Page 1

01/06 42-126-120

O

VESTIL MANUFACTURING CORP.

2999 N. Wayne St., Angola, IN 46703

Ph: 260-665-7586 · Fax: 260- 6 65-1339

E-mail: sales@vestil.com · Website: www.vestil.com

MODEL LLW-PAILD-200

Serial number ____________

Operation Instructions ……………………….……….. 2

Safety Label Identification ............................................ 3

Routine Maintenance & Safety Checks ….…………… 4

Structural Parts BOM ..................................…….……. 4

IMPORTANT NOTES, WARNINGS AND SAFETY INSTRUCTIONS

Ensure that all employees understand and follow the following.

* Failure to read and understand this owner’s manual before using or

servicing the pail dumper constitutes a misuse of the product. All

persons who will use or care for this product must be familiar with this

material.

o The pail carrier must be fully lowered before any work is performed on

the pail dumper.

o Ensure that all information/safety/warning labels stay in place and are

legible.

o Do not use the pail dumper if any damage or unusual noise is observed.

o Always watch the pail and the pail carrier carefully when transporting or

dumping material.

o The pail dumper is intended for use only on compacted, improved surfaces.

♦ Do not perform any modifications to the pail dumper without the

manufacturer’s approval. Failure to receive authorization for changes to

the equipment could void the warranty.

♦ Maintenance and repairs are to be done only by personnel qualified to

perform the required work. Consideration will not be given for warranty

repair charges without prior written authorization by the manufacturer.

Structural Parts Drawing …..............................……...... 5

Troubleshooting …………………………....………….. 6

Warranty …………………………………….……..….. 6

WNER’S

MANUAL

WHEN ORDERING

REPLACEMENT PARTS:

We take pride in using quality

parts on the equipment we

manufacture. We are not

responsible for equipment

problems resulting from the use

of unapproved replacement

parts.

To order replacement or

spare parts for this equipment,

contact the factory.

In any communication with

the factory please be prepared

to provide the machine’s serial

number, which is indicated on

the machine dataplate.

RECEIVING INSTRUCTIONS

It is possible that this product

could incur damage during

transit.

Inspect the unit closely when

it arrives. If you see evidence

of damage or rough handling to

either the packaging or to the

product when it is being

unloaded, immediately

note of it on the Bill Of Lading!

It is important that you

remove the product’s packaging

upon its arrival to ensure that

there is no concealed damage

or to enable a timely claim with

the carrier for freight damage.

Also verify that the product

and its specifications are as

ordered.

make a

ESTIL MFG. CO. 1

V

Page 2

01/06 42-126-120

OPERATION INSTRUCTIONS – LLW-PAILD-200

o Ensure that all employees involved in the operation of this pail dumper understand and follow these instructions!

The standard model pail dumper is suitable for use indoors in most industrial and commercial locations. It is

intended to be used to transport (sealed pails only), lift (up to 52”), and rotate plastic or steel 5-gallon pails containing

stable, relatively free-flowing non-hazardous materials.

Loading:

The load rating, in pounds, is shown on the machine dataplate located on the operator’s side at the top of the left

frame upright. It indicates the net capacity of the pail dumper when used to dump freely-flowing materials.

Warning: Do not exceed the pail dumper’s load rating. Injury to personnel or permanent damage to the pail dumper

could result from exceeding the listed capacity.

Raise or lower the carrier so that its pivot point is positioned at approximately half the height of the pail to be

dumped. Unhook the pail carrier’s saddle strap and move it out of the way so that it does not obstruct the pail from

entering the saddle. Move the dumper up to the pail so that the pail is inside of, and up against, the inside of the

carrier saddle.

Place the pail-securing strap around the front of the pail and fasten it into the slot at the side of the saddle. Use the

saddle strap’s ratchet to cinch it down snugly to the pail.

Caution: Take care to not tighten the strap so much that it crushes the sides of the pail!

Raise the pail slightly from the floor and ensure that it is secure for lifting and rotating. When properly gripped, the

pail should not be able to spin or move within the straddle.

Operation:

Warning: Keep all personnel clear of the machine when it is in operation. Be certain no part of any person or o bject is

under any part of the pail before lowering the carrier.

Warning: Always carefully observe the pail and the material inside it when dumping.

Note: A material’s viscosity should be considered before determin ing the maximum rate at which to dump material

from a pail.

Warning: Take care when moving the pail dumper into final position if the pail’s lid is removed for dumping.

Warning: In moving a pail from one location to another, the pail must be securely closed with a tight-fitting lid,

oriented vertically, and kept as low to floor as possible.

Do not exceed a rate of two feet per second when moving the pail dumper.

Caution: If the pail has a carrying handle and the pail will be rotated more than 100° from vertical, consideration must

be given to any potential problems that might arise from the handle dropping into the flow path of the material coming

out of the drum.

The pail dumper utilizes a hand winch to lift pails to a maximum height of 52” off the floor.

Standing from the operator’s position, the winch handle is to be rotated clockwise to raise the pail carrier, and

counterclockwise to lower it. The winch has a braking mechanism which helps to control the descent of the pail

carrier -- the operator does not need to engage a pawl on the winch in order to lower a load in a controlled manner.

Raise the pail to the required dump height.

To rotate the pail and dump its contents, use the right hand to grip the rotating handle and pull the sprocket-locking

mechanism. Rotate the handle slowly counterclockwise to dump the contents of the pail. The sprocket-locking

mechanism can be released at any time to lock the carrier saddle into an angle setting. (There are nine locking

positions between vertical and 135° forward rotation from vertical.)

To upright the pail, grasp the rotating handle, pull the sprocket-locking mechanism, and rotate the handle clockwise.

To remove the pail from the dumper, orient the pail to the vertical position and lower it until the bottom of the pail

touches the floor. To remove the pail, grasp the ratchet handle and pull the release lever inside the handle as you do

so. Pull outward on the ratchet handle to loosen the saddle strap. Unhook the saddle strap from the slot in the side of

the saddle and remove the pail from inside the saddle.

The pail dumper incorporates design elements of a hand truck, and has two wheels underneath the push handle to

allow it to be easily loaded into a van or truck when it is being transported to another location.

Ensure that all information/safety/warning labels stay in place and are legible.

(Refer to the labels page in this manual.)

ESTIL MFG. CO. 2

V

Page 3

01/06 42-126-120

SAFETY LABEL IDENTIFICATION -- LLW-PAILD-200

* Product safety signs or labels should be periodically inspected and cleaned by the product users as necessary to

maintain good legibility for safe viewing distance -- ANSI 535.4 (10.21). Contact the manufacturer for replacement

labels.

ESTIL MFG. CO. 3

V

Page 4

01/06 42-126-120

ROUTINE MAINTENANCE & SAFETY CHECKS – LLW-PAILD-200

o Warning: Care should be taken to identify all potential hazards and comply with applicable safety procedures

before beginning work.

o Only qualified individuals trained to understand mechanical devices should attempt trou bleshooting and repair of

this equipment

(A) Inspect daily for:

1.) Broken strands, fraying or kinking of the lifting cable.

2.) Damage or structural deformation to the structural members.

3.) Unusual noise or binding, or evidence thereof.

(B) Inspect monthly for:

1.) Worn or damaged lifting cable.

2.) Pivot point wear of the pail carrier.

3.) Pail carrier saddle strap looseness and/or wear.

4.) Integrity of the retaining hardware on all rollers and on all pivot point pins.

5.) Looseness, wear, or damage to the casters’ bearings, mounting hardware, or su rface material.

6.) Unusual noises or movement during operation.

7.) All the information/safety/warning labels being in place and in good condition.

8.) The need to clean off dirt and debris.

B

ILL OF MATERIALS -- LLW-PAILD-220

Item #: Description Part number Qty.

1 Weldment, frame sub-assembly 21-514-005 1

2 Sub-assembly, deck 42-538-004 1

3 Roller, with bushing 21-527-002 2

4 Pulley, with bushing 21-527-001 1

5 Washer, flat, 9/16” ID A/L 4

6 Pin, clevis, ½”Ø x 1¾” long 21-112-003 3

7 Pin, cotter, 1/8” x 1” long A/L 3

8 Wheel, MR-6/2-RB 16-132-058 2

9 Retaining ring, external, for ¾” ID pin 15-117-002 2

10 Washer, flat, ½” ID A/L 4

11 Nut, hex, 3/8”-16 UNC A/L 5

12 HHCS, 3/8”-16 UNC x 1¼” A/L 5

13 Washer, lock, 3/8” ID A/L 5

14 Cable, aircraft, 3/16” A/L 1

15 Thimble, cable, 3/16” A/L 1

16 Anchor, cable A/L 1

17 Stiffener, bar 21-017-016 1

18 Pin, roller, ½”Ø HR x 113/16” long 21-112-002 4

19 Roller, guide (13/8” OD x ½” ID x .35” thick 21-027-003 8

20 Winch (Dutton-Lainson DLB 800) 21-042-002 1

21 Wheel, HR-4/1.25-SLB 16-132-009 2

22 Bolt, hex head, 3/8”-16 UNC x 2½” long A/L 2

23 Nut, hex, nylock, 3/8”-16 UNC A/L 2

ESTIL MFG. CO. 4

V

Page 5

01/06 42-126-120

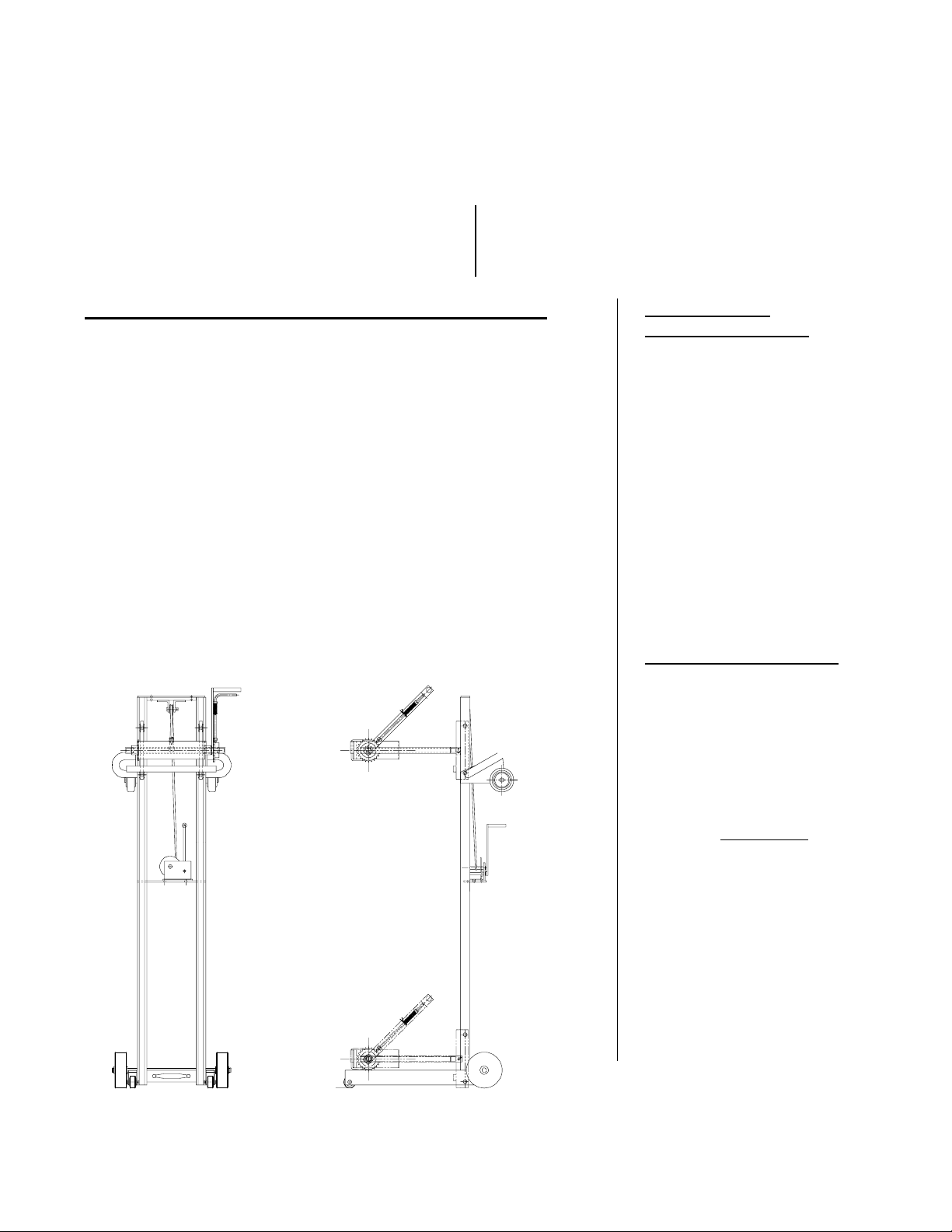

EXPLODED PARTS VIEW -- LLW-PAILD-220

ESTIL MFG. CO. 5

V

Page 6

01/06 42-126-120

TROUBLESHOOTING GUIDE -- LLW-PAILD-200

Warning: Before performing any task, always lower the pail dumper fully to the floor and remove the pail.

Consult the factory for any problems not addressed below.

Problem: Possible cause(s): Action:

The pail carrier will not raise or

is very difficult to raise.

The pail carrier will not lower. Same as the previous two line items, above.

The pail carrier will not rotate. Something has caused the pivot point(s) to

The pail carrier travels the

wrong direction when the

winch handle is turned

clockwise.

The pail carrier’s saddle strap

will not stay tight.

The pail carrier will not lock

into a rotated position.

Too much load in the carrier.

The cable has come off the upper pulley.

One or more guide rollers has seized.

The guide rollers are bound up by an

obstruction in, or damage to, the guide track.

Not enough load on the winch.

Winch is bound up.

seize.

Cable is wound backwards around the winch

drum.

Worn web strap.

Worn or damaged strap ratchet.

Ratchet strap release mechanism is stuck in the

“release” position.

The locking mechanism is stuck in the “release”

position.

Remove some of the pail’s contents.

Rotate the winch crank counterclockwise one

full turn after the carrier is lowered to the

floor. Reinstall the cable into the upper

pulley’s groove. Rotate the winch clockwise

to wind the slack cable back onto the spool.

Lubricate or replace the roller(s).

Inspect for damage to the roller guide track.

Repair or lubricate as necessary.

Same as above.

Lubricate the roller guide track. Pull or push

down on the pail carrier as the crank

handle is turned counterclockwise.

Repair or replace the winch. Consult factory.

Check for corrosion or hardened material

buildup at the carrier saddle’s pivoting

points.

Rotate the crank handle to unspool all the

cable from the winch. Continue rotating

the handle in the same direction until all

the cable slack is taken up on the spool.

Replace the strap and ratchet assembly.

Same as above.

Inspect for and eliminate the cause of the

release mechanism sticking. If damaged,

replace the strap and ratchet.

Inspect the locking mechanism for damage,

bowing, or buildup of material that could

be causing it to stick. Take the

appropriate steps to correct the problem

found.

PRODUCT WARRANTY

90-DAY LIMITED WARRANTY

The manufacturer warrants for the original purchaser against defects in materials and wo rkmanship under normal use

for 90 days after date of shipment. Any part that is determined by the manufacturer to be defective in material or

workmanship and returned to the factory, shipping costs prepaid, will be, as the exclusive remedy, repaired or

replaced at our option. Labor costs for warranty repairs and/or modifications are not covered unless pre-approved by

the manufacturer or done at the manufacturer’s facilities. Any modifications performed without prior written approval

of the manufacturer may void warranty. This limited warranty gives purchaser specific legal rights which vary from

state to state.

All specifications are subject to change without notice.

LIMITATION OF LIABILITY

To the extent allowable under applicable law, the manufacturer’s liability for consequential and incidental damages is

expressly disclaimed. The manufacturer’s liability in any event is limited to, and shall not exceed, the purchase price

paid. Misuse or modification may void warranty.

Warranty does not cover labor or consequential damages including, but not limited to, business interruption costs, lost

profits, or lost business opportunities.

WARRANTY DISCLAIMER

The manufacturer has made a diligent effort to accurately illustrate and describe their products. However, such

illustrations and descriptions are for the sole purpose of identification, and do not express or imply a warranty that the

products are merchantable or fit for a particular purpose, or that the products will necessarily conform to the

illustrations or descriptions.

The provisions of the warranty shall be construed and enforced in accordance with the Uniform Commercial Code and

laws as enacted in the State of Indiana.

DISPOSITION

Our company will make a good faith effort for prompt correction or other adjustment with respect to any product that

proves to be defective within the Limited Warranty Period. Warranty claims must be made in writing within s aid year.

ESTIL MFG. CO. 6

V

Loading...

Loading...