Page 1

VESTIL MANUAFACTURING CORPORATION

2999 North Wayne St., Angola, IN 46703

Phone (260) 665-7586 • Fax (260) 665-1339

sales@vestil.com • Website: www.vestil.com

Ergonomic Solutions

Contents

Revised 04-04 21-126-103

A company dedicated to solving ergonomic and material

handling problems since 1955

.

OWNER'S

MANUAL

MECHANICAL POST TABLE • MODEL MT

Warning & Safety Instructions ......................... 1

Receiving Instructions ..................................... 1

Warranty .......................................................... 1

Ordering Replacement or Extra Parts ............. 2

Installation Instructions .................................... 2

Operating Instructions ..................................... 2

WARNINGS & SAFETY INSTRUCTIONS

Read owner's manual completely before operating unit!

• Not a personnel lift.

• Remove weight & disconnect power before working on unit.

• Use only maintenance parts supplied or approved by the

manufacturer.

• Never operate the lift unless you are watching it.

• Transport loads in the lowered position only.

• Don't continue to operate the control if unit is not moving.

• Consult factory before adding or performing any

modification to the original equipment.

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected prior to

shipment. However, it is possible that the unit may incur

damage during transit. If you see damage when unloading

make a note of it on the SHIPPER RECEIVER.

Remove all packing and strapping material, inspect

for damage. IF DAMAGE IS EVIDENT, FILE A CLAIM WITH

THE CARRIER IMMEDIATLY! Also, check the unit size, type

of power unit, etc., to ensure the unit is correct for the intended

application.

Mechanical Post Table Parts List ............. 3-4

DC Powered Post Table Parts List ........... 5-6

Trouble Shooting Guide ............................... 7

Electrical Diagram ........................................ 7

Instructions for Battery-Powered Units .........8

instructions, or disassembly, repair or alteration by any

person prior to authorization from a factory representative.

ORDERING REPLACEMENT OR EXTRA PARTS

Our company takes pride in using the finest available

parts for our equipment. We are not responsible for

equipment failure resulting from the use of unapproved

replacement parts. To order replacement or extra parts for

your equipment contact Customer Service at the factory.

In any correspondence with the factory please include the

Serial Number which is inscribed on the nameplate of the

piece of equipment. Use only the part numbers provided

in this Owner's Manual. When ordering parts for AC power

units please indicate the motor phase and voltage that the

equipment is operating on.

E

N

G

L

I

S

H

E

S

P

A

N

O

L

WARRANTY

This product is warranted for 1 YEAR from date of

purchase to be free of manufacturing defects in material and

workmanship. The manufacturer's obligation hereunder is

limited to either providing replacement parts or repairing the

product, provided the product is sent prepaid back to the

factory.

This warranty does not cover normal wear of parts or

damage resulting from any of the following: negligent use or

misuse of the product, use or application contrary to installation

MECHANICAL POST TABLE

MODEL MT

1

Page 2

INSTALLATION INSTRUCTIONS

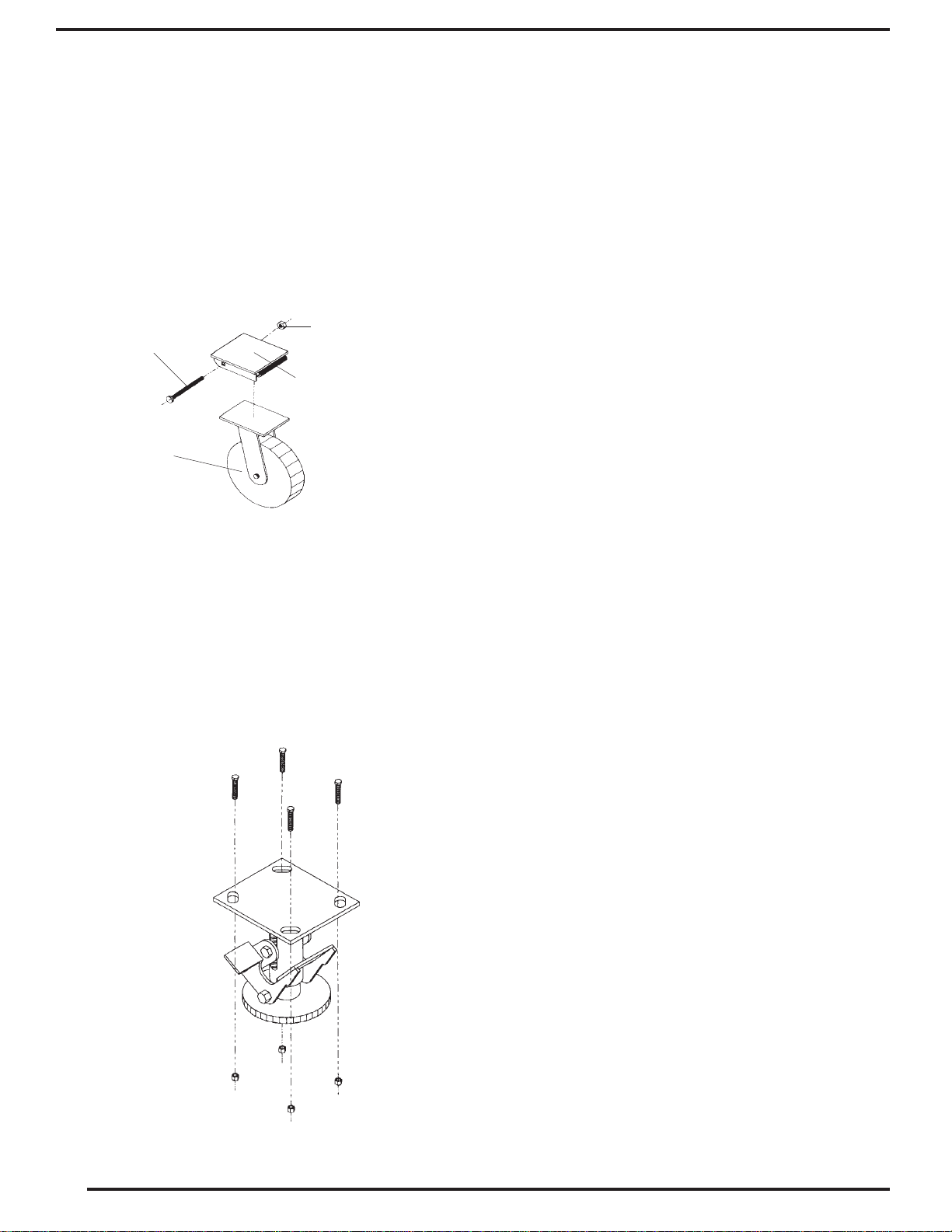

INSTALLING CASTERS (fig. 1)

1.) Two 5" dai. swivel casters are installed on one end of

base frame (handle end of platform) and 5" dia. rigid

casters are installed on other end.

2.) Place the caster base plate into the caster pad bracket

(located on the bottom of frame).

3.) Insert 3/8" x 16 UNC x 5" long carriage bolt through

the square hole in the caster pad to hold the caster in

place.

4.) Place 3/8"-16 UNC lock nut on each bold and tighten

securely.

NUT

BOLT

CASTER PAD

BRACKET

CASTER

Figure 1

OPERATING INSTRUCTIONS

MANUAL HAND CRANK

Attach hand crank. Turn clockwise to raise unit and counter

clockwise to lower unit.

DC POWERED

Position of the deck is controlled by the hand-held pendent

control. The arrows display direction of travel of deck.

In order to operate the unit, pressure must be maintained in

the UP or DOWN position to raise or lower deck. On releasing

either button, the deck will remain at that particular position

until the button is depressed again.

RESPONSIBILITIES OF OWNERS/USERS

It is the responsibility of the owner/user for the following:

1.) The lift must be inspected and maintained in accordance

with the guidelines in this manual.

2.) Any lift not in safe operating condition must be removed

from service until it is returned to proper operating condition.

Unsafe condition may include, but is not limited to the following:

missing rollers, pins, or fasteners, any cracked or deformed

structural members, cut or frayed electric lines, and damaged

controls or safety devices.

INSTALLING FLOOR LOCK - (fig. 2)

1.) Align mounting plate of floor lock with predrilled holes

on bottom of frame.

2.) Install floor lock with foot pedal bracket facing out.

3.) Insert four 3/8"-16 x 1" long hex head cap screws

through top of frame.

4.) Place four 3/8" - 16 lock nuts on each bolt and tighten

securely.

All repairs and maintenance must be performed by qualified

personnel.

3.) Lift may only be used be used by authorized personnel.

All lift operators must have read and understood all

operating procedures and safety guidelines in this Owner's

Manual.

4.) Lift must never be overloaded.

5.) Operator must ensure that all safety features of the lift are

functioning properly before each use.

6.) Any modifications to the lift must be approved in writing by

the manufacturer.

Figure 2

2

Page 3

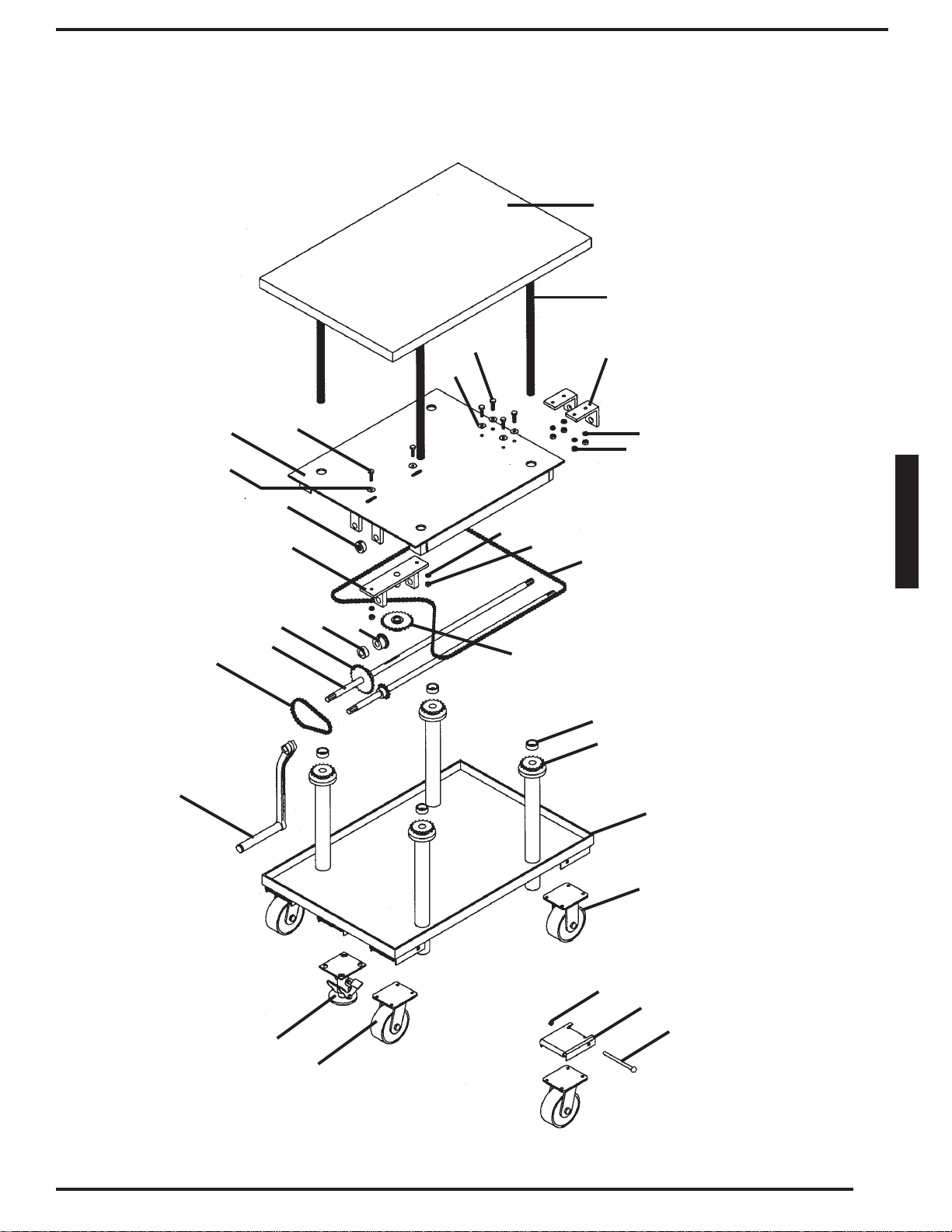

PARTS IDENTIFICATION

MECHANICAL POST TABLE • MODEL MT

3

21

10

16

23

2

24

14

20

15 17

12

18

23

24

22

19

25

22

8

8

16

27

26

1

E

N

G

L

I

S

H

4

8

6

7

9

5

3

Page 4

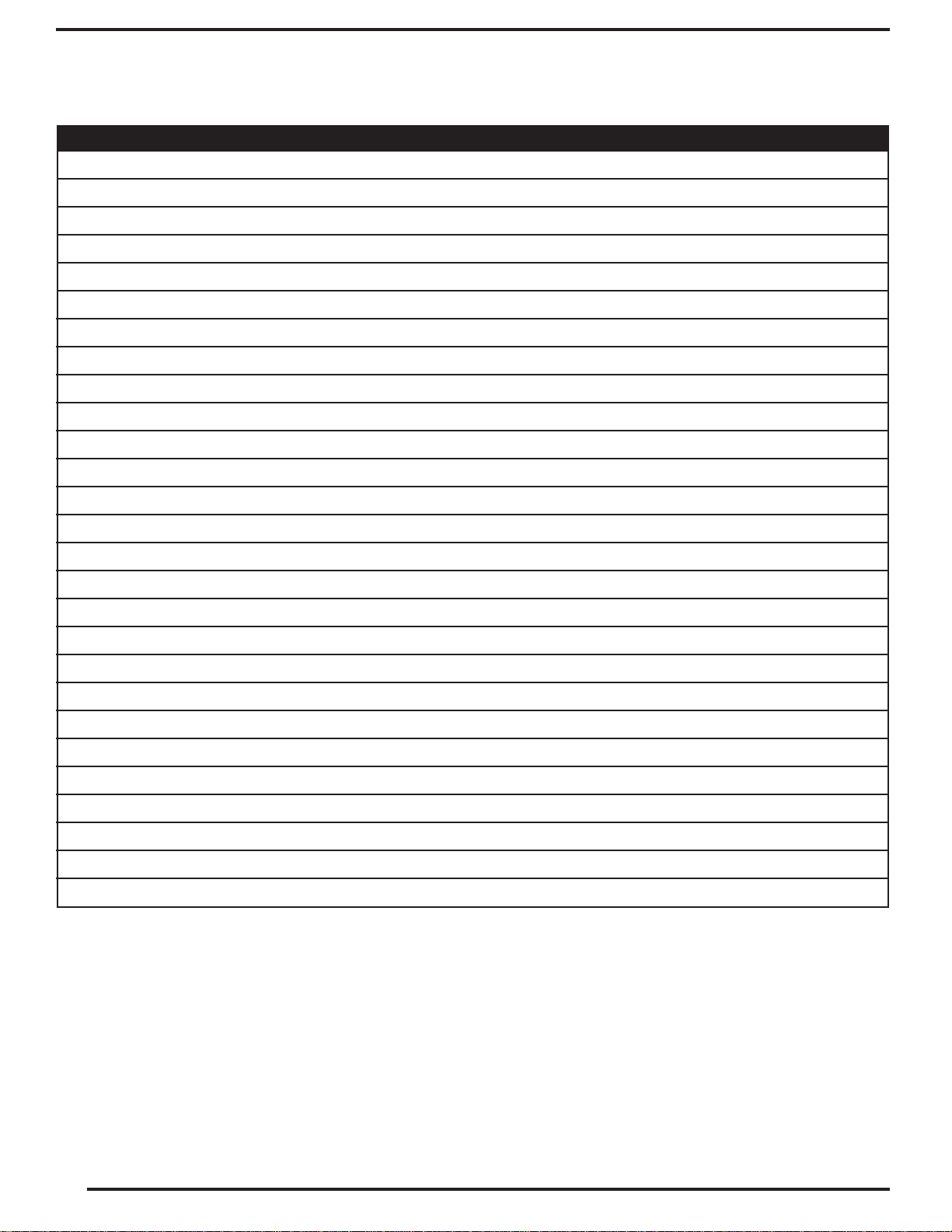

PARTS IDENTIFICATION

MECHANICAL POST TABLE • MODEL MT

ITEM NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

DESCRIPTION

Frame, Base Sub-Assy, MT

Deck, Center Plate (weldment), MT

Deck, Table Top, MT

Caster, Rigid, 5 x 2 poly on steel

Caster, Swivel, 5 x 2 poly on steel

Bracket, Caster Mount (bulldog)

Bolt, Carriage, 3/8 - 16 UNC x 5 Lg.

Nut, Hex, 3/8 - 16 UNC

Foot Lock

Crank Handle

Shaft, Slow Speed Gear, MT

Shaft, High Speed Gear, MT

Sprocket, #41 Chain (12 teeth)

Shaft collar, Split Shaft, with set screw 3/4"

Sprocket #41 Chain (24 teeth)

Chain, Roller

ENGINEER NO.

21-514-023/030

21-513-009

21-013-024/027

16-132-022

16-132-021

16-132-076

n/a

n/a

16-132-080

14-025-001

14-026-004/006

14-026-007/009

21-042-007

n/a

21-042-006

21-042-011

QTY.

1

1

1

2

2

4

4

10

1

1

1

1

1

1

1

2

17

18

19

20

21

22

23

24

25

26

27

n/a - Not Available

Spacer, High Speed Shaft

Gear, Bevel

Gear Ass'y, Bevel and Sprocket

Bracket, Sub-Ass'y, Tension Adjust, MT

Specialty Hardware, Lifting Thread

Washer, Lock, 3/8 Diameter

Washer, Flat, 7/16 Diamter

Bolt, HHCS, 2/8 - 16 UNC x 1-1/4 Lg.

Bracket, Removable Shaft Mtg.

Sprocket, Lifting, Post Crank

Spacer, Diameter 1-1/2 x 5/32 Wall x 5/8 Lg.

21-113-024

21-042-005

21-542-001

21-516-001

14-145-006

n/a

n/a

n/a

21-016-026

14-042-003

21-113-023

1

1

1

1

4

6

6

6

2

4

4

4

Page 5

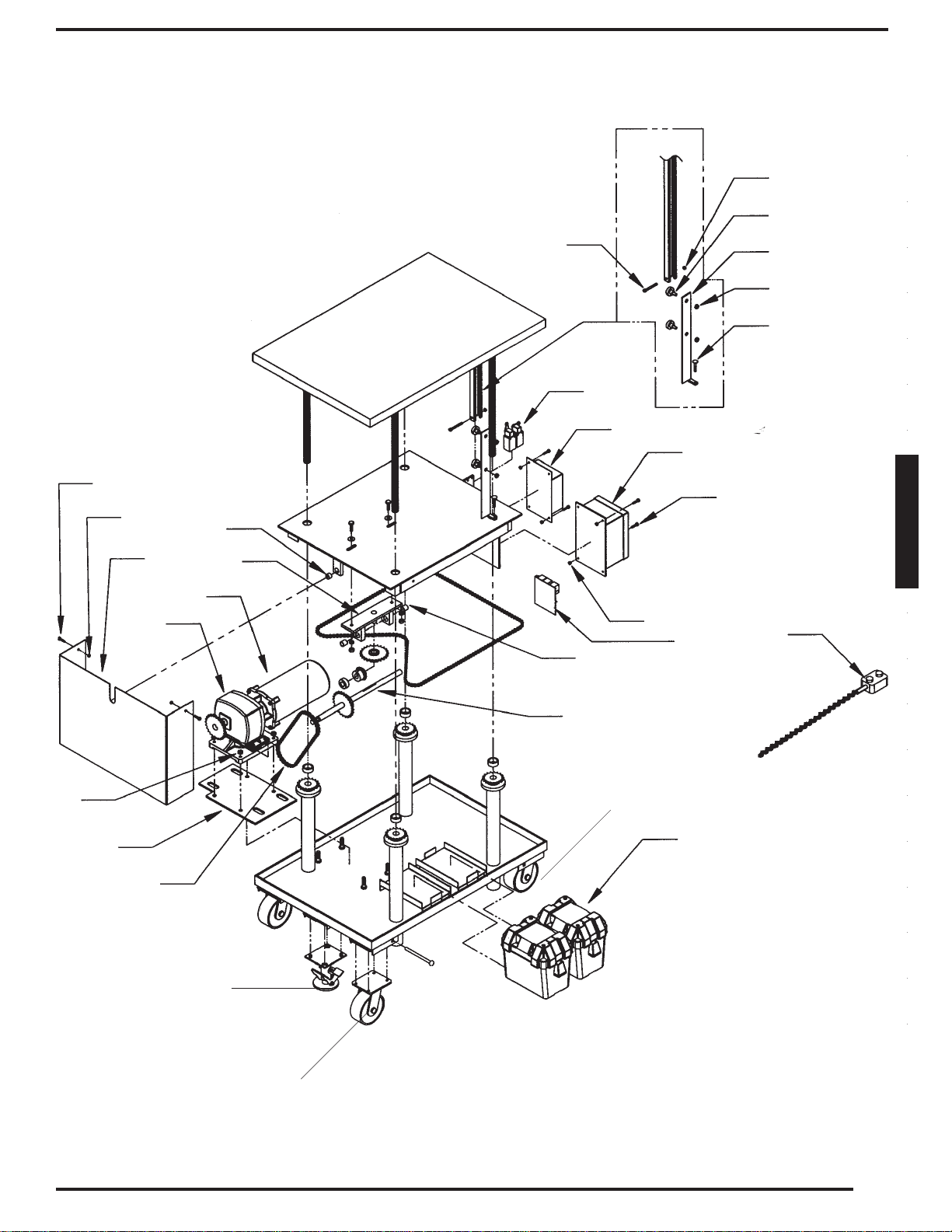

PARTS IDENTIFICATION

MECHANICAL POST TABLE DC POWER • MODEL MT-DC

1

2

14

15

16

17

18

13

19

6

7

8

9

10

11

30

12

3

4

5

E

N

G

L

I

S

H

28

20

21

23

25

24

22

27

26

5

Page 6

PARTS IDENTIFICATION

MECHANICAL POST TABLE DC POWER • MODEL MT-DC

ITEM NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

DESCRIPTION

1/4 - 20 UNC Hex Nut

Bearing, Roller (SWA-48 PMO)

Travel Bar Locator Weldment

5/16 - 18 UNC Lock Nut

Elevator Bolt 1/4 x 20 x 1-3/4 lg.

HHCS 1/4-20 UNC x 2-1/2 lg.

Roller Arm Limit Switch

Guest Battery Charger

6 x 8 Control Box

1/4 - 20 UNC x 1 lg.

1/4 - 20 UNC Hex Nut

Bushing Sleeve 3/4 x 3/4 lg.

Bushing Sleeve 3/4 x 1/2 lg.

1/4 - 20 UNC x 1 lg.

ENGINEER NO.

36102

20-110-008

21-516-004

37021

22805 (Fastenal)

11013

01-022-001

21-034-001

01-029-007

11005

36102

01-111-009

01-111-008

11005

PART NO.

MTDC-HXNT

MTDC-BRLR

MTDC-TBLW

MTDC-LN516

MTDC-EVBLT

MTDC-11013

MTDC-RALS

MTDC-GBC

MTDC-CB68

MTDC-11005

MTDC-HXNT

MTDC-BS34

MTDC-BS12

MTDC-11005

QTY.

1

2

1

2

1

1

2

1

1

4

4

2

1

2

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

1/4 - 20 UNC Hex Nut

Safety Shroud, Chain Cover

Reducer, Hub city (SWA-48)

DC Motor (1 hp) (PEL-400)

Brkt. Weldment, Tension Adj.

1/2 x 13 UNC Hex Nut

Brkt. Motor Base

Chain RC-41 (MT-2436)

ShaftGear

Battery (w/case) (PEL-400)

Rigid Caster 5" x 2"

Swivel Caster 5" x 2"

Floor Lock

Hand Control with Coil Cord

Circuit Breaker (not shown)

36102

21-024-020

20-141-002

21-641-001

21-516-005

36109

21-016-064

21-042-001

21-026-005

21-139-002

16-132-022

16-132-021

16-132-080

01-022-015

21-146-001

MTDC-HXNT

MTDC-SSCC

MTDC-HCR

MTDC-DCMTR

MTDC-TAWB

MTDC-36109

MTDC-MTRBS

MTDC-CHAIN

MTDC-SFTGR

MTDC-BAT

MTDC-5X2PRC

MTDC-5X2PSC

MTDC-FL

MTDC-HNDCNT

MTDC-CB

2

1

1

1

1

4

1

1

1

2

2

2

1

1

1

30

6

Motor Controller

21-156-003

MTDC-MTRCONT

1

Page 7

Troubleshooting Quick Reference Guide

for DC Powered Mechanical Post Table

(For further information contact the factory)

WARNING! BEFORE PERFORMING ANY MAINTENANCE WORK ALWAYS UNLOAD UNIT AND INSTALL MAINTENANCE SAFETY BAR(S)

Observation Possible Cause Remedy

1.) Power unit does not run when hand

control is operated.

a. Battery voltage low.

b. Bad wiring connection / broken

wire in circuit.

a. Charge battery.

b. Visually inspect wires, do continuity

checks with meter. Refer to electrical

diagram.

2.) Motor hums, platform would not move.

3.) Unit turns off before reaching the fully

raised or lowered height.

ELECTRICAL DIAGRAM WITH 24 VDC POWER OPTION

c. Problem with motor / control.

a. Chain / master link broken.

b. Obstruction / jamed chain.

a. Battery voltage low.

b. Platform roller bearing obstructed

or is binding.

c. The "platfrom raised" limit switch

engaging too soon, or is bad (where

applicable).

d. Wire inside control cable broken.

e. Platform overloaded.

c. Consult factory.

a. Inspect and replace if necessary.

b. Inspect chain, rollers, roller track and

pully assembly.

a. Charge battery.

b. Inspect roller track for interference

or damage.

c. Adjust the limit switch pully spring's

tension: test switch with meter.

d. Rotate control around while pressing

button(s). If the unit operates

intermittently, change the control.

e. Check load; reduce if neccessary.

E

N

G

L

I

S

H

7

Page 8

ADDITIONAL INSTRUCTIONS FOR BATTERY-POWERED UNITS

WARNING!

Working with or near lead acid batteries is dangerous. Batteries

contain sulfuric acid and produce explosive gases. A battery

explosion could result in loss of eyesight or serious burns.

Do not smoke or allow a spark or flame near batteries. Charge

batteries in locations which are clean, dry and well ventilated.

Do not lay tools or anything metallic on top of any battery. All

repairs to a battery must be made by experienced and qualified

personnel.

When working with batteries, remove personal items such as

rings, bracelets, necklaces, and watches. A battery can

produce enough voltage to weld jewelry to metal causing a

severe burn.

Always have plenty of fresh water and soap nearby in case

battery acid contacts skin, clothing, or eyes.

Operating the battery with a low battery voltage can cause

permature motor contact failure.

Do not expose the lift or charger to rain or adverse conditions.

Replace defective cords or wires immediately.

When properly connected, the charger will indicate the status

of charger output.

Flashing green, solid red LED - the charger is not seeing a good

connection to the battery, or the charger's ouput fuse has

blown.

Solid yellow and red LED's - the charger is providing a charging

current to the battery.

Solid green and red LED's - the charger is maintaining a fullycharged battery.

Caution: Remember to unplug the charger before moving the

equipment. Fauilure to do so could cause damage to cords,

receptacles and other equipment.

TROUBLESHOOTING

If the unti does not operate, check all the wiring connections to

make sure they're both machanically and electrically sound specifically at the battery, the motor, and at any location a wire

is connected to the chassis. Also make sure the quick-connect

plug on the end of the pendant control cord is plugged in

correctly.

BATTERY CHARGER

OPERATING INSTRUCTIONS

Never operate the charger with either of the cables coiled.

Operating the unit wit the cord wrapped around itself could

cause the cord to overheat, melt, and cause a short-circuit or

file.

Plug the charger into a standard 115V receptacle. If an

extension cord must be used, keep it as short as possible.

Connection: the ribbed wire of the charger's output cord must

be connected to the batter's negative (-) terminal. The nonribbed wire must be connected to the batter's positive (+)

terminal. Reversing this polarity will blow the charger's ouput

fuse.

A fully-charged lead acid battery is good condition at room

temperature should read 12.65 volts. At 11.9 volts it is

considered to be fully discharged an in need of charging. When

checking battery voltage, wait at leas 1/2 hour after the charger

as been turned off before checking the battery's voltage.

If the batteries don't seem to be taking a charger, check the

charger's 115V supply circuit, the charger's 10A output fuse,

and the charger's output with a voltmeter. If all check okay,

confirm the battery's state of charge using a hydrometer or a

voltmeter.

8

Page 9

VESTIL MANUAFACTURING CORPORATION

2999 North Wayne St., Angola, IN 46703

Phone (260) 665-7586 • Fax (260) 665-1339

sales@vestil.com • Website: www.vestil.com

Soluciones Ergonómicas

Contenido

Avisos e instrucciones de seguridad ....................... 9

Instrucciones de recibo ........................................... 9

Garantia .................................................................. 9

INstrucciones de instalación ................................. 10

Instrucciones de operación ................................... 10

Revisado 04-04 21-126-103

Una compañia dedicada a resolver problemas ergonómicos

y de manejo del material desde 1955.

MANUAL DEL

PROPIETARIO

MESA DE POSTE MECÁNICA • MODELO MT

Pedidos de reemplazo o partes extra ................... 10

Lista de partes de la mesa de poste mecànica.....11

Mesa de poste eléctrica DC .................................. 12

Instrucciones de operación del cargador de batería .. 13

ADVERTENCIAS E INSTRUCCIONES DE

SEGURIDAD

Lea el manual del propietario completamente antes de usar la unidad!

• No es un ascensor de personal.

• Nunca vaya debajo de las horquillas si la unidad tiene peso.

• Quite el peso y desconecte la electricidad antes de trabajar

en la unidad.

• Use solo partes de mantenimiento suministradas y

aprobadas por el fabricante.

• No cambie la válvula de relieve de presión.

• No agarre el cilindro hidráulico y a que podria romper el barril.

• Nunca opere el ascensor a no ser que lo este vigilando.

• No se hacerque si hay goteras-el aceite de alta presión pica

la piel con facilidad cuasando daños serios, gangrena y

hasta muerte.

• Carge la carga segura contra la mampara dentro de la

capacidad indicada.

• Transporte la carga solo en la posición baja.

• No continue apretando el control arriba (UP) si la unidad no

se está elevando.

• Alivie la presión del sistema apretando el control de bajada

(DOWN) después de que la unidad se haya parado.

• Consulte con el fabricante antes de añadir o hacer cualquier

modificación en el equipo originial.

• No use aceites de freno ni de gatos. Use solo aceite

hidráulica AW-32 o similar.

GARANTIA LIMITADA

Este producto está garantizado durante 365 DIAS

desde la fecha de compra de estar libre de defectos de

material y mano de obra. La obligación del fabricante está

limitada a reparar tales productos durante el periodo de

garantia, provisto que el producto se envie previo envio

flete pagado a la fábrica.

Esta garantia no cubre el gasto normal de partes

o daños que resulten de lo siguiente: uso negligente o mal

uso del producto, uso o aplicación contraria a las

instrucciones de instalación, o desensamble, reparaciones

o alteraciones por cualquier persona antes de la previa

autorización de un representante de la fábrica.

E

S

P

A

N

O

L

INSTRUCCIONES DE RECIBO

Cada unidad es inspeccionada a fondo y probada antes

del envio. Aún asi, es posible que la unidad se dañe durante el

envio. Si ve algún daño durante la descarga anótelo en el

RECIBO DE ENVIO.

Quite todo el material de empaquetado y las correas,

inspeccione por daños. Si hay daños evidentes, archive una

reclamación con el transportista immediatamente.

MESA DE POSTE MECÁNICA

MODELO MT

9

Page 10

INSTRUCCIONES DE INSTALACIÓN

INSTALACIÓN DE LAS RUEDAS (fig. 1)

1.) Dos ruedas locas de 12.7 cm de diam. se tienen que instalar

en cada extremo de la base del bastidor (en el extremo

de la manivela de la plataforma) y dos ruedas rígidas de

12.7 cm de diam. se tienen que instalar en el otro extremo.

2.) Ponga el plato de la base de la rueda en la almohadilla

de soporte. (Localizada debajo del bastidor).

3.) Inserte un tornillo largo de .95 cm-16 unc x 12.7 cm a

través del agujero cuadrado en la almohadilla de la rueda

para aguantar la rueda en su lugar.

4.) Ponga una tuerca de cierre de 0.95 cm x 16 unc en cada

tornillo y apriete con seguridad.

INSTRUCCIONES DE OPERACIÓN

MANIVELA MANUAL

Agarre la manivela manual. Gire hacia la derocha para elevar

la unidad y hacia la izquierda para descender la unidad.

ELÉCTRICO DC

La posición de la plataforma es controlada por el control

manual. Las flechas indican la dirección de viaje de la

plataforma.

Para usar la unidad, se tiene que mantener presión en los

botones de arriba (UP) o abajo (DOWN) para elevar o

descender la plataforma. Cuando se suelte el botón, la

plataforma se mantendrá en esa posición particular hasta

que el botón se presione de nuevo.

TORNILLO

TUERCA

ALMOHADILLA DE

SOPORTE DE LA

RUEDA

RUEDA

Figura 1

INSTALACIÓN DEL FIJAMENTO AL PISO (fig. 2)

1.) Alinie el plato montante del fijamento del piso con las

perforaciones pretaladradas de debajo del bastidor.

2.) Instale el agarro del piso con el soporte del pedal hacia

fuera.

3.) Inserte cuatro tornillos largos de hex de 0.95 cm x 16 x

2.54 cm a través de la parte superior del bastidor.

4.) Ponga cuatro tuercas de cierre de

0.95 cm x 16 en cada tornillo y apriete con seguridad.

Responsabilidades de los Propietarios/

Usuarious

El propietario/usuario es responsable de lo siguiente:

1.) El elevador debe de ser inspeccionado y reparado de

acuerdo con las instrucciones de este manual.

2.) Cualquier elevador que no funcione con seguridad debe

de ser removido del servicio hasta que vuelva a funcionar

correctamente.

Condiciones de seguridad pueden incluir, pero no se limitan

a lo siguiente: aire o goteras hidráulicas excesivas, ruedas,

pasadores, o cerrojos en falta, partes estructurales

deformadas o rotas, lineas hidráulicas, eléctricas o de aire

rotas, y controles o partes de seguridad dañadas.

Todas las reparaciones deben de ser hechas por

personal calificado.

3.) El elevador solo debe ser usado por personal autorizado.

Todos los operarios del elevador deben de leer y entender

todos los procedimientos y guias de seguridad en este

manual del propietario.

10

Figura 2

4.) Nunca se debe sobrecargar el elevador.

5.) El operario se debe asegurar que todas las partes de

seguridad funcionan correctamente antes de cada uso.

6.) Cualquier modificación del elevador debe de ser

aprobada por escrito por el fabricante.

PEDIDO DE PARTES EXTRA O DE

REEMPLAZO

Nuestra compañia está orgullosa de utilizar en nuestro

equipo las partes disponibles más buenas. No nos hacemos

responsables si el equipo no funciona correctamente si se

han usado partes de reemplazo sin aprobar. Para pedir

partes extras o de reemplazo para su equipo contacte el

Servicio del Cliente de la fábrica. En toda la correspondencia

con la fábrica porfavor incluya el Número de Serie que está

inscrito en la placa del equipo. Solo use los números de

partes provistos en este Manual del Propietario. Cuando pida

partes para las unidades eléctricas AC porfavor indique la

fase y el voltaje del motor que el equipo utiliza.

Page 11

IDENTIFICACIÓN DE PARTES

MESA DE POSTE MECÁNICA • MODELO MT

3

21

10

16

23

24

23

12

15

14

20

24

17

22

8

18

19

2

16

25

27

26

22

8

E

S

P

A

N

O

1

L

4

8

6

7

9

5

11

Page 12

IDENTIFICACIÓN DE PARTES

MESA DE POSTE MECÁNICA

PARTIDA

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

DESCRIPCIÓN

Frame, Base Sub-Assy, MT

Deck, Center Plate (weldment), MT

Deck, Table Top, MT

Rueda, rigida, acero de poly

Rueda, giratoria, acero de poly

Bracket, Caster Mount (bulldog)

Tornillo

Tuerca, hex

Freno de piso

Manivela de elevación

Eje, engranaje de baja velocidad

Eje, engranaje de alta velocidad

Sprocket, #41 Chain (12 teeth)

Collar del eje, eje con juego de tornillos

Sprocket #41 Chain (24 teeth)

Cadena, rodillo

NO. DE INGENIERO

21-514-023/030

21-513-009

21-013-024/027

16-132-022

16-132-021

16-132-076

n/a

n/a

16-132-080

14-025-001

14-026-004/006

14-026-007/009

21-042-007

n/a

21-042-006

21-042-011

CTD.

1

1

1

2

2

4

4

10

1

1

1

1

1

1

1

2

17

18

19

20

21

22

23

24

25

26

27

n/a - Not Available

Espacio, eje de alta velocidad

Engranaje, cónico

Ensamble de engranaje, cónico y de cadena

Soporte del sub-ensamble del ajuste de tensión

Specialty Hardware, Lifting Thread

Arandela, de cierre de 3/8 de diámetro

Arandela, plana

Tornillo

Soporte, eje movible

Manivela del poste de elevación de cadena

Espacio

21-113-024

21-042-005

21-542-001

21-516-001

14-145-006

n/a

n/a

n/a

21-016-026

14-042-003

21-113-023

1

1

1

1

4

6

6

6

2

4

4

12

Page 13

PARTS IDENTIFICATION

MECHANICAL POST TABLE DC POWER • MODEL MT-DC

1

2

20

14

15

16

17

18

13

19

6

7

8

9

10

11

30

12

23

25

3

4

5

28

E

S

P

A

N

O

L

21

24

22

27

26

13

Page 14

IDENTIFICACIÓN DE PARTES

MESA DE POSTE ELÉCTRICA DC • MODELO MT

ITEM NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

DESCRIPCIÓN

1/4 - 20 UNC tuerca hexagonal

Cojinete de rodillos

Localizador de la soldadura de la barra de viaje

5/16 - 18 UNC Tuerca de cierre

Tornillo del ascensor 1/4 x 20 x 1-3/4 lg.

HHCS 1/4-20 UNC x 2-1/2 lg.

Interruptor de limite del brazo del rodillo

Cargador de batería de recambio

6 x 8 Caja de control

1/4 - 20 UNC x 1 lg.

1/4 - 20 UNC Tuerca hexagonal

Manga del buje 3/4 x 3/4 lg.

Manga del buje 3/4 x 1/2 lg.

1/4 - 20 UNC x 1 lg.

ENGINEER NO.

36102

20-110-008

21-516-004

37021

22805 (Fastenal)

11013

01-022-001

21-034-001

01-029-007

11005

36102

01-111-009

01-111-008

11005

PART NO.

MTDC-HXNT

MTDC-BRLR

MTDC-TBLW

MTDC-LN516

MTDC-EVBLT

MTDC-11013

MTDC-RALS

MTDC-GBC

MTDC-CB68

MTDC-11005

MTDC-HXNT

MTDC-BS34

MTDC-BS12

MTDC-11005

QTY.

1

2

1

2

1

1

2

1

1

4

4

2

1

2

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

1/4 - 20 UNC Tuerca hexagonal

Mampara de protección, cubierta de la cadena

Reductor, tapa

Motor DC (1 hp) (PEL-400)

Soldadura del soporte, ajuste de tensión

1/2 x 13 UNC Tuerca hexagonal

Soporte de la base del motor

Cadena RC-41 (MT-2436)

Eje

Bateria (con caja)

Rueda rigida 5" x 2"

Rueda giratoria 5" x 2"

Freno del piso

Hand Control with Coil Cord

Circuit Breaker (not shown)

36102

21-024-020

20-141-002

21-641-001

21-516-005

36109

21-016-064

21-042-001

21-026-005

21-139-002

16-132-022

16-132-021

16-132-080

01-022-015

21-146-001

MTDC-HXNT

MTDC-SSCC

MTDC-HCR

MTDC-DCMTR

MTDC-TAWB

MTDC-36109

MTDC-MTRBS

MTDC-CHAIN

MTDC-SFTGR

MTDC-BAT

MTDC-5X2PRC

MTDC-5X2PSC

MTDC-FL

MTDC-HNDCNT

MTDC-CB

2

1

1

1

1

4

1

1

1

2

2

2

1

1

1

14

30

Motor Controller

21-156-003

MTDC-MTRCONT

1

Page 15

Guia de Referencia Rápida para Problemas

para Mesa de Poste Mecánia Eléctrica

(Par más información contacte a la fábrica)

AVISO! ANTES DE TRABAJAR EN LA UNIDAD SIEMPRE DESCARGUE LA UNIDAD E

Observación Causa Posible Remedio

1.) La unidad no funciona cuando el control

manual es usado.

INSTALLE LAS BARRAS DE MANTENIMIENTO DE SEGURIDAD

a. El voltaje de la batería es bajo.

b. Male conexión de los alambres/circuito

eléctrico roto.

a. Cargue la batería.

b. Inspeccione los alambres visualmente,

compruebe con el contador. Refierase al

diagrama eléctrico.

2.) El motor hace ruido, la plataforma

no se mueve.

3.) La unidad se apaga antes de alcanzar la

posición elevada o de descenso.

c. Problemas con el motor/control.

a. Cadena/el enlace principal está roto.

b. Obstrucción/cadena obstruida.

a. Voltaje de la batería es bajo.

b. El perno de la rueda de la plataforma está

obstruido o doblado.

c. El interruptor de límite de "plataforma

elevada" se pone en marcha demasiado

rápido, o esta roto.

d. El alambre interior del cable de control

está roto.

e. La plataforma está sobreacargada.

DIAGRAMA ELÉCTRICO

c. Consulte con la fábrica.

a. Inspeccione y reemplace si es necesario.

b. Inspeccione la cadena, ruedas,

engranajes, y el ensamble de la polea.

a. Cargue la batería.

b. Inspeccione el engranaje por

interferencias o daños.

c. Ajuste el muelle de la polea de tensión

del interruptor de limite: compruebe con un

contador.

d. Gire el control mientras se aprieta el

botón. Si la unidad functiona

intermitentmente, cambie el control.

e. Check load; reduce if neccessary.

E

S

P

A

N

O

L

15

Page 16

INSTRUCCIONES DE USO DEL CARGADOR DE LA BATERIA

Carador de Bateria Estilo Banco

(Para models DC Equipados con nuestro cargador de bateria estilo banco)

AVISO!

El trabajar con o cerca de baterias de ácido es peligroso.

Las baterias continene ácido sulfurico y producen gases

explosivos. Una explosión de la baterias podria resultar en la

perdida de la vista o en quemaduras serias.

No fume o permita que una chispa o una llama este cerca

de las baterias. Carge las baterias en lugares limpios, secos

y bien ventilados. No ponga herramientas o algo metálico

encima de la bateîa. Todas loas reparaciones de la bateria

deben de ser hechas por personal calificado y con experiencia.

Cuando se trabaje con baterias, quitese todos los articulos

personales como anillos, pulseras, collares y relojes. La

bateria puedde producir tal voltage que las joyas se adhieran

al metal causando quemaduras severas.

Siempre tenga abundante agua fresca y jobón cerca en

caso de que el ácido de la bateria torque la piel, ropa o los

ojos.

INSTRUCCIONES DE USO

Aunque usted no haya comprada el cargador de bateria

opcional, su nuevo Mesa de Poste Eléctrica DC tiene un

enchufe que conecta directamente al cargador de banco.

Contacte a su distribuidor si desea comprar un cargador de

bateria.

QUE HACER Y QUE NO HACER

NO deje el cargador conectado durante un tiempo indefinido.

NO fume, encienda una llama o cause chispas cerca de la

bateria cuando se está cargado.

ASEGURESE de que las conexiones de la bateria estan

limpias.

NO exponga a la lluvia o a condiciones adversas.

REEMPLACE cordones defectivos y alambres imediatamente

PONGA el cargador como minimo a 24" por encima del piso

cuando se este cargando.

NO sobrecarge la bateria (solo en la posición manual).

Si se opera la bateria con poco voltage podria causar que

el motor fallase prematuramente.

16

Loading...

Loading...