Page 1

08/28/06 drb Manual, trailer stabilizing jacks, 13126120.doc

VESTIL MANUFACTURING CORP.

2999 N. Wayne St., Angola, IN 46703

Ph: 260-665-7586 · Fax: 260- 6 65-1339

E-mail: sales@vestil.com · Website: www.vestil.com

OWNER’S

MANUAL

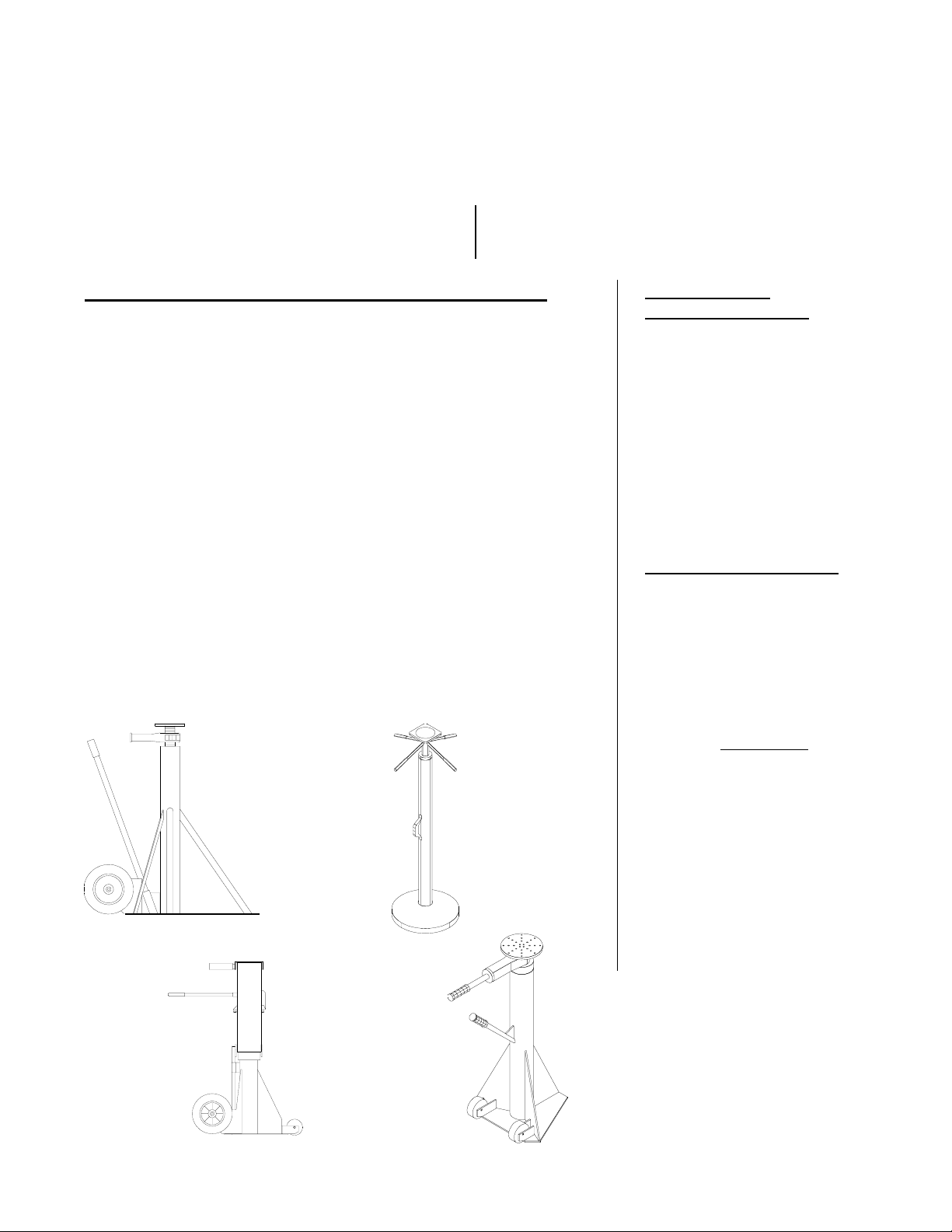

TRAILER STABILIZING JACKS

(Models BFSJ-2748, LO-J-BEAM, H-LO-J-BEAM, LO-J, HI-J, SP-TOP, SP-TOP-R, SJ-35, SJ-35-EF)

User Instructions ..........……………………….……… 2

Routine Maintenance & Safety Checks …………….... 3

Exploded Structural Parts Drawing & BOM ………... 4-7

IMPORTANT NOTES, WARNINGS AND SAFETY INSTRUCTIONS

Ensure that all employees understand and follow the following.

* Failure to read and understand this owner’s manual before using or

servicing any model of trailer stabilizing jack constitutes a misuse of

the product. All persons who will use or care for this product must be

familiar with this material.

o Any load must be removed from the jack before performing repairs or

maintenance.

o Ensure that all of the information / safety / warning labels stay in place

and remain legible.

o Do not use the trailer stabilizing jack if any damage is observed.

o Trailer stabilizing jacks are intended to be used only on compacted,

improved surfaces to support the ends of semitrailers to help prevent

tipover during loading and unloading of the trailer.

o If oil is needed (H-LO-J-BEAM only), use a mineral-based hydraulic oil

with a viscosity grade of 75 SUS at 100°F, (ISO 15 cSt @ 40°C).

♦ Do not perform any modifications to a trailer stabilizing jack without the

manufacturer’s approval. Failure to receive authorization for changes to

the equipment could void the warranty.

♦ Maintenance and repairs are to be done only by personnel qualified to

perform the required work. Consideration will not be given for warranty

repair charges without prior written authorization by the manufacturer.

BFSJ-2748

SJ-35

Safety Label Identification .............................................7

Warranty …………………………………….……..…. 8

WHEN ORDERING

REPLACEMENT PARTS:

We take pride in using quality

parts on the equipment we

manufacture. We are not

responsible for equipment

problems resulting from the use

of unapproved replacement

parts.

To order replacement or

spare parts for this equipment,

contact the factory.

RECEIVING INSTRUCTIONS

It is possible that this product

could incur damage during

transit.

Inspect the unit closely when

it arrives. If you see evidence

of damage or rough handling to

either the packaging or to the

product when it is being

unloaded, immediately

note of it on the Bill Of Lading!

It is important that you

remove the product’s packaging

upon its arrival to ensure that

there is no concealed damage

or to enable a timely claim with

the carrier for freight damage.

Also verify that the product

and its specifications are as

ordered.

make a

H-LO-J-BEAM

ESTIL MFG. CO. 1

V

LO-J & SP-TOP-R

Page 2

08/28/06 drb Manual, trailer stabilizing jacks, 13126120.doc

USER INSTRUCTIONS – TRAILER STABILIZING JACK (ALL MODELS)

o Consult OSHA regulations 29 CFR 1910.178 “Powered Industrial Trucks” and the text below for requirements

affecting the use of this product.

* 29 CFR 1910.178(k)(1) -- “The brakes of highway trucks shall be set and wheel chocks placed under the rear wheels

to prevent the trucks from rolling while they are boarded with powered industrial trucks.

* 29 CFR 1910.178(k)(3) -- “Fixed jacks may be necessary to support a semitrailer and prevent upending during the

loading or unloading when the trailer is not coupled to a tractor”

* 29 CFR 1910.178(m)(7) -- “Brakes shall be set and wheel blocks shall be in place to prevent movement of trucks,

trailers, or railroad cars while loading or unloading. Fixed jacks may be necessary to support a semitrailer during

loading or unloading when the trailer is not coupled to a tractor. The flooring of trucks, trailers, and railroad cars

shall be checked for breaks and weakness before they are driven onto.”

o If any damage to the stabilizing jack is evident, remove it from service immediately.

o Ensure that all employees involved in the use of this product understand and follow these instructions!

Installation and Operation:

The standard model trailer stabilizing jack is intended to be used to support the ends of a semitrailer that is

parked against a loading dock and not connected to a truck’s fifth-wheel. The semitrailer must be situated on a flat,

stable, improved (preferably concrete) surface.

The load rating, in pounds, is shown on the product’s information label located on the side of the jack. The jack has

two ratings -- a static rating (how much weight the jack will support), and a lifting rating (how much weight the jack’s

screw mechanism can lift).

* Note: The need for trailer stabilizing jacks, as well as the quantity to use and their exact placement under the

semitrailer, shall be determined by a qualified individual responsible for the loading or unloading of the trailer.

The following is a list (not all-inclusive) of circumstances in which utilization of a trailer jack is recommended:

• To reduce the risk of the semitrailer’s landing gear failure.

• To reduce the risk that the front of the semitrailer might tend to tip up when a fork truck enters the rear of

the semitrailer, such as with trailers having axles that are further away from the dock than is typical.

• The heavier the fork truck and load, the more likely it is that a trailer stabilizing jack(s) will be needed.

• Shorter semitrailers are more likely to need two jacks -- one under each corner of the nose end.

Warning: Before installing stabilizing jacks underneath it, the semitrailer must be fully supported by its landing gear.

Warning: Before installing stabilizing jacks, the semitrailer must first have its wheels secur ed so that they will resist

creep or roll during the loading or unloading of the semitrailer.

Warning: Confirm that the surface on which the jack(s) will rest is sufficient to prevent the jack from sinking

Warning: Confirm that the strength of the trailer jack’s point of contact with the bottom of the semitrailer is sufficient

to prevent the jack from breaking through the trailer’s floor.

Warning: Do not exceed the trailer stabilizing jack’s load ratings. Injury to personnel or permanent damage to the

semitrailer and/or its contents could result from exceeding the listed capacity.

→ To raise and lower the top cap: models BFSJ-2748, LO-J-BEAM, LO-J, HI-J, and SP-TOP-R all utilize a ratcheting

mechanism (the same handle used for moving the jack around is used for the ratchet), models SP-TOP, SJ-35, and

SJ-35-EF utilize handles that are affixed to the screw hub, and model H-LO-J-BEAM utilizes a hydraulic jack.

Tip the stabilizing jack(s) backward onto its wheels and roll it under the nose-end (front) of the semitrailer. When

using a single jack, place it at the centerline of the trailer’s width. When using two, place one under each corner.

Note: Additional stabilizing jacks might be needed under the rear corners of the semitrailer if the distance from the

axle to the back end of the semitrailer is more than ¼ the length of the trailer.

Adjust the height of the jack so that the jack’s top cap is firmly set against the underside of the semitrailer frame.

Note: The landing gear must remain lowered and firmly against the ground in order to provide additional support.

To remove a trailer jack, lower the top cap so that it is no longer in contact with the bottom of the trailer. Tip the

jack backwards and roll it out from under the trailer.

Caution: The jack(s) must be removed before backing a tractor underneath the semitrailer.

* Ensure that all information/safety/warning labels stay in place and are legible.

Refer to the labels page in this manual.

ESTIL MFG. CO. 2

V

Page 3

08/28/06 drb Manual, trailer stabilizing jacks, 13126120.doc

ROUTINE MAINTENANCE & SAFETY CHECKS – TRAILER STABILIZING JACK (ALL MODELS)

o Warning: Care should be taken to identify all potential hazards and comply with applicable safety procedures

before beginning work.

o Only qualified individuals trained to understand mechanical devices should attempt troubleshooting and repair of

this equipment

To ensure the proper operation of trailer jacks, regular safety inspections and maintenance must be performed.

Inspections should be conducted at regular intervals based on the frequency and severity of usage, and the jacks should

be serviced at least every two months.

Note: If damage is evident, or if any problems are observed based on the insp ecti on items below, remove the

stabilizing jack from service immediately.

(A) Inspect daily for:

1.) Visible damage to the screw, base, or screw hub.

2.) Free movement of the jack’s top cap.

3.) Oil leaks (H-LO-J-BEAM onl y ).

(B) Inspect monthly for:

1.) Adequate grease on the lifting screw threads.

A standard bearing grease should be used on the screw. (To grease the jack screw, adjust it out to its full

extended length and apply grease liberally to the threads. Once greased, run the screw back down into the

jack to coat the entire thread. In colder climates, synthetic grease will reduce the amount of effort required

to install the jack but is not required. Remove any excess grease that may be on the frame or handles.)

2.) Worn or damaged lifting screw threads.

the screw in the screw hub.

3.) Smooth movement of the screw adjustment mechanism.

4.) Evidence of weld cracks or metal fatig u e anywhere on the jack.

5.) Looseness, excessive wear, or damage to the wheels, axles, or wheel bearings (where applicable).

6.) Damaged, loose, or missing handle grip(s). Install adhesive to the inside of the grips and reinstall them if they

become loose.

7.) Proper oil level (H-LO-J-BEAM only). The oil level sh ould be just below the reservoir’s fill hole with the jack in

the lowered position. Use a hydraulic oil having a viscosity grade of 70 to 85 SUS at 100°F, (ISO 15 at 40°C).

8.) All the information/safety/warning labels being in place and in good condition. Contact the manufacturer for

replacements if necessary.

Wear of the screw assembly is characterized by movement (wobble) of

* The following is from CFR Part 1910 (Occupational Safety and Health Standards), Subpart P, titled “Hand and

Portable Powered Tools and Other Hand-Held Equipment:”

1910.244(a) -- Jacks -

1910.244(a)(1) -- Loading and marking.

1910.244(a)(1)(i) -- The operator shall make sure that the jack used has a rating sufficient to lift and sustain the

load.

1910.244(a)(1)(ii) -- The rated load shall be legibly and permanently marked in a prominent location on the jack by

casting, stamping, or other suitable means.

1910.244(a)(2) -- Operation and maintenance.

1910.244(a)(2)(i) -- In the absence of a firm foundation, the base of the jack sh all be blocked. If there is a possibility

of slippage of the cap, a block shall be placed in between the cap and the load.

1910.244(a)(2)(ii) -- The operator shall watch the stop indicator, which shall be kept clean, in order to determine the

limit of travel. The indicated limit shall not be overrun.

1910.244(a)(2)(iii) -- After the load has been raised, it shall be cribbed, blocked, or otherwise secured at once.

1910.244(a)(2)(iv) -- Hydraulic jacks exposed to freezing temperatures shall be supplied wit h an adequate antifreeze

liquid.

1910.244(a)(2)(v) -- All jacks shall be properly lubricated at regular intervals.

1910.244(a)(2)(vi) -- Each jack shall be thoroughly inspected at times which depend upon the service conditions.

Inspections shall be not less frequent than the following:

1910.244(a)(2)(vi)(a) -- For constant or intermittent use at one locality, once every 6 months,

1910.244(a)(2)(vi)(b) -- For jacks sent out of shop for special work, when sent out and when returned,

1910.244(a)(2)(vi)(c) -- For a jack subjected to abnormal load or shock, immediately before and immediately

thereafter.

1910.244(a)(2)(vii) -- Repair or replacement parts shall be examined for possible defects.

1910.244(a)(2)(viii) -- Jacks which are out of order shall be tagged accordingly , and shall not be used until repairs are

made.

ESTIL MFG. CO. 3

V

Page 4

08/28/06 drb Manual, trailer stabilizing jacks, 13126120.doc

EXPLODED PARTS VIEWS AND BOMS -- TRAILER STABILIZING JACK (ALL MODELS)

-

-

-

ESTIL MFG. CO. 4

V

Page 5

08/28/06 drb Manual, trailer stabilizing jacks, 13126120.doc

-

-

-

-

ESTIL MFG. CO. 5

V

Page 6

08/28/06 drb Manual, trailer stabilizing jacks, 13126120.doc

-

-

-

ESTIL MFG. CO. 6

V

Page 7

08/28/06 drb Manual, trailer stabilizing jacks, 13126120.doc

-

-

-

SAFETY LABEL IDENTIFICATION -- TRAILER STABILIZING JACK (ALL MODELS)

* Product safety signs or labels should be periodically inspected and cleaned by the product users as necessary to

maintain good legibility for safe viewing distance -- ANSI 535.4 (10.21). Contact the manufacturer for replacement

labels.

ESTIL MFG. CO. 7

V

Page 8

08/28/06 drb Manual, trailer stabilizing jacks, 13126120.doc

PRODUCT WARRANTY

90-DAY LIMITED WARRANTY

The manufacturer warrants for the original purchaser against defects in materials and wo rkmanship under normal use

for 90 days after date of shipment. Any part that is determined by the manufacturer to be defective in material or

workmanship and returned to the factory, shipping costs prepaid, will be, as the exclusive remedy, repaired or

replaced at our option. Labor costs for warranty repairs and/or modifications are not covered unless pre-approved by

the manufacturer or done at the manufacturer’s facilities. Any modifications performed without prior written approval

of the manufacturer may void warranty. This limited warranty gives purchaser specific legal rights which vary from

state to state.

All specifications are subject to change without notice.

LIMITATION OF LIABILITY

To the extent allowable under applicable law, the manufacturer’s liability for consequential and incidental damages is

expressly disclaimed. The manufacturer’s liability in any event is limited to, and shall not exceed, the purchase price

paid. Misuse or modification may void warranty.

Warranty does not cover labor or consequential damages including, but not limited to, business interruption costs, lost

profits, or lost business opportunities.

WARRANTY DISCLAIMER

The manufacturer has made a diligent effort to accurately illustrate and describe their products. However, such

illustrations and descriptions are for the sole purpose of identification, and do not express or imply a warranty that the

products are merchantable or fit for a particular purpose, or that the products will necessarily conform to the

illustrations or descriptions.

The provisions of the warranty shall be construed and enforced in accordance with the Uniform Commercial Code and

laws as enacted in the State of Indiana.

DISPOSITION

Our company will make a good faith effort for prompt correction or other adjustment with respect to any product that

proves to be defective within the Limited Warranty Period. Warranty claims must be made in writing within s aid year.

ESTIL MFG. CO. 8

V

Loading...

Loading...