Page 1

VESTIL MANUFACTURING CORPORATION

2999 North Wayne St., Angola, IN 46703

Phone (260) 665-7586 • Fax (260) 665-1339

E-mail: sales@vestil.com • www.vestil.com

Ergonomic Solutions

Contents

Warnings and Safety Instructions.................. 1

Operation Instructions ................................ 2-3

Receiving Instructions & Warranty ................ 4

Maintenance & Safety Checks ...................... 4

Revised 05-07 29-126-101

A company dedicated to solving ergonomic and material

handling problems since 1955

.

OWNERS

MANUAL

WORK PLATFORM

MODEL WP, WP-3737-FD and SP-175

Caster Installation ........................................... 5

Emergency Stop Option .................................. 6

Parts List ......................................................... 7

Warning Labels ............................................... 8

WARNINGS & SAFETY INSTRUCTIONS

Ensure that all employees understand and follow the

following instructions.

• Read and understand the owner’s manual before

using the work platform.

• Ensure that all safety and warning labels stay in

place and are legible. See the labels page in this

manual.

• Observe all applicable OSHA laws regulating the use

of this platform.

•

Warning:

wear appropriate fall prevention gear and keep it

tethered to the platform at the lanyard attachment

point at all times.

• The work platform cannot have a width greater than

the overall width of the fork truck being used

(measured across the load bearing tires) plus

250mm on either side.

See ASME/ANSI B56.1; 7.36.3(e).

• Ensure that the forks are fully inserted through both

sets of the fork pockets.

• Secure the work platform to the forklift mast before

use.

• Do not use the work platform if any damage to the

standing surface, the handrails, or any part of the

gate is observed.

• Do not use the work platform unless the fork tine

lock, securing chain, and gate latch are all in good

condition and functioning properly.

• The fork truck’s parking brake must be applied before

elevating the work platform.

• Never transport personnel in basket at any time.

Personnel are to be raised and lowered only.

• A fork truck carrying a work platform must only be

used on a firm and level finished surface in good

Each person aboard the work platform must

repair, and the truck’s forks must be kept level with

the ground at all times.

• Be alert for personnel moving underneath the

platform.

•

Warning:

safety chains as a step, or as a support for leaning

out of the work platform.

•

Warning:

type of structural load. It is to be used only to lift and

transport personnel along with their associated light

tools and equipment.

• Do not use the optional caster kit to support and / or

move the platform while personnel or equipment are

aboard. Always elevate the platform off the floor when

transporting equipment or personnel!

• Fork truck manufacturers are to be consulted when

accessories are used that affect the truck’s capacity

and safe operation. The stockpicker’s load-loss and

center-of-gravity will be made available on request.

See OSHA 1910.178(a)5.

Do not use any part of the gate, siderails, or

Never use the platform to lift or support any

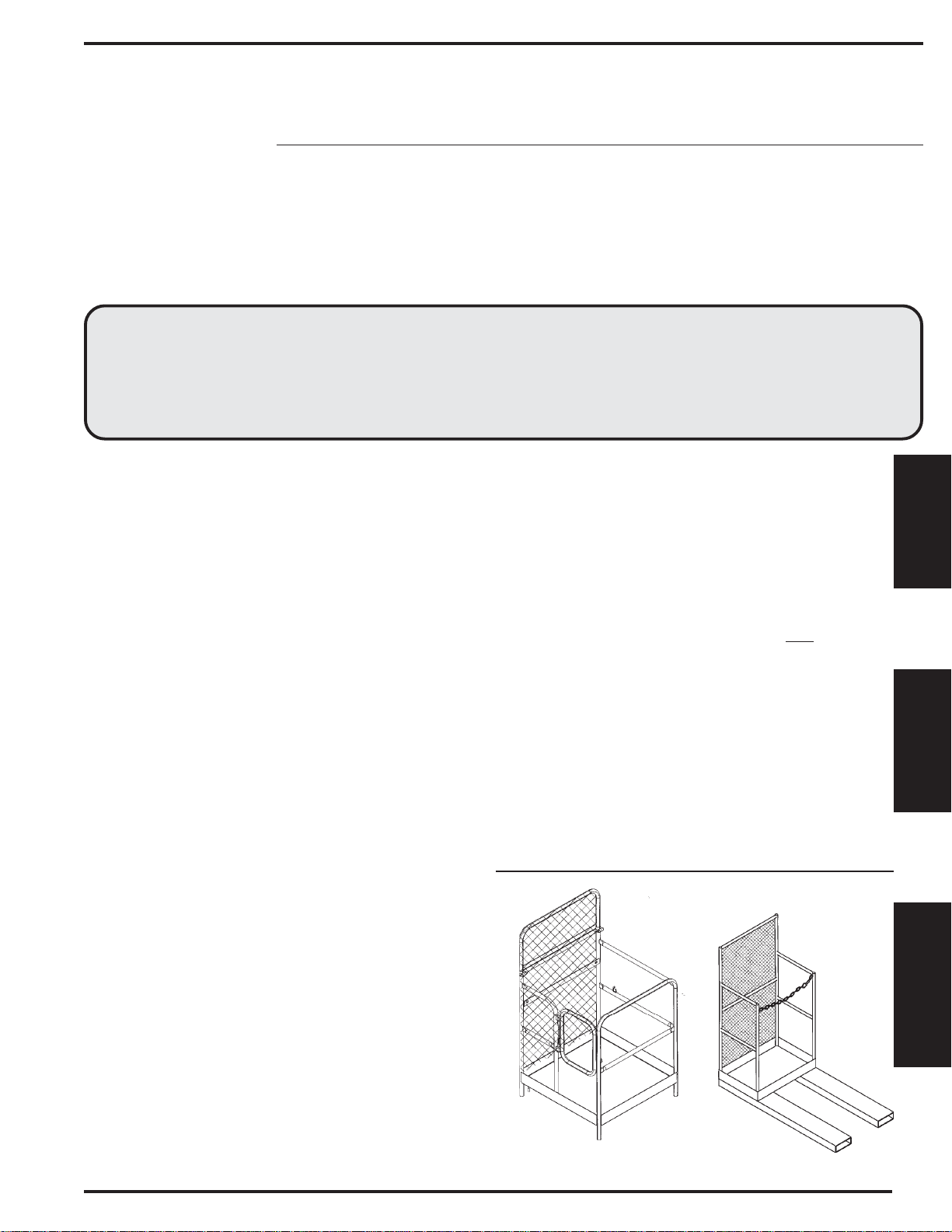

WP

SP-175

WORK PLATFORM

MODEL WP, WP-3737-FD and SP-175

E

N

G

L

I

S

H

E

S

P

A

N

O

L

F

R

A

N

Ç

A

I

S

1

Page 2

OPERATION INSTRUCTIONS - WP, SP

You must read and understand all the following instructions carefully before using the work platform.

Consult the manufacturer for any questions not resolved to your satisfaction in this owner’s manual.

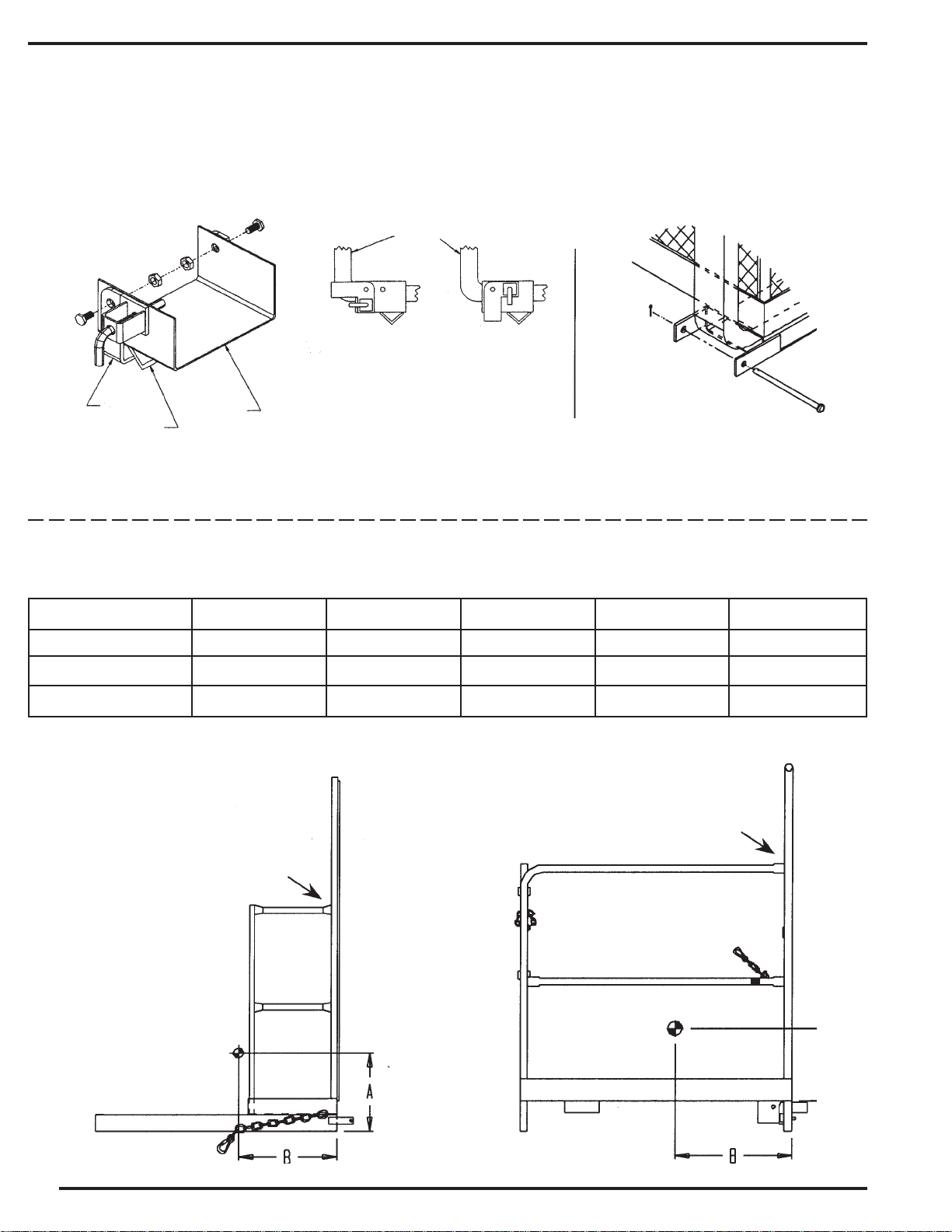

ATTACHING THE PLATFORM TO A FORK TRUCK:

Insert the fork truck’s forks all the way into the backside fork tubes (opposite the gate side). Entering from the back side of the work

platform, the forks must extend through the front fork pockets. Attach the platform to the fork truck’s fork carriage with the securing

chain, and capture the heel of the fork with the tine lock underneath the corner of the platform.

Locked Unlocked

WP tine lock. Pull the pin, then

rotate the tine lock 90° until the

Tine Lock

pin locks.

Fork Pocket

Welded Angle

SP-175 tine lock. Install the

pin after the fork is inserted.

CENTER OF GRAVITY AND LOAD LOSS INFORMATION

WP-4848 (-DD)

Vert. C.O.G. (A)

Horiz. C.O.G. (B)

Lost Load (lbs.)

Note: For the 84” high back units, add 12 pounds.

Lanyard attachment points

Model SP-175

center of gravity

(C.O.G.)

13-1/2”

21-3/4”

240

WP-3648 (-DD)

13-1/2”

21-3/4”

190

WP-3636 (-DD)

15-1/2”

17”

160

Lanyard attachment points

WP- models’

center of gravity

(C.O.G.)

SP-175

15”

21-1/2”

210

WP-3737-FD

16 - 1/2”

18”

175

2

Page 3

LOADING THE PLATFORM:

The model WP work platform and model SP stock picker are medium-duty platforms intended to be used with a sit-down

rider, high lift fork truck having a minimum load capacity of 3,000 pounds at a 24” load center.

The model WP’s (all models) net load rating of 1,000 pounds is shown on the safety instructions placard mounted on its

expanded metal back. The platform is intended to be used to lift personnel along with their associated light tools and

equipment to allow work and inspections to be safely performed on elevated equipment. The maximum occupancy for

model WP-3737-FD is one person. For all other WP models, maximum occupancy is two persons.

The model SP stock picker’s net load rating is 2,000 pounds. It is intended to be used to lift one person and a skid to

allow stock to be either removed from, or placed onto, shelves. A skid loaded onto the fork tubes must not at any time

have a horizontal load center of more than 20” from the front of the stock picker platform.

•

Warning:

Damage to the platform or injury to personnel could result from exceeding a platform’s listed capacity.

OPERATION AND USE:

Before using the work platform, review all of the items on the “Warning And Safety Instructions” page included herein!

Consult standard ANSI / ASME B56.1-2000, “Safety Standard For Low Lift and High Lift Fork Trucks,” for further information regarding proper procedures to be used when operating a fork truck with a work platform attached.

• Before entering the work platform, verify that it is positively secured to the fork truck mast by both the securing chain

and the tine lock. Inspect all of the platform structure for signs of damage, and verify that the gate latch and / or

chain(s) will secure properly.

• For the standard model WP: enter the work platform and pull the gate closed. The latch will automatically rotate

and drop into the locked position. Push outward on the gate to verify it has locked. Secure the gate with its safety

chain.

For model WP-xxxx-DD: upon entering this work platform from either side, the doors will close automatically once

you are clear of them. Verify that both gates are fully closed before allowing the platform to be raised.

For model WP-3737-FD: enter the platform from either side and pull the gate closed. Rotate the gate latch up

before closing the gate fully. With the gate up against the latch stop, push the gate latch down so that the door is

secured.

Push outward on both gates to verify they are locked. Secure each gate to the back frame with its own safety chain.

For model SP175: Enter the platform and latch each of the safety chains. The SP should be positioned parallel, not

perpendicular, to the stock’s shelving.

•

Warning:

• For all units:

the back of the platform.

•

Caution:

•

Caution:

•

Caution:

•

Caution:

designed to allow for movement of the platform across a floor while personnel or equipment are in the platform.

• An optional stop button kit is available to allow personnel on the work platform to disable the ignition system of fork

trucks powered by combustible engines. For installation on electric fork trucks, consult the manufacturer for proper

installation instructions.

Do not lean against the handrails or safety chains to support the weight of your body.

Warning:

Use the work platform only on a smooth, level, finished surface. Avoid sudden stops or quick turns.

Set the parking brake before lifting personnel overhead.

Hold onto the handrail on two sides of the work platform whenever it is in motion.

The optional caster kit is designed to allow for easier access to and storage of the work platform. It is not

Latch your safety harness rope to an attachment slot on either end of the angle that runs across

E

N

G

L

I

S

H

INSTRUCTIONS TO FOLD DOWN / SET UP THE MODEL WP-3737-FD:

•

Caution:

or fingers become pinched between the folding parts.

When you wish to fold down the work platform for storage:

• Fold the gates back against the front side, then lift the front side so that the bottom post pins are at the top of their

slots. Pivot the folded gates and front side down into the platform.

• Pull up the top half of the back section of the work platform up so that the center post pins can slide into their horizontal

slots. Rotate the top section downward so that it is folded against the lower back section. Pull the folded sections up

so the bottom post pins are at the top of their slots, then rotate the sections down into the platform.

use reasonable care when folding down or setting up the work platform in order to avoid having hands and /

3

Page 4

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected prior to shipment. However, it is possible that the unit may incur damage during

transit. If you see damage when unloading make a note of it on the SHIPPER RECEIVER.

Remove all packing and strapping material and inspect unit for damage.

IF DAMAGE IS EVIDENT, FILE A CLAIM WITH THE CARRIER IMMEDIATELY!

WARRANTY

This product is warranted for 90 DAYS from date of purchase to be free of manufacturing defects in material and

workmanship. The manufacturer's obligation hereunder is limited to repairing such products during the warranty period,

provided the product is sent prepaid back to the factory.

This warranty does not cover normal wear of parts or damage resulting from any of the following: negligent use or misuse

of the product, use or application contrary to installation instructions, or disassembly, repair or alteration by any person prior

to authorization from a factory representative.

ORDERING REPLACEMENT PARTS

We take pride in using quality parts on the equipment we manufacture. We are not responsible for equipment problems

resulting from the use of unapproved replacement parts.

To order replacement or spare parts for this equipment, contact the factory.

In any communication with the factory please be prepared to provide the platform’s serial number.

ROUTINE MAINTENANCE & SAFETY CHECKS

(A) Before each use inspect for the following:

1.) Proper operation of the tine lock.

2.) Proper operation of the securing chain’s snap.

3.) Proper operation of the gate’s latch and chain.

4.) Obvious damage to, or structural deformation of, the base, handrails, and gate.

5.) Wear or damage to the safety harness lanyard attachment angle.

6.) Wear or possible damage to the safety harness lanyard or its clasp.

7.) (If applicable) Proper attachment of the casters to the bottom of the platform. Bending or damage to the casters.

(B) Inspect monthly for:

1.) Worn, loose, or damaged hardware on the tine lock, safety chains, gate latch, gate hinges, and casters (if

applicable).

2.) Damage to the fork pockets or the optional casters.

3.) The overall condition of the platform.

4.) The integrity of the welds at all joints.

5.) Overall squareness and rigidness of the platform.

6.) Information and warning labels being in place and in good condition.

7.) The need to clean off rust, dirt and debris.

• Maintenance and repairs are to be done only by personnel qualified to perform the required work.

•

Caution:

authorization for changes to the equipment could void the warranty.

4

Do not perform any modifications to the platform without the manufacturer’s approval. Failure to receive

Page 5

INSTRUCTIONS FOR:

MOUNTING THE WP-CA CASTER KIT

READ ALL INSTRUCTIONS BEFORE PROCEEDING!

Only trained and qualified service personnel should work on this equipment!

1. Verify that the bottoms of all four of the platform’s

corner handrail posts are undamaged and that there

is no foreign material plugging the inside of the

posts.

2. Raise the work platform high enough to allow the

casters to be inserted into the bottom of each of the

four posts.

3. Verify that the stems of the casters have, in this order

from the rig to the end of the stem: a plastic spacer, a

black rubber expansion sleeve, and a knurled nut.

4. Hold onto the 2-1/2” tightening hub at the top of the

caster rig with your hand and snug the knurled nut

against the top rubber expansion sleeve.

5. Insert the caster stem into the bottom of the post until

the tightening hub is up against the bottom of the

handrail post.

6. Turn the tightening hub counterclockwise. If the hub

doesn’t tighten, apply side pressure to the caster

while turning the hub.

Note:

Be sure that the tightening hub stays up

against the bottom of the handrail post when

tightening.

7. Once hand-tightened as far as possible, pull

downward on the caster rig to be certain the caster is

held securely in the post.

CORNER

HANDRAIL

POST

CASTER STEM

KNURLED NUT

EXPANSION

RUBBER

PLASTIC SPACER

TIGHTENING HUB

E

N

G

L

I

S

H

CAUTIONS:

•

Inspect the casters regularly for damage and to

verify that the caster stem is still inserted fully

and that it is securely held in the post.

• The casters are intended to be used only on solid,

smooth finished surfaces.

• Do not roll a platform across a surface when loaded

with equipment or personnel. The casters are only

intended to facilitate moving an unloaded platform.

• Do not lower the platform to the floor at a rate greater

than one foot per second.

5

Page 6

FIGURE C:

WORK PLATFORM

JUNCTION BOX

EMERGENCY STOP BUTTON

WP-SB

FIGURE B:

FORK TRUCK

JUNCTION BOX

BILL OF MATERIALS

ITEM NO. DESCRIPTION QUANTITY

1. 1/4 - 20 x 1 Machine Bolt 8

2. 1/4 - 20 Lock Nut 8

3. 1/4 Flat Washer 8

4. 1/4 Fender Washer 4

5. Fork Truck Junction Box (pre-assembled) 1

6. Work Platform Junction Box (pre-assembled) 1

GAS POWERED FORK TRUCKS

1) Mount the supplied 4” square junction box with the short pig tail near the front of the fork truck (see figure

“A”) using the 1/4”-20 x 1” machine bolts and lock nuts provided.

2) Disconnect the wire on the key switch coming from the ignition coil and attach it to one of the receptacle

terminals inside the junction box mounted on the fork truck’s dashboard.

TIONS

3) Connect the appropriate wire from the ignition

key switch to the other receptacle terminal

inside of the fork truck mounted junction box.

4) Mount the “Emergency Stop” junction box

inside the work platform within easy reach of

the operator/maintenance person.

NOTE: Fork trucks powered by Battery or Diesel fuel:

contact the fork truck manufacturer for installation

instructions.

-----------------------------------------------------------------------------

OPERATING INSTRUCTIONS

FOR USE WITHOUT THE WORK PLATFORM ATTACHED:

C

MALE PLUG

FROM COIL CORD/

WORK PLATFORM

FIGURE “A”

MUSHROOM HEAD

PUSH BUTTON

MALE JUMPER

PLUG

FORK TRUCK

MOUNTED

JUNCTION BOX

TO POSITIVE

SIDE OF COIL

1) Plug the 12” long jumper plug into the fork truck mounted

junction box. This will provide the necessary connection

for operation without the work platform attached to the

fork tr uck.

FOR USE WITH THE WORK PLATFORM ATTACHED:

2) Plug the 20’ coil cord into the fork truck mounted

junction box. This will provide the necessary connection

for operation with the work platform attached. (The

mushroom head pushbutton must be pulled out).

INSTALLATION INSTRUC

6

JUMPER PLUG

KEY SWITCH

ON FORK TRUCK

TO IGNITION

KEY SWITCH

DISCONNECT HERE

AND CONNECT TO

FORK TRUCK

JUNCTION BOX

IGNITION/COIL

TERMINAL

Page 7

PARTS IDENTIFICATION

models WP-3636, WP-3648, WP-4848

E

N

G

L

I

S

H

ITEM NO.

1

2

3

4

5

6

7

8

9

10

PARTS IDENTIFICATION

models WP-3636, WP-3648, WP-4848

DESCRIPTION

FRAME, WELDMENT

HHCS #2 Z PLATED, 1/2” - 13 X 1-1/4” LG

1/2” - 13 NYLON INSERT LOCK NUT

WELDMENT, HINGED GATE, WP-DD

#11 HITCH PIN CLIP

1/2” X 2” HEX HEAD

1/2” - 13 UNC HEX NUT

7/16” X 14” LG ROUND HEAD PIN

9/16” X 2-1/4” LG SPRING

ASSEMBLY, TINE LOCK, WP

PART NO.

14-514-118

11207

37030

14-514-093

45286

10211

36109

14-112-009

14-146-002

14-537-007

QTY.

1

2

2

1

1

2

2

1

1

1

7

Page 8

WARNING LABEL IDENTIFICATION

MAKE SURE ALL WARNING LABELS ARE IN PLACE!

Most of our labels will be trilingual. The labels on the Fold Down Work Platform are located in

approximately the same locations as on the standard Work Platform.

1

2

4

3

3

1 2

1

2

4

BACK

*Product safety signs or labels should be periodically inspected and cleaned by the product

users as necessary to maintain good legibility

for safe viewing distance . . .

ANSI 535.4 (10.21)

Contact manufacturer for replacement labels

if needed.

#080

3

4

!

WARNING

SECURELY ATTACH SAFETY

CHAIN TO FORKLIFT

VESTIL MANUFACTURING COMPANY • Angola, Indiana USA • Phone (260) 665-7586

VESTIL MANUFACTURING COMPANY • Angola, Indiana USA • Phone (260) 665-7586

sales@vestil.com • www.vestil.com

!

CAUTION

FASTEN SAFETY

RESTRAINT HERE

sales@vestil.com • www.vestil.com

#082

#525

#253

8

Loading...

Loading...