Vestil SL-xxx-AA User Manual

OPERATION & SERVICE MANUAL

SL SERIES SEMI-ELECTRIC STACKER WITH MANUAL DRIVE & POWERED LIFT

Vestil Manufacturing Corp.

2999 North Wayne St., Angola, IN 46703

Ph: 260-665-7586

. Fax: 260-665-1339

E-mail: Sales@vestil.com

Website: www.vestil.com

1

General

Read and follow the instructions contained in this operating

manual without fail!

Only trained, well-informed personnel, who have been instructed in accordance with this operation manual, may use

or work on the machine.

Liability or guarantee is waived if:

The instructions in this operating manual are not observed.

The high-lift stacking truck is operated, cleaned or maintained incorrectly.

Alterations to the functions are carried out without the consent of manufacturer.

Original spare parts are not used.

Safety instructions

This chapter informs the user about residual dangers relating to the correct use of the products. It contains generally

valid safety instructions which must be observed.

Safety instructions relating to specific actions or situations are listed prior to the respective action and/or description of

the situation in the chapter.

Principles

This product complies with state-of-the –art technical standards and recognized safety regulations, but there are still

dangers which may occur which must be considered.

Only operate the product in a perfect condition and observing the information contained in the operating manual.

The operator is responsible for integrating the product with as little risk as possible into his working environment. This

obligation continues through every phase of the products lifespan, beginning at the planning stage. Residual dangers

are to be minimized.

Only trained, competent personnel who have been instructed using the operating manual and the product are

permitted to work with the truck.

The operating manual must be understood (responsibility, checking)

Declaration:

I have read this manual and, in particular, have taken note of the caution.

Name Date Signature

2

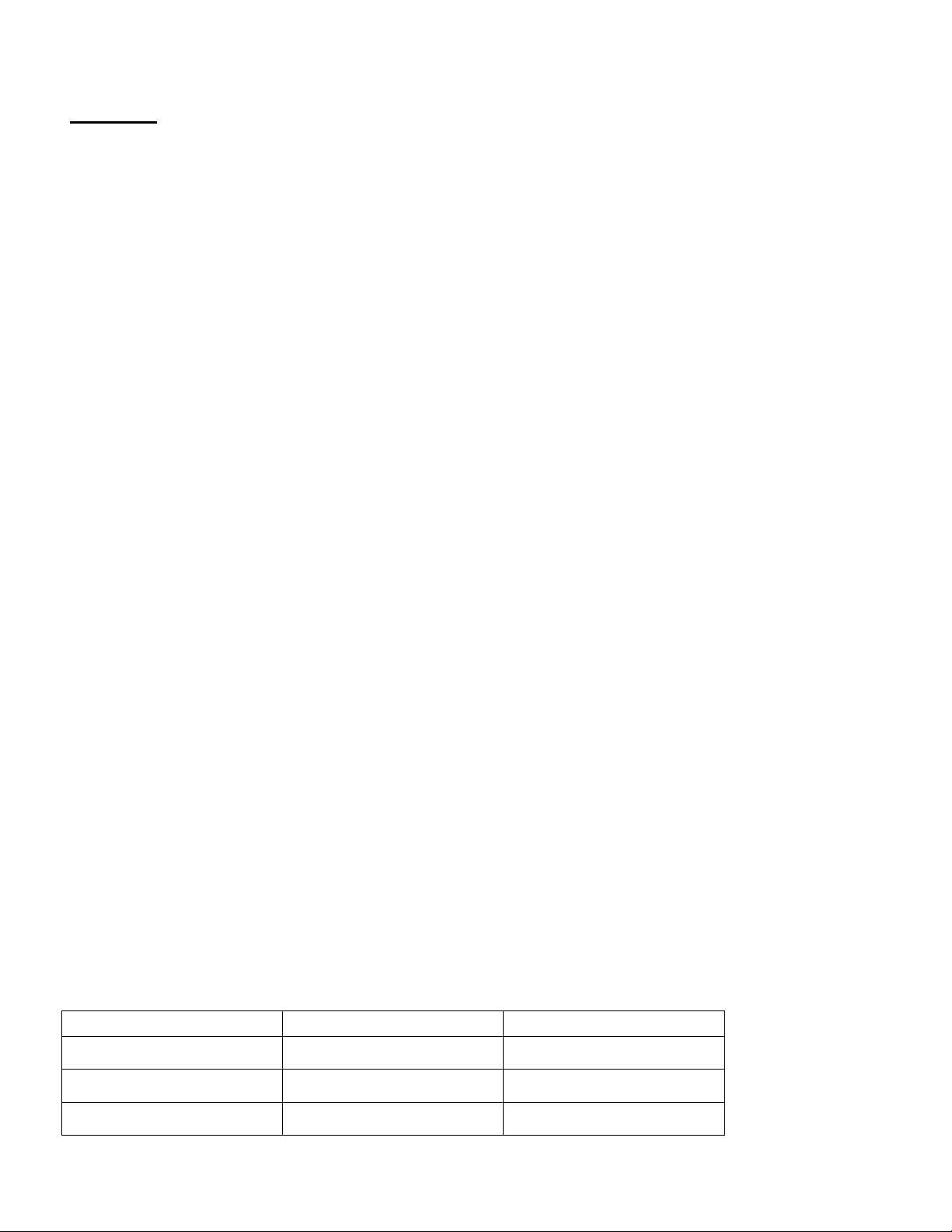

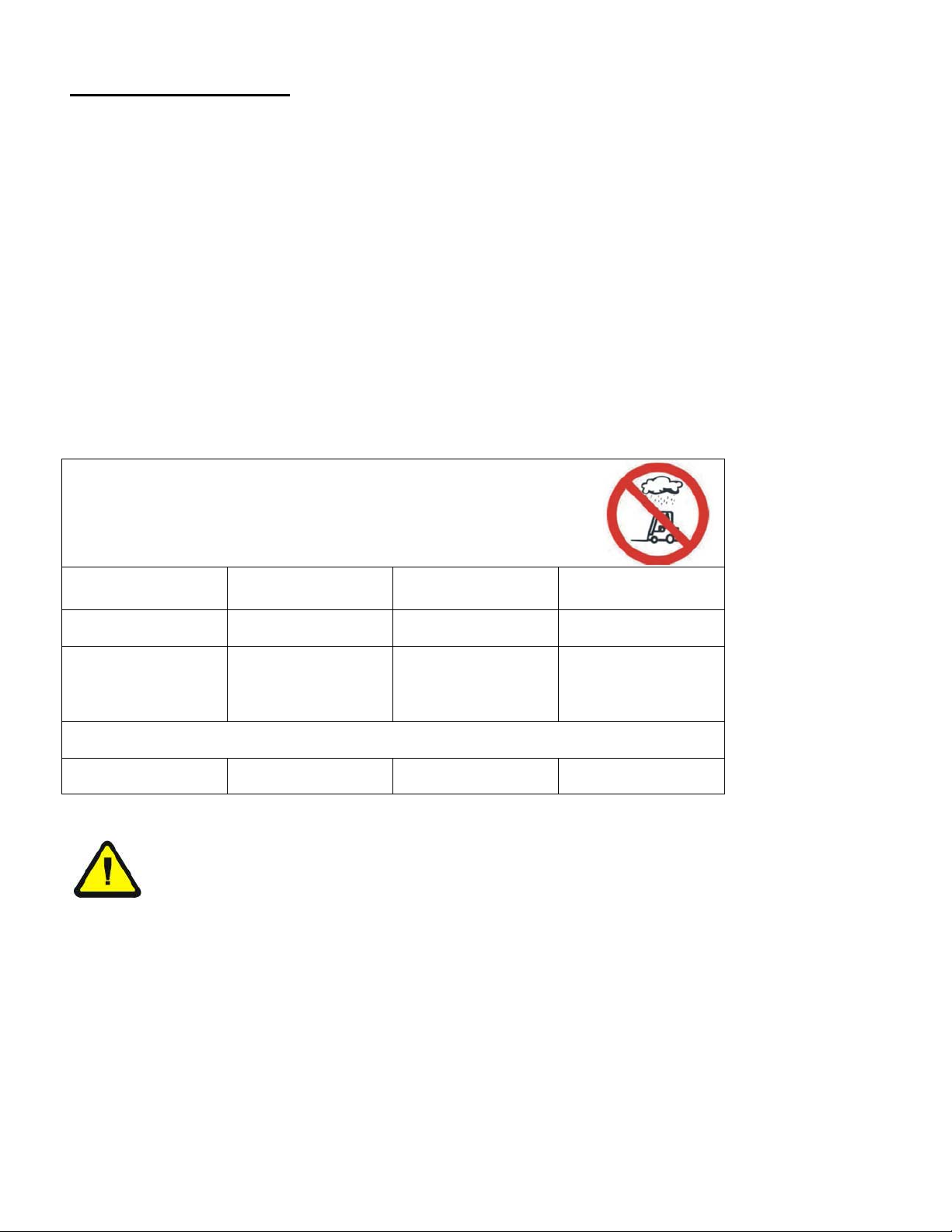

Specification

SPECIFICATION

Capacity

Fork Lift Height

Capacity

Fork Dimension

FF

AA

Overall Fork Width

Ground Clearance

Lowered Fork H.

FF

AA

H. Overall Extended

Head Dimension

Loading Center

Wheel Base

FF

AA

Turning Radius

Steering Wheel

Front Wheel

FF

AA

Overall Size

FF

AA

Lift

Speed

Lower

Speed

Lift Motor

Amperage (Loaded)

Amperage (Unloaded)

Battery

Battery Charger

Weight

FF

AA

Load Grade ability

Unload Grade ability

Width of Aisle

Load

Unload

Load

(1 spd.)

Load

(2 spd.)

Unload (1

spd.)

Unload (2

spd.)

SL-63-AA/FF SL-118-AA/FF SL-137-AA

2000 lbs. 2000 lbs. 2000 lbs.

62” 118” 137”

2000 lbs. @ 62” 1500 lbs (62”-118”)

42x5.9 x2 3/8”

42x4 x1 ¼”

26 ¾” 26 ¾” 26 ¾”

1” 1” 1”

3 ¼”

2 1/8”

81 7/8” 140” 159”

29 1/8x19 5/8x37” 29 1/8x19 5/8x37” 29 1/8x19 5/8x37”

21” 21” 21”

39 ¾”

40 ½”

51” 51” 51”

Φ7x2” Φ7x2” Φ7x2”

Ø3x3 ¼”

Ø4x2.9”

67 5/16x29 1/8x81 7/8”

66 1/8x29 1/8x81 7/8”

2.74”/s 3.18”/s 3.18”/s

4.84”/s 4.41”/s 4.41”/s

2.42”/s 2.3”/s 2.3”/s

4.5”/s 5.4”/s 5.4”/s

2.42”/s 2.3”/s 2.3”/s

4.2”/s 5.4”/s 5.4”/s

12V/1.5KW 12V/1.5KW 12V/1.5KW

165 amps. 177 amps. 177 amps.

65 amps. 107 amps. 107 amps.

12V/70Ah 2x12V/70Ah 2x12V/70Ah

DC24V/6A Soneil DC24V/6A Soneil DC24V/6A Soneil

830 lbs.

870 lbs.

6% 6% 6%

10% 10% 10%

32” 32” 32”

67 5/16x29 1/8x81 7/8”

66 1/8x29 1/8x81 7/8”

42x5.9x2 3/8”

42x4 x1 ¼”

3 ¼”

2 1/8”

39 ¾”

40 ½”

Ø3x3 ¼”

Ø4x2.9”

1020 lbs.

1070 lbs.

b)1500 lbs. @ (62-118”)

c)1000 lbs. @ (118-137”)

None

42x4 x1 ¼”

None

2 1/8”

None

40 ½”

None

Ø4x2.9”

None

66 1/8x29 1/8x877/8”

None

1140 lbs.

FF: FIXED FORKS OVER SUPPORT LEGS

AA: ADJUSTABLE FORKS OVER ADJUSTABLE LEGS

Note: The load capacity is based on the situation when the center of the gravity is located at the center of length of

forks. When the center of gravity of goods is out of the center of forks, the load capacity will be lessened

compared to the center.

3

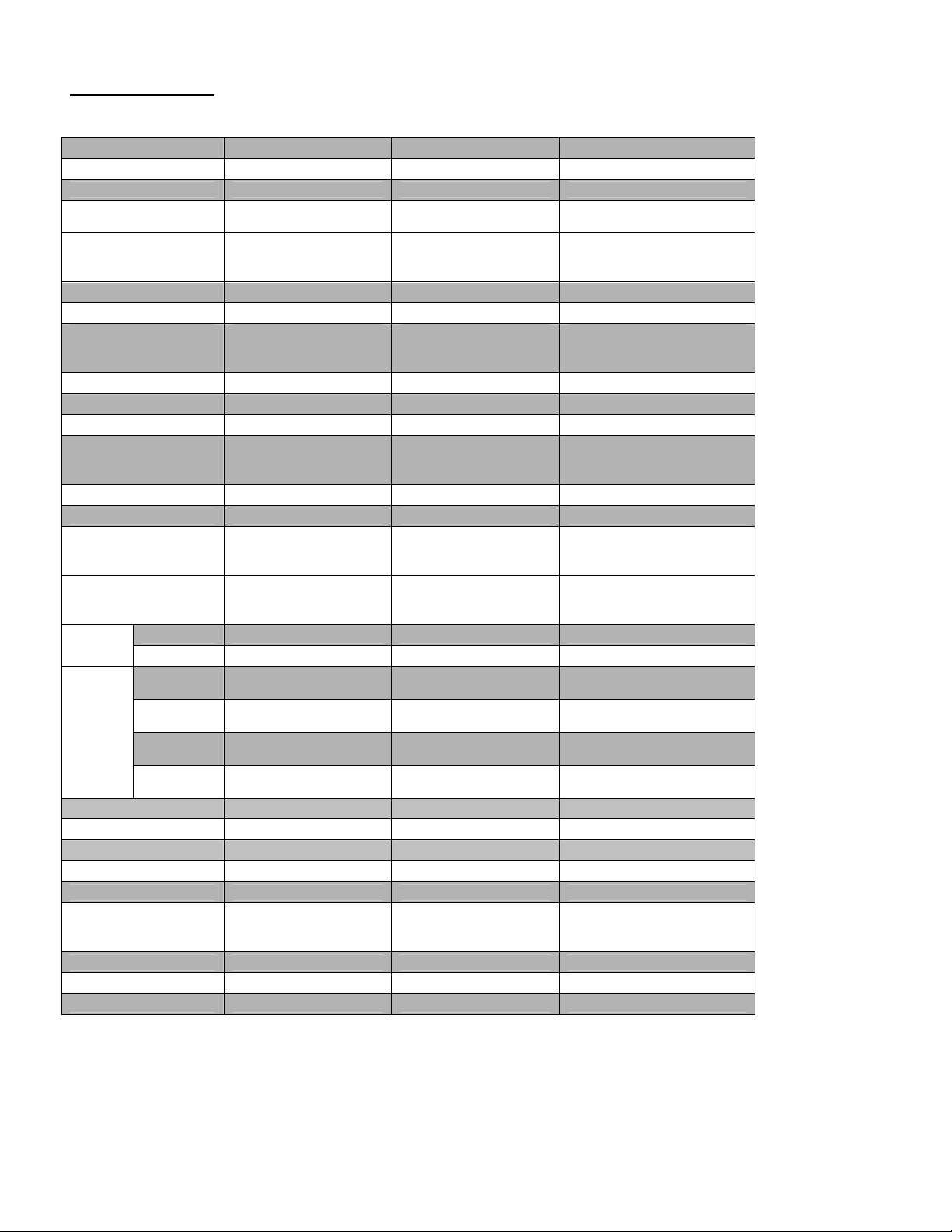

CCOONNTTEENNTTSS

General …………………………………………………………………………………

2

Specification ……………………………………………………

Receiving instructions ………………………………………………………………

Safety Notes ……….……………………………………………………………………

Product description ………………………………………………………………

Designated use …. … …... … …………………………………………………….

Signs on the Truck …………………………………………………………………

Removing from the pallet ………………………………………………………

Operation …………………………………………………………………………….

Operation …………………………………………………………………………….

Operating elements ………………………………………………………………..

Traveling …………………………………………………………………………….

Lifting and lowering ………… …………………………………………………….

Parking Brake ………………………………………………………………………

Lifting the load………………………………………………………………………

Transporting on inclined surfaces ………………………………………………..

Maintenance and repair ……………………………………………………………

Trouble shooting …………………………………………………………………….

Changing batteries ………………………………………………………………….

Maintenance daily/before use, monthly, annually …………….…………………

Maintenance and care of the load chains ………………………………………..

Chain inspections ……………………………………………………………………

Temporary lay-up …………………………………………………………………….

3

5

6

7

7

8

9

10

11

12

13

14

15

16

17

17-18

19-20

21

22

23

24

Parts drawing & Parts list ………………………………………………….

4

25-35

Receiving Instructions

Every unit is thoroughly tested and inspected prior to shipment. However, it is possible

that the unit may incur damage during transit. If you see damage when unloading, make a

note of it on the SHIPPER RECEIVER.

Remove all packing & strapping material, inspect for damage. IF DAMGE IS EVIDENT, FILE A CLAIM WITH THE

CARRIER IMMEDIATELY! Also, check fork size, type of power unit, etc., to see that the unit is correct for the

intended application.

Warnings & Safety Instructions

Insure that all employees understand and follow the following instructions

• Read and understand the owner’s manual before using or servicing the stacker.

• Do not use the stacker if any damage or unusual noise is observed.

• Improper use of this lift truck could result in injury and damage to load or equipment.

• Always watch the stacker and any load on it carefully when it is being used or moved.

• Avoid sudden stops or quick turns to prevent accidental tipping of the load.

• Load must be centered and evenly distributed on the forks.

• Park the truck on level surfaces and not in the way of other products

• When parked, lower the load fork completely.

• When parked, push E-switch push-button down.

• Do not perform any modifications to the stacker without the manufacturer’s approval. Failure to receive

authorization for changes to the equipment could void the warranty.

• Do not use brake fluid or jack oil in the hydraulic system. If oil is needed, use an anti-wear hydraulic oil with a

viscosity grade of 150 SUS at 100°F, (ISO 32 @ 40°C ), or a non-synthetic transmission fluid.

• Use only replacement parts either supplied or approved by the manufacturer.

5

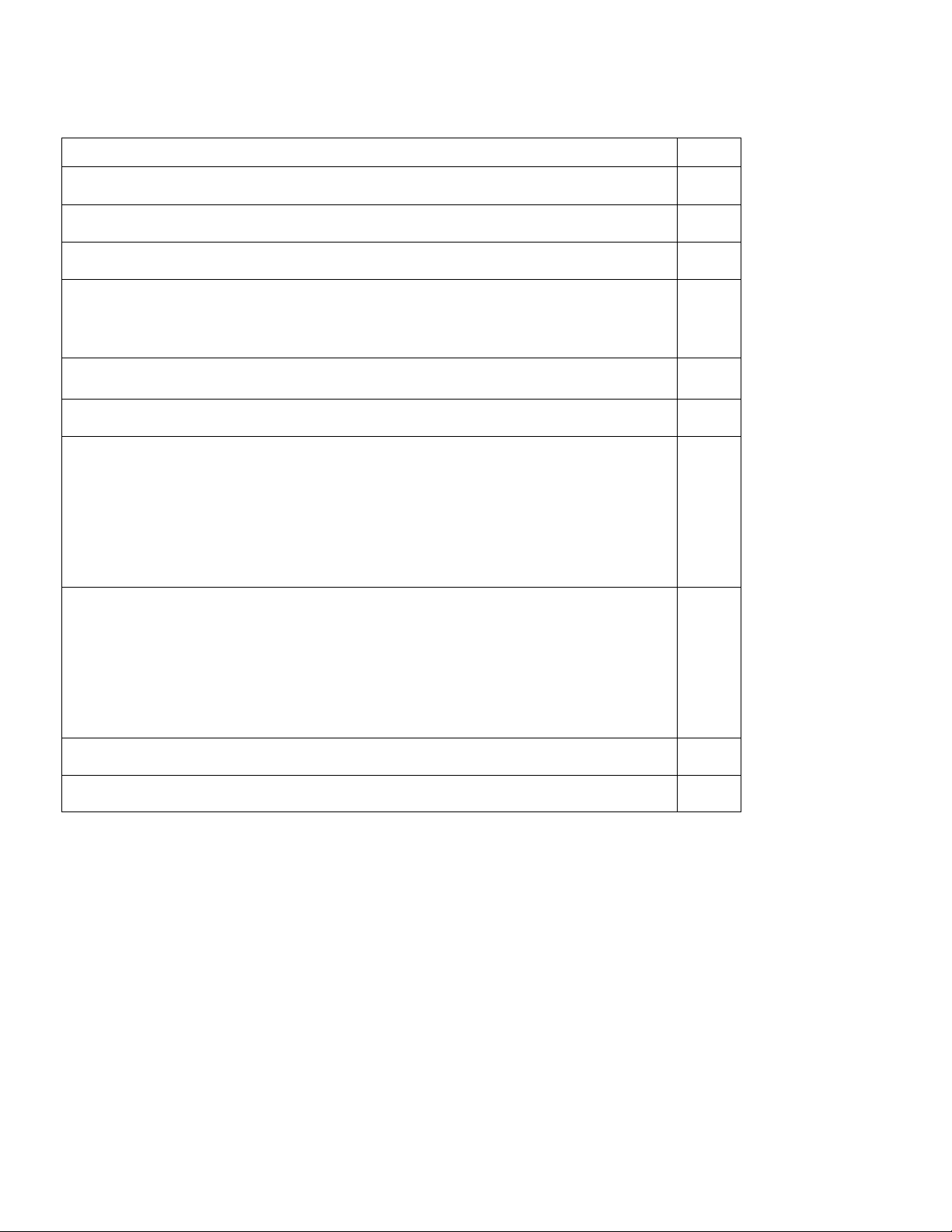

Safety notes

Symbols and pictures

In addition to the text and illustrations, this operating manual contains various symbols which should draw attention to

the safety requirements.

They generally have the following appearance:

Signal wording Explanation

DANGER

WARNING

CAUTION

Other definitions:

DIRECTION

IMPORTANT

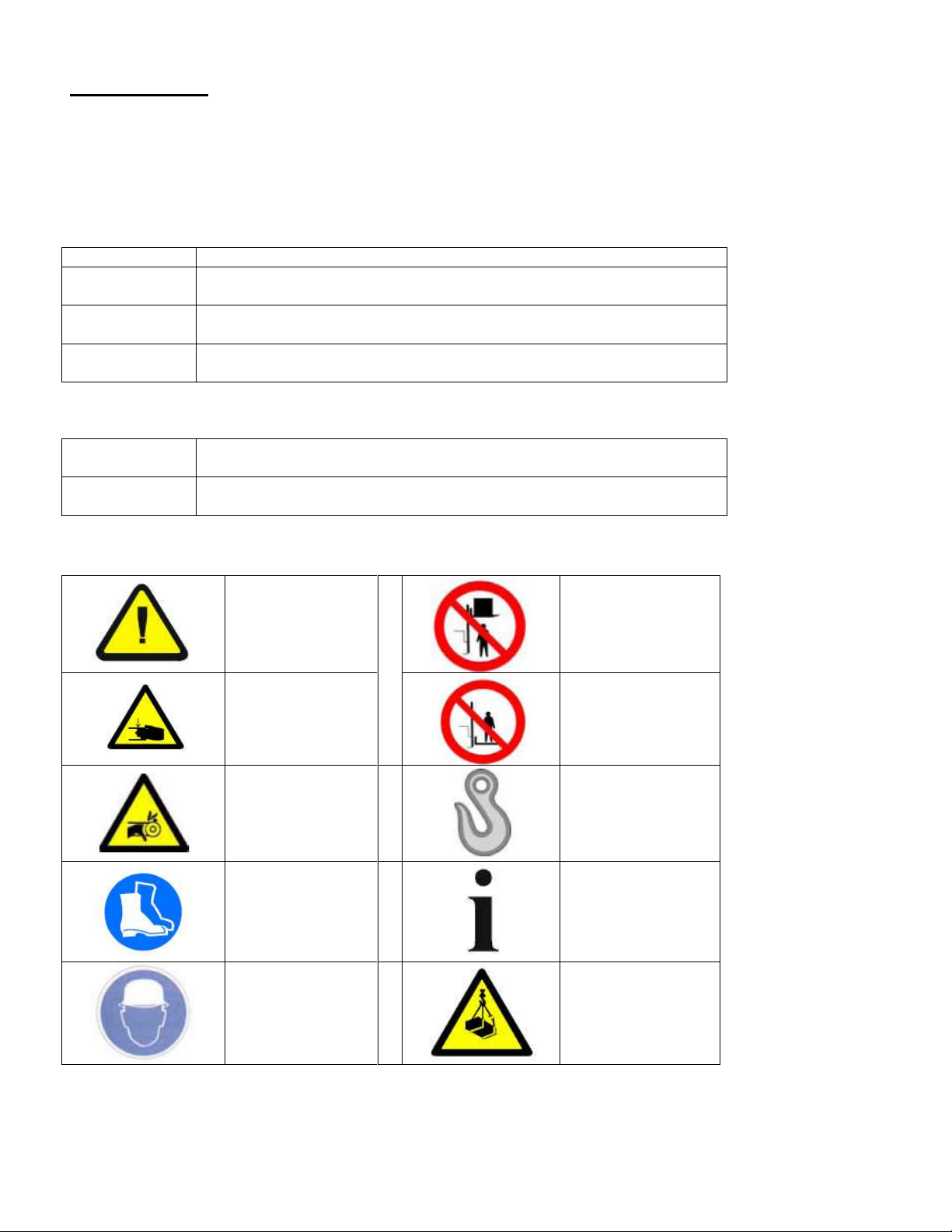

USE SYMBOLS & PICTURES

Warning of an imminent danger!

Non-observance cause death or serious injury

Warning of a possibly incoming dangerous situation.

Non-observance may cause death or serious injury.

Warning of a possibly incoming dangerous situation.

May also be used for warnings of major damage to property.

Marks recommendations for use and other useful information.

Does not warn of dangerous situations.

Warns of a harmful situation.

Non-observance may cause damage to material.

Possible danger to

file and limb or

machine!

Do not step onto when

load is raised!

Danger of crushing!

Do not reach into

running motor!

Wear safety shoes

Wear helmet

It is forbidden to ride

on the truck!

Suspension points for

transport of truck!

Important

Suspended load

warning!

6

Product description

Designated use

The stacker is designated for lifting, lowering and transportation of loads according to the specifications of the

identification plate.

The stacker is to be used on hard level surfaces.

To move the stacker between buildings, warehouses etc

The gradient of the slope must not be more than 10%

Make sure load is not loose or unstable.

Do not pick up loads on tips or forks or edge of platform.

Do not overload.

The road surfacing must be solid and have a good grip.

Travel routes must offer sufficient load-bearing capacity for the loaded truck.

The stacker is not suitable for continuous use in cool-houses!

Ambient conditions

Temperature From

To

14

113

°F

°F

Degree of humidity ≤70 %

Permitted floor

incline

Loaded

Unloaded ¹

Max. 0.5

Max. 2.0

%

%

Dimensions and weights

Mass (dead weight) m 480/750 kg

WARNING!

The user is responsible for determining the actual load bearing capacity of a high-lift stacking truck. This can depend

on the user, the condition of both the floor and the high-lift stacking truck and the regularity of the maintenance

intervals.

7

Product description

Signs on the Stacker

8

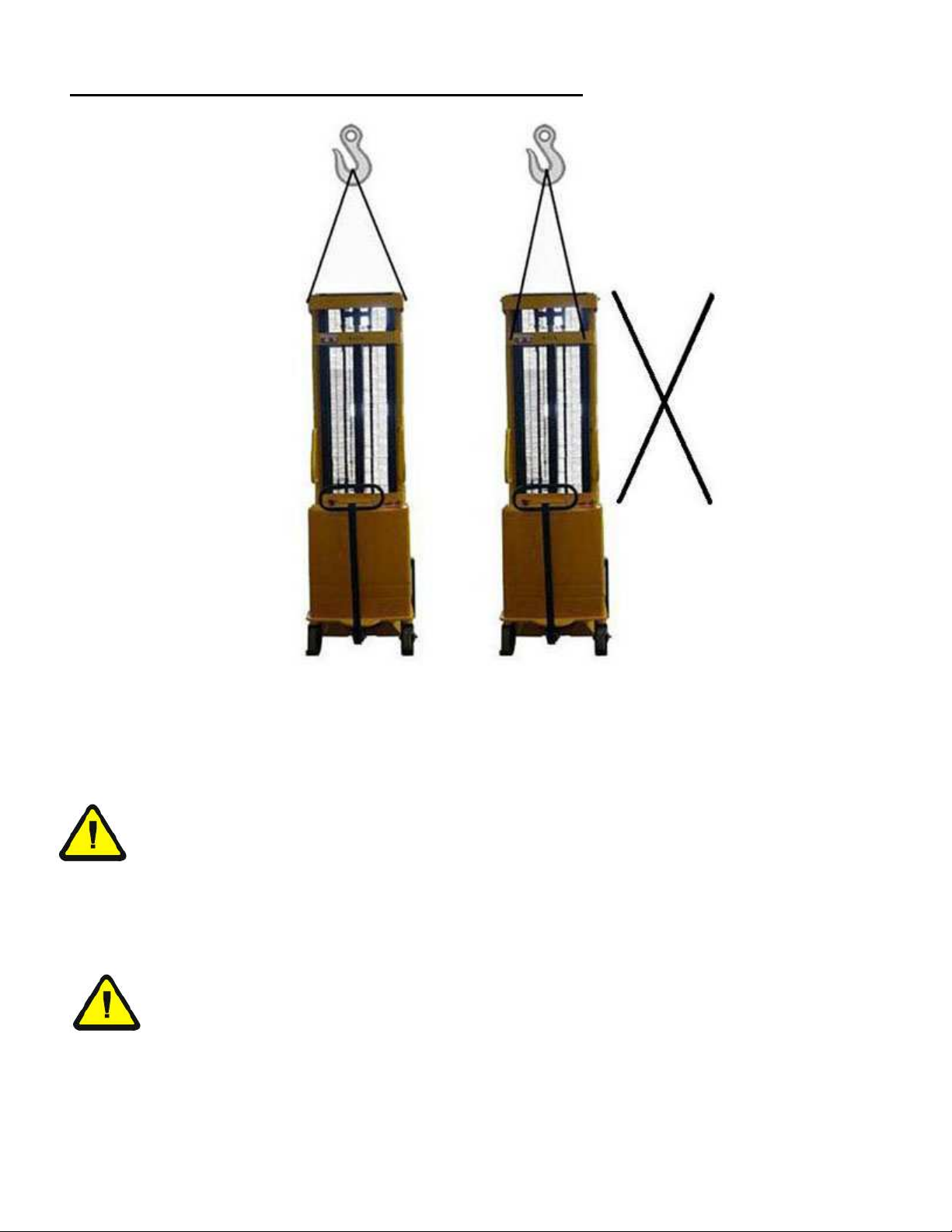

Removing from the pallet or lifting the product

Lifting belt specification— Use polyester lifting sling or nylon sling and hoist with a minimum of

2,000 lb. capacity.

CAREFUL

To pick up the unit only use overhead hoist, forklift or loading crane with sufficient

carrying capacity!

Refer to the identification plate for the weight of the truck.

DANGER

When unloading the truck, all personnel should be cleared from area.

9

OPERATION

Visually inspect stacker for damaged and worn parts, before stacker is taken into

operation. Authorized person should read and understand all instructions

The lifting truck is ready for immediate use once the packaging has been removed.

The battery is full and charged.

The hydraulic tank is full.

The steering roller and the running rollers are equipped with bearings which do not require maintenance; all

mast rollers are also free from maintenance.

Caution!

Pedestrian controlled industrial trucks may only be operated by persons who have been satisfactorily

instructed in operating the truck and have proved their ability to operate the truck to the responsible

representative of the operating company.

The first driving attempts should take place on level and spacious surfaces.

Recommendation:

The operator who is to maneuver the truck and is to control the lifting mechanism should be allowed to

practice, when unloaded, until they can safely operate these functions.

Only then should they undertake the loading, transporting and unloading of load.

10

Loading...

Loading...