Page 1

Vestil Manufacturing Corporation

2999 North Wayne St., Angola, IN 46703

Ph 260-665-7586 • Fax: 260-665-1339

E-mail: sales@vestil.com • www.vestil.com

Fork Truck Attachments

Revised 11-07 08-005-143

A company dedicated to solving ergonomic and material

handling problems since 1955

.

OWNER'S

MANUAL

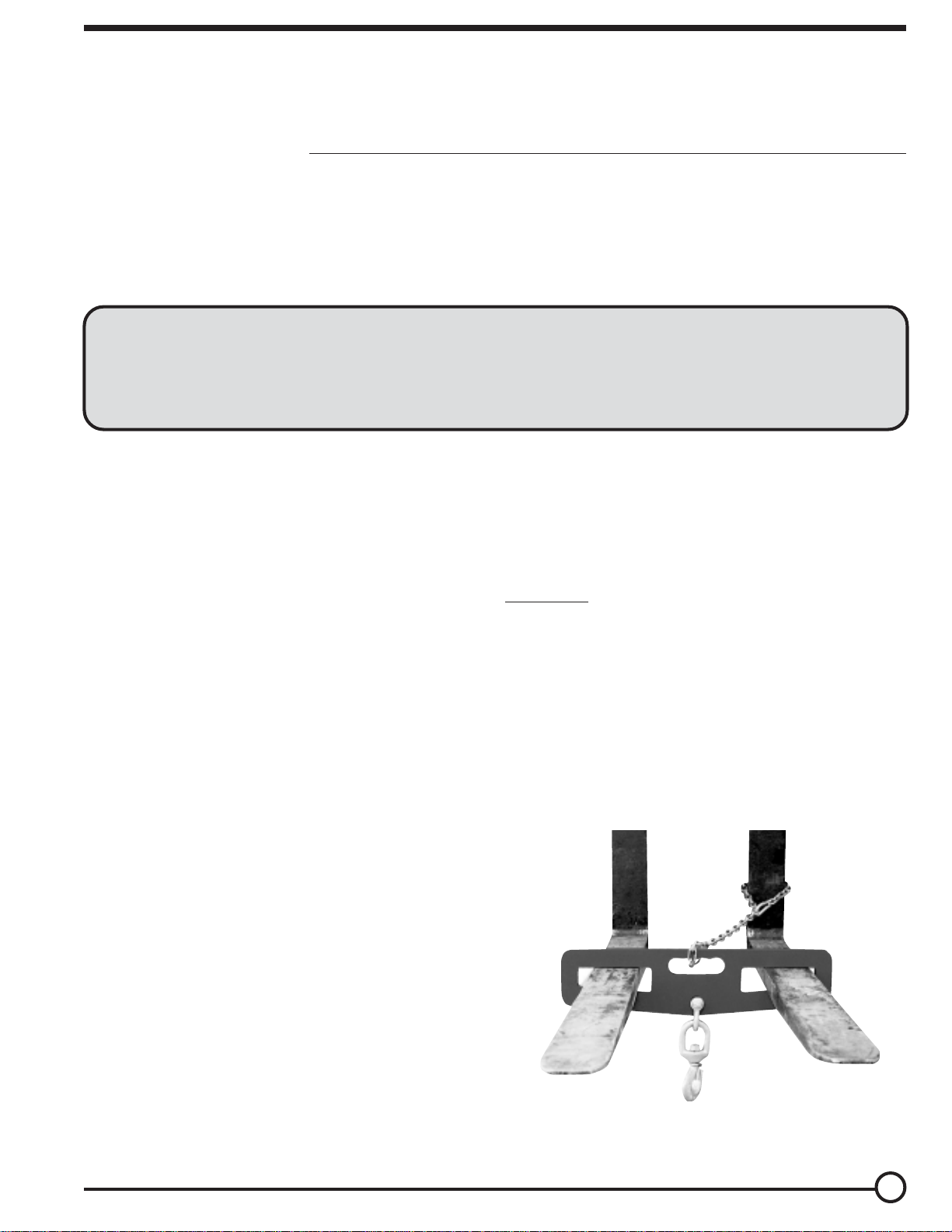

HOISTING HOOK • MODEL LM-HP-4/6

CONTENTS

Warning & Safety Instructions ................................ 1

Replacement Parts ................................................ 1

Receiving Instructions ............................................ 1

WARNINGS & SAFETY INSTRUCTIONS

Ensure that all employees understand and follow the

following.

• Read and understand the owner’s manual before using

or servicing the hoisting hook.

• Ensure that all safety and warning labels stay in place

and are legible.

• Do not use the hoisting hook if any damage is

observed.

• Always watch the load and the hook carefully when the

hoisting hook is in operation.

• The lifting rigging must be fully retained within the

hook’s safety latch before lifting any load off the

ground.

• Make certain that the load is properly slung and

balanced under the hook before lifting with the hoisting

hook.

• Do not perform modifications to any part of the hoisting

hook. Doing so could cause failure, and will void the

warranty.

• Maintenance and repairs are to be done only by

personnel qualified to perform the required work.

• Do not use the hoisting hook to pull loads horizontally.

• Always secure the hoisting hook to the fork truck mast

with the safety securing strap before connecting to a

load.

• Consult the fork truck’s manufacturer for ratings prior to

using.

REPLACEMENT PARTS

We take pride in using quality parts on the equipment

we manufacture. We are not responsible for equipment

problems resulting from the use of unapproved

replacement parts.

To order replacement or spare parts for this equipment,

contact the factory.

In any communication with the factory please be

prepared to provide the machine’s serial number, which is

indicated on the machine dataplate.

Routine Maintenance & Safety Checks .................. 2

Exploded Parts Drawing & BOM ............................. 2

Operation Instructions ............................................. 3

Safety Label Identification & Warranty .................... 4

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected prior to

shipment. However, it is possible that the unit could incur

damage during transit.

Inspect the unit closely when it arrives.

evidence of damage or rough handling to either the

packaging or to the product when it is being unloaded,

immediately make a note of it on the bill of lading!

It is important that you remove the product’s packaging

upon its arrival to ensure that there is no concealed

damage or to enable a timely claim with the carrier for

freight damage.

Also verify that the product and its specifications are as

ordered.

If you see

LM-HP

1

E

N

G

L

I

S

H

E

S

P

A

N

O

L

F

R

A

N

Ç

A

I

S

Page 2

ROUTINE MAINTENANCE & SAFETY CHECKS

MODELS -S (with Swivel Hook) AND -R (with Rigid Hook)

(A) Before each use inspect for the following:

1. Visible damage to the main body, the lifting hook, or the clevis.

2. Proper operation of the load hook’s safety latch.

3. Excessive play in the load hook swivel (-S models only).

4. The clevis bolt screws in easily.

5. Apparent damage or fatigue to the safety strap (used to secure the LM-HP to

the fork truck mast), or to the safety latch at the end of the strap.

(B) Closely inspect each month for:

1. Structural damage, deformation, or cracks to the body of the LM-HP.

2. Signs of fatigue, cracks, or deformation to the clevis, the clevis attachment

point, or the load hook.

3. Proper operation of, and no damage to, the safety latch on the load hook.

4. Excessive wear or deformation of the clevis or clevis bolt.

5. Signs of excessive wear or damage to any part of the safety strap, including

the strap hook’s safety latch.

6. Legibility of all the information, safety, and warning markings.

(C) Yearly inspection

If possible, load the LM-HP to full rated capacity. Carefully observe

the hook (and swivel on -S models) for looseness and for deflection of

any of the hoisting hook’s parts. After the load is removed, closely inspect all

parts and surfaces for fatigue and deformation.

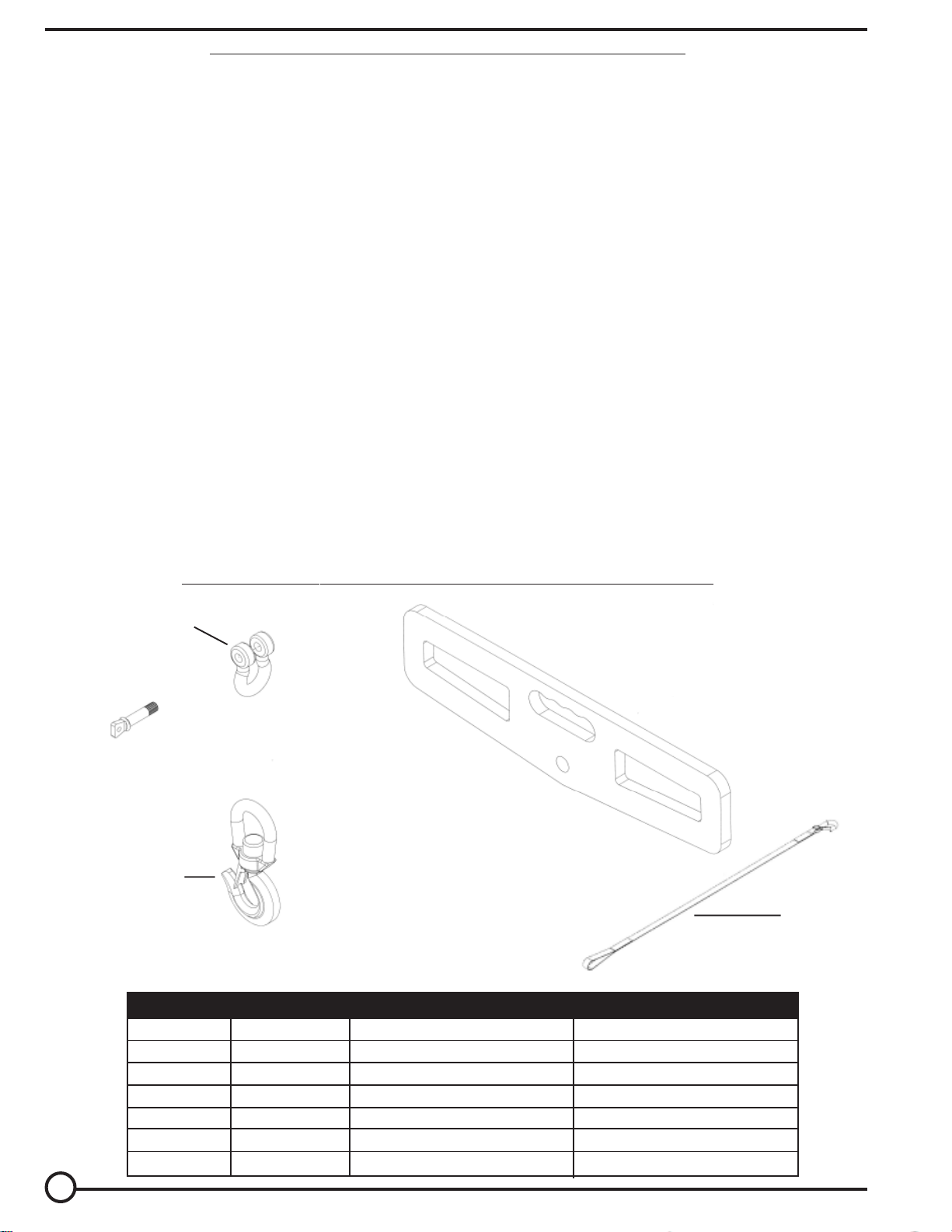

EXPLODED PARTS VIEW AND BILL OF MATERIALS

2

3

1

Item:

1

2A

2B

3A

3B

3C

3D

2

Qty:

1

1

1

1

1

1

1

Part No:

LMHP-STRAP

LMHP-SHKL4

LMHP-SHKL6

LMHP-CLHOOK4-S

LMHP-CLHOOK6-S

LMHP-CLHOOK4-R

LMHP-CLHOOK6-R

Description:

Strap & Hook

Shackle (4K cap.)

Shackle (6K cap.)

Clevis Hook (4K swivel)

Clevis Hook (6K swivel)

Clevis Hook (4K rigid)

Clevis Hook (6K rigid)

Page 3

OPERATION INSTRUCTIONS

¨ Ensure that all employees involved in the operation of this hoisting hook

understand and follow these instructions!

The LM-HP fork-mounted plate hook is intended to be used to lift and transport stable, hanging loads, up to its

rated capacity, from a properly-rated fork truck’s fork. The rating of the required fork truck, and the position of the

hoisting hook on the fork truck’s fork, will depend on the center of gravity of the load and the height to which the load

will need to be lifted. Consult the fork truck manufacturer for a fork truck’s rating.

Note:

OSHA 29CFR, Chapter XVII, Part 1910.178 (a)(4) states, “Modifications and additions which affect capacity

and safe operation (of a fork truck) shall not be performed by the customer or user without manufacturer’s prior

written approval. Capacity, operation, and maintenance instruction plates, tags, or decals shall be changed

accordingly. And 1910.178 (a)(5) states that “If (a fork) truck is equipped with front-end attachments other than

factory installed attachments, the user shall request that the truck be marked to identify the attachments and show

the approximate weight of the truck and attachment combination at maximum elevation with load laterally centered.”

• Consult ASME B30.10-2005 “Safety standards for Hoists, Hooks, and Slings” for further information regarding

safety, testing and maintenance of hoisting hooks.

Attaching the LM-HP to a fork truck:

Slide the hoisting hook plate onto the fork truck’s fork to the desired point. Secure the hoisting hook to the fork truck’s

mast by wrapping the hoisting hook’s securing strap around a vertical member of the fork carriage and fasten the

strap’s snap hook back onto the strap.

Loading:

The load rating, in pounds and kilograms, is shown on the top of the hoisting hook. It indicates the static capacity of

the hoisting hook plate.

•

Warning:

•

Warning:

personnel could result from exceeding the listed capacity.

•

Warning:

plate. Swinging suspended loads can injure personnel and damage equipment.

•

Caution:

center-of-gravity of the load.

Operation:

Before using the hoisting hook, review all of the sections included in this manual!

•

•

Warning:

mast. The strap hook’s safety latch must be closed around the strap.

Tilt the fork truck’s mast back before attaching a load to the hoisting hook.

Use an appropriate lifting chain, nylon strap, or choker to connect the load to the hoisting hook.

Alert personnel in the area to stand at a safe distance from the load before attempting to lift or lower a load.

Lift the load slowly.

Watch the rigging and the load carefully for slippage or uneven lifting. If necessary, lower the load and adjust the

rigging to ensure the load will remain stable while hanging from the hook plate.

Keep loads as close to the ground as possible and do not exceed a travel rate of two feet/second when loads are

being transported. Accelerate and decelerate slowly to minimize load swing.

Avoid bumps, potholes, and inclined surfaces when transporting a load.

When loads are lowered into place, be certain that the load is stable and well-supported before attempting to remove

the rigging.

•

Warning:

rated lifting chains, nylon straps, chokers, and connecting hardware when lifting loads.

•

Warning:

plate. Be certain no part of any person or object is under or near any part of the load.

•

Caution:

•

Caution:

•

Caution:

Notify your supervisor or maintenance personnel if you notice anything out of the ordinary.

Ensure that all information, safety, and warning markings are legible.

Do not attempt to use the hook plate in any pulling application.

Do not exceed the hook plate’s load rating. Permanent damage to the hoisting hook or injury to

Caution must be exercised when determining the best method by which to hang a load from the hook

Consult the fork truck owner’s manual for the forklift’s capacity at the intended vertical and horizontal

Consult ANSI / ASME B56.1-2000, “Safety Standard For Low Lift And High Lift Fork Trucks,” for further

information regarding procedures to be used when operating a fork truck with a hoisting hook attached.

Do not attempt to use the hoisting hook without the safety strap securely attached to the fork truck’s

Improper rigging practices could result in injury to personnel or damage to property. Use only properly-

All personnel must maintain a safe distance from loads whenever they are suspended from the hook

Use the hoisting hook only on a smooth, level, finished surface. Avoid sudden stops or quick turns.

Always carefully watch the hook and any load hanging from it when it is in use.

Never use the hoisting hook if any damage is observed or if it is in need of repairs.

E

N

G

L

I

S

H

3

Page 4

WARNING LABEL IDENTIFICATION

MAKE SURE ALL WARNING LABELS ARE IN PLACE!

90-DAY LIMITED WARRANTY

The manufacturer warrants for the original purchaser against defects in materials and workmanship under normal use

one 90 days after the date of shipment. Any part that is determined by the manufacturer to be defective in material or

workmanship and returned to the factory, shipping costs prepaid, will be, as the exclusive remedy, repaired or replaced

at our option. Labor costs for warranty repairs and/or modifications are not covered unless done at manufacturer’s

facilities or pre-approved in advance by the manufacturer. Any modifications performed without written approval of the

manufacturer may void warranty. This limited warranty gives purchaser specific legal rights which vary from state to

state.

All specifications are subject to change without notice.

LIMITATION OF LIABILITY

To the extent allowable under applicable law, the manufacturer’s liability for consequential and incidental damages is

expressly disclaimed. The manufacturer’s liability in any event is limited to, and shall not exceed, the purchase price

paid. Misuse or modification may void warranty.

Warranty does not cover labor or consequential damages including, but not limited to, business interruption costs, lost

profits, or lost business opportunities.

WARRANTY DISCLAIMER

The manufacturer has made a diligent effort to accurately illustrate and describe their products. However, such

illustrations and descriptions are for the sole purpose of identification, and do note express or imply a warranty that the

products are merchantable or fit for a particular purpose, or that the products will necessarily conform to the

illustrations or descriptions.

The provisions of the warranty shall be construed and enforced in accordance with the Uniform Commercial Code and

laws as enacted in the State of Indiana.

DISPOSITION

Our company will make a good faith effort for prompt correction or other adjustment with respect to any product that

proves to be defective within the Limited Warranty Period. Warranty claims must be made within the stated warranty

period.

4

Copyright 2007 VESTIL MANUFACTURING CORPORATION

Loading...

Loading...