Page 1

Table of Contents Rev. 10/17/2019 HOOK-BASE MANUAL

Web: www.vestilmfg.com e-mail: info@vestil.com

Vestil Manufacturing Corp.

2999 North Wayne Street, P.O. Box 507, Angola, IN 46703

Telephone: (260) 665-7586 -or- Toll Free (800) 348-0868

Fax: (260) 665-1339

HOOK-BASE

Instruction Manual

Receiving instructions:

After delivery, remove the packaging from the product. Inspect the product closely to determine

whether it sustained damage during transport. If damage is discovered, record a complete description of

it on the bill of lading. If the product is undamaged, discard the packaging.

NOTE: The end-user is solely responsible for confirming that product design, use, and maintenance

comply with laws, regulations, codes, and mandatory standards applied where the product is used.

Replacement Parts and Technical Assistance:

For answers to questions not addressed in these instructions and to order replacement parts, labels,

and accessories, call our Technical Service and Parts Department at (260) 665-7586. The department

can also be contacted online at http://www.vestilmfg.com/parts_info.htm.

Signal Words….……………………..…………………………………………………………………………………….…….. 2

Hazards of Improper Use…..……………………………………………………………..…………………………………..… 2

Specifications…………………………………………………………………………………….………………………… 3, 4, 5

Record of Normal Condition………………………………………………………………………………………………….… 5

Exploded View & Bill of materials………………………………………….……...…………….………………………….…. 6

Using the HOOK-BASE……………………………..…………………………………………………………………….. 6, 7, 8

Inspections & Maintenance……………………………………………………………………………………………………... 9

Labeling Diagram……...………………………………………………………………………………………………………… 9

Limited Warranty…...…………………………………………………………………………………………………………….10

Table of Contents

Table of Contents Copyright 2016 Vestil Manufacturing Corp Page 1 of 10

Page 2

Table of Contents Rev. 10/17/2019 HOOK-BASE MANUAL

Signal Words:

This manual classifies personal injury risks and situations that could lead to property damage with SIGNAL

WORDS. A safety message appears with a signal word that describes an improper/dangerous use of the product.

The signal word indicates the seriousness of the injury that could result from the described use.

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or

Identifies practices likely to result in product/property damage, such as operation that might

SERIOUS INJURY.

damage the product.

Each person who assembles, installs, uses, or maintains this product should read the entire manual in advance

and fully understand the directions. If after reading the manual you do not understand an instruction, ask your

supervisor or employer for clarification, because failure to adhere to the directions in this manual might result in

serious personal injury.

Hazards of Improper Use:

Vestil strives to identify foreseeable hazards associated with the use of its products. However, no manual can address

every conceivable risk. The most effective way to avoid injury from misusing this product is to exercise sound judgment

whenever the HOOK-BASE is in use

Improper or careless use of this product might result I serious personal injuries.

• Read and understand the entire manual before assembling, installing, using or servicing the product. Read

the manual to refresh your understanding of proper use and maintenance procedures whenever necessary.

• DO NOT exceed the 4,000 lb. (1,818.2kg) capacity/maximum rated load. See Label 287 on product; also see Labeling

Diagram on p. 9.

• Inspect the product before each use following the instructions in Inspections & Maintenance on p. 9. DO NOT use the

HOOK-BASE unless it is in normal condition.

• Before attaching the HOOK-BASE to the coupler of a piece of towable equipment, inspect the coupler and latch.

Confirm that all parts are in good condition. DO NOT use the HOOK-BASE to tow equipment UNLESS the coupler

seats onto the correct ball hitch and latches properly. ONLY USE THE HOOK-BASE TO PUSH TOWED EQUIPMENT.

DO NOT PULL EQUIPMENT WITH THIS DEVICE!

• Whenever using the load hook, always test the soundness of the connection between the hook and the suspended

load before transporting the load. Lift the load a few inches above the ground. Load swing should be minimal and the

load should not shift. If the load is not stable while suspended, return it to the ground and adjust the load rigging.

• Minimize load swing. Position the lifting hook directly above the center of the top of the load; then attach the load to

the hook with appropriate rigging and slowly raise the load.

• DO NOT remove or obscure any label.

• Verify the placement and legibility of all labels shown in the Labeling Diagram on p. 9. DO NOT use this device

UNLESS all product labels are easily readable and undamaged.

• DO NOT ride, or sit, on the HOOK-BASE.

• DO NOT use the HOOK-BASE to tow anything while people are onboard.

• DO NOT use the lifting hook to lift any apparatus that supports people, such as a work platform.

• DO NOT leave towed equipment attached to the HOOK-BASE. Properly immobilize the equipment (e.g. with wheel

chocks) and disengage it from the towing attachment when towing is finished.

• DO NOT leave suspended loads unattended. Always disengage any load suspended from the lifting hook before

leaving it unattended.

• DO NOT modify the HOOK-BASE without written approval from Vestil. Unauthorized modifications automatically

void the Limited Warranty (p. 10) and might make the HOOK-BASE unsafe to use.

• ONLY raise the forks as high as necessary to put the trailer in a horizontal (level) position for towing.

• If using the hoist hook attachment to lift loads, only raise the forks as high as necessary to raise the load off of the

ground and to avoid contact with objects in the path of travel.

• DO NOT use the HOOK-BASE to transport anything but trailers or equipment designed to be towed. The towing

attachment, e.g. ball or pintle hook, should match the towing adapter on the trailer or other towable equipment.

• Use this HOOK-BASE consistently with the fork truck training you received.

• DO NOT use the unit UNLESS all product labels are easily readable and undamaged. See Labeling Diagram on p. 9.

.

Table of Contents Copyright 2016 Vestil Manufacturing Corp Page 2 of 10

Page 3

Table of Contents Rev. 10/17/2019 HOOK-BASE MANUAL

40”

101.6cm

36”

91.4cm

323/8”

82.2cm

0.77”

2.0cm

19.91”

50.6cm

4,000 lb.

1,818.2kg

88 lb.

(40kg)

46”

116.8cm

42”

106.7cm

383/8”

97.5cm

0.74”

1.9cm

23.08”

58.6cm

4,000 lb.

1,818.2kg

96 lb.

(43.6 kg)

52”

132.1cm

48”

121.9cm

443/8”

112.7cm

0.72”

1.8cm

26.23”

66.6cm

4,000 lb.

1,818.2kg

105 lb.

(47.7 kg)

4219/32”

108.2cm

40”

101.6cm

36”

91.4cm

373/16”

94.5cm

0.90”

2.3cm

21.52”

54.0cm

4,000 lb.

1,818.2kg

98 lb.

(44.5 kg)

4819/32”

123.4cm

46”

116.8cm

42”

106.7cm

433/16”

109.7cm

0.87”

2.2cm

24.85”

63.1cm

4,000 lb.

1,818.2kg

106 lb.

(48.2 kg)

5419/32”

138.7cm

52”

132.1cm

48”

121.9cm

493/16”

124.9cm

0.86”

2.2cm

28.12”

71.4cm

4,000 lb.

1,818.2kg

114 lb.

(51.8 kg)

HOOK-BASE only—

HOOK-BASE with 3-Ball

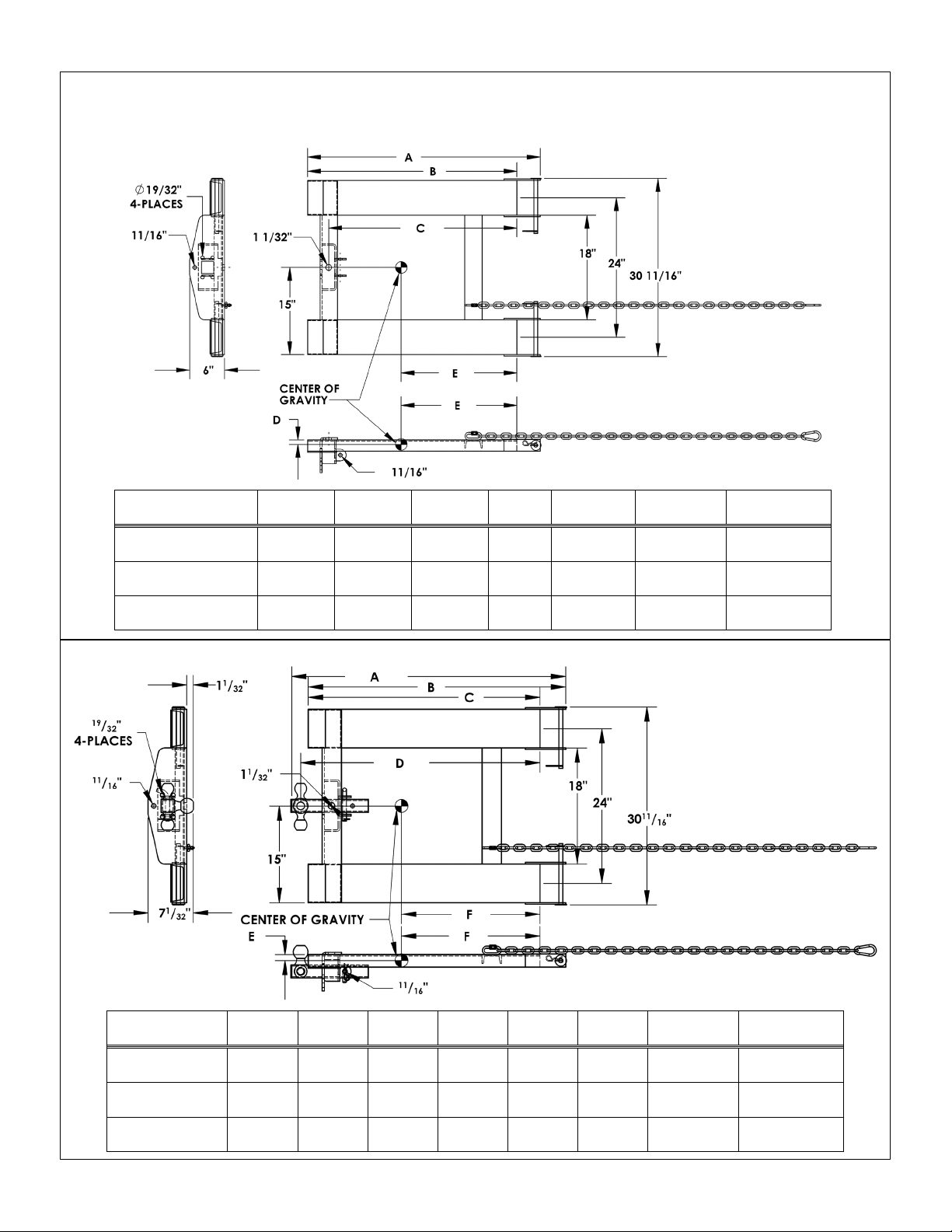

Specifications:

Dimensions and other specifications of each standard model HOOK-BASE appear in the diagrams and tables

below and on pages 4 & 5.

Model A B C D E Capacity Net Weight

HOOK-BASE-32

HOOK-BASE-38

HOOK-BASE-44

Model A B C D E F Capacity Net Weight

HOOK-BASE-32

HOOK-BASE-38

HOOK-BASE-44

No towing or lifting

attachments.

Hitch Attachment.

Installation instructions

on p. 7.

Table of Contents Copyright 2016 Vestil Manufacturing Corp Page 3 of 10

Page 4

Table of Contents Rev. 10/17/2019 HOOK-BASE MANUAL

40”

101.6cm

36”

91.4cm

1.07”

2.7cm

20.40”

51.8cm

4,000 lb.

1,818.2kg

91 lb.

(41.4kg)

46”

116.8cm

42”

106.7cm

1.02”

2.6cm

23.62”

60.0cm

4,000 lb.

1,818.2kg

99 lb.

(45 kg)

52”

132.1cm

48”

121.9cm

0.99”

2.5cm

26.81”

668.1cm

4,000 lb.

1,818.2kg

108 lb.

(49.1 kg)

4315/16”

111.6cm

40”

101.6cm

36”

91.4cm

0.90”

2.3cm

21.44”

54.5cm

4,000 lb.

1,818.2kg

97 lb.

(44.1 kg)

4915/16”

126.8cm

46”

116.8cm

42”

106.7cm

0.87”

2.2cm

24.71”

62.8cm

4,000 lb.

1,818.2kg

105 lb.

(47.7 kg)

5515/16”

142.1cm

52”

132.1cm

48”

121.9cm

0.84”

2.1cm

27.96”

71.0cm

4,000 lb.

1,818.2kg

113 lb.

(51.4 kg)

HOOK-BASE with Hook

on p. 7.

HOOK-BASE with Pintle

Specifications (continued):

Model A B C D Capacity Net Weight

HOOK-BASE-32

HOOK-BASE-38

HOOK-BASE-44

Model A B C D E Capacity Net Weight

HOOK-BASE-32

HOOK-BASE-38

and Shackle.

Installation instructions

Hook.

Installation instructions

on p. 6.

HOOK-BASE-44

Table of Contents Copyright 2016 Vestil Manufacturing Corp Page 4 of 10

Page 5

Table of Contents Rev. 10/17/2019 HOOK-BASE MANUAL

Model

Jaw Opening

Vertical Capacity

Uniform Trailer Capacity

Net Weight

40”

101.6cm

36”

91.4cm

323/8”

82.2cm

0.68”

1.7cm

21.44”

54.5cm

4,000 lb.

1,818.2kg

91 lb.

(41.4 kg)

46”

116.8cm

42”

106.7cm

383/8”

97.5cm

0.67”

1.7cm

23.58”

59.9cm

4,000 lb.

1,818.2kg

99.1 lb.

(45.0 kg)

52”

132.1cm

48”

121.9cm

443/8”

112.7cm

0.66”

1.7cm

26.77”

68.0cm

4,000 lb.

1,818.2kg

108 lb.

(49.1 kg)

HOOK-BASE with

Specifications (continued):

Model A B C D E Capacity Net Weight

HOOK-BASE-32

HOOK-BASE-38

HOOK-BASE-44

Hitch Attachments:

Ball Hitches Ball Diameter Shank Diameter Capacity Net Weight

Tow Ball. Installation

instructions on p. 6.

BALL-178 17/8” (4.8cm) 1” (2.5cm) 2,000 lb. (909.1kg) 3 lb. (1.4kg)

BALL-200 2” (5.1cm) 1” (2.5cm) 5,000 lb. (2272.7kg) 3 lb. (1.4kg)

BALL-2516 25/16” (5.9cm) 1” (2.5cm) 5,000 lb. (2272.7kg) 4 lb. (1.8kg)

HITCH-3B

Use with 3” (inner

diameter) pintle ring

Record of Normal Condition:

When the unit is first unpacked, make a written record of its condition. Include observations about all

features, i.e. pins, pin clips, welds, the frame, safety chain, quick link, and snap hook. Thoroughly

photograph the unit and all labels applied to it. Add the photographs to the record. Describe where each

label is located. This record establishes “normal condition”. During future inspections, compare your

observations to the record to determine if the unit is in normal condition. See Inspections &

Maintenance on p. 9.

PINTLE

7

/8”, 2”, & 25/

1

16”

(4.8cm; 5.1cm; 5.9cm)

1¾” (~4½ cm)

N/A (hitches permanently

mounted to 2”x2”x12”

square tube)

2,000 lb.

(909.1kg)

2,000 lb. (909.1kg)

3,500 lb. (1590.9kg)

7,500 lb. (3409.1kg)

10,000 lb.

(4545.5kg)

12 lb.

(5.5kg)

12 lb.

(4.7kg)

Table of Contents Copyright 2016 Vestil Manufacturing Corp Page 5 of 10

Page 6

Table of Contents Rev. 10/17/2019 HOOK-BASE MANUAL

TOW BALL

PINTLE HOOK

BASE: first

EQUIPMENT WITH

THIS DEVICE!

Item

Part no.

Description

Qty.

08-514-102

Frame weldment:

HOOK-BASE-42

1

#11 hitch pin clip, 1/8” x

25/8”

Tine lock

Quick

link

Front

end

Fork

Hitch

Hitch plate

Exploded View and Bill of Materials:

receiver

Using the HOOK-BASE: Refer to the Exploded View (above) for locations of features described.

OF YOUR LIFT TRUCK.BEFORE USING THIS DEVICE, US FEDERAL REGULATION 29 CFR 1910.178

REQUIRES YOU TO CONTACT THE MANUFACTURER OF YOUR LIFT TRUCK TO REQUEST:

o WRITTEN APPROVAL (29 CFR 1910.178(a)(4); AND

o MARKINGS FOR THE LIFT TRUCK THAT IDENTIFY THE ATTACHMENT AND GIVE THE APPROXIMATE

WEIGHT OF THE TRUCK AND ATTACHMENT AT MAXIMUM ELEVATION WITH A LATERALLY-CENTERED

LOAD (29 CFR 1910.178(a)(5). DO NOT USE THIS DEVICE UNTIL YOUR LIFT TRUCK IS MARKED WITH

CORRECTED CAPACITY TAGS. ONLY USE THIS DEVICE WITH LIFT TRUCKS THAY HAVE BEEN

MARKED WITH CORRECTED CAPACITY TAGS.

Step 1: Select the appropriate towing attachment and install it.

A) Insert the bolts through the four bolt holes in the

hitch plate (shown by dashed arrows).

B) Fasten the pintle hook to the HOOKapply a lock washer to each bolt; then apply a hex nut.

Fully tighten the nuts to secure the connections.

ONLY USE THE HOOK-BASE TO PUSH TOWED

EQUIPMENT. DO NOT PULL

bracket

08-514-140

1

08-514-139

HOOK-BASE-32

HOOK-BASE-38

1

1

2 45286

2

3 14-612-001 Pin, lock, weldment 2

4 09-145-018 5/16” chain 56” long 1

tube

5 08-145-041 Snap hook, 5/16” 1

USING THIS (LIFT TRUCK) FRONT END ATTACHMENT AFFECTS THE CENTER OF GRAVITY

A) Insert the tow ball

through the opening in the

top of the hitch plate.

B) Fasten the tow ball to

the HOOK-BASE: first

apply a lock washer to each

bolt; then apply a hex nut.

Fully tighten the nuts to

secure the connections.

ONLY USE THE HOOKBASE TO PUSH TOWED

EQUIPMENT. DO NOT

PULL EQUIPMENT WITH

THIS DEVICE!

Table of Contents Copyright 2016 Vestil Manufacturing Corp Page 6 of 10

Page 7

Table of Contents Rev. 10/17/2019 HOOK-BASE MANUAL

Hitch pin

clip

Locking

pin

Tine lock bracket

Secure locking pins with hitch pins

3-BALL HITCH (model HITCH-3B)

ONLY PUSH TOWED EQUIPMENT with the HOOK-BASE. DO NOT PULL EQUIPMENT WITH THIS DEVICE!

2”

25/16”

17/8”

Heel of

Side view of fork

HOOK AND SHACKLE (models HOOK-S-4 and HOOK-R-4)

Shackle

Shackle

Insert shackle pin here

NOTE:

Select the appropriate tow ball and insert the hitch through the (square) hitch receiver (see Exploded View on p.

6) in the hitch plate with the selected tow ball facing upwards. Align the pin holes in the hitch with the pin holes in

the hitch brackets. Insert the lock pin through the pin holes and secure it in place with a hitch pin.

Unscrew the shackle pin. Align the shackle with the bottom hole of the hitch plate and reattach the shackle pin.

Swivel

hook

model

HOOKS-4

shown.

Step 2: Remove the locking pins from the tine lock brackets and adjust the positions of the forks of your lift truck to

match the locations of the fork tubes. Slowly drive the truck forward until the forks extend all the way through the fork

pockets and the heels of the forks contact the ends of the fork tubes (the tine lock brackets should project behind the

heels of the forks). Reinstall the locking pins; then reinstall the hitch pin clips.

NOTE: The forks of your lift truck should be AT LEAST as long as the fork tubes.

pin

fork

Table of Contents Copyright 2016 Vestil Manufacturing Corp Page 7 of 10

Page 8

Table of Contents Rev. 10/17/2019 HOOK-BASE MANUAL

Snap hook

Quick link

Fork carriage

Safety chain

Unlock snapper pin and

Press upwards on upper jaw

Pintle jaws open

Step 3: Fasten the safety chain to the carriage

of the forklift WITH NO SLACK. Loop the

safety chain around the carriage. Attach the

snap hook at the end of the chain to the quick

link (welded to the frame). Wrap the chain

around the carriage as many times as is

necessary to remove slack from the chain. The

chain must not be able to disconnect from the

carriage without deliberate effort.

with snap

hook

wrapped around the forklift carriage and proper attachment of the snap hook to the quick link. In order to

clearly show the connections, slack is left in the chain. However, there must be no slack in the chain whenever

the HOOK-BASE is used. Wrap the chain around the carriage to remove all slack. Otherwise, the chain will not

prevent the unit from sliding on the forks.

The chain is an essential safety-enhancing feature. This photograph shows the safety chain

Step 4: Connect the trailer or other item to be towed to the towing attachment. Raise the forks sufficiently to put

the tongue of the trailer in a horizontal position.

To connect a trailer to the pintle hook attachment:

a) Unlock the snapper pin and remove it from the upper jaw of the pintle hook;

b) Open the jaws by pressing the upper jaw upwards, while also pressing the opening lever forward.

The jaw will maintain the open position when the lever is pressed all the way forward.

2

then pull out the pin

and press opening lever

forward

Table of Contents Copyright 2016 Vestil Manufacturing Corp Page 8 of 10

Page 9

Table of Contents Rev. 10/17/2019 HOOK-BASE MANUAL

B C D

B: Label 287 (covered with label 815)

C: Label 218

D: Label 658

A

A: Label 1049

Inspections & Maintenance:

Proper use, maintenance, and storage are essential for this product to function properly.

o Inspect the unit as described and at least as frequently as recommended.

o Use the product in accordance with the instructions in this manual.

o Store the HOOK-BASE and all towing and lifting attachments in a dry location.

Before each use, inspect the HOOK-BASE to confirm that it is in normal condition.

1. Safety chain and snap hook (attached to the free end of the safety chain): confirm that the spring latch (of the

hook) automatically closes firmly. Do not continue to use the HOOK-BASE if the tine locks, snap hook, chain,

or quick link are damaged or worn severely enough to prevent normal function.

2. Labeling: all labels should be readable and located as shown in the Labeling Diagram (below). If a label is unreadable or missing, contact Vestil to order a replacement.

At least 1 time per month, inspect:

1. Fasteners (hardware):

Bolts, nuts, washers, pins, cotter pins;

Chain and snap hook.

2. Fork pockets: confirm that each pocket is structurally sound and free of significant rust. Do not use the HOOKBASE if the fork pockets are structurally compromised.

3. Welds: confirm that all welds are intact. Only use this product if all welds are in normal, undamaged condition.

4. Towing attachments, fork pockets, and hitch plate: confirm normal condition, i.e. no structural deformation,

warps, or cracks, etc.

5. Overall condition: the structure should be clean, square and rigid, and free of rust and corrosion. Remove dirt

and debris. Apply touchup paint to area where the finish is damaged. Do not use the HOOK-BASE if the

supporting frame is structurally unsound.

Labeling Diagram:

Each unit should be labeled as shown in the diagram. However, label content and locations are subject to

change so your product might not be labeled exactly as shown. Compare the diagram below to your Record

of Normal Condition. If there are any differences between actual labeling and this diagram, adapt the

diagram to reflect actual labeling. Replace all labels that are damaged, missing, or not easily readable (e.g.

faded). To order replacement labels or to inquire whether your unit is properly labeled, contact the technical

service and parts department online at http://www.vestilmfg.com/parts_info.htm

and asking for the Parts Department.

or by calling (260) 665-7586

Table of Contents Copyright 2016 Vestil Manufacturing Corp Page 9 of 10

Page 10

Table of Contents Rev. 10/17/2019 HOOK-BASE MANUAL

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this product to be free of defects in material and workmanship

during the warranty period. Our warranty obligation is to provide a replacement for a defective, original part covered by

the warranty after we receive a proper request from the Warrantee (you) for warranty service.

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

Definition of “original part”?

An original part is a part used to make the product as shipped to the Warrantee.

What is a “proper request”?

A request for warranty service is proper if Vestil receives: 1) a photocopy of the Customer Invoice that displays the

shipping date; AND 2) a written request for warranty service including your name and phone number. Send requests

by one of the following methods:

US Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 info@vestil.com

2999 North Wayne Street, PO Box 507 Phone Enter “Warranty service request”

Angola, IN 46703 (260) 665-7586 in subject field.

In the written request, list the parts believed to be defective and include the address where replacements should be

delivered. After Vestil receives your request for warranty service, an authorized representative will contact you to

determine whether your claim is covered by the warranty. Before providing warranty service, Vestil will require you to

send the entire product, or just the defective part (or parts), to its facility in Angola, IN.

What is covered under the warranty?

The warranty covers defects in the following original, dynamic parts: motors, hydraulic pumps, motor controllers, and

cylinders. It also covers defects in original parts that wear under normal usage conditions (“wearing parts”), such as

bearings, hoses, wheels, seals, brushes, and batteries.

How long is the warranty period?

The warranty period for original dynamic components is 90 days. For wearing parts, the warranty period is 90 days.

Both warranty periods begin on the date Vestil ships the product to the Warrantee. If the product was purchased from

an authorized distributor, the periods begin when the distributor ships the product. Vestil may, at its sole discretion,

extend a warranty period for products shipped from authorized distributors by up to 30 days to account for shipping

time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will

contact you to discuss your claim.

What is not covered by the warranty?

The Warrantee (you) is responsible for paying labor costs and freight costs to return the product to Vestil for

warranty service.

Events that automatically void this Limited Warranty.

• Misuse;

• Negligent assembly, installation, operation or repair;

• Installation/use in corrosive environments;

• Inadequate or improper maintenance;

• Damage sustained during shipping;

• Collisions or other accidents that damage the product;

• Unauthorized modifications: Do not modify the product IN ANY WAY without first receiving written authorization from

Vestil.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to the extent

allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty. Vestil

makes no warranty or representation that this product complies with any state or local design, performance, or safety

code or standard. Noncompliance with any such code or standard is not a defect in material or workmanship.

Table of Contents Copyright 2016 Vestil Manufacturing Corp Page 10 of 10

Loading...

Loading...