Page 1

Vestil Manufacturing Corporation

2999 North Wayne St., Angola, IN 46703

Phone (260) 665-7586 • Fax (260) 665-1339

E-mail: sales@vestil.com Website: www.vestil.com

Ergonomic Solutions

Revised 1009 33-126-101

A company dedicated to solving ergonomic and material

handling problems since 1955.

OWNER'S

MANUAL

HEFTI-LIFT • MODEL HYD-5 & HYD-10

Contents

Safety Precautions .......................................... 1

Receiving Instructions ..................................... 1

Warranty.......................................................... 1

SAFETY PRECAUTIONS

Read owner's manual completely before operating unit!

• Never exceed the maximum loading capacity of 880

pounds.

• Stand clear of load while loading and unloading.

• Load must be evenly distributed on deck to insure

stability.

• Use caution in moving a loaded unit; avoid obstructions

and floor defects.

• Always apply wheel brakes when unit is not in motion.

• Never go under deck if there is weight on unit.

• Do not continue to pump on the foot lever if the deck is

not raising.

• Remove weight before working on unit.

• Do not use brake fluid or jack oils. Use AW-32 hydraulic

oil or equivalent.

• Use only replacement parts supplied or approved by the

manufacturer.

• Consult factory before performing any modification to the

original equipment.

• Make sure all operator safety labels are in place (p.11).

Parts List for HYD-5 & HYD-10 ..................... 2-3

Troubleshooting Guide for HYD-5 & HYD-10... 4

Warning Label Identification............................. 5

WARRANTY

This product is warranted for 90 DAYS from date of

purchase to be free of manufacturing defects in material and

workmanship. The manufacturer's obligation hereunder is

limited to repairing such products during the warranty period,

provided the product is sent prepaid back to the factory.

This warranty does not cover normal wear of parts

or damage resulting from any of the following: negligent use

or misuse of the product, use or application contrary to

installation instructions, or disassembly, repair or alteration

by any person prior to authorization from a factory representative.

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected prior

to shipment. However, it is possible that the unit may incur

damage during transit. If damage is noticed when unloading,

make a note of it on the BILL OF LADING. Remove all

packing and strapping material, then inspect the unit again

for damage. IF DAMAGE IS EVIDENT, FILE A CLAIM

WITH THE CARRIER IMMEDIATELY!

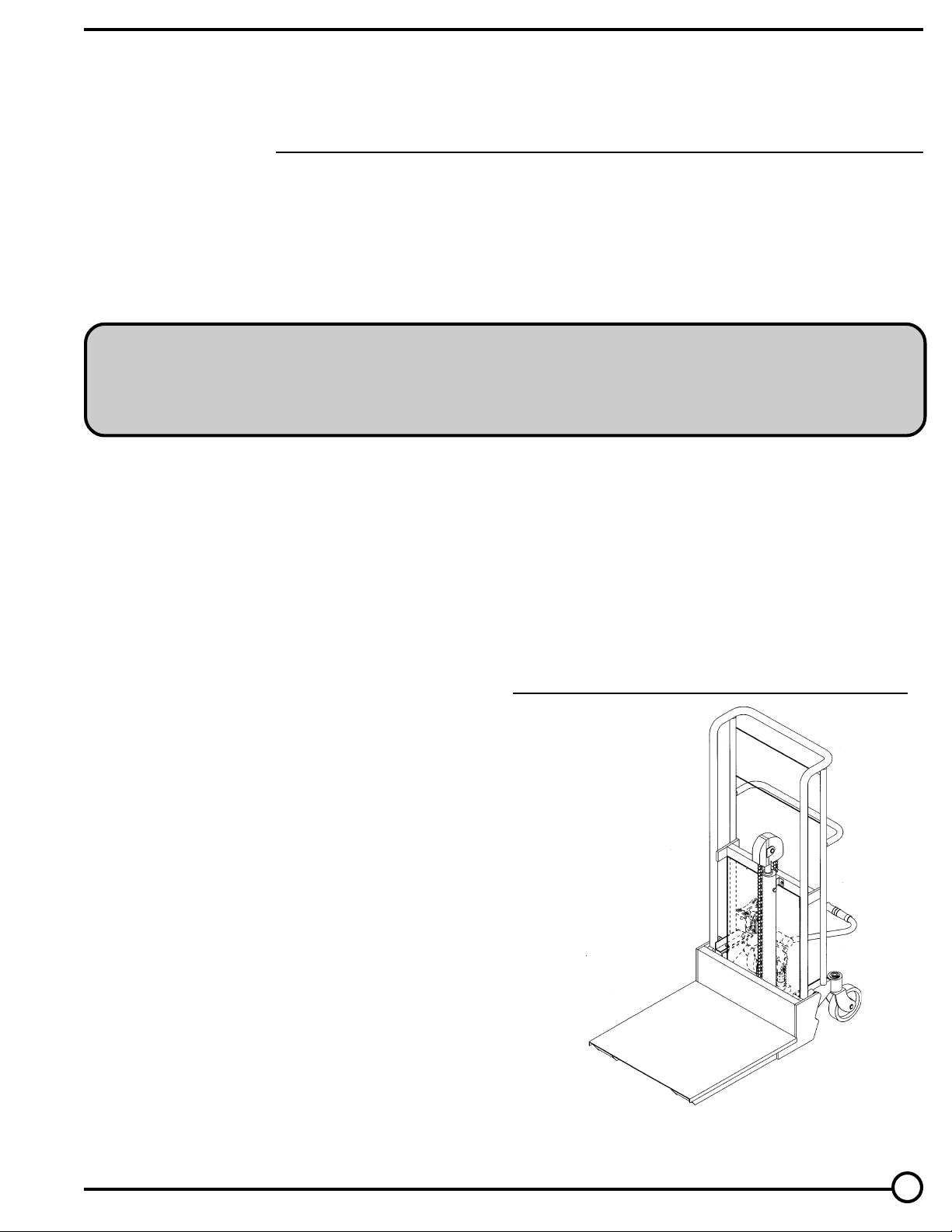

HEFTI-LIFT

MODEL HYD 5 & HYD-10

1

Page 2

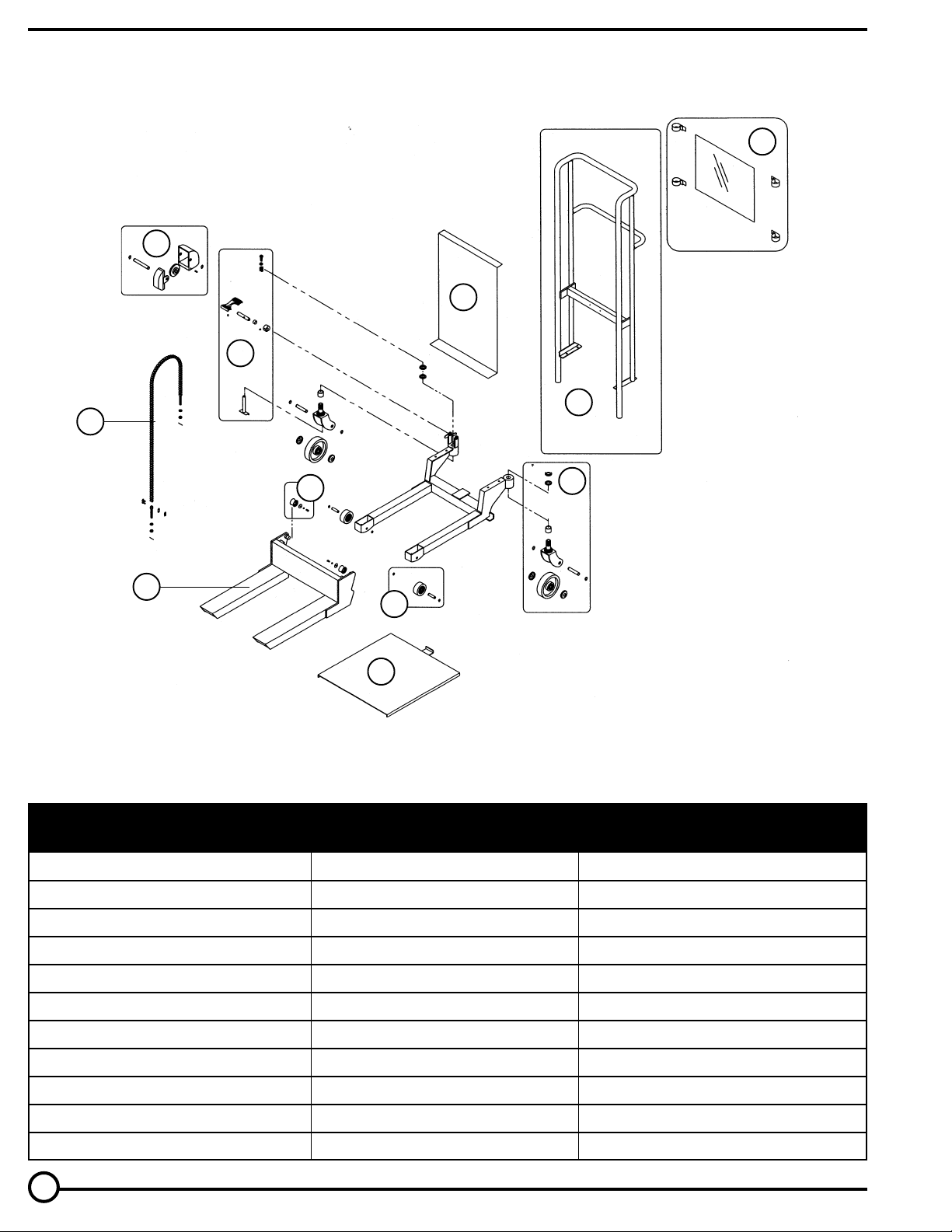

PARTS LIST

HEFTI-LIFT • HYD-5 & HYD-10

11

1

10

3

4

2

ITEM

NO.

1

2

3

4

5

6

7

8

9

10

11

8

DESCRIPTION

Chain Cover

Chain Assembly

Brake Assembly

Mast

Guide Wheel and Axle

Front Wheel and Axle

Rear Wheel and Axle

Forks Assembly

Top Deck

Front Metal Shield

Back Plastic Shield

5

7

6

9

PARTS IDENTIFICATION HEFTI-LIFT

MODEL HYD-5 & HYD-10

HYD-5

ENGINEER NO.

33-154-004

33-154-005

33-154-006

33-154-032

33-154-007

33-154-008

33-154-009

33-528-004

33-013-001

33-024-011

33-024-010

QTY.

1

1

1

1

4

2

2

1

1

1

1

HYD-10

ENGINEER NO.

33-154-016

33-154-017

33-154-006

33-514-018

33-154-007

33-154-008

33-154-009

33-528-004

33-013-001

33-024-013

33-024-012

QTY.

1

2

1

1

4

2

2

1

1

1

1

2

Page 3

1 2

FOOT PUMP

HEFTI-LIFT • HYD-5 & HYD-10

3

4

KIT

NO.

1

2

3

4

A

B

a/k Available only with purchase of kit

ITEM

NO.

1

2

3

4

A

B

DESCRIPTION

Release Knob Assembly

Pump Assembly

Foot Pedal Assembly

Plunger Assembly

Pump Seal Kit

Complete Assembly

PARTS IDENTIFICATION

FOOT PUMP (HEFTI-LIFT)

HYD-5

ENGINEER NO.

33-154-010

33-154-011

33-154-012

33-154-013

33-144-401

33-154-014

HYD-5

PART NO.

HYD5-FP01

-HYD5-FP03

HYD5-FP04

HYD5-KITA

HYD5-KITB

HYD-10

ENGINEER NO.

33-154-010

33-154-018

33-154-012

33-154-013

33-144-401

33-154-022

HYD-10

PART NO.

HYD10-FP01

-HYD10-FP03

HYD10-FP04

HYD10-KITA

HYD10-KITB

QTY.

1

1

1

1

1

1

3

Page 4

Troubleshooting Quick Reference Guide for HYD-5 & HYD-10

(For further information please contact the factory)

WARNING! BEFORE PERFORMING ANY MAINTENANCE WORK ALWAYS ENSURE THAT THE DECK/FORKS ARE IN LOWER POSITION

Observation Possible Cause Remedy

1.) Deck/forks do not raise.

a. Excessive load.

a. Remove part of the load.

2.) Foot pedal goes down but deck/forks do not

raise.

3.) Unit will pump under no load or when rapidly

stroked, or pedal will stroke without

pumping.

4.) Deck/forks raise when the pump is stroked

but lower on return stroke.

b. Oil is low.

c. Relief valve set too low.

d. Released pin is not rotating to closed

position.

e. Breather cap is not allowing air into cylinder.

a. Particle of dirt under the pressure relief

valve.

b. Particle of dirt under inlet check valve.

a. Pump is air locked.

b. Inlet check valve has foreign material on

seat.

c. Relief valve setting is out of adjustment.

d. Foreign material on pressure relief valve

seat.

e. Release pin has foreign material on the seat

or is stuck in the open position.

a. Outlet check valve is leaking.

b. Fill oil as necessary.

c. Increase only as necessary.

d. Check linkage for proper rotation.

e. Be sure cap has air hole. Clean cap out

with compressed air.

a. Lower deck/forks - Remove and clean

steel ball and seat. (Refer figure 1)

b. Lower deck/forks - Remove and clean inlet

ball and seat. (Refer figure 1)

a. Bleed air from system inlet.

b. Same as 2(b).

c. Adjust relief valve setting higher.

d. Same as 2(a).

e. Lower deck/forks - Remove and clean

steel ball and seat. (Refer figure 1)

a.1. Lower deck/forks - Remove and clean

steel ball and seat. (Refer figure 1)

a.2. Pump vigorously to remove debris.

5.) Deck/forks raise but is too slow.

6.) Spongy or jerky operation.

7.) Deck/forks raise but do not lower.

(PRESSURE RELIEF VALVE)

a. Foreign material stuck under pressure relief

valve or under inlet check valve.

a. Check for foreign material stuck in the deck

or frame rails.

b. Oil is low.

a. Foreign object blocking roller travel.

b. Release pin is not rotating to open position.

RELEASE PIN

STEEL BALL

VALVE PLUG

SPRING

STEEL BALL

STEEL BALL

SPRING

VALVE PLUG

STEEL BALL

SPRING

SPACER

SCREW

VALVE PLUG

FIGURE 1

a. Same as 2(a) / 2(b).

a. Correct as necessary.

b. Same as 1(b).

a. Correct as necessary.

b. Same as 1(d).

(OUTLET CHECK VALVE)

(INLET CHECK VALVE)

4

Page 5

WARNING LABEL IDENTIFICATION

MAKE SURE ALL WARNING LABELS ARE IN PLACE!

1

2

*Product safety signs or labels should be

periodically inspected and cleaned by the

product users as necessary to maintain

good legibility for safe viewing distance.

ANSI 535.4 (10.21)

Contact manufacturer for replacement labels.

CAPA400Kgs (880lbs)

1

2

CAUTION

!

PLATFORM MUST BE

LOWERED BEFORE

MOVING LIFT

210

PRECAUCIÓN

!

LA PLATAFORMA DEBE DE

ESTAR EN LA POSICIÓN

BAJA ANTES DE MOVER

EL ELEVADOR

ATTENTION

!

LA PLATE-FORME

DOIT ÊTRE ABAISSÉE

AVANT D’ACTIVER LE

MONTE-CHARGE

5

Page 6

Material Handling Prob lem Solvers

Scissor Lift Table

Pallet Server

XII

I

XI

High Rise Lift

Mobile Lift & Tilt

Work Stand

X

IX

Time is money.

Increased productivity

equals greater profitability ,

cost minimization and worker

compatibility . Ergonomic

products will assist you

with your production and

safety goals.

VIII

V

VII

VI

II

III

VI

45° Container Tilter

Ground Lift Tilter

Copyright 2008 Vestil Manufacturing Corporation

6

Loading...

Loading...