Page 1

INSTRUCTION MANUAL

POSITIVE LOCKING PLATE CLAMP

MODEL LPC (20, 40, & 60)

MODEL NO. ________________________

SERIAL NO. ________________________

VESTIL MANUFACTURING CORP.

2999 NORTH WAYNE STREET, P.O. BOX 507, ANGOLA, IN 46703

TELEPHONE: (260) 665-7586 -OR- TOLL FREE (800) 348-0868

FAX: (260) 665-1339

URL: WWW.VESTILMFG.COM EMAIL: SALES@VESTIL.COM

Page 2

We produce several models of positive locking plate clamp so that our customers may

select a product that satisfies specific requirements. Each unit conforms to the generalized

specifications disclosed in this manual and fulfills our demanding standards for quality,

safety and durability.

SAFETY PRINCIPLES

Vestil Manufacturing Corp. recognizes the critical importance of workplace safety. Each

person who might participate in the assembly, use, operation, or maintenance of the

product must read this manual. Read the entire manual and fully understand the

directions BEFORE using or maintaining the clamp. If you do not understand an

instruction, contact Vestil for clarification. Failure to adhere to the directions in this

manual might lead to serious personal injury or even death.

Vestil is not liable for any injury or property damage that occurs as a consequence of

failing to apply the safe operation and maintenance procedures explained in this manual or

that appear on labels affixed to the product. Failure to exercise good judgment and

common sense may result in property damage, serious personal injury, or death, and are

not the responsibility of Vestil.

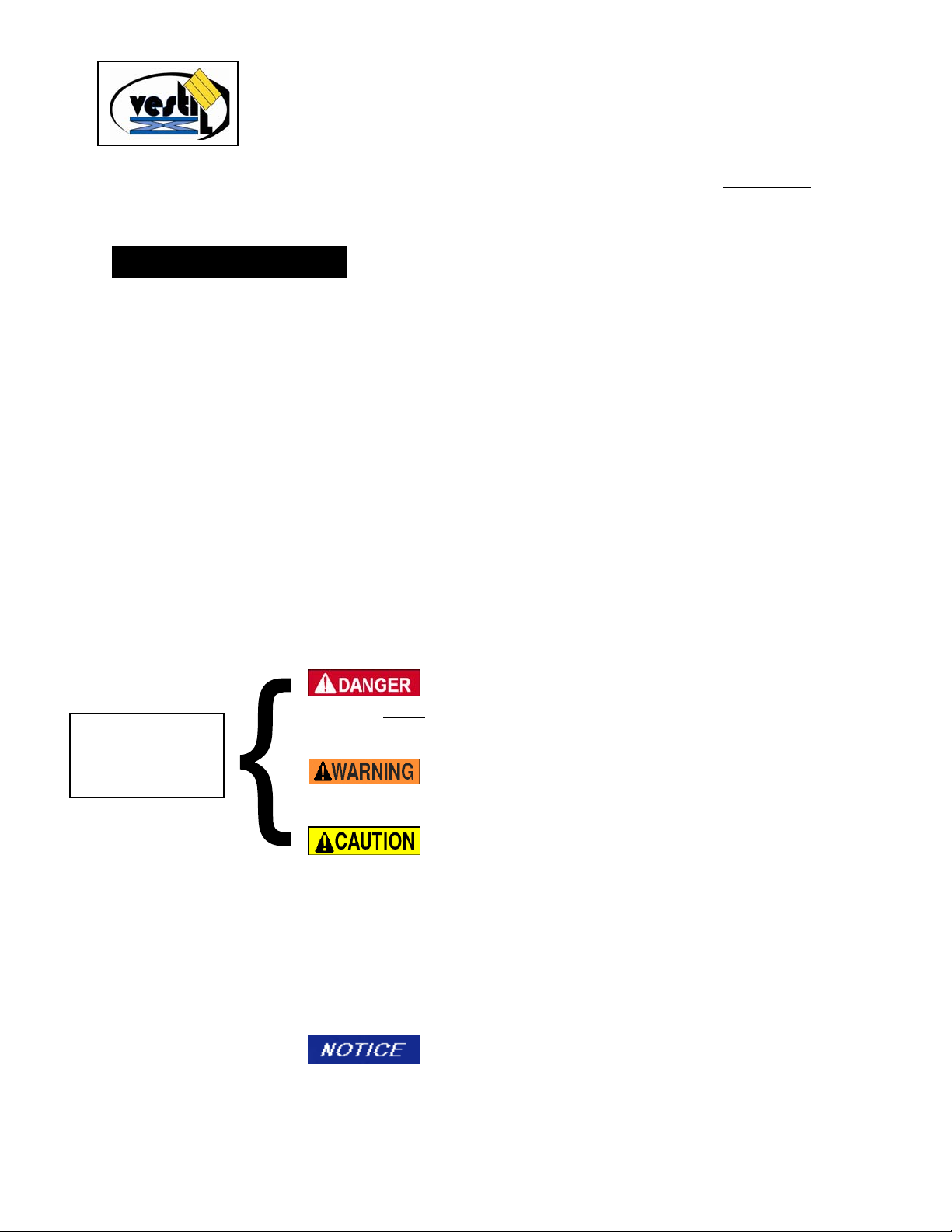

This manual applies the hazard identification methods suggested for instruction manuals

by the American National Standards Institute (ANSI) in ANSI standard Z535.6-2006. In

accordance with ANSI guidelines for hazard warning language, this manual identifies

personal injury risks and situations that could lead to property damage with SIGNAL

WORDS. These signal words announce an associated safety message. The reader must

understand that the signal word chosen to identify a particular safety hazard categorizes the

seriousness of that hazard according to the following convention:

These symbols

identify hazards

that may result in

personal injury

Identifies a hazardous situation which, if not

avoided, WILL

result in DEATH or SERIOUS INJURY. Use of

this signal word is limited to the most extreme situations.

Identifies a hazardous situation which, if not

avoided, COULD result in DEATH or SERIOUS INJURY.

Indicates a hazardous situation which, if not

avoided, COULD result in MINOR or MODERATE injury.

Although Z535.6-2006 approves the use of “CAUTION” without an

accompanying safety alert symbol (black equilateral triangle with

yellow exclamation point) as an alternative to “NOTICE”, this

manual differentiates between hazards that pose a risk of

personal injury and those that create mere property damage

situations. CAUTION appears exclusively in conjunction with

the safety alert symbol to identify injury risks.

Identifies practices not related to personal injury,

such as operation that could damage the clamp. No safety alert

symbol (equilateral triangle enclosing an exclamation point)

accompanies this signal word.

- 2 -

Page 3

TABLE OF CONTENTS

Safety Principles 2

Product Introduction 4

Safety Guidelines 5

Use Instructions 7-10

Maintenance & Inspections 11-12

TABLE OF FIGURES

FIG. 1: Parts Diagram 6

FIG. 2: Label Placement Diagram 12

- 3 -

Page 4

P

RODUCT INTRODUCTION

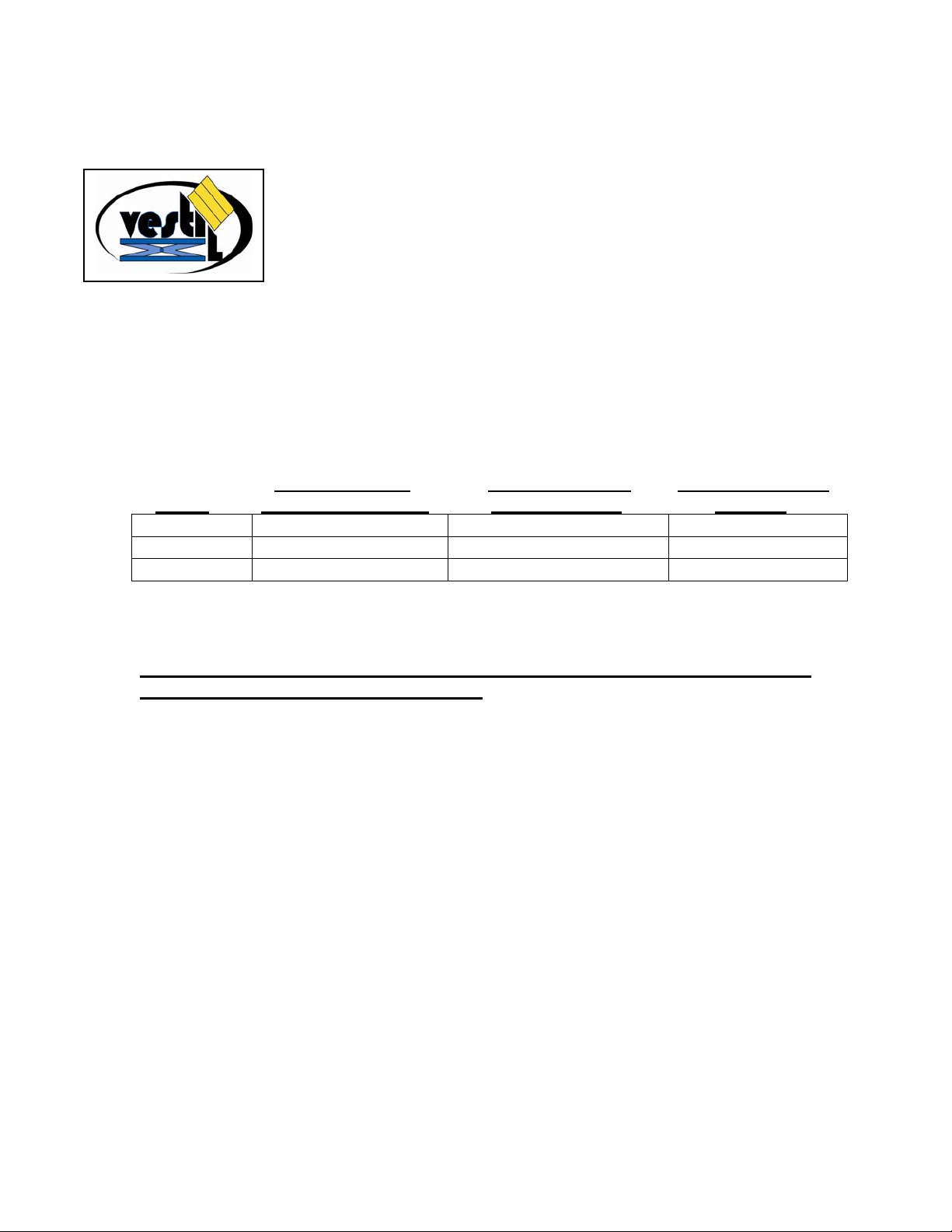

We produce 3 types of clamp, the LPC-20, LPC-40, and the LPC-60. Each

clamp is constructed from steel and has a powder coat finish. All models

incorporate a heavy duty formed shackle for easy use with overhead hoists. The

three models are distinguishable by lifting capacity, maximum thickness of the

sheet material to be lifted, and the bale diameter (point of connection with the

hoist) as indicated in the following table:

Maximum Plate Maximum Rated Shackle Opening

Model Thickness (inches) Load (Pounds) (inches)

LPC-20 0.80 2,000 1.9

LPC-40 1-3/16 4,000 2.2

LPC-60 1-9/16 6,000 1.9

Vestil Manufacturing Corp. created this manual to acquaint owners and

users of our clamps with safe use and maintenance procedures. Employers are

responsible for instructing employees to use the product properly.

Employees and any other persons, who might foreseeably use, install, or

perform maintenance on the clamp, must read and understand every

instruction before using the device. Persons who use the clamp should

have access to the manual at all times, and in particular should consult the

directions before each use. Contact Vestil for answers to any question you

have after reading the entire manual.

Although Vestil strives to identify foreseeable hazardous situations that

could arise during use, this manual cannot address every conceivable danger.

The end-user is responsible for exercising sound judgment at all times.

Thank you for purchasing a Positive Locking Plate Clamp

(“plate clamp” or simply “clamp”) made by Vestil Manufacturing

Corporation (“Vestil”). Our plate clamps are durable, high-quality

products that combine safety features and superior lifting

capabilities. Despite the clamp’s relatively simple mechanics, all

personnel must familiarize themselves with the safe operation

instructions provided in this manual.

- 4 -

Page 5

SAFETY GUIDELINES

Read the entire manual before you use the clamp for the first time and before each subsequent

use. Refer to the manual for safe use and maintenance procedures described on p. 7-12. If

questions remain after you finish reading the manual, contact Vestil for answers. DO NOT attempt

to resolve any problems with the clamp unless you are certain

afterwards. NEVER modify the product in any way without the express, written approval of Vestil.

that it will be safe to use

• Electrocution Risk: DO NOT contact live electrical wires with the clamp or the load!

• Consult the safety messages included in the manuals for your crane, trolley, hoist, and any other device used

in conjunction with the clamp.

• DO NOT open the clamp while lifting or moving mate rial. BEFORE opening the clamp, be certain that the

sheet material is fully supported by the ground or other surface, and is fully immobilized (can’t fall over, roll,

slide, or move in an uncontrolled manner). If a second person is needed to immobilize the material, find

someone to help you. DO NOT open the clamp while using it to lift or move sheet material.

• ALWAYS inspect the plate clamp before each use according to the inspection procedur es described in the

most recent revision of ASME B30.20. B30.20 also recommends “frequent” and “periodic” inspections.

• Properly maintain the plate clamp according to the maintenance procedures on p. 11-12 of the manual.

Vestil developed these procedures to supplement the maintenance practices of ASME B30.20.

• ALWAYS attach the plate clamp to a safety hook (e.g. a hoist that has a safety hook attached to the end of

the chain or rope), or to a connection that includes safety mechanisms to prevent accidental/unintended

detachment from the hoist. DO NOT use the device on a hoist hook that might accidentally/unintentionally

release the clamp. DO NOT connect the clamp to a safety hook that does not function properly or that is

damaged.

• DO NOT grip material that has any debris or surface contamination on it that might affect the quality of the

connection between the clamp and the load. Remove all debris, such as oil, grease, water and dirt, before

gripping the material with the plate clamp.

• Clear all debris, including fluids, from the path of travel if the job requires moving the material to a new

location BEFORE picking up the load. If moisture is present in the path of travel, absorb it before using the

clamp.

• Make sure that no person is in the travel path.

• DO NOT remove or obscure any label. Verify the placement and legibility of all labels as shown in FIG. 2 on

p. 12. If a label is damaged or unreadable, immediately contact Vestil for a replacement. DO NOT use the

clamp UNLESS all labels are securely attached and readable.

• DO NOT attempt an unbalanced lift. Before performing the lift, attach enough clamps to properly balance the

load. (See “Use Instructions,” p. 7-10).

• DO NOT lift a sheet of material from the bottom of a stack. Only lift the top sheet of a stack.

• DO NOT lift a sheet from the side. ONLY attach the clamp to the top edge of a plate.

• DO NOT lift more than 1 sheet at a time.

• DO NOT lift a sheet from a horizontal position. LPC’s are vertical plate clamps, meaning that they should

ONLY be used to lift a plate as shown in the, “Proper Vertical Lift” warning message of Step 3 on p. 7.

• DO NOT sit on or apply any weight/pressure to the material held by the clamp.

• DO NOT attempt to lift material that weighs more than the rated load of the clamp. ALWAYS make sure that

the material weighs no more than the rated load of the clamp.

• DO NOT lift a load higher than necessary. (See “Use Instructions” on p. 7-10).

• DO NOT raise the load over your feet or any other part of your body.

• DO NOT use the clamp to lift material over people or to lift any apparatus that supports people, such as a

work platform. The clamp is designed ONLY to lift sheet material.

• DO NOT get in front of or behind a suspended load while moving it. Always orient yourself so that the load is

visible to you. You are less likely to be injured if the load remains within your sight at all times. Stand to one

side of the load and hold onto the hoist’s safety hook with one hand to stabilize the material as you move it to

the desired location.

• DO NOT leave suspended material unattended. An unattended, suspended load creates a risk of injury to

yourself and others. Always move the load to its desired location, set it down and properly immobilize it, and

then disengage the clamp from the load. Disconnect the clamp from the hoist BEFORE leaving the work

area.

- 5 -

Page 6

FIG. 1

: Exploded Parts Diagram

Part No. Description Quantity

1 Cover Assembly 1

2 Cam 1

3 Heavy Bolt 1

4 Lock Nut 1

5 Connecting Link 2

6 Ring 2

7 Lock Wheel Assembly 1

8 Gripper Pin 2

9 Axis Pin 2

10 Link Pin 1

11 Gripper 1

12 Gripper Pin 1

13 Lock Nut 1

14 Spring Pin 1

15 Shackle 1

16 Spring Pin 1

17 Spring Pin 1

18 Spring Pin 1

19 Spring 1

20 Chain Link 2

21 Lock Ring 1

- 6 -

Page 7

Use Instructions:

The operating instructions in this manual are meant to supplement the operation recommendations of

ASME standard B30.20.

Only trained, designated persons should use the plate clamp. “Designated person” means someone selected by his

or her employer, or by a representative of the employer, as competent to use the plate clamp. Trainees under the

direct supervision of a designated person may use the clamp. Maintenance persons and personnel who perform tests

also may use the plate clamp when necessary for the performance of their employment duties.

Step 1: Perform a proper, “Every Lift” inspection as described in the most recent edition of ASME B30.20, BEFORE

you connect the clamp to a hoisting device. Proceed to the next step ONLY IF the clamp passes the inspection and is

deemed safe to use by designated inspection personnel

: Connect the clamp to the hoisting device. Only connect the clamp to the hoist via a safety hook to prevent

Step 2

accidental detachment from the hoist.

.

Hoist

Safety

Properly

functioning

safety latch

Step 3: Unlock the clamp by pulling the lock ring away from the clamp and rotating the lock wheel

assembly downwards (white arrow in photo 1). Move the trolley to position the clamp above the sheet

material. The sheet must balance when lifted, so position the clamp above the center of the sheet. The

center of the sheet is indicated by a dashed line in photo 2.

DO NOT attempt a horizontal lift; only lift vertically.

Proper

Vertical

Lift

Improper

Horizontal

Lift

• DO NOT push or pull the clamp so that the hoist chain/rope is not vertical. All horizontal adjustments

in the position of the clamp must be accomplished by moving the trolley. This is important because

any deflection of the chain/rope from straight up-and-down will cause the load to swing when lifted. A

swinging load may cause serious personal injuries.

1 2

The gripper (11) must

contact the cam (2). If

they do not, adjust the

position of the gripper

until contact is made.

- 7 -

Page 8

6

p

5

4

Step 4

contacts the back of the clamp mouth (photo 3a). Lock the clamp by pulling the lock ring and rotating the lock

wheel assembly upwards.

: Engage the sheet with the clamp. Press down firmly on the clamp until the top of the sheet material

3a

The top of the sheet

contacts the back of the

mouth (arrow).

clam

3b

Step 5: Test the balance of the material in the clamp. Grasp the hoist hook to stabilize the lift, and raise the

load a few inches off of the ground or other supporting surface (see photo 6 below). The material is

improperly balanced if it slides or hangs lower on one side. If improperly balanced, return the material to the

ground or other supporting surface and immobilize it. Reposition the clamp to improve balanc e by moving the

clamp slightly towards the end that hung lower during the test; then raise the object again to see if it is

balanced. DO NOT proceed to the next step until the load is properly balanced. DO NOT use the clamp if

you cannot achieve a balanced hold; use a different lifting device to raise and move the sheet.

¾ If a single clamp cannot balance the load, use a combination of two or more clamps. For instance, you

could connect a chain adapter to the hoist hook, and attach a plate clamp to each end of the adapter via

safety hooks. This setup is demonstrated in the “Use of 2 or More Clamps” diagram below. Afterwards,

retest the balance of the material according to the process described in Step 5. Raise the material ONLY

after achieving proper balance.

Diagram: Use of 2 or More Clamps

Hoist Chain

with Safety

Hook

Level line

This side of the sheet

material hangs lower

than the other. Return

the material to the

Plate

Clamp

Chain Sling with

Central Islet

and Safety

Hooks at both

ends

Plate

Clamp

ground (or other

Raised a few inches

supporting surface)

and reposition the

clamp by moving it

closer to this end.

Sheet Material

Step 6: Lift the material. To raise the sheet, steady the clamp and load by grasping the hoist hook. [Note:

The photographs demonstrate the procedure as it applies to a lift using a single plate clamp. For

combinations of two or more clamps, grasp the safety hook of the clamp attached to the back end of the sheet

as shown in the diagram next to photograph 8.]

Lift the load to approximately waist height. Continue to grasp the hook. Walk slowly and move the load to a

position above the desired location. Refer to the “Warning” messages and follow the lifting rules below.

Review all “Safety Guidelines” on p.5 and always follow these “Lifting Rules” when using the

clamp:

1. NEVER lift material over yourself or other persons. Inform persons in the area that you are going to use the

clamp and make sure that all persons have cleared the area before lifting and moving material.

- 8 -

Page 9

2. DO NOT press down on the sheet material. Grasp ONLY the hoist hook while raising, lowering or moving

7

8

9

material to a different location. Your grasp will stabilize the load.

3. Always stand at arm’s length to the side of the material and hold onto the safety hook as shown in photo

7. If you must use two clamps to balance the load, grasp the safety hook that connects plate clamp #2 to the

chain adapter. This is demonstrated in the, “Grasp the Safety Hook Attached to the Second Clamp” diagram

below. Make sure that your clothing, feet, and the rest of your body stay out from underneath the load. This

stance allows the operator to exercise some control of the load and optimizes safety.

4. The sheet must remain level during movement. Walk slowly to keep the load level. If the material has to be

removed from a container or be lifted over an obstacle, use a different device if you will not be able to

maintain the safe stance described in Rule 3.

If you use a motorized trolley:

• DO NOT push or pull the clamp or the load. Allow the trolley to provide all movement. Your hold on the

hook is a means ONLY for stabilizing the load.

If you use a manual trolley:

• Grasp the hoist hook with one hand. DO NOT push or pull the sheet. Move the trolley with your hand that

grasps the safety hook. Walk slowly to keep the load level.

Diagram: Grasp the safety hook

Grasp the

attached to the second clamp

hoist

hook to

stabilize

load

Plate

Clamp #2

Chain adapter

with central islet

and safety hooks

at both ends

Plate Clamp #1

Direction of Travel

Step 8: Lower the material. Make sure that the load is not swinging or rotating. Slowly lower the hoist until the

load contacts the ground or other supporting surface. Lower the load sufficiently to create slack in the hoist chain

(or rope). The chain/rope is adequately slacked when the shackle leans to the left or right. The hoist hook and the

shackle should remain in contact (see Photos 10 and 11). DO NOT disconnect the clamp from the load until you

appropriately immobilize the material to prevent it from rolling, falling over, or moving in an uncontrolled manner

.

In the following photographs, the load is light and lacks dangerous projections that could cause injury. It can

easily be controlled by the operator. If you cannot control BOTH the clamp and sheet material without

- 9 -

Page 10

difficulty, find someone to help you. You should always use the procedures developed by your employer for

safely handling material.

10

11

Safety

Hook still

supports

the

Shackle

Shackle leans to the right

Step 9: Disengage the clamp. Pull the latch ring to open the clamp and then rotate the lock wheel assembly

downwards. You may need to rotate the connecting link (5) downwards to loosen the gripper (photo 13b).

Pull the clamp free of the immobilized sheet; then disconnect the clamp from the hoist hook.

12

13a

13b

- 10 -

Page 11

Maintenance and Inspections:

A designated person must verify that the clamp complies with all regulations, codes, and standards that

apply to “Under-the-Hook Lifting Devices” in the location where the clamp is used. The person(s)

designated to conduct inspections by your employer must do so before

time, and EACH

time it is installed for use.

Inspections:

The end-user is responsible for performing inspections as recommended in ASME B30.20.

The standard categorizes inspections based on regularity of performance. Highlights of the

recommended inspection procedures appear below. However, the full procedures written in the

published standard must be followed.

DO NOT use a clamp that is structurally damaged. Structural damage includes, but is

not limited to, bending, warping, cracking or other deformation of one or more of the shackle, gripper,

cam, connecting arm, lock wheel assembly, spring or spring pins, chain or lock ring (see FIG. 1 on p.6).

Restore the clamp to normal operating condition BEFORE using it again.

Inspections Before & During EVERY lift

: visual examination must be performed by the operator prior to

AND during each lift. In particular, the operator should inspect for:

1. Debris on the load surfaces; AND

2. Condition and operation of the controls.

Frequent Inspections

: the specific meaning of “frequent” varies from daily to monthly depending on the

service classification (normal, heavy, severe, and special/infrequent) of the clamp. Definitions of the

service classifications appear in ASME B30.20. The operator or other designated person(s) should

visually inspect the clamp for:

1. Deformation, cracking, or excessive wear of any part of the clamp;

2. Operating mechanisms for conditions that interfere with proper function; AND/OR

3. Loose or missing fasteners, stops or nameplates.

Periodic Inspections

: complete visual inspections performed AND recorded by a qualified person. The

inspection should specifically look for:

1. Loose bolts or fasteners;

2. Excessive wear of friction pads, linkages, and other mechanical parts; AND/OR

3. Excessive wear at the points where the clamp connects to the hoist hook, and load support

clevises or pins.

Maintenance: the end-user

must implement a maintenance program to ensure the proper function and

safety of the clamp. A qualified person may establish a program that is used in preference to the

maintenance procedures described below. However, if you apply the procedure that follows, complete

EVERY step each time

maintenance is performed.

ONLY qualified persons may perform maintenance on the clamp. A qualified person is

someone “who, by possession of a recognized degree in an applicable field or certificate of professional

training, and experience, has successfully demonstrated the ability to solve or resolve problems relating

to the subject matter [beam clamp] and work [use of the beam clamp].” See ASME B30.20-0.2-2003.

: All sources of power must be disconnected, locked out and tagged, “Out of Service.”

Step 1

: Disconnect the clamp from the hoist hook and tag it, “Out of Service.”

Step 2

Step 3

: Perform all adjustments indicated as necessary during any inspection (every lift, frequent, or

periodic).

: If other conditions exist which require new/replacement parts to repair, contact Vestil. Deformity,

Step 4

corrosion, rusting, or excessive wear of structural members warrants immediate replacement.

The reader should understand the significant difference between “Adjustments” and

“Repairs,” and “Modifications”.

¾ An adjustment or repair refers to a simple correction that restores the clamp to normal operating

condition, such as tightening loose fasteners, or removing debris from the surface of the clamp.

(Continued on p. 12)

the clamp is used for the first

- 11 -

Page 12

¾ DO NOT use the clamp if adjustments and/or repairs are incomplete! Return the clamp to service

ONLY after finishing all necessary repairs and adjustments.

¾ A modification is a change that alters the clamp from normal operating condition, like bending the

structural members. NEVER modify the clamp w ithout the express, w ritten approval of Vestil.

Modifications may render the clamp unsafe to use.

: Perform a periodic inspection, as recommended in ASME B30.20.

Step 5

: Make a dated record of the repairs, adjustments and/or replacements made.

Step 6

Markings:

Only use the clamp if ALL labels are readable and undamaged. Contact Vestil for replacement labels.

FIG. 2: Product label placement

Rated Load

Rated Load Tag

- 12 -

Loading...

Loading...