Page 1

INSTRUCTION MANUAL

FOR Two Speed Traction-Drive Carts

MODELS COVERED: NE-CART-1, NE-CART-2, NE-CART-3, NE-CART-4

NE-CART-1 NE-CART-2

NE-CART-3 NE-CART-4

2999 NORTH WAYNE STREET, P.O. BOX 507, ANGOLA, IN 46703

TELEPHONE: (260) 665-7586 -OR- TOLL FREE (800) 348-0868

FAX: (260) 665-1339

VESTIL MANUFACTURING CORP.

URL: WWW.VESTILMFG.COM EMAIL: SALES@VESTIL.COM

1

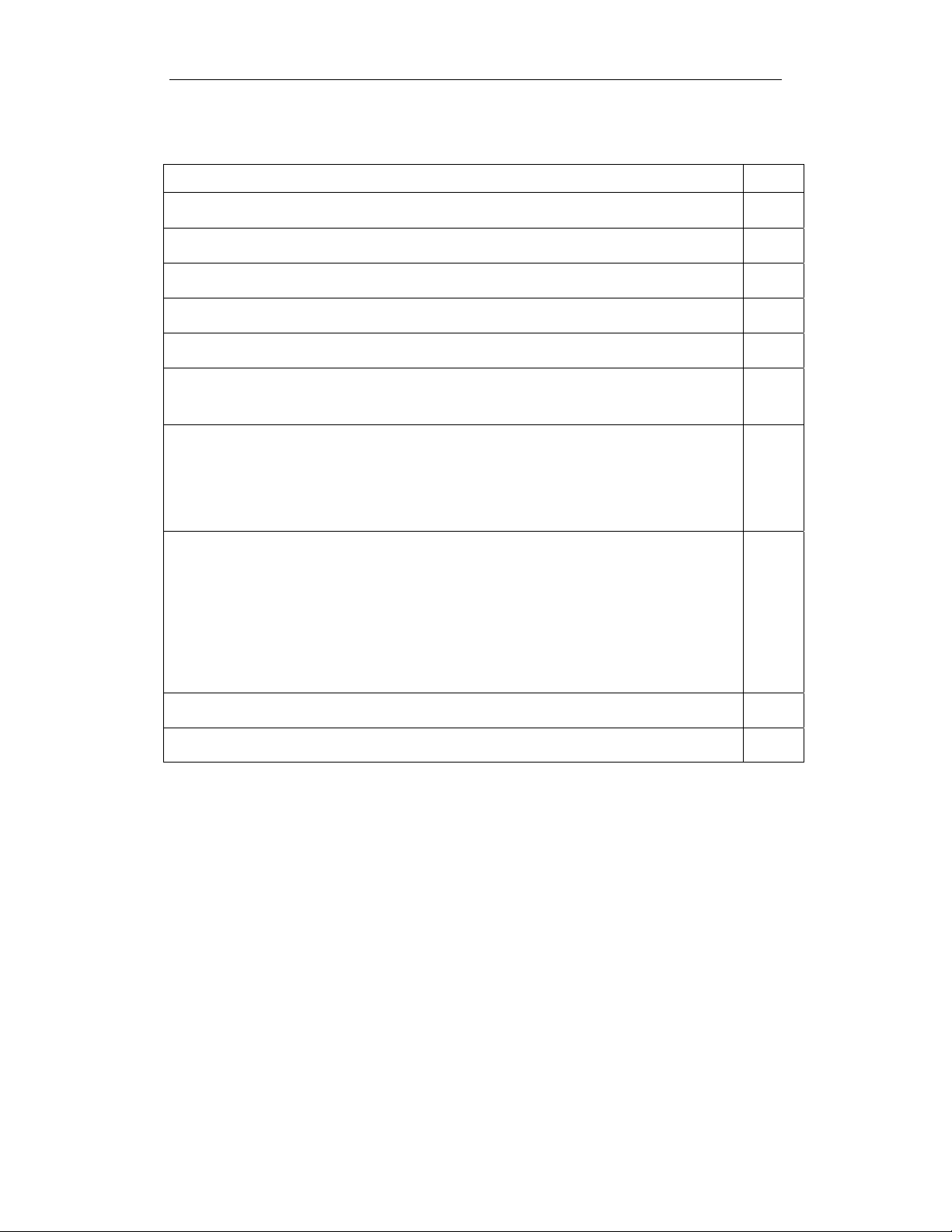

Page 2

E-CART (ELECTRIC CART)

CCOONNTTEENNTTSS

General …………………………………………………………………………………..

Specification ……………………………………………………………………………

Receiving instructions ………………………………………………………………

Rules for Safe use ……….……………………………………………………………

Safety Instructions & Warnings ……………………………………………

Symbols & Pictures ………………………………………………………….

Product description …………………………………………………………………

Designated use …. … …... … …………………………………………………….

Operation ……………………………………………………………………………….

Travel ………………………………………………………………………………..

Safety Reverse Switch …………………………………………………………….

Brake ………… …………………………………………………………………….

Horn …………………………………………………………………………………

Maintenanc e an d repair …………………………………………………………….

Trouble Shooting …………………………………………………………………….

Changing Batteries ………………………………………………………………….

Changing Motor Controller ………………………………………………………….

Belly Switch Trouble Shoot ………………………………………………………….

Free Wheeling ………………………………………………………………………..

Maintenance daily/before use, monthly, annually …………….………………….

Drive Transmission Lubrication …………………………………………………….

Warranty ……………………………………………………………………..

3

4

5

6

7

8

9

9

9

10

10

11

11

12

12-15

16-17

18

19-33

34-35

36

37

38

Parts drawing & Parts list ………………………………………………….

2

39-49

Page 3

E-CART (ELECTRIC CART)

Introduction

Read and follow the instructions contained in

this operating manual.

Please read and follow all instructions in this User’s Instruction Manual before attempting

to operate your Material Handling Cart (E-CART) for the first time. If there is anything in this

manual that you don’t understand, or if you require additional assistance for setting it up.

Contact factory at 26-665-7586.

Only trained, well-informed personnel, who have been instructed in accordance with this

operation manual, may use or work on the stacker.

Liability or guarantee is waived if:

z The instructions in this operating manual are not observed.

z The high-lift stacking truck is operated, cleaned or maintained incorrectly.

z Alterations to the functions are carried out without the consent of manufacturer.

z Original spare parts are not used.

Safety instructions

This chapter informs the user about residual dangers relating to the correct use of the

products. It contains generally valid safety instructions which must be observed.

Safety instructions relating to specific actions or situations are listed prior to the respective

action and/or description of the situation in the chapter.

Principles

This product complies with state-of-the –art technical standards and recognized safety

regulations, but there are still dangers which may occur which must be considered.

Only operate the product in a perfect condition and observing the information contained in

the operating manual.

The operator is responsible for integrating the product with as little risk as possible into his

working environment. This obligation continues through every phase of the products

lifespan, beginning at the planning stage. Residual dangers are to be minimized.

Only trained, competent personnel who have been instructed using the operating manual

and the product are permitted to work with the truck.

The operating manual must be understood (responsibility, checking)

3

Page 4

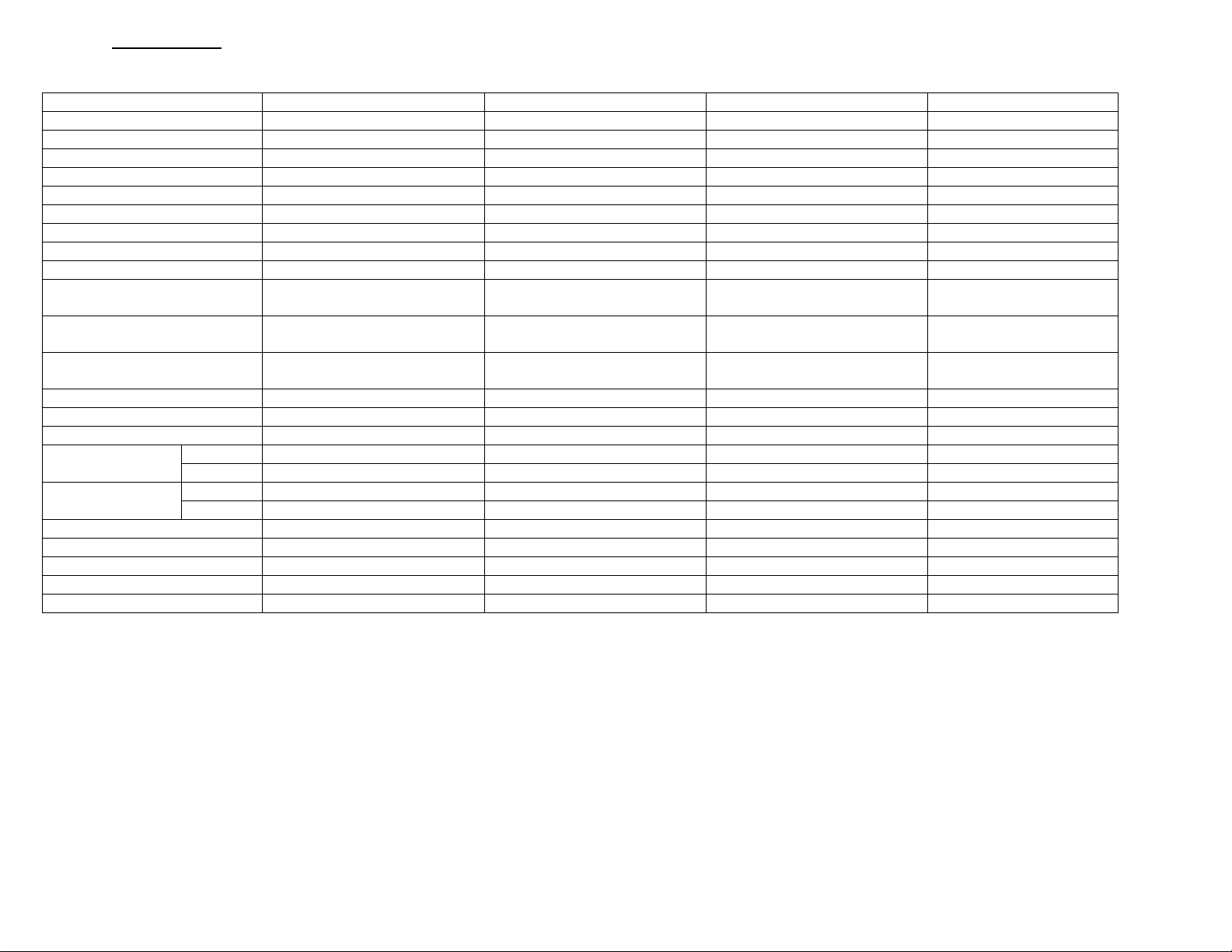

Specifications

Model #

Total Capacity

2nd Shelf Capacity

3rd Shelf Capacity

Platform Size (L x W)

2nd deck platform size (L x W)

2nd deck platform size (L x W)

Platform Height

2nd Deck Height

3rd Deck Height

Distance between the

platforms

Steering wheel

Drive wheel

Overall Size (L x W x H)

Handle Height

Railing Height

Travel Speed

(Fast)

Travel Speed

(Slow)

Turning Radius

Controller

Drive Motor

Battery

Battery Charger

Loaded

Unloaded

Loaded

Unloaded

Frame Height: 25¾” Frame Height: 11½” Frame height: 45⅜”

Hi/Low speed

Variable speed control throttle

24V Battery system

Battery Level Indicator

Automatic Brake

Steel Construction

Tread plate surface

Maximum incline is 7 degrees

On-board battery Charger (3-4 hour operation at full charge - 8 hours when used intermittently)

Horn & Belly-bump emergency safety stop.

4

NE-CART-1 NE-CART -2 NE-CART -3 NE-CART-4

750 lbs 500 lbs 750 lbs 400

N/A 250 lbs N/A 200

N/A N/A N/A 150

28 x 48” 24¾” x 46” 24¾” x 46” 24¾” x 46”

N/A 24¾” x 46” N/A 24¾” x 46”

N/A N/A N/A 24¾” x 46”

14” 14” 14” 14”

N/A 33” N/A 33”

N/A N/A N/A 49¾”

N/A 17¾” N/A 17¾” (1 & 2) 16¾” (2 & 3)

(2) Ø9 x 3⅛” (solid-foam tires) (2) Ø9 x 3⅛” (solid-foam tires) (2) Ø9 x 3⅛” (solid-foam tires) (2) Ø9 x 3⅛” (solid-foam

tires)

(2) Ø10¼ x 3⅛” (solid-foam

tires)

59 x 28 x 44 11/16” 59 x 28 x 44 11/16” 59 x 28 x 44 11/16”

44 11/16” 44 11/16” 44 11/16” 44 11/16”

N/A 40” 12” 59¾”

2.5 mph 2.5 mph 2.5 mph 2.5 mph

2.8 mph 2.8 mph 2.8 mph 2.8 mph

1.3 mph 1.3 mph 1.3 mph 1.3 mph

1.5 mph 1.5 mph 1.5 mph 1.5 mph

23⅝” 23⅝” 23⅝” 23⅝”

Curtis 1212 Curtis 1212 Curtis 1212 Curtis 1212

DC24V/500W DC24V/500W DC24V/500W DC24V/500W

2 x 12V/80-95Ah 2 x 12V/80-95Ah 2 x 12V/80-95Ah 2 x 12V/80-95Ah

DC 24V/6A DC 24V/6A DC 24V/6A DC 24V/6A

(2) Ø10¼ x 3⅛” (solid-foam

tires)

(2) Ø10¼ x 3⅛” (solid-foam

tires)

(2) Ø10¼ x 3⅛” (solid-

foam tires)

59 x 28 x 59⅜”

Page 5

E-CART (ELECTRIC CART)

Receiving Instructions

Every unit is thoroughly tested and inspected prior to shipment. However, it is possible

that the unit may incur damage during transit. If you see damage when unloading, make a

note of it on the SHIPPER RECEIVER.

Remove all packing & strapping material, inspect for damage. IF DAMGE IS EVIDENT,

FILE A CLAIM WITH THE CARRIER IMMEDIATELY! Also, check fork size, type of power

unit, etc., to see that the unit is correct for the intended application.

Warnings & Safety Instructions

Insure that all employees understand and follow the following instructions

• Read and understand the owner’s manual before using or servicing the stacker.

• Do not use the stacker if any damage or unusual noise is observed.

• Improper use of this lift truck could result in injury and damage to load or

equipment.

• Always watch the stacker and any load on it carefully when it is being used or

moved.

• DO NOT load beyond rated capacity.

• DISTRIBUTE load evenly

• Avoid sudden stops or quick turns to prevent accidental tipping of the load.

• Load must be centered and evenly distributed on the forks.

• Park the truck on level surfaces and not in the way of other products

• When parked, lower the load fork completely.

• When parked, push E-switch push-button down.

• Do not perform any modifications to the stacker without the manufacturer’s

approval. Failure to receive authorization for changes to the equipment could void

the warranty.

• Do not use brake fluid or jack oil in the hydraulic system. If oil is needed, use an

anti-wear hydraulic oil with a viscosity grade of 150 SUS at 100°F, (ISO 32 @

40°C), or a non-synthetic transmission fluid.

• Use only replacement parts either supplied or approved by the manufacturer.

5

Page 6

E-CART (ELECTRIC CART)

Rules For Safe Use

These symbols below are used in this owners manual to identify warnings and cautions. It

is very important for to read and understand them.

Warning: Failure to note the warnings in this users manual may result in

personal injury

Caution: Failure to observe the cautions in this users manual may result in

damage to your E-CART.

Your E-CART is a powerful machine, for your safety and safety of the bystanders, please

read all instructions in this manual before operating your E-CART, they have been

prepared from years of experience with this type of equipment. Follow notes carefully to

ensure safety at all times.

Always make certain your machine is in full working order before your operation.

1. Do not operate E-CART without reading this instruction manual. Also read all of the

safety instructions and warnings stated in this manual.

2. Do not exceed the maximum safe gradient outlined for your vehicle.

3. Do not carry passengers or exceed the maximum carrying weight.

4. Do not turn suddenly at full speed, especially on uneven or sloping ground.

5. Avoid climbing or descending curbs, you may permanently damage E-CART.

6. Always stop fully before changing direction (forward or reverse)

7. Always avoid uneven surfaces.

6

Page 7

E-CART (ELECTRIC CART)

SAFETY INSTRUCTIONS AND WARNINGS

WARNING: Don’t attempt to operate E-CART for the first time without completely reading

and understanding all of the facts in this instruction manual.

When you begin to use E-CART, you will probably encounter situations in which you will

need some practice. Simply take your time and practice to control as you maneuver

through the doorways, on and off elevators, up and down ramps and over moderate terrain.

SAFETY CHECK

Get to know the feel of your E-CART and it’s capabilities. Factory recommends that you

perform a safety check before each use to make sure that E-CART operates smoothly and

safe. For details on how to perform these necessary inspections, see the care and

maintenance section of this manual. Perform following inspection prior to using your

E-CART.

• Check all battery connections, make sure they are serviceable and not corroded.

• Check batteries if they are fully charged.

• Check operation of brakes.

• Before leaving the cart, make sure turn off the power.

Warning: Don’t carry people on the E-CART, this may cause in personal injury and/or

property damage.

WEIGHT LIMIT

E-CART is designed for a maximum user weight limit of 750 lbs. (340 kgs.)

Warning: Exceeding the weight limit will avoid your warranty and may result in personal

injury and damage to E-CART. Vestil will not be held responsible for injuries and/or

property damage resulting from failure to observe these weight limitations.

Excessive high cornering speeds can create the possibility of cargo tipping. Factors which

affect the possibility of cargo tipping include, but are not limited to, cornering speed,

uneven surfaces, inclined surfaces, and abrupt directional changes. Don’t corner at high

speed! If you feel that your cargo may tip over on a corner, reduce your speed and steering

angle to prevent your cargo from tipping.

OUTDOOR DRIVING SURFACES

• Reduce speed when operating on uneven terrain or soft surfaces.

• Avoid long and unsafe grass that can tangle in the running gear or may hide debris

and holes.

• Avoid loosely packed sand and gravel.

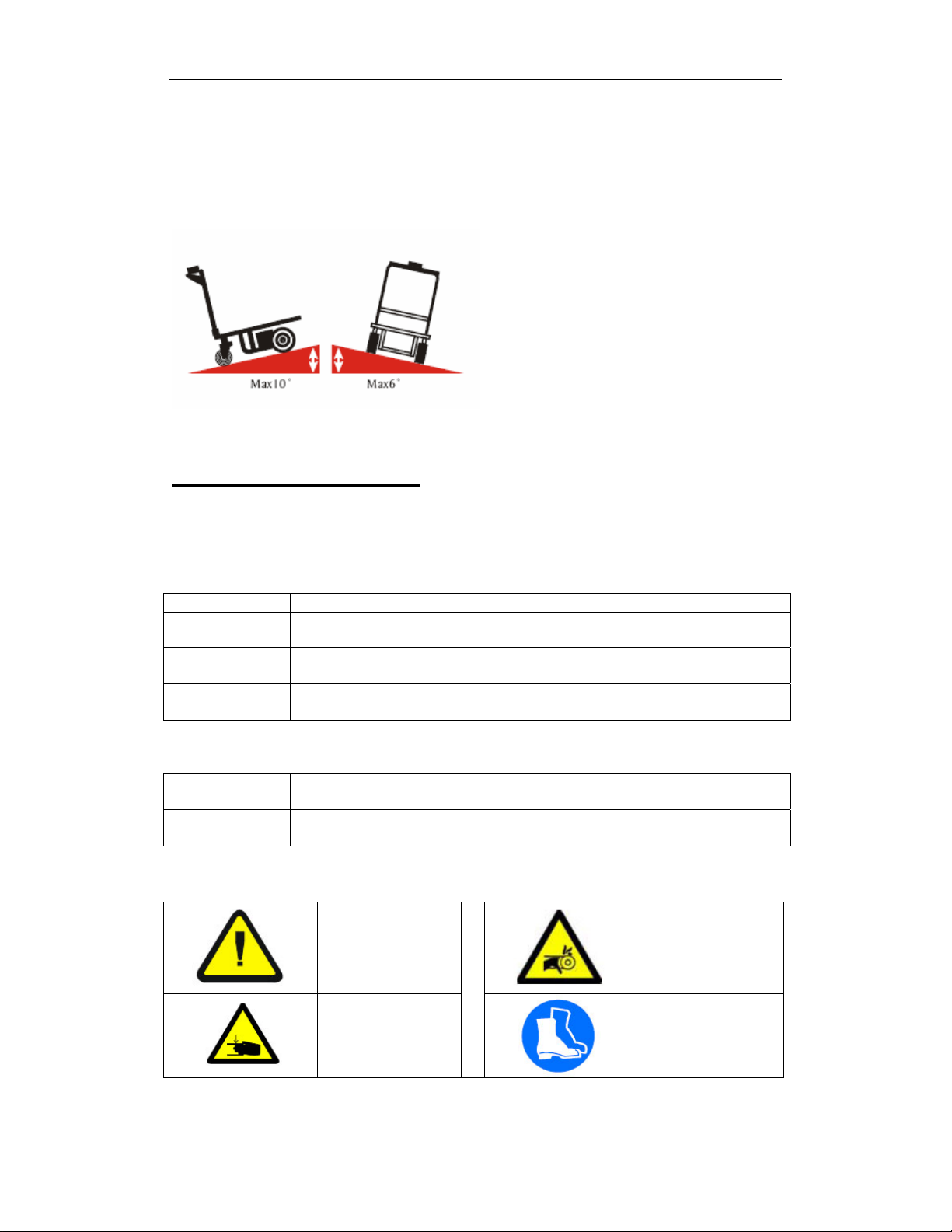

INCLINES

• When descending an incline keep your speed adjustment set to the slowest speed

setting to ensure a safely controlled descent and drive in forward direction only.

Warning: Never drive down an incline at full speed.

• When climbing an incline, try to keep your E-CART moving, if you must stop, start

7

Page 8

E-CART (ELECTRIC CART)

up again slowly and then accelerate smoothly with caution. Avoid sudden stops,

lean forward towards your handlebars to increase stability.

Warning: Any attempt to climb or descend an incline steeper than shown below may

put your E-CART in an unstable position and cause it to tip, resulting in personal injury.

SYMBOLS & PICTURES

In addition to the text and illustrations, this operating manual contains various symbols

which should draw attention to the safety requirements.

They generally have the following appearance:

Signal wording Explanation

DANGER

WARNING

CAUTION

Other definitions:

DIRECTION

IMPORTANT

USE SYMBOLS & PICTURES

Warning of an imminent danger!

Non-observance cause death or serious injury

Warning of a possibly incoming dangerous situation.

Non-observance may cause death or serious injury.

Warning of a possibly incoming dangerous situation.

May also be used for warnings of major damage to property.

Marks recommendations for use and other useful information.

Does not warn of dangerous situations.

Warns of a harmful situation.

Non-observance may cause damage to material.

Possible danger to file

and limb or machine!

Danger of crushing!

Do not reach into

running motor!

Wear safety shoes

8

Page 9

E-CART (ELECTRIC CART)

Product description

Designated use

The CART is to be used on hard level surfaces.

¾ To move the stacker between buildings, warehouses etc

The gradient of the slope must not be more than 10%

Make sure load is not loose or unstable.

Do not pick up loads on tips or forks or edge of platform.

Do not overload.

The road surfacing must be solid and have a good grip.

Travel routes must offer sufficient load-bearing capacity for the loaded CART.

The CART is not suitable for continuous use in cool-houses!

Ambient conditions

Temperature From

To

14

113

°F

°F

Degree of humidity ≤70 %

Permitted floor

incline

y Loaded

y Unloaded ¹

Max. 0.5

Max. 2.0

%

%

OPERATION

Visually inspect E-CART for damaged and worn parts, before

Electric Cart is taken into operation.

read and understand all instructions

Caution!

Pedestrian controlled industrial trucks may only be operated by persons who

have been satisfactorily instructed in operating the truck and have proved their

ability to operate the truck to the responsible representative of the operating

company.

The first driving attempts should take place on level and spacious surfaces.

Recommendation:

The operator who is to maneuver the CART should be allowed to practice, when

unloaded, until they can safely operate these functions.

Authorized person should

9

Page 10

E-CART (ELECTRIC CART)

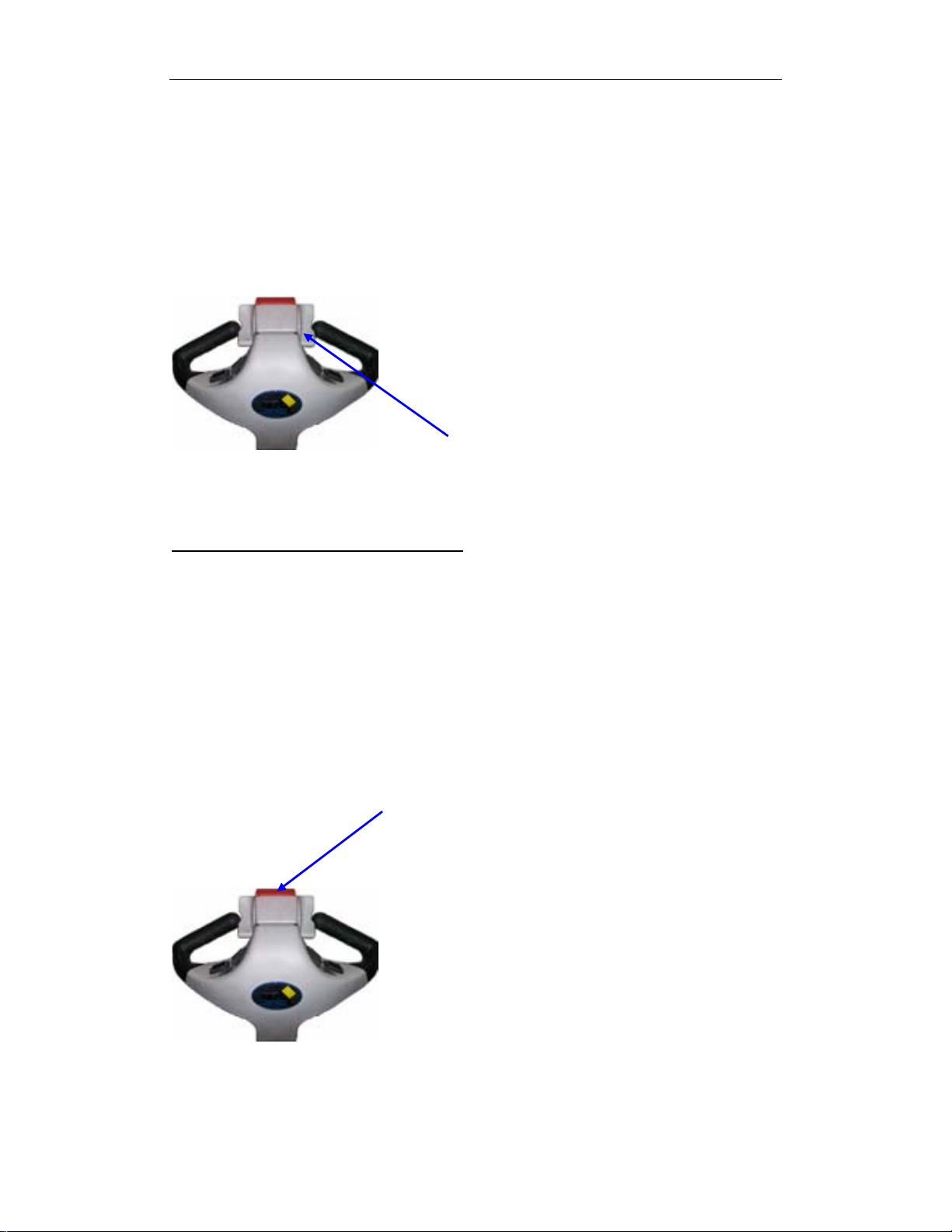

Travel

The butterfly switch controls the direction and speed of the lift truck.

Rotating the butterfly control towards the f o rks moves the truck in the forward

direction. Rotating the butterfly control away from the forks, moves the truck

in the reverse dir ection. The control is progre ssive – the further you rotate the

control, the faster the truck will travel.

DIRECTIONAL SPEED CONTROL THROTTLE

Emergency reverse safety button

At the top of the handle is a red safety reverse button. The button is

designed to change the travel direction away fro m the operator when depressed.

The truck will stop moving away from the operator when the button is re leased.

When the fork truck is traveling forward (away from the operator) the button

has no effect when activated.

If the belly switch becomes jammed or stuck, it will move forward (away

from the operator) for a maximum of 3 seconds at which time the control circuit

will become disabled until the handle is re-set to the full up or full down position

and the belly switch is returned to normal operation.

BELLY SWITCH (SAFETY REVERSE BUTTON)

10

Page 11

E-CART (ELECTRIC CART)

TO BRAKE

This cart is equipped with a brake that is applied between 1~5 degrees of the

vertical position . When you release your hand from the handle. It will resume

the neutral position automatically, as the brake in work. Always make sure that

the brake is in work before operating the cart .

HORN

A horn is located on the front side of the handle.

HORN

11

Page 12

E-CART (ELECTRIC CART)

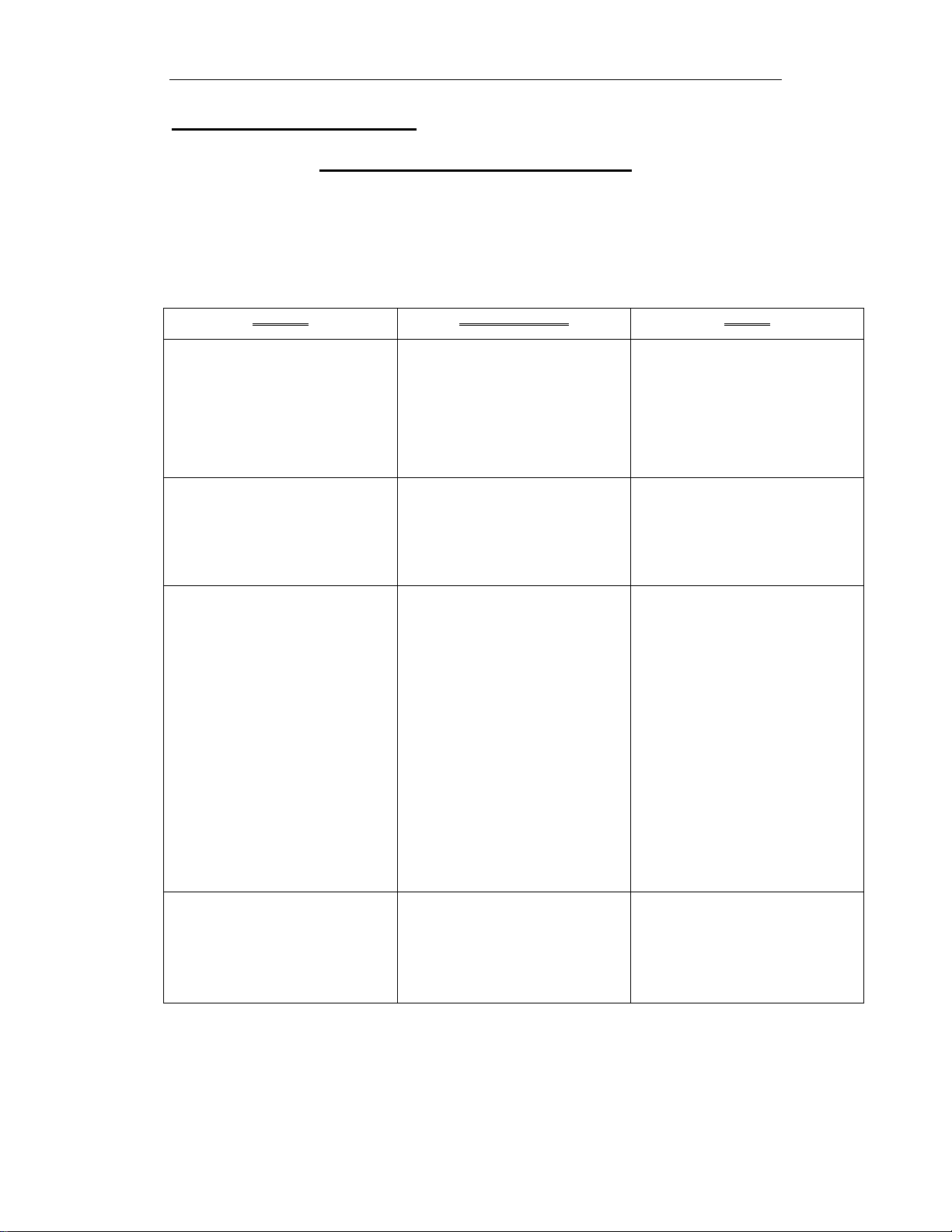

Maintenance and repair

TROUBLESHOOTING GUIDE -- ______

Warning: Before performing any task, always block drive wheel off of the ground.

Consult the factory for problems at time of installation, or for any problems not addressed

below.

Problem: Possible cause(s): Action:

Unit doesn’t mov e wh en c on t r ols a r e

used.

Unit will not charge

Unit will not go forward; reverse

works; belly switch just kills unit

(does not go forward and time out)

Unit will not go reverse; belly switch

works (i.e. when the handle is in

operating range and rotating

throttle in reverse and the belly

switch is hit, the unit moves

forward and times out)

Battery voltage low (<17)

Problem with motor controller

(check for LED flash code on side

of controller)

Fuse blown

Charger malfunction

Bad batteries

Broken wire, or loose connection

Contactor bad, motor controller bad

Broken wire, or loose connection,

contactor bad, motor controller

bad

Charge batteries.

Consult diagnostics

page/factory

Remove back shroud and check

fuses (3 fuses).

Verify output voltage on charger,

will only get a reading when

connected to batteries; should be

approximately 28 volts.

Load test batteries

Locate Pin 2 on Molex connector at

motor controller. Trace wiring to

contactor and verify connection.

When forward is depressed, there

should be 24 volts on this wire

from Molex connector to the

contactor, if not, the motor

controller may be bad; consult

diagnostics page/factory. If 24

volts is present at contactor,

verify ground connection. If

ground is good, remove both wires

and check with ohm meter;

resistance should be

approximately 38 ohms. If it’s

open or zero, the contactor should

be replaced.

Same as above; except locate Pin 3

on Molex connector on motor

controller…and follow procedure.

12

Page 13

E-CART (ELECTRIC CART)

Problem: Possible cause(s): Action:

Unit will not go forward, or reverse,

but belly switch still functions

properly.

Unit will not move forward, or

reverse, and the Belly switch will

not function, unit does turn on as

indicated by the battery gage

lighting up.

Broken wire, or loose connection,

bad motor controller,

Throttle assembly bad

Blown fuse

Broken wire, or loose connection

Locate Pin 6 on Molex connector at

the motor controller. Try to drive

the unit in forward, there should

be 0 to 5 volts (5v is full throttle)

at this pin. If there is voltage and

the unit does not move, the motor

controller may be bad, consult

diagnostics page/factory. If

there is no voltage, trace the

wiring back towards the tiller head

and check voltage on each side of

connectors. Continue this until

bad connection is found.

If the connections are all good, and

there is no voltage coming out of

throttle assembly, then the

throttle assembly may be bad.

Verify there is 24 volts going into

the assembly and that there is a

good ground. If there is still no

output voltage for pin 6, replace

throttle assembly. See Fig. 1

Verify fuses are good, replace if

blown.

Locate Pin 7 on Molex connector at

the motor controller. Trace wire

back up to tiller head and verify

continuity all the way to the

throttle assembly. Repair any

loose connections.

If there is continuity up to the

throttle assembly, then check the

ground wire that comes off of B-

on the motor controller (3

rd

terminal down). Add more length

to this wire if necessary, and

re-terminate with a ring terminal.

13

Page 14

E-CART (ELECTRIC CART)

Unit will not go forward; the belly

switch functions; reverse works.

Unit will not reverse; belly switch

does not function; forward ok

Belly switch does not function;

forward ok; reverse ok

Broken wire, or loose connection,

bad motor controller

Bad throttle assembly

Broken wire, or loose connection,

bad motor controller

Bad throttle assembly

Broken wire, or loose connection,

bad motor controller

Bad belly switch

Locate Pin 11 on Molex connector at

the motor controller. Try to drive

the unit in forward; there should

be 24 volts at this pin. If there is

voltage and the unit does not

move, the motor controller may be

bad, consult diagnostics

page/factory. If there is no

voltage, trace th e wiring back

towards the tiller he ad and check

voltage on each side of

connectors. Continue this until

bad connection is found.

If the connections are all good, and

there is no voltage coming out of

throttle assembly, then the

throttle assembly may be bad.

Verify there is 24 volts going into

the assembly and that there is a

good ground. If there is still no

output voltage for pin 11, replace

throttle assembly. See Fig. 1

Locate Pin 12 on Molex connector at

the motor controller. Try to drive

the unit in reverse; there should

be 24 volts at this pin. If there is

voltage and the unit does not

move, the motor controller may be

bad, consult diagnostics

page/factory. If there is no

voltage, trace th e wiring back

towards the tiller head and check

voltage on each side of

connectors. Continue this until

bad connection is found.

If the connections are all good, and

there is no voltage coming out of

throttle assembly, then the

throttle assembly may be bad.

Verify there is 24 volts going into

the assembly and that there is a

good ground. If there is still no

output voltage for pin 12, replace

throttle assembly. See Fig. 1

Locate Pin 13 on Molex connector at

the motor controller. Try to drive

the unit in reverse, and hit the

belly switch… there should be 24

volts at this pin. If there is

voltage and the unit does not

move, the motor controller may be

bad, consult diagnostics

page/factory. If there is no

voltage, trace th e wiring back

towards the tiller he ad and check

voltage, or continuity on each side

of connectors. Continue this until

bad connection is found.

If the connections are all good, and

there is no voltage, then the

switch may be bad. Verify there

is 24 volts going into the switch.

14

Page 15

E-CART (ELECTRIC CART)

Unit will not reverse. The unit only

goes forward for about 1 second

and dies when the handle is pulled

down. When the handle is re-set

and pulled down the unit will move

forward again then die.

Unit will not reverse; belly switch

does not function; forward ok

Stuck Switch

Broken wire, or loose

connection, bad throttle

assembly, bad motor controller.

If there is still no output voltage

for pin 13, replace the switch.

The belly switch is stuck on.

Tap the orange assembly to see

if the switch can be freed. If

this doesn’t work, disassemble

the tiller head by removing 3

screws from bottom. Slightly

loosen up the two screws that

hold the switch in place, this

may free the switch. If it is still

stuck, contact the factory for a

replacement switch.

Locate Pin 12 on Molex

connector at the motor

controller. Try to drive the unit

in reverse; there should be 24

volts at this pin. If there is

voltage and the unit does not

move, the motor controller may

be bad, consult factory. If

there is no voltage, trace the

wiring back towards the tiller

head and check voltage on each

side of connectors. Continue

this until bad connection is

found. If the connections are

all good, and there is no voltage

coming out of throttle assembly,

then the throttle assembly may

be bad. Verify there is 24 volts

going into the assembly and that

there is a good ground. If there

is still no output voltage for pin

12, replace throttle assembly.

15

Page 16

E-CART (ELECTRIC CART)

Instructions for Changing the Batteries, estimated time, 15 min.

READ ALL INSTRUCTIONS BEFORE PROCEEDING!

Only qualified personnel should work on this equipment!

Lock out all potential energy sources before attempting this inst allation; turn off the un it

and remove the key.

Warning!

! Working with or near lead acid batteries is dangerous. Batteries contain sulfuric acid and

produce explosive gases. A battery explosion could result in loss of eyesight or serious burns.

! Do not smoke or allow a spark or flame near batteries. Charge batteries in locations which

are clean, dry, and well-ventilated. Do not lay tools or anything metallic on top of any battery.

All repairs to a battery must be made by experienced and qualified personnel.

! When working with batteries, remove personal items such as rings, bracelets, necklaces, and

watches. Batteries can produce enough energy to weld jewelry to metal, causing a severe burn.

! Always have fresh water and soap nearby in case battery acid contacts skin, clothing, or eyes.

! Operating the battery with a low battery voltage can cause premature motor contact failure.

! Do not expose the lift or charger to rain or adverse conditions.

! Replace defective cords or wires immediately.

! Check the battery’s water level frequently if this applies to your battery type.

! Make sure the battery charger is unplugged from 115vac source.

Battery Charger Operating Instructions

Plug the charger into a standard 115V receptacle. If an extension cord must be

used, keep it as short and as large as possible. A small cord will decrease the output

of the charger due to the voltage drop in the line. This will increase the charging time.

It can also cause the 115V cord to overheat.

When properly connected, the charge LED will indicate the status of charge current

flowing to the battery, as follows: Power LED is always green when charger is plugged in.

The status light is as follows:

Red only – the charger is providing full output to the battery.

Yellow – the charger is “topping off” the battery.

Green – the charger is providing a “float,” or maintenance, charge.

Remember to unplug the charger before moving the equipment. Failure to do so could cause damage to cords, receptacles

and other equipment.

16

Page 17

E-CART (ELECTRIC CART)

Troubleshooting:

If the unit does not operate, check all of the wiring connections to make sure they’re both

mechanically and electrically sound – specifically at the battery, and the motor.

A fully-charged lead acid battery in good cond ition at room temperature should read 12.65

volts. At 11.9 volts it is considered to be fully discharged and in ne ed of char gi ng. When checking

battery voltage, wait at least 1\2 hour after the charger has been turned off before checking the

battery’s voltage.

If the batteries aren’t being charged by the charger, check the output

charger fuse. Verify fuse is good with an ohmmeter, or close visual

(ohm meter best). Fuse is a 10Amp 250 Volt; GBD 10A. If it is good,

check the battery’s state of charge with a voltmeter. The charger must

be connected to the battery in order to read the output voltage of the

battery charger. Depending on the state of charge of the batteries, the

voltage should be somewhere around 27 to 28 volts dc.

If it is determined the batteries are dead, and need replaced, change the batteries.

Tools Required:

14mm wrench, or crescent wrench

Regular flat bladed screw driver

17

Page 18

E-CART (ELECTRIC CART)

Instructions; Changing the Motor Controller in; estimated time, 30 min.

READ ALL INSTRUCTIONS BEFORE PROCEEDING!

Only qualified personnel should work on this equipment!

Lock out all potential energy sources before attempting this inst allation; turn off the un it

and remove the key.

Warning!

! Working with or near lead acid batteries is dangerous. Batteries contain sulfuric acid and

produce explosive gases. A battery explosion could result in loss of eyesight or serious burns.

! Do not smoke or allow a spark or flame near batteries. Charge batteries in locations which

are clean, dry, and well-ventilated. Do not lay tools or anything metallic on top of any battery.

All repairs to a battery must be made by experienced and qualified personnel.

! When working with batteries, remove personal items such as rings, bracelets, necklaces, and

watches. Batteries can produce enough energy to weld jewelry to metal, causing a severe burn.

! Always have fresh water and soap nearby in case battery acid contacts skin, clothing, or eyes.

! Operating the battery with a low battery voltage can cause premature motor contact failure.

! Do not expose the lift or charger to rain or adverse conditions.

! Replace defective cords or wires immediately.

! Check the battery’s water level frequently if this applies to your battery type.

! Make sure the battery charger is unplugged from 115vac source.

Troubleshooting:

If it has been determined the motor controller needs to be replaced, the following procedure

can be used.

Tools Required:

2x 14mm wrench, open face

Philips head screwdriver

8mm wrench

18

Page 19

Filename: Belly Switch trouble shoot

This is the top side of the tiller. Fig1

E-CART (ELECTRIC CART)

Fig.1

This is the driver side of the tiller, looking at the belly switch. Fig 2

Fig.2

19

Page 20

E-CART (ELECTRIC CART)

Filename: Belly Switch trouble shoot

This is the bottom side of the tiller handle. 3 Allen head screws need to be removed. Fig.3

Fig.3

Lift the front top edge of the tiller cover u p. Fig4

Fig.4

20

Page 21

E-CART (ELECTRIC CART)

Filename: Belly Switch trouble shoot

Fig.5

Carefully pull the belly switch back off of the tiller while tipping the front up.

Fig 6

Fig.6

21

Page 22

E-CART (ELECTRIC CART)

Filename: Belly Switch trouble shoot

The tiller assembly cover should come off, just be careful not to drop it and rip out the wiring from

the connectors. At this point, the tiller throttle assembly can be replaced

with a new one by just unplugging the two connectors. Or, if the problem appears to be in the

belly switch itself, further breakdown of t he assembly can continue to search for the problem. Fig 7

Fig.7

Unplug the two connectors from the tiller throttle assembly. Fig8

Fig.8

22

Page 23

E-CART (ELECTRIC CART)

Filename: Belly Switch trouble shoot

Remove Philips screw on throttle. Fig.9

Fig.9

Throttle wheel will then pull off. Take note of the orientation of the wheel on the shaft. Correct

orientation is shown here. Fig 10

Fig.10

23

Page 24

E-CART (ELECTRIC CART)

Filename: Belly Switch trouble shoot

Do the same on the other side, taking note of th e orientation of the two plastic bushings. If the

throttle wheel had a tendency to stick , contact Vestil Manufacturing for replacement bushings. Fig

11

Fig.11

The front of the red cover should be connected via the gray nub. Fig 12

Fig.12

24

Page 25

E-CART (ELECTRIC CART)

Filename: Belly Switch trouble shoot

To remove the red cover, use a small scr ewdriv er and carefully lift the plastic up over the gray nub.

Fig 13

Fig.13

Do the same on the other side, and remove. Fig 14

Fig.14

25

Page 26

E-CART (ELECTRIC CART)

Filename: Belly Switch trouble shoot

This should expose a spring. This spring has a specific o rientation. When assembled the spring

sets in the red cup on the inside of the red belly cover. Fig 15

Fig.15

The other side of the spring fits over the gray plastic nub above the switch. Fig 16

Fig.16

26

Page 27

E-CART (ELECTRIC CART)

Filename: Belly Switch trouble shoot

Another picture of the nub, spring not shown. At this point, verify the solder joints are in tact and

the two wires are attached to the switch as shown below. Also verify the belly switch is not stuck

in. You should be able to push on the switch and the actuator will move freely in and out, you

should here a click as you do this. If the switch is stuck in contact Vestil Manufacturing for

replacement options. Fig17

Solder

connection

Belly Switch

actuator

Solder

connection

Fig.17

Replace any broken/missing components. To assemble, press the red belly switch cover back on

the tiller head seating the red holes over the gray nubs. Basically the opposite of the procedure in

Fig. 17, but without a screwdriver. Fig 18

Fig.18

27

Page 28

E-CART (ELECTRIC CART)

Filename: Belly Switch trouble shoot

The spring can be pushed into position.

Fig. 19

Fig.19

This is the spring shown not seated completely. Push the spring into the pocket, and over the gray

plastic nub. Fig20

Fig.20

28

Page 29

Install bushings. Fig21

E-CART (ELECTRIC CART)

Filename: Belly Switch trouble shoot

Fig.21

Put throttle thumb wheels back on. Fig22

Fig.22

29

Page 30

Install Philips screw. Fig23

E-CART (ELECTRIC CART)

Filename: Belly Switch trouble shoot

Fig.23

Re-installing the tiller cover is basically reversing steps Fig 3 thru 7; with the following

precautions/steps.

Make sure red tabs on each side goes on top of black nub s when inst alli ng tiller cov er on the ha ndle.

Fig 24

Red Tab on

each side

Fig.24

30

Page 31

E-CART (ELECTRIC CART)

Filename: Belly Switch trouble shoot

Black nub for right side shown here; and the next photo Fig 25

Fig.25

The red tab slides over the top of this black nub on each side when installing the tiller throttle

assembly back on the handle. Fig 26

Plastic Nub

Fig.26

31

Page 32

E-CART (ELECTRIC CART)

Filename: Belly Switch trouble shoot

This shows sliding the red tabs over the black nub. This is basically the reverse of Fig6.

Red tab

Black nub

Fig.27

This is the top front where the two connectors are. Make sure they are on each side of the stand off

so the wires do not get pinched. Fig28

Stand off

between

connectors

Fig.28

32

Page 33

E-CART (ELECTRIC CART)

Filename: Belly Switch trouble shoot

Gently push the tiller throttle assembly in place. Again, it’s just reversing steps 3 through 7 to get

the tiller throttle assembly back on the handle. Re-install the 3 Allen screws, verify no switches are

sticking, and that the thumb wheel moves freely. Turn the unit on and verify operation. This

completes the assembly.

5mm Allen

screws; 3

places

Fig.29

33

Page 34

E-CART (ELECTRIC CART)

Free Wheeling E-CART

If for reasons of convenience, you require to push your E-CART for a short distance, the

drive system can be put into ‘freewheels mode’. This will allow your E-CART to roll freely.

E-CART Freewheel Procedure

The freewheel device is a lever located at the front right hand side of your E-CART (Fig.1)

Fig.1

To freewheel E-CART first switch off the power switch located on control handle (Fig.2)

Old handle with Key switch assembly

New handle with ON/OFF switch

34

Page 35

E-CART (ELECTRIC CART)

push down

Pull up

Push down the lever until a distinct click is felt (disengage) Fig.3.

Fig.3

Push and maneuver E-CART manually with ease.

To re-engage the drive system, simply pull backwards on the lever until a distinct click is felt

(engage).

Turn the power switch “ON” on the control handle and you will be able to operate the

E-CART once again.

Warning: Always check that the freewheel device is in the drive position before attempting

to operate your E-CART after it has been left unattended for a period of time. Failure to

observe this warning may result in an accident.

35

Page 36

E-CART (ELECTRIC CART)

Maintenance and repair

(A) DAILY CHECK THE FOLLOWING:

1) Frayed wires

2) Damage or structural deformation to the structural members.

3) Unusual noise or binding, or evidence thereof.

4) Proper functioning of all limit switches, including those on the perimeter pinch point

guard (if applicable)

5) Horn works

6) Battery, keep the surface of battery clean and dry. Make sure battery is secured

against slipping. Make sure batteries are fully charged.

7) Tire condition.

(B) SIX MONTHS Check and adjust as necessary:

1) Tire wear, replace as necessary

2) All fasteners and fittings for sound function. Unusual noises or movement during

operation

3) Tension of handle bar lock and hinge bolt

4) Battery connections

5) Inspect all electrical plugs and sockets for damage and good contact and fit. Proper

water level in the battery

6) Proper functioning of any hand-or foot-operated mechanisms

7) All the information, safety, and wearing labels being in place and in good condition

8) The need to clean off dirt and debris

(C) ANNUALLY Check the following and adjust as necessary:

1) Tire bearings for wear

2) Handle bar bolts and nuts

3) Chassis for sounds

4) Drive wheel hub keys

5) All wheel bolts

6) Drive axle securing bolts

7) Motor mounting bolts

8) Magnetic motor brake disc and function

9) Main wiring harness for damage

10) Clean chassis and repaint any exposed parts

11) Lubricate ON/OFF power key barrel

12) Replace any damaged axle seals

13) Cycle test charger for full operation function

14) Cycle test batteries for operating capacity

15) Check motor brushes for any wear in the lift motor, & if necessary change motor

brushes.

16) Check the condition of your tires regularly. Look for sign of wears, cuts and foreign

objects lodged in the tread.

Note the items listed under weekly and six months should be incorporated into this

annual inspection.

Use a general purpose light lubricating oil on moving parts.

All wheel bearings are factory sealed and should not normally need lubrication.

36

Page 37

E-CART (ELECTRIC CART)

DRIVE TRANSMISSION LUBRICATION

This unit is factory filled and will not normally need additional lubrication.

Note: E-CART transmission is filled with a special lubricant. Don’t attempt to force

grease into the transmission as this will contaminate the original lubrication and will

invalidate your warranty.

37

Page 38

Serial No. __________________

Model: ____________________

LIMITED WARRANTY

Vestil Manufacturing Corporation (Vestil) warrants E-CART model Traction-Drive Carts, to be free of defects in

material and workmanship during the warranty period. Our warranty obligation is to provide a replacement for a

defective original part (a part that used to make the product as shipped to the warrantee) after we receive a

proper request for warranty service. “Proper request” means that we must receive: 1) a photocopy of the

Customer Invoice from Vestil (or authorized distributor) that displays the shipping date; AND 2) a written request

for warranty service. Send requests by any of the following methods:

Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 sales@vestil.com

2999 North Wayne Street, PO Box 507

Angola, IN 46703

In the written request, list the parts you believe are defective and include the address where replacements

should be delivered. After Vestil receives your request, an authorized representative will contact you to

determine whether your claim is covered by the warranty (also see “What will Vestil do to correct defects”

below). Before providing warranty service, Vestil may require you to send the entire product or the defective

part or parts to its facility in Angola, IN.

Who may request service?

Only the warrantee may request service. You are a warrantee if you purchased the product from Vestil or from

an authorized distributor AND the product is fully paid for.

What is covered under the warranty?

The warranty covers the following original drive components: drive motors, electronic controllers, and switches.

It also covers original parts that wear under normal usage conditions (“wearing parts”): bearings, wheels, seals,

motor brushes, batteries, and the battery charger. The warranty period for drive and lift components is 1 year

For wearing parts, the warranty period is 90 days

. Both warranty periods begin on the date when Vestil ships

the product to the warrantee. If you purchased the product from an authorized distributor, the periods begin

when the distributor ships the product, which extends the warranty by up to an additional 30 d ays.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will

contact you to discuss your claim and to arrange warranty service.

What is not

covered by the warranty?

1. Labor costs;

2. Any of the following automatically void the warranty:

• Product misuse;

• Negligent operation or repair;

• Corrosion or use in corrosive conditions;

• Inadequate or improper maintenance;

• Failure to exercise good judgment;

• Damage sustained during shipping;

• Accidents involving the product;

• Unauthorized modifications

: Do NOT modify the product IN ANY WAY without first receiving

written authorization from Vestil. Modifications may render the pallet truck or stacker unsafe

to use or might cause excessive and/or abnormal wear.

Do any other warranties apply to the ladder stand?

Vestil Manufacturing Corp. makes no other express warranties. Any warranty implied-by-law is limited in

duration to the warranty period.

.

Loading...

Loading...