Page 1

S-Fok-4-AT manual 07/19/11

A

S-FORK-4-AT HOIST HOOK FORK TRUCK ATTACHMENT

USE AND MAINTENANCE MANUAL

VESTIL MANUFACTURING CORP.

2999 North Wayne Street, P.O. Box 507, Angola, IN 46703

Telephone: (260) 665-7586 –or– Toll Free (800) 348-0868 Fax: (260) 665-1339

Website

Receiving Instructions: Compliance with laws, regulations, codes, and mandatory standards (i.e. standards

either written into the text of law, or incorporated by reference into law; standards published by ANSI, CS

ISO, etc. are NOT law unless incorporated by reference) enforced in the location where the device is used is

exclusively the responsibility of the end-user. If law enforced where the fork attachment is used contradicts all

or part of at least one instruction and requires you to depart from these directions, Vestil is not responsible for

any consequential damages sustained as a result.

Table of Contents Table of Figures

Product Introduction …………………….. 2 FIG. 1 “S-Fork-4-AT Exploded Parts Diagram”……………….…………..3

Safety Principles ………………………… 2 FIG. 2 “Label placement diagram”..........................................................6

Safety Guidelines ……………………….. 2 - 3

Use Instructions………………………….. 4

Inspections & Maintenance………………5

Limited Warranty…………………………. 7

: www.vestilmfg.com Email: sales@vestil.com

yright 2011 Vestil Manufacturing Corp.

Cop

Page 1 of 7

,

Page 2

S-Fok-4-AT manual 07/19/11

Product Introduction

Thank you for purchasing an S-Fork-4-AT model fork attachment. Our S-Forks are durable, high-quality products that

integrate safety-enhancing features. Although use is relatively intuitive, all persons who might use, maintain or repair this

device should familiarize themselves with the instructions provided in this manual. Product specifications appear in the

following table:

Model Hook type

S-FORK-4-AT

Auto-tensioning

swivel hook

Usable fork pocket dimensions

(W x H) in inches (~cm)

5½ x 17/8

(14 x 4.8)cm

Uniform capacity

in pounds (~kg)

4,000

(1,818 kg)

Net weight in

pounds (~kg)

16

(7.3 kg)

Safety Principles

This manual classifies personal injury risks and situations that could lead to property damage with signal words.

These signal words announce an associated safety message. The reader must understand that the signal word chosen

indicates the seriousness of the hazard described in the message.

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or SERIOUS

INJURY. Use of this signal word is limited to the most extreme situations.

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or SERIOUS

INJURY.

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or MODERATE

Identifies practices likely to result in product/property damage, such as operation that might damage the

injury

fork attachment (hoist hook).

Safety Guidelines:

Failure to read and understand the instructions included in this manual before using or servicing this fork attachment

constitutes misuse of the product. Product misuse automatically voids the “Limited warranty”

Study the entire manual before you use the product for the fi

rst time and before each subsequent use as necessary to

refresh your understanding of the use, inspection and maintenance procedures explained on p. 4 & 5. Each person, who

will or might use or maintain the attachment, should read the entire manual and fully understand the directions BEFORE

using or performing maintenance on the device. If you do not understand an instruction, ask your employer/supervisor for

clarification, because failure to apply the directions in this manual might lead to serious personal injury or even death

Vestil is not liable for any injury or property damage that occurs as a consequence of failing to apply either: 1) the

instructions that appear in this manual; or 2) the information disclosed on labels affixed to the product. Furthermore,

failure to exercise good judgment and common sense while using or maintaining the product could result in property

damage, serious personal injury or death.

Electrocution hazard: DO NOT contact electrified wires with any part of the fork attachment (S-Fork), the

fork lift, or the attached load. Always inspect the area where the device will be used prior to use.

Improper use might result in serious personal injuries. Therefore, EVERY PERSON who might use,

perform maintenance on, or service the fork attachment must understand and apply all of the following recommendation s :

DO NOT attempt to resolve any problem with the fork attachment unless: 1) you are authorized to do so; AND 2) you

are certain that it will be safe to use afterwards.

Inspect the attachment before each use if necessary to recall “Use instructions” (p. 4).

DO NOT use the device unless it is in satisfactory condition! If you observe any significant damage to, for instance, the

fork tube weldment, tension arm, hook or shackle (see FIG. 1 on p. 3), immediately tag the unit “Out of Service” and

inform authorized maintenance personnel about your observations. DO NOT use the attachment until it is restored to

normal condition.

This device is designed for material handling only. DO NOT use the attachment in conjunction with personn el-conveying

equipment, such as work platforms.

DO NOT leave an elevated load unattended. Lower the forks until the load is fully supported by the ground, and

disengage the load from the hoist hook before leaving it unattended.

DO NOT alter the device from its original configuration. Unauthorized modifications might make the fork attachment

unsafe to use. If injuries and/or property damage occurs AFTER modifying (altering from original form) the

product without authorization from Vestil, fault belongs exclusively to the person who modified the product.

DO NOT use the fork attachment to lift and move a load that cannot be adequately stabilized when lifted with the S-

Fork. ALWAYS apply the relevant lifting practices implemented at your worksite.

DO NOT sit on or apply any weight/pressure to a suspended load.

(see p. 7).

.

yright 2011 Vestil Manufacturing Corp.

Cop

Page 2 of 7

Page 3

S-Fok-4-AT manual 07/19/11

DO NOT attempt to lift a load that weighs more than the rated load of the attachment OR the lift truck, whichever is

smaller. ALWAYS make sure that the net weight applied to the fork attachment does not exceed the rated load of the

attachment OR the lift truck, whichever is smaller.

DO NOT lift a load higher than necessary. (See “Use Instructions” on p. 4).

DO NOT raise a load above a person(s) or allow anyone to stand or reach beneath a suspended load.

NEVER use the device to lift a load over people or to lift any apparatus that supports people, such as a work platform.

To maximize the service life of the fork attachment:

Use only replacement parts supplied or approved by the manufacturer.

ALWAYS store the S-Fork in a dry location that shelters it from the elements to prevent damage that might occur if

contact with water or other liquids occurs.

Maintain the product as suggested in “Maintenance & Inspections” on p. 5.

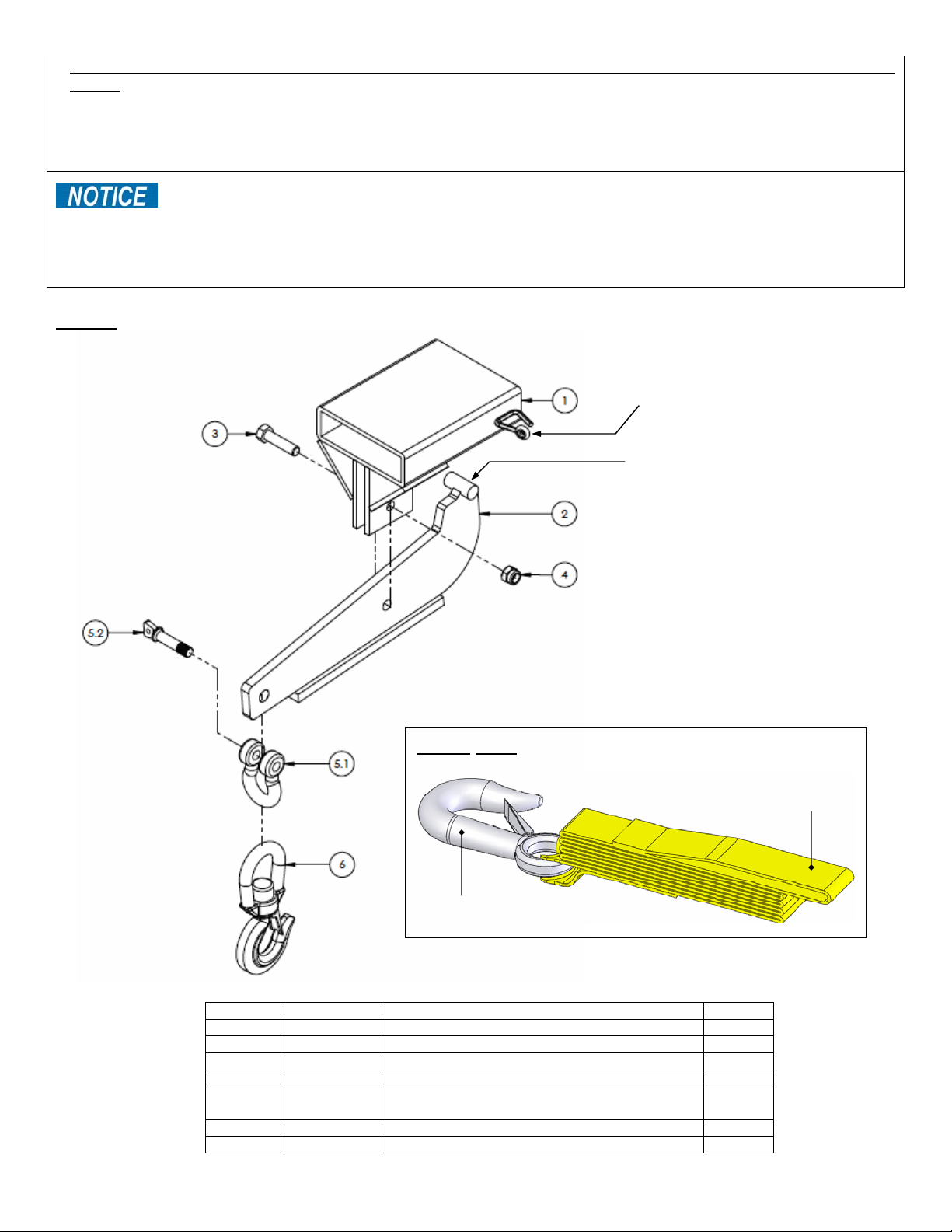

FIG. 1: S-Fork-4-AT Exploded Parts Diagram

Cold shut (point of

attachment to fork

tube for nylon

safety strap)

Tine lock

Safety strap:

End connected

to cold shut

Snap hook

Item No. Part No. Description Quantity

1 08-528-218 Fork tube weldment 1

2 08-514-218 Tension arm weldment 1

3 13211 1/2 inch – 13 x 2 inch HHCS #5 zinc-plated bolt 1

4 37030 1/2 inch – 13 nylon insert lock nut 1

5.1

5.2

08-145-003

Bow Shackle: 2-ton maximum rated load

Shackle pin

1

6 08-145-001 Load hook: 2-ton maximum rated load 1

7 08-145-028 Fork attachment safety strap 1

yright 2011 Vestil Manufacturing Corp.

Cop

Page 3 of 7

Page 4

S-Fok-4-AT manual 07/19/11

Use Instructions:

Only trained, designated persons should use the fork attachment. “Designated person” means someone selected by

his employer to use the device. Trainees under the direct supervision of a designated person also may use the S-Fork.

Maintenance personnel also may use the S-Fork when necessary to perform employment duties.

Step 1

The user should perform an “Inspection[s] Before & During EVERY Lift” on p. 5, prior to connecting the attachment to the

tine of a fork truck. Proceed to the next step ONLY IF the attachment passes the inspection

Step 2: Connect S-Fork to a fork truck tine.

Slide the device over the end of a tine;

then position the S-Fork at the desired

point along the length of the fork tine

Step 4: Connect the load to the load hook.

Position the S-Fork above the load and adjust the vertical position as necessary. Follow the lifting/hoisting procedures

applied at your worksite to properly attach the load to the S-Fork hook.

otherwise reorienting when it is lifted from the ground. The swinging motion could result in serious injuries to the fork lift operator

or other persons in the area.

Step 5

Tell every person in the area to clear the usage area including the travel path and then raise the forks sufficiently to

elevate the load just a few inches. Verify that the connection is sound by leaving the load suspended for a moment.

Proceed to the next step ONLY IF the connection is stable.

the ground and adjust the connection; then repeat step 5. If the connection still is not stable, return the load to the ground

and select a different lifting device to lift and move the load.

Step 6

Slowly drive the forklift to the desired location and adjust the driving speed to minimize the degree of drum swing. Always

follow the procedures applied at your worksite for safely hoisting material and operating a forklift

NOTE 1: The load will swing more significantly the greater the driving speed. Drive slowly to minimize movement

NOTE 2: The load will tend to swing opposite the direction of a turn and will swing out in front of the forklift during

Step 7

Only set the load on a flat, level surface to prevent unintended or uncontrolled movement as the load settles. Before

lowering the load, make sure that it is not swinging or rotating. Slowly lower the forks until the load contacts the ground.

Continue to lower the load to create slack between the shackle and load hook (of the S-Fork), and then disconnect the

load from the hook. DO NOT disconnect the load from the hook until the load

from rolling, falling over, or otherwise moving in an uncontrolled manner.

: Inspect the S-Fork.

Step 3

: Secure the S-Fork to a tine

with the safety strap.

Attach the safety strap to the

.

Tine of forklift

carriage of the fork truck WITHOUT

slack and connect the snap hook (at

the end of the strap) to the strap.

Remove any slack in the strap by

pulling it tight. Pull the strap from the

end that connects to the cold shut

(see FIG. 1 on p. 3). Verify that the

S-Fork cannot slide off of the tine by

tilting the fork truck mast forward.

The S-Fork should be positioned on

the tine as shown in Photo 1.

NOTE: The S-Fork can still slide

Photo 1 – Position

S-Fork on Tine

toward the lift carriage UNTIL the

weight of the load presses the tine

lock against the underside of the

Tine lock

tine.

Account for the possibility of load swing by making sure that the load is oriented to prevent tipping, rolling, or

: Test the contact between the hook (of the S-Fork) and the load.

DO NOT attempt to lift and/or transport a load if a secure connection cannot be achieved. Return the load to

: Transport the load to the intended location.

.

during transport.

braking. Apply the brakes gradually and reduce speed during all turns to reduce the effect on the

suspended load.

: Return the load to the ground and disconnect the S-Fork from and load.

is immobilized (if necessary) to prevent it

yright 2011 Vestil Manufacturing Corp.

Cop

Page 4 of 7

Page 5

S-Fok-4-AT manual 07/19/11

Maintenance & Inspections:

A designated person must verify that the S-Fork complies with all regulations, codes, and standards that apply to hoisting

devices in the location where it is used. A person designated to conduct inspections by your employer must do so before

the S-Fork is used for the first time and prior to EACH

Inspections:

DO NOT use an S-Fork that is structurally damaged. Structural damage includes, but is not limited to,

bending, warping, cracking or other deformation of one or more of the following components: shackle; tension arm

weldment; or fork tube weldment (see FIG. 1, p. 3). Restore the S-Fork to normal operating condition BEFORE using it

again.

Inspections Before & During EVERY lift

lift. In particular, the operator should:

1. Inspect for and remove all debris on load surfaces of the load hook, especially debris that might interfere with

or prevent the S-Fork from adequately engaging the load; AND

2. Inspect the S-Fork to confirm that all parts are in normal operating condition.

Frequent Inspections

: maintenance personnel or other designated person(s) should visually inspect the S-Fork at least

once per month for:

1. Deformations, cracks, or excessive wear of any

inspect the load hook, follow the recommendations of ASME B30.10-2005;

2. Loose or missing fasteners;

3. Excessive wear and tear to the safety strap or snap hook (at the free end of the strap).

Maintenance: the end-user must implement a maintenance program to ensure the proper function and safety of the SFork. A qualified person may, OF COURSE, establish a program used in preference to the maintenance procedures

described below. However, if you apply the procedure that follows, complete EVERY step each

performed.

: visual examination must be performed by the operator prior to AND during each

use thereafter.

part of the S-Fork, including nuts, bolts, or washers. To

time maintenance is

ONLY qualified persons should perform maintenance on the S-Fork. A qualified person is someone “who,

by possession of a recognized degree in an applicable field or certificate of professional training, and experience, has

successfully demonstrated the ability to solve or resolve problems relating to the subject matter [S-Fork] and work [use of

the S-Fork].” See ASME B30.16-2003, Section 16-0.2, p. 1.

: Disconnect the S-Fork from the forklift and tag it, “Out of Service.”

Step 1

Step 2

“Frequent”).

: Perform all adjustments indicated as necessary during any inspection (“Before & During Every Lift” or

Step 3: If conditions exist that require replacement parts to repair, contact the manufacturer to order replacement

parts. Deformity, cracks, corrosion, rusting, or excessive

replacement.

wear of structural members warrants immediate

The reader should understand the significant difference between “Adjustments” or “Repairs,” and

“Modifications”.

An adjustment or repair refers to a simple correction that restores the S-Fork to normal operating condition, such as

tightening loose fasteners, or removing debris from the surface of the device.

DO NOT use the S-Fork if adjustments and/or repairs are incomplete! Return the S-fork to service ONLY after finishing all

necessary repairs and adjustments.

A modification is a change that alters the S-Fork from normal operating condition, like bending the structural

members. NEVER modify the S-Fork. Modifications may render the device unsafe to use.

: Perform a periodic inspection.

Step 5

: Make a dated record of the repairs, adjustments and/or replacements made.

Step 6

yright 2011 Vestil Manufacturing Corp.

Cop

Page 5 of 7

Page 6

S-Fok-4-AT manual 07/19/11

Markings:

Only use the device if ALL labels shown in FIG. 2 below are readable and undamaged. Contact Vestil for replacement

labels if necessary. DO NOT use the S-Fork until all replacement labels are affixed to the device.

FIG. 2

A: Label #218

: Label placement diagram

B: Label #675

A (on top surface)

B (on right side)

C: Label #203-1

C (on left side)

D: Label #287

D (on left side)

Cop

Page 6 of 7

yright 2011 Vestil Manufacturing Corp.

Page 7

S-Fok-4-AT manual 07/19/11

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this product to be free of defects in material and workmanship during

the warranty period. Our warranty obligation is to provide a repla

by the warranty, after we receive a proper request from the warrantee (you) for warranty servi ce.

cement for a defective original part if the part is covered

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

What is an “original part”?

An original part is a part used to make the product as shipped

to the warrantee.

What is a “proper request”?

A request for warranty service is proper if Vestil receives: 1) a photocopy of the Customer Invoice

shipping date; AND 2) a written request

any of the following methods:

for warranty service including your name and phone number. Send requests by

that displays the

Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 sales@vestil.com

2999 North Wayne Street, PO Box 507 Phone

Angola, IN 46703 (260) 665-7586

In the written request, list the parts believed to be defective and include the address where replacements should be

delivered.

What is covered under the warranty?

After Vestil receives your request for warranty service, an authorized representative will contact you to determine whether

your claim is covered by the warranty. Before providing warranty service, Vestil may require you to send the entire

product, or just the defective part or parts, to its facility in Angola, IN. The warranty covers defects in the following original

dynamic

original

and batteries.

components: motors, hydraulic pumps, electronic controllers, switches and cylinders. It also covers defects in

parts that wear under normal usage conditions (“wearing parts”), such as bearings, hoses, wheels, seals, brushes,

How long is the warranty period?

The warranty period for original components is 30 days

. The warranty period begins on the date when Vestil ships the

product to the warrantee. If the product was purchased from an authorized distributor, the period begins when the

distributor ships the product. Vestil may extend the warranty period for products shipped from authorized distributors by

up to 30 days to the duration necessary to account for shipping time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will contact you

to discuss your claim.

What is not covered by the warranty?

1. Labor;

2. Freight;

3. Occurrence of any of the following, which automatically voids the warranty

:

Product misuse;

Negligent operation or repair;

Corrosion or use in corrosive conditions;

Inadequate or improper maintenance;

Damage sustained during shipping;

Accidents involving the product;

Unauthorized modifications

: DO NOT modify the product IN ANY WAY without first receiving

written authorization from Vestil. Modification(s) might make the product unsafe to use or might

cause excessive and/or abnormal wear.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to the extent allowed

by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty.

Copyright 2011 Vestil Manufacturing Corp.

Page 7 of 7

Loading...

Loading...