Page 1

VESTIL MANUFACTURING CORPORATION

2999 North Wayne St., Angola, IN 46703

Phone (260) 665-7586 · Fax (260) 665-1339

E-mail: sales@vestil.com · www.vestil.com

Ergonomic Solutions

Contents

Safety Precautions ........................................ 1

Receiving Instructions ...................................1

Warranty ........................................................1

Revised 0507 16-126-104

A company dedicated to solving ergonomic and material

handling problems since 1955

.

OWNER'S

MANUAL

LO-PROFILE DRUM CADDIES

MODELS LO-DC-MR-A, LO-DC-PU-A & LO-DC-CI-A

MODELS LO-DC-MR, LO-DC-PU, LO-DC-CI & LO-DC-PH

Assembly Instructions .................................... 1

Operation ....................................................... 1

Parts List & Drawing ................................2 & 3

SAFETY PRECAUTIONS

Read owner's manual completely before operating unit!

• Never exceed the maximum capacity of 1,000 pounds.

• Never load more than one drum at a time.

• Never load the unit unless you are watching it.

• Stand clear of drum while loading and unloading.

• Drum must be pushed all the way to the back of the

craddle before moving.

• Use caution in moving a loaded unit; avoid obstructions

and floor defects.

• Wear steel-toe shooes when operating.

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected prior

to shipment. However, it is possible that the unit may incur

damage during transit. If damage is noticed when unloading,

make a note of it on the BILL OF LADING. Remove all

packing and strapping material, then inspect the unit again

for damage. IF DAMAGE IS EVIDENT, FILE A CLAIM WITH

THE CARRIER IMMEDIATELY!

WARRANTY

This product is warranted for 90 DAYS from date of

purchase to be free of manufacturing defects in material and

workmanship.

This warranty does not cover normal wear of parts

or damage resulting from any of the following: negligent use

or misuse of the product, use or application contrary to

installation instructions, or disassembly, repair or alteration

by any person prior to authorization from a factory

representative.

ASSEMBLY INSTRUCTIONS

1) Attach casters using hardware included.

2) Bolt wheel assembly to cradle using hardware included.

3) Slide Handle into Wheel Assembly

(Please refer to the next page for the assembly drawing)

OPERATION

1) Align unit in front of drum, remove handle, grip drum with

handle.

2) Tip drum up while guiding the cradle under the drum.

3) Reattach handle and transport drum to desired location.

LO-PROFILE DRUM CADDIES

MODELS LO-DC-MR-A, LO-DC-PU-A

& LO-DC-CI-A

1

Page 2

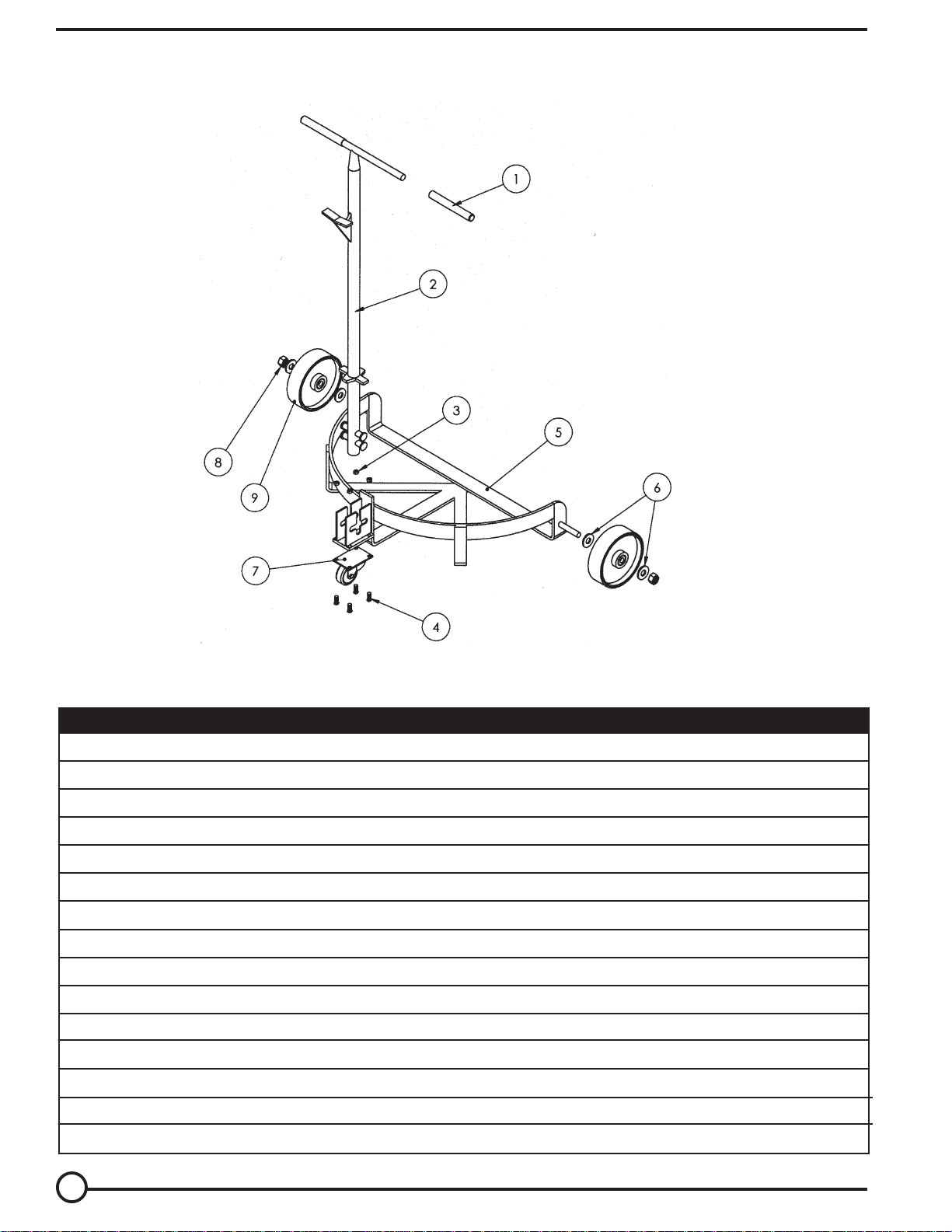

LO-PROFILE DRUM CADDIES • MODELS LO-DC-MR-A, LO-DC-PU-A & LO-DC-CI-A

Assembly & Parts Drawing

PARTS IDENTIFICATION

LO-PROFILE DRUM CADDIES • MODELS LO-DC-MR-A, LO-DC-PU-A & LO-DC-CI-A

KIT NO.

A

A

A

A,B,C,D

B,C,D

A,B,C,D

B,C,D

B,C,D

B,C,D

ITEM NO.

1

2

3

4

5

6

7

8

9

9

9

A

B

C

DESCRIPTION

Handle grip

Handle

Lock Nut, M8-1.25

Bolt, M8 - 1.25 x 20 mm

Craddle Assembly

Washer, 13mm ID x 35mm OD x 2mm

Rear Caster (1-3/8" x 3")

Lock Nut, M12-1.75

Mold-on-Rubber Wheel (2" x 6")

Cast Iron Wheel (2" x 6")

Poly-on-Steel Wheel (2" x 6")

Hardware Kit (includes 1,3,4,6,8)

Mold-on-Rubber Wheel Kit (includes 6A-9B)

Cast Iron Wheel Kit (includes 6A-9C)

ENGINEER NO.

16-025-007

16-025-026

N/A

N/A

16-538-003

N/A

16-514-097

N/A

16-132-058

16-132-161

16-132-162

16-154-024

16-154-021

16-154-022

QTY.

2

1

4

4

1

4

2

2

2

2

2

1

1

1

D

Poly-on-Steel Wheel Kit (includes 6A-9D)

16-154-023

1

2

Page 3

LO-PROFILE DRUM CADDIES • MODELS LO-DC-MR, LO-DC-PU, LO-DC-CI & LO-DC-PH

Assembly & Parts Drawing

PARTS IDENTIFICATION

LO-PROFILE DRUM CADDIES • MODELS LO-DC-MR, LO-DC-PU, LO-DC-CI & LO-DC-PH

KIT NO.

A

A

A

A,B,C,D

B,C,D

A,B,C,D

B,C,D

B,C,D

B,C,D

B,C,D

ITEM NO.

1

2

3

4

5

6

7

8

9

9

9

9

A

B

DESCRIPTION

Handle grip

Handle

Lock Nut, M8-1.25

Bolt, M8 - 1.25 x 20 mm

Craddle Assembly

Washer, 14mm ID x 37mm OD x 3mm

Rear Caster (1-1/4" x 3")

Lock Nut, M12-1.75

Mold-on-Rubber Wheel (1-1/2" x 6")

Cast Iron Wheel (1-1/2" x 6")

Poly-on-Steel Wheel (1-1/2" x 6")

Phenolic Wheel (1-1/2" x 6")

Hardware Kit (includes 1,3,4,6,8)

Mold-on-Rubber Wheel Kit (includes 6A-9B)

ENGINEER NO.

16-025-007

16-025-026

N/A

N/A

16-538-003

N/A

16-514-097

N/A

16-132-058

16-132-161

16-132-162

16-132-817

16-154-024

16-154-021

QTY.

2

1

4

4

1

4

2

2

2

2

2

2

1

1

C

D

E

Cast Iron Wheel Kit (includes 6A-9C)

Poly-on-Steel Wheel Kit (includes 6A-9D)

Phenolic Wheel Kit (includes 6A-9E)

16-154-022

16-154-023

16-154-026

1

1

1

3

Page 4

Material Handling Problem Solvers

Scissor Lift Table

Pallet Server

XII

I

XI

High Rise Lift

Mobile Lift & Tilt

Work Stand

X

equals greater profitability,

cost minimization and worker

IX

with your production and

Time is money.

Increased productivity

compatibility. Ergonomic

products will assist you

safety goals.

VIII

VII

VI

II

III

VI

V

Drum Carrier/Rotator

Ground Lift Tilter

Copyright 2007 VESTIL MANUFACTURING CORPORATION

4

Loading...

Loading...