Page 1

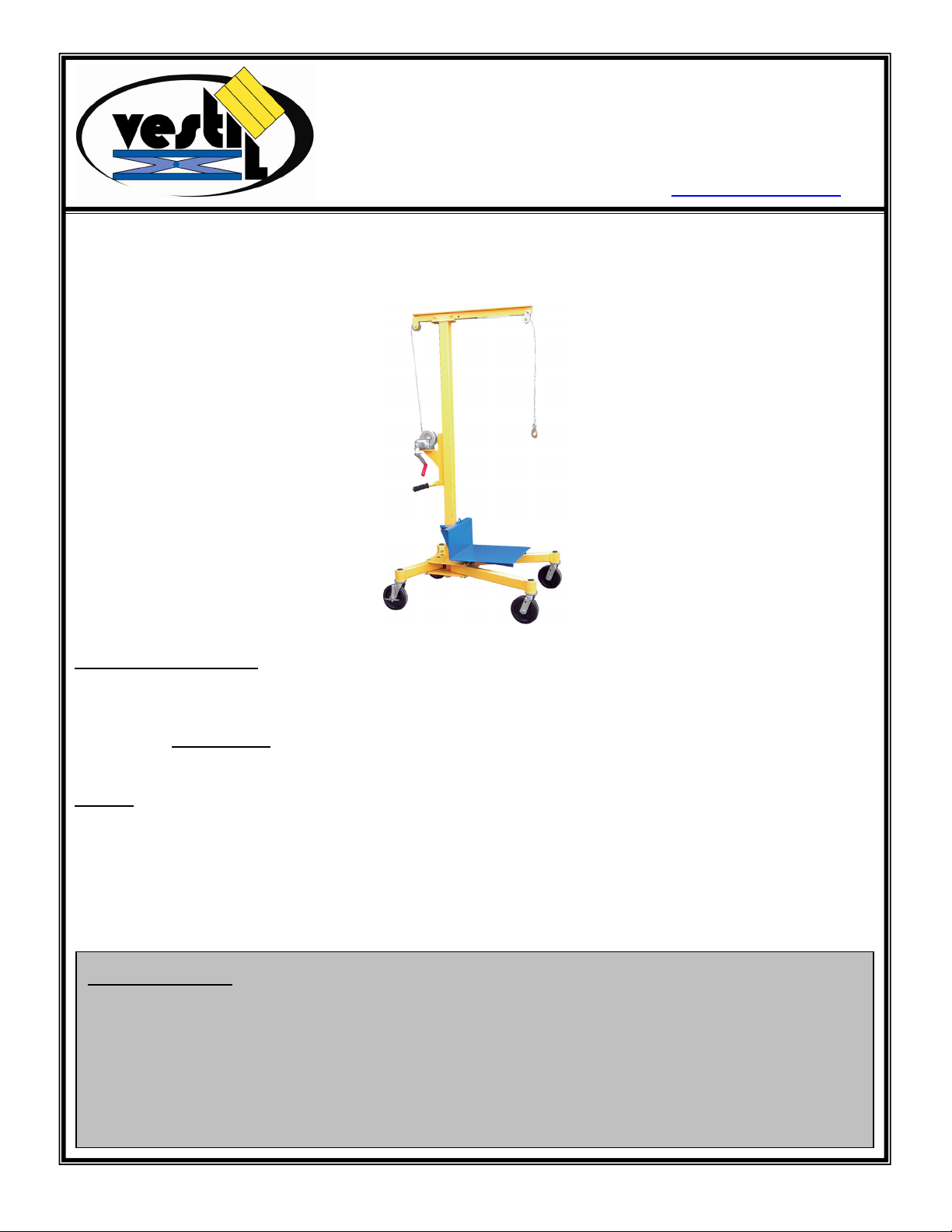

LIFTER-2 PORTABLE WORKSITE LIFT

rev. 2/22/2013 Product manual, operation instructions.doc

VESTIL MANUFACTURING CORP.

2999 North Wayne Street, P.O. Box 507, Angola, IN 46703

Telephone: (260) 665-7586 -or- Toll Free (800) 348-0868

Fax: (260) 665-1339

www.vestilmfg.com e-mail: sales@vestil.com

I

NSTRUCTION MANUAL

Receiving instructions

After delivery, IMMEDIATELY remove the packaging from the product in a manner that preserves the

packaging and maintains the orientation of the product in the packaging; then inspect the product closely

to determine whether it sustained damage during transport. If damage is discovered during the

inspection, immediately

product is undamaged, discard the packaging.

NOTES

:

1) Compliance with laws, regulations, codes, and non-voluntary standards enforced in the location where

the product is used is exclusively the responsibility of the owner/end-user.

2) VESTIL is not liable for any injury or property damage that occurs as a consequence of failing to apply either: a)

the instructions in this manual; or b) information provided on labels affixed to the product.

responsible for any consequential damages sustained as a result of failing to exercise sound judgment

while assembling, installing, using or maintaining this product.

Table of Contents

Hazard identification: explanation of signal words……………………………………………………………………. .. 2

Safety Guidelines…………………………………………………………………………..………………………….…... 2

Assembly and Use Instructions………………..………..……………………………………………………………...... 3

Loading the Lifter………………………………………………………………………………………………………...... 4

Inspections & Maintenance……………………………………………………………………………………………... .. 4

Exploded Parts Diagram and Bill of Materials………………………………………………………………………….. 5

Label placement diagram …………..

Limited warranty………………………………………………………………………………………………………….. . 7

:

record a complete description of the damage on the bill of lading. If the

Neither is Vestil

…………………………………………………………..................................... 6

Copyright 2013 Vestil Manufacturing Corp. Page 1 of 7

Page 2

rev. 2/22/2013 Product manual, operation instructions.doc

HAZARD IDENTIFICATION: explanation of signal words

This manual uses SIGNAL WORDS to indicate the likelihood of personal injuries, as well as the probable

seriousness of those injuries, if the product is misused in the ways described. Other signal words call attention to

uses of the product likely cause property damage.

The signal words used appear below along with the meaning of each word:

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or

SERIOUS INJURY. Use of this signal word is limited to the most extreme

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or

Identifies practices likely to result in product/property damage, such as operation that

Each person who assembles, installs, uses, or maintains this product should read the entire manual and fully

understand the directions in advance. If after reading the manual you do not understand an instruction, ask

your supervisor or employer for clarification, because failure to adhere to the directions in this manual

might result in serious personal injury.

SAFETY GUIDELINES

Vestil diligently strives to identify foreseeable hazards associated with the use of its products. However, material

handling is inherently dangerous and no manual can address every conceivable risk. The end-user ultimately is

responsible for exercising sound judgment at all times.

situations.

SERIOUS INJURY.

MODERATE injury.

might damage the product.

Electrocution might result if any part of the product contacts electrified wires. Reduce the likelihood of

electrocution by applying common sense:

DO NOT contact electrified wires with any part of the lifter or the load, your body, or your clothing.

DO NOT use or store the product where contact with electrified wires is likely.

Always inspect the usage area before using the product & implement precautions that account for conditions.

If this product is used improperly or carelessly, the operator and/or bystanders might sustain serious

personal injuries or even be killed. To reduce the likelihood of injury:

Read this manual in its entirety. Failure to read and understand the entire manual before assembling,

installing, using or servicing the product is a misuse of the product.

Read the manual to refresh your understanding of proper use and maintenance procedures.

DO NOT attempt to resolve any problem(s) with the product unless you are both authorized to do so and certain that it

will be safe to use afterwards.

DO NOT modify the product in any way UNLESS you first obtain written approval from Vestil. Unauthorized

modifications automatically void the Limited Warranty and might make the product unsafe to use.

DO NOT exceed the maximum rated load (see Label 287 on product).

Inspect the product before each use.

A. DO NOT use this product if the inspection reveals structural damage. Examples of structural damage include,

but are not limited to, the following: 1) Cracked, broken or significantly deformed load-bearing members; 2)

cracked welds; 3) corrosion, severe wear, or other condition that affects the ability of the product to support

weight or itself. Replace each part that fails to pass an inspection, and DO NOT use the product until it is fully

restored to normal condition.

B. DO NOT use the product if any unusual noise or movement is observed. If a malfunction occurs, remove the unit

from service and notify your supervisor & maintenance personnel about the issue.

DO NOT use this device UNLESS all product labels (see “Label Placement Diagram”) are readable and undamaged.

BEFORE operating, inspect mast, carriage, forks/deck, cable/chain, wheels, and brakes for damage. DO NOT use if

damaged.

ALWAYS walk travel path before using truck to identify hazards:

DO NOT contact electrical lines or overhead objects with device or load;

DO NOT travel up/down inclines if an alternate route is available;

DO NOT travel over debris.

ONLY travel with forks/deck in lowest position appropriate for conditions.

Cop

yright 2013 Vestil Manufacturing Corp. Page 2 of 7

Page 3

rev. 2/22/2013 Product manual, operation instructions.doc

(continued from p. 2)

ALWAYS center and evenly distribute loads on forks/deck.

ALWAYS secure load to forks/deck.

ONLY drive or operate truck functions from operator position.

DO NOT exceed maximum rated load (capacity).

DO NOT allow people to ride on device.

DO NOT lift loads over people; DO NOT permit people to walk beneath the forks/deck when raised (loaded or

unloaded).

DO NOT leave unattended UNTIL fully lowered AND unloaded.

DO NOT modify device in any way.

Proper use, maintenance, and storage are essential for this product to function properly.

o Always use this product in accordance with the instructions in this manual and consistent with any training relevant

to machines, devices, etc. used in conjunction with this product.

o Keep the product clean & dry. Lubricate moving parts.

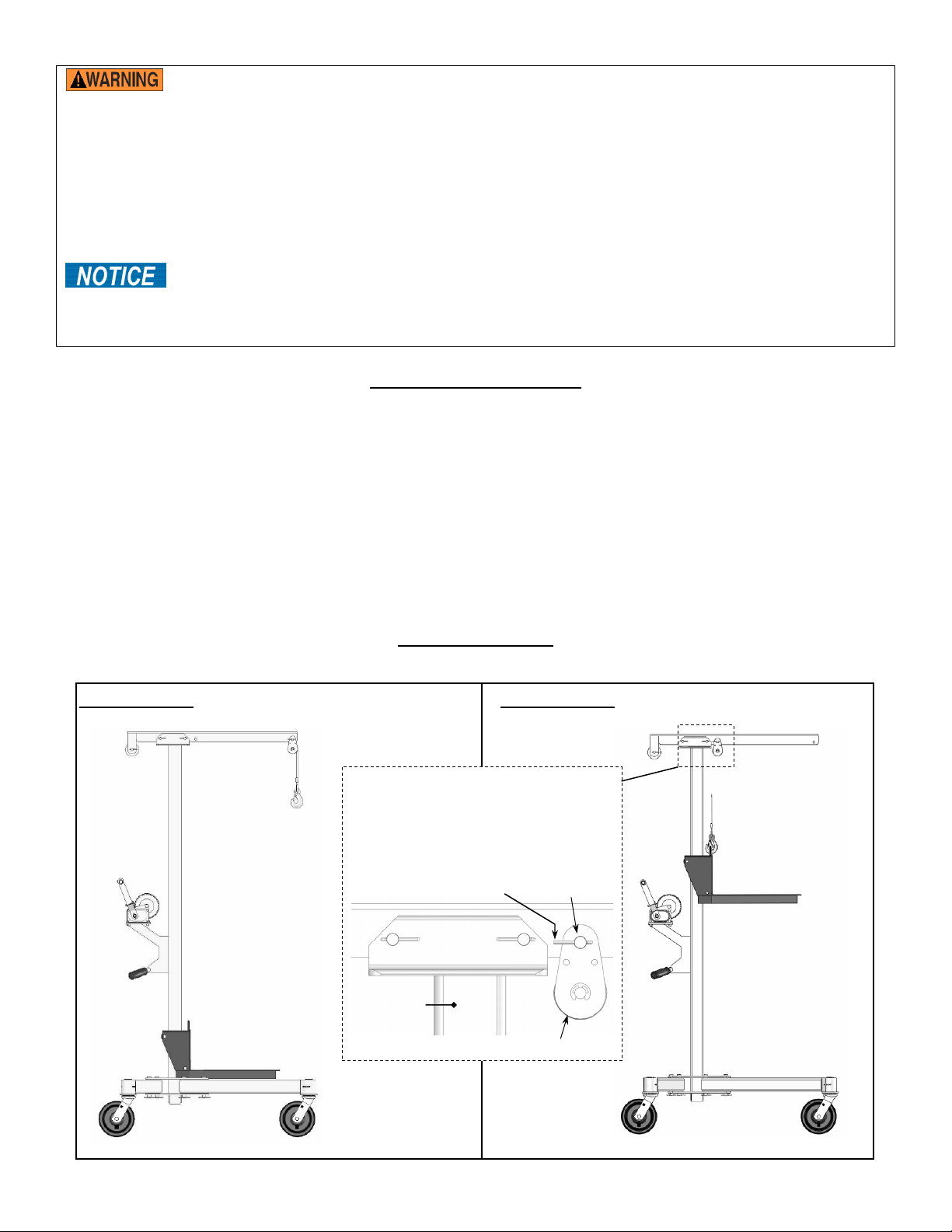

Assembly Instructions

The Lifter-2 ships in fully assembled form. However, the lifter can easily be disassembled. Refer to the exploded parts

diagram and bill of materials on p. 3, and then:

1. Disconnect the hook (on the winch cable) from the deck (5);

2. Remove the upright (2) from the base (1). Loosen the 4-handle bolt (18) and then lift the upright out of the

opening in the base.

3. Unfasten the jib (26) from the upright (2). The jib fastens to the upright by means of two clevis pins (10). Pull

the cotter pins (12) out of the clevis pins; then remove the clevis pins and separate the jib and the upright.

[NOTE: Reinstall the clevis pins in the bracket at the top of the upright and reinstall the clevis pins to prevent

the pins from being lost.]

4. Unpin the legs. Remove the (four) outer clevis pins that fasten the legs (3 & 4) to the base. Each pin is

secured in place with a hitch pin underneath the base. Each leg should still be fastened to the base.

5. Store the disassembled lifter in a location where it will remain dry.

Use Instructions

The lifter has 2 use configurations. In the first configuration, the lifter is a hoisting apparatus with a stationary deck. The

second configuration connects the winch to the deck to allow the lifter to function as a manually-propelled high lift truck.

Configuration #1

resting on base

: Pulley pinned to end of jib with deck

To change the location of the pulley,

pull the cotter pin out of the pulley

clevis pin and remove the pulley clevis

pin; then re-pin the pulley in the

necessary position on the jib.

Cotter pin

Upright

Configuration #2

winch hook attached to deck lifting eye.

Pulley

clevis pin

Pulley

: Pulley pinned to jib above deck with

Cop

yright 2013 Vestil Manufacturing Corp. Page 3 of 7

Page 4

rev. 2/22/2013 Product manual, operation instructions.doc

Loading the lifter

Configuration 1: Attach a load to the hook using proper hoisting practices. Raise the load sufficiently to be able to rest it

on the deck. The load should be stable, centered, and evenly-distributed on the deck.

Configuration 2: Fully lower the deck, if necessary and then set the load on the deck. Be sure to center and evenlydistribute the load on the deck. Transport the load with the deck lowered.

Model Deck dimensions Service range of deck Service range of winch Boom reach Net weight

LIFTER-2

20 in. x 20 in.

51 cm x 51 cm

14¾ in. to 70 in.

37½ cm to 178cm

14¾ in. to 70 in.

37½ in. to 178 cm

25 in.

63½ cm

310 lbs

140.9 kg

Uniform capacity = 500 lbs (227.3 kg)

Deck capacity = 500 lbs (227.3 kg)

Winch capacity = 500 lbs (227.3 kg)

Maintenance and Inspections

Only trained, authorized persons should inspect and maintain the lifter. The end-user is responsible for ensuring that

the lifter is properly inspected and maintained.

Inspections:

DO NOT use the lifter if structural damage exists. Structural damage includes, but is not limited to,

cracked welds, warping or other deformation of the upright, the deck, one or more legs, or the jib. Restore the lifter to

normal operating condition BEFORE using it again.

Inspect the lifter UbeforeU it is used for the first time and Ubefore each subsequent useU. If the lifter is infrequently used,

inspect the unit at least once every 2 weeks. Inspect the lifter for:

1. Fraying of or damage to the cable, such as a marked decrease in cable diameter;

2. Structural damage or deformation;

3. Proper functioning of the winch;

4. Unusual noise, binding or rough movement of the deck when the winch handle is rotated;

5. Excessive wear of any part(s);

6. Noisy or rough operation of the castors;

Maintenance: the Uend-userU/Uyour employerU must implement a maintenance program to ensure the proper function and

safety of the lifter. Page 9 of ANSI/ITSDF standard B56.10-2006 describes some recommended maintenance

procedures, and the following steps should be utilized in conjunction with those recommendations.

Step 1U: Tag the lifter, “Out of Service.”

U

UStep 2U: Inspect the lifter as described above. If deformity, corrosion, rusting, or excessive wear of structural members

is present, DO NOT use the lifter. If the deck does not move smoothly or makes noise as it moves up or down the

upright, apply a silicon wax or silicon spray to the inside of the mast frame.

UStep 3U: Remove any dirt or other matter from the cable and pullies (22, 25 & 27 on p. 5) and other lifter surfaces.

UStep 4U: Perform all other necessary adjustments and/or repairs. DO NOT modify the lifter.

The reader should understand the significant difference between necessary adjustments and repairs,

and modifications. An UadjustmentU is a simple correction that restores the lifter to normal operating condition, such as

tightening loose fasteners or removing dirt or other debris from surfaces; a UrepairU refers to replacing worn parts with

new replacement parts.

DO NOT use the lifter if adjustments and repairs are incomplete! Return it to service ONLY after finishing all

necessary repairs and adjustments.

A UmodificationU is a change that Ualters the lifter from its original operating conditionU, like bending the structural members

or removing a part or several parts. UNEVERU modify the unit. Modifications automatically void the Limited

Warranty (p. 7) and might make the lifter unsafe to use.

UStep 5U: Make a dated record of the repairs, adjustments and/or replacements made.

:

Cop

yright 2013 Vestil Manufacturing Corp. Page 4 of 7

Page 5

rev. 2/22/2013 Product manual, operation instructions.doc

Exploded Parts Diagram and Bill of Materials

Cop

yright 2013 Vestil Manufacturing Corp. Page 5 of 7

Page 6

rev. 2/22/2013 Product manual, operation instructions.doc

Label Placement Diagram

Cop

yright 2013 Vestil Manufacturing Corp. Page 6 of 7

Page 7

rev. 2/22/2013 Product manual, operation instructions.doc

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this product to be free of defects in material and workmanship

during the warranty period. Our warranty obligation is to provide a

covered by the warranty, after we receive a proper request from the warrantee (you) for warranty service.

replacement for a defective original part if the part is

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

What is an “original part”?

An original part is a part used to make the product as shipped

to the warrantee.

What is a “proper request”?

A request for warranty service is proper if Vestil receives: 1) a photocopy of the Customer Invoice

shipping date; AND 2) a written request

by any of the following methods:

for warranty service including your name and phone number. Send requests

that displays the

Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 sales@vestil.com

2999 North Wayne Street, PO Box 507 Phone

Angola, IN 46703 (260) 665-7586

In the written request, list the parts believed to be defective and include the address where replacements should be

delivered.

What is covered under the warranty?

After Vestil receives your request for warranty service, an authorized representative will contact you to determine

whether your claim is covered by the warranty. Before providing warranty service, Vestil may require you to send the

entire product, or just the defective part or parts, to its facility in Angola, IN. The warranty covers defects in the following

original dynamic components: motors, hydraulic pumps, electronic controllers, switches and cylinders. It also covers

defects in original parts that wear under normal usage conditions (“wearing parts”): bearings, hoses, wheels, seals,

brushes, batteries, and the battery charger.

How long is the warranty period?

The warranty period for original components is 90 days

. The warranty period begins on the date when Vestil ships the

product to the warrantee. If the product was purchased from an authorized distributor, the period begins when the

distributor ships the product. Vestil may extend the warranty period for products shipped from authorized distributors

by up to 30 days to account for shipping time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will contact

you to discuss your claim.

What is not covered by the warranty?

1. Labor;

2. Freight;

3. Occurrence of any of the following, which automatically voids the warranty

:

Product misuse;

Negligent operation or repair;

Corrosion or use in corrosive environments;

Inadequate or improper maintenance;

Damage sustained during shipping;

Collisions or other incidental contacts causing damage to the product;

Unauthorized modifications

: DO NOT modify the product IN ANY WAY without first receiving written

authorization from Vestil. Modification(s) might make the product unsafe to use or might cause excessive and/or

abnormal wear.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to the extent

allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty.

Copyright 2013 Vestil Manufacturing Corp. Page 7 of 7

Loading...

Loading...