.

Check if Inverter IVR1 is working.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 49 -

Page 52

11-3-1 Film-seat motor brake (BK2) not working

Condition:

a). Relay RYBK2 is working on PC board KS-050201-MB and LED BK2 would light up.

b). Fuse F1 (2A) on PC board KS-050201-MB is normal. (If a fuse F1 was blown, red LED BK2

Fuse fail on PC board KS-050202-KEY would light up.)

Check if brake B2+ and B2- contain

DC24V.

NO

Check if there’s DC24V at terminal 0V and

24V of CN9 on PC board KS-050201-MB.

NO

Refer to1-3, check if switching power

PS-65-24 is working.

YES

Replace brake BK2.

YES

Replace Relay RYBK2

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 50 -

Page 53

11-3-2 Film-seat elevator motor not rising

f

Condition:

a). LED M2 is lighting up on PC board KS-050202-KEY. IC OP1 has controlled elevator rising.

b). Relay RYBK2 is working, LED BK2 on PC board KS-050202-KEY and LD26 on PC board

KS-050201-MB are lighting up. Relay RYBK2 has controlled brake BK2 working.

c). Brake BK2 is working.

d). LED MD and MD1 can’t work at the same time when LED MU and MU1 are working.

e). There’s AC110V at terminal R and S terminal on Inverter IVR2.

f). Emergency Stop is normal and does not activate.

g). Variable resister VR2 has been normal and has been turned to maximum

position.

Check if there’s AC220V at outputs U,V

and U,W and V,W on Inverter IVR2.

Refer to Inverter IVR2, short terminal MI1

and DCM (ascending) with a wire. Check if

the display screen on Inverter changes and

motor M2 is working.

Refer to Limit Switch LS1, short Terminal

Block TB2 at terminal MU and MU1 with a

wire on PC board KS-0502030-TB. Check if

the display screen on Inverter changes and

motor M2 is working.

Refer to Limit Switch LS1, short Terminal

NO

YES

NO

YES

Replace Motor M2.

NO

Replace Inverter IVR2.

YES

Replace Limit Switch LS1.

Block TB2 at terminal MU and MU1 with a

wire on PC board KS-0502030-TB. Check i

the display screen on Inverter changes and

motor M2 is working.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 51 -

Page 54

11-3-3 Film-seat elevator motor not setting

Condition:

a). LED M2 is lighting up on PC board KS-050202-KEY. IC OP2 has controlled elevator setting.

b). Relay RYBK2 is working, LED BK2 on PC board KS-050202-KEY and LD26 on PC board

KS-050201-MB are lighting up. Relay RYBK2 has controlled brake BK2 working.

c). Brake BK2 is working.

d). LED MU and MU1 can’t work at the same time when LED MD and MD1 are working.

e). There’s AC110V at terminal R and S terminal on Inverter IVR2.

f). Emergency Stop is normal and does not activate.

g). Variable resister VR2 has been normal and has been turned to maximum

position.

h). Limit Switch LS2,LS2-1,LS2-2 doesn’t be activated.

Check if there’s AC220V at outputs U,V

and U,W and V,W on Inverter IVR2.

Refer to Inverter IVR2, short terminal MI2

and DCM (descending) with a wire. Check if

the display screen on Inverter changes and

motor M2 is working.

Refer to Limit Switch LS2, short Terminal

Block TB2 at terminal MD and MD1 with a

wire on PC board KS-050203-TB. . Check if

the display screen on Inverter changes and

motor M2 is working.

NO

NO

NO

YES

Replace Motor M2.

YES

Replace Inverter IVR2.

YES

Replace Limit Switch LS2.

Replace PC board KS-050201-MB.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 52 -

Page 55

11-4 Film-seat doesn’t stop when reached package limit

Check if Photo switch PH is working.

Refer to 3-1,check if Brake BK2 is

working.

Replace PC board KS-050201-MB

YES

NO

11-5 Film-seat doesn’t pause

NO

YES

Replace PC board KS-050201-MB

Replace Brake Bk2.

Check if Relay RYBK2 on PC board

KS-050201-MB, LED M2, MU and LED MD

on PC board KS-050202-KEY is not working.

(LED M2, MU and MD are dark on PC board

KS-050202-KEY and Pause indicator should

light up on operation panel if working).

Refer to 3-1,Brake BK2, check if Brake

BK2 is Normal.

YES

NO

Replace PC board KS-050201-MB.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 53 -

Page 56

11-6-1 Film-seat doesn’t stop after reaching maximum packaging limit

Condition:

a). LED LS1 lights up on PC board KS-050202-KEY when Film-seat touched limit switch LS1.

b). Brake BK2 is normal.

c). LED M2, MU and MD are dark on PC board KS-050202-KEY.

Move connection cord of CN8 away from

PC board KS-050201-MB, check if film-seat

stops.

Check Inverter IVR2 and motor M2.

NO

YES

Replace PC board KS-050201-MB.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 54 -

Page 57

11-6-2 Film-seat doesn’t stop after returning to starting position

Condition:

a). LED LS2 lights up on PC board KS-050202-KEY when Film-seat touched limit switch LS2.

b). Brake BK2 is normal.

c). LED M2, MU and MD are dark on PC board KS-050202-KEY.

Move connection cord of CN8 away from

PC board KS-050201-MB, check if film-seat

stops.

Check Inverter IVR2 and motor M2.

NO

YES

11-6-3 Film-seat motor speed not adjustable

Check if Variable resister VR2 is working.

Check if Inverter IVR2 is working.

Yes

NO

NO

Replace PC board KS-050201-MB.

Replace Variable resister VR2

Replace Inverter IVR2.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 55 -

Page 58

11-7-1 Turntable hasn’t slowed down before completing wrapping cycle

Check if LED TURNTABLE SLOW

DOWN lights up on PC board

KS-050202-KEY.

NO

Check if LED PS2 flashes once on PC

board KS-050202-KEY when turntable

rotated a time.

YES

Replace PC board KS-050201-MB. Check

if turntable has slowed down.

NO

Replace Inverter IVR1.

YES

Replace PC board KS-050201-MB.

NO

Replace Proximity Switch PS2.

YES

Replace PC board KS-050201-MB.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 56 -

Page 59

11-7-2 Turntable doesn’t stop after completing wrapping cycle

Condition:

a). Turntable has slowed down.

Check if LED M1 and LED Turntable Slow

Down are dark on PC board

KS-050202-KEY.

Check if LED M1 and LED Turntable Slow

Down are dark on PC board

KS-050202-KEY.

Replace PC board KS-050201-MB. Check

if turntable has stooped.

Replace Inverter IVR1.

NO

YES

NO

YES

Replace PC board KS-050201-MB.

NO

Replace Proximity Switch PS1.

YES

Replace Proximity Switch PS1.

11-8 LS1, LS2, LS2-1, LS2-2, PS1, PS2 and PH not operating normally on PC board

KS-050202-KEY

11-8 LS1, LS2, LS2-1, LS2-2, PS1,

NO

Replace limit switches, photo switch

PS2 and PH not operating normally on

PC board KS-050202-KEY

and proximity switches.

Replace PC board KS-050202-KEY. Check

if normal operation resumes.

YES

NO

Replace PC board KS-050201-MB.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 57 -

Page 60

11-9.Control panel buttons not working

Condition:

a). Power supply SP1 is normal (DC5V and DC12V).

b). Emergency Stop is normal and does not be activated.

c). Fuse F3 and F4 are normal.

Replace connection cord CN2 26P and

CN4 50P on PC board KS-050202-KEY and

then check if normal operation resumes.

NO

Replace PC board KS-050202-KEY and

then check if normal operation resumes.

NO

Replace PC board KS-050202-KEY and

then check if normal operation resumes.

NO

Contact manufacturer.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 58 -

Page 61

11-10 Pre-stetch motor M3 hasn’t worked:

Condition:

a). LED M3 lights up on PC board KS-050202-KEY.

b). There’s AC110V at terminal R and S terminal on Inverter IVR3.

c). Power supply SP2 has worked normal. (Supply DC24V to proximity switch SPS1)

Check if there’s AC220V at outputs U,V

and U,W and V,W on Inverter IVR3.

NO

Refer to Inverter IVR3, short between

terminal MI1 and DCM with a wire. Check if

the display screen on Inverter changes and

motor M3 is working.

NO

Refer to Inverter IVR3, short between

terminal MI1 and DCM with a wire. Check if

the display screen on Inverter changes and

motor M3 is working.

YES

Replace Motor M3.

YES

Replace PC board KS-050201-MB.

NO

Replace Inverter IVR3.

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 59 -

Page 62

12 Machine parts diagram

11000 Pillar

12000 Film-Seat

14000 Bottom Plate

18000 Control Box

19000 Pre-stretch Unit

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 60 -

Page 63

12-1-1 Fig-11000 Pillar Parts Diagram

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 61 -

Page 64

12-1-2. Fig-1100 Pillar parts table (1)

Qty

Ref. Part No. Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

FMS-6 x 15

1506-11002

1506-11003

CAP-8 x 30

SPW-8

WS-8

BH-8 x 30

SPW-8

WS-8

HN-8

1506-11011

BH-8 x 30

SPW-8

WS-8

1517R-11015

Key-6×6×30

M6 x 15 Flat Machine Screw

Bracket

Pillar

M8×30 Hexagon Square Head Bolt

M8 Spring Washer

M8 Plan Washer

M8×30 Hex Socket Head Bolt

M8 Spring Washer

M8 Plan Washer

M8 Hexagon Nut

Flange

M8×30 Hex Socket Head Bolt

M8 Spring Washer

M8 Plan Washer

Reduction Worm Gear 1:100

6 x 6 x 30 Key

6

1

1

4

4

4

4

4

4

4

1

4

4

4

1

1

Remarks

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

1506-11017

UCFL-204

WS-12

SPW-12

CAP-12×30

1506-11022

1506-11023

Key-6×6×65

Key-6×6×30

1517R-11026

CAP-12x 30

SPW-12

WS-12

UCF-204

1506-11031

1506-11032

1506-11033

Motor 220V 1/2HP 3ph

UCFL-204Bearing

M12 Plan Washer

M12 Spring Washer

M12×30 Hexagon Square Head Bolt

M8 x 8 Hex Socket Head Set Screw

#40 x 17T xψ20 x 6 Sprocket

6 x 6 x 65 Key

6 x 6 x 30 Key

Shaft ψ20 x 370L

M12×30 Hexagon Square Head Bolt

M12 Spring Washer

M12 Plan Washer

UCF-204Bearing

None

None

None

1

1

2

2

2

2

1

1

1

1

4

4

4

1

0

0

0

34

35

36

37

F:\Manual\SM-1517R-110V-100514 14.05.2010.

1506-11034

1506-11035

1506-11036

1506-11037

None

None

None

#40 x 350L Chain (Standard Size)

- 62 -

0

0

0

1

Page 65

12-1-2. Fig-1100 Pillar parts table (2)

Qty

Ref. Part No. Description

38

1506-11038

39

1506-11039

40

SPW-8

41

HN-8

42

1517-11042

43

1517-11043

44

1517-11044

45

1517-11045

46

RTW-37

47

HN-8

48

SPW-8

49

HSS-6 x 6

50

6904ZZ

51

6904ZZ

52

1506-11052

53

CAP-8 x 16

#40 Chain Link

Bracket

M8 Spring Washer

M8 Hexagon Nut

M8 x 75L Screw

Ring 38 x 15 x 20 (D x W x d)

Ring 32 x 15 x 20 (D x W x d)

Shaft ψ20-265

"R" Snap Ring ψ37

M8 Hexagon Nut

M8 Spring Washer

M6 x 6 Hex Socket Head Set Screw

6904ZZ Bearing

#40 x 17T xψ37 Sprocket

None

M8 x 16 Hexagon Square Head Bolt

1

2

4

4

2

2

2

1

1

2

2

2

1

1

1

2

Remarks

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

SPW-8

WS-8

WS-8

SPW-8

CAP-8 x 16

ATM-2

STW-14

1506-11061

1506-11062

1506-11063

1506-11064

TZ-8108

1506-11066

BH-5x12

BH-5×10

SPW-5

WS-5

M8 Spring Washer

M8 Plan Washer

M8 Plan Washer

M8 Spring Washer

M8 x 16 Hexagon Square Head Bolt

ATM-2 TIE MOUNTS

"S" Snap Ring ψ14

Shaft-14- 90L

None

None

None

Limit Switch TZ8104, 5A 250V AC

Switch Bracket

M5×12 Hex Socket Head Bolt

M5×10 Cross Recessed Round Head Screw

M5 Spring Washer

M5 Plan Washer

2

2

2

2

2

1

4

2

0

0

0

2

2

4

4

4

4

71

TZ-8104

72

1506-11072

73

HSS-6 x 16

74

WS-5

F:\Manual\SM-1517R-110V-100514 14.05.2010.

Limit Switch TZ8104, 5A 250V AC

Switch Plate

M6 x 16 Hex Socket Head Set Screw

M5 Plan Washer

- 63 -

1

1

1

2

Page 66

12-1-2. Fig-1100 Pillar parts table (3)

Qty

Ref. Part No. Description

75

SPW-5

76

BH-5 x 35

77

1506-11077

78

1506-11078

79

WS-6

80

SPW-6

81

BH-6 x 35

82

1506-11082

83

1506-11083

84

WS-4

85

SPW-4

86

PMS-4x10

87

PMS-3×10

88

SPW-3

89

WS-3

90

1506-11090

M5 Spring Washer

M5 x 35 Hex Socket Head Bolt

Guide 13 x 13 x 300L

Ring 12 x 13 x 6 (D x W x d)

M6 Plan Washer

M6 Spring Washer

M6 x 35 Hex Socket Head Bolt

CP11401627 IP67

CP00401627 IP67

M4 Plan Washer

M4 Spring Washer

M4×10 Round Head Screw

M3 x 10 Round Head Screw

M3 Spring Washer

M3 Plan Washer

Plug XP2

2

2

1

2

2

2

2

1

1

4

4

4

4

4

4

1

Remarks

91

1506-11091

92

1506-11092

93

1517R-19093

94

SPW-5

95

WS- 5

96

WS-5

97

SPW-5

98

CAP-5x 10

99

1506-11099

100

BH-5×10

101

SPW-5

102

WS-5

103

FMS-5x10

104

1506-11104

Socket XS2

Cable Chain

M5 x 10 Flat Machine Screw

M5 Spring Washer

M5 Plan Washer

WS-5

M5 Spring Washer

M5 x 10 Hexagon Square Head Bolt

Cable Chain Plate

M5×10 Cross Recessed Round Head Screw

M5 Spring Washer

M5 Plan Washer

Flat Machine Screw M5x10

Assembly Cover

1

1

2

2

2

2

2

2

1

5

5

5

6

1

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 64 -

Page 67

12-2-1. Fig-12000 Film-seat Elevator parts diagram

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 65 -

Page 68

12-2-2. Fig-12000 Film-seat Elevator parts table

Qty

Ref. Part No. Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1506-12001

HN-15

SPW-15

WS -15

WS-15

HN-15

1506-12007

STW-15

RTW-32

6002ZZ

1506-12011

1506-12012

1506-12013

CAP-6×25

1506-12015

SPW-6

Film-set Elevator Base

M15 Hexagon Nut

M15 Hexagon Nut

M15 Plan Washer

M15 Plan Washer

M15 Hexagon Nut

Shaft

"S" Snap Ring ψ15

"R" Snap Ring ψ32

6002ZZ Bearing

Roller

#40 Chain

#40 Chain Link

M5×25 Hexagon Square Head Bolt

M5 Hexagon Nut

M5 Hexagon Nut

1

8

8

8

8

8

8

16

8

8

8

1

1

2

2

2

Remarks

17

18

19

20

CAP-6×15

SPW-6

WS-6

1506-12020

M6×15 Hexagon Square Head Bolt

M6 Spring Washer

M6 Plan Washer

Chain Cover

2

2

2

1

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 66 -

Page 69

12-3-1 Fig-14000 Bottom Plate Diagram

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 67 -

Page 70

12-3-2 Fig-14000 Bottom Plate parts Table (1)

Qty

Ref. Part No. Description

1

1517-14001

2

CAP-6×15

3

SPW-6

4

WS-6

5

CAP-10×25

6

SPW-10

7

WS-10

8

1517-14008

9

CAP-10×25

10

SPW-10

11

WS-10

12

KEY-7-40

13

S50-19T-28-7

14

HSS-8×8

15

UMW-70

16

1517-14016

Motor Cover

M6 x 15 Hexagon Square Head Bolt

M6 Spring Washer

M6 Plan Washer

M10×25 Hexagon Square Head Bolt

M10 Spring Washer

M10 Plan Washer

Motor 1HP 50/60Hz,220/380V

M10×25 Hexagon Square Head Bolt

M10 Spring Washer

M10 Plan Washer

7×7×40 Key

#50×19T-28-7 Sprocket

M8×8 Hex Socket Head Set Screw

#70 Reduction Worm Gear 1:30

Chain Cover

. Remarks

1

4

4

4

4

4

4

1

4

4

4

1

1

2

1

1

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

CAP-6x10

SPW-6

WS-6

STW-17

RTW-30

6903ZZ

S50-12T

1517-14024

1517-14025

1517-14026

1517-14027

CAP-8x

SPW-8

WS-8

PMS-4×8

SPW-3

WS-3

M6×10 Hexagon Square Head Bolt

M6 Spring Washer

M6 Plan Washer

"S" Snap Ring ψ17

"R" Snap Ring ψ30

6903ZZ Bearing

#50×12T Sprocket

Pressing Arm

51211 Bearing

6005ZZ Bearing

Bearing Set

M8×25 Hexagon Square Head Bolt

M8 Spring Washer

M8 Plan Washer

M3 x20 Round Head Screw

M3 Spring Washer

M3 Plan Washer

2

2

2

1

1

1

1

1

1

1

1

6

6

6

6

6

6

34

1517-14034

35

1517-14035

36

HN-8

37

SPW-8

F:\Manual\SM-1517R-110V-100514 14.05.2010.

TP-SM5N1 Proximity Switch

Proximity Switch Set

M8 Hexagon Nut

M8 Spring Washer

- 68 -

4

4

4

2

Page 71

12-3-2 Fig-14000 Bottom Plate parts Table (2)

Qty

Ref. Part No. Description

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

1517-14038

CAP-8×15

None

None

6002ZZ

1517-14043

SH-15-110

1517-14045

STW-15

CAP-6×25

1517-14048

S50-85T

1517-14050

1517-14051

CAP-6×20

SPW-6

M8×100L Screw

M8×15 Hexagon Square Head Bolt

None

None

6002ZZ Bearing

Roller

ψ15×110 Shaft

ψ23×1.2×ψ15 Washer (D × W × d)

"S" Snap Ring ψ15

M6×25 Hexagon Square Head Bolt

Roller Seat

#50×85T Sprocket

#50 Chain Link

#50×216L Chain

M6×20 Hexagon Square Head Bolt

M6 Spring Washer

. Remarks

1

2

0

0

2

1

1

2

2

12

6

1

1

1

1

1

54

55

56

57

58

59

60

130

WS-6

1517-14055

R-25-16-17

PIN-8-50

1517-14058

FMS-12×40

1517-14062

1517-14130

M6 Plan Washer

Proximity Switch Sense Bar

Ring ψ25x16xψ17 (D x L x d)

8×50 Pin

ψ1500 Turntable

M12x40 Flat Machine Screw

Ring Bolt

Roller Unit

1

1

4

1

1

4

2

6

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 69 -

Page 72

12-4-1 Fig-18000 Control Box Diagram

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 70 -

Page 73

12-4-2 Fig-18000 Control Box Table (1)

Qty

Ref. Part No. Description

1

1517R-18001

2

1517R-18002

3

None

4

None

5

PMS-4×35

6

1517R-18006

7

WS-4

8

HN-4

9

1517R-18009

10

1517R-18010

11

SPW-4

12

PMS-4×15

13

None

14

1517R-18014

15

1517R-18015

16

1517R-18016

Control Box

Fun Safety Web

None

None

M4×35 Round Head Screw

Fun SJ-8025HA2SAL

M4 Plan Washer

M4 Hexagon Nut

Bracket for Control Box

Resister 80W 200Ω

M4 Spring Washer

M4 x15 Round Head Screw

None

Fuse GFE 4A

Copper Support 17mm

Power Supplies PS-65-24

. Remarks

1

2

0

0

4

1

4

4

1

1

2

2

0

1

4

1

17

SPW-4

18

1517R-18018

19

1517R-18019

20

1517R-18020

21

SPW-3

22

WS-3

PMS-3×15

23

24

1517R-18024

25

1517R-18025

26

1517R-18026

27

1517R-18027

28

1517R-18028

29

1517R-18029

30

1517R-18030

31

1517R-18031

32

1517R-18032

33

1517R-18033

M4 Spring Washer

Copper Support 42mm

Electric Cable 3.96-3P

Protection Cover

M3 Spring Washer

M3 Plan Washer

M3 x15 Round Head Screw

Electric Cable 3.96-6P

Fuse S2.5A

Electric Cable 3.96-3P

Power Supplies PD-25A

Protection Cover

Electric Cable 3.96-4P

PCB KS-050201-MB

Electric Cable VH-4P

Electric Cable VH-2P

WIRE Cable 50P

4

4

1

1

4

4

4

1

1

1

1

1

1

1

1

1

1

34

1517R-18034

35

1517R-18035

36

1517R-18036

F:\Manual\SM-1517R-110V-100514 14.05.2010.

Electric Cable VH-5P

WIRE Cable 26P

Electric Cable VH-2P

- 71 -

1

1

1

Page 74

12-4-2 Fig-18000 Control Box Table (2)

Qty

Ref. Part No. Description

37

1517R-18037

38

1517R-18038

39

1517R-18039

40

1517R-18040

41

1517R-18041

42

1517R-18042

43

1517R-18043

44

1517R-18044

45

1517R-18045

46

1517R-18046

47

1517R-18047

48

1517R-18048

49

1517R-18049

50

1517R-18050

51

1517R-18051

IC Please specify main PC board's IC

version when place order

Fuse GFE 2A/GFE1A

Electric Cable VH-4P

Electric Cable VH-2P

Electric Cable VH-4P

Electric Cable VH-2P

Electric Cable VH-6P

Electric Cable VH-5P

3/16 x15 Round Head Screw

Electric Cable VH-4P

Electric Cable VH-4P

Electric Cable VH-3P

Electric Cable VH-3P

Electric Cable VH-2P

Electric Cable VH-2P

. Remarks

1

2

1

1

1

1

1

1

3

1

1

1

1

1

1

52

1517R-18052

53

1517R-18053

54

1517R-18054

55

1517R-18055

PMS-4×6

56

57

WS-4

58

SPW-4

59

1517R-18059

60

1517R-18060

61

1517R-18061

62

1517R-18062

63

1517R-18063

64

1517R-18064

65

1517R-18065

66

1517R-18066

67

None

68

None

69

1517R-18069

Electric Cable VH-8P

Electric Cable VH-2P

Terminal Block PCB KS-050203-TB

RAIL L TS35

M4×6 Round Head Screw

M4 Plan Washer

M4 Spring Washer

Fuse Base FM-04-L-OP-B

Fuse GFE 1A,1A,2A,2A

MOTOR BREAKER MS25-10

RAIL L TS35

END STOPPER TBRF

M4×6 Cross Recessed Round Head Screw

Terminal Block D4/6

Inverter VFD004E11T

None

None

ψ24 Hole Plugs

1

1

1

1

2

2

2

1

4

1

1

2

4

16

1

0

0

4

70

1517R-18070

71

SPW-4

72

WS-4

M4×10 Round Head Screw

M4 Spring Washer

M4 Plan Washer

2

2

2

F:\Manual\SM-1517R-110V-100514 14.05.2010.

- 72 -

Page 75

12-4-2 Fig-18000 Control Box Table (3)

Qty

Ref. Part No. Description

73

1517R-18073

74

1517R-18074

PMS-4×10

75

76

SPW-4

77

WS-4

78

1517R-18078

79

1517R-18079

80

SPW-4

PMS-4×10

81