Page 1

VESTIL MANUFACTURING CORP.

2999 North Wayne Street, P.O. Box 507, Angola, IN 46703

Telephone: (260) 665-7586 -or- Toll Free (800) 348-0868

Fax: (260) 665-1339

www.vestilmfg.com e-mail: sales@vestil.com

HYDRA SERIES MANUAL HYDRAULIC LIFT TRUCKS

A

SSEMBLY, USE, AND MAINTENANCE MANUAL

RECEIVING INSTRUCTIONS:

After delivery, IMMEDIATELY remove the packaging from the product in a manner that preserves the packaging and

maintains the orientation of the product in the packaging; then inspect the product closely to determine whether it

sustained damage during transport. If damage is discovered during the inspection, immediately record a complete

description of the damage on the bill of lading. If the product is undamaged, discard the packaging.

NOTES:

1) Compliance with laws, regulations, codes, and non-voluntary standards enforced in the location where the product is

used is exclusively the responsibility of the owner/end-user

2) VESTIL is not liable for any injury or property damage that occurs as a consequence of failing to apply either:

a) Instructions in this manual; or b) information provided on labels affixed to the product. Neither is Vestil responsible for

any consequential damages sustained as a result of failing to exercise sound judgment while assembling, installing, using

or maintaining this product.

Table of Contents

Product Specifications…………………………………..………………………………………………………………………………………. 2

Signal Words….………………………………………………………………………………………………………………………………….. 3

Safety Recommendations………………………………………………………………..…...………………………………………………… 3

FIG. 1: HYDRA-2 exploded parts diagram & bill of materials……………………………………………………………………………….. 4

FIG. 2: HYDRA-4 exploded parts diagram & bill of materials……………………………………………………………………………….. 5

FIG. 3: HYDRA-HD exploded parts diagram & bill of materials…………………………………………………………………………….. 6

Function tests before use……………………………………………………………………………………………………………………….. 7

Operation instructions…………………………………………………………………………………………………………………………… 7 - 8

Inspections & Maintenance……………………………………………………………………………………………………………………... 9

Troubleshooting Guide………………………………………………………………………………………………………………………….. 10

Detailed Troubleshooting—Foot Pump………………………………………………………………………………………………………... 11-15

FIG. 4: Hydraulic System Diagram…………………………………………………………………………………………………………….. 15

Detailed explanation of Hydraulic System Operation………………………………………………………………………………………… 16

Label Placement Diagram……...……………………………………………………………………………………………………………….. 17

Limited Warranty…...……………………………………………………………………………………………………………………………. 18

Copyright 2015 Vestil Manufacturing Co. Page 1 of 18

Page 2

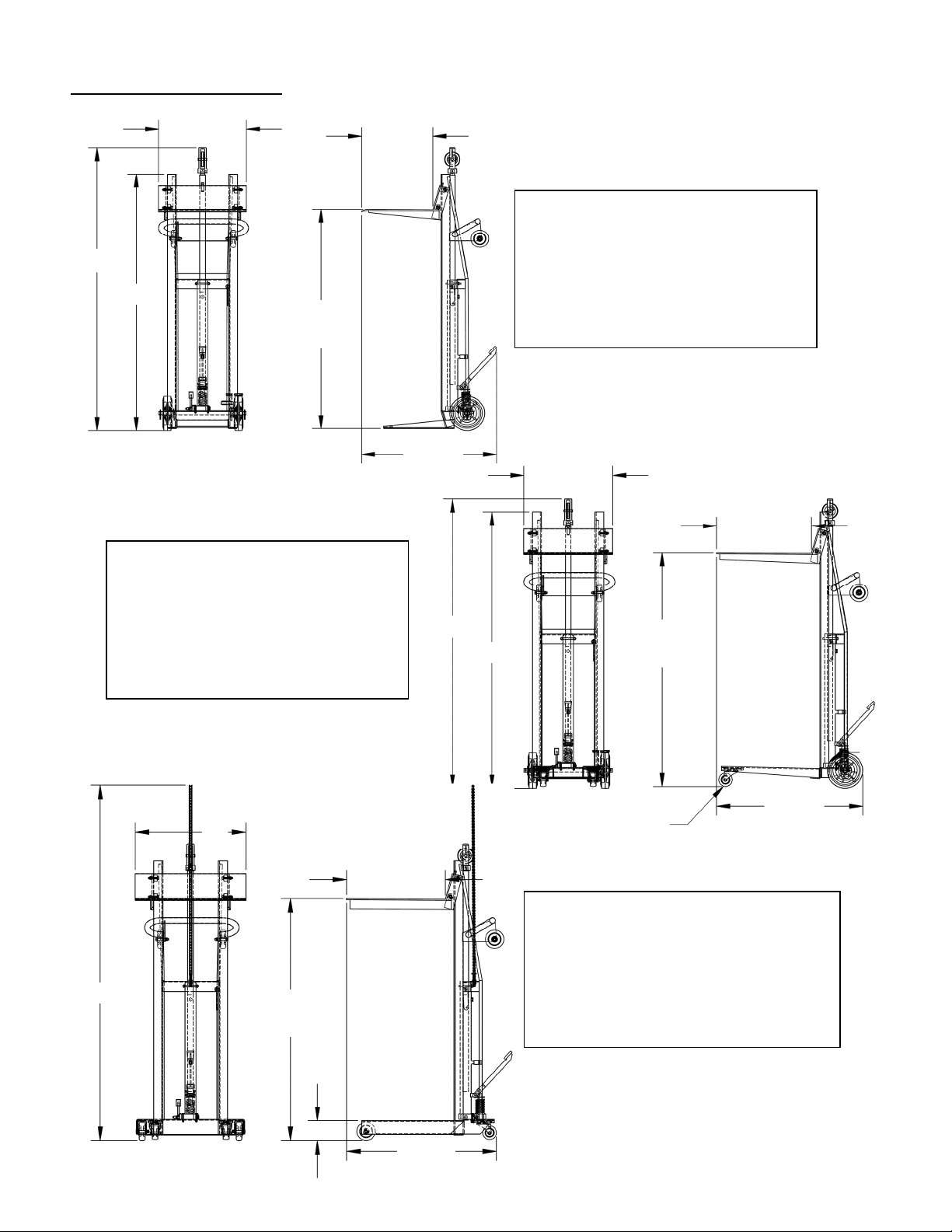

Product specifications:

g

/

Dimensions and other product specifications appear in the following table based on the following diagrams.

20”

161/4”

6413/16”

5813/16”

0” to 48”

service

range

HYDRA-2

Deck operated by foot pump

Capacity: 750 lb.

Overall width: 20 inches

Overall length: 30

Overall height: 64

Deck dimensions: 20 inches x 16

11

/16 inches

13

/16 inches

1

/4 inches

Service range: 0 inches to 48 inches

3011/16”

20”

213/8”

HYDRA-4

Deck operated by foot pump

Capacity: 750 lb.

Overall width: 20 inches

Overall length: 32

Overall height: 64

15

/16 inches

13

/16 inches

Deck dimensions: 20 inches x 21

Service range: 4 inches to 523/4 inches

20”

771/4”

43/4” to

3

/4”

52

service

3

/8 inches

213/8”

6413/16”

617/16”

43/4” to

3

/4”

52

service

3” x 11/4” hard rubber

swivel caster

HYDRA-HD

Deck operated by foot pump

Capacity: 1,000 lb.

Overall width: 24 inches

Overall length: 32

Overall height: 77

7

/16 inches

1

/4 inches

Deck dimensions: 24 inches x 21

Service ran

e: 43/4 inches to 52

3215/16”

3

/8 inches

3

inches

4

43/8”

327/16”

Copyright 2015 Vestil Manufacturing Co. Page 2 of 18

Page 3

Signal Words:

This manual uses SIGNAL WORDS to indicate the likelihood of personal injuries, as well as the probable seriousness

of those injuries, if the product is misused in the ways described. Other signal words call attention to uses of the

product likely cause property damage. The signal words used appear below along with the meaning of each word:

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or SERIOUS

INJURY. Use of this signal word is limited to the most extreme situations.

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or SERIOUS

INJURY.

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or MODERATE

injury

.

Identifies practices likely to result in product/property damage, such as operation that might

damage the product.

Each person who assembles, installs, uses, or maintains this product should read the entire manual in advance and

fully understand the directions. If after reading the manual you do not understand an instruction, ask your supervisor

or employer for clarification, because failure to adhere to the directions in this manual might result in serious personal

injury.

Safety Recommendations:

We strive to identify foreseeable hazards associated with the use of our products. However, material handling is dangerous and no

manual can address every risk. The end-user ultimately is responsible for exercising sound judgment at all times.

Improper or careless operation might result in serious personal injuries sustained by the operator and bystanders.

Always apply material handling techniques learned during training and use the product properly.

Failure to read and understand the entire manual before assembling, using or servicing the product constitutes misuse. Read the

manual to refresh your understanding of proper use and maintenance procedures as necessary.

Prior to each use, ALWAYS inspect the area where you intend to use the lifter. Inspect the area for unusual

conditions that might require special precautions. See “Warning” messages on p. 7.

DO NOT use a malfunctioning lifter; always perform the “Functions Checks/Tests” described on p. 7 before each

use.

Regardless of whether the lifter is loaded or unloaded, DO NOT stand or travel under the deck and DO NOT allow

any other person to stand or travel under the deck.

Inform all persons in the area that you are going to use the lifter. Instruct them to stay clear of the device and the

supported load during operation.

ALWAYS make sure that your clothing and body do not contact the moving parts during operation. In particular,

avoid contact with the chain assembly (Item #21, Fig. 1; Item #22, Fig. 2; and Item #17, Fig. 3) and with the roller

bearings. ONLY control the lifter from the “Operator Position,” shown in the figures that appear on p. 8. DO NOT

move the lifter or raise or lower the forks unless you are in the operator position.

DO NOT allow people to ride on the lifter.

ALWAYS load the HYDRA-Lift according to the list of 5 recommendations that appears below. Failure to properly

position a load on the deck might cause the lifter to tip over and you could be injured as a consequence.

1. DO NOT exceed the maximum rated load (capacity). The rated load of your lifter is posted on a label (see

Fig. 5 on p. 18).

2. ONLY move loads using the deck platform or the optional forks.

3. ALWAYS properly center the load. DO NOT handle off-center loads or loads that cannot be centered.

4. Start and stop gradually to avoid upsetting the load on the deck.

5. NEVER tilt the lifter while carrying a load. All four castors must maintain contact with the ground when a load

is on the deck (or forks).

NOTE: The HYDRA-2 model has only 2 wheels and thus operates like a dolly: it must be tilted

towards the operator in order to drive it from one location to another. After loading the deck of a

Hydra-2, verify that you will be able to control the loaded lifter, by tilting it into the drivable

position. If the weight is too much for you to safely control, DO NOT use the Hydra-2 to transport

the load.

DO NOT transport loads up or down stairs.

Copyright 2015 Vestil Manufacturing Co. Page 3 of 18

Page 4

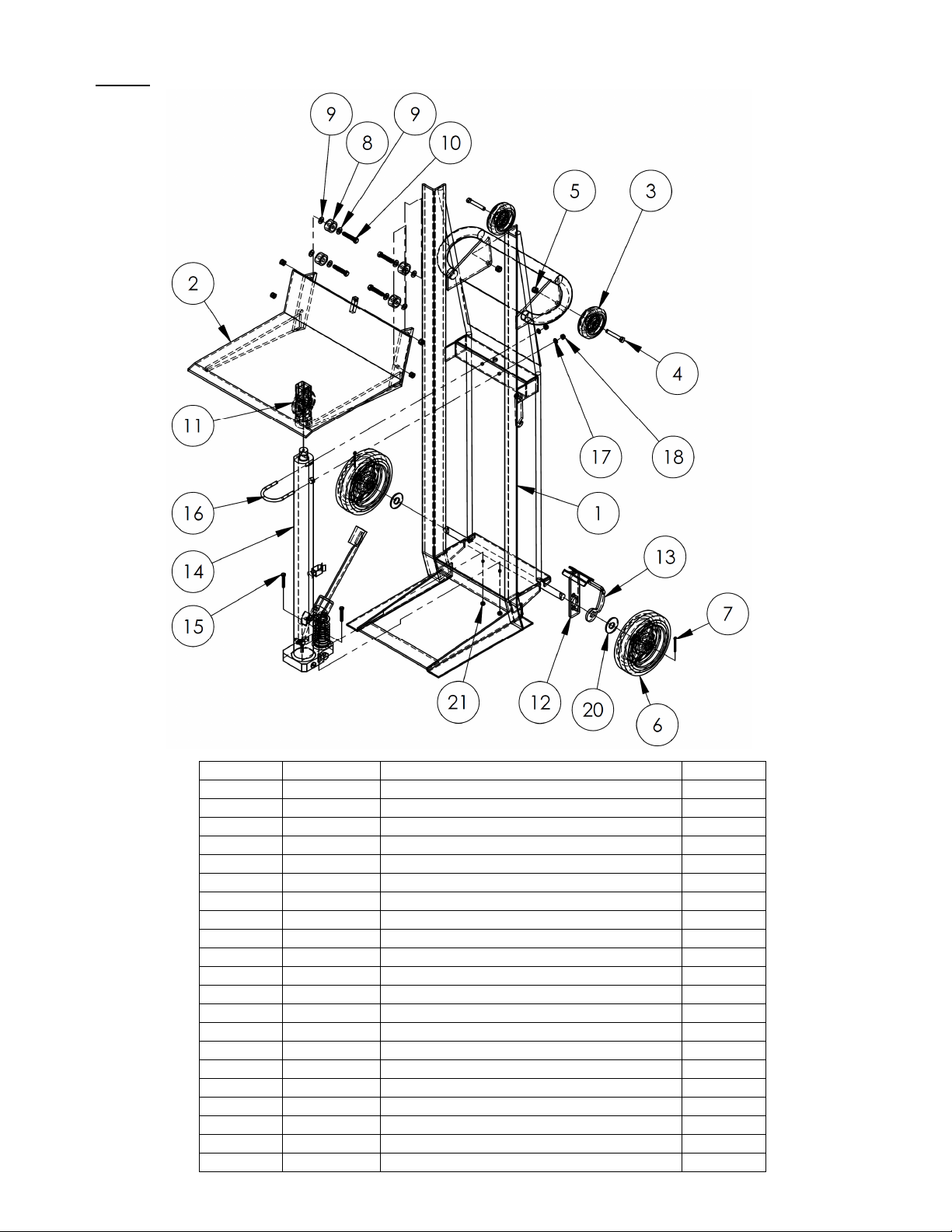

Fig. 1: HYDRA-2 exploded parts diagram & bill of materials

Item No. Part No. Description Quantity

1 33-514-092 Frame Weldment 1

2 33-513-044 Deck Plate Weldment 1

3 16-132-009 HR–4/1.25–SLB-S 2

4 11113 3/8”-16 x 21/2” Zinc-plated HHCS Bolt 2

5 37024 3/8”-16 nylock nut 6

6 16-132-200 8” x 2” red hard rubber wheel (red) 2

7 65107 5/32” x 2” zinc-plated cotter pin 2

8 33-027-003 Cam roller, bearing, deck 4

9 33008 3/8” USS Zinc-Plated Flat Washer 8

10 11111 3/8” - 16 x 2” Zinc-Plated Bolt HHCS 4

11 33-542-001 Assembly, pulley 1

12 21-537-002 Weldment, wheel brake assembly 1

13 21-037-015 Brake lever, formed 1

14 01-640-031 Pump, manual, 24in. stroke 1

15 11010 1/4” - 20 x 13/4” HHCS zinc-plated #2 bolt 2

16 42034 5/16” – 18UNC x 21/2” U-bolt 1

17 33620 5/16” zinc-plated lock washer 2

18 36104 5/16” – 18 zinc-plated hex nut 2

19 33-542-002 Chain assembly (#50), hydrapulley 1

20 33018 3/4” USS zinc—plated flat washer 2

21 36102 1/4” – 20 zinc-plated hex nut 2

Copyright 2015 Vestil Manufacturing Co. Page 4 of 18

Page 5

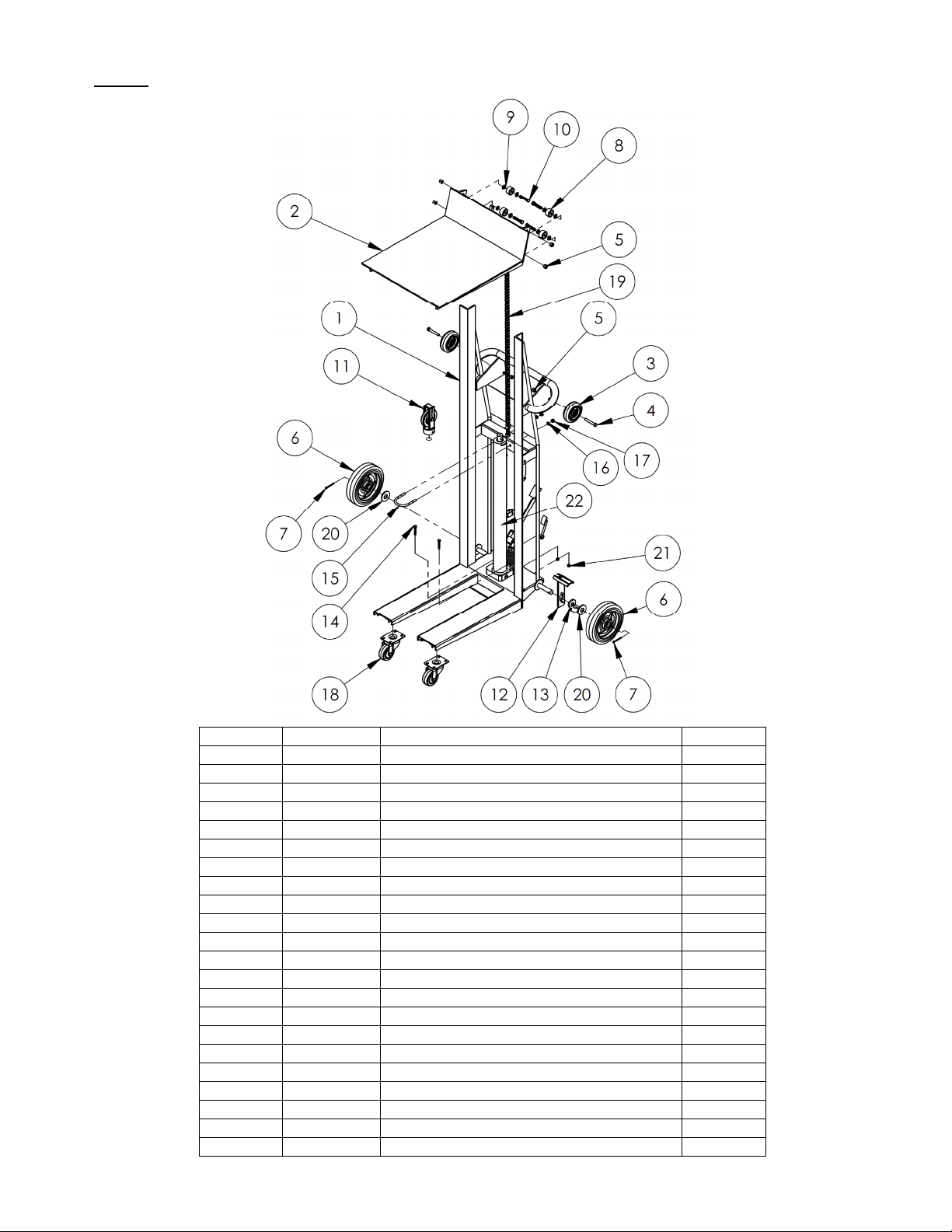

Fig. 2: HYDRA-4 exploded parts diagram & bill of materials

Item No. Part No. Description Quantity

1 33-514-093 Frame Weldment 1

2 33-513-043 Deck Plate Weldment 1

3 16-132-009 HR–4/1.25–SLB-S 2

4 11113 3/8”-16 x 21/2” Zinc-plated HHCS Bolt 2

5 37024 3/8”-16 nylock nut 6

6 16-132-200 8” x 2” red hard rubber wheel (red) 2

7 65107 5/32” x 2” zinc-plated cotter pin 2

8 33-027-003 Cam roller, bearing, deck 4

9 33008 3/8” USS Zinc-Plated Flat Washer 8

10 11111 3/8” - 16 x 2” Zinc-Plated Bolt HHCS 4

11 33-542-001 Assembly, pulley 1

12 21-537-002 Weldment, wheel brake assembly 1

13 21-037-015 Brake lever, formed 1

14 11010 1/4” - 20 x 13/4” HHCS zinc-plated #2 bolt 2

15 42034 5/16” – 18UNC x 21/2” U-bolt 1

16 33620 5/16” zinc-plated lock washer 2

17 36104 5/16” – 18 zinc-plated hex nut 2

18 16-132-201 Caster, PP-3/1.25 swivel (red) 2

19 33-542-003 Chain assembly (#50), hydrapulley 1

20 33018 3/4” USS zinc—plated flat washer 4

21 36102 1/4” – 20 zinc-plated hex nut 2

22 01-640-031 Pump, manual, 24in. stroke 1

Copyright 2015 Vestil Manufacturing Co. Page 5 of 18

Page 6

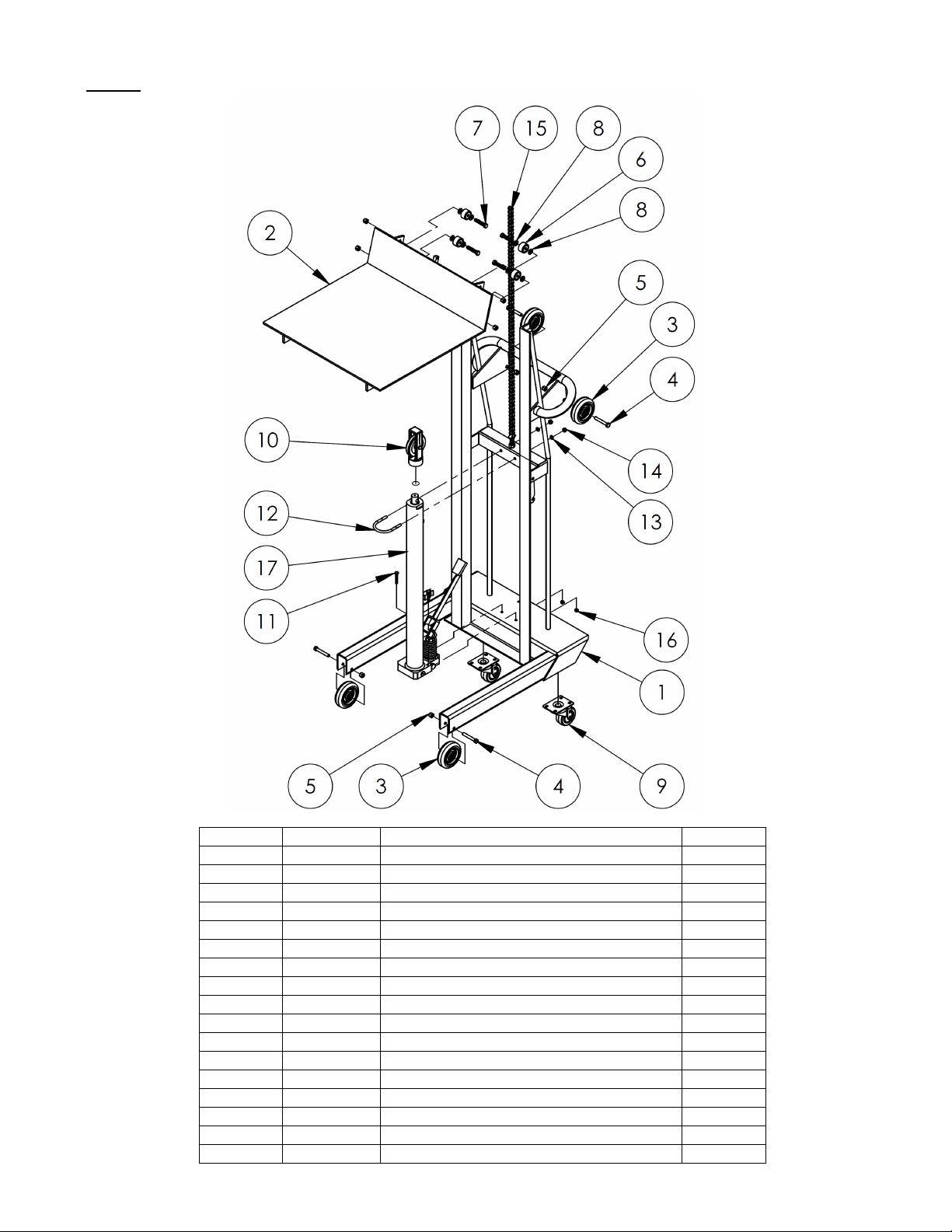

Fig. 3: HYDRA-HD exploded parts diagram & bill of materials

Item No. Part No. Description Quantity

1 33-514-094 Frame Weldment 1

2 33-513-045 Deck Plate Weldment 1

3 16-132-009 HR–4/1.25–SLB-S 4

4 11113 3/8”-16 x 21/2” Zinc-plated HHCS Bolt 4

5 37024 3/8”-16 nylock nut 8

6 33-027-003 Cam roller, bearing, deck 4

7 11111 3/8” - 16 x 2” Zinc-Plated Bolt HHCS 4

8 33008 3/8” USS Zinc-Plated Flat Washer 8

9 16-132-327 Caster, PU-3/1.5-S swivel (red) 2

10 33-542-001 Assembly, pulley 1

11 11010 1/4” - 20 x 13/4” HHCS zinc-plated #2 bolt 2

12 42034 5/16” – 18UNC x 21/2” U-bolt 1

13 33620 5/16” zinc-plated lock washer 2

14 36104 5/16” – 18 zinc-plated hex nut 2

15 33-542-003 Chain assembly (#50) 1

16 36102 1/4” – 20 zinc-plated hex nut 2

17 01-640-043 Pump, manual, 24in. stroke 1

Copyright 2015 Vestil Manufacturing Co. Page 6 of 18

Page 7

Functions Checks/Tests:

Before operating the HYDRA lift, verify that each of the following systems function normally:

I. Hydraulic system: raise and lower the deck to verify normal operation.

Normal Function — Pump the hydraulic pedal several times with your foot. Press down on the pedal; when the

pedal reaches the bottom of its stroke, release it to allow the pedal to return to the neutral position. With each stroke,

the deck should rise by a noticeable increment, and should maintain its position after the pedal is released.

Raise the deck

by pressing the

hydraulic pedal

several times;

pedal shown in

neutral position.

Deck should

maintain

elevation

after pedal

released.

II. Wheels/Rollers: to verify that the wheels turn smoothly and are undamaged, push the lifter far enough to allow the

rear wheels to complete a few full revolutions. If the lifter wobbles as you push it, check the surface of each

wheel for embedded debris. Remove all debris; then repeat the process to determine whether the vibration

problem has been resolved. If the problem persists, notify maintenance personnel.

III. Brakes [HYDRA-2 and -4 models]: engage the brakes; then try to roll the lifter. The HYDRA should not be able to

roll (forward or reverse) more than an insignificant amount.

Step 1: Engage

wheel with brake.

To engage the

brake, press

the brake lever

(circled) with

your foot. To

disengage the

brake, lift the

brake lever.

Alternatively, to engage the brake,

step directly on the brake assembly.

Operation:

Safe operation is the operator’s responsibility [ANSI/ITSDF B56.10]. The operating instructions in this manual

supplement the rules applied at your workplace.

DO NOT operate the HYDRA lift until you read AND understand every instruction. If you do not

understand an instruction, contact Vestil for clarification. To reduce the possibility of sustaining or causing serious

personal injuries, always:

Review the safety guidelines on p. 3 before each use;

Apply proper loading techniques (p. 8);

Ask a coworker to help you load and unload the lifter.

“Operator” means a person, who is trained and authorized to use a manually propelled high lift device. ONLY

persons who have successfully completed a training program, like the courses outlined on p. 4-5 of B56.10-2006,

should operate the HYRDA-Lift. Safe operation requires operators to:

Develop safe working habits and a process for identifying hazards that exist or might be encountered during

operation;

Conduct thorough inspections of the usage area to identify unusual/hazardous conditions. Walk the path you will

use to transport loads with the lifter beforehand. Do not use the HYDRA lift if the floor (or other supporting

surface) is uneven or damaged or cannot support the combined weight of the operator, the lifter and the load.

Make sure that the lifter has been inspected as recommended in the “Inspections & Maintenance” section of this

manual (p. 9). Use the lifter ONLY IF it is deemed safe to use by designated inspection personnel.

Press the deck lowering pedal (release

pedal) down to allow the deck to descend to

the fully lowered position. Pedal is circled

below.

Step 2: Try to push lifter while the brake is

engaged.

Step 3: Secure the disengaged brake to the

frame.

Pivot the brake

assembly inwardly

until the round

frame brace fits

into the notch in

the brake (circled).

Copyright 2015 Vestil Manufacturing Co. Page 7 of 18

Page 8

r

Step 1: Always maneuver the HYDRA-lift from the “Operator Position” (shown below). Maneuver the lifter to a position

near the load and then apply the brake.

NOTE: Although Hydra-4 and –HD models have 4 wheels/casters, and therefore can be pushed, Hydra-2’s only

have 2 wheels. Consequently, a Hydra-2 functions like a dolly. To drive a Hydra-2, pivot the dolly towards

yourself, i.e. towards the operator, and push the dolly to the desired location.

Step 2: Place the load on the deck. Always center the load and secure it to the deck if the material is likely to slide.

Side View

Overhead View

Center of deck

Center of deck

Load center

OPERATOR

POSITION

Properly centered load.

Center of load very close

to or aligned with center

of deck.

Properly

centered load.

Center of load

close to or aligned

with centerline of

deck

OPERATOR POSITION

Load center

OPERATOR

POSITION

Load

cente

Improperly

centered load.

Center of load in

front of deck

center.

O

PERATOR POSITION

Improperly

centered load.

Center of load

close to either

side of deck.

Step 3: Slowly lower the deck by pressing the release pedal

(identified with an arrow in the photograph). Allow the deck to

descend until it is fully lowered. Disengage the brake, and push

the lifter to the desired location. If obstacles in the travel path

require you to raise the deck to avoid contact between the load

and those obstacles, raise the deck to an appropriate elevation,

pass over the obstacle, and then return the deck to the lowered

position.

Step 4: Unload the lifter; then return the HYDRA to its storage

location. Engage the brake and secure the hydraulic pedal in the

stored position (circled).

A proper storage location is one where the

unused lifter will not:

1. Interfere with or obstruct traffic or other operations;

2. Be exposed to corrosive chemicals or water, either as a

consequence of weather or of worksite conditions.

Copyright 2015 Vestil Manufacturing Co. Page 8 of 18

Page 9

Inspections & Maintenance:

The end-user is responsible for ensuring that the lifter is properly inspected and maintained. Only trained, authorized

persons should be allowed to perform inspections of and maintenance on the lifter.

Inspections:

Inspection and maintenance personnel should engage the brake and immobilize the deck before

conducting inspections or performing maintenance on the HYDRA-Lift.

DO NOT use the lifter if structural damage exists. Structural damage includes, but is not limited to, cracked

welds, warping or other deformation of the frame, deck, chain or hydraulic cylinder.

Restore the lifter to normal operating condition BEFORE using it again.

Before each use: The person(s) authorized by the end-user (your employer, for instance) to inspect the lifter must do

so before it is used for the first time and before each use thereafter. If the lifter is infrequently used, inspect the unit at

least once every 2 weeks. Inspect the HYDRA-lift for:

1. Warping or other damage of the lift chain;

2. Noisy or abnormal movement of the deck when either the hydraulic pedal or the release pedal is pressed;

3. Frame damage or deformation;

4. Excessive wear of any load-bearing part(s);

5. Noisy or rough operation of the castors/wheels;

6. Dirt or other matter on the surface of the lifter.

Maintenance: the end-user, i.e. you and/or your employer, must implement a maintenance program to ensure the

proper function and safe condition of the lifter. Page 9 of ANSI/ITSDF standard B56.10-2006 describes some

recommended maintenance procedures, and the following steps should be utilized in conjunction with those

recommendations.

The end-user is responsible for selecting and training employees to work on the lifter. “Work on” refers

to operating, loading, cleaning, servicing, maintaining, or repairing the product. ONLY trained, authorized

maintenance personnel or contractors should perform inspection, maintenance, or repair work.

Step 1: Tag the lifter, “Out of Service.”

Step 2: Conduct a “Before each use” inspection. If deformity, corrosion, rusting, or excessive wear of structural

members is found, DO NOT use the lifter. If the deck does not move smoothly or makes noise as it moves up or

down, apply a silicon wax or silicon spray to the mast frame (part of the frame that the roller bearings contact). Oil the

chain if it squeaks or articulates roughly.

Step 3: Remove any dirt or other matter from the chain, deck and other lifter surfaces.

Step 4: Perform all other necessary adjustments and/or repairs, but DO NOT modify the lifter.

The reader should understand the important difference between necessary adjustments and repairs,

and modifications.

An “adjustment” is a simple correction that restores the lifter to normal operating condition, such as tightening

loose fasteners, or removing dirt or other debris from the surface. “Repair” refers to removing worn parts and installing

replacement parts.

DO NOT use the HYDRA-lift if adjustments and/or repairs are incomplete! Return it to service ONLY after

finishing all necessary repairs and adjustments.

A “modification” is a change that alters the lifter from normal operating condition, like bending the structural

members or removing a part or several parts. NEVER modify the unit without the express, written approval of Vestil.

Modifications may render the lifter unsafe to use.

Step 5: Make a dated record of any repairs, adjustments and/or replacements.

Copyright 2015 Vestil Manufacturing Co. Page 9 of 18

Page 10

Troubleshooting Guide

Fully lower the deck before beginning maintenance work on the lifter. If the issue/problem with your HYDRA lift is not

addressed in the table below, contact Vestil for answers.

Issue / Problem Possible Causes Suggested Corrective Action

1. I pump the pedal, but the

deck does not rise;

-OR-

I can move the pedal with

very little force.

2. Deck rises during pedal

down stroke, but lowers

during pedal upstroke.

3. Deck rises but does not

maintain raised position

(slowly returns to lowered

position over time).

4. Deck rises when pedal

pumped, but in smaller

increments than normal.

5. Great effort required to

operate foot pump.

6. Deck will not lower.

7. Deck lowers

maddeningly slowly when

release pedal pressed.

8. Deck lowers too quickly. A. Release pedal screw out of adjustment.

9. Deck lowers in jerks. A. Air trapped in hydraulic system. A. Bleed air from system (see “Remove air

A. Oil not getting through the pump because

i) too little oil in reservoir or ii) pump is airlocked.

B. Relief valve is opening.

C. Foreign material holding inlet check valve

open.

D. Foreign matter in release valve.

A. Foreign material preventing outlet-check

from closing.

A. Foreign material holding outlet-check

open

B. Foreign material holding relief-valve open

C. Foreign material holding release-valve

open

A. Foreign matter holding open relief valve.

B. Foreign matter holding inlet check valve

open.

C: Foreign matter holding outlet check open.

A. Operating pressure exceeds the pump’s

force capability.

A. Release pedal screw out of adjustment.

B. Pedal not properly positioned on release

cam.

C. Pedal lock-screw not tight.

D. Release cam broken.

E. Debris obstructing flow control.

F. Internal components missing.

G. Something preventing deck cam roller

bearing(s) from rolling (see Fig. 2 item #9;

Fig. 3 item #9; Fig. 4 item #6).

A. Release pedal screw improperly adjusted.

B. Pedal not properly positioned on release

cam.

C. Pedal lock screw not tight.

D. Release cam broken.

E. Debris obstructing flow control.

B. Pedal lock-screw not properly positioned

on release cam.

A. i) Check oil level in reservoir.

ii) Bleed air from hydraulics (see “Remove air

from hydraulic system,” p. 11).

B. Verify that load does not exceed lifter’s

maximum rated load (see “Product Introduction”

on p.2)

C. Remove material from inlet check valve

assembly (see “Inlet Check Valve Assembly

Cleaning,” p. 11; photograph on p. 14).

D. Disassemble release valve and clean the

components. (See photograph of release valve

assembly on p. 13).

A. Clean outlet check assembly

A. Disassemble and clean the outlet check

valve components.

B. Disassemble and clean the relief-valve

components.

C. Disassemble and clean the release-valve

components.

A. Disassemble and clean the relief valve

components.

B. Disassemble and clean inlet check valve

parts. (p. 11 and 13).

C. Clean outlet check assembly.

A. Reduce load weight.

A. See “pedal adjustment” on page 11.

B. Pedal lock screw must be seated into the

mating detent on the release-cam.

C. The screw must be snug against the release

cam to prevent it from rotating relative to the

cam during use.

D. Replace broken components.

E. Flush the jack assembly and add fresh

hydraulic fluid.

F. Study break-down (p. 12-15); replace and

install components as shown.

G. Inspect frame for obstructions interfering

with roller bearing movement; remove

obstruction(s).

A. See “pedal adjustment” on page 11.

B. Pedal lock screw must be seated in the

mating detent on the release-cam.

C. The screw must be snug against the release

cam to prevent it from rotating relative to the

cam during use.

D. Replace broken components.

E. Flush jack assembly and install new fluid.

A. See “pedal adjustment” procedure on page

11.

B. Pedal lock screw must be seated into the

mating detent on the release-cam.

from hydraulic system,” p. 11).

B. Add oil to hydraulic reservoir.

Copyright 2015 Vestil Manufacturing Co. Page 10 of 18

Page 11

Detailed Troubleshooting — Hydraulic Foot Pump

The following tools are required to resolve the issues listed

above:

5mm hex key wrench

Standard (flat head) screwdriver

Adjustable crescent wrench

Hydraulic Fluid Level Adjustment

1. Remove the fill/breather plug.

2. Hydraulic fluid level should be 2 - 2.5 inches

below the bottom of the fill hole when the

cylinder rod is fully lowered. Do not overfill the

reservoir; if overfilled, oil may leak or seep

around the fill plug.

ONLY use ISO AW-32 anti-wear hydraulic

pump oil. The oil must be clean; strain the oil, if

necessary, before adding it to the reservoir.

Remove Air Trapped Inside Hydraulic System

1. Pump the foot pedal until the cylinder rod is fully

extended. The small hole near the base of the

rod will pass by the high pressure seal and air

will automatically vent into the reservoir tube.

Release Pedal Adjustment

1. Loosen the release pedal screw retaining nut (p.

13).

2. Loosen the release pedal screw: ½ to a full

counterclockwise turn using either a 5mm hex

key wrench (Allen wrench) or flat blade

screwdriver.

3. Apply a test weight to the deck; pump the foot

pedal until the deck rises ~2ft; then press the

release pedal down. [If the deck lowers, turn the

release pedal screw by another ½ turn, and

repeat step 3. The deck should not lower when

you press the release pedal.]

4. Turn release pedal screw clockwise 1/8 to ¼

turn; repeat step 3. The deck now should lower;

if it does not, turn the screw clockwise by

another 1/8 turn. Repeat this step until the

desired deck-lowering rate is achieved.

5. Tighten the retaining nut. To prevent the screw

from rotating while tightening the nut, either hold

the screw with your fingers or insert the 5mm

hex key wrench (or flat blade screwdriver) into

the fitting.

Proper Hydraulic Fluid Level

Fill / Breather Plug

Release Pedal Adjustment

Inlet Check Valve Assembly Cleaning

1. Remove inlet check port plug with a crescent wrench

(see p. 14).

2. Clean the valve components.

3. While the valve is disassembled, pump the foot pedal at

least 5 times. Fluid will discharge from the inlet check

valve opening, which should dislodge debris clogging the

valve.

4. Reassemble the valve & reconnect the port plug.

5. Add hydraulic fluid as necessary according to the

“Hydraulic Fluid Level Adjustment” instructions above.

Copyright 2015 Vestil Manufacturing Co. Page 11 of 18

Page 12

y

Hydraulic foot pump

Cylinder

rod

Threaded rod

guide

Release Port Plug

Reservoir tube

Release

pedal

Foot Pedal

Pedal piston

assembly

Release valve

assembly

Relief valve assembly

Release

Inlet check valve

assembly

Copyright 2015 Vestil Manufacturing Co. Page 12 of 18

valve

mechanism

Port plug

Inlet check valve

assembl

Page 13

Release Valve and High Pressure Relief Valve Assemblies

Release pedal

screw retaining

nut

Mating detent

for pedal lock

screw

Pedal Piston Assembly

Copyright 2015 Vestil Manufacturing Co. Page 13 of 18

Page 14

Inlet Check Valve Assembly

Release Valve Assembly

Threaded Rod Guide

Copyright 2015 Vestil Manufacturing Co. Page 14 of 18

Page 15

Close-up View of Cylinder Assembly

FIG. 4: Hydraulic System Diagram

Chamber A

The pump assembly consists of 10 primary components:

1. Oil reservoir 6. Release valve assembly

2. Inlet check poppet 7. Cylinder

3. Pump body 8. Piston return spring

4. Pressure relief valve 9. Pump pedal

5. Outlet check 10. Piston rod

The piston assembly incorporates a two-speed mechanism comprised of five main components:

1. Piston blind-side – Chamber A 4. High-volume / low-volume relief poppet

2. Rod-side – Chamber B 5. Piston rod

3. Back-fill check

Cylinder Assembly

.

Chamber B

B

Copyright 2015 Vestil Manufacturing Co. Page 15 of 18

Page 16

Detailed Explanation of Hydraulic System Operation:

Raising the deck:

The sequence of events begins with the foot pedal in the neutral, or “home”, position. The operator first activates

the hydraulic system by pressing the foot pedal down. This is referred to as the “power-stroke”. Next, after releasing

the foot pedal, the piston return spring (B) exerts an upward force on the piston. Consequently, oil flows from the

reservoir, through the inlet check valve, and into chamber A. At the same time, oil trapped in chamber B (from a prior

cycle) flows across the back-fill check into chamber A. When another power stroke occurs, the inlet check valve

closes, which prevents oil from flowing back into the reservoir; simultaneously, the outlet check valve opens and oil

flows into the cylinder. In preparation for the next stroke, the piston return spring forces the piston and the foot pedal

back to the home position. Chamber A again fills with oil as the piston rises.

The pump piston has two modes of operation: 1) Low-pressure, high-volume; and 2) High-pressure, low-volume.

1. Low-pressure, High-volume.

When raising an unloaded or lightly loaded platform, the piston will function in low-pressure mode. As the

operator presses the foot pedal (power stroke):

a. Back-fill check remains closed;

b. High / low volume relief poppet remains closed; and

2. High-pressure, low-volume

Pressure relief system

If a load that exceeds the maximum rated load is placed on the deck, or a mechanical malfunction interferes with

the movement of the deck, the pressure relief valve will open during a power-stroke. The pressure relief valve reduces

the likelihood that excessive loads will damage the lifter frame or the hydraulic system. The pressure relief valve

shunts oil directly from chamber A to the reservoir.

Release valve assembly

The foot-actuated release valve assembly is the mechanism that allows the deck to lower. When the release pedal

is pressed down, the release valve opens, and oil flows from the cylinder to the reservoir. The lowering rate is

adjustable; instructions appear under “Release pedal adjustment” on p. 11. Lowering rate is also variable: the farther

down the release pedal is pressed, the more rapidly the deck descends. The weight of a load on the deck affects the

flow rate, and therefore, a heavier load will lower more rapidly than a lighter load, regardless of the lowering rate

selected. When the operator lets the pedal loose, the release pedal tensioning spring returns the release pedal to the

home position, which automatically closes the valve.

c. All oil in chamber A flows into the cylinder.

When raising a partly loaded or heavily loaded platform, the piston will function in high-pressure mode. As the

operator executes a power stroke:

a. Back-check remains closed;

b. High / low volume relief poppet opens;

c.

A volume of oil equal to the annulus (piston diameter minus the rod diameter) flows from A to B;

d. Oil equal to the cross-sectional area of the rod flows to the cylinder; and

e. The opening force of the high / low volume relief poppet adds to the cylinder load resistance.

Copyright 2015 Vestil Manufacturing Co. Page 16 of 18

Page 17

Label placement diagram:

Only use the HYDRA-Lift if ALL labels are readable and undamaged. Contact Vestil to order replacement labels.

Label 287: Model & serial number

Label

display

panel

Label 208: Pinch point (apply to outside of both forks)

Labels 527 & 287 affixed to operator side of display panel

Label 527: Hazards of improper use

Copyright 2015 Vestil Manufacturing Co. Page 17 of 18

Page 18

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this product to be free of defects in material and workmanship

during the warranty period. Our warranty obligation is to provide a replacement for a defective original part if the part

is covered by the warranty, after we receive a proper request from the warrantee (you) for warranty service.

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

What is an “original part”?

An original part is a part used to make the product as shipped to the warrantee.

What is a “proper request”?

A request for warranty service is proper if Vestil receives: 1) a photocopy of the Customer Invoice that displays the

shipping date; AND 2) a written request for warranty service including your name and phone number. Send requests

by any of the following methods:

Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 sales@vestil.com

2999 North Wayne Street, PO Box 507 Phone

Angola, IN 46703 (260) 665-7586

In the written request, list the parts believed to be defective and include the address where replacements should be

delivered.

What is covered under the warranty?

After Vestil receives your request for warranty service, an authorized representative will contact you to determine

whether your claim is covered by the warranty. Before providing warranty service, Vestil may require you to send the

entire product, or just the defective part or parts, to its facility in Angola, IN. The warranty covers defects in the

following original dynamic components: motors, hydraulic pumps, electronic controllers, switches and cylinders. It

also covers defects in original parts that wear under normal usage conditions (“wearing parts”), such as bearings,

hoses, wheels, seals, brushes, and batteries.

How long is the warranty period?

The warranty period for original dynamic components is 90 days. For wearing parts, the warranty period is 90 days.

The warranty periods begin on the date when Vestil ships the product to the warrantee. If the product was purchased

from an authorized distributor, the periods begin when the distributor ships the product. Vestil may, at its sole

discretion, extend the warranty periods for products shipped from authorized distributors by up to 30 days to account

for shipping time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will contact

you to discuss your claim.

What is not covered by the warranty?

1. Labor;

2. Freight;

3. Occurrence of any of the following, which automatically voids the warranty:

Product misuse;

Negligent operation or repair;

Corrosion or use in corrosive conditions;

Inadequate or improper maintenance;

Damage sustained during shipping;

Accidents involving the product;

Unauthorized modifications: DO NOT modify the product IN ANY WAY without first receiving written

authorization from Vestil. Modification(s) might make the product unsafe to use or might cause excessive

and/or abnormal wear.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to the extent

allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty.

Copyright 2015 Vestil Manufacturing Co. Page 18 of 18

Loading...

Loading...