Page 1

Safety Signal™ Installation Guide

Safety Signal™

Models SS0550 thru SS0554

340 Gateway Park Drive

North Syracuse, NY 13212

Phone: 315-463-7348

Toll Free: 866-235-7468

Fax: 315-463-8559

Email: sales@dlmanufacturing.com

www.dlmanufacturing.com

A Product of

7/19/2011 SS9556 REV A

Page 2

Safety Signal™ Installation Guide

Page 1

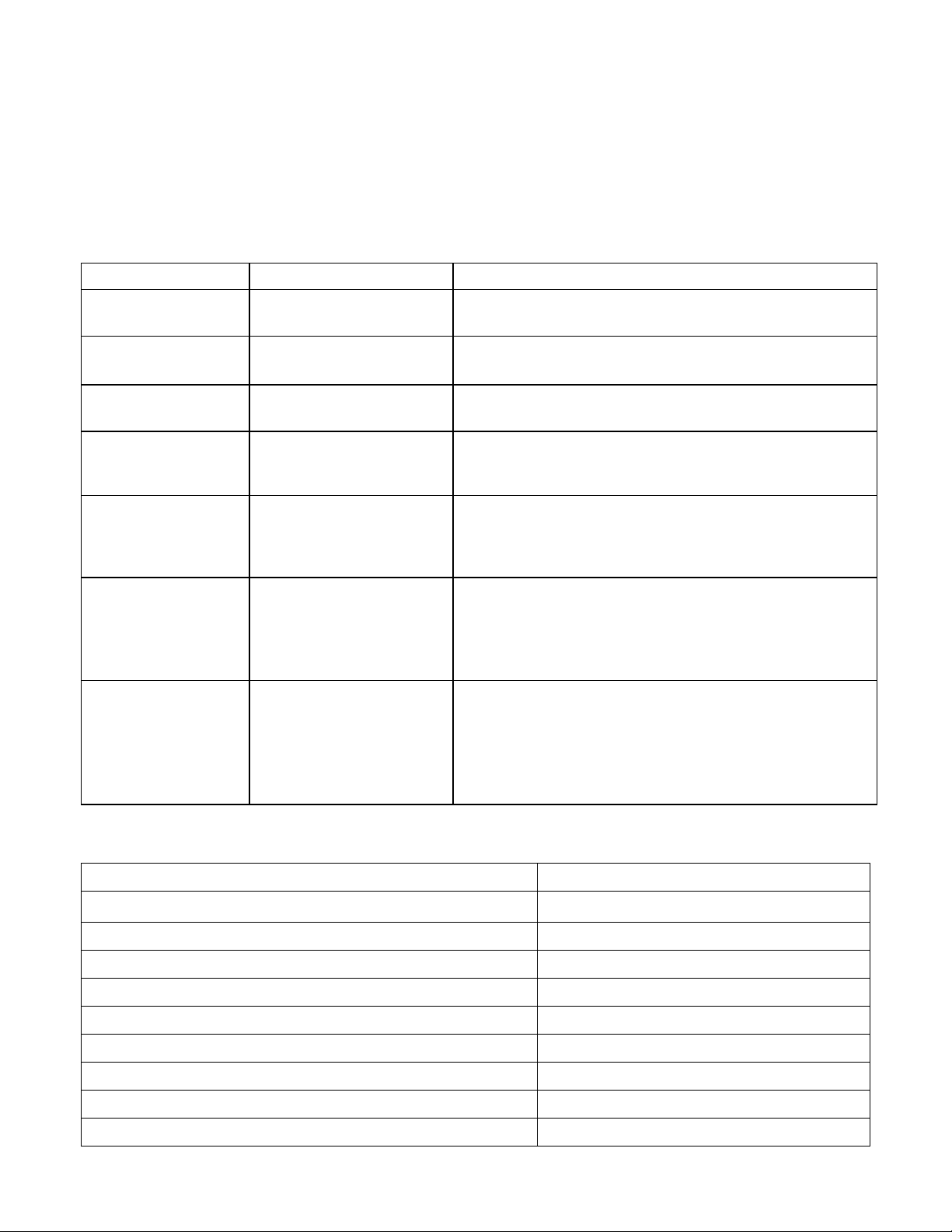

INPUT VOLTAGE

120 VAC

INPUT FREQUENCY

60 HZ

MAXIMUM INPUT CURRENT

12 A

INPUT CURRENT WITH NO OUTLET(S) OR LEVELER LOAD

<.5 A (MODEL 550)

MAXIMUM OUTLET(S) CURRENT

12 A

MAXIMUM LEVELER LOAD CURRENT (J7 OR J8)

12 A

OUTSIDE LIGHT BOX VOLTAGE

12 VDC

MAXIMUM OUTSIDE LIGHT BOX LOAD CURRENT

1.25 A (12 V POWER SUPPLY CURRENT LIMIT)

SENSOR VOLTAGE (J2, J3 & J4)

12 VDC

MAXIMUM SENSOR CURRENT (J2, J3 & J4)

.2 A (J2, J3 & J4 PROTECTED BY PTC THERMISTOR)

Model #

Part #

Description

550

SS0550

Standard Safety Signal™

No options: No outlets or interlocks

551

SS0551

Powers & controls one outlet for dock light

Dock light turns off when door is closed

552

SS0552

Powers & controls two outlets

Dock light & fan turn off when door is closed

552-02

SS0552-02

No Inside Red & Green Light

Powers & controls two outlets

Dock light & fan turn off when door is closed

553

SS0553

Powers & controls two outlets & interlocks

Electric/Hydraulic leveler

Dock light and fan turn off when door is closed

Leveler will not run when door is closed

554

SS0554

Powers & controls two outlets & interlocks Pneumatic

leveler

Dock light and fan turn off when door is closed

Leveler will not run when door is closed

Fan turns off when leveler runs

554-02

SS0554-02

No Inside Red & Green Light

Powers & controls two outlets & interlocks Pneumatic

leveler

Dock light and fan turn off when door is closed

Leveler will not run when door is closed

Fan turns off when leveler runs

INTRODUCTION

This manual is used for all Safety Signal™ model types. The control board is programmed

for each model’s function. The description explains the differenced between model types.

ELECTRICAL RATINGS:

7/19/2011 SS9556 REV A

Page 3

Safety Signal™ Installation Guide

Page 2

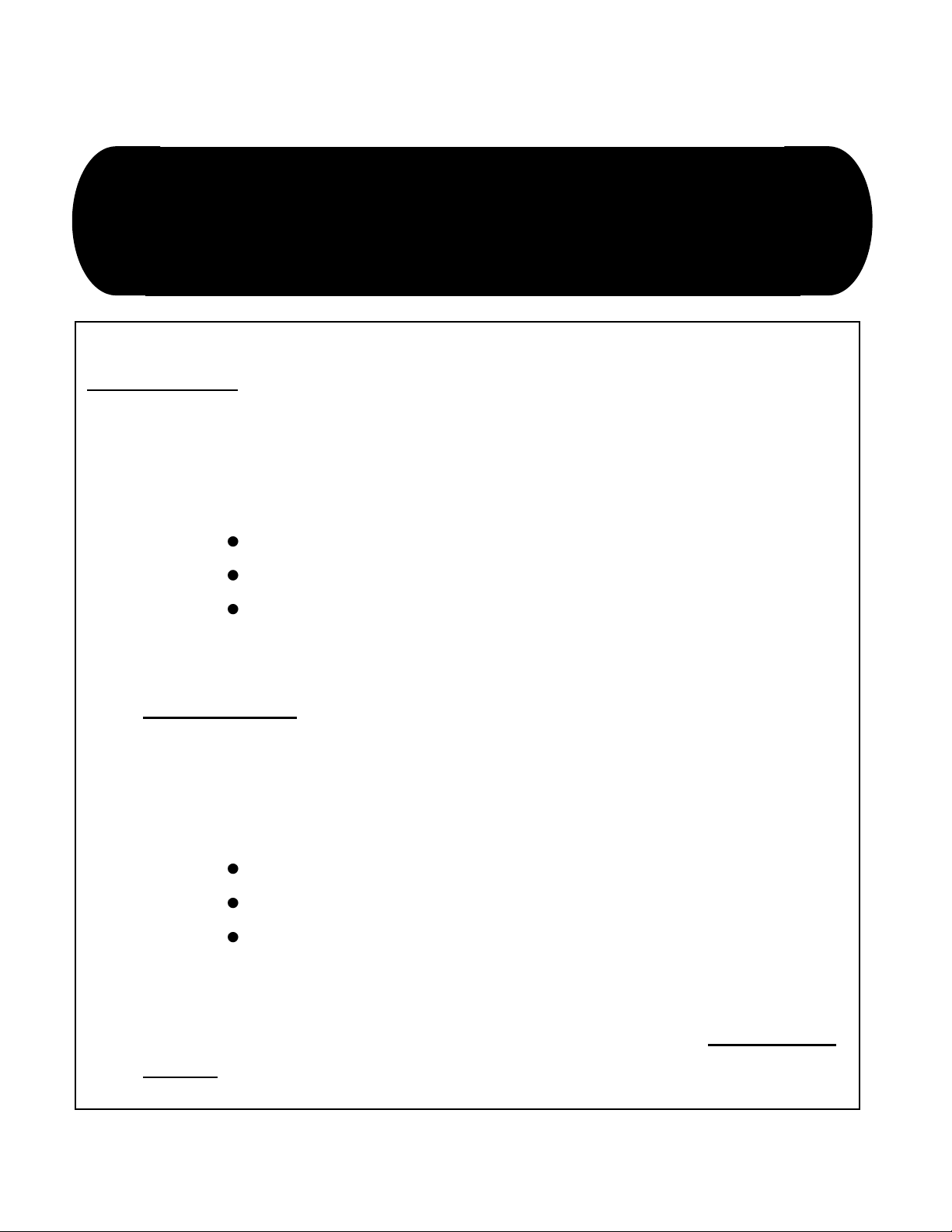

Door Opens

Outside light turns red

Inside light turns green

Interlock items now function

Dock light

Fan

Leveler & OPT 1 Contacts close

Door Closes

Outside light turns green

Inside light turns red

Interlock items turn off

Dock light

Fan

Leveler & OPT 1 Contacts open

Please Note: When dock door is closed, the light will

switch to red inside and green outside after a 10 second

delay.

Safety Signal™

---Sequence of Operations--Testing

7/19/2011 SS9556 REV A

Page 4

Safety Signal™ Installation Guide

Page 3

Drill bits, masonry bit for tap-con / wood bits 3/16” for pilot hole in dock seal

Tape measure

Hammer Drill

Wire strippers

Drill screw gun

Hammer

Precision flat blade screwdriver 1/8” wide

Felt tip marker

Wire labels

Description

Page

COVER

-

INTRODUCTION / ELECTRICAL RATINGS

1

SEQUENCE OF OPERATIONS

2

GENERAL INFO / INDEX / REQUIRED TOOLS

3

INSTALLER SUPPLIED HARDWARE & FASTENERS

4

INSIDE LIGHT BOX MOUNTING

5

INSIDE LIGHT BOX MOUNTING CONTINUED

6

PHOTO EYE INSTALL – TYPICAL & MxV DOOR

7

PHOTO EYE INSTALL – ROLLING STEEL DOOR

8

EXTERNAL BOX INSTALLATION

9

CONTROL BOARD WIRING OVERVIEW / INDEX

10

WIRING DIAGRAM J1 & J2

11

WIRING DIAGRAM J6, J7 & J8

12

INSIDE TO OUTSIDE BOX WIRING DIAGRAM J15

13

DOCK SEAL BRACKET (OPTIONAL)

14

BOLLARD MOUNTING BRACKET (OPTIONAL)

15

MODEL 550 SYSTEM WIRING DIAGRAM

16

MODEL 551 SYSTEM WIRING DIAGRAM

17

MODEL 552 SYSTEM WIRING DIAGRAM

18

MODEL 553 SYSTEM WIRING DIAGRAM

19

MODEL 554 SYSTEM WIRING DIAGRAM

20

DL MANUFACTURING TERMS/CONDITIONS/WARRANTY

21

WARNING!!!!

Do not use in hazardous or corrosive environments!

INDEX

YEARLY MAINTENANCE

1. Inspect inside connections for any

damage

2. Inspect mounting bolts for tightness

3. Clean unit with compressed air

4. Clean Photo Sensor Lenses

REQUIRED TOOLS

7/19/2011 SS9556 REV A

Page 5

Safety Signal™ Installation Guide

Page 4

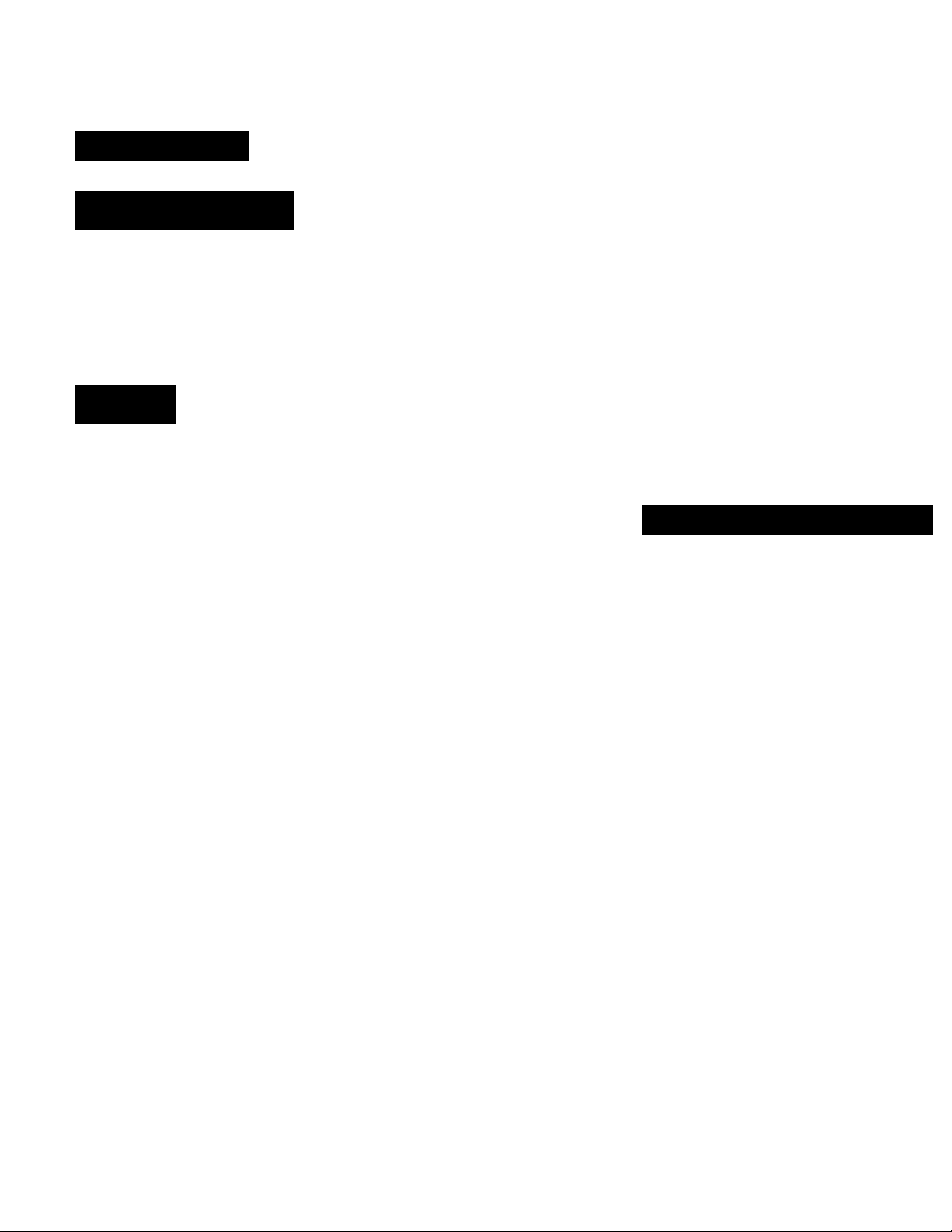

Mounting Surface

Inside Light Box

Outside Light Box

Cement Block

(4) ¼” x 1¼” Tapcon

(4) #10 x 1” Tapcon

Tip up concrete panel

(4) ¼” x 1¼” Tapcon

(4) #10 x 1” Tapcon

Sheet Metal

Sheet metal walls are not

thick enough to hold inside

box

Sheet metal walls are not

thick enough to hold outside

box

Steel

(4) ¼” x ¾” self-drilling

screws

(4) ¼” x ¾” self-drilling screws

Bollard

Use DL Manufacturing

supplied fasteners

Dock Seal

Use 1-1/4” x ¼” lag screws to

attach dock seal bracket to

dock seal.

Wiring the inside and outside

box together

3 conductor 18 gauge wire

½” flexible conduit with

connector for 7/8 knockout

FOR SERVICE ASSISTANCE CALL DL MANUFACTURING TOLL FREE 866-235-7468

Safety Signal Model #:

Safety Signal Serial #:

(LOCATED LOWER PORTION OF CONTROL BOARD)

Door Location:

Customer:

Installer-supplied hardware & fasteners

Also needed:

Field Notes:

7/19/2011 SS9556 REV A

Page 6

Safety Signal™ Installation Guide

Page 5

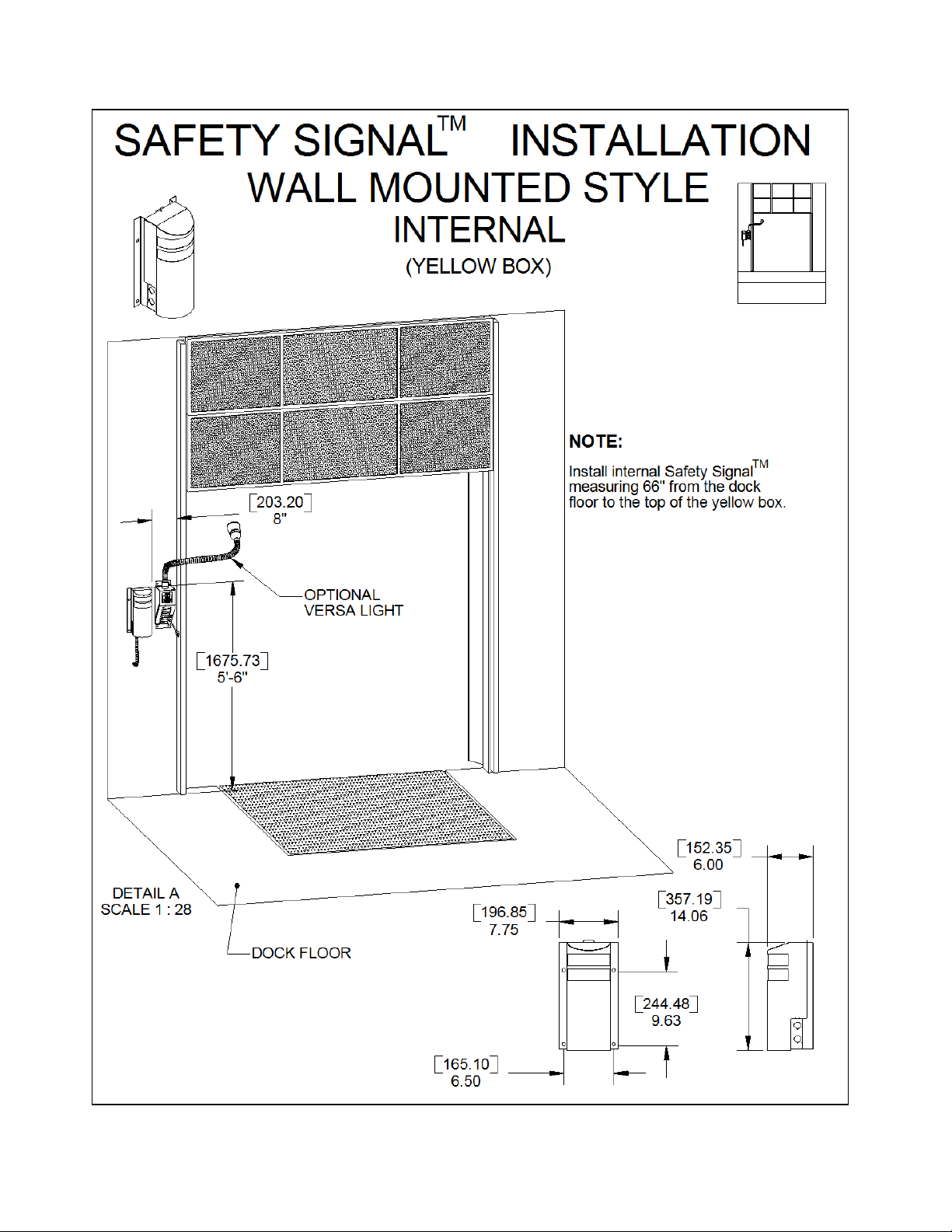

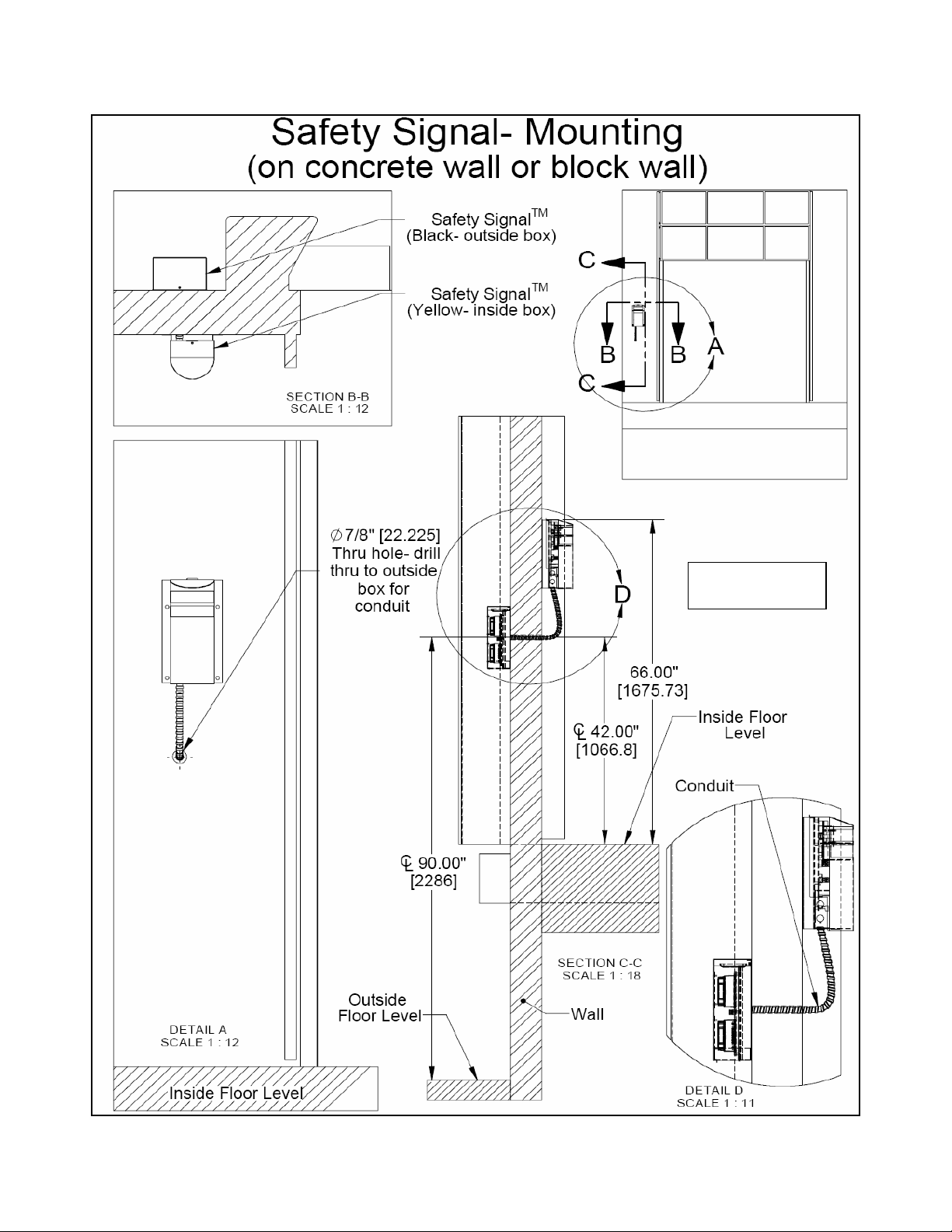

INSIDE LIGHT BOX MOUNTING

7/19/2011 SS9556 REV A

Page 7

Safety Signal™ Installation Guide

Page 6

INSIDE LIGHT BOX MOUNTING CON’T.

SEE PAGE 4 FOR

FASTENER USAGE

7/19/2011 SS9556 REV A

Page 8

Safety Signal™ Installation Guide

Page 7

PHOTO EYE INSTALL – TYPICAL & MxV DOORS

PHOTO EYE MOUNTING KIT

(FOR TYPICAL LOCATIONS & MxV DOOR)

SEE PAGE 8 FOR MOUNTING BRACKET LOCATION ON A ROLLING STEEL DOOR

NOTE:

PHOTO SENSOR HAS A RANGE

OF 1/2” TO 3-1/2”.

2” TO 3” IS RECOMMENDED.

DETAIL A

SCALE 1 : 20

PHOTO SENSOR NUT KIT

CP3268

1 2 MOUNTING BRACKET KIT

CP5016

1

1

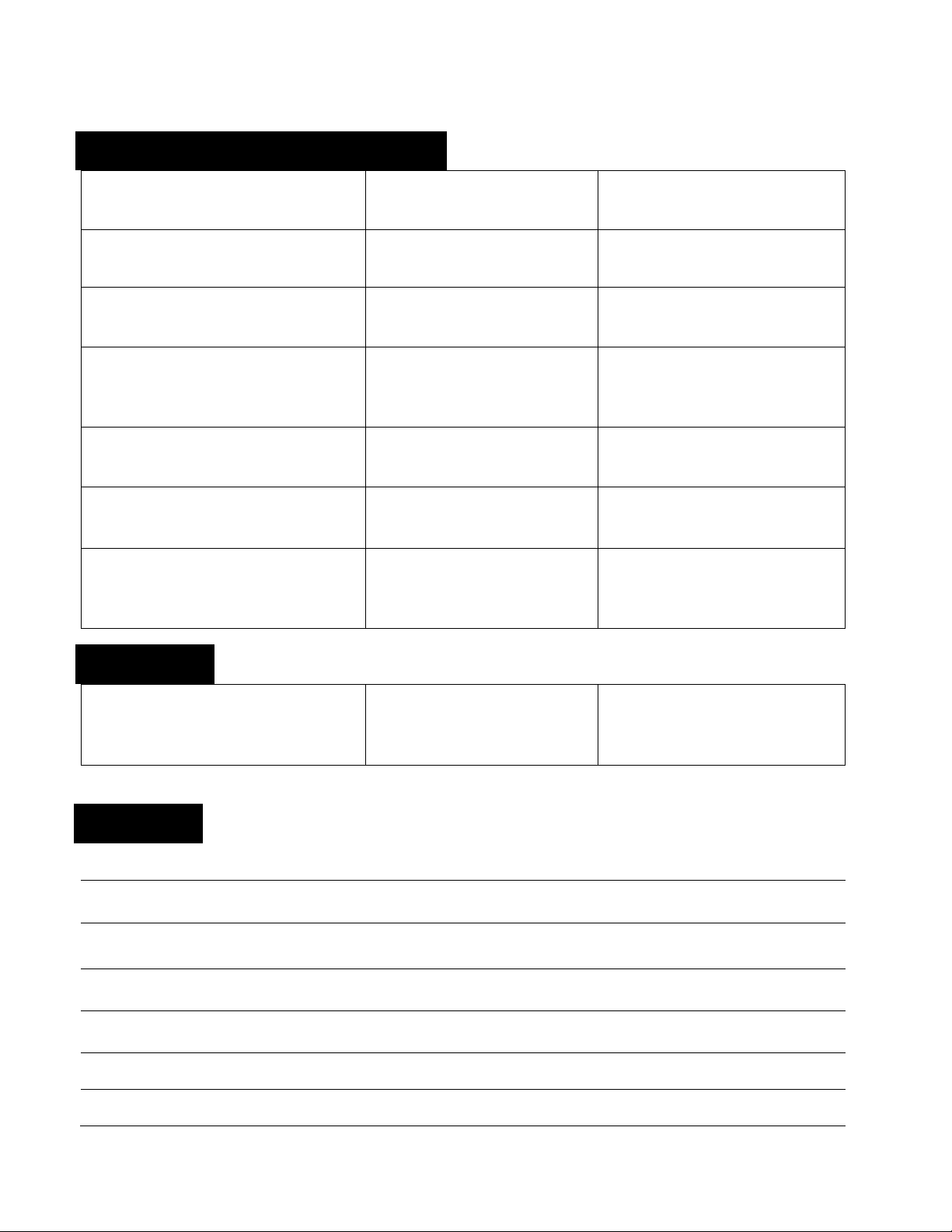

DESCRIPTION

PART#

QTY.

ITEM #

STEP 1

MEASURE 18” ABOVE THE

DOOR (START AT THE TOP OF

DOOR JAMB) TO INSTALL

PHOTO SENSOR

STEP 2

DRILL 2 HOLES IN ROLLER

TRACK. USE 17/64” DRILL BIT

REFER TO PAGE 11 FOR

WIRING INSTRUCTIONS

1 2 2 2 1

1

7/19/2011 SS9556 REV A

Page 9

Safety Signal™ Installation Guide

Page 8

BOTTOM OF

DOOR WHEN

FULLY OPEN

(Top View)

PHOTO EYE INSTALL – ROLLING STEEL DOORS

PHOTO EYE MOUNTING KIT

(FOR ROLLING STEEL DOOR)

SEE PAGE 7 FOR MOUNTING BRACKET LOCATION ON A SECTIONAL DOOR

STEP 1

TO LOCATE THE MOUNTING BRACKET

POSITION, OPEN THE DOOR ALL THE WAY.

STEP 2

POSITION THE TOP OF THE BRACKET SO

THAT IT LINES UP JUST BELOW THE BOTTOM

SECTION OF THE DOOR AND MARK HOLES.

STEP 3

DRILL 2 HOLES IN ROLLER TRACK. USE

17/64” DRILL BIT.

STEP 4

LOCATE THE PHOTO SENSOR OPERATING

ADJUSTMENT (SEE FIGURE BELOW). SET

THE PHOTO SENSOR FOR LIGHT OPERATE.

STEP 5

ATTACH THE PHOTO SENSOR TO THE

MOUNTING BRACKET USING THE NUTS AND

WASHERS SUPPLIED WITH SENSOR.

STEP 6

ATTACH THE MOUNTING BRACKET TO THE

TRACK RAIL USING HARDWARE SUPPLIED

WITH MOUNTING KIT.

REFER TO PAGE 11 FOR WIRING

INSTRUCTIONS

7/19/2011 SS9556 REV A

Page 10

Safety Signal™ Installation Guide

Page 9

EXTERIOR

(BLACK BOX)

90"

[2.286 mm]

DETAIL A

SCALE 1 : 32

GROUND LEVEL

LEVELER

DOCK SEAL

12.50 [317.50]

6.90 [175.30]

4.48 [113.90]

SAFETY SIGNAL

TM

INSTALLATION

WALL MOUNTED STYLE

NOTE:

1. RED LIGHT MUST BE ON

TOP

2. SEE PAGE 14 FOR

ALTERNATE MOUNTING

WHEN BOX CAN’T BE

MOUNTED TO WALL

3. MOUNT BOX PARALLEL

TO WALL

4. CONSULT DL

MANUFACTURING IF

DRIVEWAY IS SLOPED

STEP 1

INSTALL EXTERNAL SAFETY SIGNAL

MEASURING 90” [2,286mm] FROM THE

GROUND TO THE CENTER OF THE

BLACK BOX AND 3” FROM THE DOCK

SEAL OR SHELTER, OR 18” FROM

INSIDE WALL EDGE. SEE PAGE 4 FOR

MOUNTING HARDWARE. SEE PAGE 14

WHEN USING DOCK SEAL BRACKET.

STEP 2

REFER TO PAGE 13 FOR WIRING

INSTRUCTIONS. USE KNOCKOUT

LOCATED ON THE BACK OR BOTTOM.

EXTERNAL BOX INSTALLATION

7/19/2011 SS9556 REV A

Page 11

Safety Signal™ Installation Guide

Page 10

J17

NOT

USED

RED LED STRIP

CP8006

GRN LED STRIP

CP8005

NO RED OR GREEN LED

STRIPS INSTALLED IN

MODELS 552-02 & 554-02

J16 (CHOCK) NOT USED

ON SAFETY SIGNAL

J5

NOT

USED

PHOTO SENSOR

SEE PAGE 12 FOR

CONNECTIONS

J2-3, COMMON GND

J2-2, SENSOR SIGNAL

J2-1, +12 VDC, .2A MAX

DockLogic OPTION

RS485 CONNECTION

5 VDC, 60 mA MAX

9100 bps

J10-3, COMMON GND

J10-2, CHANNEL A

J10-1, CHANNEL B

OPTIONAL SENSOR

SEE INSTRUCTIONS

THAT OPTIONAL

SENSOR COMES WITH

J3-3, COMMON GND

J3-2, SENSOR SIGNAL

J3-1, +12 VDC, .2A MAX

120 VAC INPUT

120 VAC, 12 A MAX

60 HZ

SEE PAGE 12 FOR

CONNECTIONS

J1-1, 120 VAC LINE

J1-2, 120 VAC NEUTRAL

J1-3, GROUND

OUTSIDE LIGHT BOX

SEE PAGE 13 FOR

CONNECTIONS

J15-1, +12 VDC, 1.25 A MAX

J15-2, RED LIGHT

J15-3, NO CONNECTION

J15-4, GREEN LIGHT

MODEL 554 LEVELER

BUTTON

SEE PAGE 12 FOR

CONNECTIONS

DO NOT APPLY

VOLTAGE TO J6

TERMINALS, FOR

SWITCH ONLY

J6-1, 8.2 VDC, 3 mA MAX

J6-2, COMMON GND

OPTIONAL TERMINAL

BLOCK JUMPERS FOR OPT2

& OPT 3

SEE PAGE 16 FOR JUMPER

SETTINGS

J3-3 OR J4-3, COMMON GND

J3-2 OR J4-2, INPUT SIGNAL

J3-1 OR J4-1, +12 VDC, .2A

12 AMP BREAKER

FOR SWITCHED

VERSA LIGHT AND

FAN OUTLETS ONLY

1 AMP SLO-BLO 250V

FUSE UNDER FUSE

COVER

REPLACE WITH ONLY

SAME TYPE AND

RATING

FOR BEST RESULTS

WHEN REPLACING

FUSE, PLACE FUSE IN

COVER, THEN PLACE

COVER OVER CLIPS

AND THEN SNAP FUSE

INTO CLIPS

MODEL

553 & 554

GRND

REMOVE POWER

BEFORE SERVICING.

MUST BE INSTALLED

BY QUALIFIED

ELECTRICIAN

ASSEMBLY NUMBER

& REV. LABEL

WIRING OVERVIEW / INDEX

MODEL 553 & 554 OPTIONAL

ALTERNATE CONTACTS

120 VAC, 12 A MAX 60 HZ

J8-1 & 2 CONNECTED TO K4

ISOLATED RELAY CONTACTS

REFER TO PAGE 13

MODEL 653 & 654 LEVELER

INTERLOCK

120 VAC, 12A MAX 60 HZ

J7-1 & 2 CONNECTED TO K3

ISOLATED RELAY CONTACTS

REFER TO PAGE 13

Switching Relays for J7, J8,

Versa Light Outlet and Fan

Outlet are Rated 120 - 240

VAC, 12 A .75 Power Factor

7/19/2011 SS9556 REV A

Page 12

Safety Signal™ Installation Guide

Page 11

MUST BE

INSTALLED

BY QUALIFIED

ELECTRICIAN

SAFETY SIGNALTM FIELD WIRING DIAGRAM

INCOMING POWER

INTERNAL (YELLOW BOX)

J1 1 2

3

ON MODELS 553 & 554

USE CHASSIS GND

CONNECTION

(NOT USED ON OTHER MODELS)

GND WIRE FROM

CHASSIS GND IS

PRE-INSTALLED ON

MODELS 553 & 554

GREEN (GND) - MODELS 553 & 554 ONLY

DOOR PHOTO SENSOR

1 BROWN +12 VDC, .2A MAX

2 BLACK

3 BLUE -COM

J2

PHOTO SENSOR IS 12 VDC. DO NOT RUN IN SAME CONDUIT WITH 120 AND HIGHER VOLTAGE.

TRANSIENTS CAN DAMAGE CONTROL BOARD

SENSING REVERSAL

ROTATE ADJUSTMENT 3/4 TURN TO CHANGE

OPERATION FROM (N/O TO N/C OR N/C TO N/O)

NORMALLY SET FOR DARK OPERATE OR N/C

WHEN LOCATED ABOVE PANELED DOOR OPENING

LED

Light OpDark Op

DOOR

BLACK (120 VAC, 12 A MAX, 60Hz)

WHITE (120 VAC NEUTRAL)

GREEN (GND) - ALL MODELS EXCEPT 553 & 554

WIRING DIAGRAM J1 & J2

7/19/2011 SS9556 REV A

Page 13

Safety Signal™ Installation Guide

Page 12

WIRING DIAGRAM J6, J7 & J8

SAFETY SIGNAL

TM

FIELD WIRING DIAGRAM

MODEL 554 LEVELER CONTROL SIGNAL

FX LEVELER

BUTTON

J6-1, 8.2 VDC, 3mA MAX

J6-2, COMMON GND

NOTE:

WHEN LEVELER SWITCH IS ACTIVATED, THE CONTROL SIGNAL WILL LET THE MICRO

PROCESSOR KNOW TO SHUT THE FAN OFF. IT WILL THEN TURN ON THE LEVELER (J7)

AND OPT1 (J8) AFTER A 2 SECOND DELAY. FAN WILL TURN ON WHEN LEVELER STOPS.

DO NOT

APPLY ANY

EXTERNAL

VOLTAGE TO

J6 TERMINALS

MODEL 554 LEVELER INTERLOCK / OPT1

120 - 240 VAC LINE, 12 A MAX, 50 / 60 HZ

TO LEVELER MOTOR

J8 (OPT1) CONTACTS CLOSE

WHEN J7 (LEVELER) CLOSE.

CONTACTS CONNECTED TO

J7 & J8 ARE RATED 120 VAC

12 A,

.75 POWER FACTOR.

CONTACTS CONNECTED

TO J7 & J8 ARE DRY

CONTACTS (ISOLATED

FROM INTERNAL

CONTROL BOARD

CIRCUITRY).

MODEL 553 LEVELER INTERLOCK / OPT1

J8 (OPT1) CONTACTS CLOSE

WHEN J7 (LEVELER) CLOSE.

CONTACTS CONNECTED TO

J7 & J8 ARE RATED 120 VAC

12 A,

.75 POWER FACTOR.

CONTACTS CONNECTED

TO J7 & J8 ARE DRY

CONTACTS (ISOLATED

FROM INTERNAL

CONTROL BOARD

CIRCUITRY).

(1)

CONNECT LEVELER INTERLOCK FROM

LEVELER CONTROL BOX TO J7-1 AND J7-2.

120 VAC, 12A MAX, 50 / 60 HZ

(1)

SEE MANUFACTURERS’ DOCK LEVELER

INSTRUCTIONS FOR INTERLOCK CONNECTIONS

7/19/2011 SS9556 REV A

Page 14

Safety Signal™ Installation Guide

Page 13

SAFETY SIGNALTM FIELD WIRING DIAGRAM

OUTSIDE LIGHTS

EXTERNAL (BLACK) BOX

FROM CONTROL BOARD

INTERNAL (YELLOW) BOX

TO OUTSIDE R&G LED EXTERNAL (BLACK) BOX

FOR GREEN LIGHT

FOR RED LIGHT

+12 VDC, 1.25A MAX

3

2

1

J1

TO RED LIGHT

NOT USED

+ 12 VDC, 1.25A MAX

J15

1

2 3 4

TO GREEN LIGHT

OUTSIDE LIGHTS

WIRING DIAGRAM – INSIDE TO OUTSIDE BOX

7/19/2011 SS9556 REV A

Page 15

Safety Signal™ Installation Guide

Page 14

DOCK SEAL

FRAME

BUMPER

GROUND LEVEL

102"

[2590.8mm]

DETAIL A

WALL

SEE DETAIL A

DOCK SEAL

FRAME

WALL

DOCK SEAL

SAFETY SIGNAL

TM

DOCK SEAL BRACKET

PART # SS5019

BUMPER

DOCK SEAL FRAME

ALTERNATE OUTSIDE

LIGHT BOX MOUNTING

Surface must be

Parallel to wall.

(3CM) 1 1/4" LONG TECH

SCREWS (4 PLACES)

(NOT INCLUDED)

SIGN & LIGHT BOX MOUNT

ON BRACKET (SS5019).

(6) #10 SELF TAPPING

SCREWS (INCLUDED)

SIGN

GOES

ABOVE

LIGHT

BOX

OPTIONAL DOCK SEAL BRACKET

INSTALL DOCK SEAL BRACKET AT

MOUNTING HEIGHT OF 102”. IF BRACKET

IS NOT USED, REFER TO PAGE 9 FOR

CORRECT MOUNTING HEIGHT

OPTIONAL DOCK SEAL BRACKET

7/19/2011 SS9556 REV A

Page 16

Safety Signal™ Installation Guide

Page 15

OPTIONAL BOLLARD BRACKET

7/19/2011 SS9556 REV A

Page 17

Safety Signal™ Installation Guide

Page 16

J10-1 RS485 CHANNEL B

J10-2 RS485 CHANNEL A

J10-3 SIGNAL GROUND

J9-1 RS232 RXD (DB9-3, RED)

J9-2 RS232 TXD (DB9-2, BRN)

J9-3 SIGNAL GROUND (DB9-5, YEL)

J9 & J10

RS-232/485 COM PORT

IR OPTION

NOT USED

POWER

SUPPLY

CONTROL BOARD

Inside Green LEDs

Inside Red LEDs

RED

GRN

J1

+12

RED

GRN

PC ASM SS8023

J1 1

J1 2

J1 3

OUTSIDE LIGHT BOX

LINEGROUND

NEUTRAL

1

2

LEV CNTRL

J6

1

2

3

OPT3

J4

1

2

3

OPT2

J3

F1

1 A

BRKR1

12A

123

4

OUTSIDE LIGHTS

J15

1

2

3

DOOR

J2

1

2

OPT1

J8

1

2

LEVELER

J7

K2 K3

K4

K1

J5

E7 EMULATOR

BLK

BRN

BLU

E

R

PHOTOSEN

123

CHOCK

J16

1

2

3

4

5

FAN

P1

1

2

3

4

5

VERSALITE

P2

123

J17

1

2

3

AC INPUT

J1

J18

123

RS232

J9

1

2

3

RS485

J10

MODEL 550 WIRING DIAGRAM

7/19/2011 SS9556 REV A

Page 18

Safety Signal™ Installation Guide

Page 17

J10-1 RS485 CHANNEL B

J10-2 RS485 CHANNEL A

J10-3 SIGNAL GROUND

J9-1 RS232 RXD (DB9-3, RED)

J9-2 RS232 TXD (DB9-2, BRN)

J9-3 SIGNAL GROUND (DB9-5, Y EL)

Inside Red LEDs

Inside Green LEDs

CONTROL BOARD

POWER

SUPPLY

IR OPTION

NOT USED

J9 & J10

RS-232/485 COM PORT

123

RS485

J10

RS232

J9

J18

1

2

3

AC INPUT

J1

123

J17

1

2

3

4

5

VERSALITE

P2

1

2

3

4

5

FAN

P1

123

CHOCK

J16

BLK

BRN

BLU

E

R

PHOTOSEN

LIGHT

J5

E7 EMULATOR

K1

K4

K3K2

1

2

LEVELER

J7

1

2

OPT1

J8

1

2

3

DOOR

J2

123

4

OUTSIDE LIGHTS

J15

BRKR1

12A

F1

1 A

1

2

3

OPT2

J3

1

2

3

OPT3

J4

1

2

LEV CNTRL

J6

NEUTRAL

GROUND LINE

RED

GRN

J1

+12

RED

GRN

PC ASM SS8023

J1 1

J1 2

J1 3

MODEL 551 WIRING DIAGRAM

7/19/2011 SS9556 REV A

Page 19

Safety Signal™ Installation Guide

Page 18

Inside Red LEDs

Inside Green LEDs

CONTROL BOARD

POWER

SUPPLY

IR OPTION

NOT USED

J9 & J10

RS-232/485 COM PORT

J10-1 RS485 CHANNEL B

J10-2 RS485 CHANNEL A

J10-3 SIGNAL GROUND

J9-1 RS232 RXD (DB9-3, RED)

J9-2 RS232 TXD (DB9-2, BRN)

J9-3 SIGNAL GROUND (DB9-5, YEL)

RED

GRN

J1

+12

RED

GRN

PC ASM SS8023

J1 1

J1 2

J1 3

LINEGROUND

NEUTRAL

FAN

1

2

LEV CNTRL

J6

1

2

3

OPT3

J6

1

2

3

OPT2

J4

F1

1 A

BRKR1

12A

123

4

OUTSIDE LIGHTS

J15

1

2

3

DOOR

J2

1

2

OPT1

J8

1

2

LEVELER

J7

K2 K3

K4

K1

J5

E7 EMULATOR

LIGHT

BLK

BRN

BLU

E

R

PHOTOSEN

123

CHOCK

J16

1

2

3

4

5

FAN

P1

1

2

3

4

5

VERSALITE

P2

123

J17

1

2

3

AC INPUT

J1

J18

123

RS232

J9

1

2

3

RS485

J10

MODEL 552 WIRING DIAGRAM

7/19/2011 SS9556 REV A

Page 20

Safety Signal™ Installation Guide

Page 19

J10-1 RS485 CHANNEL B

J10-2 RS485 CHANNEL A

J10-3 SIGNAL GROUND

J9-1 RS232 RXD (DB9-3, RED)

J9-2 RS232 TXD (DB9-2, BRN)

J9-3 SIGNAL GROUND (DB9-5, YEL)

480 3 PH

Inside Red LEDs

Inside Green LEDs

CONTROL BOARD

POWER

SUPPLY

IR OPTION

NOT USED

J9 & J10

RS-232/485 COM PORT

TYPICAL

HYDRAULIC

LEVELER

WIRING

DIAGRAM

123

RS485

J10

123

RS232

J9

J18

1

2

3

AC INPUT

J1

123

J17

1

2

3

4

5

VERSALITE

P2

1

2

3

4

5

FAN

P1

3 PH MOT CONTACTOR

MOT CONTACTOR COIL

O/L

480/120

123

CHOCK

J16

LEVELER BUTTON

BLK

BRN

BLU

E

R

PHOTOSEN

LIGHT

J5

E7 EMULATOR

K1

K4

K3K2

1

2

LEVELER

J7

1

2

OPT1

J8

1

2

3

DOOR

J2

123

4

OUTSIDE LIGHTS

J15

BRKR1

12A

F1

1 A

1

2

3

OPT2

J3

1

2

3

OPT3

J4

1

2

LEV CNTRL

J6

FAN

NEUTRAL

GROUND LINE

CIR BRKR

T1

T2

T3

LEV MOTOR

GRND

RED

GRN

J1

+12

RED

GRN

PC ASM SS8023

J1 1

J1 2

J1 3

MODEL 553 WIRING DIAGRAM

7/19/2011 SS9556 REV A

Page 21

Safety Signal™ Installation Guide

Page 20

TYPICAL

PNEUMATIC

LEVELER

WIRING

DIAGRAM

INCOMING 120V POWER

Inside Red LEDs

Inside Green LEDs

CONTROL BOARD

POWER

SUPPLY

IR OPTION

NOT USED

J9 & J10

RS-232/485 COM PORT

COM PORT CONNECTIONS:

J10-1 RS485 CHANNEL B

J10-2 RS485 CHANNEL A

J10-3 SIGNAL GROUND

J9-1 RS232 RXD (DB9-3, RED)

J9-2 RS232 TXD (DB9-2, BRN)

J9-3 SIGNAL GROUND (DB9-5, YEL)

RED

GRN

J1

+12

RED

GRN

PC ASM SS8023

J1 1

J1 2

J1 3

LEVELER BUTTON

123

RS485

J10

123

RS232

J9

J18

1

2

3

AC INPUT

J1

123

J17

1

2

3

4

5

VERSALITE

P2

1

2

3

4

5

FAN

P1

123

CHOCK

J16

BLK

BRN

BLU

E

R

PHOTOSEN

LIGHT

J5

E7 EMULATOR

K1

K4

K3K2

1

2

LEVELER

J7

1

2

OPT1

J8

1

2

3

DOOR

J2

123

4

OUTSIDE LIGHTS

J15

BRKR1

12A

F1

1 A

1

2

3

OPT2

J3

1

2

3

OPT3

J4

1

2

LEV CNTRL

J6

FAN

NEUTRAL

GROUND LINE

M

LEVELER MOTOR

GRND

MODEL 554 WIRING DIAGRAM

7/19/2011 SS9556 REV A

Page 22

Safety Signal™ Installation Guide

Page 21

Shipping Times

~ Orders for stock items received by 3:00pm EST will be processed for shipment the next day. Orders requesting

2nd Day Air or Overnight Air received by 1:00pm will be processed for same day shipment.

Shipments / Freight

~ All DL Manufacturing orders will ship directly from our facility in North Syracuse, NY.

~ All parts will be shipped via UPS Ground unless you authorize a different service. UPS shipments are prepaid

and the charges are added to your invoices.

~ For orders shipping by common carrier, the freight will be FOB, North Syracuse, NY. When “best way” is the

preferred shipping method on your order, DL Manufacturing will choose the carrier, unless otherwise stated, for the

orders shipping from this facility. No adjustments will be made after the order has shipped.

Returns

~ DL Manufacturing will issue a Returned Material Authorization (RMA) number for any product, parts and

accessories. Products should not be returned without an RMA number.

~ Replacement parts will be invoiced at the time of shipping. Invoices will be credited upon receipt and inspection

of Returned Material Authorization (RMA).

~ Freight for returns is paid for by the shipper unless otherwise specified by DL Manufacturing.

~ A restocking fee of 25% of net price or a minimum $20.00 is charged for returns.

~ All replacement parts are warranted for a period of 90 days from shipment.

DL Manufacturing

Terms / Conditions/ Warranty

Cancellation Fees

~ Cancellation charges may be incurred on orders cancelled with DL Manufacturing. Please contact DL

Manufacturing to discuss each situation.

Warranty Policy

~ All Products (excluding bulbs) manufactured by DL Manufacturing are warranted to be free from defects for a

period of 12 months from the date of shipment, excluding doors, which have a warranty period of 12 months from

date of installation or 18 months from shipment, whenever occurs first.

This warranty does not cover unreasonable/improper use or use beyond rated conditions, improper storage,

negligence or accident; damage because of incorporated use of equipment with Goods, after Customer has or

reasonably should have, knowledge of any defect; or improperly installed by any other Person that is unauthorized

by DL Manufacturing.

This warranty is subject to customer covenants to inform all subsequent buyers of the Goods of the limitation on

and exclusive of warranties provided for herein. Customer hereby indemnifies and agrees to hold DL

Manufacturing harmless from and against all losses, costs and expenses, including reasonable attorney’s fees

incurred by DL Manufacturing as a result of any third party claim relating to the purchase, sale or use of, or

otherwise relating to, the Goods covered by this Agreement.

In no event shall DL Manufacturing be required to repair, replace or reimburse Customer for more than the part or

material that is found to be defective and DL Manufacturing’s liability shall in such event be no greater than the

invoiced price of the item and shall not include labor, shipping or other costs incurred in connection with the

reshipment of defective Goods to DL Manufacturing or the reinstallation of such Goods after any repair or

replacement. The remedy set forth in this paragraph is expressly agreed to be the sole and exclusive remedy for

any breach of warranty. This warranty is exclusive and in lieu of all other warranties expressed or implied, including

but not limited to any warranty of merchantability or of fitness for a particular purpose.

Limitation of Liability - In no event as a result of breach of contract, warranty or negligence shall DL Manufacturing

be liable for special, or consequential damages including but not limited to loss of profits or revenues, loss of any

equipment, cost of capital, cost of substitute equipment, facilities or services, downtime costs or claims of

purchasers of the Customer for such damages. Additionally, DL Manufacturing will not be liable for any delay in

the performance of contracts and orders, or in the shipment and delivery of goods, or for any damage suffered by

the Customer by reason of delay, when such delay is, directly or indirectly, caused by force majeure, including war,

Government interference, strikes, embargoes, shortage of labor, fuel, fires, floods, or any other cause or cause

whether or not similar in nature to any of those herein before specified beyond DL Manufacturing’s control.

7/19/2011 SS9556 REV A

Loading...

Loading...