Vestil SE/HP-63, SE/HP-98, SE/HP-118 User Manual

6/30/2016

SE-HP, Manual

SE/HP-63, SE/HP-98 and

SE/HP-118

SE/HP-63-AA, SE/HP-98-AA and

SE/HP-118-AA

Table of Contents

Hazard identification: explanation of signal words…………………………………………………...…………………….

2

Safety Guidelines………………………………………………………………………………………………………..........

2

Introduction……………………………………………………………………………………………...……….………….....

3

Operation…….…………………………………………………………………………………………………………...…..

3

Specifications……………………………………………………………………………………………...…………………..

5

Inspections & Maintenance……………………………………………………………………………………………...….

6

Trouble Shooting…………………………………………………………………………………………………...………….

9

Limited warranty…………………………………………………………………………………………………...…………..

11

VESTIL MANUFACTURING CORP.

2999 North Wayne Street, P.O. Box 507, Angola, IN 46703

Telephone: (260) 665-7586 -or- Toll Free (800) 348-0868

SE/HP SERIES COMBINED HAND PUMP & ELECTRICAL STACKER

INSTRUCTION MANUAL

Receiving instructions:

After delivery, IMMEDIATELY remove the packaging from the product in a manner that preserves the packaging and

maintains the orientation of the product in the packaging; then inspect the product closely to determine whether it

sustained damage during transport. If damage is discovered during the inspection, immediately record a

complete description of the damage on the bill of lading. If the product is undamaged, discard the packaging.

Notes:

1) Compliance with laws, regulations, codes, and non-voluntary standards enforced in the location where the product

is used is exclusively the responsibility of the owner/end-user.

2) VESTIL is not liable for any injury or property damage that occurs as a consequence of failing to apply either: a)

the instructions in this manual; or b) information provided on labels affixed to the product. Neither is Vestil

responsible for any consequential damages sustained as a result of failing to exercise sound judgment while

assembling, installing, using or maintaining this product.

Copyright 2016 Vestil Manufacturing Corp. Page 1 of 11

6/30/2016

SE-HP, Manual

HAZARD IDENTIFICATION: explanation of signal words

This manual uses SIGNAL WORDS to indicate the likelihood of personal injuries, as well as the probable

seriousness of those injuries, if the product is misused in the ways described. Other signal words call attention to

uses of the product likely cause property damage.

The signal words used appear below along with the meaning of each word:

Each person who assembles, installs, uses, or maintains this product should read the entire manual and fully

understand the directions in advance. If after reading the manual you do not understand an instruction, ask

your supervisor or employer for clarification, because failure to adhere to the directions in this manual might

result in serious personal injury.

SAFETY GUIDELINES

Vestil diligently strives to identify foreseeable hazards associated with the use of its products. However, material

handling is inherently dangerous and no manual can address every conceivable risk. The end-user ultimately is

responsible for exercising sound judgment at all times.

Electrocution might result if any part of the product contacts electrified wires. Reduce the likelihood of

electrocution by applying common sense:

DO NOT contact electrified wires with any part of this device, your body, or clothing.

DO NOT use or store the product where contact with electrified wires is likely.

If this product is used improperly or carelessly, the operator and/or bystanders might sustain serious

personal injuries or even be killed. To reduce the likelihood of injury:

Failure to read and understand the entire manual before assembling, installing, using or servicing the

product is a misuse of the product.

Read the manual to refresh your understanding of proper use and maintenance procedures.

DO NOT attempt to resolve any problem(s) with the product unless you are both authorized to do so and certain

that it will be safe to use afterwards.

DO NOT modify the product in any way UNLESS you first obtain written approval from Vestil. Unauthorized

modifications automatically void the Limited Warranty and might make the product unsafe to use.

DO NOT exceed the maximum rated load shown on the model plate or sticker.

Inspect the product before each use.

A. DO NOT use this product if the inspection reveals structural damage. Examples of structural damage

include, but are not limited to, the following: 1) Cracked, broken or significantly deformed load-bearing

members; 2) cracked welds; 3) missing or deformed safety chain/strap; 3) corrosion, severe wear, or other

condition that affects the ability of the product to support weight or itself. Replace each part that fails to

pass an inspection, and DO NOT use the product until it is fully restored to normal condition.

B. DO NOT use the product if any unusual noise or movement is observed. If a malfunction occurs, remove

the unit from service and notify your supervisor & maintenance personnel about the issue.

DO NOT use this device UNLESS all product labels (see “Label Placement Diagram”) are readable and

undamaged.

Proper use, maintenance, and storage are essential for this product to function properly.

o Always use this product in accordance with the instructions in this manual and consistent with any training

relevant to machines, devices, etc. used in conjunction with this product.

o Keep the product clean & dry. Lubricate moving parts.

o FOR HYDRAULIC UNITS: Do not use brake fluid or jack oils in the hydraulic system. If oil is needed, use an anti-

wear hydraulic oil with a viscosity grade of 150 SUS at 100°F, (ISO 32 cSt @ 40°C), or Dexron transmission fluid.

o Contact the manufacturer for MSDS information.

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or

SERIOUS INJURY. Use of this signal word is limited to the most extreme situations.

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or

SERIOUS INJURY.

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or

MODERATE injury.

Identifies practices likely to result in product/property damage, such as operation that

might damage the product.

Copyright 2016 Vestil Manufacturing Corp. Page 2 of 11

6/30/2016

SE-HP, Manual

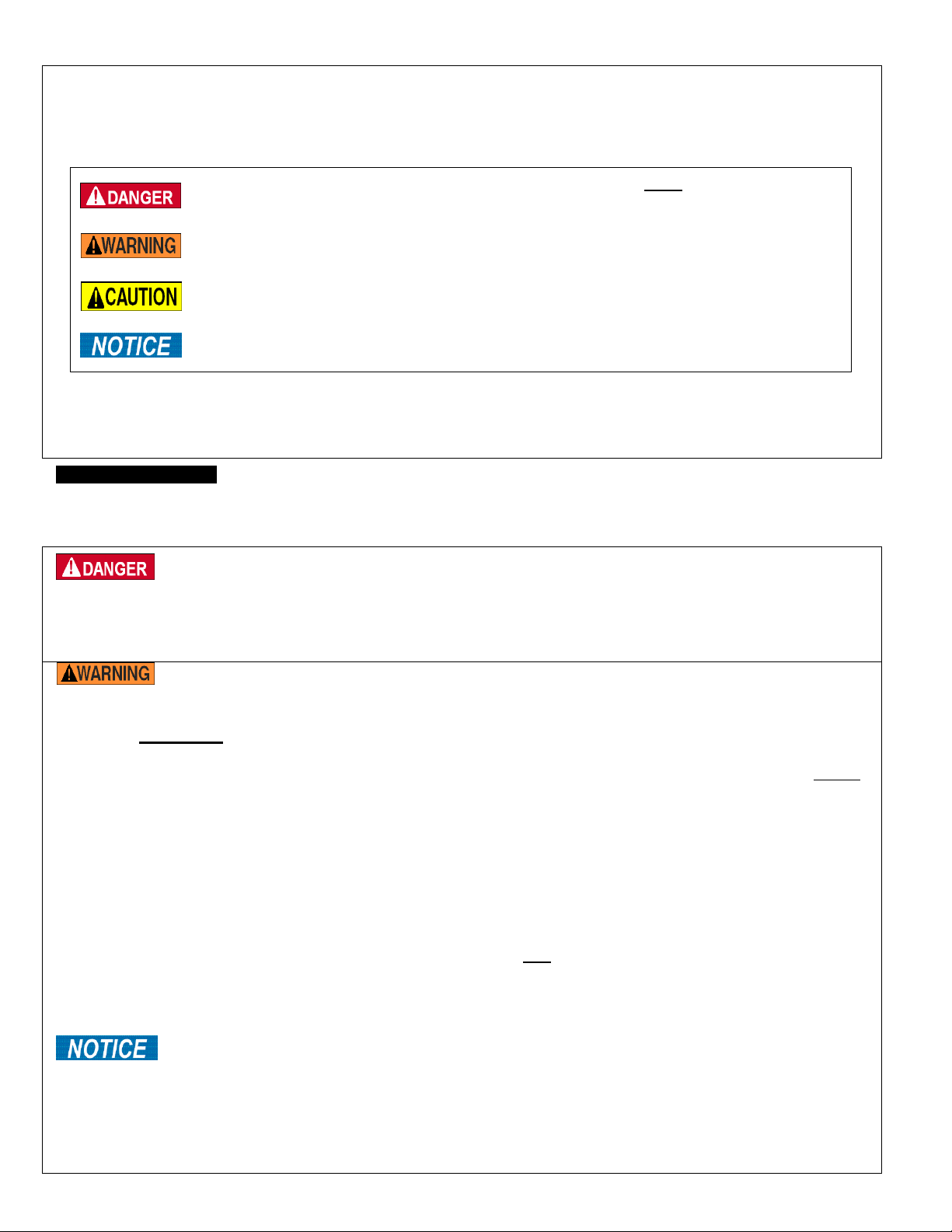

Figure: Suspended Stacker

Operating Elements

1. Pump Handle

2. Power Meter

3. Lift Button

4. Receptacle for

Remote Input

(optional)

5. Manual Release

6. E-Stop

7. Push / Pull Bars

1

5

7

6 3 2

4

Receiving Instructions

Inspect the unit and verify damage has not occurred during shipment. If damage is

evident, FILE A CLAIM WITH THE CARRIER IMMEDIATELY.

The unit is removed from the pallet by an overhead hoist, crane, fork truck, etc with a

lifting and carrying capacity rated for the weight of the SE/HP stacker. The stacker has

specifically designed features for unloading located on the outside of each lifting

channel, as shown in Figure: Suspended Stacker. Use a lifting belt, shown in red, with a

minimum tensile strength, 2,000 lb. capacity.

When unloading the stacker, all personnel should be cleared from the area.

The stacker is ready for service once unpacked and unloaded. The battery is fully

charged. The hydraulic aggregate tank has been filled. The steering roller, running

rollers and the mast rollers are equipped with maintenance-free bearings.

Introduction

The SE/HP stacker is ideal for maintenance and commercial applications. The economical, alternative stacker can lift

loads with DC power or manually with a hand pump. The high quality, hand pump is ideal for small height increments.

The DC lifter is powered by two 12V, 40Ah batteries. The user manages the battery power with the integral battery

charger, battery level gauge and adjustable lowering speed control. The solid, compact design is ideal to transport dies,

molds and open bottom pallets. All models are easily maneuverable with standard push/pull handles. The individual

forks are 6” wide. The “–AA” models come with adjustable width outriggers for improved stability at higher heights.

Operation

Only trained operators can use the stacker. The minimal recommended training should include reading this complete

manual, proficiently able to perform all stacker operations without load and augmented instruction deemed necessary by

your company’s safety practices.

The trained operator is responsible for determining the actual load’s weight and for evaluating the safety of the

environmental conditions within the stacker will operate. Some conditions to consider are:

The floor’s available space, degree of levelness and condition to transport and lift the load.

The stacker’s condition. Reference Inspection and Maintenance section for proper care.

The inventory rack’s or stowage structure’s stability and condition to support the transported load.

Copyright 2016 Vestil Manufacturing Corp. Page 3 of 11

6/30/2016

SE-HP, Manual

Closed Gap

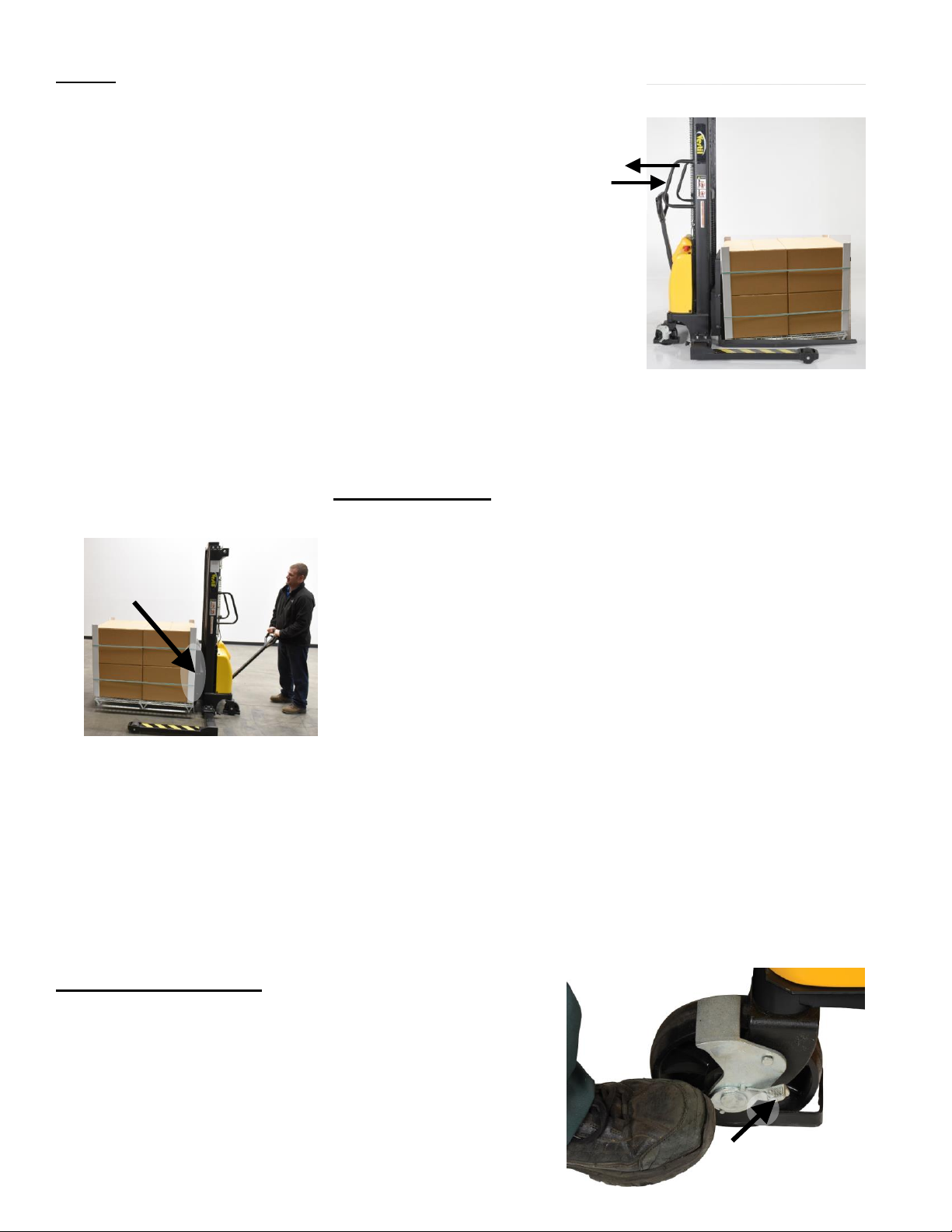

Figure: Minimizing the Gap

Figure: De-activing the Brake

Press the “ON” flange

to apply brake.

Push

Figure: Transporting a load

Pull

Moving:

To transport a load, start with completely lowered forks. Verify the load

is evenly distributed across the forks. Make adjustments as appropriate.

Slowly raise the forks just high enough so the load can be transported.

When ready, the trained operator will push or pull the Push/Pull Bars to

transport the load over a level, smooth and spacious surface. Push the

stacker forward to transport the load over longer distances.

Only when setting down or picking up a load with raised, loaded forks is

it permissible to move the stacker forwards or in reverse. This activity

should be on a smooth, level surface. Once the load is completely over

the floor, lower the forks to the floor then raise the load just enough so

the load can be transported.

When unloaded, completely lower the forks before moving the stacker.

Always avoid sudden stops, quick turns or quick starts to prevent accidental tipping or shifting of the load.

Lifting and Lowering:

Before lifting, verify the load does not exceed the stacker’s carrying capacity

or its lifting height. Ensure the load is evenly distributed across both forks.

Verify the load will not extend or project into the stacker’s lifting frame.

Prevent and ensure no one will be under the load, even if they are just

walking through or by. Lastly, verify the surface is level.

For the –AA version, widen the stability forks as necessary.

The trained operator positions the stacker’s forks securely under the load.

The space between the load and the stacker is as close as possible, as shown

in Figure: Minimizing the Gap. If the forks are shorter than the load, the load

should not extend 50mm beyond the lifting forks’ end reach.

To raise the load, the trained operator has two options. First, if the Power Meter, item 2, indicates the batteries have a

charge, the trained operator can press the Lift Button, item 3. Secondly, the manual option is always available.

Lowering the Pump Handle, item 1, will incrementally raise the load. Continue to actuate the lifting mechanism with the

Pump Handle until the load is at the desired height.

Lowering the load can be achieved with the Lowering Handle, item 4. Squeezing the Lowering Handle towards the

Pump Handel will lower the load. When the Lowering Handle is released, the load stops descending. Lower the load

in a smooth and safe manor as not to disturb the weight distribution on the forks.

Before Leaving the Stacker:

The stacker needs to be stowed on a level, clean surface that is clear of

other vehicles.

There are a few steps to follow: First, lower the forks completely. Then,

depress the E-Stop push-button down. Lastly, activate the parking

brake by pressing down on the “ON” flange until it is snug, as shown in

Figure: De-activating the Brake.

Copyright 2016 Vestil Manufacturing Corp. Page 4 of 11

Loading...

Loading...