Page 1

VESTIL MANUFACTURING CORPORATION

2999 North Wayne Street

Angola, Indiana 46703 USA

Phone (260) 665-7586 Fax (260) 665-1339

E-mail: sales@vestil.com • www.vestil.com

Contents

Warnings and Safety Instructions .......................... 1

Receiving Instructions............................................ 1

Loading Instructions............................................... 2

Operating Instructions............................................ 2

Electric Schematic ................................................. 3

Battery Charger Operation.................................. 4-5

Hydraulic Operation and Schematic.................... 6-7

Trouble Shooting Guide ...................................... 8-9

Revised 09-03 15-126-101

A company dedicated to solving ergonomic and material

handling problems since 1955.

OWNER'S

MANUAL

HIGH RISE LIFT • MODEL HIPM

Exploded Parts Drawing ......................................10

Parts Identification ...............................................11

Periodic Maintenance Instructions .......................12

Foot Pump Operation...........................................13

Warning Label Identification .................................14

Warranty..............................................................15

WARNINGS & SAFETY INSTRUCTIONS

Read owner's manual completely before operating unit!

• Not a personnel lift.

• Never go under forks if there is weight on unit.

• Remove weight & disconnect power before working on

unit.

• Use only maintenance parts supplied or approved by the

manufacturer.

• Do not change pressure relief valve setting.

• Do not clamp hydraulic cylinder in a vise as you may

distort the barrel.

• Never operate the lift unless you are watching it.

• Do not go near leaks - High pressure oil easily punctures

skin causing serious injury, gangrene, or death.

• Load tight agianst the bulkhead within the rated capcity.

• Transport loads in the lowered position only.

• Do not continue to operate the UP control if unit is not

raising.

• Relieve system pressure by operating the DOWN control

after the unit has come to rest.

• Consult factory before adding or performing any

modification to the original equipment.

• Do not use brake fluids or jack oils. Use AW-32 Hydraulic

oil or equal.

• Make sure all operator safety labels and guards are

in place.

damage during transit. If you see damage when unloading

make a note of it on the SHIPPER RECEIVER.

Remove all packing and strapping material, inspect

for damage. IF DAMAGE IS EVIDENT, FILE A CLAIM

WITH THE CARRIER IMMEDIATLY! Also, check the unit

size, type of power unit, etc., to ensure the unit is correct

for the intended application.

SERIAL NUMBER AND CAPACITY

The serial number and capacity is inscribed on the

nameplate (See p. 14 for location). Please remember to

include these numbers in any correspondence with your dealer

or the factory.

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected prior

to shipment. However, it is possible that the unit may incur

HIGH RISE LIFT

MODEL HIPM

1

Page 2

LOADING INSTRUCTIONS

The load capacity rating as inscribed on the

nameplate of your unit designates the net capacity

for an evenly distributed load. This capacity must

never be exceeded, as permanent damage or

injury may result.

3.) Lift may only be used be used by authorized

personnel. All lift operators must have read

and understood all operating procedures

and safety guidelines in this Owner's Manual.

4.) Lift must never be overloaded.

When loading the lift always follow these guidelines:

1.) Always load tightly agianst the bulkhead.

2.) Transport loads in the lowered position only.

OPERATING INSTRUCTIONS

The High Rise Lift is furnished with a constant pressure rocker switch control as standard

equipment.

In order to operate the unit, pressure must

be maintained in the UP or Down position to raise

or lower the forks. On releasing either button, the

forks will remain in that particular position until the

switch is depressed again.

Responsibilities of Owners/Users

It is the responsibility of the owner/user for

the following:

5.) Operator must ensure that all safety

features of the lift are functioning properly

before each use.

6.) Any modifications to the lift must be

approved in writing by the manufacturer.

ORDERING REPLACEMENT OR EXTRA PARTS

Our company takes pride in using the finest

available parts for our equipment. We are not

responsible for equipment failure resulting from the

use of unapproved replacement parts. To order

replacement or extra parts for your equipment

contact Customer Service at the factory. In any

correspondence with the factory please include the

Serial Number which is inscribed on the nameplate

of the piece of equipment. Use only the part

numbers provided in this Owner's Manual. When

ordering parts for AC power units please indicate

the motor phase and voltage that the equipment is

operating on.

1.) The lift must be inspected and maintained in

accordance with the guidelines in this

manual.

2.) Any lift not in safe operating condition must

be removed from service until it is returned

to proper operating condition.

Unsafe condition may include, but is not

limited to the following : excessive hydraulic or air

leakage, missing rollers, pins, or fasteners, any

cracked or deformed structural members, cut or

frayed hydraulic, electric or air lines, and damaged controls or safety devices.

All repairs and maintenance must be per-

formed by qualified personnel.

2

Page 3

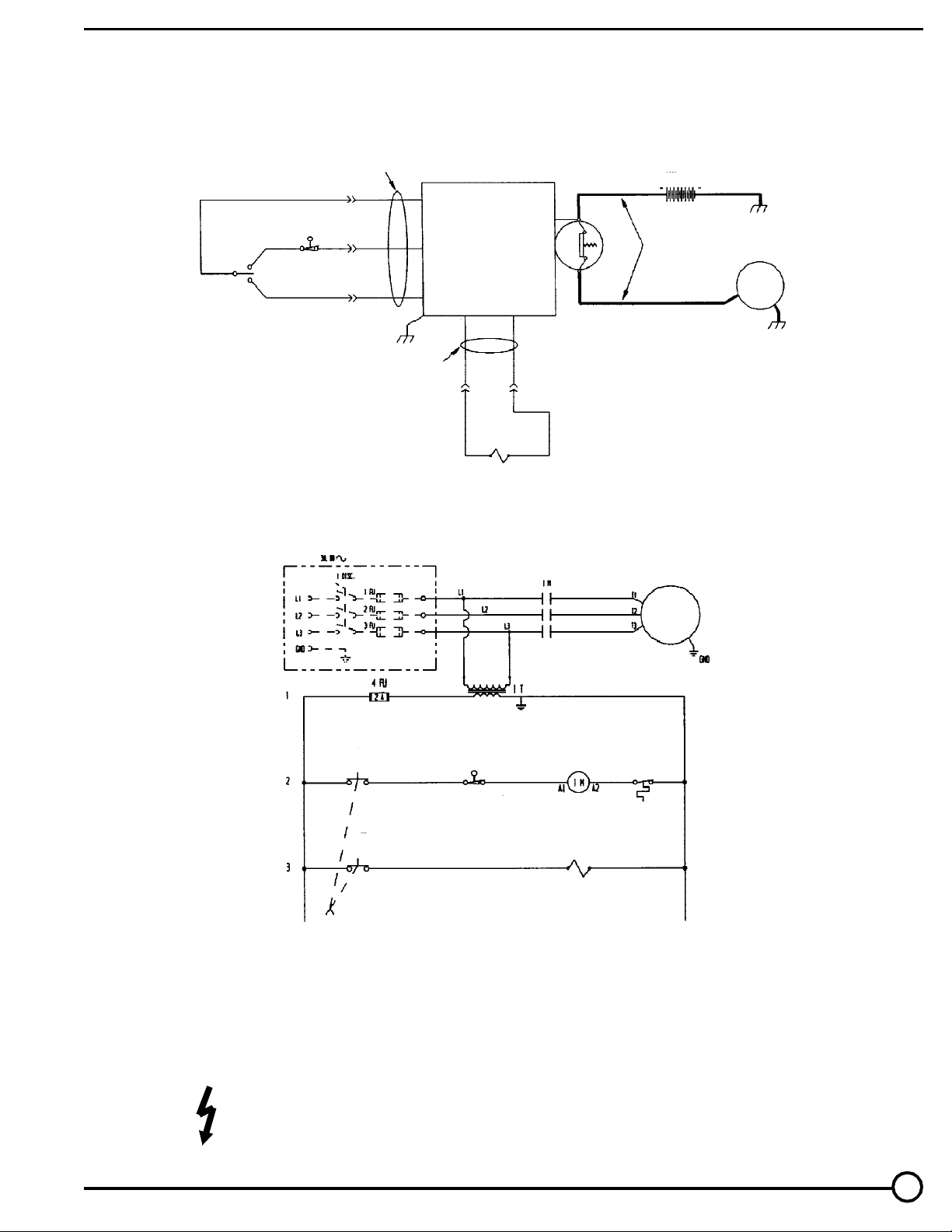

ELECTRICAL SCHEMATIC

blk

ROCKER

SWITCH

RAISE

LOWER

RAISED

brn

blu

blk

Pigtail

12

VDC

DC, MOTOR START

SWITCH AND

LOW-VOLTAGE CUT-OFF

VOLTAGE

yel blk

Pigtail

1 SOL H

N.C.

LOWERING

VALVE

12 VDC

(DEEP CYCLE)

1 M

#4 WELDING CABLE

1 MTR

1 MTR

red

1 PB

RAISE

red whi blk

1 LS

PLATFORM RAISED

1 SOL H

blk whiorg

1MTR

T'STAT

N.C. PLATFORM

LOWERING VALVE

BE SURE ALL POWER IS OFF BEFORE ATTEMPTING TO WORK ON THIS EQUIPMENT!

CAUTION: SERVICE WORK SHOULD BE PERFORMED ONLY BY TRAINED & QUALIFIED PERSONNEL

3

Page 4

Operating Instructions for Optional Bench Top Style Battery Charger

(for DC models equipped with our Bench Top Charger)

WARNING!

Working with or near lead acid batteries is dangerous.

Batteries contain sulfuric acid and produce explosive gases.

A battery explosion could result in loss of eyesight or serious

burns.

Do not smoke or allow a spark or flame near batteries.

Charge batteries in locations which are clean, dry, and well

ventilated. Do not lay tools or anything metallic on top of any

battery. All repairs to a battery must be made by experienced

and qualified personnel.

When working with batteries, remove personal items

such as rings, bracelets, necklaces, and watches. A battery

can produce enough voltage to weld jewelry to metal causing

a severe burn.

Always have plenty of fresh water and soap nearby in

case battery acid contacts skin, clothing, or eyes.

Operating the battery with a low battery voltage can

cause premature motor contact failure.

Do's and Don'ts

DO NOT leave charger connected for an indefinite length

of time.

DO NOT smoke, strike a match or cause a spark in the

vicinity of battery during charging.

DO make sure all battery connections are tight and clean.

DO NOT expose to rain or adverse conditions.

DO replace defective cords and wires immediately.

DO locate charger at least 24" above floor while charging.

DO NOT overcharge battery (manual position only)

OPERATING INSTRUCTIONS

Even if you did not purchase an optional battery

charger, your new High Rise Lift Truck has been fitted with

a matching plug which will connect directly to the Bench

Top Charger we offer. Contact your distributor if you wish

to purchase a battery charger.

4

Page 5

Operating Instructions for Standard On Board Style Battery Charger

(for DC models equipped with our On Board Charger)

WARNING!

Working with or near lead acid batteries is dangerous.

Batteries contain sulfuric acid and produce explosive

gases. A battery explosion could result in loss of eyesight

or serious burns.

Do not smoke or allow a spark or flame near batteries. Charge batteries in locations which are clean, dry,

and well ventilated. Do not lay tools or anything metallic

on top of any battery. All repairs to a battery must be

made by experienced and qualified personnel.

When working with batteries, remove personal items

such as rings, bracelets, necklaces, and watches. A

battery can produce enough voltage to weld jewelry to

metal causing a severe burn.

Always have plenty of fresh water and soap nearby in

case battery acid contacts skin, clothing, or eyes.

Operating the battery with a low battery voltage can

cause premature motor contact failure.

Our On Board charger is equipped with an external

ground wire (small green). During installation the charger

must be grounded to the equipment which it is connected

to. Be sure this wire is always connected to the chassis,

frame, or other metallic surface considered to be ground.

OPERATING INSTRUCTIONS

1.) Plug charger into a receptacle known to have

approximately 115V and 60 Hz. If an extension cord

must be used, keep it short and as large as possible.

A small cord will decrease the output of the charger

due to the voltage drop in the line. This will increase

the charging time.

ADDITIONAL INFORMATION

The On Board charger is current limited and will not

exceed its rated output, even if loads are placed on the

battery while the battery is charging.

The On Board chargers fuse will blow if the charger is

connected in reverse polarity

TROUBLESHOOTING

1) Make sure battery connections are electrically and

mechanically sound.

2) Check AC source for power.

3) Check fuse. Replace only with a fuse having the

same rating as originally supplied.

4.) Check battery condition. A highly sulfated battery

may take some time before current begins to flow

through it.

DO'S AND DON'TS

DO NOT leave charger connected for an indefinite length

of time.

DO NOT smoke, strike a match or cause a spark in the

vicinity of battery during charging.

DO make sure all battery connections are tight and clean.

DO NOT expose to rain or adverse conditions.

DO replace defective cords and wires immediately.

2.) When properly connected, the charge LED will

indicate the status of charge current flowing to the

battery.

3.) With only the red LED lit, the charger is providing full

output to the battery.

With both the red and green LED's lit the charger is

"topping off" the battery.

When only the green LED is on, the unit is providing a

"float" or maintenance, charge.

4.) Remember to unplug the charger before moving

equipment. Failure to do so could cause damage to

cords, receptacles and other equipment.

5

Page 6

HYDRAULIC OPERATIONFOR AC/DE

When the operator wants to raise the unit, he/she depresses the UP button. This starts the electric motor

which turns the hydraulic pump. Oil from the reservoir is drawn in through the suction filter and into the pump.

The pump delivers pressurized oil through a check valve before it enters the cylinders.

The function of the check valve is to allow the oil to flow in one direction, (towards the cylinders), and prevents

the flow of oil back into the pump circuit when the pump stops running. This holds the oil in the cylinders and will

maintain any particular barrel elevation, for extended periods of time.

If the load is excessive, and the UP button is still depressed, excessive pressure will build up in the circuit

between the pump and the cylinders. This forces the relief valve to unseat allowing the pump flow to circulate to

the reservoir preventing hydraulic or structural damage.

When the operator desires to lower the unit, he/she depresses the DOWN button. This energizes the

lowering solenoid valve coil, unseating the poppet valve and allowing oil return from the cylinders through the

pressure-compensated flow control valve, to the reservoir.

Releasing the DOWN button will de-energize the solenoid, closing the valve poppet. This and the check

valve prevents the oil from returning to the reservoir and the cylinders will stop retracting. The unit will maintain

that particular elevation until the operator chooses to move it once again.

Cartridge Valves

The lowering valve, as discussed above, is of cartridge construction and is virtually maintenance-free.

If there is a faulty operation, check Trouble Shooting Section. To clean the cartridge valve, follow this procedure:

1.) WARNING! Lower forks completely before removing cartridge valve.

2.) Use a sharp object to push poppet in from the bottom to open the valve.

3.) Repeat several times while valve is immersed in kerosene or mineral spirits. Blow dry.

4.) Blow compressed air through valve while holding the valve open as described in step 2.

5.) Inspect "o" rings and the teflon washer. If either shows nicks, tears, or cuts, replace.

6.) Reinstall. The valve should be tightened to approximately 20 ft. lbs.

Velocity Fuse

There is a brass velocity fuse with a stainless steel spring in the base of each cylinder (Item 10). In the

event of a hydraulic hose or fitting failure, the platform starts to lower at a fast rate. As soon as the descent speed

exceeds the preset speed, the Velocity Fuse will shut off the oil flow and the platform will remain nearly stationary

until pressure is re-applied after repairs are done. This safety feature reduces the possibility of accidental

personal injury or damage to the table or contents. If air is introduced into the system, the velocity fuse can lock

up even though no failure has occurred. To reset the velocity fuse just activate the pump by jogging the UP button.

Remove the load and cycle the unit several times to purge air.

6

Page 7

Air Bleed Procedure

If the forks descend very slowly or will not descend at all, air is likely trapped in the hydraulic circuit and must be bled from the system. The High Rise Lift Truck utilizes a bleeder screw at the top of

the cylinder. To bleed air from the hydraulic circuit, follow these directions.

1.) Loosen the bleeder screw at the to of the cylinder approximately 1/4 to 1/2 turn to allow trapped

air to escape. Depressed the foot pump treadle or job the motor to push the out of the system.

2.) When the cylinder is free of air only clear hydraulic fluid will be visible at the bleeder screw. Tighten

the hose fitting.

HYDRAULIC SCHEMATIC

1 MTR.

1.5" X 18" DISPLACEMENT

CYLINDER W/INTERNAL

VELOCITY FUSE

HYD.

PUMP

SUCTION

FILTER

LC/TC

PRESSURE

CHECK VALVE

ADJ. PRESSURE

RELIEF VALVE

100 Micron

LOWERING VALVE

PRESS. COMPENSATED

FLOW CONTROL

RETURN

FILTER

10 Micron

LC/TC

LY/FC

TWO-SPEED

FOOT PUMP

PRESSURE

CHECK VALVE

1.5" x 18" DISPLACEMENT CYLINDER

W/INTERNAL VELOCITY FUSE

PRESS. COMPENSATED

PRESSURE

CHECK VALVE

ADJ. PRESSURE

RELIEF VALVE

FLOW CONTROL

LOWERING VALVE

1 GPM

ELECTRIC POWER UNIT

HYDRAULIC DIAGRAM

MANUAL FOOT PUMP

HYDRAULIC DIAGRAM

7

Page 8

HYDRAULIC EQUIPMENT

Trouble Shooting Quick Reference Guide

(For further information contact the factory)

1.) Forks do not raise but pump is running or

humming.

Possible Cause

a. Voltage at motor terminals may be too low

to run pump at existing load.

b. Hose or hydraulic line is leaking.

c. Fluid level in reservoir is low.

d. Load exceeds capacity requirements. Relief

Valve is bypassing the fluid back into the

reservoir.

e. Suction filter is clogged, starving pump.

f. Suction line may be leaking air, due to loose

fittings.

g. Filler/Breather cap on tank may be clogged.

h. Down Valve may be energized by faulty

wiring or stuck open.

i. Hydraulic pump may be inoperative.

RemedyObservation

a. Measure voltage at motor terminals or as

near as possible, while pump is running

under load. If voltage is sufficient, check for

inadequate or incorrect wiring as this can

starve the motor. (Refer to chart in Owner's

Manual for recommendations.) Correct as

necessary.

b. Correct as necessary.

c. Add fluid. Refer to Owner's Manual for

proper fluid levels.

d. DO NOT CHANGE RELIEF VALVE

SETTING. Instead, reduce the load to rated

capacity.

e. Remove and clean.

f. Inspect all fittings for proper fit.

g. Remove and clean.

h. Remove Solenoid Valve. Check and clean

(Refer to Hydraulic Section of Owner's

Manual p. 6).

i. Disconnect hydraulic line at power unit. Put

pressure line in a large container and cycle

pump. If no output, check the pump motor

coupling, which may be defective, and

correct as necessary. If pump is worn,

consult factory for replacement parts

service.

2.) Forks raise too slowly.

3.) Motor labors, or is excessively hot.

j. Low battery (DC units only).

a. Foreign material stuck in Down Solenoid,

causing some fluid to bypass back into tank.

b. Foreign material clogging suction filter,

breather cap, or a pinched hose.

c. Low motor voltage.

d. Table overloaded.

e. Pump is inoperative.

f. Low battery (DC units only).

a. Voltage may be low.

b. Incorrect wiring.

c. Oil starvation causes pump to bind. High

internal heat is developed. If this occurs,

pump may be permanently damaged.

d. Binding cylinders.

e. Low battery (DC units only).

j. Adequately charge battery before further

operation. (Refer to Charging Section of

Owner's Manual.)

a. Lower the forks. Remove the Solenoid

Valve and clean (Refer to Hydraulic Section

of Owner's Manual p.6).

b. Correct as necessary. (See also, 1(f), (h).

c. See 1(a).

d. See 1(e).

e. See 1(j).

f. Charge battery.

a. See 1(a).

b. Check that one leg of the motor lines is not

connected to ground.

c. See 1(d), (f), (g), (h), (j).

d. Align cylinders correctly.

e. Charge battery.

8

Page 9

Possible CauseObservation

Remedy

4.) "Spongy" or "Jerky" table operation. Do not

confuse spongy operation with small surges

caused by foreign material on table wheel

roller plate.

5.) Forks lower too slowly when loaded.

6.) Forks lower too quickly.

7.) Forks raise then lower slowly.

a. Fluid starvation.

b. Air is trapped in cylinder.

a. Down Valve filter clogged.

b. Pinched tube or hose.

c. Foreign material in Flow Control Valve.

d. Binding cylinders

e. Foreign material in Velocity Fuse.

a. Leaking hoses and/or cracked fittings.

b. Check valve is stuck open.

c. Foreign material stuck in Flow Control

Valve.

a. Down Solenoid Valve may be incorrectly

wired or is stuck open due to dirt.

a. See 1(d), (f), (g), (j).

b. See air bleed procedure on p.7.

a. Remove Solenoid Valve and clean filter.

b. Correct as necessary.

c. Remove and clean Flow Control Valve.

(Refer to Hydraulic Section of Owner's

Manual p. 6).

d. Align cylinders correctly.

e. Remove and clean Velocity Fuse. (Refer to

Hydraulic Section of Owner's Manual p. 6).

a. Correct as necessary.

b. Remove and clean Check Valve. (Refer to

Hydraulic Section of Owner's Manual p. 6).

c. Remove Flow Control Valve from the Valve

Block and clean. (Refer to Hydraulic Section

of Owner's Manual p. 6).

a. See 2(a).

8.) Forks raise, but do not lower.

b. Check Valve may be stuck open.

c. Check for leaking hoses, fittings, pipes.

d. Cylinder packings may be worn or

damaged.

a. Incorrect Down Solenoid Valve wiring.

b. Down Solenoid Valve is stuck.

c. Faulty Down Solenoid Coil.

d. Object blocking down travel.

e. Binding cylinders.

f. In case of excessive down speeds, the

Velocity Fuse will become operative and

shut off the oil flow from the cylinders, thus

the platform will remain stationary.

b. Remove and clean Check Valve. (Refer to

Hydraulic Section of Owner's Manual.)

c. Correct as necessary.

d. Replace packings.

a. Correct as necessary. (Refer to Electrical

Section of Owner's Manual.)

b. Lightly tap down the Solenoid Coil body to

seat it properly. (DO NOT hit coil hard as it

will permanently damage the internal stem).

DO NOT remove the Solenoid Valve from

the Block as the unit will come down at a

dangerous speed.

c. Remove and replace. (Refer to Electrical

Section of Owner's Manual.

d. Raise forks and remove the object blocking

the down travel, then press the down

button.

e. See 2(e).

f. To unlock, re-pressurize the hydraulic

system.

9.) Erratic or uncontrolled operation.

g. Check if the Limit Switch is inoperative and

the platform has raised all the way so that

the mechanical stops are engaged. If

mechanical stops are engaged, the Velocity

Fuse has been locked up.

a. Low battery (DC units only).

g. Refer to Velocity Fuse Section of the

Owner's Manual.

a. Charge battery.

9

Page 10

EXPLODED PARTS DRAWING

High Rise Lift • Model HIPM

38

23

22

23

22

35

36

44

39

26

25

45

40

25

26

28

41

2

3

1

8

7

6

16

17

18

15

4

8

10

9

37

33

27

34

20

23

22

24

21

17

19

5

11

12

13

14

10

Page 11

PARTS IDENTIFICATION - High Rise LIft • Model HIPM

KIT NO.

D

D

C,D

C

C

B

B

A

A

A

A

A

ITEM NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

33

34

35

36

37

38

39

39A

39B

39C

39D

40

41

44

45

A

B

C

D

E

DESCRIPTION

Hydraulic cylinder (1-½ x 28)

3/8" x 1" hex head cap screw

3/8" split lock washer

Inner leg

Outer leg

Inner leg roller

Inner leg roller pin

3/4" clip ring

Outer leg roller

Outer leg roller pin

3/4" clip ring

3/4" x 18 ga. machinery bushing

- narrow rim

Outer leg hinge bearing

Outer leg hinge pin

1" x 18 ga. machinery bushing

- narrow rim

Axle pin bearing

1" x 18 ga. machinery bushing

- narrow rim

1" clip ring

3/4" clip ring

Floor lock

Inner leg hinge pin bearing

3/8-16 nylon insert lock nut

3/8" USS flat washer

Swivel caster

(add a "-B" for caster with brake)

3/8-16 x 1-¼" hex head cap screw

3/8" USS flat washer

5/16-18 nylon nut

5/16" USS flat washer

Battery box (includes lid)

Battery (SHIPS VIA TRUCK ONLY)

¼"-20 x 1-¼" slotted head screw

¼" I.D. fender washer

Battery box strap

(included with battery)

Hydraulic reservoir

DC Motor / pump assembly

DC motor only

Hydraulic pump only

Motor start solenoid

Cartridge valve assembly

3/8-16 x 1" self drill and tap screw

3/8-16 x 1" hex head cap screw

Power unit shroud

Raise / lower control switch

Caster kit

(includes items 22-26)

Bearing kit (includes items 16,21)

Outer roller kit (includes items 8-10)

Inner roller kit (includes items 6-8)

Cylinder seal repair kit (includes all seals for repair)

ENGINEER NO.

15-021-006

n/a

n/a

15-010-005

15-010-006

16-132-001

15-112-008

n/a

16-132-001

01-112-008

n/a

n/a

01-111-007

05-112-006

n/a

01-111-006

n/a

n/a

n/a

16-132-080

01-111-007

n/a

n/a

16-132-034

n/a

n/a

n/a

n/a

15-139-002

15-139-001

n/a

n/a

n/a

15-023-001

15-137-001

01-135-041

01-143-015

01-034-026

01-153-009

n/a

n/a

15-024-006

15-022-006

15-022-006

15-154-012

15-154-013

15-154-014

15-154-015

PART NO.

HIPM-CYL

n/a

n/a

HIPM-INLG

HIPM-OTLG

HIPM-ILG-RLR

HIPM-ILG-RP

n/a

HIPM-OLG-RLR

HIPM-OLG-RP

n/a

n/a

HIPM-OLG-HB

HIPM-OLG-HP

n/a

HIPM-APB

n/a

n/a

n/a

HIPM-FLK

HIPM-ILG-BG

n/a

n/a

HIPM-CST-S

n/a

n/a

n/a

n/a

HIPM-BTBX

HIPM-BT

n/a

n/a

HIPM-BTBX-ST

HIPM-RES

HIPM-DCPU

HIPM-MTR

HIPM-PMP

HIPM-SOL

HIPM-CVA

n/a

n/a

HIPM-PU-S

HIPM-CS

HIPM-KIT-A

HIPM-KIT-B

HIPM-KIT-C

HIPM-KIT-D

HIPM-KIT-E

QTY.

1

1

1

2

2

4

4

2

4

2

4

4

2

2

2

2

2

2

2

2

2

8

8

2

8

8

2

2

1

1

2

2

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

a/k Available only with purchase of kit

n/a Not Available

11

Page 12

PERIODIC MAINTENANCE INSTRUCTIONS

WARNING! REMOVE LOAD AND COMPLETELY LOWER FORKS BEFORE PERFROMING ANY MAINTENANCE.

(A) Before Each Use Check For The Following :

1.) Frayed wires (Powered models only)

2.) Oil leaks

3.) Proper caster operation

4.) Pinched or chafed hoses, loose fittings

5.) Structural deformation of forks or frame

6.) Unusual noise or binding

Do not use if there are any of the above!

(B) Monthly Inspections

1.) Check oil level. Oil should be 1" to 1-1/2" below the top of the tank with

the lift in the fully lowered position. Add as necessary.

2.) Check for oil leaks. See Trouble Shooting Section and correct

as necessary.

3.) Check water level in battery. (DC models only)

4.) Check clevis and pivot points for wear.

5.) Check for worn or damaged hydraulic hoses, electrical wires, and cords.

Repair as necessary.

6.) Check rollers for looseness and wear. See Trouble Shooting.

7.) Check retaining rings at load rollers and clevis.

8.) Check for unusual noise. See Trouble Shooting section.

9.) Make sure all warning labels are in place and in good condition.

10.) Clean off dirt and debris.

(C) Yearly Inspection

12

Hydraulic oil should be changed at least once a year, or sooner if the

oil darkens or becomes gritty. Flush reservoir before refilling. Presence of

water is indicated if the oil turns milky. Recommended oil: Purity ISO AW-32

Hydraulic fluid or equal.

All maintenance work must be performed by qualified personnel with

training in the repair of electrical and hydraulic components.

Page 13

Operating Instructions for Two-speed Hydraulic Foot Pump

Features:

Your new lift equipment has been supplied with an exclusive two-speed foot pump. The internal features of your pump

include a primary pressure relief valve, pressure compensated return flow control valve, and an integrated lowering

valve.

Replaceable bushings, valve components, and seals have been utilized in the construction of the pump in the event

that replacements are necessary.

Operating Instructions:

Stay clear of moving parts. The platform will rise as the foot pedal is pumped. Depressing the release lever will lower

the table at a controlled rate of descent.

In the event the platform has been overloaded, the pressure relief will open because of excessive pressure build-up

in the hydraulic system. Oil will bypass into the reservoir. Never change the pressure relief setting. Do not exceed

the rated capacity of your lift equipment.

Speed Selection for Two-speed Pumps:

This pump offers two "speeds". The low speed produces low volume/high pressure. The high speed produces high

volume/low pressure. The operator has the option of selecting the optimum pump speed for the application at hand.

Pump speeds are selected by sliding the "lock collar"(See item # 2A on the parts identification) in

drop of oil will keep the collar working freely.

or out. An occasional

Air Bleed Procedure:

Whether your pump is a new installation, or has been recently serviced, air has likely entered the hydraulic

system. The design of this pump includes an "air bleed screw" which will aid in the removal of unwanted air from

the foot pump area of the hydraulic system. Use the following steps to remove this air from the system.

1) Check all fittings to be sure they are tight. Ensure that the oil is filled to within 1" of the top of the reservoir

when the lift is in the fully lowered position.

2) Locate the "air bleed screw"( See item # 33 on the pump body) and loosen appoximately 1/2 turn

couterclockwise. As soon as you have loosened the screw, slowly depress the foot pedal. This will force the air

out of the pump chamber. Before you let the pump pedal return to the "up" or "home" position, tighten the air

bleed screw. This will prevent air form re-entering the pump chamber. Repeat the above procedure until the

pump chamber is completely filled with oil and a "spongy" feel is no longer present. If the air bleeding procedure

has been successful, the feel of the pump pedal will be firm and the complete stroke of the pump will produce

fluid flow.

LOCK COLLAR

PRESSURE

CHECK

VALVE

2 SPEED

FOOT PUMP

PRESSURE

CHECK VALVE

ADJ. PRESSURE

RELIEF VALVE

LOWERING

VALVE

PRESS. COMPENSATED

FLOW CONTROL 1 GPM

TO CYLINDER

AIR BLEED SCREW

LOWERING VALVE

PRESSURE RELIEF VALVE

13

Page 14

WARNING LABEL IDENTIFICATION

MAKE SURE ALL WARNING LABELS ARE IN PLACE!

1

UP

4

KEEP CLEAR

WHEN

Located on Reservoir

3

OPERATING

DOWN

5

2

1

DANGER

CORROSIVE

MATERIAL

2

PELIGRO

MATERIAL

CORROSIVO

DANGER

MATIÈRES

CORROSIVES

*Product safety signs or labels should be

periodically inspected and cleaned by the

product users as necessary to maintain

good legibility for safe viewing distance . . .

ANSI 535.4 (10.21)

Contact manufacturer for replacement labels if needed.

5

KEEP CLEAR OF

PINCH POINT

3

HYDRAULIC OIL OR EQUIVALENT

ACEITE HIDRÁULICO O EQUIVALENTE

HUILE HYDRAULIQUE AW-32 OU ÉQUIVALENT

4

WARNING

!

KEEP CLEAR

WHEN IN USE

MANTENGASE ALEJADO DE

ALEJADO CUANDO

SE ESTA OPERANDO

PUNTO DE CORTE

T & S Equipment Company

Ph (219)665-9521

Fax (219)665-1339

ISO AW-32

AVISO

!

MANTENGASE

! AVERTISSEMENT! WARNING ! AVISO

POINT DE PINCEMENT

SE TENIR À DISTANCE DU

AVERTISSEMENT

!

SE TENIR À DISTANCE

FONCTIONNEMENT

295

206

LORS DU

220

208

14

Page 15

LIMITED WARRANTY

covered unless done at manufacturer’s facilities. Any modifications performed without written approval

DISPOSITION. Our company will make a good faith effort for prompt correction or other

ONE YEAR LIMITED WARRANTY. The manufacturer warrants for the original purchaser against

defects in materials and workmanship under normal use one year after date of purchase. (Not to exceed

15 months after date of manufacture.) Any part which is determined by the manufacturer to be defective

in material or workmanship and returned to the factory, shipping costs prepaid, will be, as the exclusive

remedy, repaired or replaced at our option. Labor costs for warranty repairs and/or modifications are not

of the manufacturer may void warranty. This limited warranty gives purchaser specific legal rights which

vary from state to state.

LIMITATION OF LIABILITY. To the extent allowable under applicable law, the manufacturer’s

liability for consequential and incidental damages is expressly disclaimed.

The manufacturer’s liability in any event is limited to, and shall not exceed, the purchase price paid.

Misuse or modification may void warranty.

WARRANTY DISCLAIMER. Our company has made a diligent effort to illustrate and describe the

products shown accurately; however, such illustrations and descriptions are for the sole purpose of

identification, and do not express or imply a warranty that the products are merchantable, or fit for a

particular purpose, or that the products will necessarily conform to the illustrations or descriptions.

The provisions of the warranty shall be construed and enforced in accordance with the UNIFORM

COMMERCIAL CODE and laws as enacted in the State of Indiana.

adjustment with respect to any product which proves to be defective within the Limited Warranty.

Warranty claims must be made in writing within said year.

SERVICE RECORD

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

_______________________________________________________

_______________________________________________________

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

_______________________________________________________

_______________________________________________________

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

_______________________________________________________

_______________________________________________________

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

_______________________________________________________

_______________________________________________________

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

_______________________________________________________

_______________________________________________________

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

_______________________________________________________

_______________________________________________________

15

Loading...

Loading...